Lattice Structures Built with Different Polygon Hollow Shapes: A Review on Their Analytical Modelling and Engineering Applications

Abstract

:1. Introduction

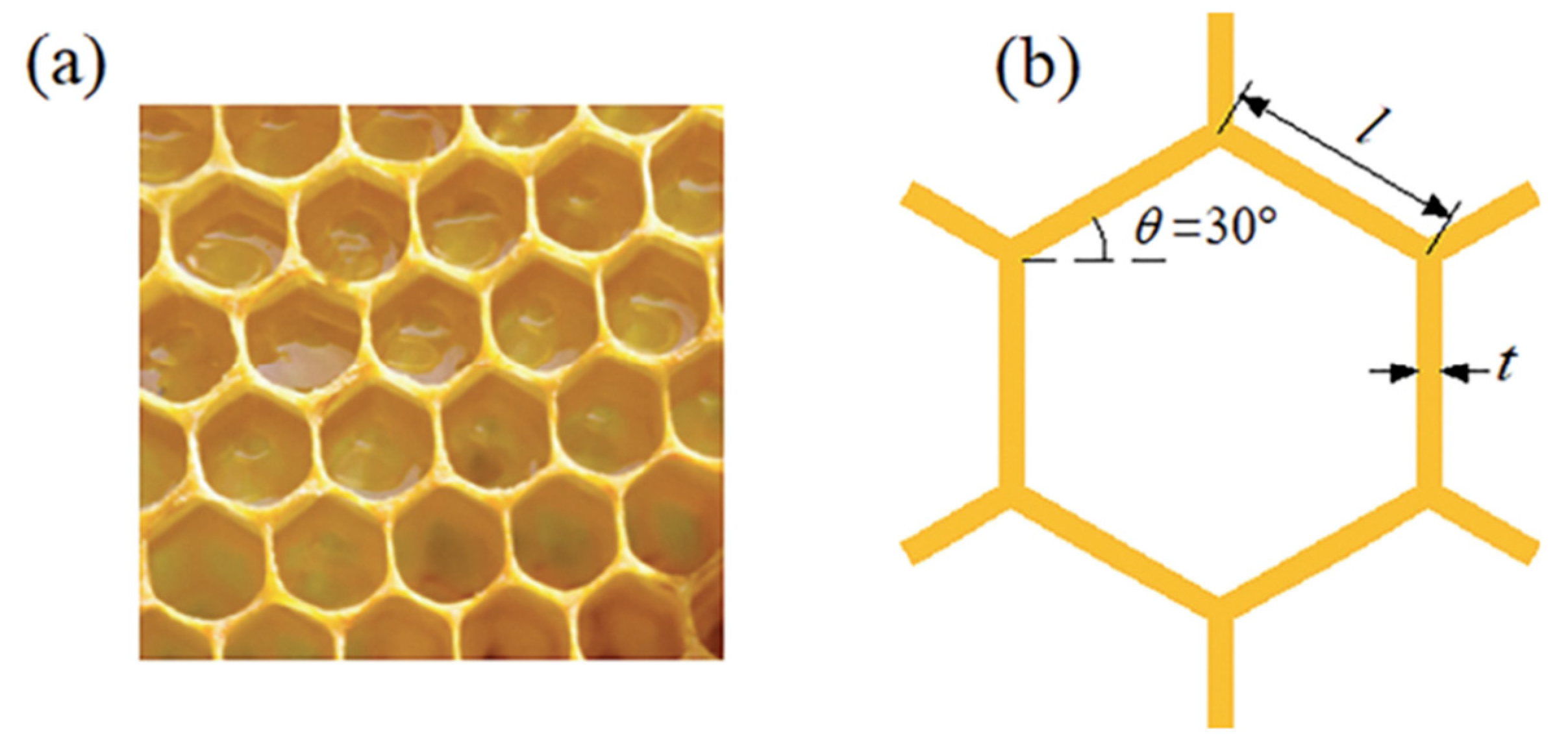

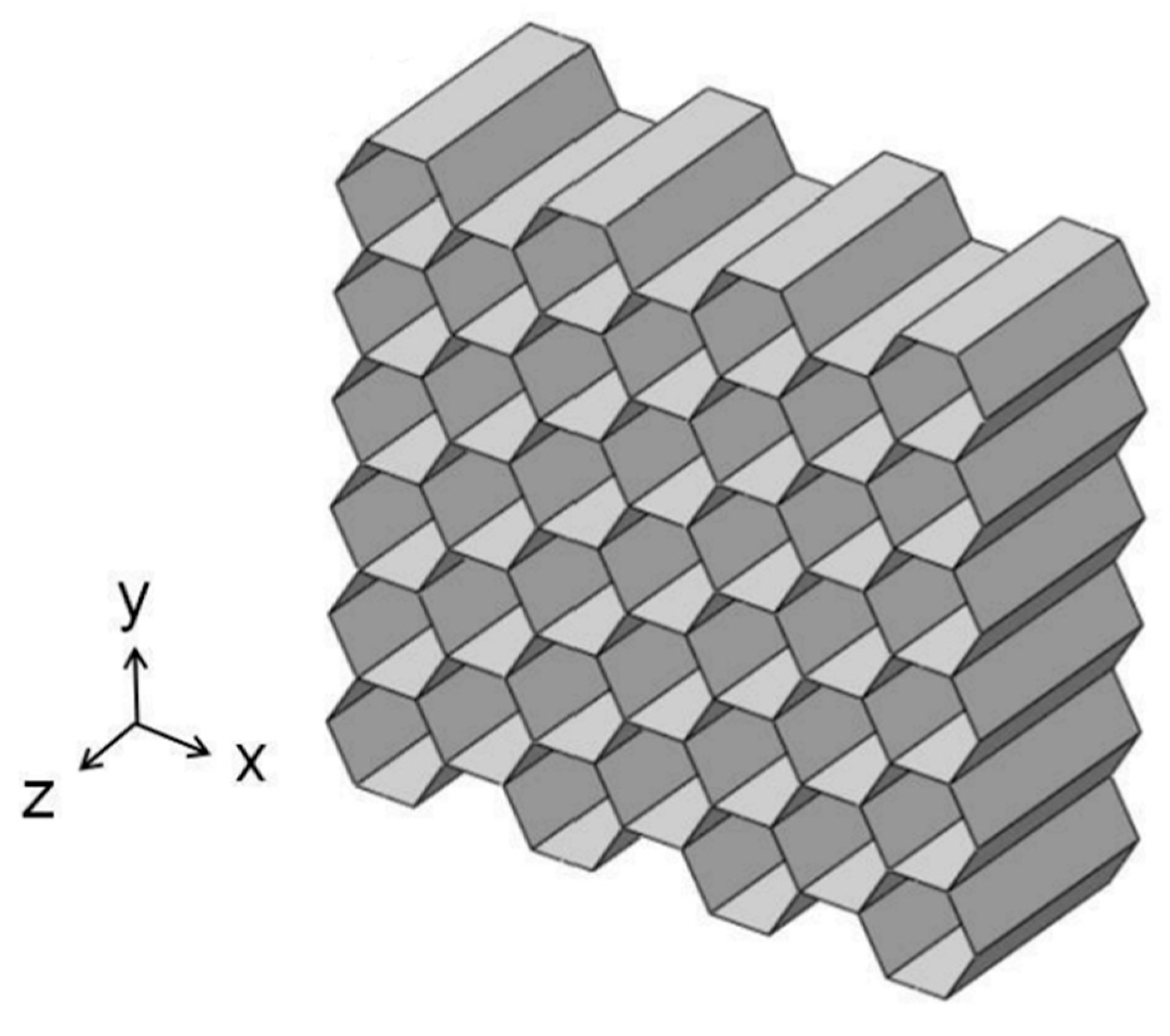

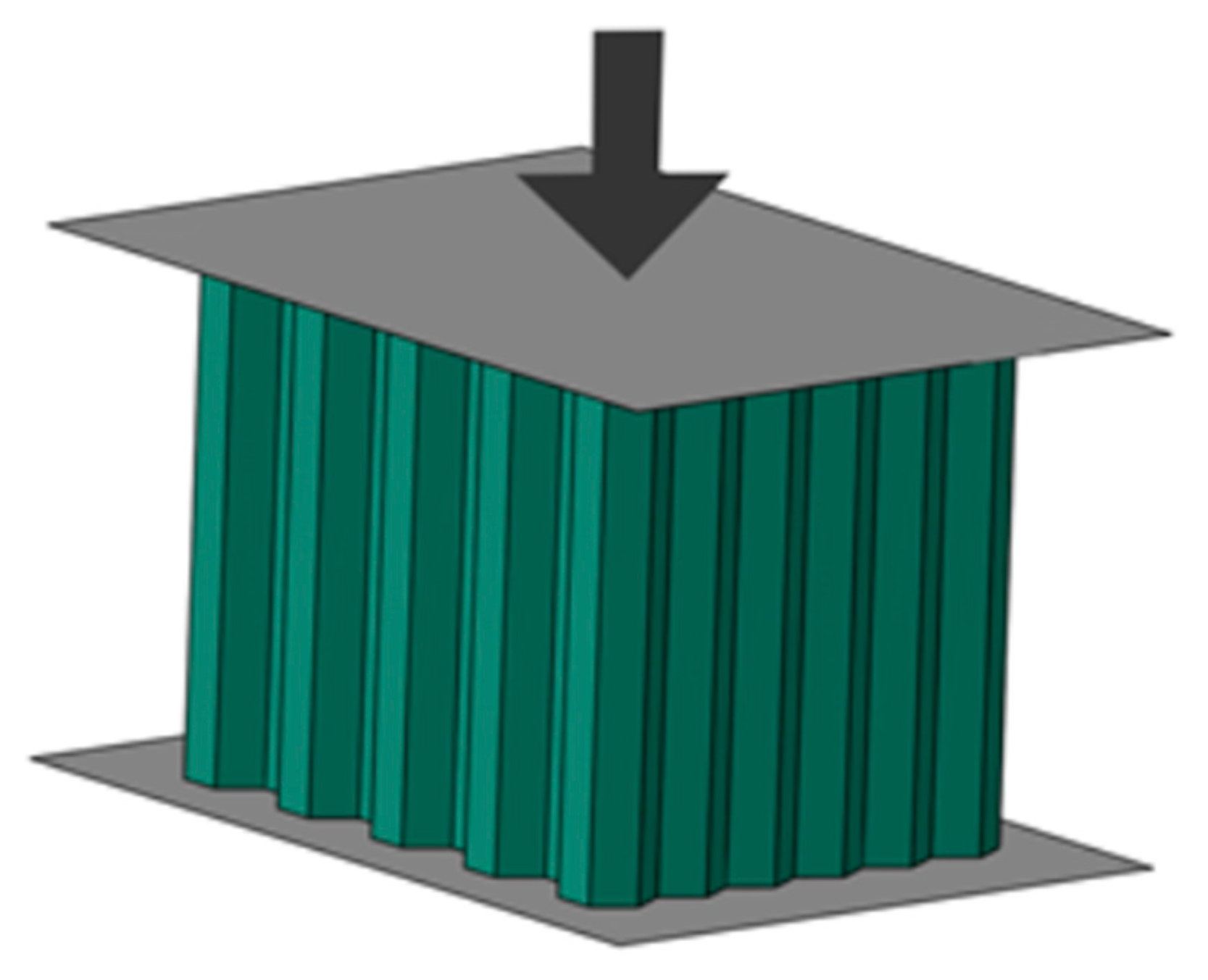

2. An Overview of Lattice Structures Built from Polygonal Hollow Shapes

3. Analytical Models of Lattice Structures Built with Polygon Hollow Shapes

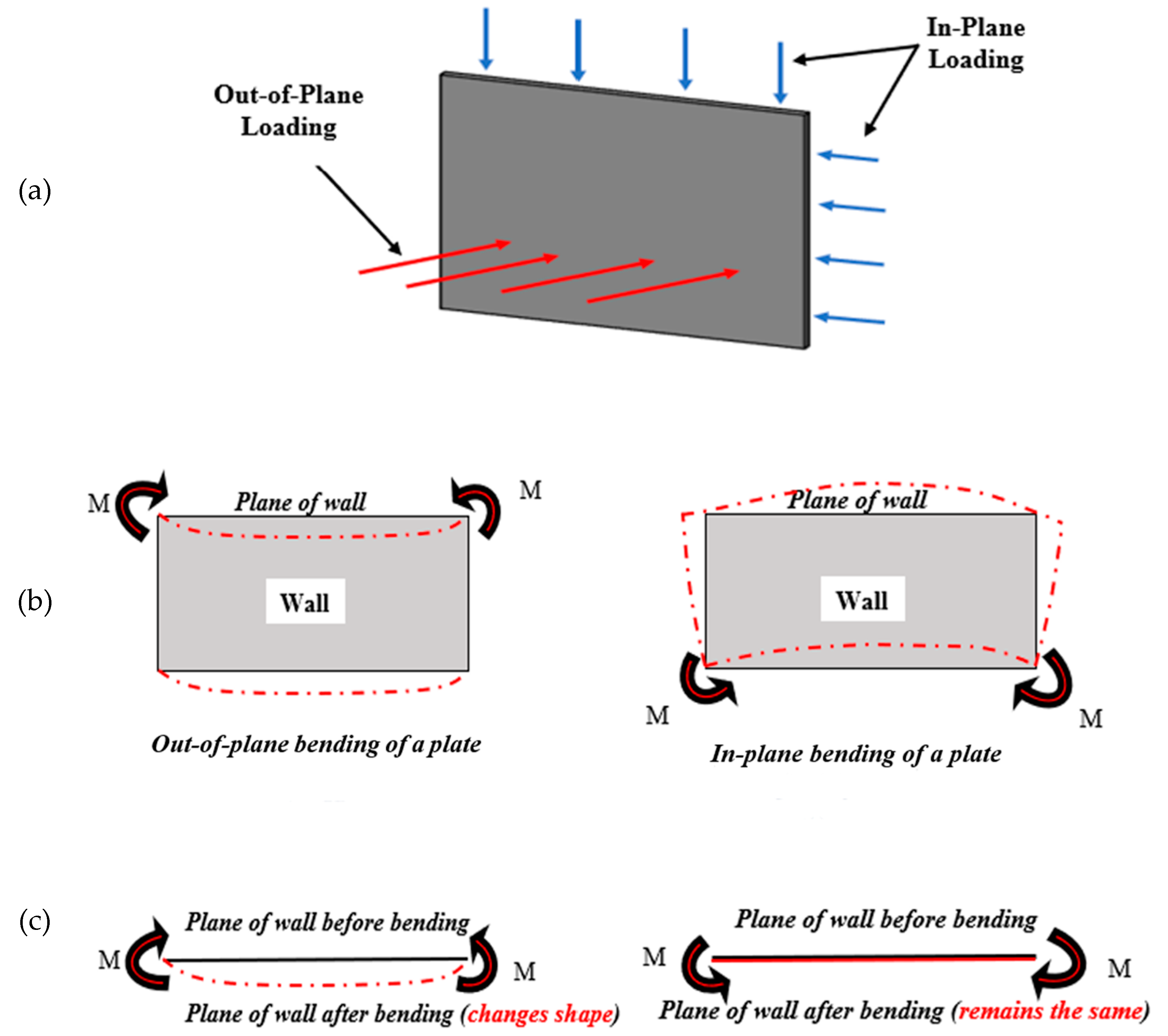

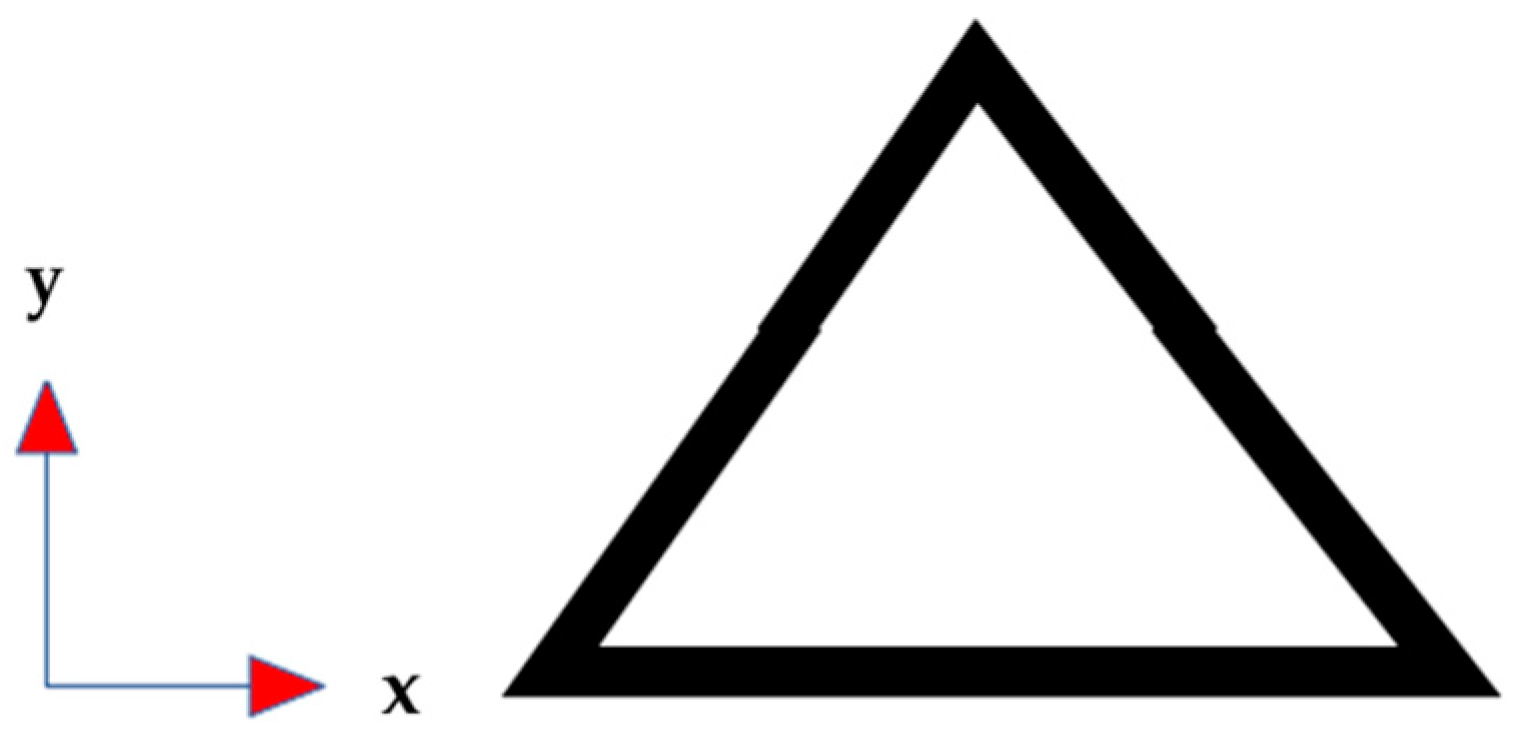

3.1. Geometry Representation Models of Selected Polygon Hollow Structures

3.2. Analytical Models for Predicting the Behaviour of Selected Polygon Hollow Structures

3.2.1. The Gibson–Ashby Model for a Regular Hexagonal Hollow Cell

3.2.2. The Gibson–Ashby Model of an Equilateral Triangular Hollow Cell

3.2.3. The Gibson–Ashby Model of a Square Hollow Cell

3.2.4. The Gibson–Ashby Model of a Circular Hollow Cell

4. Mechanical Properties of Lattice Structures Built with Polygonal Hollow Shapes

5. Engineering Applications of Lattice Structures Built with Polygon Hollow Shapes

5.1. Applications in Aerospace Industries

5.2. Applications in the Automotive Industries

5.3. Applications in Medical Industries

6. Next-Generation Structural Optimisation and Design Guide for Lattice Structures

7. Challenges and Future Prospects in Design for Additive Manufacturing of Lattice Structures

7.1. Challenges Related to Design for Additive Manufacturing of Lattice Structues

7.2. Future Prospects in Design for Additive Manufacturing of Lattice Structures

8. Summary of the Main Findings in this Paper

9. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Wu, W.; Xia, R.; Qian, G.; Liu, Z.; Razavi, N.; Berto, F.; Gao, H. Mechanostructures: Rational mechanical design, fabrication, performance evaluation, and industrial application of advanced structures. Prog. Mater. Sci. 2023, 131, 101021. [Google Scholar] [CrossRef]

- San Ha, N.; Lu, G. A review of recent research on bio-inspired structures and materials for energy absorption applications. Compos. Part B Eng. 2020, 181, 107496. [Google Scholar]

- Li, T.; Chen, Y.; Wang, L. Enhanced fracture toughness in architected interpenetrating phase composites by 3D printing. Compos. Sci. Technol. 2018, 167, 251–259. [Google Scholar] [CrossRef]

- Luo, C.; Han, C.Z.; Zhang, X.Y.; Zhang, X.G.; Ren, X.; Xie, Y.M. Design, manufacturing and applications of auxetic tubular structures: A review. Thin-Walled Struct. 2021, 163, 107682. [Google Scholar] [CrossRef]

- Maconachie, T.; Leary, M.; Lozanovski, B.; Zhang, X.; Qian, M.; Faruque, O.; Brandt, M. SLM lattice structures: Properties, performance, applications and challenges. Mater. Des. 2019, 183, 108137. [Google Scholar] [CrossRef]

- Yuan, S.; Li, S.; Zhu, J.; Tang, Y. Additive manufacturing of polymeric composites from material processing to structural design. Compos. Part B: Eng. 2021, 219, 108903. [Google Scholar] [CrossRef]

- Wang, Z. Recent advances in novel metallic honeycomb structure. Compos. Part B: Eng. 2019, 166, 731–741. [Google Scholar] [CrossRef]

- du Plessis, A.; Broeckhoven, C.; Yadroitsava, I.; Yadroitsev, I.; Hands, C.H.; Kunju, R.; Bhate, D. Beautiful and Functional: A Review of Biomimetic Design in Additive Manufacturing. Addit. Manuf. 2019, 27, 408–427. [Google Scholar] [CrossRef]

- Arisoy, E.B.; Musuvathy, S.; Mirabella, L.; Slavin, E., III. Design and topology optimization of lattice structures using deformable implicit surfaces for additive manufacturing. In Proceedings of the International Design Engineering Technical Conferences and Computers and Information in Engineering Conference, Boston, MA, USA, 2–5 August 2015; American Society of Mechanical Engineers: New York, NY, USA, 2015; Volume 57113, p. V004T05A003. [Google Scholar]

- Plocher, J.; Panesar, A. Review on design and structural optimisation in additive manufacturing: Towards next-generation lightweight structures. Mater. Des. 2019, 183, 108164. [Google Scholar] [CrossRef]

- Sefene, E.M. State-of-the-art of selective laser melting process: A comprehensive review. J. Manuf. Syst. 2022, 63, 250–274. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive Manufacturing (3D Printing): A Review of Materials, Methods, Applications and Challenges. Compos. Part B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- du Plessis, A.; Razavi, N.; Benedetti, M.; Murchio, S.; Leary, M.; Watson, M.; Bhate, D.; Berto, F. Properties and applications of additively manufactured metallic cellular materials: A review. Prog. Mater. Sci. 2022, 125, 100918. [Google Scholar] [CrossRef]

- Kumar, M.B.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Borikar, G.P.; Patil, A.R.; Kolekar, S.B. Additively Manufactured Lattice Structures and Materials: Present Progress and Future Scope. Int. J. Precis. Eng. Manuf. 2023, 24, 2133–2180. [Google Scholar] [CrossRef]

- Benedetti, M.; du Plessis, A.; Ritchie, R.; Dallago, M.; Razavi, N.; Berto, F. Architected cellular materials: A review on their mechanical properties towards fatigue-tolerant design and fabrication. Mater. Sci. Eng. R: Rep. 2021, 144, 100606. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, X.; Li, P.; Huang, G.; Feng, S.; Shen, C.; Han, B.; Zhang, X.; Jin, F.; Xu, F.; et al. Bioinspired engineering of honeycomb structure – Using nature to inspire human innovation. Prog. Mater. Sci. 2015, 74, 332–400. [Google Scholar] [CrossRef]

- Gibson, L.J.; Ashby, M.F.; Schajer, G.S.; Robertson, C.I. The mechanics of two-dimensional cellular materi-als. Proceedings of the Royal Society of London. A. Math. Phys. Sci. 1982, 382, 25–42. [Google Scholar]

- Zhong, H.; Song, T.; Li, C.; Das, R.; Gu, J.; Qian, M. The Gibson-Ashby model for additively manufactured metal lattice materials: Its theoretical basis, limitations and new insights from remedies. Curr. Opin. Solid State Mater. Sci. 2023, 27. [Google Scholar] [CrossRef]

- Benedetti, M.; Klarin, J.; Johansson, F.; Fontanari, V.; Luchin, V.; Zappini, G.; Molinari, A. Study of the Compression Behaviour of Ti6Al4V Trabecular Structures Produced by Additive Laser Manufacturing. Materials 2019, 12, 1471. [Google Scholar] [CrossRef] [PubMed]

- Maconachie, T.; Tino, R.; Lozanovski, B.; Watson, M.; Jones, A.; Pandelidi, C.; Alghamdi, A.; Almalki, A.; Downing, D.; Brandt, M.; et al. The compressive behaviour of ABS gyroid lattice structures manufactured by fused deposition modelling. Int. J. Adv. Manuf. Technol. 2020, 107, 4449–4467. [Google Scholar] [CrossRef]

- Raghavendra, S.; Molinari, A.; Zappini, G.; Benedetti, M. Correlation between as-designed and as-built Young’s modulus of cubic regular, cubic irregular, and trabecular cellular materials. Mater. Des. Process. Commun. 2021, 3, e257. [Google Scholar] [CrossRef]

- Masters, I.; Evans, K. Models for the elastic deformation of honeycombs. Compos. Struct. 1996, 35, 403–422. [Google Scholar] [CrossRef]

- Wang, N.; Deng, Q. Effect of Axial Deformation on Elastic Properties of Irregular Honeycomb Structure. Chin. J. Mech. Eng. 2021, 34, 1–12. [Google Scholar] [CrossRef]

- Luo, H.C.; Ren, X.; Zhang, Y.; Zhang, X.Y.; Zhang, X.G.; Luo, C.; Cheng, X.; Xie, Y.M. Mechanical properties of foam-filled hexagonal and re-entrant honeycombs under uniaxial compression. Compos. Struct. 2022, 280, 114922. [Google Scholar] [CrossRef]

- Chen, D.H.; Ushijima, K. Deformation of honeycomb with finite boundary subjected to uniaxial compression. Metals 2013, 3, 343–360. [Google Scholar] [CrossRef]

- Li, X.; Lin, Y.; Lu, F. Numerical simulation on in-plane deformation characteristics of lightweight aluminum honey-comb under direct and indirect explosion. Materials 2019, 12, 2222. [Google Scholar] [CrossRef]

- Lu, Q.; Qi, D.; Li, Y.; Xiao, D.; Wu, W. Impact energy absorption performances of ordinary and hierarchical chiral structures. Thin-Walled Struct. 2019, 140, 495–505. [Google Scholar] [CrossRef]

- Zhang, Y.; Xu, X.; Wang, J.; Chen, T.; Wang, C.H. Crushing analysis for novel bio-inspired hierarchical circular structures subjected to axial load. Int. J. Mech. Sci. 2018, 140, 407–431. [Google Scholar] [CrossRef]

- Santosa, S.; Wierzbicki, T. Effect of an ultralight metal filler on the bending collapse behavior of thin-walled prismatic columns. Int. J. Mech. Sci. 1999, 41, 995–1019. [Google Scholar] [CrossRef]

- Nian, Y.; Wan, S.; Zhou, P.; Wang, X.; Santiago, R.; Li, M. Energy absorption characteristics of functionally graded polymer-based lattice structures filled aluminum tubes under transverse impact loading. Mater. Des. 2021, 209, 110011. [Google Scholar] [CrossRef]

- Wang, Z.; Yao, S.; Lu, Z.; Hui, D.; Feo, L. Matching effect of honeycomb-filled thin-walled square tube—Experiment and simulation. Compos. Struct. 2016, 157, 494–505. [Google Scholar] [CrossRef]

- Liu, J.; Chen, W.; Hao, H.; Wang, Z. Numerical study of low-speed impact response of sandwich panel with tube filled honeycomb core. Compos. Struct. 2019, 220, 736–748. [Google Scholar] [CrossRef]

- Yang, C.; Xu, P.; Yao, S.; Xie, S.; Li, Q.; Peng, Y. Optimization of honeycomb strength assignment for a composite energy-absorbing structure. Thin-Walled Struct. 2018, 127, 741–755. [Google Scholar] [CrossRef]

- Safaei, B.; Onyibo, E.C.; Hurdoganoglu, D. Effect of Static and Harmonic Loading on the Honeycomb Sandwich Beam by Using Finite Element Method. Facta Univ. Series: Mech. Eng. 2022, 20, 279–306. [Google Scholar] [CrossRef]

- Djemaoune, Y.; Krstic, B.; Rasic, S.; Radulovic, D.; Dodic, M. Numerical Investigation into In-Plane Crushing of Tube-Reinforced Damaged 5052 Aerospace Grade Aluminum Alloy Honeycomb Panels. Materials 2021, 14, 4992. [Google Scholar] [CrossRef] [PubMed]

- Xiong, J.; Mines, R.; Ghosh, R.; Vaziri, A.; Ma, L.; Ohrndorf, A.; Wu, L. Advanced micro-lattice materials. Adv. Eng. Mater. 2015, 17, 1253–1264. [Google Scholar] [CrossRef]

- Liu, G.; Zhang, X.; Chen, X.; He, Y.; Cheng, L.; Huo, M.; Lu, J. Additive manufacturing of structural materials. Mater. Sci. Eng. R: Rep. 2021, 145, 100596. [Google Scholar] [CrossRef]

- Wang, S.; Shi, Z.; Liu, L.; Huang, Z.; Li, Z.; Liu, J.; Hao, Y. Honeycomb structure is promising for the repair of human bone defects. Mater. Des. 2021, 207, 109832. [Google Scholar] [CrossRef]

- Matthews, F.L.; Davies GA, O.; Hitchings, D.; Soutis, C. Finite Element Modelling of Composite Materials and Structures; Elsevier: Amsterdam, The Netherlands, 2000. [Google Scholar]

- Mahendran, M. Applications of finite element analysis in structural engineering. In Proceedings of the International Conference on Computer Aided Engineering; Indian Institute of Technology Madras: Tamil Nadu, India, 2007; pp. 38–46. [Google Scholar]

- Guo, Q.; Yao, W.; Li, W.; Gupta, N. Constitutive models for the structural analysis of composite materials for the finite element analysis: A review of recent practices. Compos. Struct. 2021, 260, 113267. [Google Scholar] [CrossRef]

- Niutta, C.B.; Ciardiello, R.; Tridello, A. Experimental and Numerical Investigation of a Lattice Structure for Energy Absorption: Application to the Design of an Automotive Crash Absorber. Polymers 2022, 14, 1116. [Google Scholar] [CrossRef]

- Qiao, P.; Yang, M.; Bobaru, F. Impact Mechanics and High-Energy Absorbing Materials: Review. J. Aerosp. Eng. 2008, 21, 235–248. [Google Scholar] [CrossRef]

- Tarlochan, F. Sandwich Structures for Energy Absorption Applications: A Review. Materials 2021, 14, 4731. [Google Scholar] [CrossRef] [PubMed]

- Zadpoor, A.A. Mechanical performance of additively manufactured meta-biomaterials. Acta Biomater. 2019, 85, 41–59. [Google Scholar] [CrossRef] [PubMed]

- Korkmaz, M.E.; Gupta, M.K.; Robak, G.; Moj, K.; Krolczyk, G.M.; Kuntoğlu, M. Development of lattice structure with selective laser melting process: A state of the art on properties, future trends and challenges. J. Manuf. Process. 2022, 81, 1040–1063. [Google Scholar] [CrossRef]

- Pelanconi, M.; Zavattoni, S.; Cornolti, L.; Puragliesi, R.; Arrivabeni, E.; Ferrari, L.; Gianella, S.; Barbato, M.; Ortona, A. Application of Ceramic Lattice Structures to Design Compact, High Temperature Heat Exchangers: Material and Architecture Selection. Materials 2021, 14, 3225. [Google Scholar] [CrossRef] [PubMed]

- Kaur, I.; Singh, P. Critical evaluation of additively manufactured metal lattices for viability in advanced heat exchangers. Int. J. Heat Mass Transf. 2021, 168, 120858. [Google Scholar] [CrossRef]

- Alqahtani, S.; Ali, H.M.; Farukh, F.; Silberschmidt, V.V.; Kandan, K. Thermal performance of additively manufactured polymer lattices. J. Build. Eng. 2021, 39, 102243. [Google Scholar] [CrossRef]

- Zhang, Y.W.; Su, C.; Ni, Z.Y.; Zang, J.; Chen, L.Q. A multifunctional lattice sandwich structure with energy harvesting and nonlinear vibration control. Compos. Struct. 2019, 221, 110875. [Google Scholar] [CrossRef]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-weighting in aerospace component and system design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Wang, J.; Li, Y.; Hu, G.; Yang, M. Lightweight Research in Engineering: A Review. Appl. Sci. 2019, 9, 5322. [Google Scholar] [CrossRef]

- Blakey-Milner, B.; Gradl, P.; Snedden, G.; Brooks, M.; Pitot, J.; Lopez, E.; Du Plessis, A. Metal additive manufac-turing in aerospace: A review. Mater. Des. 2021, 209, 110008. [Google Scholar] [CrossRef]

- Kamal, M.; Rizza, G. Design for metal additive manufacturing for aerospace applications. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 67–86. [Google Scholar]

- Katz-Demyanetz, A.; Popov, V.V.; Kovalevsky, A.; Safranchik, D.; Koptyug, A. Powder-bed additive manufacturing for aerospace application: Techniques, metallic and metal/ceramic composite materials and trends. Manuf. Rev. 2019, 6, 5. [Google Scholar] [CrossRef]

- Abbe, G.; Smith, H. Technological development trends in Solar-powered Aircraft Systems. Renew. Sustain. Energy Rev. 2016, 60, 770–783. [Google Scholar] [CrossRef]

- Zhang, T.; Li, Y.; Chen, Y.; Feng, X.; Zhu, X.; Chen, Z.; Yao, J.; Zheng, Y.; Cai, J.; Song, H.; et al. Review on space energy. Appl. Energy 2021, 292, 116896. [Google Scholar] [CrossRef]

- Najmon, J.C.; Raeisi, S.; Tovar, A. Review of additive manufacturing technologies and applications in the aerospace industry. In Additive Manufacturing for the Aerospace Industry; Elsevier: Amsterdam, The Netherlands, 2019; pp. 7–31. [Google Scholar]

- Noronha, J.; Qian, M.; Leary, M.; Kyriakou, E.; Brandt, M. Hollow-walled lattice materials by additive manufacturing: Design, manufacture, properties, applications and challenges. Curr. Opin. Solid State Mater. Sci. 2021, 25, 100940. [Google Scholar] [CrossRef]

- Ramakrishna, D.; Murali, G.B. Bio-inspired 3D-printed lattice structures for energy absorption applications: A review. Proc. Inst. Mech. Eng. Part L: J. Mater. Des. Appl. 2023, 237, 503–542. [Google Scholar] [CrossRef]

- Zhang, W.; Xu, J. Advanced lightweight materials for Automobiles: A review. Mater. Des. 2022, 221, 110994. [Google Scholar] [CrossRef]

- Picard, M.; Mohanty, A.K.; Misra, M. Recent advances in additive manufacturing of engineering thermoplastics: Challenges and opportunities. RSC Adv. 2020, 10, 36058–36089. [Google Scholar] [CrossRef]

- Cooper, D.; Thornby, J.; Blundell, N.; Henrys, R.; Williams, M.; Gibbons, G. Design and manufacture of high performance hollow engine valves by Additive Layer Manufacturing. Mater. Des. 2015, 69, 44–55. [Google Scholar] [CrossRef]

- Czerwinski, F. Current Trends in Automotive Lightweighting Strategies and Materials. Materials 2021, 14, 6631. [Google Scholar] [CrossRef] [PubMed]

- Pirozzi, M.A.; Magliulo, M.; Prinster, A. 3D-printed anatomical phantoms. In Handbook of Surgical Planning and 3D Printing; Academic Press: Cambridge, MA, USA, 2023; pp. 305–334. [Google Scholar]

- Gomes, M.E.; Rodrigues, M.T.; Domingues, R.M.; Reis, R.L. Tissue Engineering and Regenerative Medicine: New Trends and Directions—A Year in Review. Tissue Eng. Part B: Rev. 2017, 23, 211–224. [Google Scholar] [CrossRef]

- Jia, Z.; Liu, F.; Jiang, X.; Wang, L. Engineering lattice metamaterials for extreme property, programmability, and multifunctionality. J. Appl. Phys. 2020, 127, 150901. [Google Scholar] [CrossRef]

- Lincoln, R.L.; Scarpa, F.; Ting, V.P.; Trask, R.S. Multifunctional composites: A metamaterial perspective. Multifunct. Mater. 2019, 2, 043001. [Google Scholar] [CrossRef]

- Pan, C.; Han, Y.; Lu, J. Design and Optimization of Lattice Structures: A Review. Appl. Sci. 2020, 10, 6374. [Google Scholar] [CrossRef]

- Garland, A.P.; White, B.C.; Jensen, S.C.; Boyce, B.L. Pragmatic generative optimization of novel structural lattice metamaterials with machine learning. Mater. Des. 2021, 203, 109632. [Google Scholar] [CrossRef]

- Hanifi, M.; Chibane, H.; Houssin, R.; Cavallucci, D.; Ghannad, N. Artificial intelligence methods for improving the inventive design process, application in lattice structure case study. Artif. Intell. Eng. Des. Anal. Manuf. 2022, 36. [Google Scholar] [CrossRef]

- Kantaros, A.; Piromalis, D.; Tsaramirsis, G.; Papageorgas, P.; Tamimi, H. 3D Printing and Implementation of Digital Twins: Current Trends and Limitations. Appl. Syst. Innov. 2021, 5, 7. [Google Scholar] [CrossRef]

- Eskandarpour, R.; Ghosh KJ, B.; Khodaei, A.; Paaso, A.; Zhang, L. Quantum-enhanced grid of the future: A primer. IEEE Access 2020, 8, 188993–189002. [Google Scholar] [CrossRef]

| Section of Review | Main Findings |

|---|---|

|

|

|

|

|

|

|

|

|

|

|

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chibinyani, M.I.; Dzogbewu, T.C.; Maringa, M.; Muiruri, A. Lattice Structures Built with Different Polygon Hollow Shapes: A Review on Their Analytical Modelling and Engineering Applications. Appl. Sci. 2024, 14, 1582. https://doi.org/10.3390/app14041582

Chibinyani MI, Dzogbewu TC, Maringa M, Muiruri A. Lattice Structures Built with Different Polygon Hollow Shapes: A Review on Their Analytical Modelling and Engineering Applications. Applied Sciences. 2024; 14(4):1582. https://doi.org/10.3390/app14041582

Chicago/Turabian StyleChibinyani, Munashe Ignatius, Thywill Cephas Dzogbewu, Maina Maringa, and Amos Muiruri. 2024. "Lattice Structures Built with Different Polygon Hollow Shapes: A Review on Their Analytical Modelling and Engineering Applications" Applied Sciences 14, no. 4: 1582. https://doi.org/10.3390/app14041582

APA StyleChibinyani, M. I., Dzogbewu, T. C., Maringa, M., & Muiruri, A. (2024). Lattice Structures Built with Different Polygon Hollow Shapes: A Review on Their Analytical Modelling and Engineering Applications. Applied Sciences, 14(4), 1582. https://doi.org/10.3390/app14041582