Fatigue Performance Analysis of an Underwater Vehicle Rudder Mechanism Considering Arctic Low Temperatures

Abstract

1. Introduction

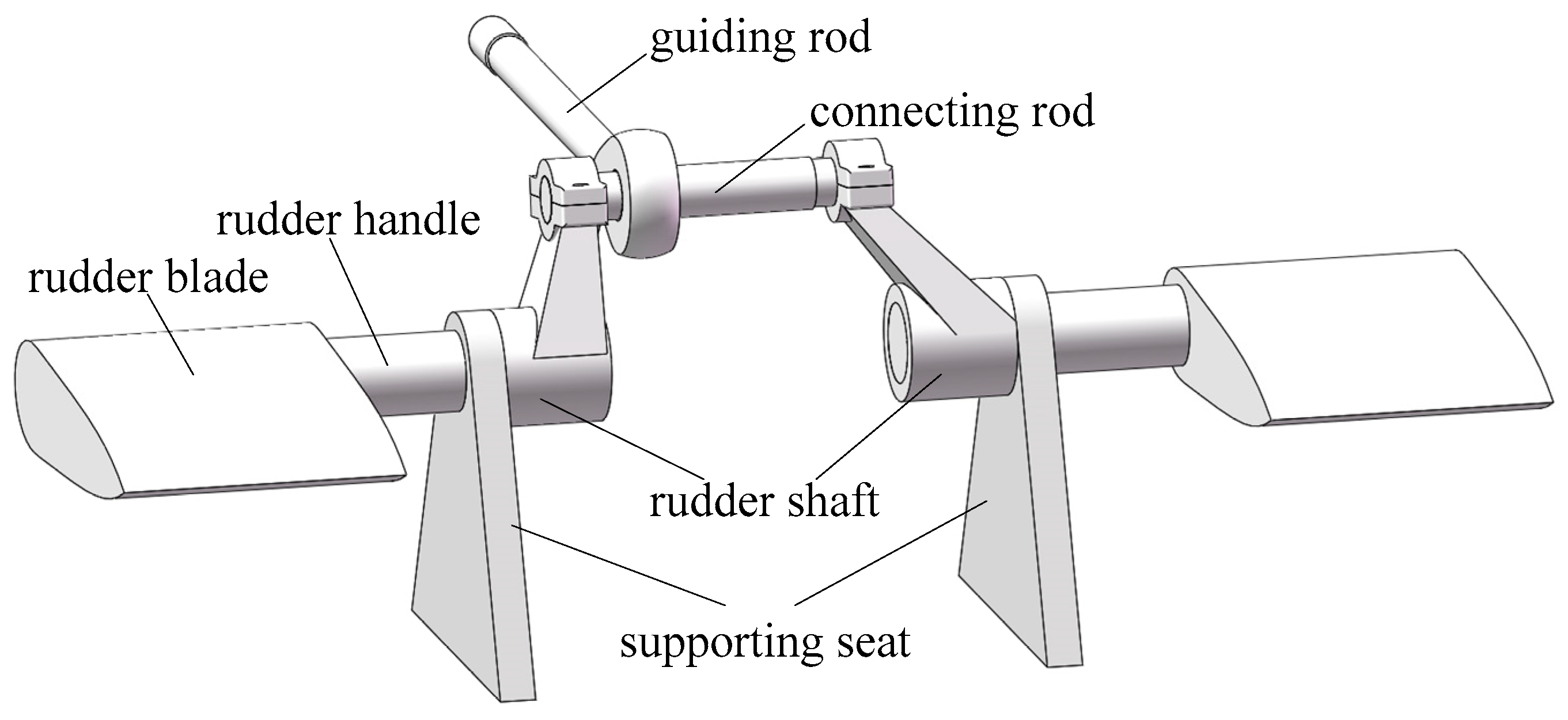

2. Introduction to the Rudder Mechanism

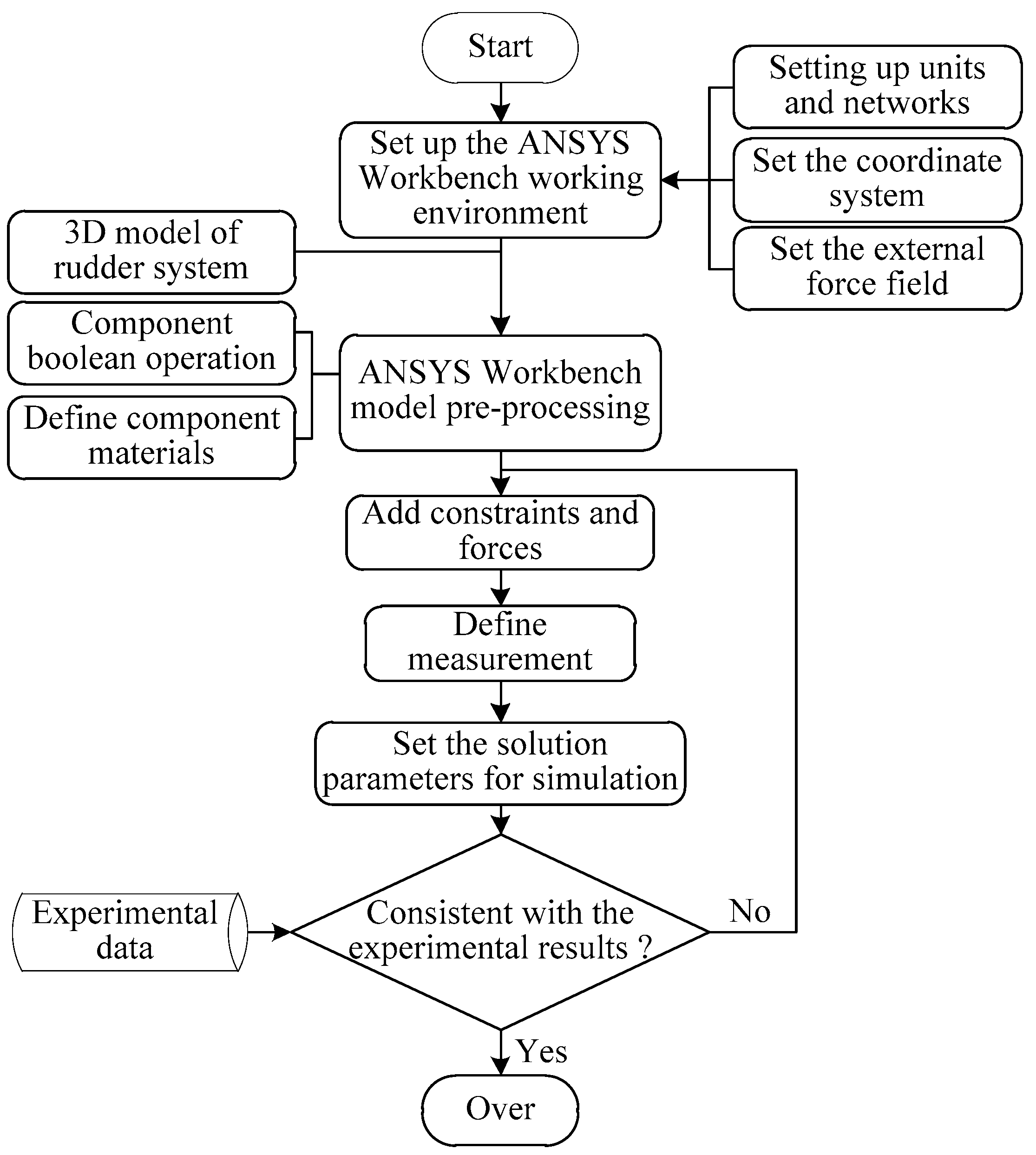

3. Simulation Modeling and the Validation of the Rudder Mechanism

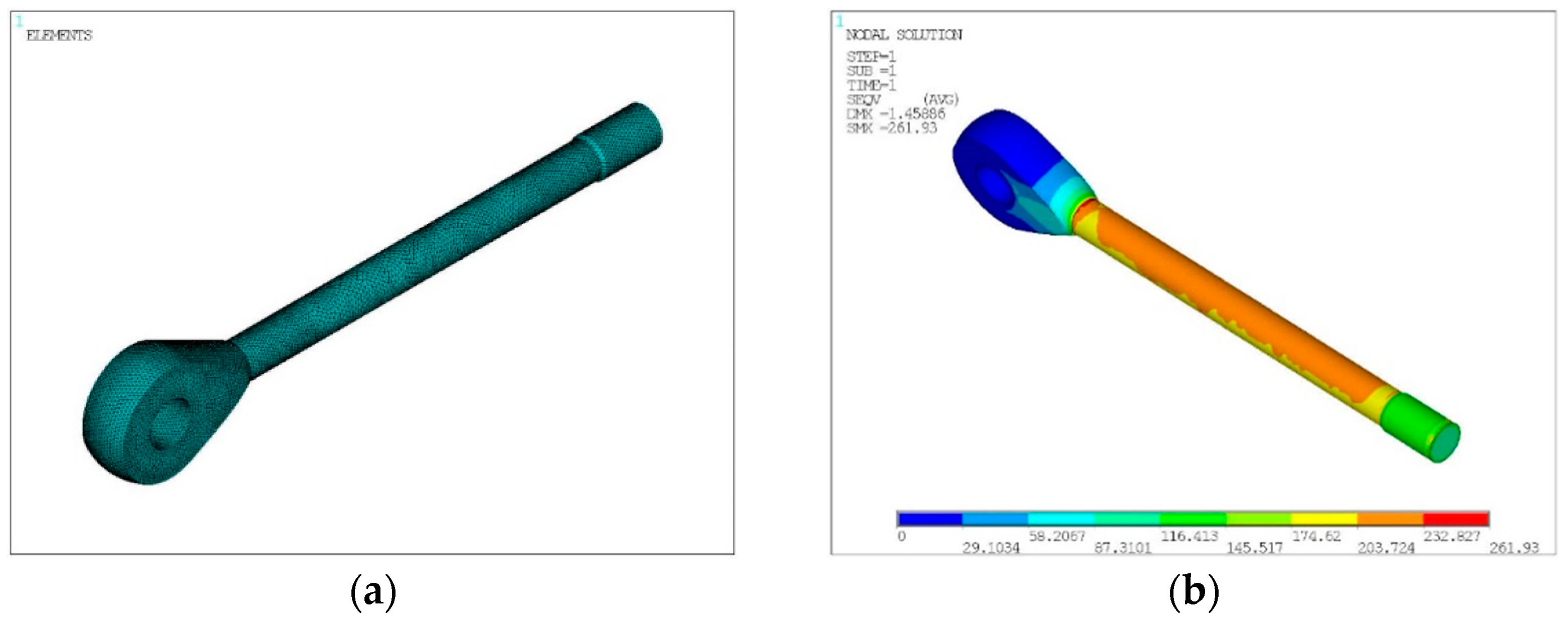

3.1. Simulation Modeling

- (1)

- Set up the working environment and material properties. After importing the 3D model of the rudder mechanism into ANSYS Workbench, adjust the grid settings, gravitational acceleration direction, coordinate axes, and other system operating environments. At the same time, couple and fix the components that do not have relative motion with each other, to reduce the number of model components, rename the components of the simplified model, and define their material properties.

- (2)

- Add constraints. After defining the material properties of the components, define the relative position and relative motion between the components, i.e., add constraints to the model and couple the components to form a mechanical system to simulate the actual operating conditions of the machinery. The members of the high rudder bar mechanism that have motion are connected by friction, and the rest of the members are connected by the constraints provided by ANSYS Workbench.

- (3)

- Apply a force and a load. According to the working principle of the aforementioned mechanism, the driving force of the rudder bar mechanism acts on the joint end of the guiding tie rod; therefore, the load is applied here in the model. Through the above steps, the preprocessing of the dynamic simulation model of the actuator mechanism is completed, and the simulation model of the rudder bar mechanism shown in Figure 3 is established.

- (4)

- Set up the solver. The rudder bar simulation model contains stress and strain and other force problems; therefore, select the Direct Solver, in the Solver settings, select the solution accuracy and other related settings according to the need, and finally click the Solve button to solve.

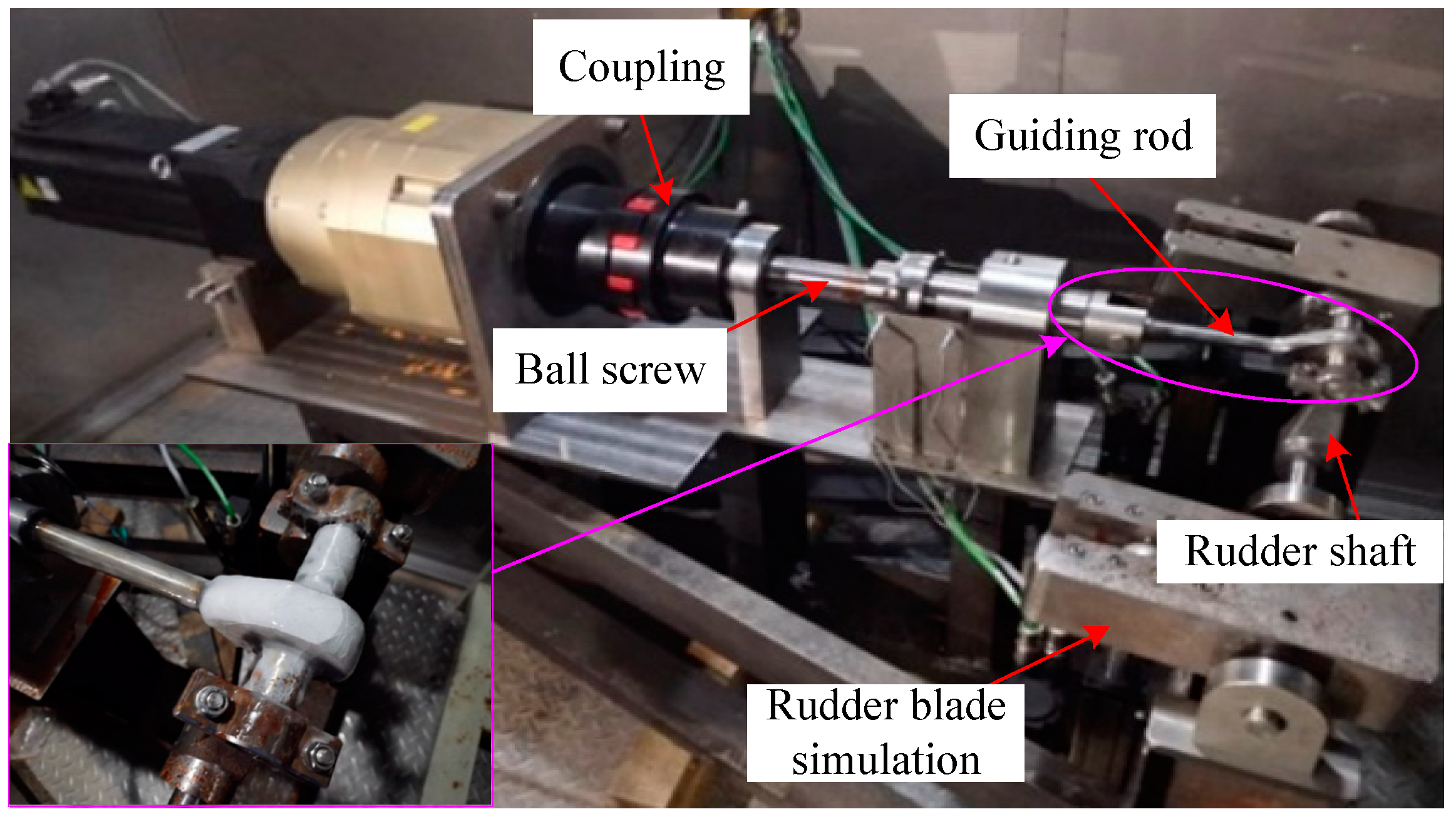

3.2. Experimental Verification

4. Results Analysis

4.1. Simulation Results Analysis

- (1)

- The areas where fatigue damage may occur in the rudder rod mechanism are located at the welded connection between the tie rod head and the connecting rod and the guide tie rod step.

- (2)

- There is no significant difference in the fatigue life of the rudder bar mechanism when the temperature is 20 °C and 0 °C.

- (3)

- When the temperature drops to −40 °C, the fatigue life suddenly decreases from 5.26 × 106 to 3.25 × 106, a decrease of 38.2% compared with the temperature of −20 °C. The reason may be a significant increase in equivalent stress related to the material properties of the steel structure itself. At low temperatures, the mechanical properties of the material decrease, making the effect of cyclic loading on the mechanism more significant.

4.2. Experimental Result Analysis

- (1)

- The number of cyclic loads under each temperature band is relatively discrete, which is in line with the discrete characteristics of the fatigue test data.

- (2)

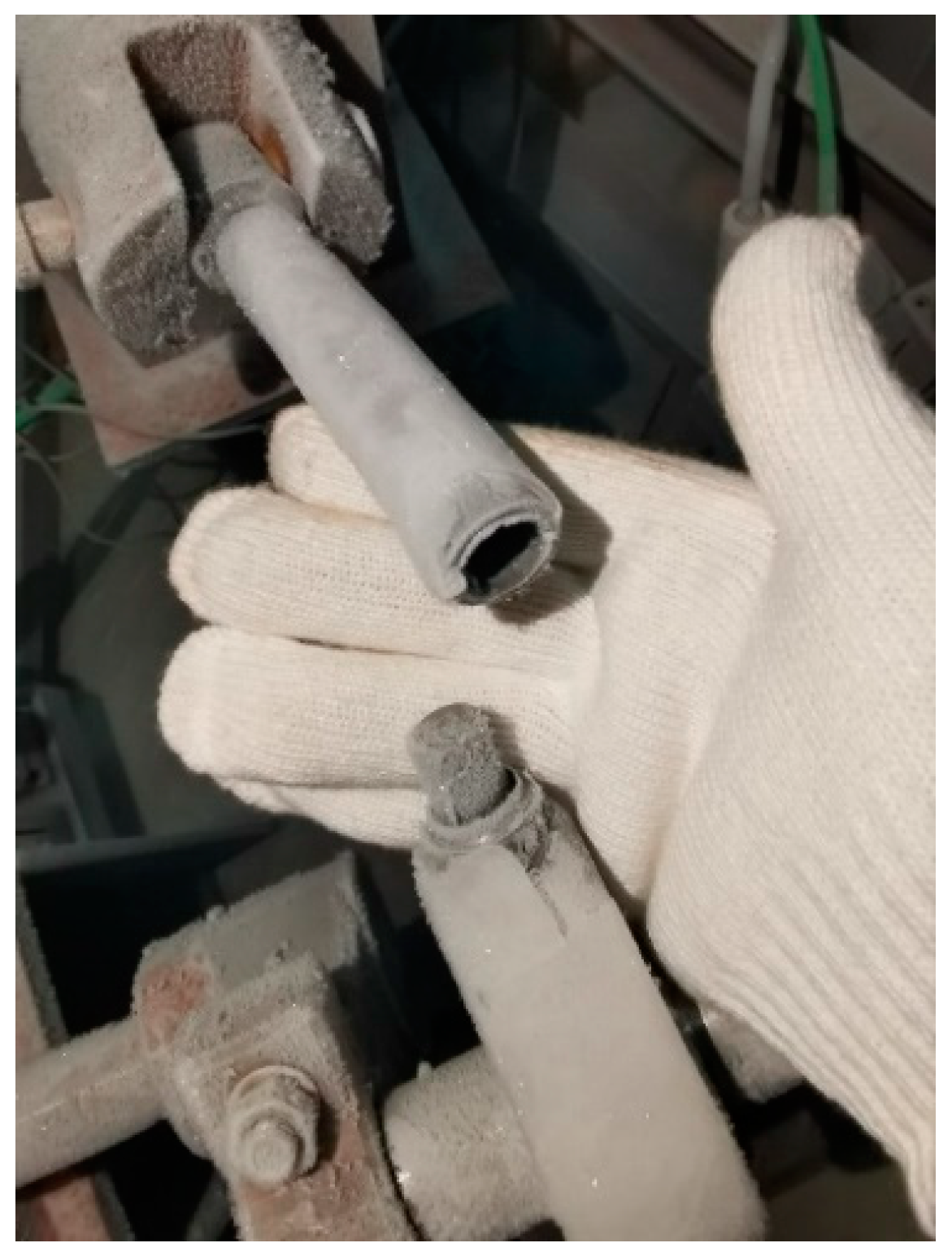

- At 20 °C and 0 °C, there is no ice cover on the rudder bar specimen; at −20 °C, the surface of the rudder bar specimen exhibits an ice shell with a thickness of 0.6 mm. At −40 °C, at the moment when the rudder bar specimen is removed from the icy water, the thickness of the ice cover on the surface of the rudder bar specimen reaches more than 1 mm, the moisture in the air continuously gathers on the rudder bar specimen in the experimental process, and the final thickness of the ice cover reaches 1.6 mm. The existence of ice cover affects the temperature distribution of the structural surface, resulting in the dispersion characteristics of structural fatigue test data. The presence of ice will affect the temperature distribution on the surface of the structure, resulting in a lower temperature on the surface of the structure, which reduces the strength of the steel. Ice cover increases the loading on the structure, resulting in additional loads being applied to the structure [29]. This results in the structure being subjected to greater loads, which may cause mechanical effects such as bending, shearing, and twisting of the structure, thus affecting the performance of the structure.

- (3)

- The relationship between the number of cyclic loads of the rudder bar specimen and the simulated Arctic environment is as follows: when the temperature is 20 °C and 0 °C, the number of cyclic loads does not change much; when the temperature decreases to −20 °C, the number of cyclic loads decreases to 53.7% of that at room temperature. When the temperature decreases to −40 °C, the number of cyclic loads shows a precipitous drop, a decrease of 96.7% compared with that at room temperature.

- (4)

- The reason for the precipitous drop in the number of cyclic loads at −40 °C can be categorized into two points: first, the low temperature significantly increases the sensitivity of the rudder bar specimen to grooves and cracks; and second, the ice coating on the surface of the rudder bar specimen affects it, leading to a significant reduction in its fatigue life.

5. Conclusions

- In the polar low-temperature environment, the material properties of the rudder rod mechanism decrease, which leads to the shortening of its fatigue life, especially when the temperature is reduced to −40 °C, and the fatigue performance of the rudder rod specimen is reduced by 96.7%.

- Cyclic loading is one of the main factors leading to fatigue cracking of the rudder bar mechanism. In a low-temperature environment, the mechanical properties of the material decrease, making the effect of cyclic loading on the mechanism more significant.

- Ice-covered conditions have a significant effect on the fatigue life of rudder rod specimens, and the reasons can be summarized as follows: increased structural loads, reduced strength, weakened stability, the formation of local support, corrosion, and hydrogen embrittlement aggravation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhao, W.; Feng, G.; Liu, W.; Ren, H. Research on fatigue properties of typical welded joints of DH36 steel at −60 °C. Appl. Sci. Eng. 2020, 10, 3742. [Google Scholar] [CrossRef]

- Sørensen, C.T.N.; Sacks, B.; Stephenson, S.; Pezard, S.; Tingstad, A. Exploring Gaps in Arctic Governance: Identifying Potential Sources of Conflict and Mitigating Measures; RAND Corporation: Santa Monica, CA, USA, 2021. [Google Scholar] [CrossRef]

- Huang, J. Research on the Influence of Arctic Navigation on the Navigation Performance of Submarine. Ship Electron. Eng. 2020, 40, 62–66. [Google Scholar]

- Yu, L.; Guo, W.; Pan, X.; Chen, H. Analysis and Research on Cold Proof Design of Polar Marine Machinery. Phys. Conf. Ser. 2021, 11, 012060. [Google Scholar] [CrossRef]

- Park, I.; Paik, B.; Ahn, J.; Kim, J. The prediction of the performance of a twisted rudder. Appl. Sci. Eng. 2021, 11, 7098. [Google Scholar] [CrossRef]

- Liu, J.; Hekkenberg, R. Sixty years of research on ship rudders: Effects of design choices on rudder performance. Ships Offshore Struct. 2017, 12, 495–512. [Google Scholar] [CrossRef]

- Walters, C.L.; Alvaro, A.; Maljaars, J. The effect of low temperatures on the fatigue crack growth of S460 structural steel. Int. J. Fatigue 2016, 1, 110–118. [Google Scholar] [CrossRef]

- Alvaro, A.; Akselsen, O.M.; Ren, X.; Kaneko, A. Fundamental aspects of fatigue of steel in Arctic applications. In Proceedings of the The Twenty-Fourth International Ocean and Polar Engineering Conference, Busan, Republic of Korea, 15–20 June 2014; Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE14/All-ISOPE14/14349 (accessed on 18 January 2024).

- Alvaro, A.; Akselsen, O.M.; Ren, X.; Kane, A. Fatigue properties of a 420 MPa structural steel at low temperature. In Proceedings of the The Twenty-Fifth International Ocean and Polar Engineering Conference, Kona, HI, USA, 21–26 June 2015; Available online: https://onepetro.org/ISOPEIOPEC/proceedings-abstract/ISOPE15/All-ISOPE15/15184 (accessed on 18 January 2024).

- Kabakcioglu, F.; Bayraktarkatal, E. A Multihull Boat’s Fatigue Analysis at Early Design Phase. Mar. Sci. Eng. 2022, 10, 560. [Google Scholar] [CrossRef]

- Mujahid, A.S.; Nugroho, W.H. A Prediction Method of Fatigue Life at The Rudder Stock. Sci. Eng. 2017, 9, 1–6. [Google Scholar]

- Braun, M.; Milaković, A.-S.; Ehlers, S.; Kahl, A.; Willems, T.; Seidel, M.; Fischer, C. Sub-Zero Temperature Fatigue Strength of Butt-Welded Normal and High-Strength Steel Joints for Ships and Offshore Structures in Arctic Regions. In Proceedings of the ASME 2020 39th International Conference on Ocean, Offshore and Arctic Engineering, Virtual, 3–7 August 2020. [Google Scholar] [CrossRef]

- Braun, M.; Ehlers, S. Review of methods for the high-cycle fatigue strength assessment of steel structures subjected to sub-zero temperature. Mar. Struct. 2022, 82, 103153. [Google Scholar] [CrossRef]

- Wang, K.; Wu, L.; Li, Y.-Z.; Qin, C. Experimental study on low temperature fatigue performance of polar icebreaking ship steel. Ocean. Eng. 2020, 216, 107789. [Google Scholar] [CrossRef]

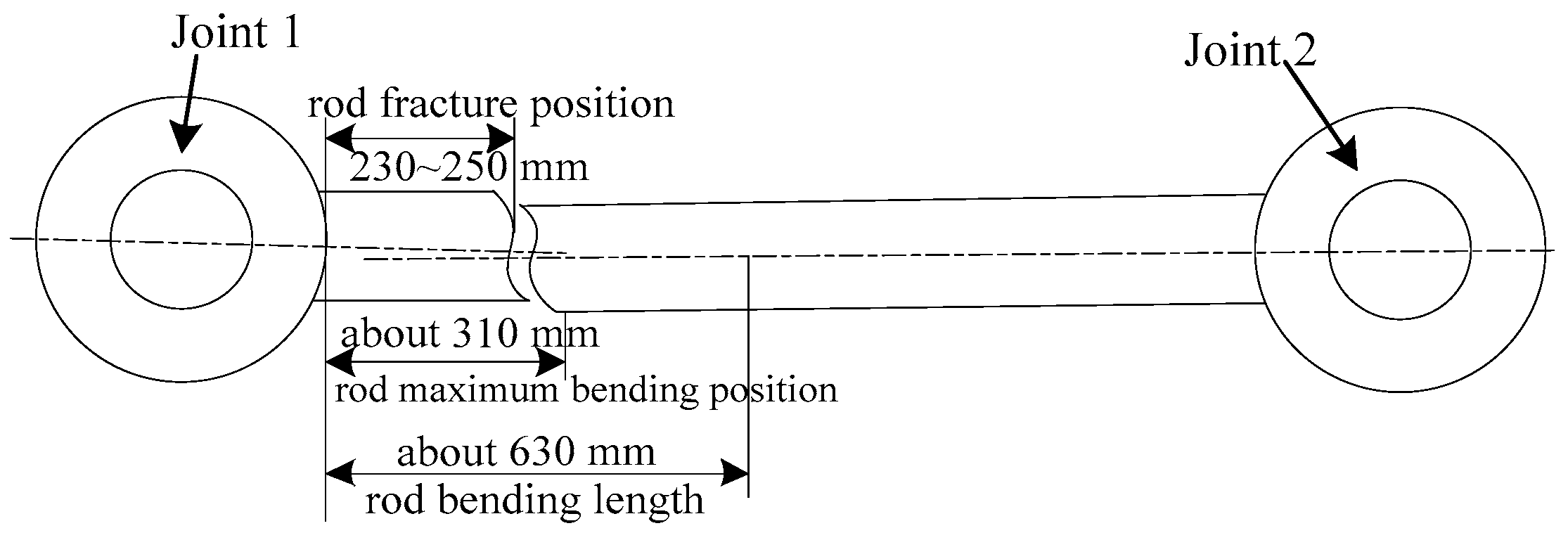

- Wang, J.; Yi, Z.; Wu, J. Fracture analysis of steering gear tie rod. Ship Eng. 2019, 95–99. [Google Scholar]

- Chen, S.; Guo, W.; Cao, C.; Huang, J.; Zhang, J.; Yu, L.; Chen, H. Fatigue Life Analysis of the Submarine Rudder Stock Mechanism at Arctic Low Temperatures. Appl. Sci. Eng. 2023, 13, 127. [Google Scholar] [CrossRef]

- Bai, Z.; Zhao, Y. Dynamics modeling and quantitative analysis of multibody systems including revolute clearance joint. Precis. Eng. 2012, 36, 554–567. [Google Scholar] [CrossRef]

- Erkaya, S.; Doğan, S.; Ulus, Ş. Effects of joint clearance on the dynamics of a partly compliant mechanism: Numerical and experimental studies. Mech. Mach. Theory 2015, 88, 125–140. [Google Scholar] [CrossRef]

- Kong, F.; Cui, H.; Liu, X.; Lu, R.; Ji, B. Creep behavior and life predication for anti-detaching spring. J. Natl. Univ. Def. Technol. 2017, 39, 74–79. [Google Scholar] [CrossRef]

- Bin Jamal, M.N.; Kumar, A.; Lakshmana Rao, C.; Basaran, C. Low Cycle Fatigue Life Prediction Using Unified Mechanics Theory in Ti-6Al-4V Alloys. Entropy 2020, 22, 24. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.W.; Fakhri, H.; Ranade, R.; Basaran, C.; Egner, H.; Lipski, A.; Piotrowski, M.; Mroziński, S. Modeling fatigue of pre-corroded body-centered cubic metals with unified mechanics theory. Mater. Des. 2022, 224, 111383. [Google Scholar] [CrossRef]

- Lee, H.; Basaran, C. Predicting high cycle fatigue life with unified mechanics theory. Mech. Mater. 2022, 164, 104116. [Google Scholar] [CrossRef]

- Lee, H.; Djukic, M.; Basaran, C. Modeling fatigue life and hydrogen embrittlement of bcc steel with unified mechanics theory. Int. J. Hydrogen Energy 2023, 48, 20773–20803. [Google Scholar] [CrossRef]

- Egner, W.; Sulich, P.; Mroziński, S.; Egner, H. Modeling thermo-mechanical cyclic behavior of P91 steel. Int. J. Plast. 2020, 135, 102820. [Google Scholar] [CrossRef]

- Woo, S.; O’Neal, D.L.; Hassen, Y.M. Systematic Methods to Increase the Lifetime of Mechanical Products Such as Refrigerators by Employing Parametric Accelerated Life Testing. Appl. Sci. Eng. 2022, 12, 7484. [Google Scholar] [CrossRef]

- Rehfeld, N.; Speckmann, B.; Stenzel, V. Parameter Study for the Ice Adhesion Centrifuge Test. Appl. Sci. Eng. 2022, 12, 1583. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, B.; Yu, D.; Ji, Y.; Han, X.; Liu, C.; Zhang, D. Analysis of Factors Influencing Ice Coating on the Surface of Wind Turbine Blades. J. Dalian Univ. Technol. 2023, 52–63. [Google Scholar]

- Wang, D.; Yan, L.; Yin, W.; Zhang, P.; Wang, Z.; Li, G.; Hu, X.; Li, B.; Zhang, W.; Zhu, J. Study on the Tensile and Fatigue Properties of the FH36 Ship Steel Plates at Room and Low Temperatures. Metals 2023, 13, 1563. [Google Scholar] [CrossRef]

- Kucharczyk, P.; Rizos, A.; Münstermann, S.; Bleck, W. Estimation of the endurance fatigue limit for structural steel in load increasing tests at low temperature. Fatigue Fract. Eng. Mater. Struct. 2012, 35, 628–637. [Google Scholar] [CrossRef]

| Materials | Density (g/m3) | Tensile Strength σb (Mpa) | Yield Strength σs (Mpa) | Young’s Modulus Y (GPa) | Poisson’s Ratio ν |

|---|---|---|---|---|---|

| 925A | 7.938 | ≥630 | ≥310 | 213 | 0.3 |

| 20# | 7.84 | ≥410 | ≥245 | 206 | 0.282 |

| Temperature (°C) | Group I | Group II | Group III | Average |

|---|---|---|---|---|

| 20 | 11,037 | 12,069 | 16,689 | 13,265 |

| 0 | 11,437 | 9526 | 14,071 | 11,678 |

| −20 | 5936 | 7496 | 7952 | 7128 |

| −40 | 193 | 656 | 469 | 439 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yu, L.; Guo, W.; Chen, H.; Wu, Z.; Cao, C.; Li, X.; Chen, S. Fatigue Performance Analysis of an Underwater Vehicle Rudder Mechanism Considering Arctic Low Temperatures. Appl. Sci. 2024, 14, 1057. https://doi.org/10.3390/app14031057

Yu L, Guo W, Chen H, Wu Z, Cao C, Li X, Chen S. Fatigue Performance Analysis of an Underwater Vehicle Rudder Mechanism Considering Arctic Low Temperatures. Applied Sciences. 2024; 14(3):1057. https://doi.org/10.3390/app14031057

Chicago/Turabian StyleYu, Li, Wenyong Guo, Hantao Chen, Zhe Wu, Chenghao Cao, Xiaofeng Li, and Siyu Chen. 2024. "Fatigue Performance Analysis of an Underwater Vehicle Rudder Mechanism Considering Arctic Low Temperatures" Applied Sciences 14, no. 3: 1057. https://doi.org/10.3390/app14031057

APA StyleYu, L., Guo, W., Chen, H., Wu, Z., Cao, C., Li, X., & Chen, S. (2024). Fatigue Performance Analysis of an Underwater Vehicle Rudder Mechanism Considering Arctic Low Temperatures. Applied Sciences, 14(3), 1057. https://doi.org/10.3390/app14031057