Design and Development of Rice Pot-Seedling Transplanting Machinery Based on a Non-Circular Gear Mechanism

Abstract

1. Introduction

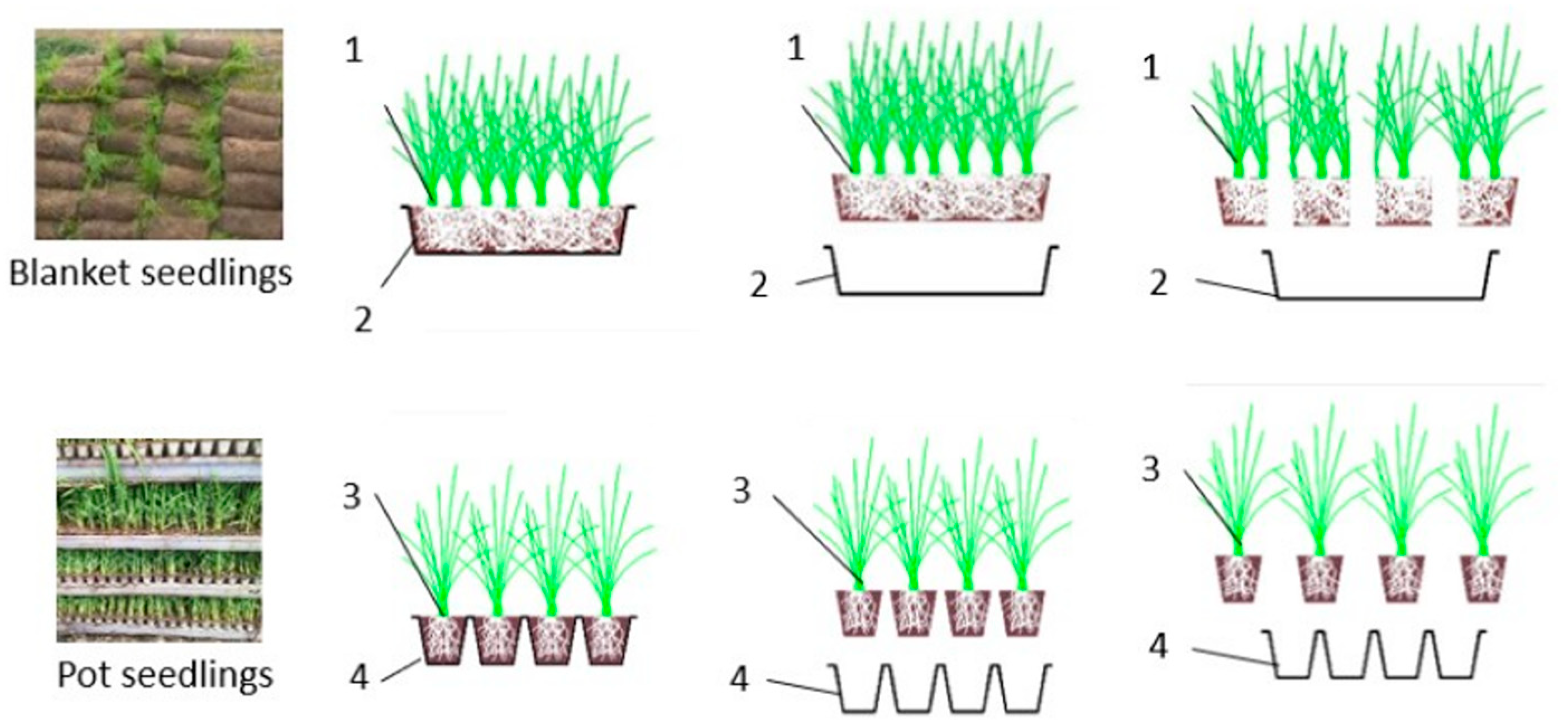

2. Working Principle and Posture Requirements

2.1. Working Principle and Attitude Requirements

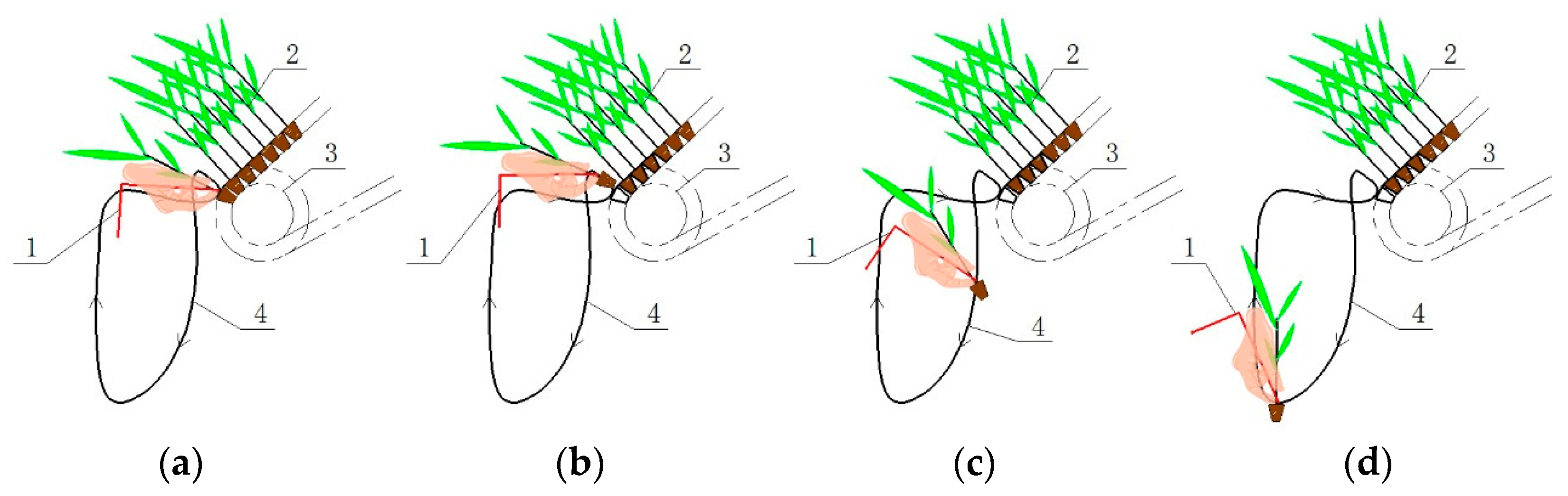

2.2. Picking-Type Trajectory and Attitude

2.3. Kinematic Model of the Non-Circular-Gear Transplanting Mechanism

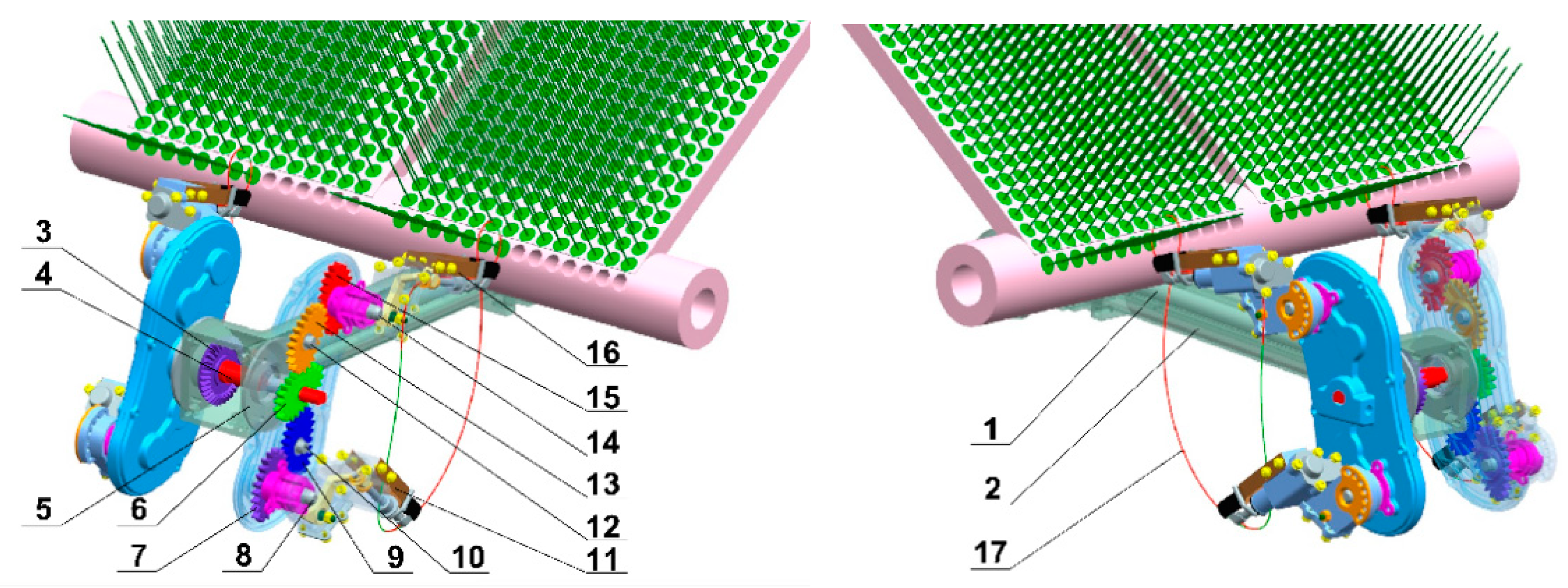

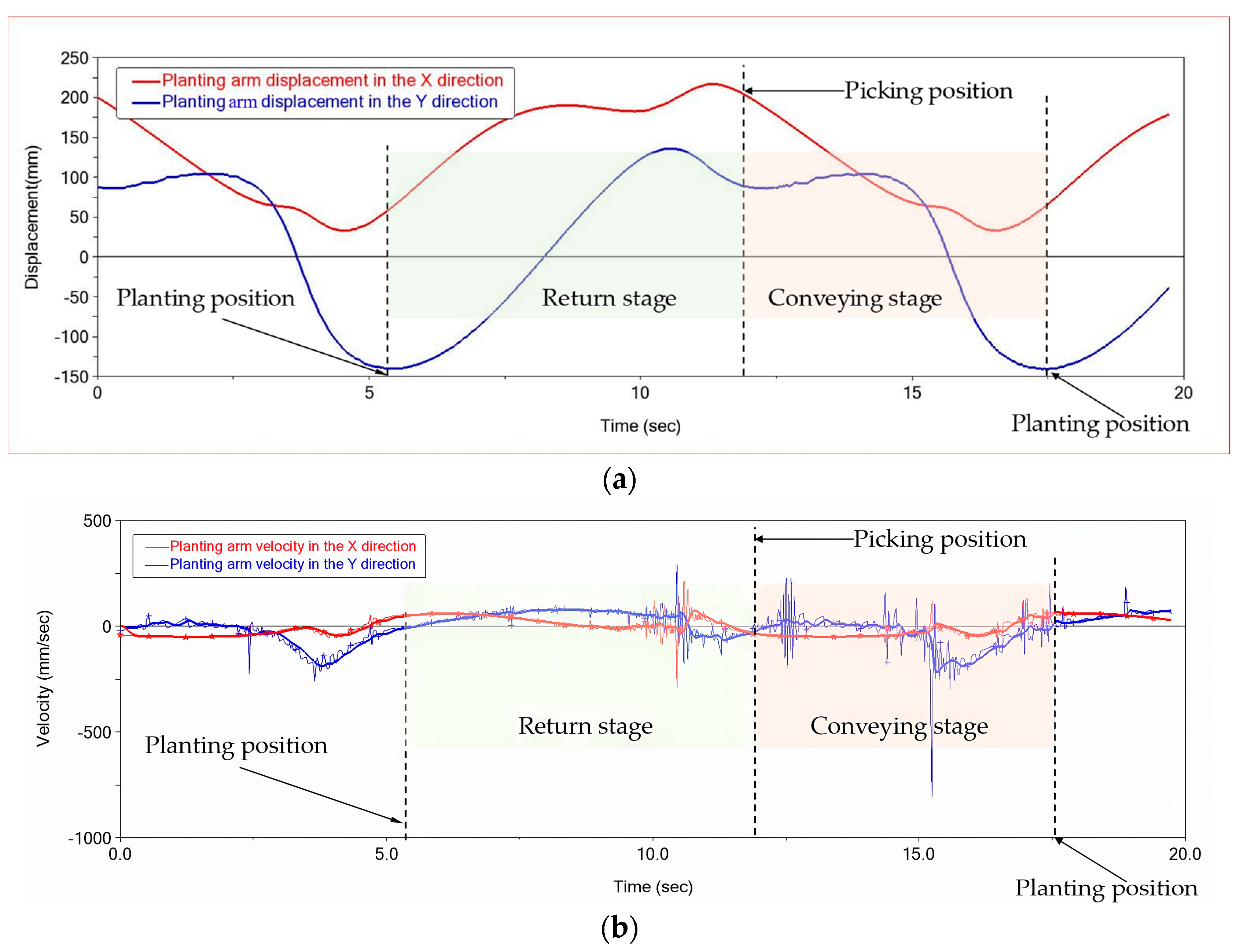

3. Description of Mechanism Parameters and the Work Cycle

4. Design of Key Parts

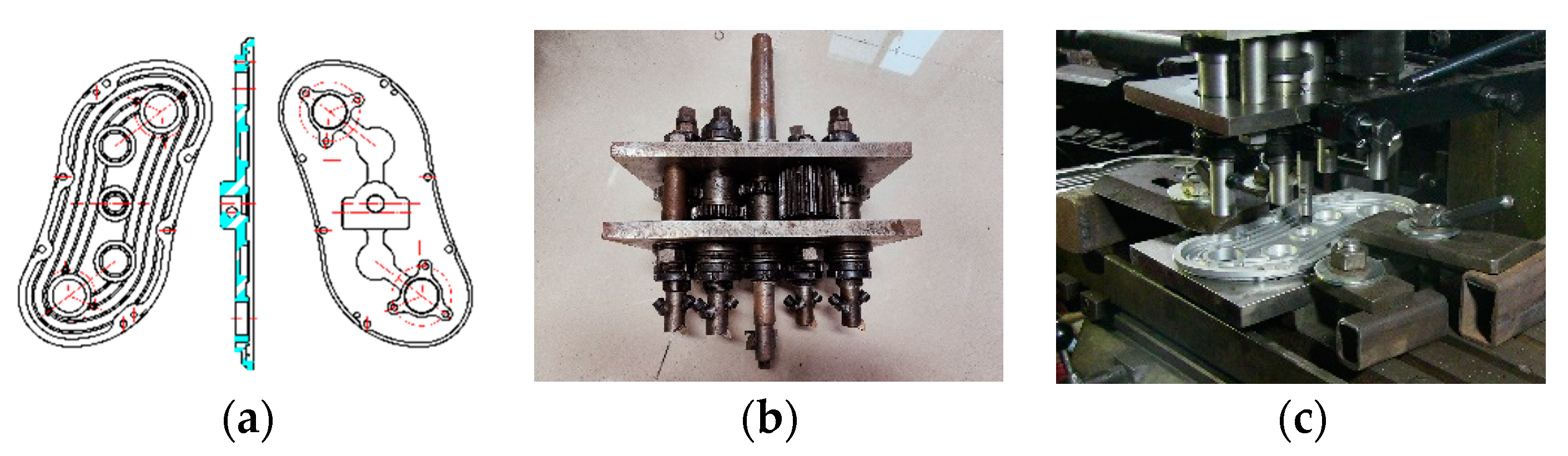

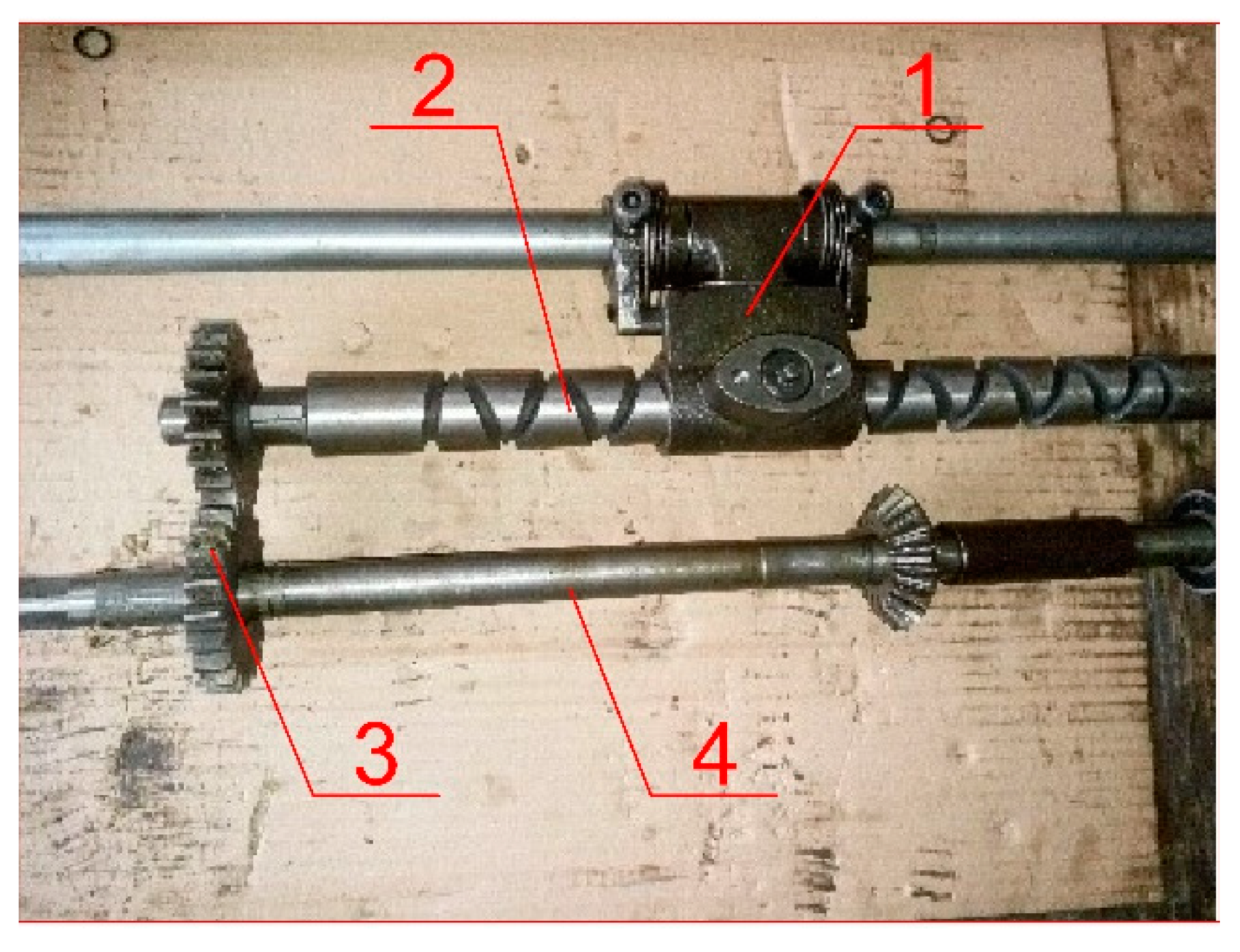

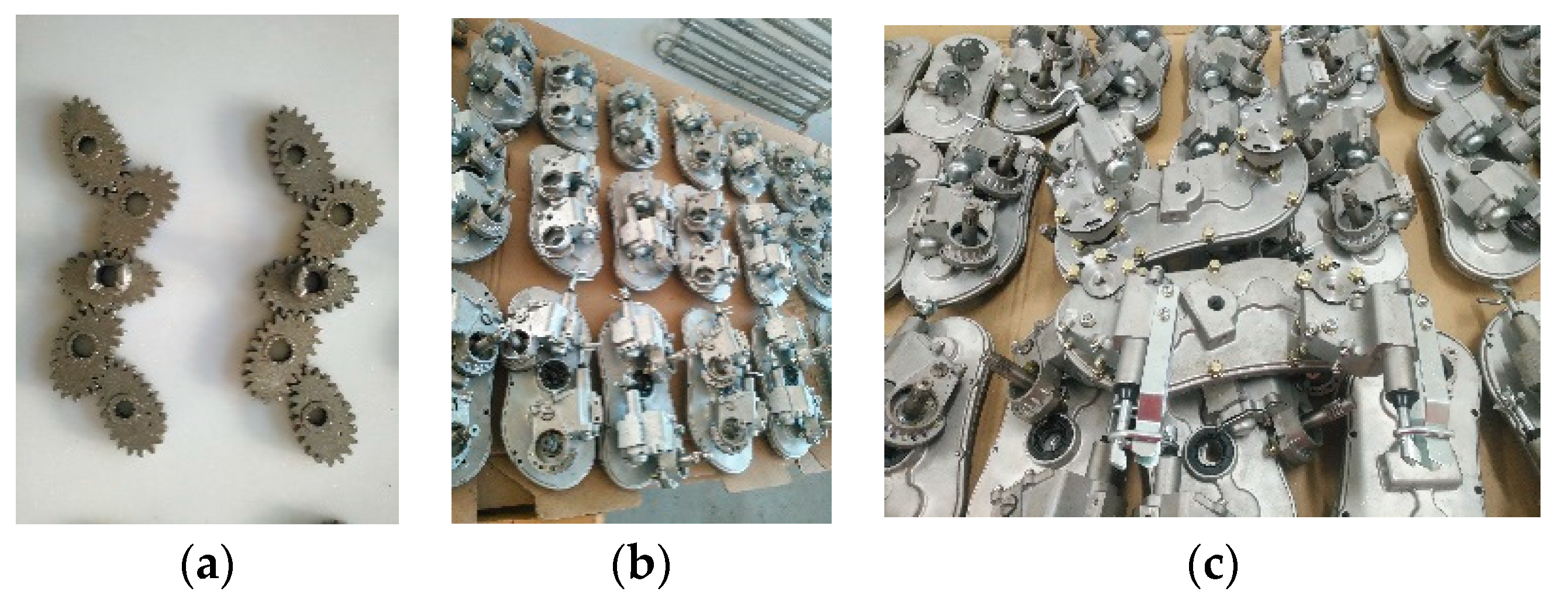

4.1. Design and Manufacture of Non-Circular Gears

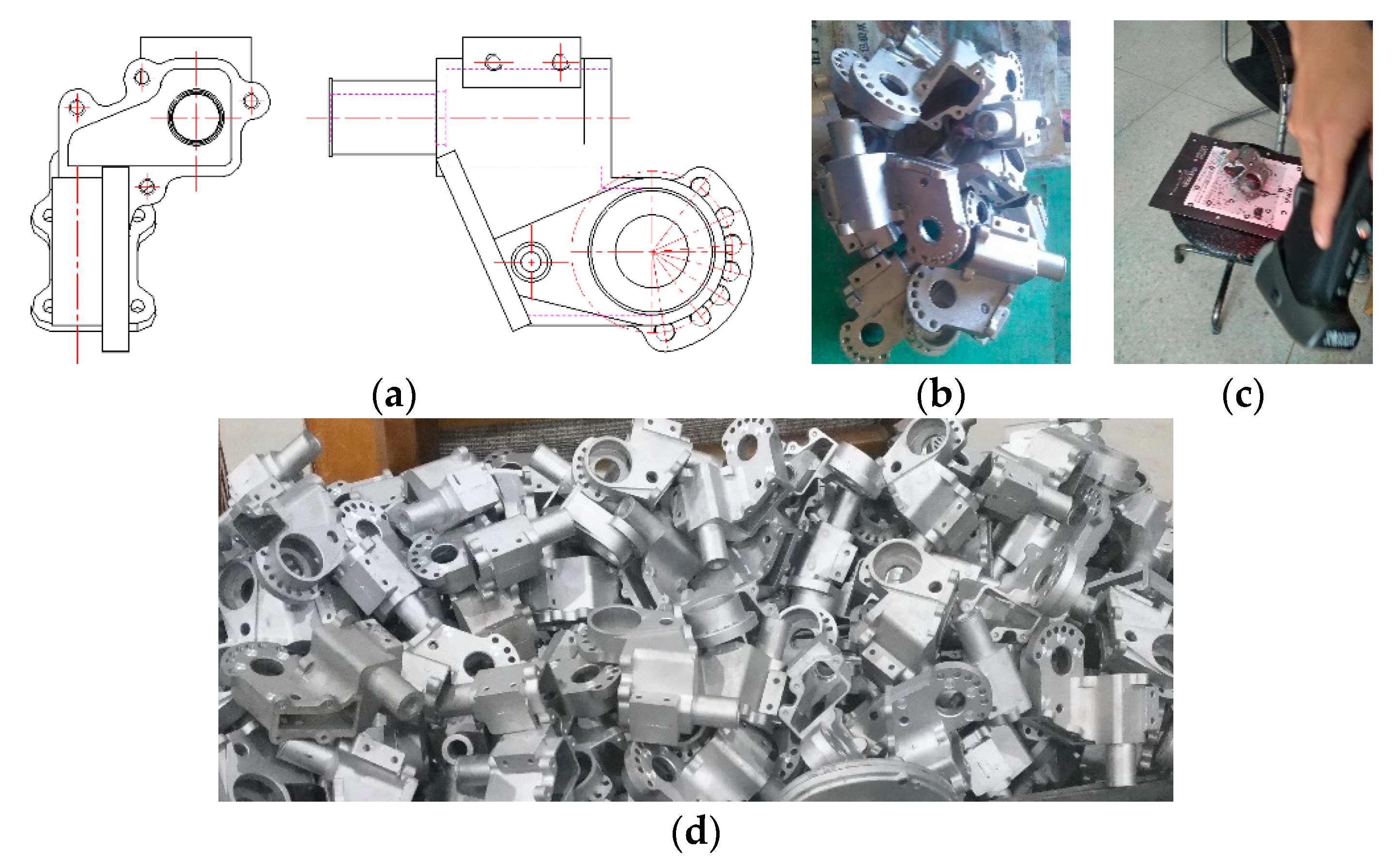

4.2. Design and Manufacture of the Gearbox

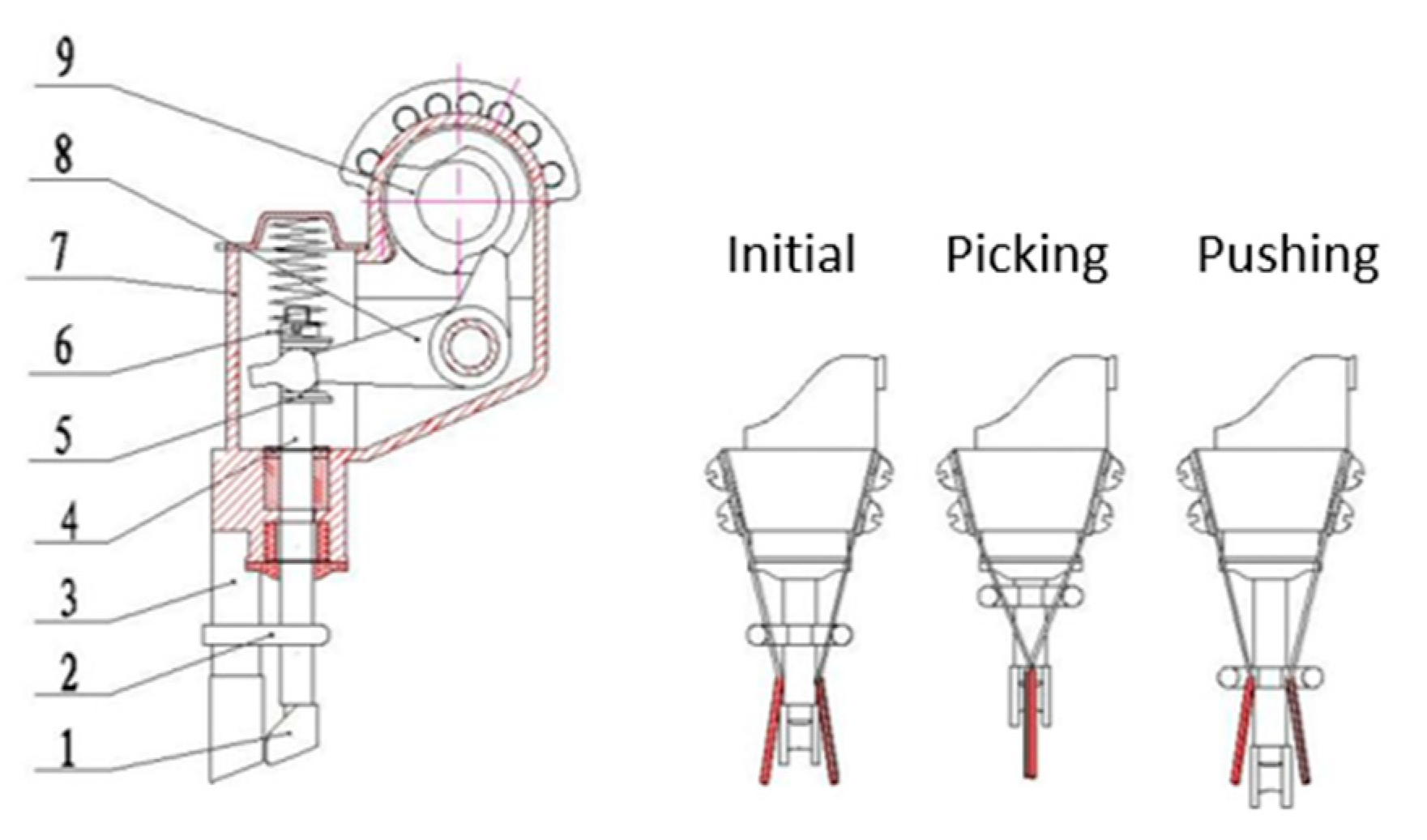

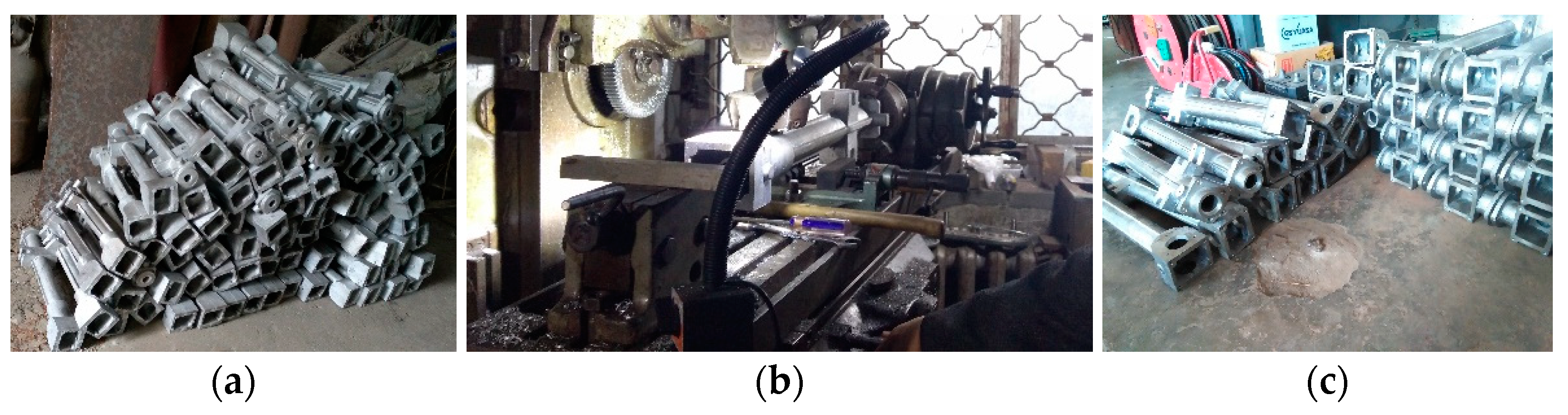

4.3. Design and Manufacture of the Transplanting Arm

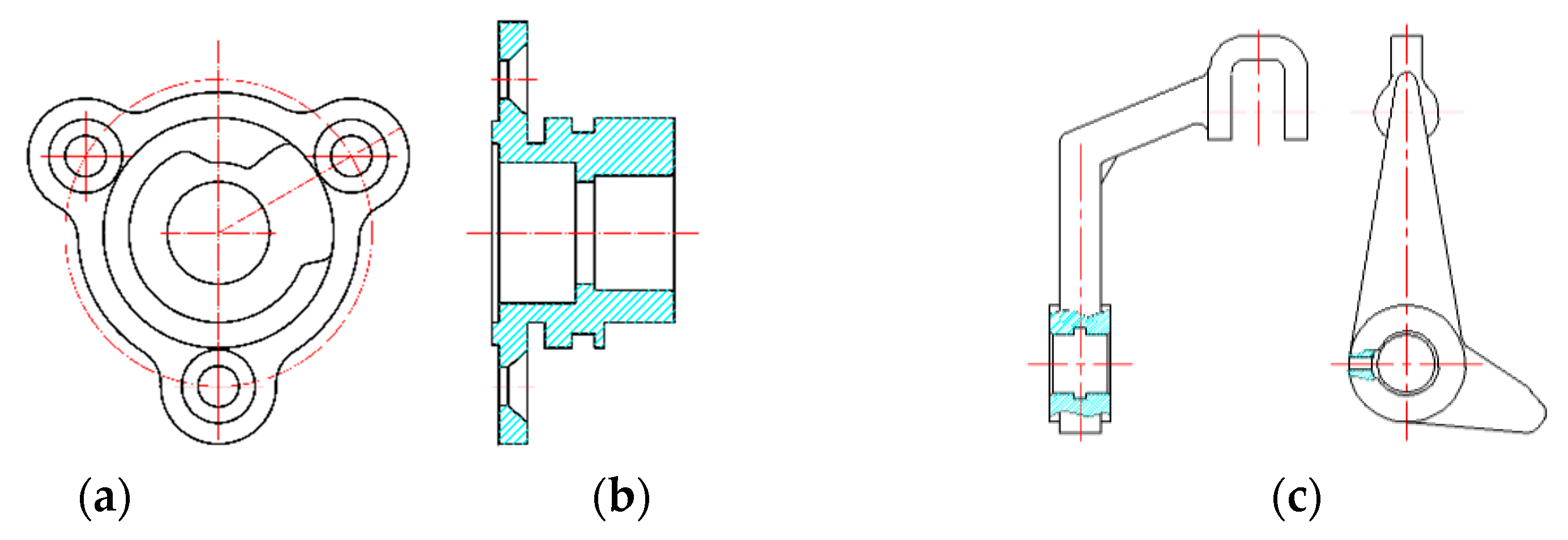

4.4. Design and Manufacture of the Cam and Shifting Fork

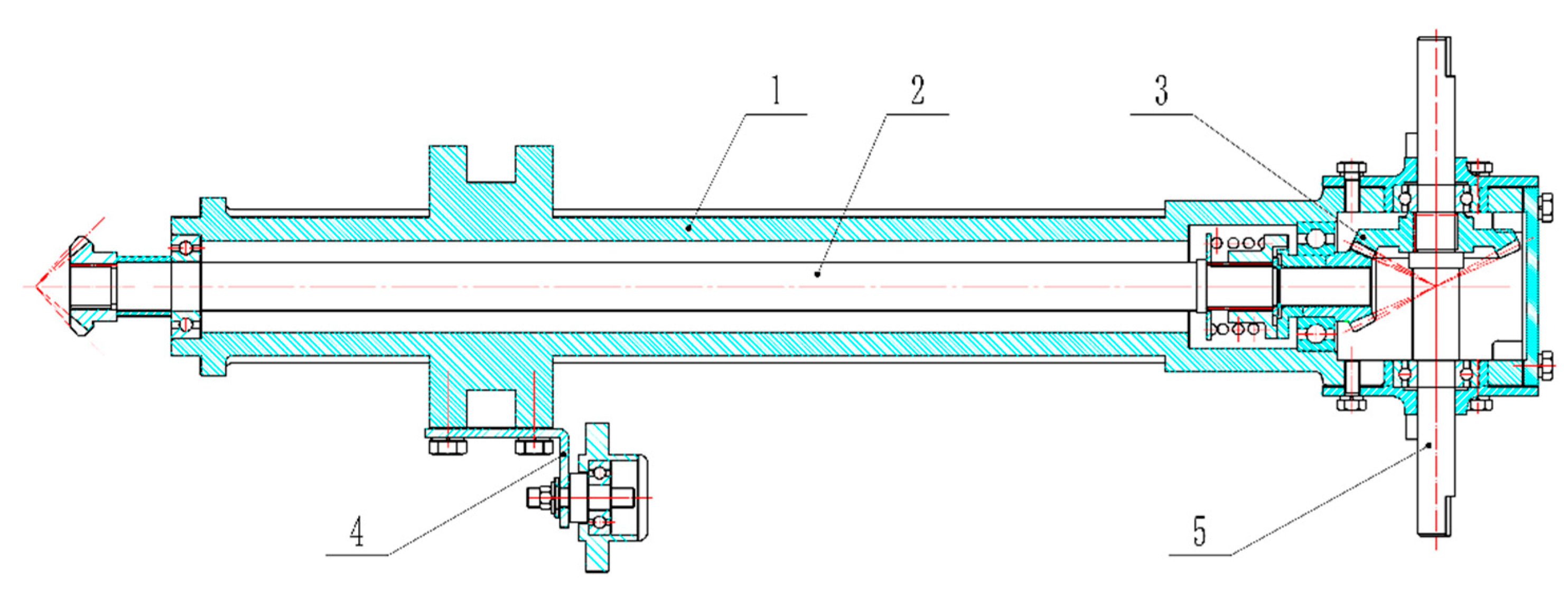

4.5. Design and Manufacture of the Transmission System

5. Design of the Other Key Devices

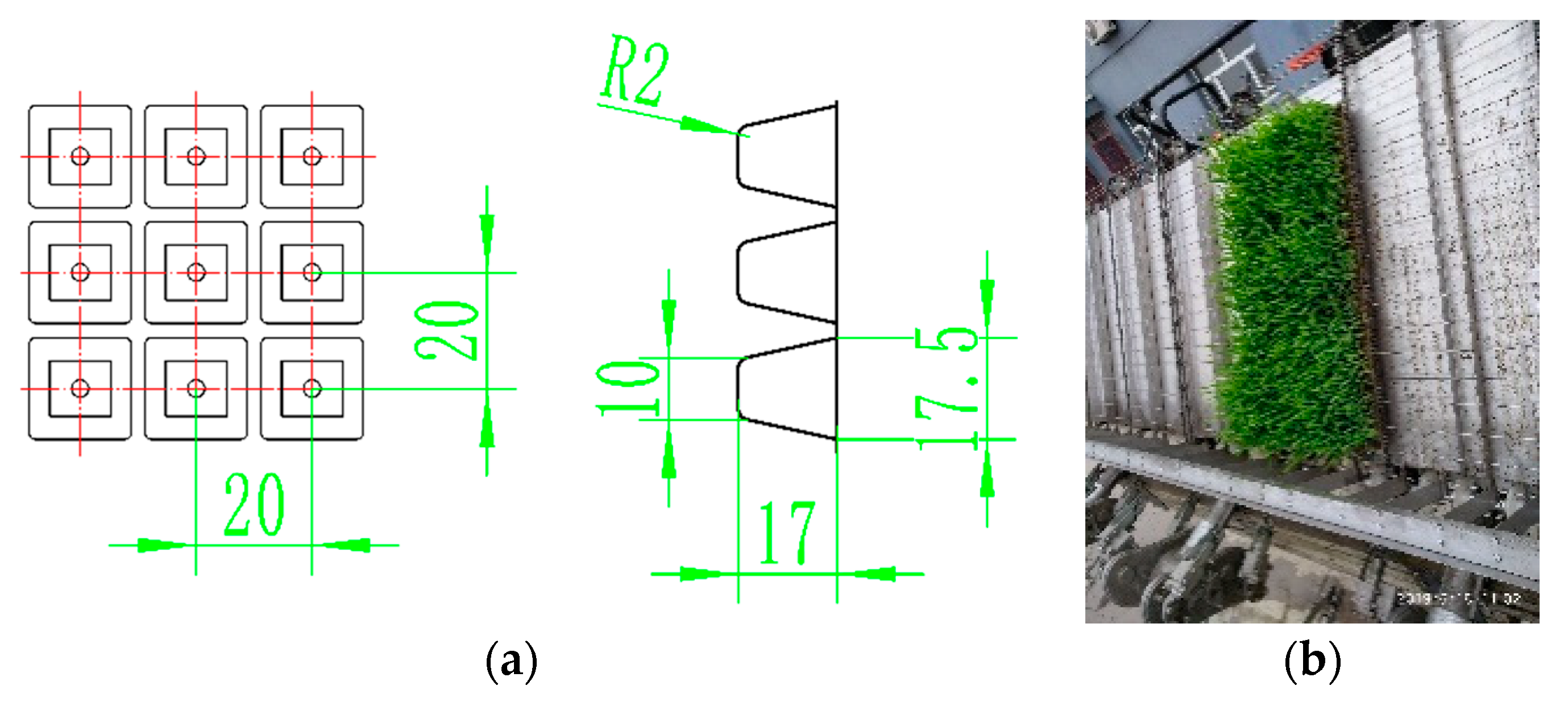

5.1. Design of the Seedling Box

5.2. Design of the Seedling Supply System

6. Experimental Research

6.1. Complete Machine Development

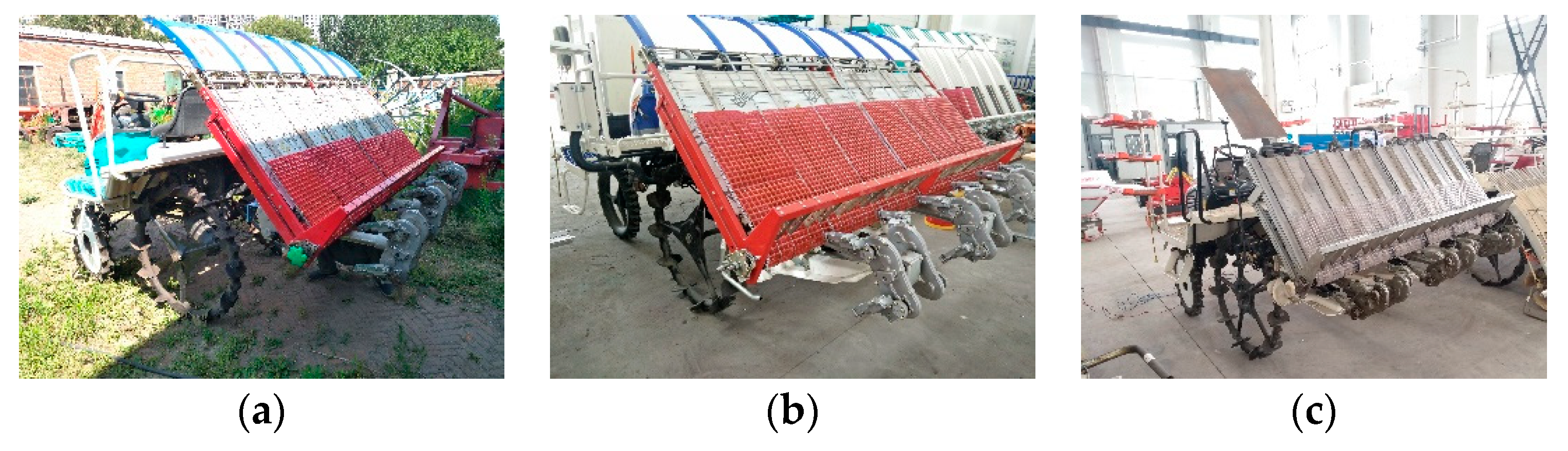

6.1.1. Ordinary Ride-Type Model

6.1.2. High-Speed Model

6.2. Field-Transplanting Experiments

7. Conclusions

- (1)

- By utilizing a non-circular gear design and developing a pull-out rice pot-seedling transplanting mechanism, it is possible to continuously realize the rice pot-seedling transplanting required for rice seedling division, transport, and planting as well as other actions. The transplanting mechanism is composed of a non-circular-gear train and two planting arms, with two transplanting actions able to be completed in one stroke. This improves the transplanting efficiency and reduces the rate of injury.

- (2)

- In order to adapt the designed pull-out transplanting mechanism to the transplanting machine, research was carried out on key technologies such as the transmission system, the rice supply system, and the rice box of the rice-bowl transplanting machine. Two types of transplanters, an ordinary ride-type and a high-speed type, were designed and developed. After experimental verification and analysis, both models were shown to achieve the expected transplanting effect of rice-bowl seedlings, with an excellent quality of transplanting.

- (3)

- Experiments and demonstrations utilizing the specially designed rice pot-seedling transplanting machine have been conducted in numerous locations throughout China. The results have shown a success rate of over 92% for proper planting depth, with less than 1.2% of the seedlings being injured, and less than 2% of the transplantings being missed. Additionally, the floating seedling rate was less than 0.5%, and the tipping rate was less than 3%. These impressive figures have resulted in a yield increase of 5% to 15% compared with traditional blanket-seedling transplanting methods.

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

References

- Yu, X.X.; Zhao, Y.; Chen, B.C.; Zhou, M.L.; Zhang, H.; Zhang, Z.C. Current situation and prospect of transplanter. Trans. Chin. Soc. Agric. Mach. 2014, 45, 44–53. [Google Scholar]

- Yu, G.H.; Wang, L.; Sun, L.; Zhao, X.; Ye, B.L. Advancement of mechanized transplanting technology and equipments for field crops. Trans. Chin. Soc. Agric. Mach. 2022, 53, 1–13. [Google Scholar]

- Rahul, K.; Raheman, H.; Paradkar, V. Design and development of a 5R 2DOF parallel robot arm for handling paper pot seedlings in a vegetable transplanter. Comput. Electron. Agric. 2019, 166, 105014. [Google Scholar] [CrossRef]

- Imran, M.S.; Abdul Manan, M.S.; Khalil, A.N.M.; MdNaim, M.K.; Ahmad, R.N. Design of transplanting mechanism for rice intensification (SRI) transplanter in Kedah, Malaysia. Mater. Sci. Eng. 2017, 226, 012036. [Google Scholar] [CrossRef]

- Felezi, M.E.; Vahabi, S.; Nariman-zadeh, N. Pareto optimal design of reconfigurable rice seedling transplanting mechanisms ssing multi-objective genetic algorithm. Neural Comput. Appl. 2016, 27, 1907–1916. [Google Scholar] [CrossRef]

- Kornecki, T.S.; Kichler, C. Development of a no-till transplanter for walk-behind tractors. Appl. Eng. Agric. 2022, 38, 865–872. [Google Scholar] [CrossRef]

- Xue, K.; Gao, K.J.; Kuang, F.M.; Zhang, S.; Liao, J.; Zhu, D.Q. Machinery-plant-paddy soil coupling model based numerical simulation method of mechanical transplanting process of big rice seedling. Comput. Electron. Agric. 2022, 198, 107053. [Google Scholar] [CrossRef]

- Tong, Z.P.; Yu, G.H.; Zhao, X.; Liu, P.F.; Ye, B.L. Design of vegetable pot seedling pick-up mechanism with planetary gear train. Chin. J. Mech. Eng. 2020, 33, 63. (In English) [Google Scholar] [CrossRef]

- Yu, G.H.; Jin, Y.; Chang, S.S.; Ye, B.L.; Gu, J.B.; Zhao, X. Design and test of clipping-plug type transplanting mechanism of rice plug-seedling. Chin. Soc. Agric. Mach. 2019, 50, 100–107. [Google Scholar]

- Sun, L.; Xing, Z.Q.; Xu, Y.D.; Liu, B.; Yu, G.H.; Wu, C.Y. Transplanting mechanism of rice seedling based on precise multi-position analysis. Chin. Soc. Agric. Mach. 2019, 50, 78–85. [Google Scholar]

- Zhou, Y.Q.; He, L.; Gu, L. Parameters optimization of seperating-planting mechanism for high-speed transplanting for super-rice based on virtual prototyping technology. Mach. Des. Res. 2019, 35, 62–65. [Google Scholar]

- Wang, L.; Sun, L.; Xu, Y.; Yu, G.; Gervais, N.L.; Huang, J. Multi-pose motion synthesis of three-arm gear train planting mechanism based on genetic algorithm. Trans. Chin. Soc. Agric. Mach. 2022, 53, 70–77. [Google Scholar]

- Yao, Y.F.; Zhu, D.Q.; Wang, Y.Q.; Xiong, W.; Wang, C.X.; Yuan, J.H. Structure design and test of high-speed rice transplanter deesling box with adjustable row spacing. ASME J. Mach. Des. 2016, 33, 80–85. [Google Scholar]

- Zhao, X.; Liao, H.; Ma, X.; Dai, L.; Yu, G.; Chen, J. Design and experiment of double planet carrier planetary gear flower transplanting mechanism. Int. J. Agric. Biol. Eng. 2021, 14, 55–61. [Google Scholar] [CrossRef]

- Li, F.; Lei, J.; Wang, W.B.; Song, B. Optimal Design and Experimental Verification of a Four-claw Seedling Pick-up Mechanism Using the Hybrid PSO-SA Algorithm. Span. J. Agric. Res. 2022, 20, e0207. [Google Scholar] [CrossRef]

- Ao, M.; Yu, G.H.; Wang, L.; Sun, L.; Zhao, J. Optimization synthesis of hybrid six-bar mechanism with non-circular gear constraints. ASME J. Mech. Des. 2023, 145, 064502. [Google Scholar] [CrossRef]

- Cheng, Y.H.; Chen, Y.C. Design, analysis, and optimization of a strain wave gear with a novel tooth profile. Mech. Mach. Theory 2022, 175, 104953. [Google Scholar] [CrossRef]

- Xu, X.; Zhou, M.L.; Chen, X.G.; Yang, J.J. Processing method of gearbox with non-circular gear train and its application in rice potted seedling transplanting mechanism. Agriculture 2022, 12, 1676. [Google Scholar] [CrossRef]

- Yu, G.H.; Du, L.H.; Li, G.; Xu, Y.P.; Ye, B.L.; Liu, D.Q. Design and experiment of feeding-seedling device for high-speed rice pot-seedling transplanter. Trans. Chin. Soc. Agric. Mach. 2015, 46, 39–45. [Google Scholar]

- Na, M.J.; Song, Z.C.; Zhou, M.L.; Zhu, H.X.; Wang, Q.; Zhao, Y. Design and experiment on longitudinal seedling feeding mechanism for rice pot seedling transplanting with ratchet gear. Trans. Chin. Soc. Agric. Mach. 2015, 46, 43–47. [Google Scholar]

| Seedling-Picking Angle | Seedling-Pushing Angle | Angle Difference | Picking Height | Picking Swing Angle | Ground Distance | Trajectory Height |

|---|---|---|---|---|---|---|

| 1.55° | 53.13° | 51.58° | 34.8 mm | 4.13° | 20.75 mm | 277.3 mm |

| Number of Teeth | Modulus | Pressure Angle | Addendum Coefficient | Coefficient of Bottom Clearance | Center-To-Center Distance | Maximal Modification Coefficient |

|---|---|---|---|---|---|---|

| 21 | 2.5753 | 20 | 1 | 0.25 | 52 | 0.45 |

| Power | Weight | Row Count | Row Space | Min Distance of the Hole | Max Distance of the Hole | Planting Depth |

|---|---|---|---|---|---|---|

| 4.2 Kw | 290 Kg | 6 | 300 mm | 140 mm | 240 mm | 0–46 mm |

| Power | Weight | Row Count | Row Space | Min Distance of the Hole | Max Distance of the Hole | Planting Depth |

|---|---|---|---|---|---|---|

| 13.2 Kw | 720 Kg | 6 | 300 mm | 140 mm | 240 mm | 10–40 mm |

| Transplanting Efficiency | Qualification Rate of Planting Depth | Seedling-Injury Rate | Missed-Transplanting Rate | Tipping Rate |

|---|---|---|---|---|

| 140 times per minute | 92% | 0.8% | 1.4% | 1.7% |

| 180 times per minute | 94% | 1.1% | 1.5% | 2.3% |

| 220 times per minute | 93% | 1.2% | 2% | 3% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, J.; Zhou, M.; Yin, D.; Yin, J. Design and Development of Rice Pot-Seedling Transplanting Machinery Based on a Non-Circular Gear Mechanism. Appl. Sci. 2024, 14, 1027. https://doi.org/10.3390/app14031027

Yang J, Zhou M, Yin D, Yin J. Design and Development of Rice Pot-Seedling Transplanting Machinery Based on a Non-Circular Gear Mechanism. Applied Sciences. 2024; 14(3):1027. https://doi.org/10.3390/app14031027

Chicago/Turabian StyleYang, Jiajia, Maile Zhou, Daqing Yin, and Jianjun Yin. 2024. "Design and Development of Rice Pot-Seedling Transplanting Machinery Based on a Non-Circular Gear Mechanism" Applied Sciences 14, no. 3: 1027. https://doi.org/10.3390/app14031027

APA StyleYang, J., Zhou, M., Yin, D., & Yin, J. (2024). Design and Development of Rice Pot-Seedling Transplanting Machinery Based on a Non-Circular Gear Mechanism. Applied Sciences, 14(3), 1027. https://doi.org/10.3390/app14031027