Degradation Assessment of In-Service Transformer Oil Based on Electrical and Chemical Properties

Abstract

:1. Introduction

2. Analysis Method

3. Results

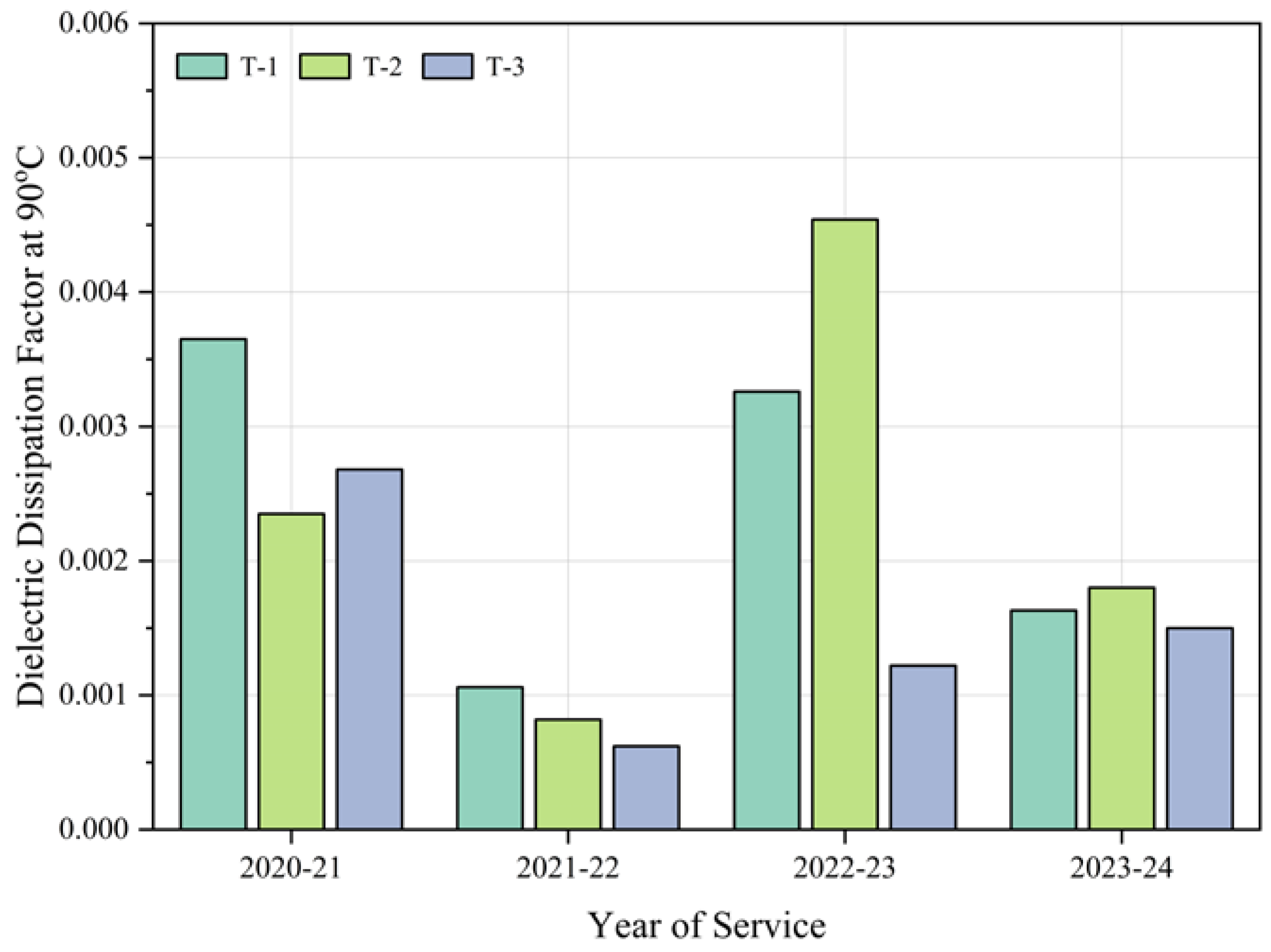

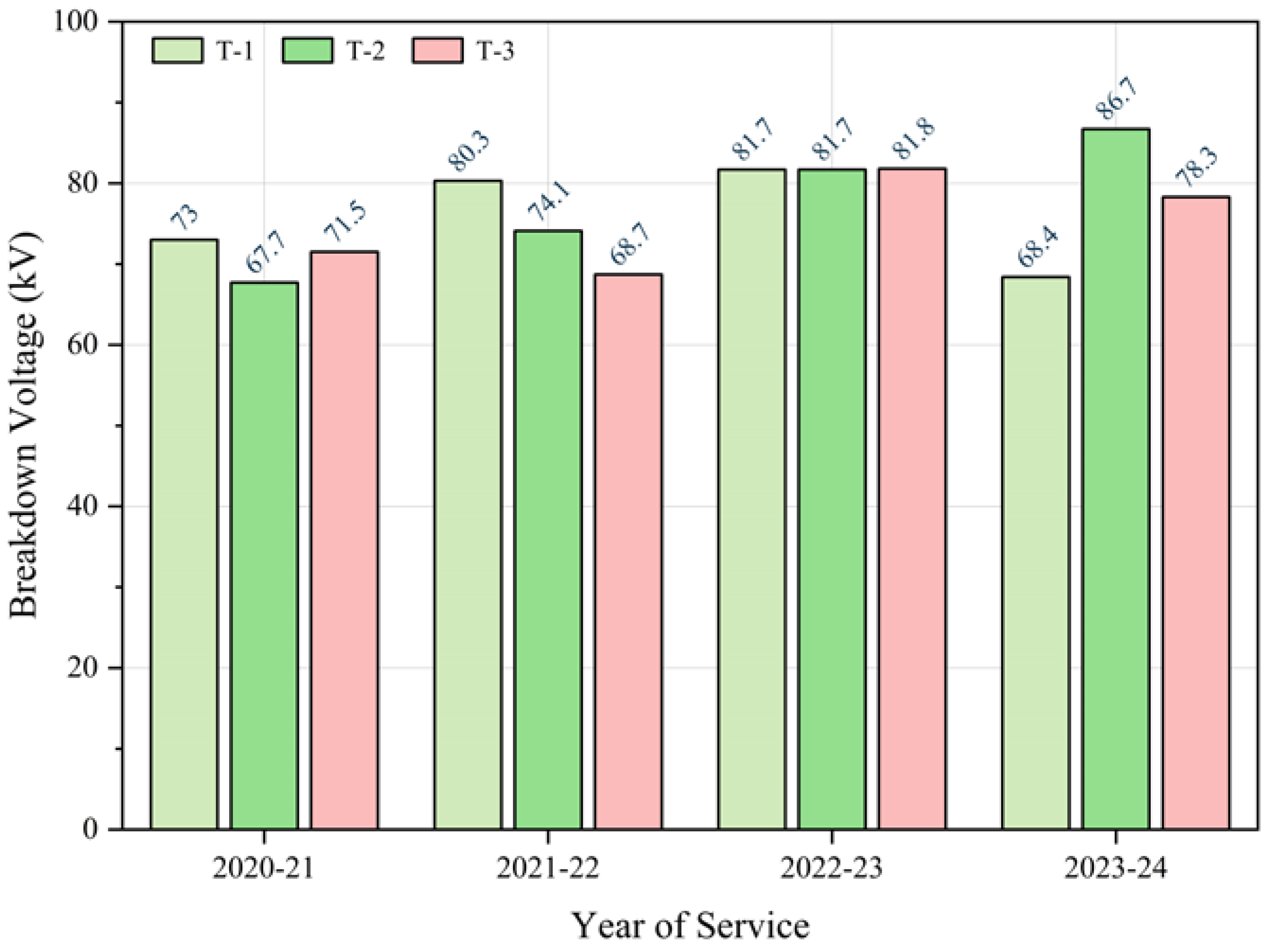

3.1. Electrical Characteristics

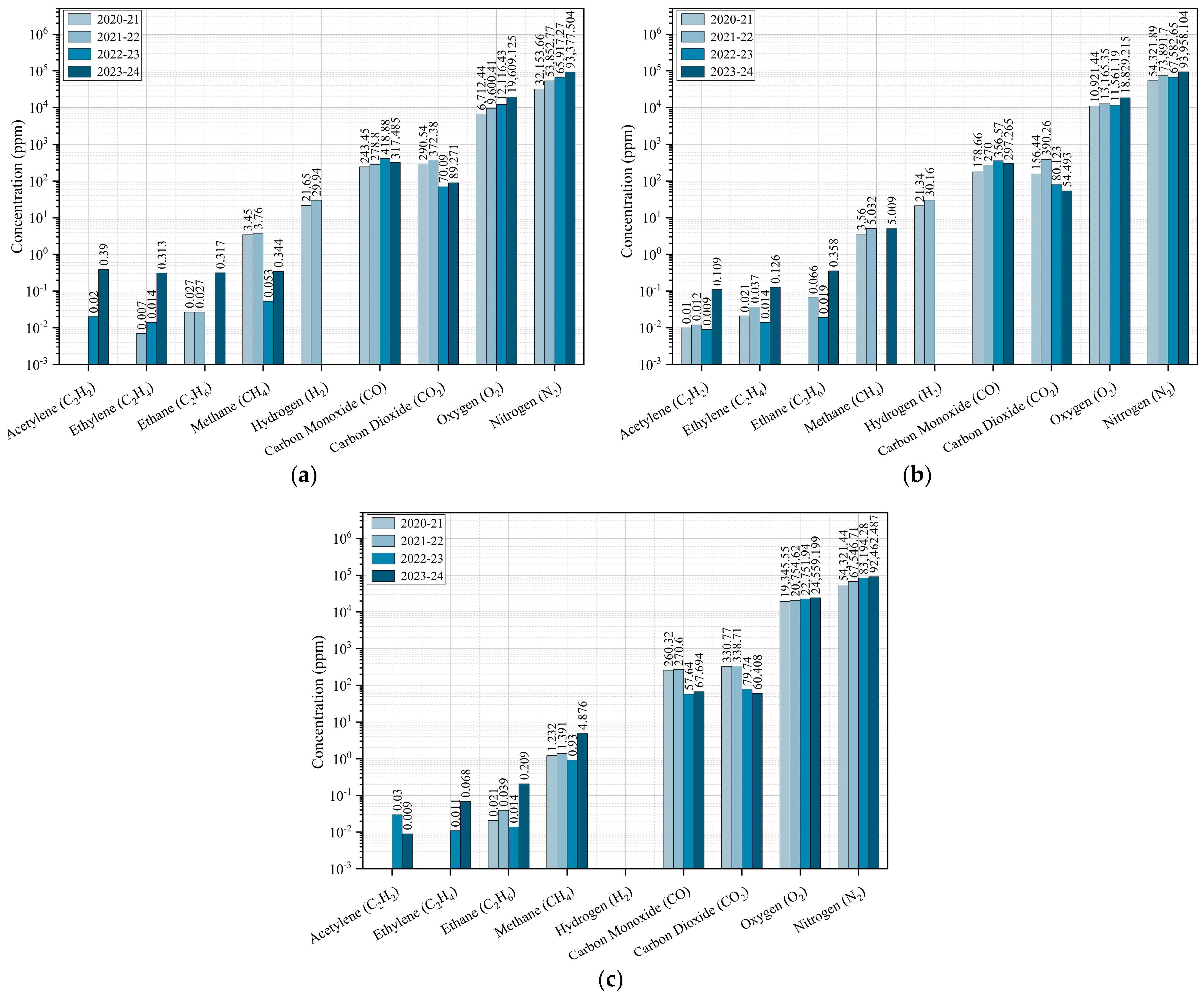

3.2. Chemical Characteristics

4. Discussion

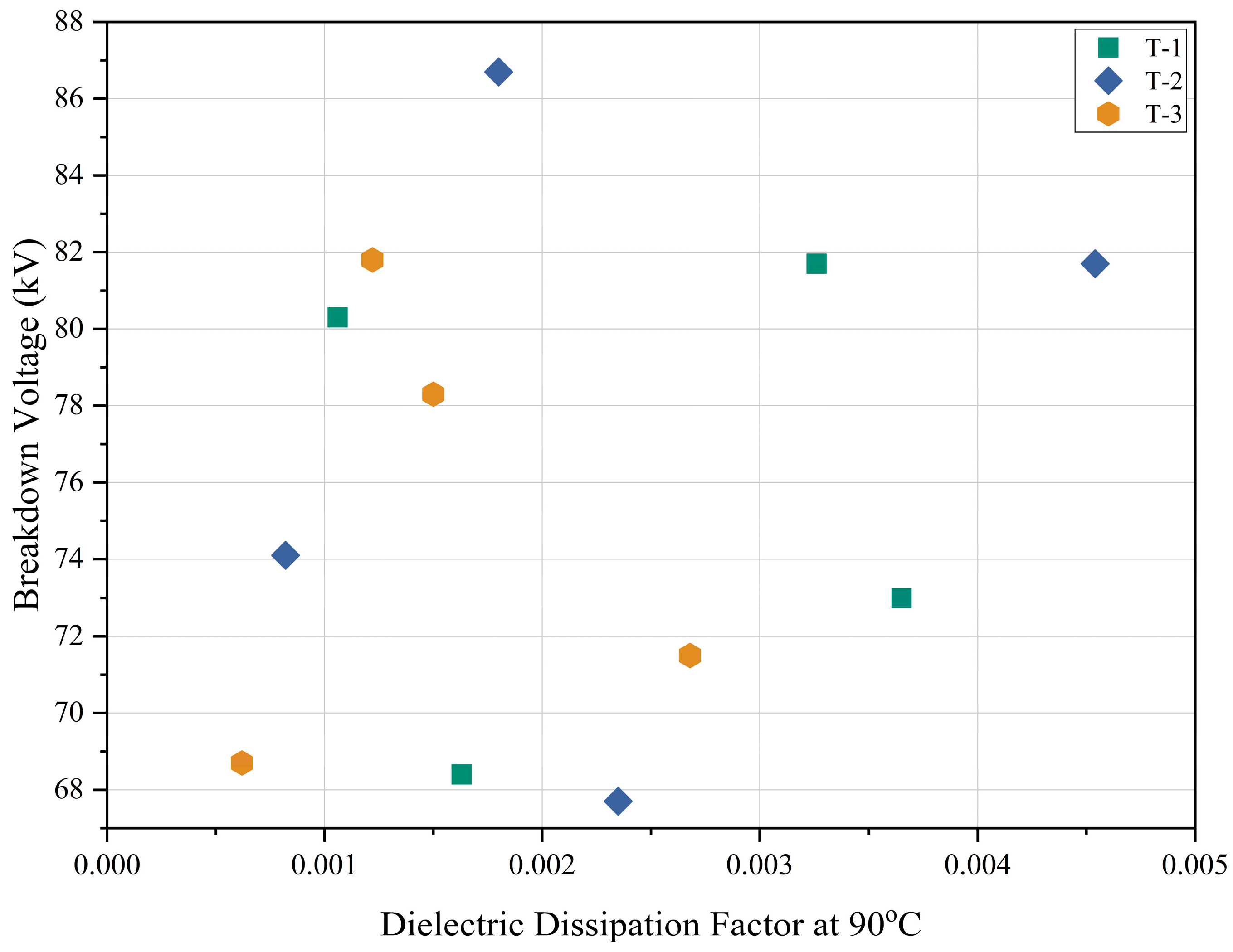

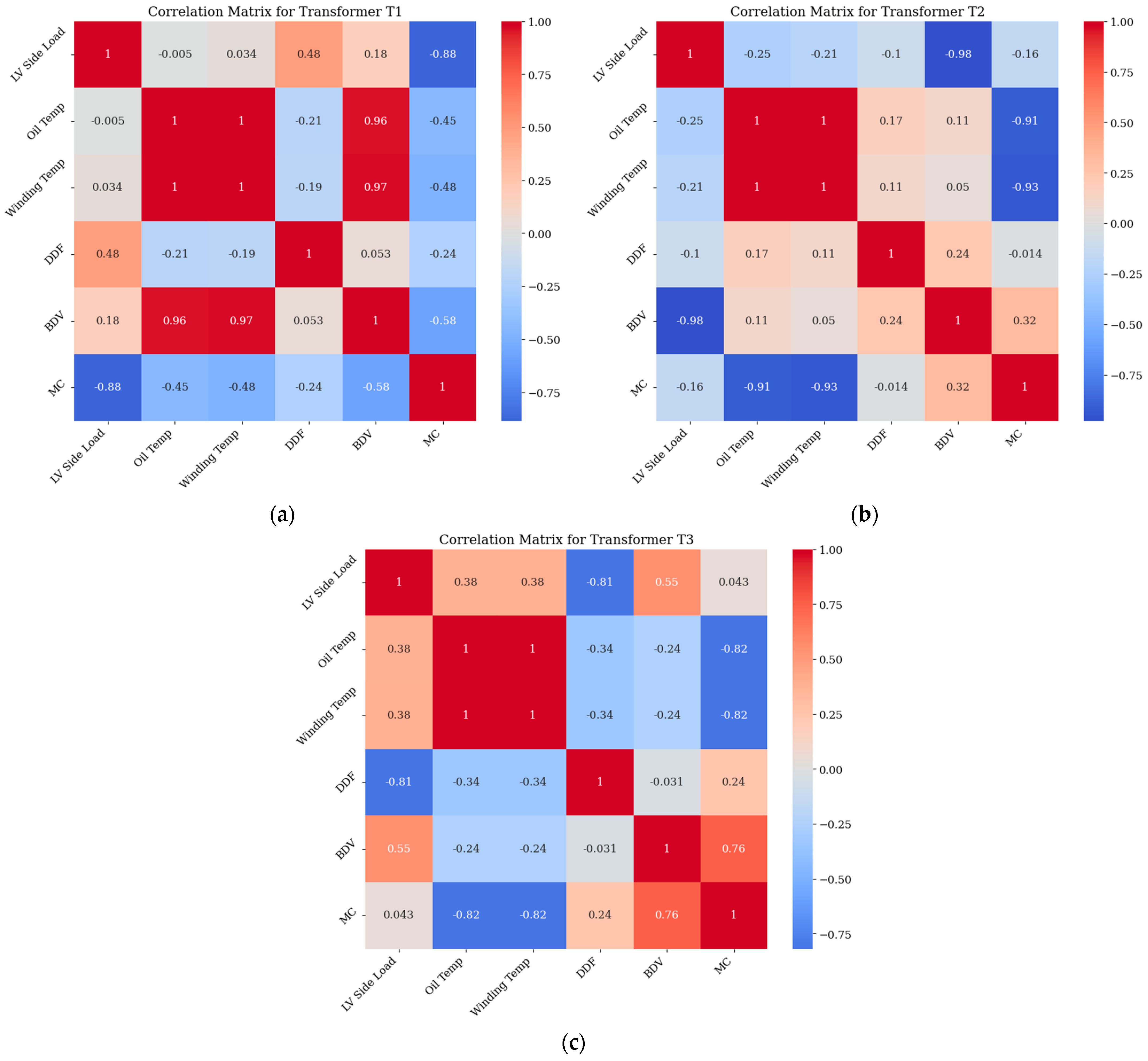

4.1. Relationship Between Different Characteristics

4.1.1. Dielectric Dissipation Factor and Breakdown Voltage Relationship

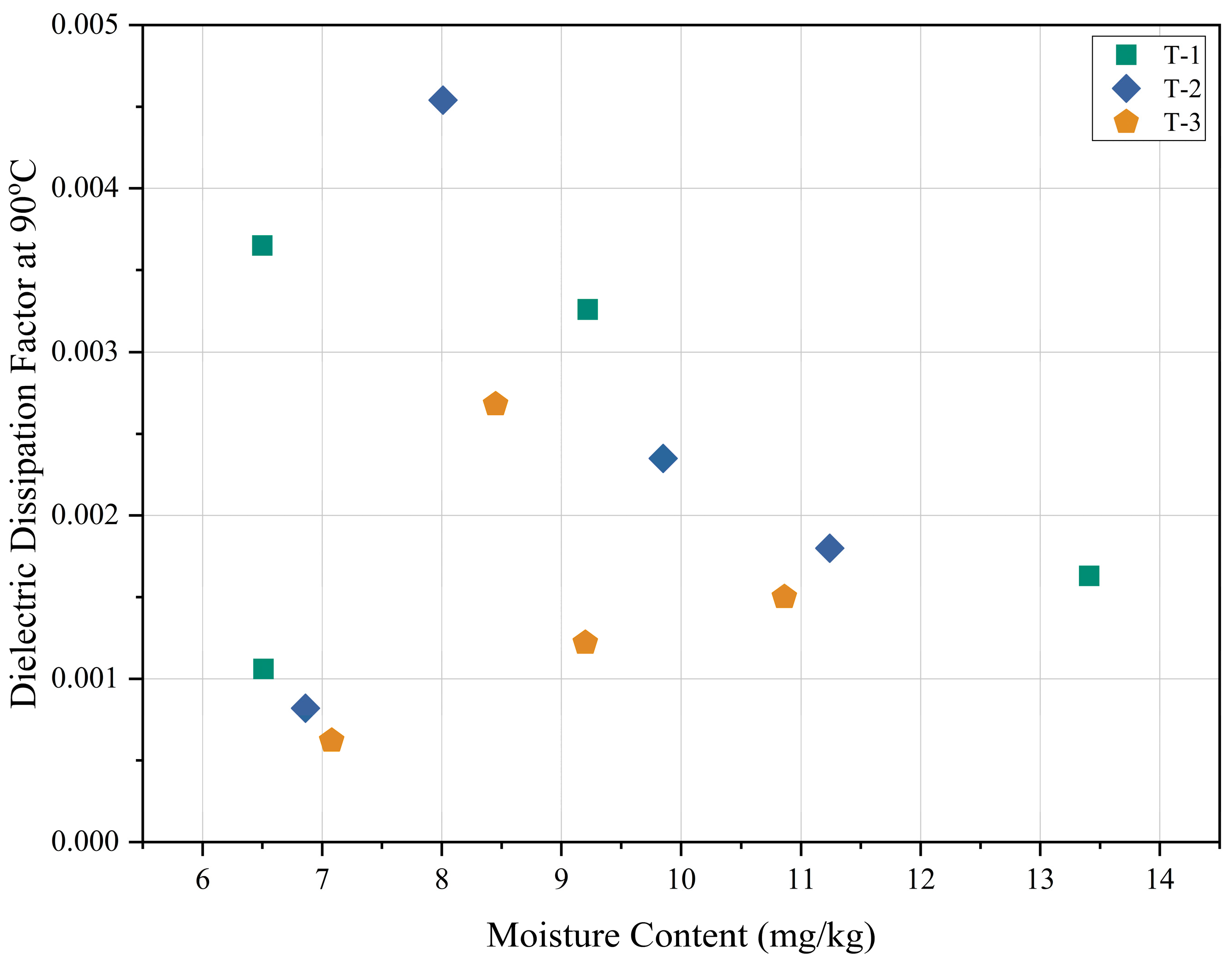

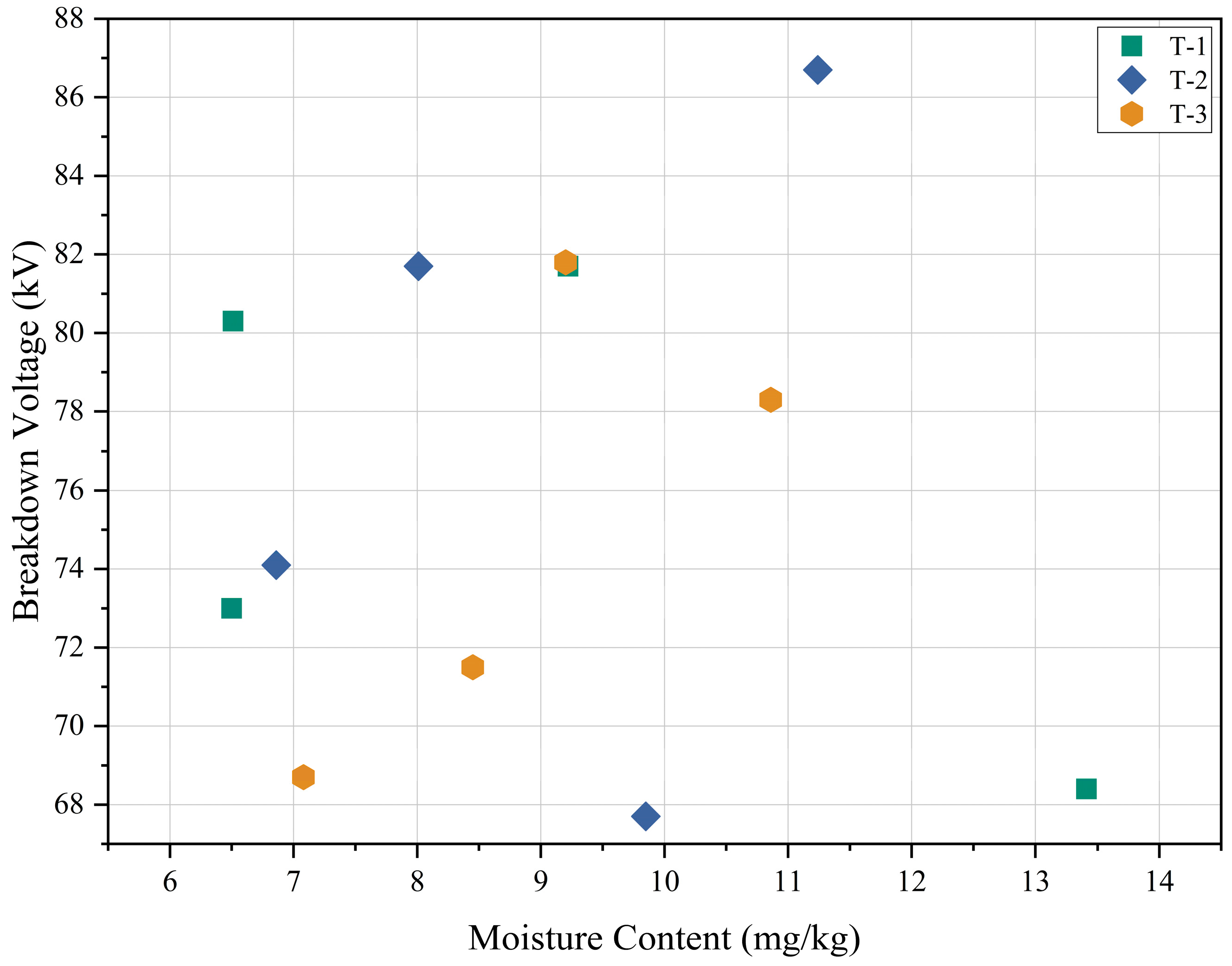

4.1.2. Impact of Moisture Contents

4.1.3. Impact of Load Variation, Oil Temperature, and Winding Temperature

4.2. Assessment of the DGA Results

4.2.1. CO2/CO Ratio

4.2.2. O2/N2 Ratio

5. Conclusions

- All three transformer oil samples showed good electrical characteristics after each service year. However, the DDF and breakdown voltage showed variation with service age for all three transformers.

- Moisture content showed an increasing trend with each service year for all transformers. The DGA results revealed that the concentrations of carbon monoxide, oxygen, and nitrogen increased after each service year.

- The LV side load variation in the transformer connected to the distribution side of the network decreased the breakdown voltage of the insulation oil, whereas the oil and winding temperatures increased. However, for the two power transformers connected to the transmission network, the breakdown voltage of the insulating oil increased with the increase in oil and winding temperatures.

- The degradation of cellulose insulation in the transformers was revealed by the concentrations of carbon monoxide, carbon dioxide, methane, oxygen, and moisture content. The carbon dioxide to carbon monoxide and oxygen to nitrogen ratios identified the presence of electrical faults in the transformers, leading to cellulose insulation degradation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Muangpratoom, P.; Suriyasakulpong, C.; Maneerot, S.; Vittayakorn, W.; Pattanadech, N. Experimental Study of the Electrical and Physiochemical Properties of Different Types of Crude Palm Oils as Dielectric Insulating Fluids in Transformers. Sustainability 2023, 15, 14269. [Google Scholar] [CrossRef]

- Rao, U.M.; Pulluri, H.; Kumar, N.G. Performance Analysis of Transformer Oil/Paper Insulation with Ester and Mixed Dielectric Fluids. IEEE Trans. Dielectr. Electr. Insul. 2018, 25, 1853–1862. [Google Scholar] [CrossRef]

- Abdi, S.; Haddad, A.M.; Harid, N.; Boubakeur, A. Modelling the Effect of Thermal Aging on Transformer Oil Electrical Characteristics Using a Regression Approach. Energies 2022, 16, 381. [Google Scholar] [CrossRef]

- Guerbas, F.; Adjaout, L.; Abada, A.; Rahal, D. Thermal Aging Effect on the Properties of New and Reclaimed Transformer Oil. In Proceedings of the 2016 IEEE International Conference on High Voltage Engineering and Application (ICHVE), Chengdu, China, 19–22 September 2016; IEEE: Chengdu, China, 2016; pp. 1–4. [Google Scholar]

- Kaur, N.; Chudasama, B. Effect of Thermal Aging on Stability of Transformer Oil Based Temperature Sensitive Magnetic Fluids. J. Magn. Magn. Mater. 2018, 451, 647–653. [Google Scholar] [CrossRef]

- Wajid, A.; Rehman, A.U.; Iqbal, S.; Pushkarna, M.; Hussain, S.M.; Kotb, H.; Alharbi, M.; Zaitsev, I. Comparative Performance Study of Dissolved Gas Analysis (DGA) Methods for Identification of Faults in Power Transformer. Int. J. Energy Res. 2023, 2023, 9960743. [Google Scholar] [CrossRef]

- Baruah, N.; Dey, S.S.; Nayak, S.K. Evaluation of Dissolved Gas Analysis and Long-Term Performance of Non-Edible Natural Ester. IEEE Trans. Dielectr. Electr. Insul. 2020, 27, 1561–1569. [Google Scholar] [CrossRef]

- Siva Sai, R.; Rafi, J.; Farook, S.; Kumar, N.; Parthasarathy, M.; Ashok Bakkiyaraj, R. Degradation Studies of Electrical, Physical and Chemical Properties of Aged Transformer Oil. J. Phys. Conf. Ser. 2020, 1706, 012056. [Google Scholar] [CrossRef]

- Ojha, S.K.; Purkait, P.; Chakravorti, S. Evaluating the Effects of Lower Molecular Weight Acids in Oil-Paper Insulated Transformer. In Proceedings of the 2017 3rd International Conference on Condition Assessment Techniques in Electrical Systems (CATCON), Rupnagar, India, 16–18 November 2017; IEEE: Rupnagar, India, 2017; pp. 138–143. [Google Scholar]

- Guo, C.; Zhang, Q.; Zhang, R.; He, X.; Wu, Z.; Wen, T. Investigation on Gas Generation Characteristics in Transformer Oil under Vibration. IET Gener. Transm. Distrib. 2022, 16, 5026–5040. [Google Scholar] [CrossRef]

- Golarz, J. Understanding Dissolved Gas Analysis (DGA) Techniques and Interpretations. In Proceedings of the 2016 IEEE/PES Transmission and Distribution Conference and Exposition (T&D), Dallas, TX, USA, 3–5 May 2016; IEEE: Dallas, TX, USA, 2016; pp. 1–5. [Google Scholar]

- Sun, H.-C.; Huang, Y.-C.; Huang, C.-M. A Review of Dissolved Gas Analysis in Power Transformers. Energy Procedia 2012, 14, 1220–1225. [Google Scholar] [CrossRef]

- Kachler, A.J.; Hohlein, I. Aging of Cellulose at Transformer Service Temperatures. Part 1: Influence of Type of Oil and Air on the Degree of Polymerization of Pressboard, Dissolved Gases, and Furanic Compounds in Oil. IEEE Electr. Insul. Mag. 2005, 21, 15–21. [Google Scholar] [CrossRef]

- Hohlein-Atanasova, I.; Frotscher, R. Carbon Oxides in the Interpretation of Dissolved Gas Analysis in Transformers and Tap Changers. IEEE Electr. Insul. Mag. 2010, 26, 22–26. [Google Scholar] [CrossRef]

- Mihajlovic, D.; Ivancevic, V.; Vasovic, V.; Lukic, J. Cellulose Degradation and Transformer Fault Detection by the Application of Integrated Analyses of Gases and Low Molecular Weight Alcohols Dissolved in Mineral Oil. Energies 2022, 15, 5669. [Google Scholar] [CrossRef]

- Li, Y.; Wu, G.; Li, W.; Cui, Y.; Gao, B. Influence of Moisture and Oxygen on Aging of Oil-Paper Insulation. In Proceedings of the 2013 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Chenzhen, China, 20–23 October 2013; IEEE: Chenzhen, China, 2013; pp. 120–123. [Google Scholar]

- Liang, Z.; Fang, Y.; Cheng, H.; Sun, Y.; Li, B.; Li, K.; Zhao, W.; Sun, Z.; Zhang, Y. Innovative Transformer Life Assessment Considering Moisture and Oil Circulation. Energies 2024, 17, 429. [Google Scholar] [CrossRef]

- Abdi, S.; Safiddine, L.; Boubakeur, A.; Haddad, A. The Effect of Water Content on the Electrical Properties of Transformer Oil. In Proceedings of the 21st International Symposium on High Voltage Engineering, Budapest, Hungary, 26–30 August 2019; Springer: Cham, Switzerland, 2020; pp. 518–527. [Google Scholar]

- Garcia, B.; Garcia, T.; Primo, V.; Burgos, J.C.; Urquiza, D. Studying the Loss of Life of Natural-Ester-Filled Transformer Insulation: Impact of Moisture on the Aging Rate of Paper. IEEE Electr. Insul. Mag. 2017, 33, 15–23. [Google Scholar] [CrossRef]

- Lundgaard, L.E.; Hansen, W.; Linhjell, D.; Painter, T.J. Aging of Oil-Impregnated Paper in Power Transformers. IEEE Trans. Power Deliv. 2004, 19, 230–239. [Google Scholar] [CrossRef]

- Villarroel, R.; García de Burgos, B.; García, D.F. Moisture Dynamics in Natural-Ester Filled Transformers. Int. J. Electr. Power Energy Syst. 2021, 124, 106172. [Google Scholar] [CrossRef]

- Melka, B.; Stebel, M.; Bodys, J.; Kubiczek, K.; Lasek, P.; Rodriguez, G.R.; Garelli, L.; Haida, M.; Palacz, M.; Nowak, A.J.; et al. Effective Cooling of a Distribution Transformer Using Biodegradable Oils at Different Climate Conditions. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1557–1565. [Google Scholar] [CrossRef]

- Ye, W.; Hao, J.; Gao, C.; Zhang, J.; Yang, L.; Liao, R. Natural Ester Replacement Effect on Thermal Degradation of Cellulose Insulation From Macroscopic Behavior to Atomic-Scale Mechanism. IEEE Trans. Dielectr. Electr. Insul. 2023, 30, 1582–1589. [Google Scholar] [CrossRef]

- Jacob, J.; Preetha, P.; Thiruthi Krishnan, S. Review on Natural Ester and Nanofluids as an Environmental Friendly Alternative to Transformer Mineral Oil. IET Nanodielectr. 2020, 3, 33–43. [Google Scholar] [CrossRef]

- Meira, M.; Ruschetti, C.; Álvarez, R.; Catalano, L.; Verucchi, C. Dissolved Gas Analysis Differences between Natural Esters and Mineral Oils Used in Power Transformers: A Review. IET Gener. Transm. Distrib. 2019, 13, 5441–5448. [Google Scholar] [CrossRef]

- Maharana, M.; Baruah, N.; Nayak, S.K.; Wu, K. Insulation Monitoring of Oxidative Aged Nonedible Ester Based Dielectric Fluid by Suitable Dissolved Gas Analysis. In Proceedings of the 2019 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Richland, WA, USA, 20–23 October 2019; IEEE: Richland, WA, USA, 2019; pp. 649–652. [Google Scholar]

- Lelekakis, N.; Martin, D.; Guo, W.; Wijaya, J. Comparison of Dissolved Gas-in-Oil Analysis Methods Using a Dissolved Gas-in-Oil Standard. IEEE Electr. Insul. Mag. 2011, 27, 29–35. [Google Scholar] [CrossRef]

- Syafruddin, H.; Nugroho, H.P. Dissolved Gas Analysis (DGA) for Diagnosis of Fault in Oil-Immersed Power Transformers : A Case Study. In Proceedings of the 2020 4rd International Conference on Electrical, Telecommunication and Computer Engineering (ELTICOM), Medan, Indonesia, 3–4 September 2020; IEEE: Medan, Indonesia, 2020; pp. 57–62. [Google Scholar]

- Godina, R.; Rodrigues, E.; Matias, J.; Catalão, J. Effect of Loads and Other Key Factors on Oil-Transformer Ageing: Sustainability Benefits and Challenges. Energies 2015, 8, 12147–12186. [Google Scholar] [CrossRef]

- Badawi, M.; Ibrahim, S.A.; Mansour, D.-E.A.; Ward, S.A.; El-Faraskoury, A.A.; Ghali, M.; Mahmoud, K.; Lehtonen, M.; Darwish, M.M.F. On Highlighting the Merits of Gas-to-Liquid Transformer Oil Under Accelerated Thermal Aging and Faults: Electrical and Physio- Chemical Properties. IEEE Access 2024, 12, 93372–93388. [Google Scholar] [CrossRef]

- Ashkezari, A.D.; Hui, M.; Ekanayake, C.; Saha, T.K. Multivariate Analysis for Correlations among Different Transformer Oil Parameters to Determine Transformer Health Index. In Proceedings of the 2012 IEEE Power and Energy Society General Meeting, San Diego, CA, USA, 22–26 July 2012; IEEE: San Diego, CA, USA, 2012; pp. 1–7. [Google Scholar]

- Shutenko, O.; Ponomarenko, S. Analysis of Ageing Characteristics of Transformer Oils under Long-Term Operation Conditions. Iran. J. Sci. Technol. Trans. Electr. Eng. 2022, 46, 481–501. [Google Scholar] [CrossRef]

- Wolmarans, C.; Cox, R. Online Transformer DGA Monitoring Case Studies in Condition Assessment. In Proceedings of the 2024 IEEE Electrical Insulation Conference (EIC), Minneapolis, MN, USA, 2–5 June 2024; IEEE: Minneapolis, MN, USA, 2024; pp. 351–355. [Google Scholar]

- Sarathkumar, D.; Raj, R.A.; Murugesan, S.; Baptist Andrews, L.J.; Alagappan, A.; Sivadasan, J. Unlocking Power Transformer Reliability: DGA in Mineral Oil and Natural Esters. In Proceedings of the 2024 IEEE International Students’ Conference on Electrical, Electronics and Computer Science (SCEECS), Bhopal, India, 24–25 February 2024; IEEE: Bhopal, India, 2024; pp. 1–5. [Google Scholar]

- Patil, A.J.; Naresh, R.; Jarial, R.K.; Malik, H. Novel Four-Gas Fault Interpretation Graphical Technique for Mineral Oil Transformer. IEEE Trans. Dielectr. Electr. Insul. 2024, 31, 2721–2730. [Google Scholar] [CrossRef]

- Kohtoh, M.; Kaneko, S.; Okabe, S.; Amimoto, T. Aging Effect on Electrical Characteristics of Insulating Oil in Field Transformer. IEEE Trans. Dielectr. Electr. Insul. 2009, 16, 1698–1706. [Google Scholar] [CrossRef]

- Luo, Y.; Zhou, X.; Zhu, L.; Bai, J.; Tian, T.; Liu, B.; Zhang, H. Transformer Oil Electrical–Thermal Characteristics Analysis and Evaluation. AIP Adv. 2024, 14, 075103. [Google Scholar] [CrossRef]

- Abdi, S.; Harid, N.; Safiddine, L.; Boubakeur, A.; Haddad, A. The Correlation of Transformer Oil Electrical Properties with Water Content Using a Regression Approach. Energies 2021, 14, 2089. [Google Scholar] [CrossRef]

- Du, Y.; Zahn, M.; Lesieutre, B.C.; Mamishev, A.V.; Lindgren, S.R. Moisture Equilibrium in Transformer Paper-Oil Systems. IEEE Electr. Insul. Mag. 1999, 15, 11–20. [Google Scholar] [CrossRef]

- Buerschaper, B.; Kleboth-Lugova, O.; Leibfried, T. The Electrical Strength of Transformer Oil in a Transformerboard-Oil System during Moisture Non-Equilibrium. In Proceedings of the 2003 Annual Report Conference on Electrical Insulation and Dielectric Phenomena, Albuquerque, NM, USA, 19–22 October 2003; IEEE: Albuquerque, NM, USA, 2004; pp. 269–272. [Google Scholar]

- Gouda, O.E.; El-Hoshy, S.H.; E.L.-Tamaly, H.H. Proposed Three Ratios Technique for the Interpretation of Mineral Oil Transformers Based Dissolved Gas Analysis. IET Gener. Transm. Distrib. 2018, 12, 2650–2661. [Google Scholar] [CrossRef]

- Singh, R. Dissolved Gas Analysis Is an Art of Testing and Analysis Method for the Incipient Faults in Power Equipment—Like Transformers and OLTCs. Power Res.-J. CPRI 2023, 18, 113–120. [Google Scholar] [CrossRef]

| Transformer | Characteristics | ||||

|---|---|---|---|---|---|

| Make | Rated Power (MVA) | Rated Primary Voltage (kV) | Rated Secondary Voltage (kV) | Taps | |

| T1 | Shandong Dachi China | 250 | 220 | 132 | 27 |

| T2 | Shandong Dachi China | 250 | 220 | 132 | 27 |

| T3 | PEL | 13/10 | 132 | 11.5 | 23 |

| Test Methods | Test Standard | Acceptance Values | Test Conditions | |

|---|---|---|---|---|

| Electrical characteristics | Dielectric dissipation factor at 90 °C | IEC-60422:13 | <0.10 | 25.0 ± 05 °C & 50% ± 15% |

| Breakdown voltage (kV) | IEC-60422:13 | >60 | ||

| Chemical characteristics | Moisture Content (mg/kg) | IEC-60422:13 | <15 | |

| DGA | IEC-60599:15 and ASTM D-3612 | ---- | ||

| Transformers | Service Years | Parameters | ||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| LV Side Load (A) | Oil Temp. (°C) | Winding Temp. (°C) | DDF 1 at 90 °C | BDV 2 (kV) | MC 3 (mg/kg) | DGA | ||||||||||

| C2H2 | C2H4 | C2H6 | CH4 | H2 | CO | CO2 | O2 | N2 | ||||||||

| T1 | 2020–21 | 348.65 | 35.78 | 37.69 | 0.00365 | 73 | 6.5 | 0 | 0 | 0.027 | 3.45 | 21.65 | 243.45 | 290.54 | 6712.44 | 32,153.66 |

| 2021–22 | 245.00 | 44.43 | 46.01 | 0.00106 | 80.3 | 6.51 | 0 | 0.007 | 0.027 | 3.76 | 29.94 | 278.8 | 372.38 | 9600.41 | 53,852.77 | |

| 2022–23 | 185.65 | 43.76 | 45.28 | 0.00326 | 81.7 | 9.22 | 0.02 | 0.014 | 0 | 0.053 | 0 | 418.88 | 70.09 | 12,116.43 | 65,917.27 | |

| 2023–24 | 112.87 | 34.87 | 36.31 | 0.00163 | 68.4 | 13.41 | 0.39 | 0.313 | 0.317 | 0.344 | 0 | 317.485 | 89.271 | 19,609.125 | 93,377.5 | |

| T2 | 2020–21 | 348.65 | 35.78 | 37.69 | 0.00235 | 67.7 | 9.85 | 0.01 | 0.021 | 0 | 3.56 | 21.34 | 178.66 | 156.44 | 10,921.44 | 54,321.89 |

| 2021–22 | 245.00 | 44.43 | 46.01 | 0.00082 | 74.1 | 6.86 | 0.012 | 0.037 | 0.066 | 5.032 | 30.16 | 270 | 390.26 | 13,165.35 | 73,891.7 | |

| 2022–23 | 202.97 | 44.01 | 44.86 | 0.00454 | 81.7 | 8.01 | 0.009 | 0.014 | 0.019 | 0 | 0 | 356.57 | 80.123 | 11,561.19 | 67,582.65 | |

| 2023–24 | 152.70 | 36.68 | 38.18 | 0.0018 | 86.7 | 11.24 | 0.109 | 0.126 | 0.358 | 5.009 | 0 | 297.265 | 54.493 | 18,829.215 | 93,958.1 | |

| T3 | 2020–21 | 64.14 | 36.19 | 38.18 | 0.00268 | 71.5 | 8.45 | 0 | 0 | 0.021 | 1.232 | 0 | 260.32 | 330.77 | 19,345.55 | 54,321.44 |

| 2021–22 | 87.65 | 40.13 | 42.52 | 0.00062 | 68.7 | 7.08 | 0 | 0 | 0.039 | 1.391 | 0 | 270.6 | 338.71 | 20,754.62 | 67,546.71 | |

| 2022–23 | 99.44 | 39.94 | 42.32 | 0.00122 | 81.8 | 9.2 | 0.03 | 0.011 | 0.014 | 0.93 | 0 | 57.64 | 79.74 | 22,751.94 | 83,194.28 | |

| 2023–24 | 82.00 | 29.02 | 30.39 | 0.0015 | 78.3 | 10.86 | 0.009 | 0.068 | 0.209 | 4.876 | 0 | 67.694 | 60.408 | 24,559.199 | 92,462.49 | |

| Fault Gas | Indication | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| Cellulose Aging | Mineral Oil Decomposition | Leaks in Oil Expansion Systems | Thermal Fault—Cellulose | Thermal Fault—Oil (150–300 °C) | Thermal Fault—Oil (300–700 °C) | Thermal Fault—Oil > 700 °C | PD 1 | Arcing | |

| CO | Y 2 | ---- | ---- | Y | ---- | ---- | ---- | ---- | ---- |

| CO2 | Y | ---- | Y | Y | ---- | ---- | ---- | ---- | ---- |

| CH4 | ---- | Y | ---- | Y | Y | Y | Y | Y | Y |

| C2H2 | ---- | Y | ---- | ---- | ---- | T 3 | Y | T | Y |

| C2H4 | ---- | Y | ---- | ---- | T | Y | Y | ---- | Y |

| C2H6 | ---- | Y | ---- | ---- | Y | Y | ---- | ---- | ---- |

| O2 | ---- | ---- | Y | Y | ---- | ---- | ---- | ---- | ---- |

| H2 | Y | Y | ---- | Y | Y | Y | Y | Y | Y |

| H2O | ---- | ---- | Y | ---- | ---- | ---- | ---- | ---- | ---- |

| Gas Ratios | Transformer and Service Years | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| T1 | T2 | T3 | ||||||||||

| 2020–21 | 2021–22 | 2022–23 | 2023–24 | 2020–21 | 2021–22 | 2022–23 | 2023–24 | 2020–21 | 2021–22 | 2022–23 | 2023–24 | |

| CO2/CO | 1.193 | 1.336 | 0.167 | 0.281 | 0.876 | 1.445 | 0.225 | 0.183 | 1.271 | 1.252 | 1.383 | 0.892 |

| O2/N2 | 0.209 | 0.178 | 0.184 | 0.210 | 0.201 | 0.178 | 0.171 | 0.200 | 0.356 | 0.307 | 0.273 | 0.266 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mustafa, E.; Ahmad, B.; Ali, M.I.; Afia, R.S.A.; Ullah, R. Degradation Assessment of In-Service Transformer Oil Based on Electrical and Chemical Properties. Appl. Sci. 2024, 14, 11767. https://doi.org/10.3390/app142411767

Mustafa E, Ahmad B, Ali MI, Afia RSA, Ullah R. Degradation Assessment of In-Service Transformer Oil Based on Electrical and Chemical Properties. Applied Sciences. 2024; 14(24):11767. https://doi.org/10.3390/app142411767

Chicago/Turabian StyleMustafa, Ehtasham, Bilal Ahmad, Malik Imran Ali, Ramy S. A. Afia, and Rahmat Ullah. 2024. "Degradation Assessment of In-Service Transformer Oil Based on Electrical and Chemical Properties" Applied Sciences 14, no. 24: 11767. https://doi.org/10.3390/app142411767

APA StyleMustafa, E., Ahmad, B., Ali, M. I., Afia, R. S. A., & Ullah, R. (2024). Degradation Assessment of In-Service Transformer Oil Based on Electrical and Chemical Properties. Applied Sciences, 14(24), 11767. https://doi.org/10.3390/app142411767