Assessment of Dielectric Strength for 3D Printed Solid Materials in Terms of Insulation Coordination

Abstract

1. Introduction

2. Materials and Methods

2.1. Solid Insulating Materials

2.2. Three-DimensionalPrinting Method

2.3. Measurement Method and Experimental Setup

3. Results

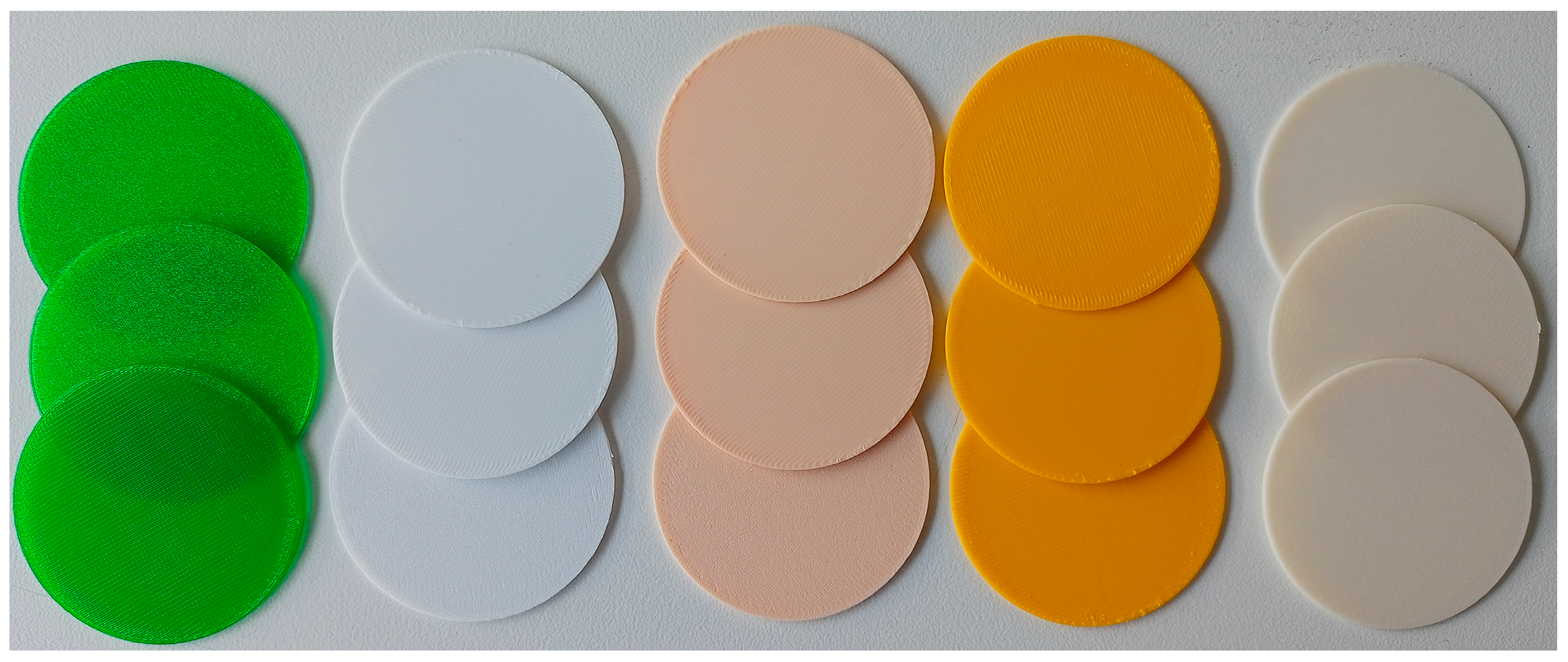

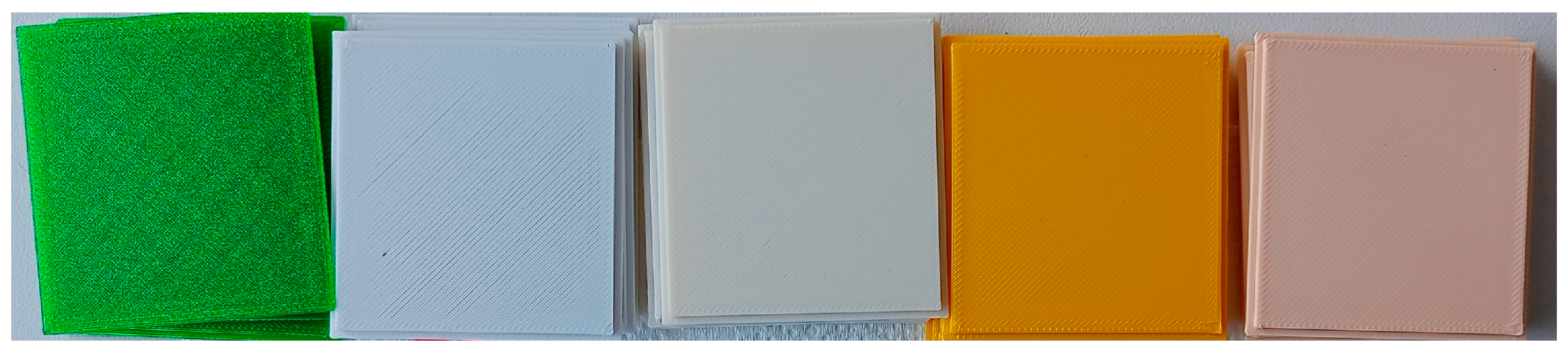

3.1. Specimen Preparation

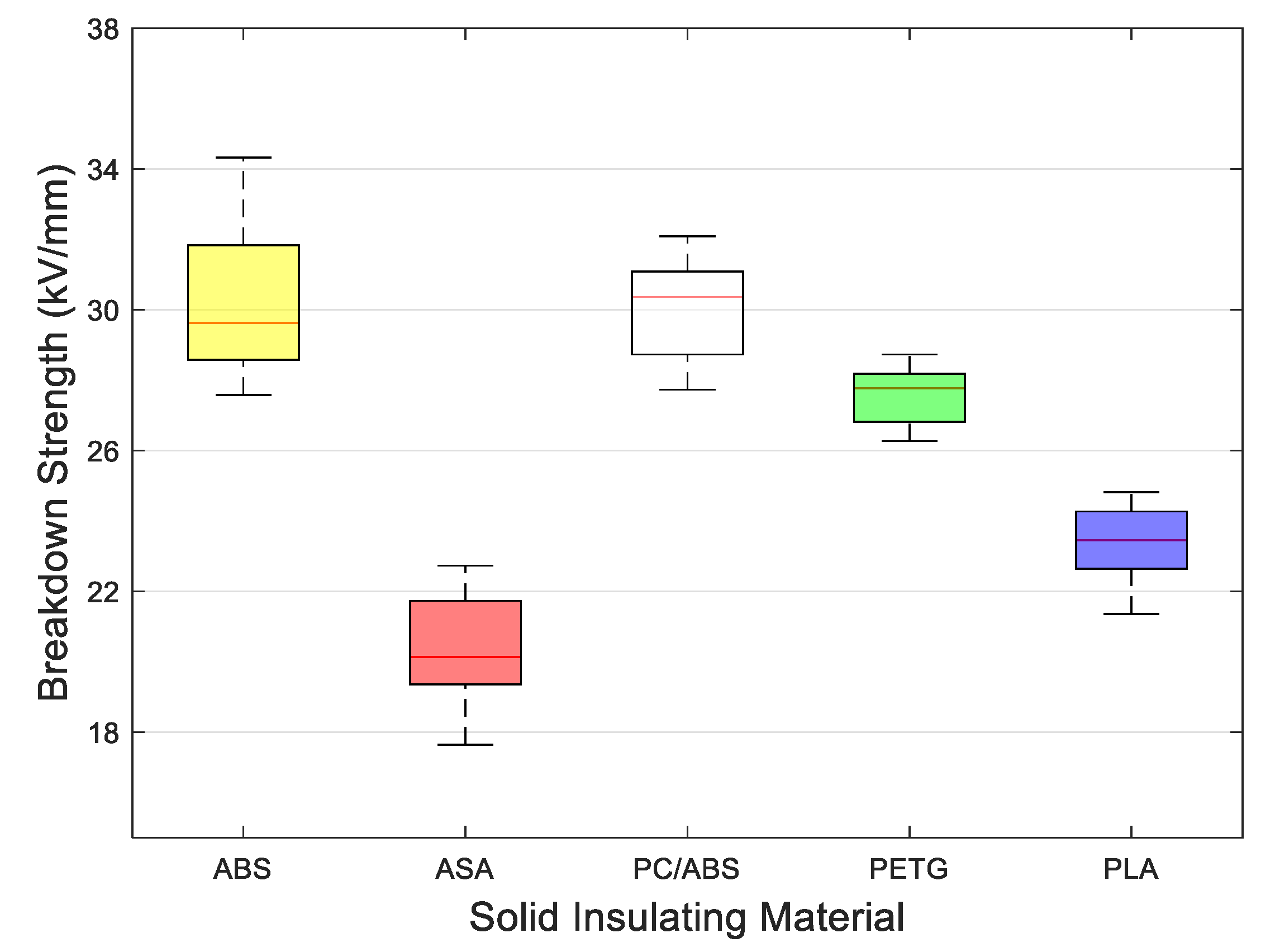

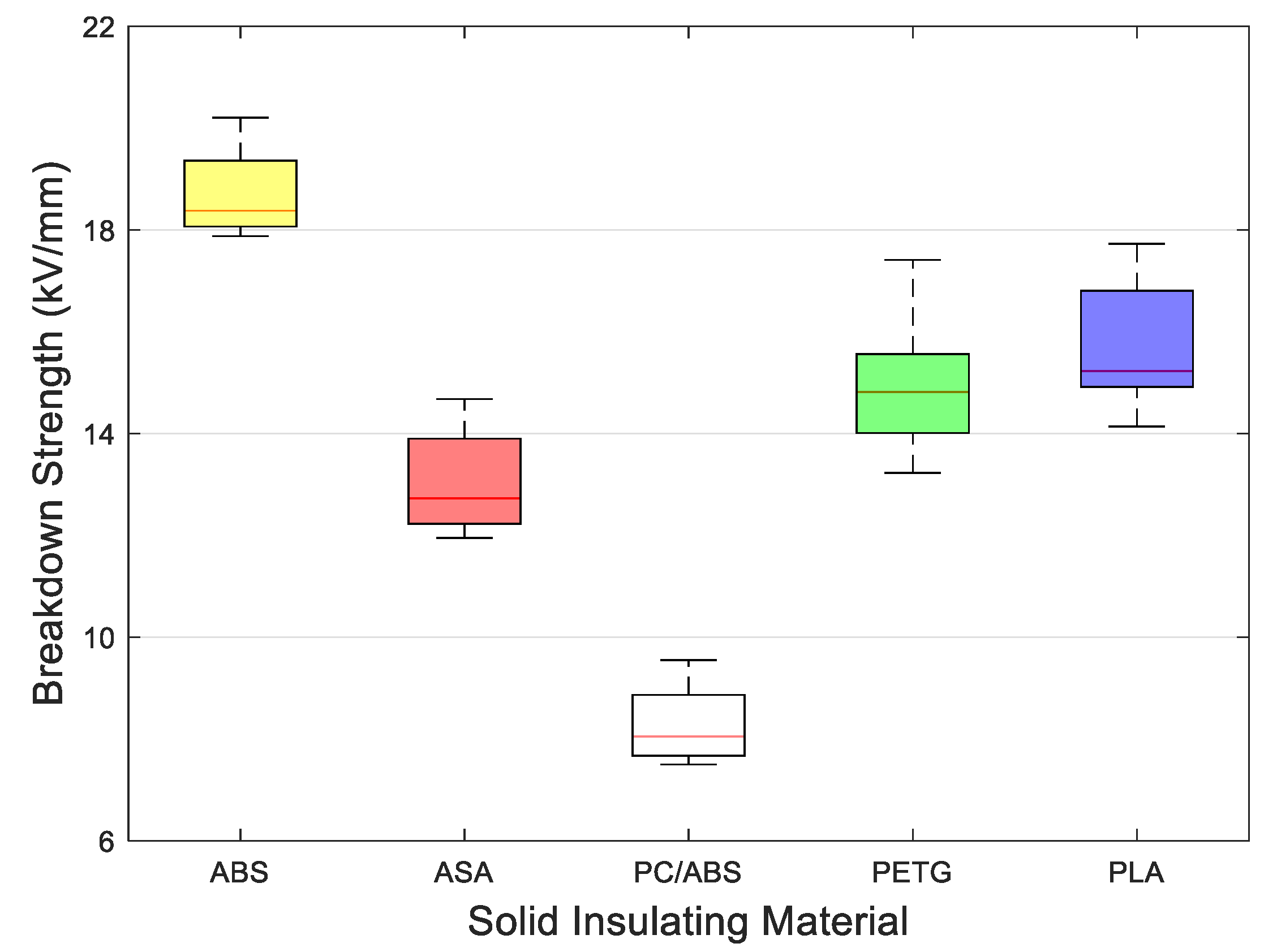

3.2. Results of Breakdown Strength Measurements

4. Discussion

4.1. Weibull Analysis

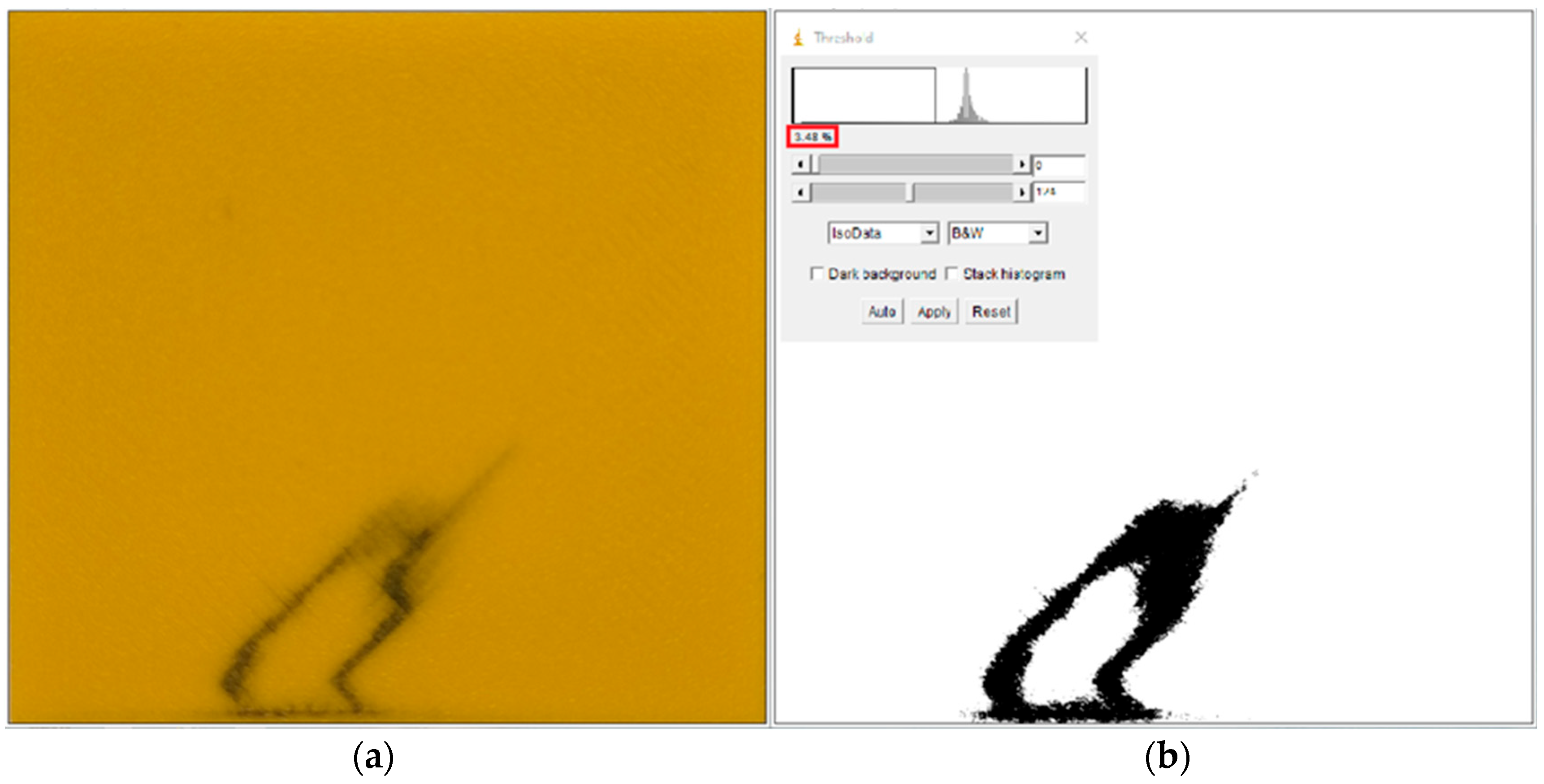

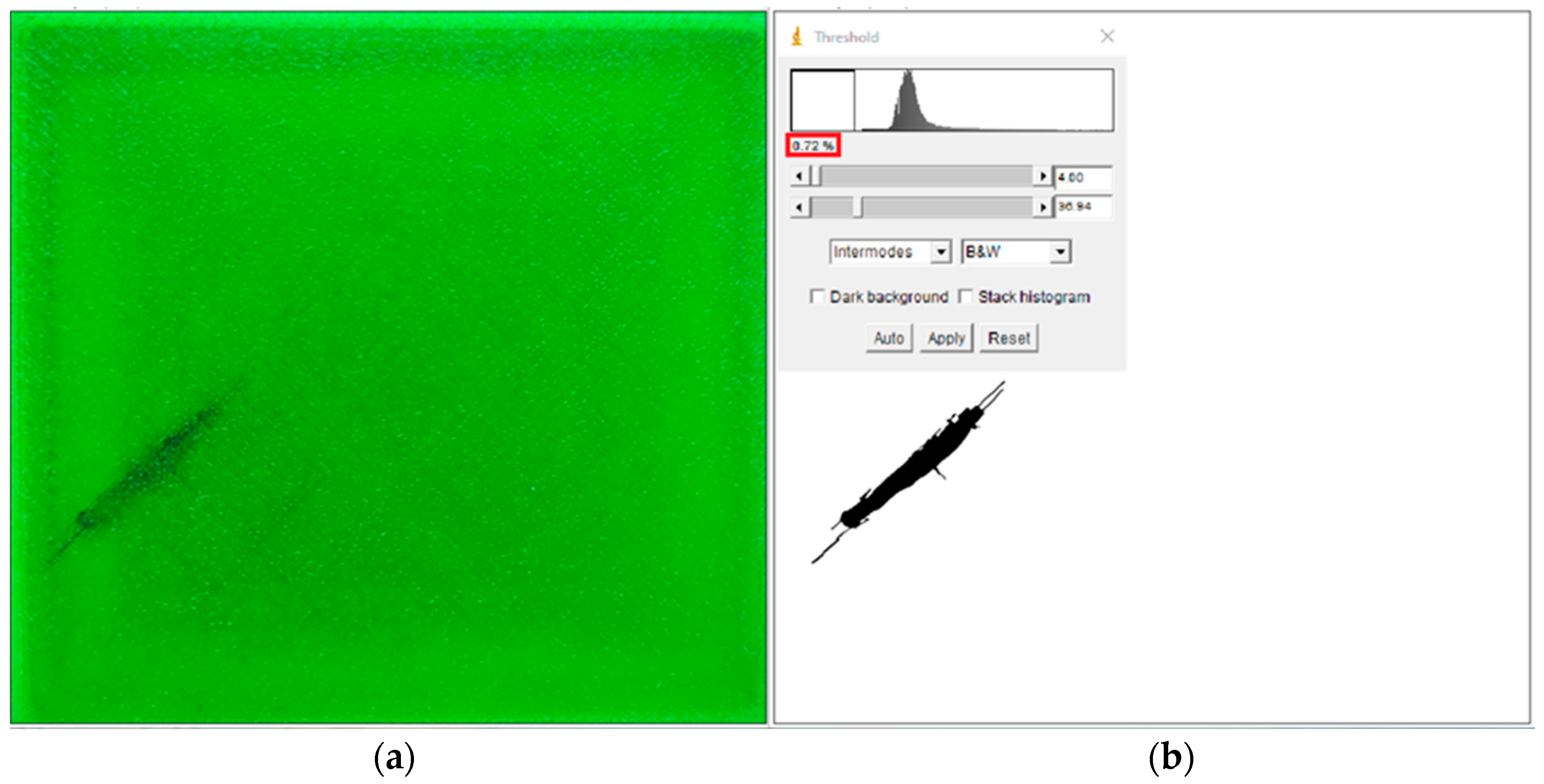

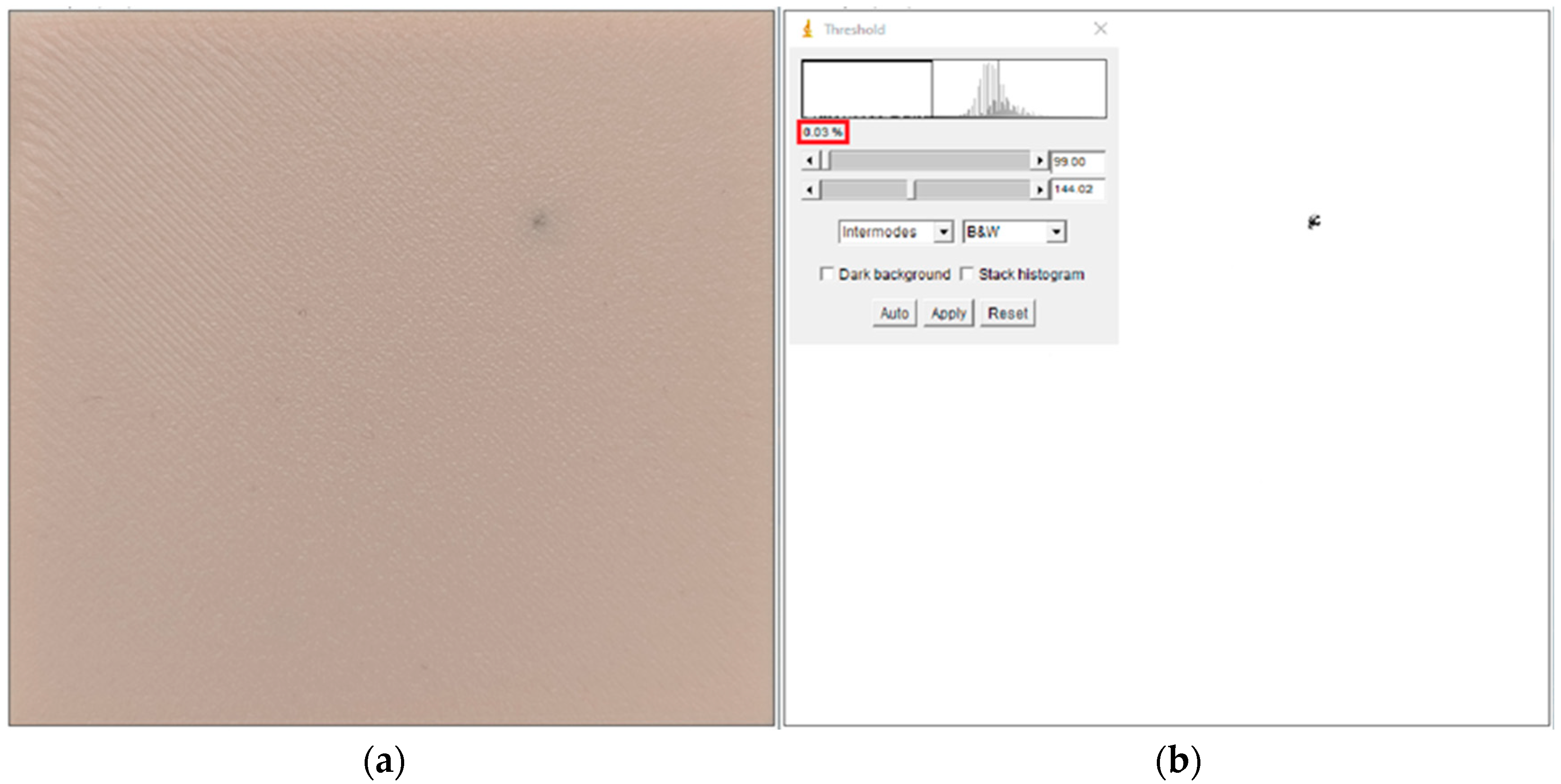

4.2. Image Processing Analysis

4.3. Simulation Results of Electric Field Distribution Analysis

5. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kim, B.G.; Choi, H.H.; Park, H.Y.; Kwon, M.S.; Byeun, Y.K.; Kang, S.; Jung, Y.G.; Son, J.H.; Yang, S.C. Preparation and characterization of organic–inorganic hybrid coatings for improving the insulation properties of electrical steel. J. Coat. Technol. Res. 2023, 20, 1383–1393. [Google Scholar] [CrossRef]

- Zou, H.; Yin, Y.; Chen, J.; Zhang, S.; Tian, F. Research on the Inner Surface Discharge of the Insulation Sheath of Electric Locomotive Cable Terminals. Appl. Sci. 2024, 14, 9681. [Google Scholar] [CrossRef]

- Kadim, E.J.; Noorden, Z.A.; Adzis, Z.; Azis, N. Nanoparticles Application in High Voltage Insulation Systems. IEEE Trans. Dielectr. Electr. Insul. 2021, 28, 1380–1399. [Google Scholar] [CrossRef]

- Chapman, M.; Frost, N.; Bruetsch, R. Insulation systems for rotating low-voltage machines. In Proceedings of the Conference Record of the 2008 IEEE International Symposium on Electrical Insulation, Vancouver, BC, Canada, 9–12 June 2008; pp. 257–260. [Google Scholar] [CrossRef]

- Zhong, L.; Du, J.; Xi, Y.; Wang, F.; Wu, L.; Li, J.; Tu, M.; Li, X.; Fei, G. Multi-material and parameter-controllable stereolithography 3D printing of graded permittivity composites for high voltage insulators. Virtual Phys. Prototyp. 2023, 18, e2271447. [Google Scholar] [CrossRef]

- Bianchi, R.A.C.; Ferraz, H.F.; Gonçalves, R.S.; Moura, B.; Sudbrack, D.E.T.; Merini, A.; Machado, M.d.L.G.; Pires, R.; Homma, R.Z. A synthetic high-voltage power line insulator images dataset. Data Br. 2024, 55, 110688. [Google Scholar] [CrossRef]

- Li, Z.; Hsieh, E.; Li, Q.; Lee, F.C. High-Frequency Transformer Design with Medium-Voltage Insulation for Resonant Converter in Solid-State Transformer. IEEE Trans. Power Electron. 2023, 38, 9917–9932. [Google Scholar] [CrossRef]

- Guo, Y.; Tian, F.; Liu, H.; Yin, Y. Research on Ultra-Fast Transient Overvoltage Characteristics of Electric Locomotive. Appl. Sci. 2024, 14, 9561. [Google Scholar] [CrossRef]

- Divakaran, N.; Alex, Y.; Mohapatra, A.; Mohanty, S. Material extrusion-based 3D printed capacitor optimization: Enhancing performance with ZnO and Cu-CNT reinforced ABS composites. Appl. Mater. Today 2024, 40, 102363. [Google Scholar] [CrossRef]

- Cheng, F. Comparative study on the application of 3D printing and digital printing technology in fashion design. In Proceedings of the 2022 World Automation Congress (WAC), San Antonio, TX, USA, 11–15 October 2022; pp. 202–206. [Google Scholar] [CrossRef]

- Jaksic, N.I.; Desai, P.D. Characterization of 3D-printed capacitors created by fused filament fabrication using electrically-conductive filament. Procedia Manuf. 2019, 38, 33–41. [Google Scholar] [CrossRef]

- Zhou, Y. Research on development and problems of 3D printing technology under intelligent background. In Proceedings of the 2019 12th International Conference on Intelligent Computation Technology and Automation (ICICTA), Xiangtan, China, 26–27 October 2019; pp. 682–685. [Google Scholar] [CrossRef]

- Zhang, J.; Ding, B. Intelligent 3D Printing Technology in Architectural Design. In Proceedings of the 2023 3rd International Conference on Mobile Networks and Wireless Communications (ICMNWC), Tumkur, India, 4–5 December 2023; pp. 1–6. [Google Scholar] [CrossRef]

- Umair, M.; Kim, W.S. An Online 3D Printing Portal for General and Medical Fields. In Proceedings of the 2015 International Conference on Computational Intelligence and Communication Networks (CICN), Jabalpur, India, 12–14 December 2015; pp. 278–282. [Google Scholar] [CrossRef]

- Shi, Y. Research on the Combination of 3D Printing Technology and Computer Aided Industrial Design. In Proceedings of the 2022 4th International Conference on Smart Systems and Inventive Technology (ICSSIT), Tirunelveli, India, 20–22 January 2022; pp. 1231–1234. [Google Scholar] [CrossRef]

- Sahin, G.; Özyildirim, H.; Sahin, A. Investigation of mechanical and printing properties of poly(lactic acid) and its composite filaments used in 3D printing. Iran. Polym. J. 2024, 33, 79–91. [Google Scholar] [CrossRef]

- Li, S.; Izquierdo, B.S.; Gao, S. Analysis of 3D Printed Dielectric Resonator Antenna Arrays for Millimeter-Wave 5G Applications. Appl. Sci. 2024, 14, 9886. [Google Scholar] [CrossRef]

- Hua, L.; Bowen, P. Application of Ceramic 3D Printing Technology in Modern Ceramic Manufacturing. In Proceedings of the 2021 7th International Symposium on Mechatronics and Industrial Informatics (ISMII), Zhuhai, China, 22–24 January 2021; pp. 160–163. [Google Scholar] [CrossRef]

- Chankuson, P.; Chumsri, P.; Plodkaew, A. The Simulation of Dielectric Barrier Discharge for Breakdown Voltage in Starch Modification. Appl. Sci. 2023, 13, 12143. [Google Scholar] [CrossRef]

- Touzin, M.; Goeuriot, D.; Guerret-Piécourt, C.; Juvé, D.; Fitting, H.J. Alumina based ceramics for high-voltage insulation. J. Eur. Ceram. Soc. 2010, 30, 805–817. [Google Scholar] [CrossRef]

- Khalid, M.; Riaz, S.; Grekov, A.E.; Santi, E.; Naseem, S. High Breakdown Voltage Characteristics in Normally-Off 4H-SiC VJFET Using TCAD Simulation; Elsevier Ltd.: Amsterdam, The Netherlands, 2015; Volume 2. [Google Scholar]

- Zhang, T.; Du, J.; Lei, Y.; Cheng, Y.; Liu, W.; Yi, X.; Yin, J.; Yu, P. Effect of pores on dielectric breakdown strength of alumina ceramics via surface and volume effects. J. Eur. Ceram. Soc. 2020, 40, 3019–3026. [Google Scholar] [CrossRef]

- Balmelli, M.; Merotto, L.; Soltic, P.; Biela, J. Ignition detection with the breakdown voltage measurement during nanosecond repetitively pulsed discharges. Energy Convers. Manag. 2023, 292, 117382. [Google Scholar] [CrossRef]

- Akin, F.; Arikan, O.; Uydur, C.C. Analysis of Solid Insulating Materials Breakdown Voltages Under Different Voltage Types. Turk. J. Electr. Power Energy Syst. 2022, 2, 85–93. [Google Scholar] [CrossRef]

- Chen, G.; Zhao, J. Space charge and thickness dependent dc electrical breakdown of solid dielectrics. In Proceedings of the 2012 International Conference on High Voltage Engineering and Application, Shanghai, China, 17–20 September 2012; pp. 12–15. [Google Scholar] [CrossRef]

- BS EN 60243-1:2013; Electric Strength of Insulating Materials—Test Methods Part 1: Tests at Power Frequencies. BSI Standards Publication: London, UK, 2014; ISBN 978 0 580 83184 3.

- IEC 60060-1:2010; High-Voltage Test Techniques—Part 1: General Definitions and Test Requirements. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- Akın, F. Katı Yalıtkan Malzemelerin Farklı Çalışma Koşulları Altında Performans Analizi. Master’s Thesis, Yıldız Technical University, İstanbul, Turkey, 2021. [Google Scholar]

- Awcock, G.J.; Thomas, R. Pattern Classification BT—Applied Image Processing; Awcock, G.J., Thomas, R., Eds.; Macmillan Education: London, UK, 1995; pp. 176–203. ISBN 978-1-349-13049-8. [Google Scholar]

- Huang, T.S.; Schreiber, W.F.; Tretiak, O.J. Image Processing. Proc. IEEE 1971, 59, 1586–1609. [Google Scholar] [CrossRef]

- Igathinathane, C.; Pordesimo, L.O.; Columbus, E.P.; Batchelor, W.D.; Methuku, S.R. Shape identification and particles size distribution from basic shape parameters using ImageJ. Comput. Electron. Agric. 2008, 63, 168–182. [Google Scholar] [CrossRef]

- Schindelin, J.; Rueden, C.T.; Hiner, M.C.; Eliceiri, K.W. The ImageJ ecosystem: An open platform for biomedical image analysis. Mol. Reprod. Dev. 2015, 82, 518–529. [Google Scholar] [CrossRef] [PubMed]

- Papadopulos, F.; Spinelli, M.; Valente, S.; Foroni, L.; Orrico, C.; Alviano, F.; Pasquinelli, G. Common tasks in microscopic and ultrastructural image analysis using ImageJ. Ultrastruct. Pathol. 2007, 31, 401–407. [Google Scholar] [CrossRef] [PubMed]

- Sahin, A. 3B Yazıcılarda Kullanılan Filamentler; All Sciences Academy: Konya, Türkiye, 2024; ISBN 978-625-6314-64-1. [Google Scholar]

- Qidi Tech. Available online: https://qidi3d.com/products/q1-pro-3d-printer (accessed on 1 November 2024).

- BS EN 60243-2:2014; Electric Strength of Insulating Materials—Test Methods Part 2: Additional Requirements for Tests Using Direct Voltage. BSI Standards Publication: London, UK, 2014; ISBN 978 0 580 83184 3.

- BS EN 60243-3:2014; Electric Strength of Insulating Materials—Test Methods Part 3: Additional Requirements for 1,2/50 μs Impulse Tests. BSI Standards Publication: London, UK, 2014; ISBN 978 0 580 83184 3.

- IEC 60060-2:2010; High-Voltage Test Techniques—Part 2: Measuring Systems. International Electrotechnical Commission: Geneva, Switzerland, 2010.

- Akin, F.; Arikan, O. Analysis of breakdown mechanism based on contact area and field enhancement factor of different electrode-material combinations. Int. J. Energy Res. 2022, 46, 12674–12686. [Google Scholar] [CrossRef]

- Akin, F.; Arikan, O. The effect of thermal aging on solid insulating materials: A case study for dielectric loss and dissipation factor based evaluations under different voltage levels and frequencies. Eng. Fail. Anal. 2023, 148, 107222. [Google Scholar] [CrossRef]

- Camalov, M.; Orucov, A.; Hashimov, A.; Arikan, O.; Akin, F. Breakdown strength analysis of XLPE insulation types: A comparative study for multi-layer structure and voltage rise rate. Electr. Power Syst. Res. 2023, 223, 109703. [Google Scholar] [CrossRef]

- White, J.S. The Moments of Log-Weibull Order Statistics. Technometrics 1969, 11, 373–386. [Google Scholar] [CrossRef]

| Parameters | ABS | ASA | PC/ABS | PETG | PLA |

|---|---|---|---|---|---|

| Density (g/m3) | 1.03 | 1.06 | 1.13 | 1.28 | 1.23 |

| Melt Flow Index (g/10min) | 5.2 | 22 | 12 | 20 | 17.3 |

| Tensile Strength (MPa) | 44 | 48 | 60 | 53 | 56 |

| Elastic Modulus (MPa) | 2100 | 2100 | 2200 | 3000 | 2850 |

| Elongation at Break (%) | 40 | 12 | 75 | 30 | 7 |

| Notched Impulse Test (kJ/m2) | 38 | 17 | 13 | 14.2 | 14.2 |

| Heat Bending Temperature (°C) | 95 | 95 | 120 | 80 | 55 |

| Glass Transition Temperature (°C) | 95–105 | 100–105 | 125–135 | 80–85 | 55–60 |

| Surface Resistance (Ω/sq) | >1012 | >1012 | >1012 | >1012 | >1012 |

| Relative Permittivity | 3 | 3.3 | 2.9 | 3 | 3.1 |

| Parameter | Qidi Tech Q1 Pro 3D |

|---|---|

| Print Size (W×D×H) | 245 × 245 × 240 mm |

| XY Structure | CoreXY |

| Print Head Temperature | ≤350 °C |

| Hot Bed Temperature | ≤120 °C |

| Max Speed of Tool Head | 600 mm/s |

| Chamber Temperature | 60 °C Independent Chamber Heating |

| Recommended Filament | PLA, ABS, ASA, PETG |

| Compatible Filament | TPU, PA, PC, Carbon/Glass Fiber-Reinforced Polymer |

| Automatic Leveling | Hands-free Automatic Leveling |

| Parameters | ABS | ASA | PC/ABS | PETG | PLA |

|---|---|---|---|---|---|

| Nozzle diameter (mm) | 0.4 | 0.4 | 0.4 | 0.4 | 0.4 |

| Layer height (mm) | 0.2 | 0.2 | 0.2 | 0.2 | 0.2 |

| Sparse infill density (%) | 100 | 100 | 100 | 100 | 100 |

| Sparse infill pattern | Rectilinear | Rectilinear | Rectilinear | Rectilinear | Rectilinear |

| Nozzle temperature (°C) | 283 | 275 | 283 | 240 | 220 |

| Build plate (°C) | 110 | 100 | 110 | 80 | 60 |

| Chamber temperature (°C) | 53 | 53 | 53 | - | - |

| Initial layer print speed (mm/s) | 50 | 50 | 50 | 50 | 50 |

| Initial layer infill print speed (mm/s) | 105 | 105 | 105 | 105 | 105 |

| Outer wall print speed (mm/s) | 200 | 200 | 200 | 200 | 200 |

| Inner wall print speed (mm/s) | 300 | 300 | 300 | 300 | 300 |

| Print cooling enable | No | Yes | No | Yes | Yes |

| Weibull Parameter | PLA | ABS | ASA | PETG | PC/ABS |

|---|---|---|---|---|---|

| α | 23.92 | 31.36 | 21.05 | 27.92 | 30.78 |

| β | 27.35 | 13.68 | 14.83 | 42.27 | 25.70 |

| Parameter | PLA | ABS | ASA | PETG | PC/ABS |

|---|---|---|---|---|---|

| Breakdown Strength (max) [kV/mm] | 24.82 | 34.33 | 22.73 | 28.73 | 32.09 |

| Breakdown Strength (critical) [kV/mm] | 23.92 | 31.36 | 21.00 | 27.92 | 30.78 |

| Breakdown Strength (%95) [kV/mm] | 24 | 34 | 22 | 28 | 32 |

| Electric Field (max) [kV/mm] | 25.79 | 33.74 | 22.80 | 30.04 | 33.04 |

| Damage Ratio | 0.03% | 3.48% | 1.39% | 0.72% | 3.49% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Uydur, C.C. Assessment of Dielectric Strength for 3D Printed Solid Materials in Terms of Insulation Coordination. Appl. Sci. 2024, 14, 11860. https://doi.org/10.3390/app142411860

Uydur CC. Assessment of Dielectric Strength for 3D Printed Solid Materials in Terms of Insulation Coordination. Applied Sciences. 2024; 14(24):11860. https://doi.org/10.3390/app142411860

Chicago/Turabian StyleUydur, Cihat Cagdas. 2024. "Assessment of Dielectric Strength for 3D Printed Solid Materials in Terms of Insulation Coordination" Applied Sciences 14, no. 24: 11860. https://doi.org/10.3390/app142411860

APA StyleUydur, C. C. (2024). Assessment of Dielectric Strength for 3D Printed Solid Materials in Terms of Insulation Coordination. Applied Sciences, 14(24), 11860. https://doi.org/10.3390/app142411860