Study of the Internal Rebreaking Characteristics of Crushed Gangue in Mine Goaf during Compression

Abstract

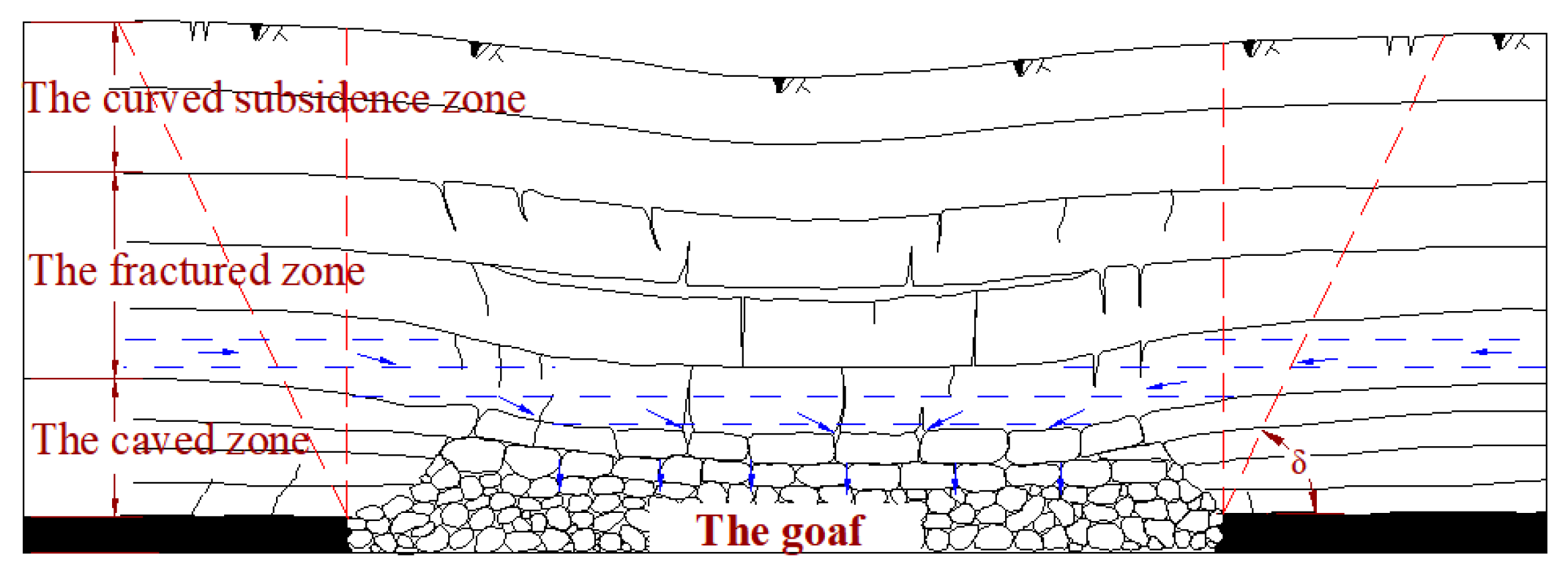

:1. Introduction

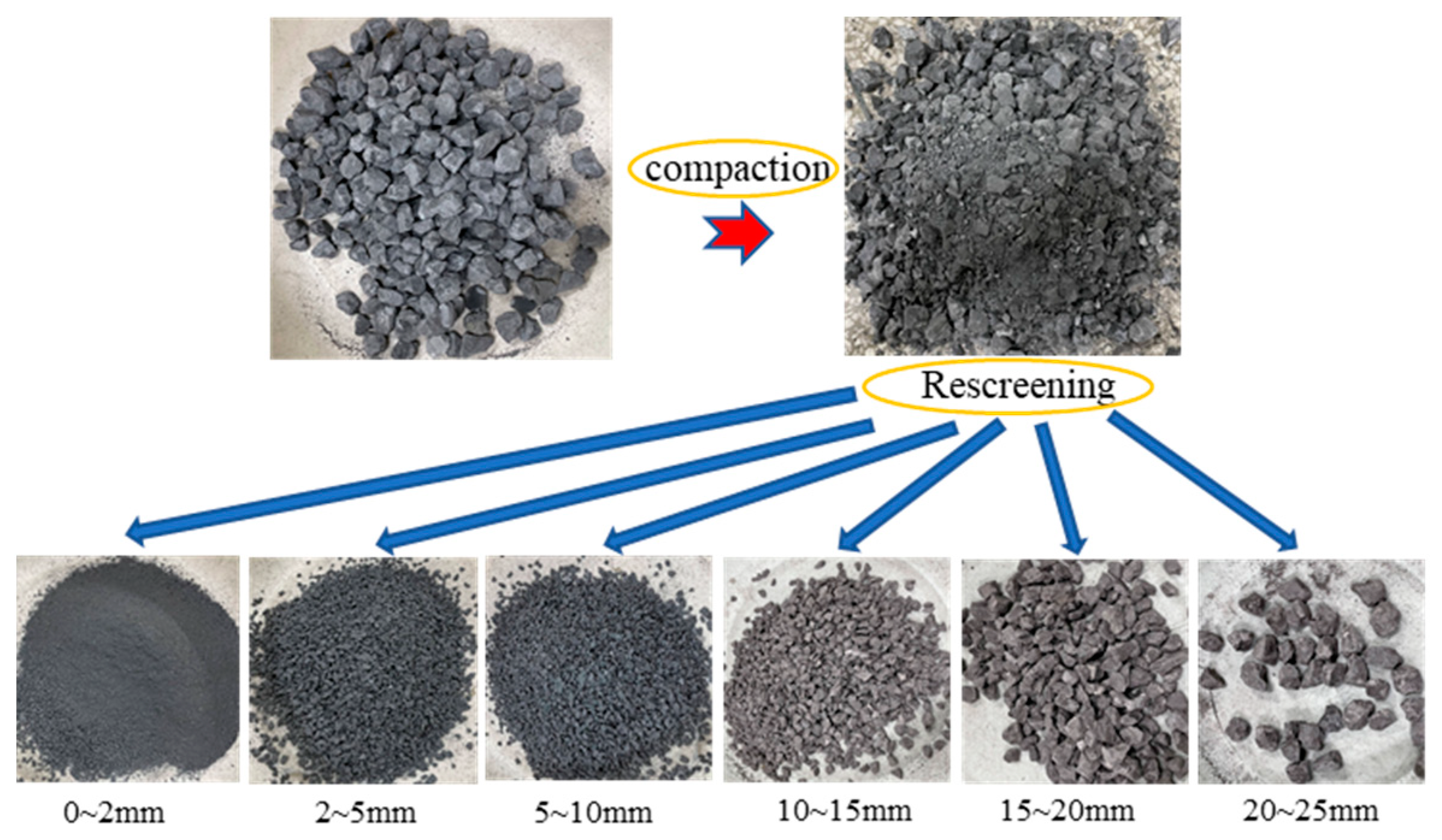

2. Materials and Methods

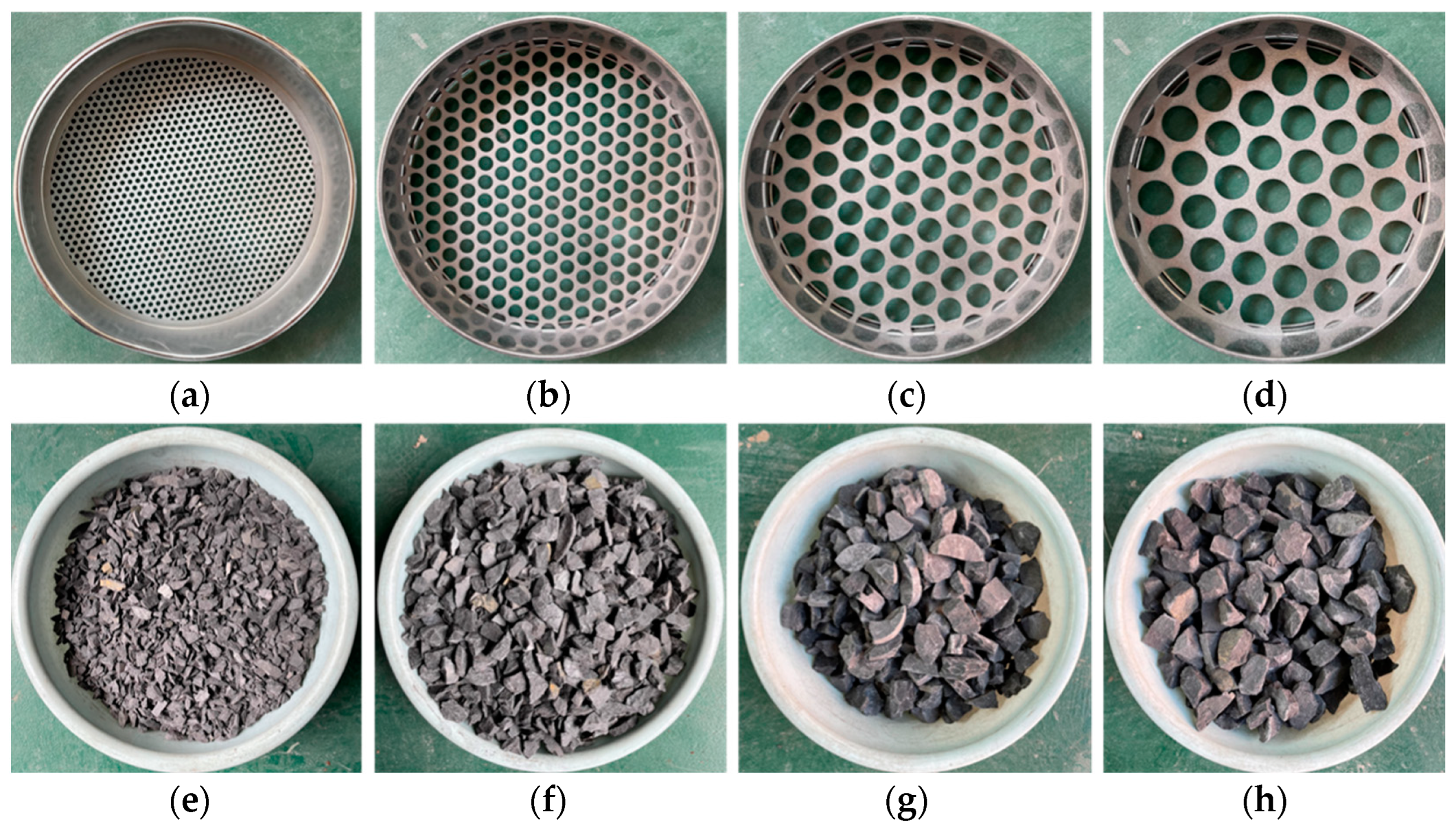

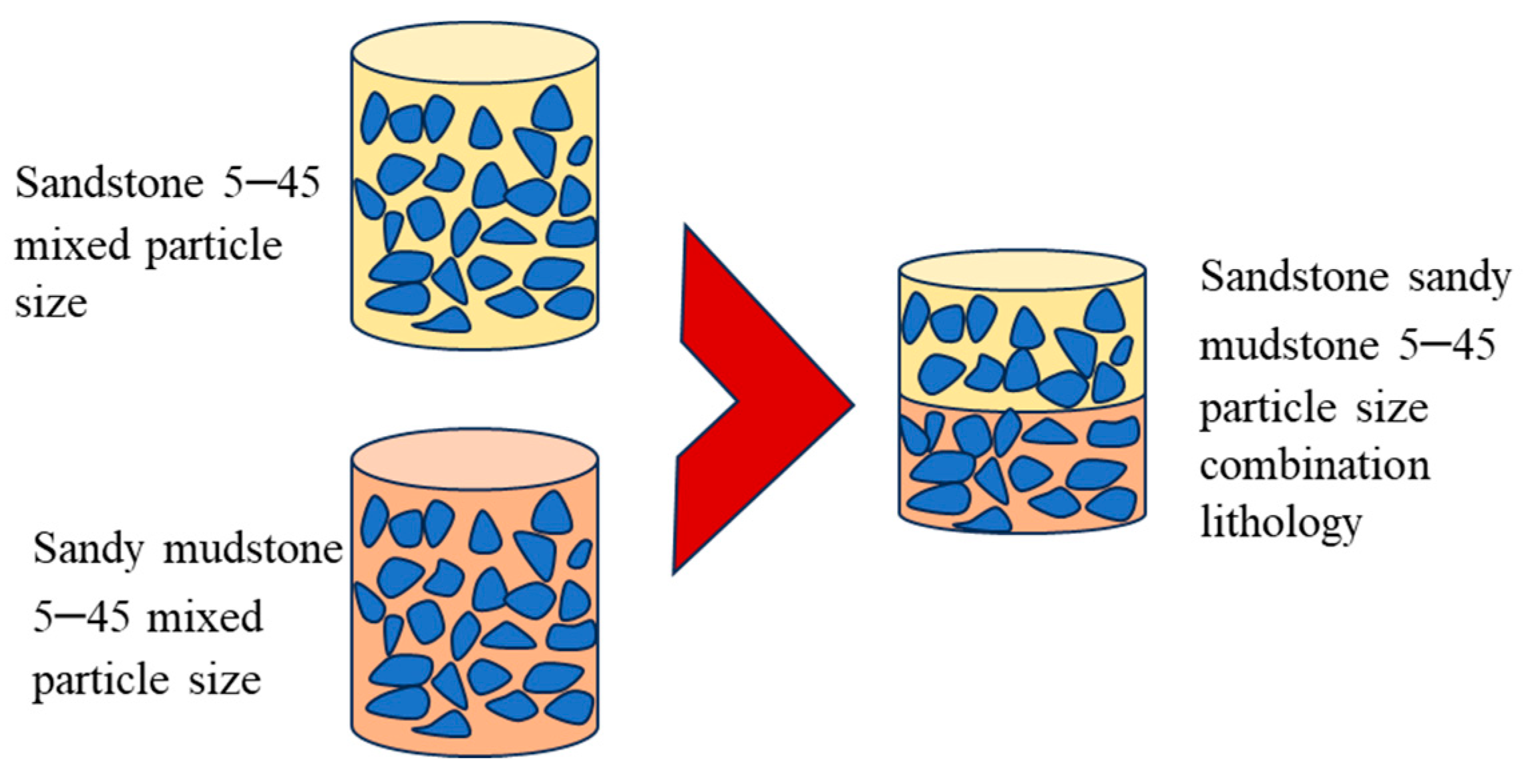

2.1. Test Materials

2.2. Testing of Physical and Mechanical Parameters of Crushed Gangue

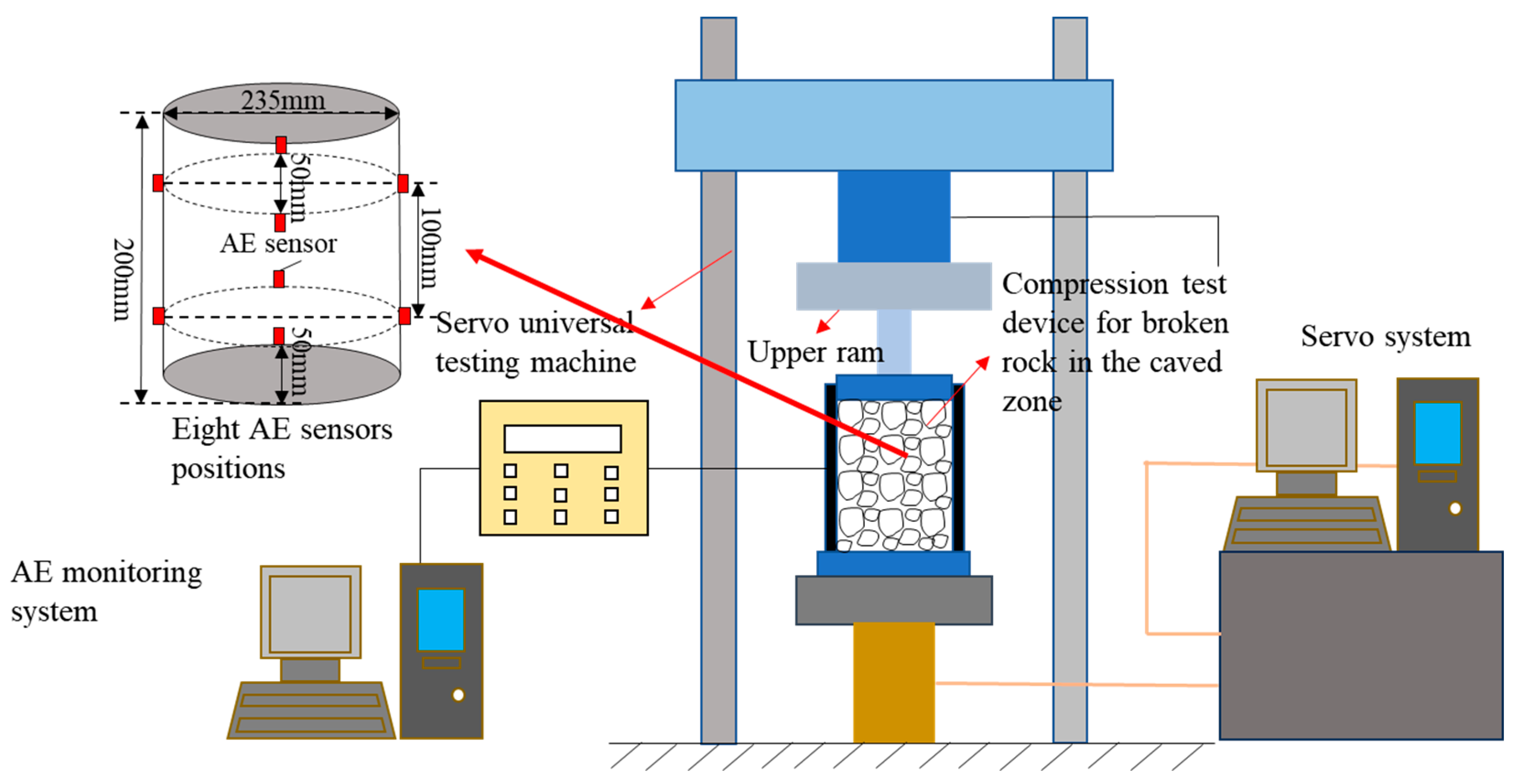

2.3. Test System

3. Results

3.1. Confined Compression Deformation Characteristics of Fractured Gangues with Different Lithologies

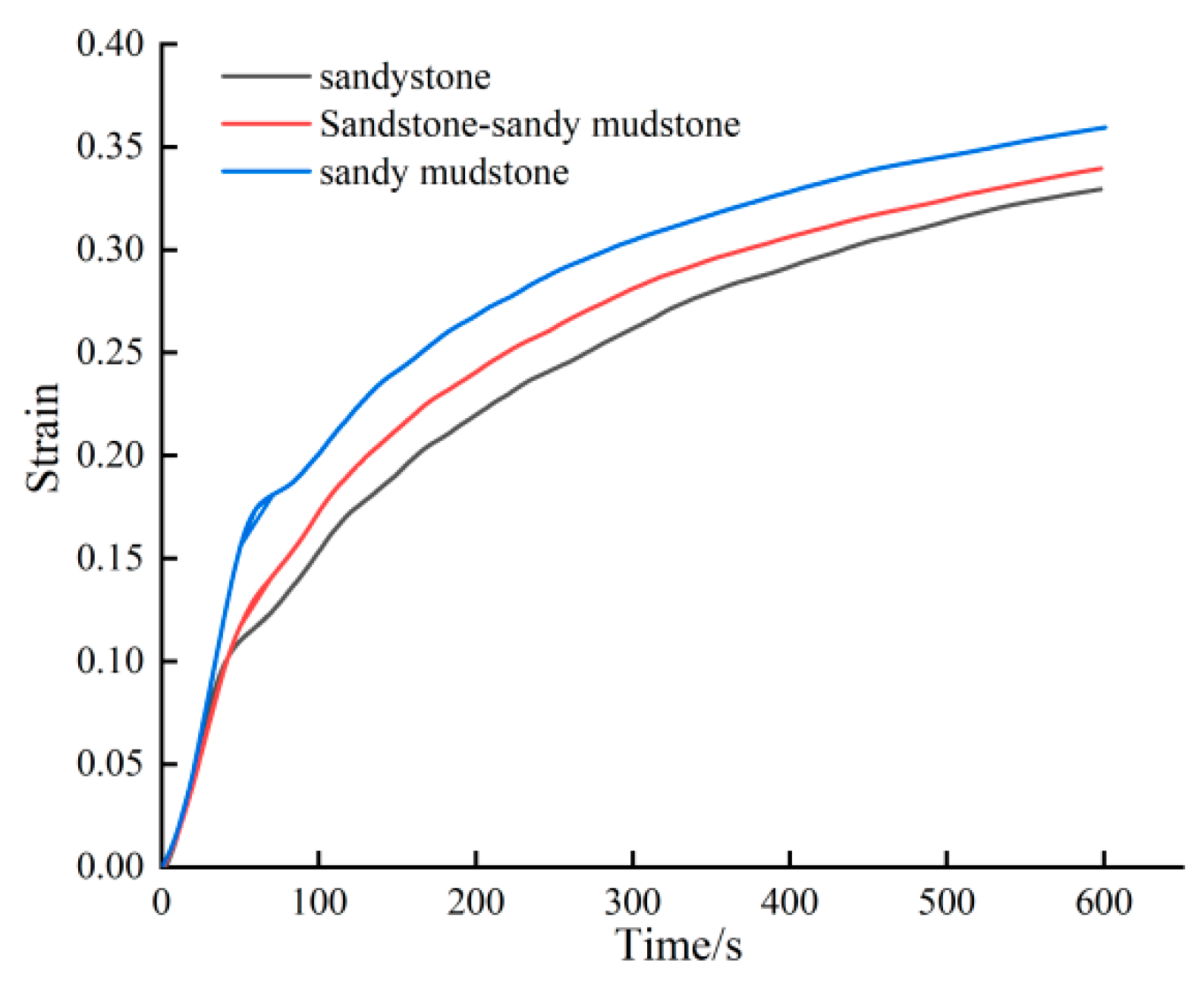

3.1.1. Time-Strain

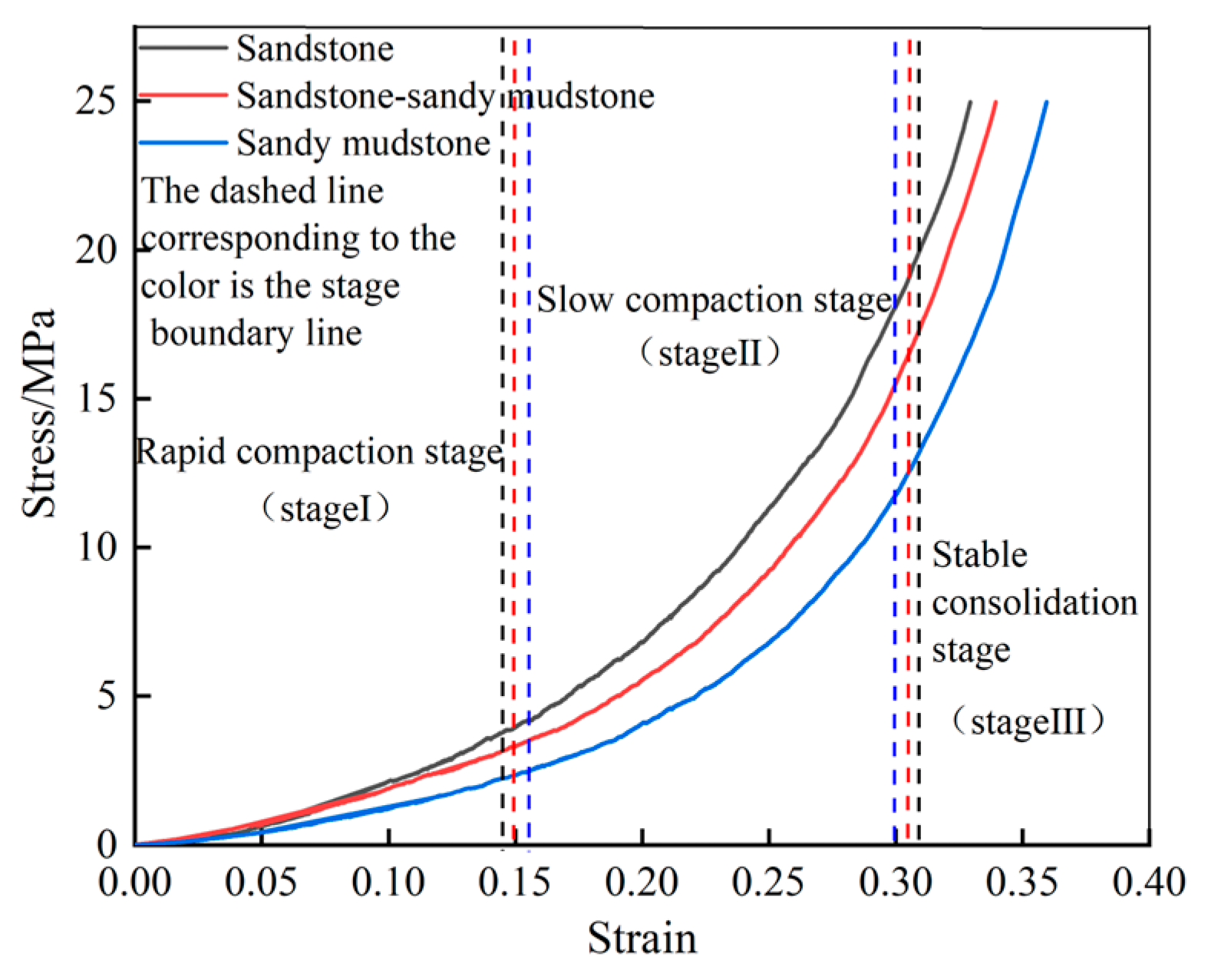

3.1.2. Stress–Strain

- (I)

- The rapid compaction stage.

- (II)

- The slow compaction stage.

- (III)

- The stable compaction stage.

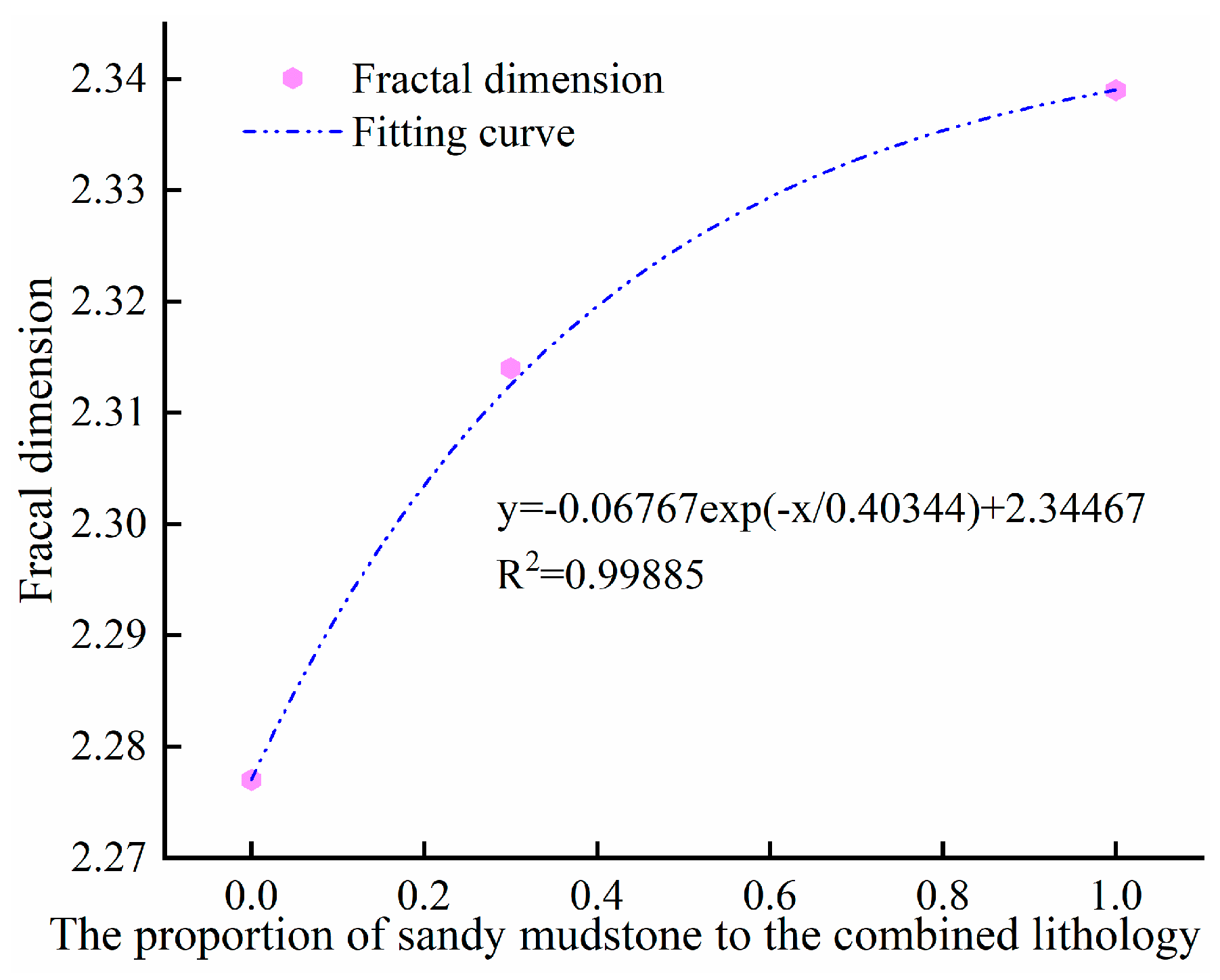

3.1.3. Fractal Dimension

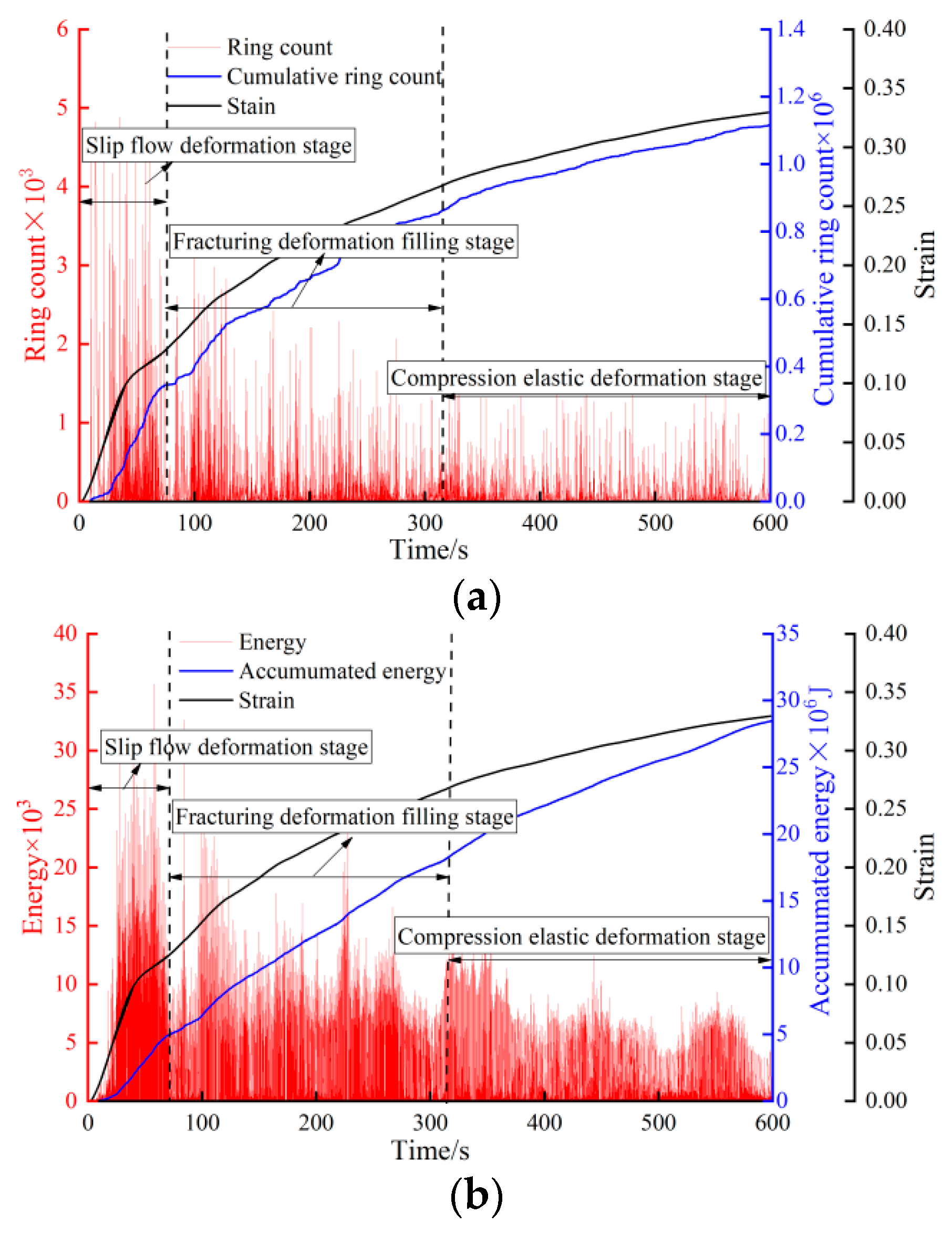

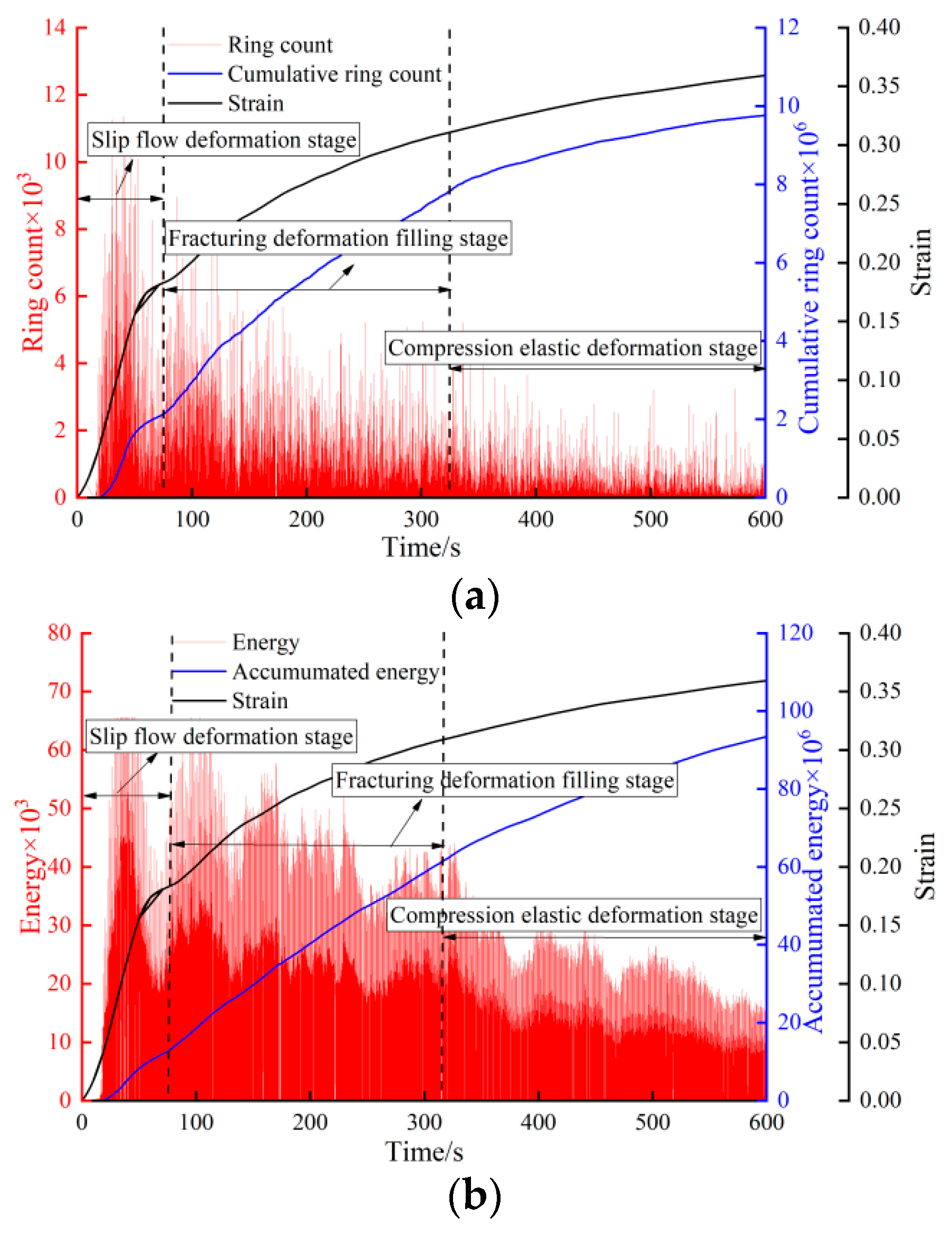

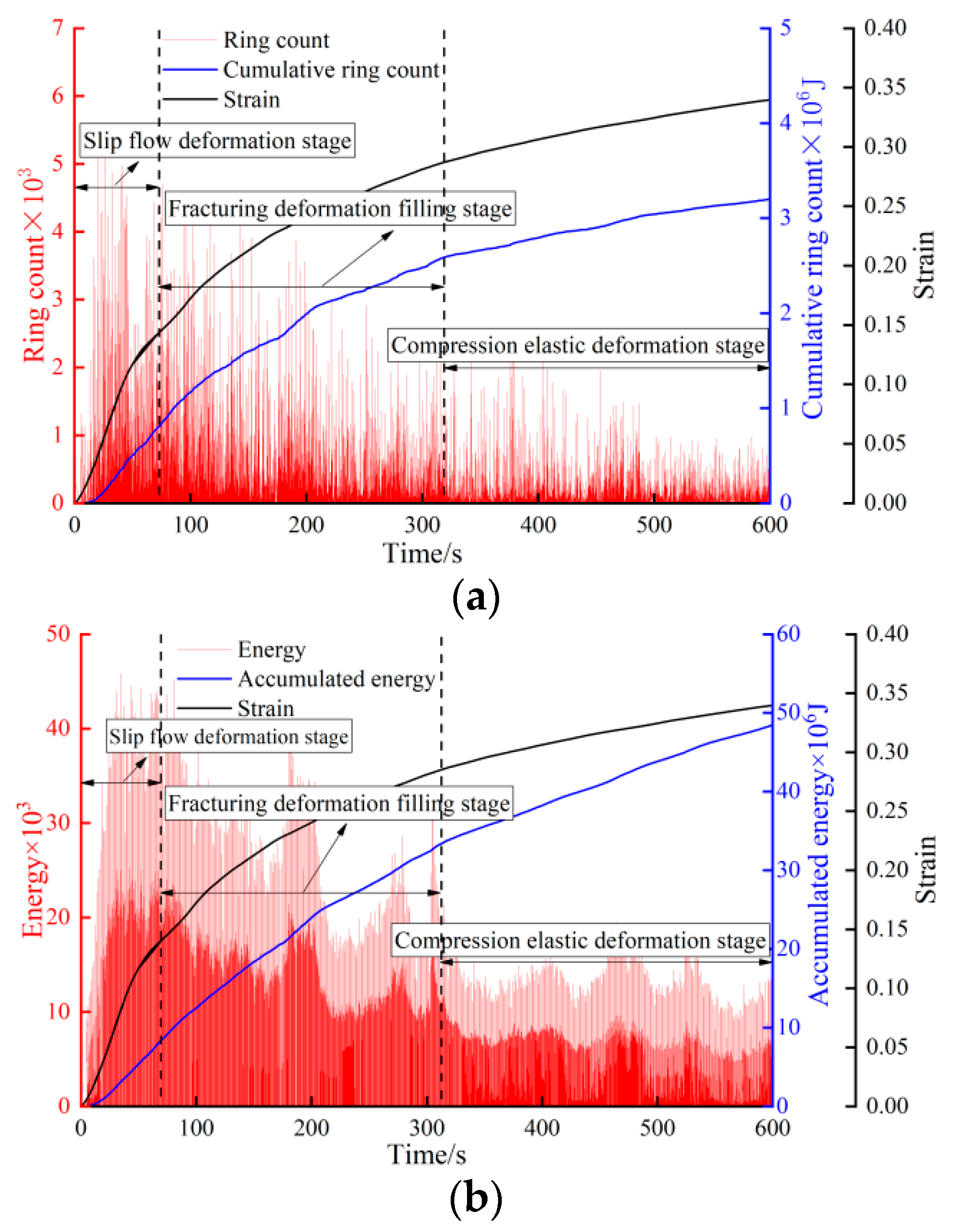

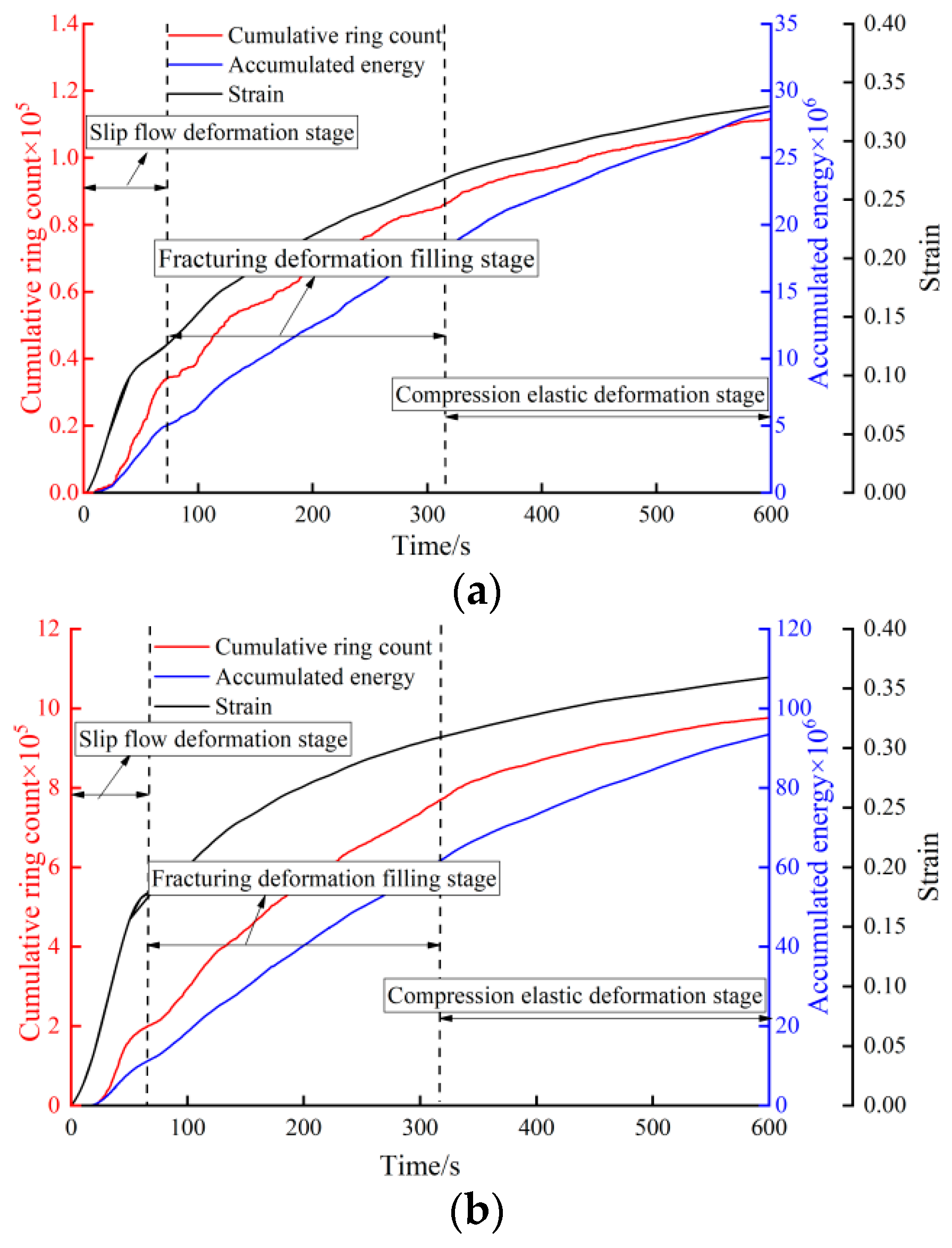

3.2. AE Characteristics and Analysis of Crushed Gangue Compaction

3.2.1. Evolution of AE Parameters during Axial Compression

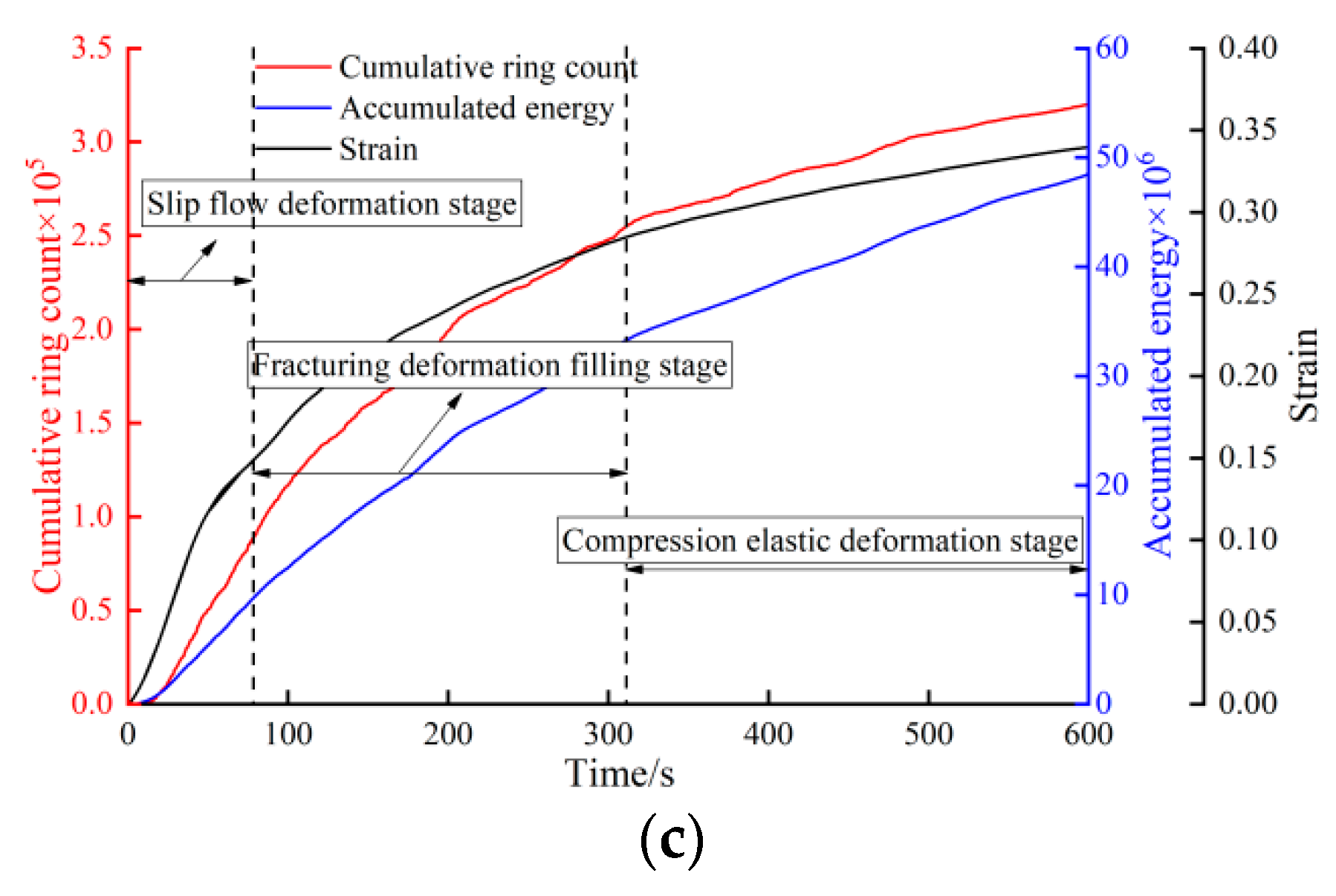

3.2.2. Analysis of AE of Crushed Gangue Compaction Deformation

4. Discussion

5. Conclusions

- (1)

- Under the condition of confined compression, the change curve of the axial strain of the crushed gangue sample in the caved zone with time showed a straight upward trend at the beginning of the test, which increased with time, showing a sharp rise at first before slowing at the end. The softer the lithology, the greater the initial rate of growth, and the greater the final strain value reached at the end of the test.

- (2)

- The stress–strain curves of crushed gangues with different lithologies in the caved zone showed nonlinear growth. The difference was that the lower the strength of the gangue sample, the slower the initial rise of the curve, and the greater the final strain. The stress–strain curves showed typical characteristics, which were divided into the rapid compaction stage, slow compaction stage, and stable compaction stage. The strain of the combined samples were somewhere between those of the individual samples.

- (3)

- In confined compression, the AE characteristics of crushed gangue were different at different deformation stages. Based on the AE test, the compaction process was divided into the sliding flow deformation stage, fracturing deformation filling stage, and compaction elastic deformation stage, corresponding to the stress and strain in the compression of the samples. The failures of the large particle skeleton, the sliding flow of medium particles, and the filling of pores by small particles were the main reasons for the compression deformation of crushed gangue samples, respectively.

- (4)

- There was a positive correlation between the fractal dimension and the proportion of gangue samples with singular and combined lithologies, with the fitting degree above 0.98. Based on the compaction characteristics of crushed gangue samples and AE tests, the crushing stage characteristics of crushed gangue during compaction were summarized.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Qian, M.G.; Xu, J.L.; Wang, J.C. Further on the sustainable mining of coal. J. China Coal Soc. 2018, 43, 1–13. [Google Scholar]

- Peng, S.P.; Bi, Y.L. Strategic consideration and core technology about environmental ecological restoration in coal mine areas in the Yellow River Basin of China. J. China Coal Soc. 2020, 45, 1211–1221. [Google Scholar]

- Guo, W.B.; Bai, E.H.; Zhao, G.B. Current status and progresson overburden and surface damage and prevention technology of fully mechanized caving mining. J. China Coal Soc. 2020, 45, 509–523. [Google Scholar]

- Guo, W.B. Damage and Protection in Coal Mining; Emergency Management Press: Beijing, China, 2019; pp. 1–8. [Google Scholar]

- Jing, Y.; Armstrong, R.T.; Mostaghimi, P. Digital coal: Generation of fractured cores with microscale features. Fuel 2017, 207, 93–101. [Google Scholar] [CrossRef]

- Li, Z.; Feng, G.R.; Luo, Y.; Hu, S.Y.; Qi, T.Y.; Jiang, H.N.; Guo, J.; Bai, J.W.; Du, X.J.; Kang, L.X. Multi-tests for pore structure characterization-a case study using lamprophyre. AIP Adv. 2017, 7, 085204. [Google Scholar] [CrossRef]

- Miao, X.X.; Li, S.C.; Chen, Z.Q.; Liu, W.Q. Experimental study of seepage properties crushed sandstone under different porosities. Transp. Porous Media 2011, 86, 805–814. [Google Scholar] [CrossRef]

- Guo, W.B. Special Mining Technology of Mine; China University of Mining and Technology Press: Xuzhou, China, 2021; pp. 10–16. [Google Scholar]

- Peng, S.S. Longwall Mining, 3rd ed.; Taylor & Francis Group: Abingdon, UK, 2019. [Google Scholar]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Cacciuttolo, C.; Marinovic, A. Experiences of underground mine backfilling using mine tailings developed in the Andean region of Peru: A green mining solution to reduce socio-environmental impacts. Sustainability 2023, 15, 12912. [Google Scholar] [CrossRef]

- Liu, H.T.; Guo, L.F.; Zhao, X.D. Expansionary evolution characteristics of plastic zone in rock and coal mass ahead of excavation face and the mechanism of coal and gas outburst. Energies 2020, 13, 984. [Google Scholar] [CrossRef]

- Jiang, Q.; Ji, L.J.; Zuo, R.S. Research on mechanism of crushing-compression of coal waste. J. China Univ. Min. Technol. 2001, 30, 31–34. [Google Scholar]

- Ma, Z.G. An experimental study of the compaction of water-saturated over-crushed rock. Chin. J. Rock Mech. Eng. 2005, 24, 1139–1144. [Google Scholar]

- Huang, Y.L.; Zhang, J.X.; Du, J. Time dependence of backfilling body in fully mechanized backfilling mining face. J. China Univ. Min. Technol. 2012, 41, 697–701. [Google Scholar]

- Huang, Y.L. Strata movement control due to bulk factor of backfilling body in fully mechanized backfilling mining face. J. Min. Saf. Eng. 2012, 29, 162–167. [Google Scholar]

- Yang, X.L.; Chu, T.X.; Yu, M.G.; Wang, L.; Chao, J.K.; Han, X.F. Evolution characteristics of bulking factor in the multi-field loading of broken coal: An experimental study. Rock Mech. Rock Eng. 2021, 54, 1481–1499. [Google Scholar] [CrossRef]

- Li, J.M.; Huang, Y.L.; Chen, Z.W.; Zhang, J.X.; Jiang, H.Q.; Zhang, Y.C. Characterizations of macroscopic deformation and particle crushing of crushed gangue particle material under cyclic loading: In solid backfilling coal mining. Powder Technol. 2019, 343, 159–169. [Google Scholar] [CrossRef]

- Yu, B.; Chen, Z.; Ding, Q.; Wang, L. Non-Darcy flow seepage characteristics of saturated broken rocks under compression with lateral constraint. Int. J. Min. Sci. Technol. 2016, 26, 1145–1151. [Google Scholar] [CrossRef]

- Liu, Y.; Dai, F. A damage constitutive model for intermittent jointed rocks under cyclic uniaxial compression. Int. J. Rock Mech. Min. Sci. 2018, 103, 289–301. [Google Scholar] [CrossRef]

- Yang, X.; Liu, E.; Han, X.; Han, X.; Da, W. Experimental Study on Energy Evolution of Sandstone under Uniaxial Cyclic Loading. Coal Technol. 2018, 37, 21–24. [Google Scholar]

- Zhou, Z.; Cai, X.; Li, X.; Cao, W.; Du, X. Dynamic Response and Energy Evolution of Sandstone Under Coupled Static–Dynamic Compression: Insights from Experimental Study into Deep Rock Engineering Applications. Rock Mech. Rock Eng. 2020, 53, 1305–1331. [Google Scholar] [CrossRef]

- Zhang, T.J.; Zhang, L.; Li, S.G.; Liu, J.L.; Pan, H.Y.; Ji, X. Wave Velocity and Power Spectral Density of Hole-Containing Specimens with Different Moisture Content under Uniaxial Compression. Energies 2018, 11, 3166. [Google Scholar] [CrossRef]

- Liu, Y.M.; Liu, H.B.; Mao, H.J. DEM investigation of the effect of intermediate principle stress on particle breakage of granular materials. Comput. Geotech. 2017, 84, 58–67. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.X.; Zhou, N.; Huang, Y.L. Effect of particle size on the energy evolution of crushed waste rock in coal mines. Rock Mech. Rock. Eng. 2017, 50, 1347–1354. [Google Scholar] [CrossRef]

- Li, M.; Zhang, J.; Gao, R. Compression characteristics of solid wastes as backfill materials. Adv. Mater. Sci. Eng. 2016, 2016, 2496194. [Google Scholar] [CrossRef]

- Zhang, C.; Tu, S.H.; Zhao, Y.X. Compaction characteristics of the caving zone in a longwall goaf: A review. Environ. Earth Sci. 2019, 78, 27. [Google Scholar] [CrossRef]

- Trueman, R. A finite element analysis for the establishment of stress development in a coal mine caved waste. Min. Sci. Technol. 1990, 10, 247–252. [Google Scholar] [CrossRef]

- Zhang, P.F.; Zhang, Y.B.; Zhao, T.B.; Tan, Y.L.; Yu, F.H. Experimental research on deformation characteristics of waste-rock material in underground backfill mining. Minerals 2019, 9, 102. [Google Scholar] [CrossRef]

- Wu, D.T.; Luo, F.; Li, M.; Diao, Y.L.; Guo, Y.J.; Xu, P.D. Macroscopic and microscopic study on the compression bearing characteristics and deformation failure mechanism of gangue with different particle sizes. Powder Technol. 2021, 383, 198–211. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.H.; Hu, Y.Z. 3D image visualization of meso-structural changes in a bimsoil under uniaxial compression using X-ray computed tomography (CT). Eng. Geol. 2019, 248, 61–69. [Google Scholar] [CrossRef]

- Cheng, Z.; Hu, M.; Wang, J.F. Discrete element modelling of the mechanical behavior of cemented carbonate sand considering the effects of particle shape and breakage. Chin. J. Comput. Mech. 2022, 39, 315–323. [Google Scholar]

- Yang, B.H.; Wu, A.X.; Miao, X.X.; Liu, J.Z. 3D characterization and analysis of pore structure of packed ore particle beds based on computed tomography images. Trans. Nonferrous Met. Soc. China 2014, 24, 833–838. [Google Scholar] [CrossRef]

- Feng, G.R.; Zhang, Y.; Li, Z.; Fang, Z.; Yang, Y.; Yang, X.; Zhang, X. Quantitative analysis of layered re-crushing of crushed coal particles during compression based on CT scanning. Powder Technol. 2023, 426, 118638. [Google Scholar] [CrossRef]

- Dong, L.; Chen, Y.; Sun, D.; Zhang, Y. Implications for rock instability precursors and principal stress direction from rock acoustic experiments. Int. J. Min. Sci. Technol. 2021, 31, 789–798. [Google Scholar] [CrossRef]

- Zou, Q.L.; Ning, Y.; Zhang, B.; Tian, S.; Jiang, Z.; An, Y. Mechanical properties and failure characteristics of sandstone under ramp loading paths. Geomech. Geophys. Geo-Energy Geo-Resour. 2023, 9, 39. [Google Scholar] [CrossRef]

- Qin, R.C.; Zhou, R.; Li, Q.; Lu, C.; Huang, L. Acoustic emission source location method for glass fibre reinforced plastics based on virtual loading focusing enhancement technology. Nondestruct. Test. Eval. 2023, 2023, 1–16. [Google Scholar] [CrossRef]

- Mao, W.; Towhata, I. Monitoring of single-particle fragmentation process under static loading using acoustic emission. Appl. Acoust. 2015, 94, 39–45. [Google Scholar] [CrossRef]

- Michlmayr, G.; Cohen, D.; Or, D. Shear-induced force fluctuations and acoustic emissions in granular material. J. Geophys. Res. Solid Earth 2013, 118, 6086–6098. [Google Scholar] [CrossRef]

- Johnson, P.A.; Ferdowsi, B.; Kaproth, B.M.; Scuderi, M.; Griffa, M.; Carmeliet, J.; Guyer, R.A.; Bas, P.Y.; Trugman, D.T.; Marone, C. Acoustic emission and microslip precursors to stick-slip failure in sheared granular material. Geophys. Res. Lett. 2013, 40, 5627–5631. [Google Scholar] [CrossRef]

- Michlmayr, G.; Or, D. Mechanisms for acoustic emissions generation during granular shearing. Granul. Matter 2014, 16, 627–640. [Google Scholar] [CrossRef]

- Feng, G.R.; Fang, Z.L.; Li, Z.; Qi, T.Y.; Zhao, J.P.; Fan, W.C.; Yang, P.; Yang, X.J.; Yu, Y.R.; Zhang, H.F.; et al. Effect of particle size on re-crushing characteristics of crushed coal during axial loading. Powder Technol. 2022, 407, 117675. [Google Scholar]

- Feng, G.R.; Zhao, J.P.; Wang, H.W.; Li, Z.; Fang, Z.L.; Fan, W.C.; Yang, P.; Yang, X.J. Study of the internal re-breaking characteristics of crushed limestone during compression. Powder Technol. 2022, 396, 449–455. [Google Scholar] [CrossRef]

- Li, J.; Huang, Y.; Chen, Z.; Li, M.; Qiao, M.; Kizil, M. Particle-crushing characteristics and acoustic-emission patterns of crushing gangue backfilling material under cyclic loading. Minerals 2018, 8, 244. [Google Scholar] [CrossRef]

- Li, J.M.; Huang, Y.L.; Zhai, W.; Li, Y.S.; Ouyang, S.Y.; Gao, H.D.; Li, W.; Ma, K.; Wu, L.W. Experimental study on acoustic emission of confined compression of crushed gangue under different loading rates: Disposal of gangue solid waste. Sustainability 2020, 12, 3911. [Google Scholar] [CrossRef]

- Xin, H.Q. Research on deformation and crushing rules and acoustic emission characteristics of gangue bulk under the condition of confined compression. J. Min. Saf. Eng. 2020, 37, 162–168. [Google Scholar]

- Qin, T.; Guo, X.; Huang, Y.; Wu, Z.; Qi, W.; Wang, H. Study on macro-meso deformation law and acoustic emission characteristics of granular gangue under different loading rates. Minerals 2022, 12, 1422. [Google Scholar] [CrossRef]

- Li, W.; Huang, Y.L.; Gao, H.D.; Li, J.M.; Ruan, Z.Y.; Song, T.Q. Study on acoustic emission characteristics of gangue of different graduations during confined compression. J. Min. Saf. Eng. 2020, 37, 159–165+172. [Google Scholar]

- Zhang, J.; Zhu, J.; Huang, W. Crushing and fractal behaviors of quartz sand gravel particles under confined compression. Chin. J. Geotech. Eng. 2008, 30, 783–787. [Google Scholar]

- Wang, Q. The Pressure-Bearing Characteristics and Deformation Mechanism of Gangue Rib in Gob-Side Entry Retaining by Roof-Fracturing and Pressure-Releasing; China University of Mining and Technology: Xuzhou, China, 2020. [Google Scholar]

- Tyler, S.W.; Wheatcraft, S.W. Fractal scaling of soil particle size distributions: Analysis and limitations. Soil Sci. Soc. Am. J. 1992, 56, 362–369. [Google Scholar] [CrossRef]

- Xu, J.L.; Qin, W.; Chen, X.J.; Hu, G.Z.; Xie, J.L.; Wang, X.Z.; Zhu, W.B. Influencing factors of accumulative effect of overburden strata expansion induced by stress relief. J. China Coal Soc. 2022, 47, 115–127. [Google Scholar]

| Lithology | Compressive Strength/MPa | Cohesion/MPa | Tensile Strength/MPa | Elastic Modulus/GPa | Internal Friction Angle/(°) |

|---|---|---|---|---|---|

| Sandstone | 67.29 | 28.65 | 3.28 | 23.02 | 37.1 |

| Sandy mudstone | 38.25 | 3.99 | 0.97 | 9.5 | 33.82 |

| Initial Particle Size | Crushed Gangue Mass | Correlation Coefficient | Fractal Dimension | |||||

|---|---|---|---|---|---|---|---|---|

| 15~25 mm | ||||||||

| after compaction | 0~2 mm | 2~5 mm | 5~10 mm | 10~15 mm | 15~20 mm | 20~25 mm | ||

| sandstone proportion/% | 15.53 | 9.25 | 21.85 | 19.1 | 19.68 | 14.59 | 0.985 | 2.237 |

| sandstone–sandy mudstone proportion/% | 16.9 | 10.42 | 20.37 | 23.27 | 18.27 | 10.77 | 0.986 | 2.265 |

| sandy mudstone proportion/% | 20.47 | 11.25 | 23 | 16.78 | 18.52 | 9.97 | 0.99 | 2.349 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wen, P.; Han, S.; Guo, W.; Yang, W.; Bai, E. Study of the Internal Rebreaking Characteristics of Crushed Gangue in Mine Goaf during Compression. Appl. Sci. 2024, 14, 1682. https://doi.org/10.3390/app14051682

Wen P, Han S, Guo W, Yang W, Bai E. Study of the Internal Rebreaking Characteristics of Crushed Gangue in Mine Goaf during Compression. Applied Sciences. 2024; 14(5):1682. https://doi.org/10.3390/app14051682

Chicago/Turabian StyleWen, Peng, Sen Han, Wenbing Guo, Weiqiang Yang, and Erhu Bai. 2024. "Study of the Internal Rebreaking Characteristics of Crushed Gangue in Mine Goaf during Compression" Applied Sciences 14, no. 5: 1682. https://doi.org/10.3390/app14051682

APA StyleWen, P., Han, S., Guo, W., Yang, W., & Bai, E. (2024). Study of the Internal Rebreaking Characteristics of Crushed Gangue in Mine Goaf during Compression. Applied Sciences, 14(5), 1682. https://doi.org/10.3390/app14051682