Modeling and Numerical Computation of the Longitudinal Non-Linear Dynamics of High-Speed Elevators

Abstract

:1. Introduction

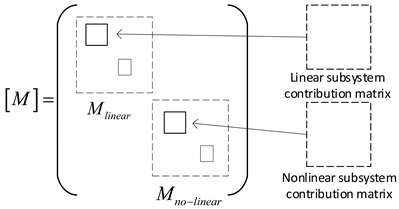

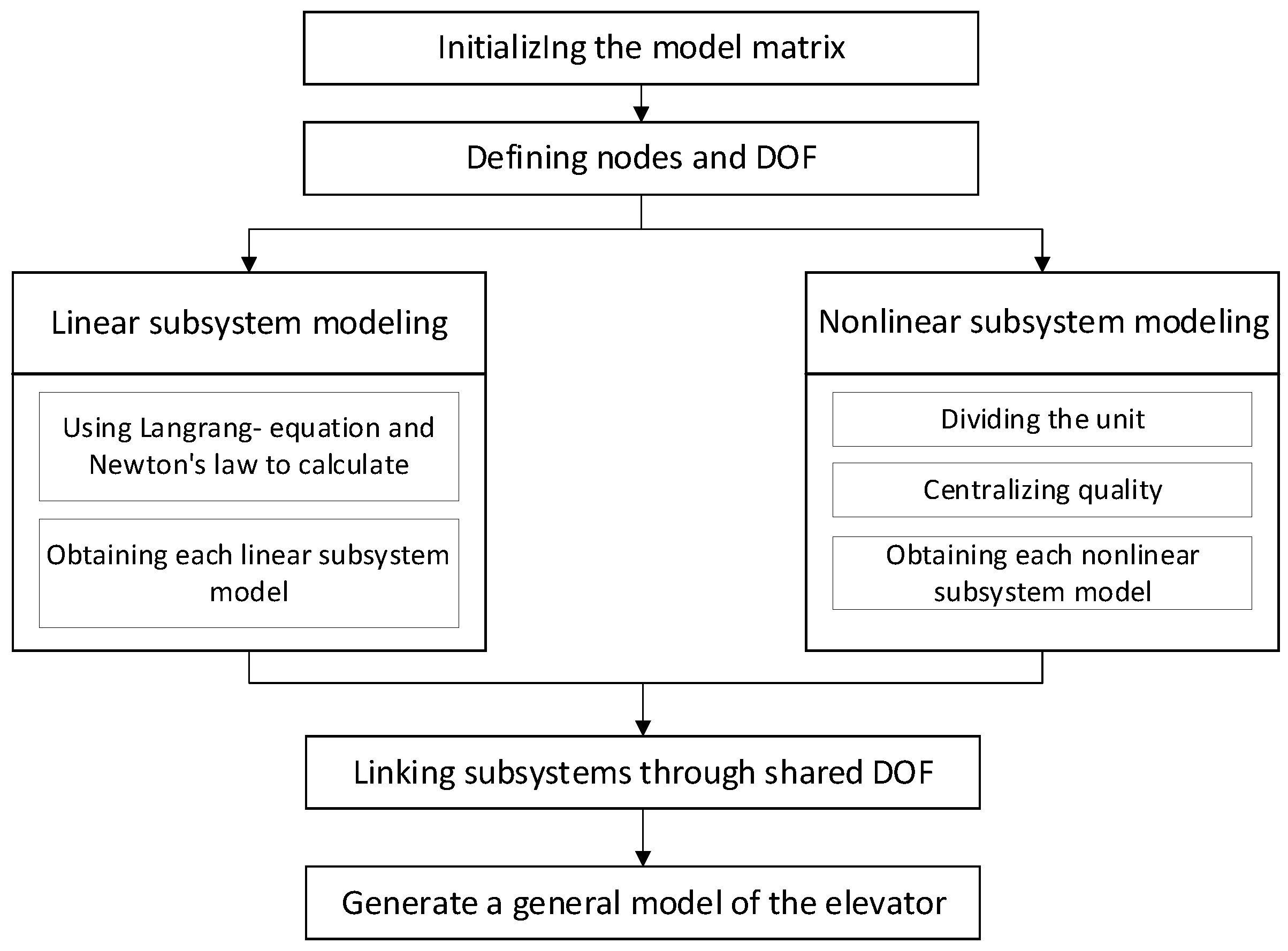

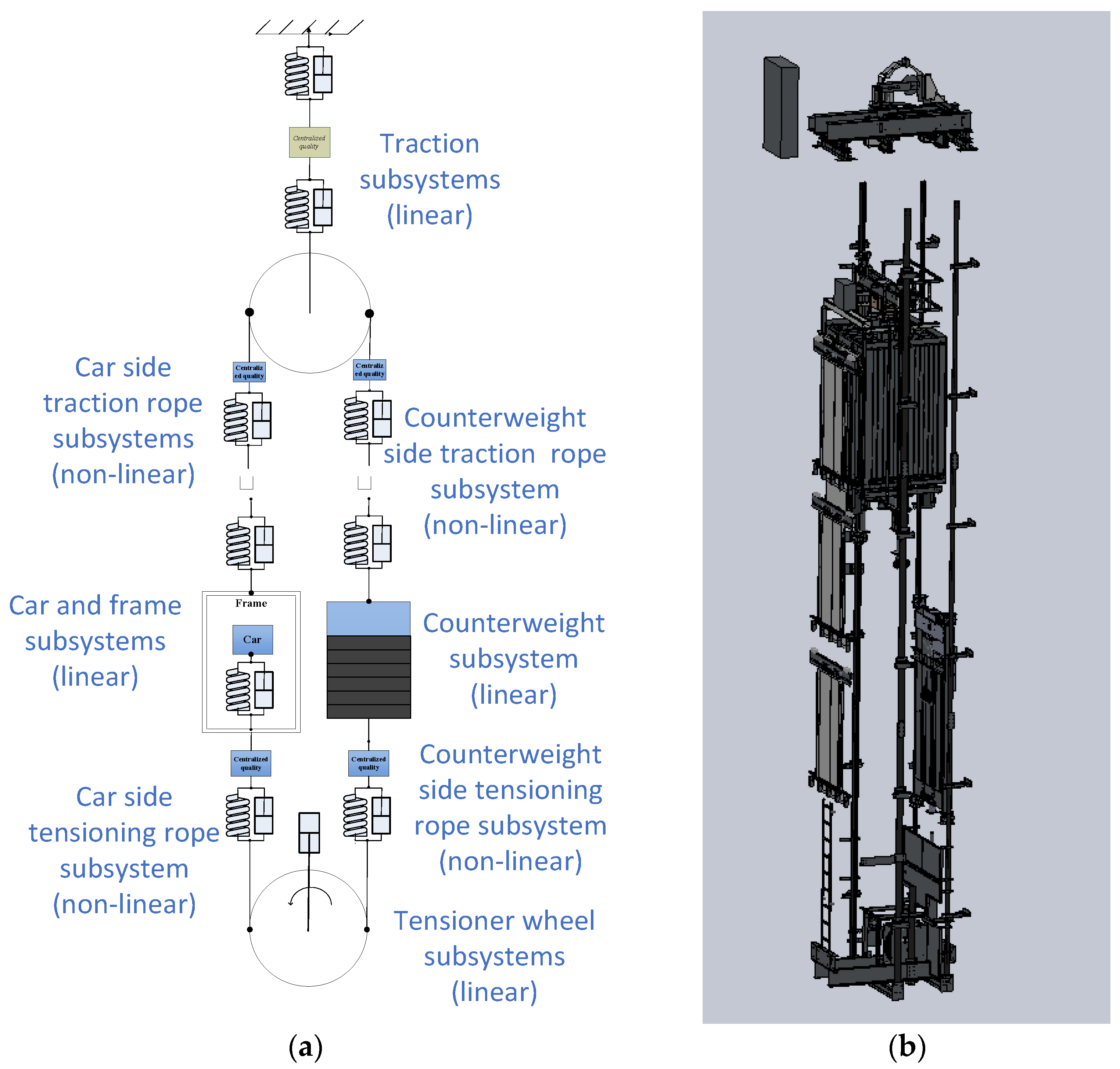

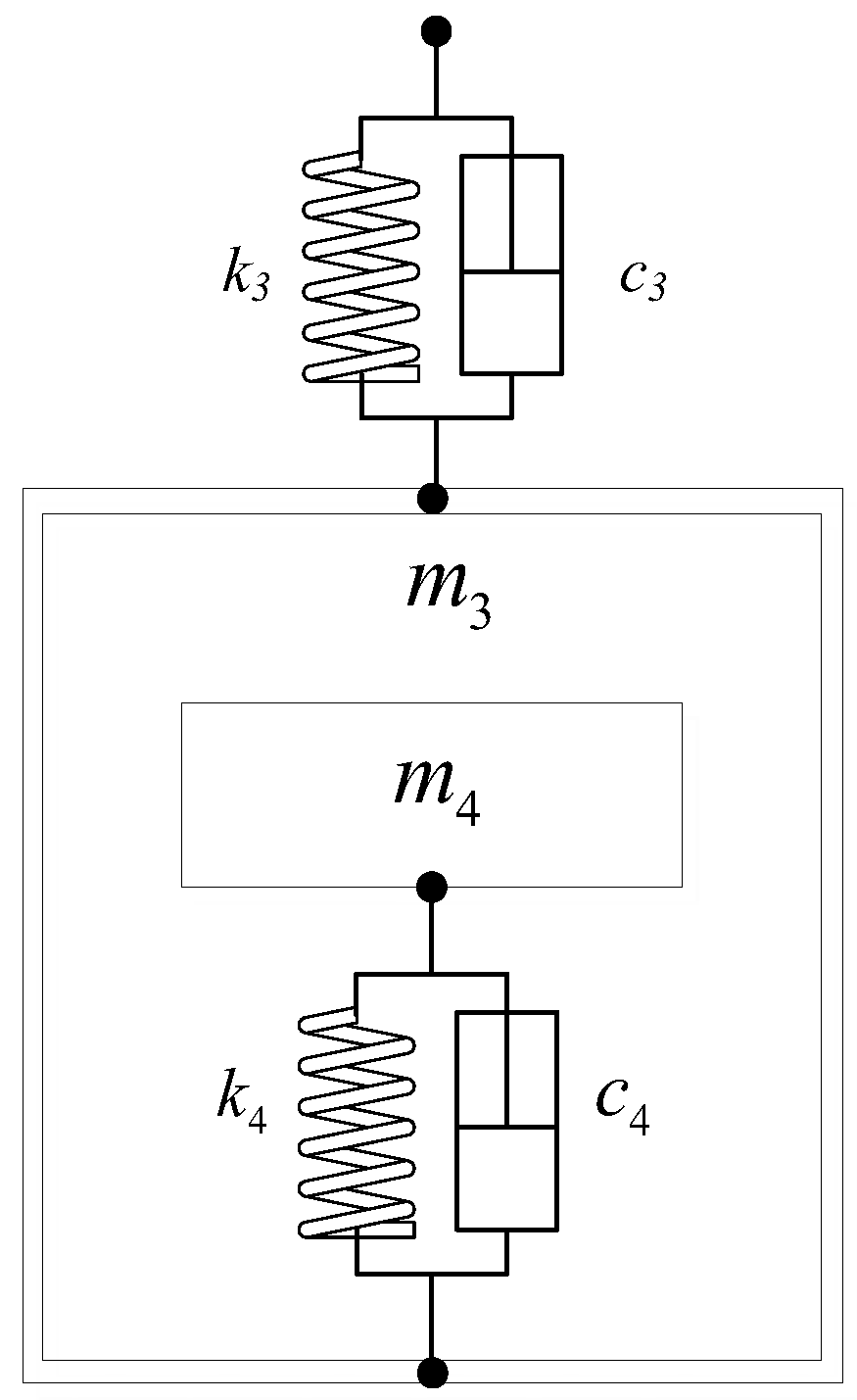

2. Elevator System Dynamics Modeling

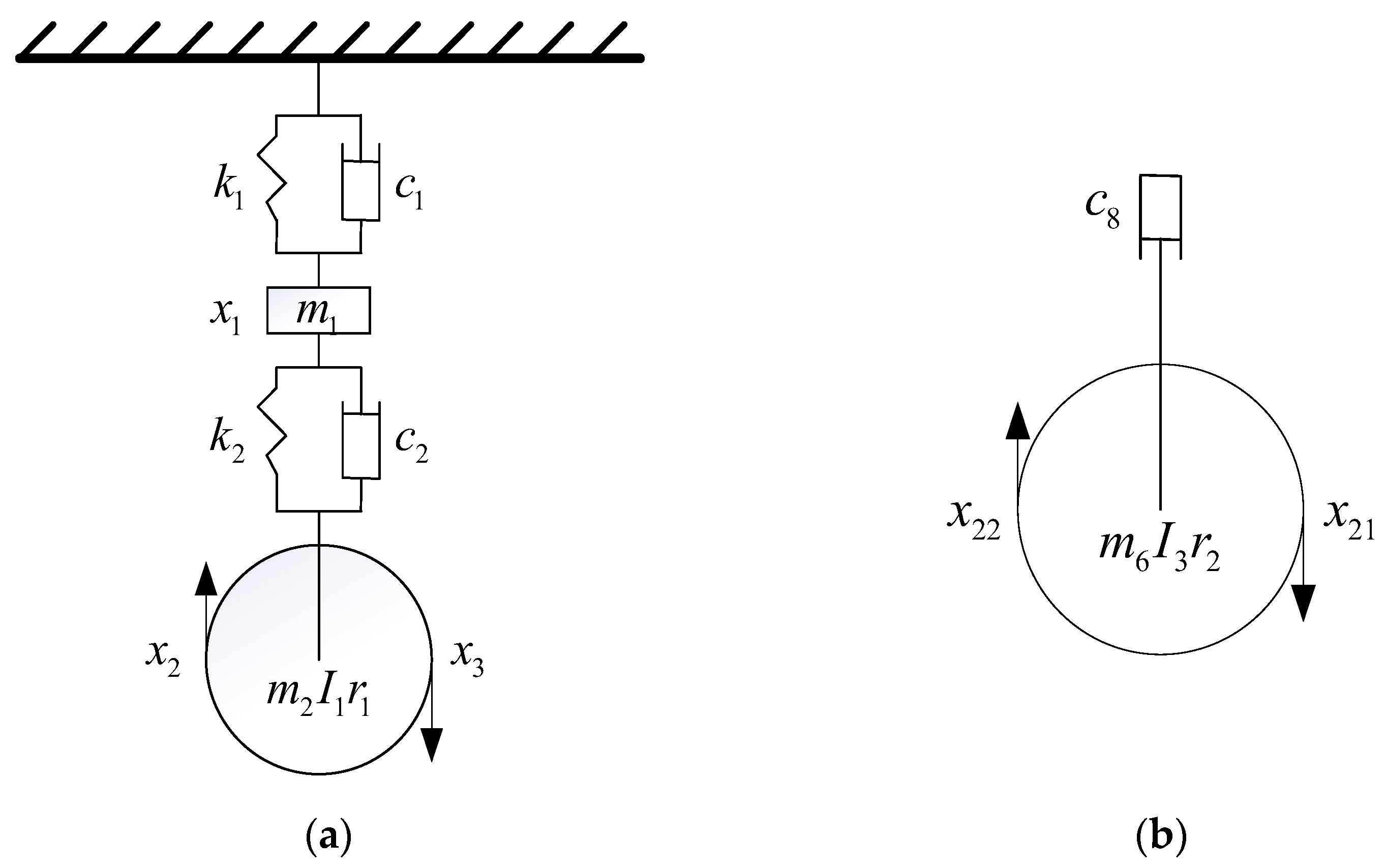

2.1. Non-Linear Subsystems

2.2. Linear Subsystem

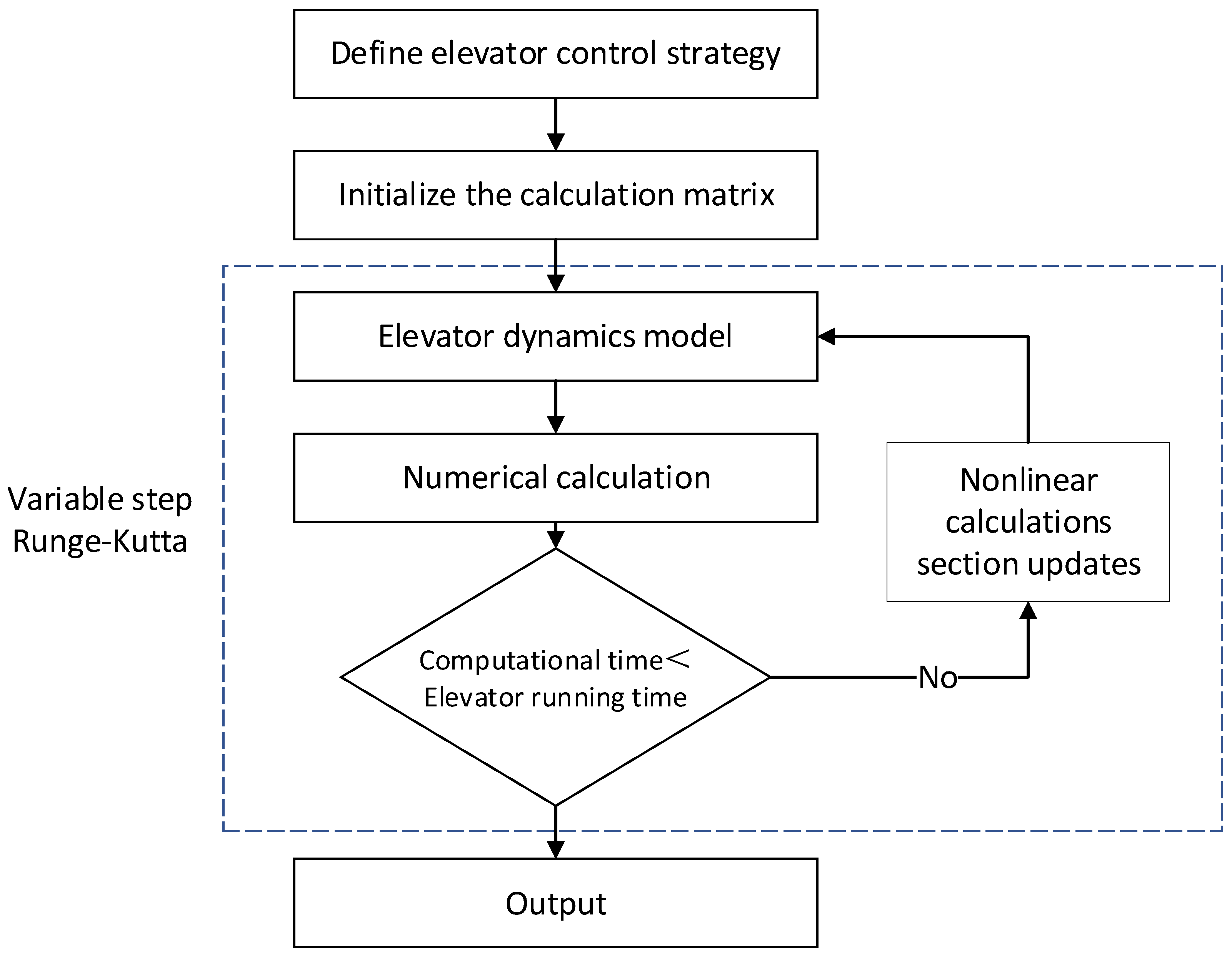

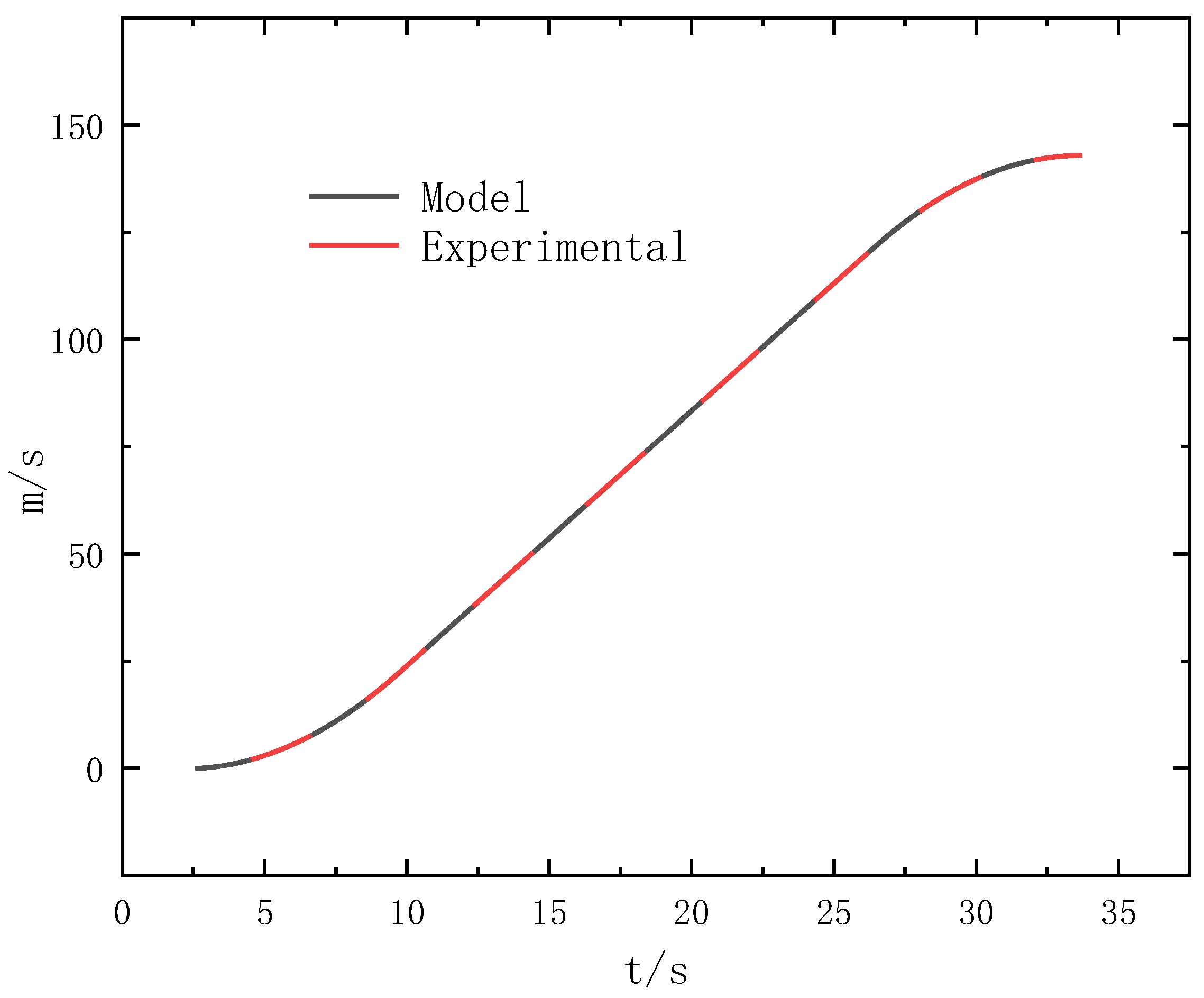

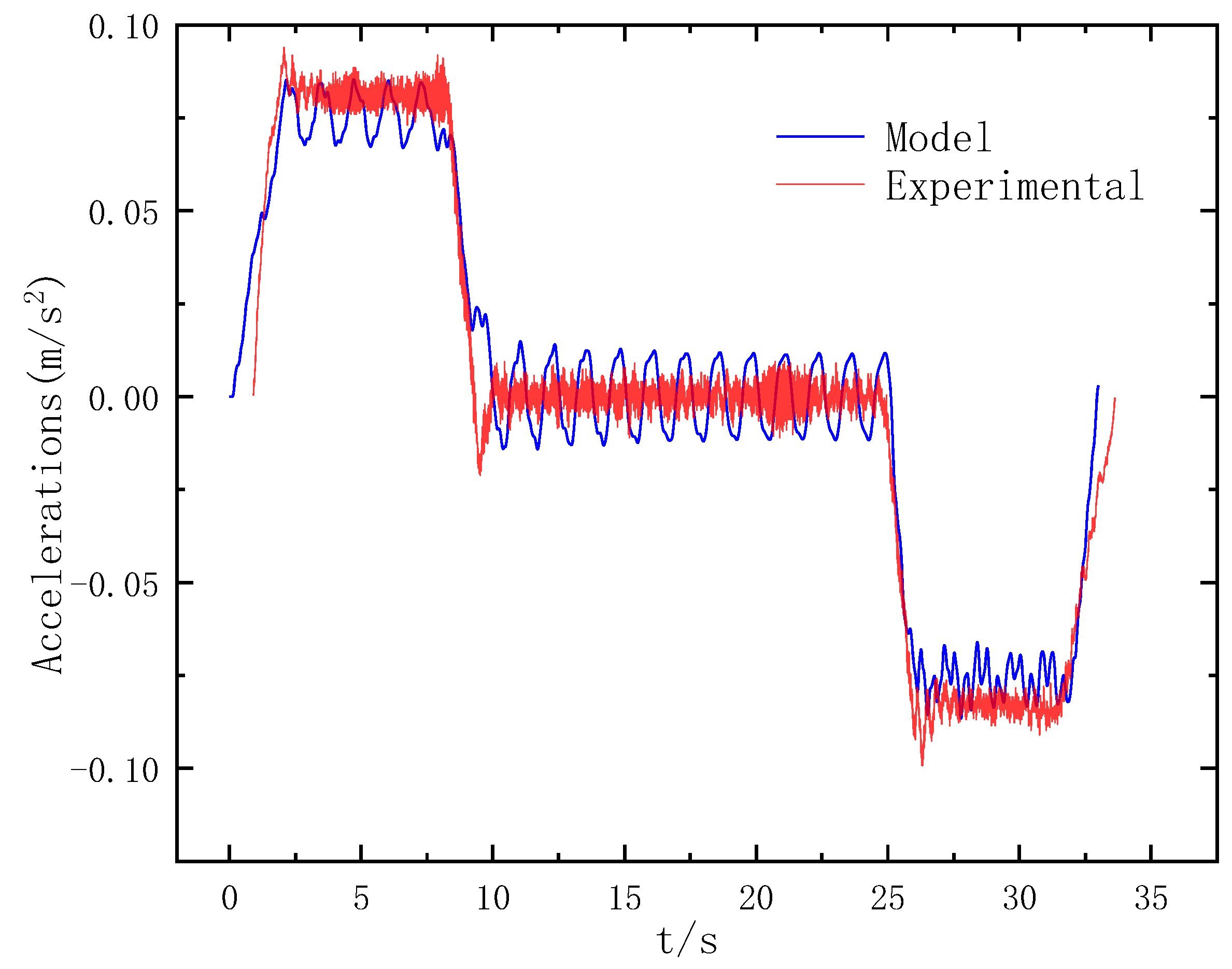

3. Time Domain Calculation Analysis

4. Study of the Nature and Law of Elevator Dynamics

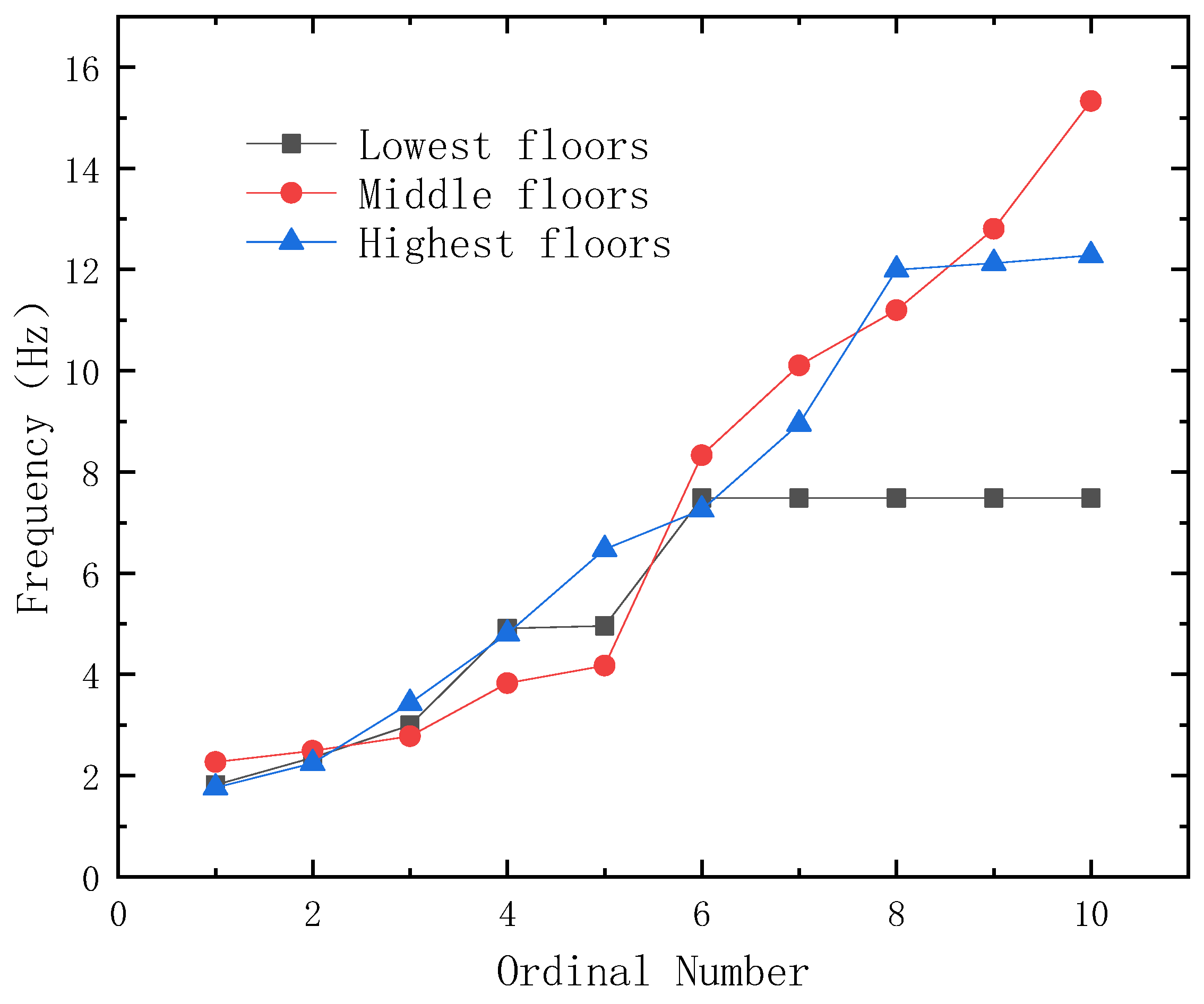

4.1. Effect of Car Height Position on Intrinsic Frequency

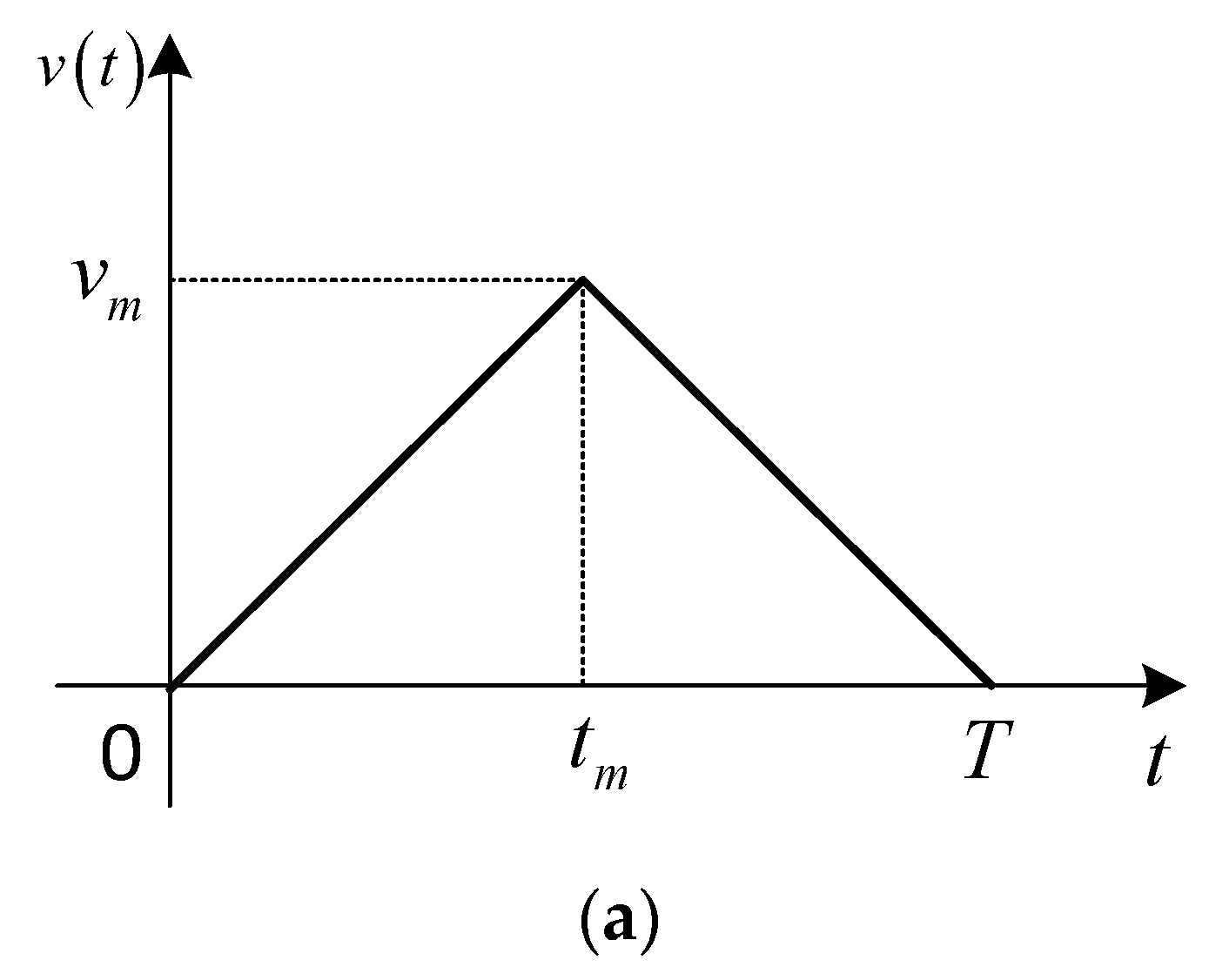

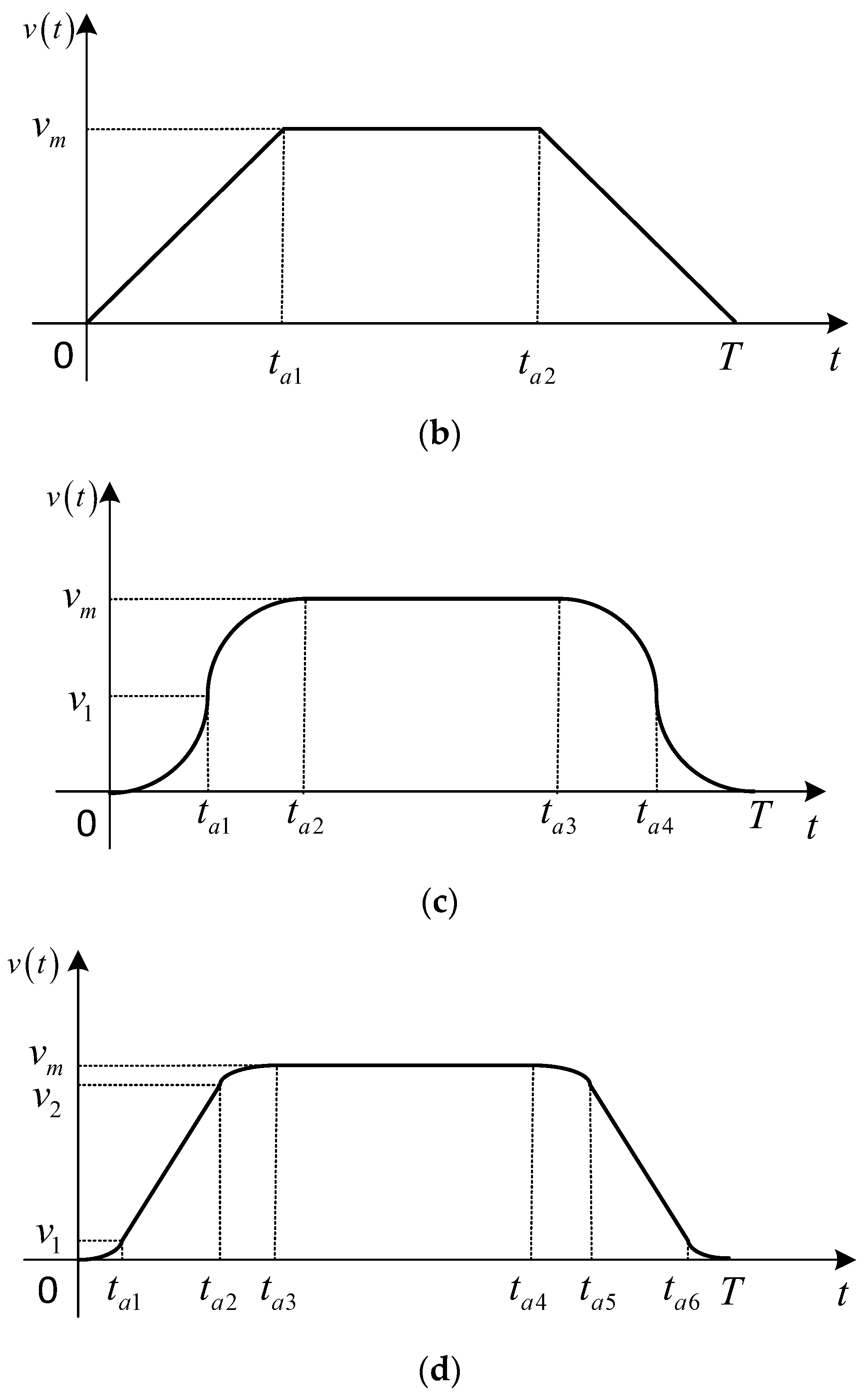

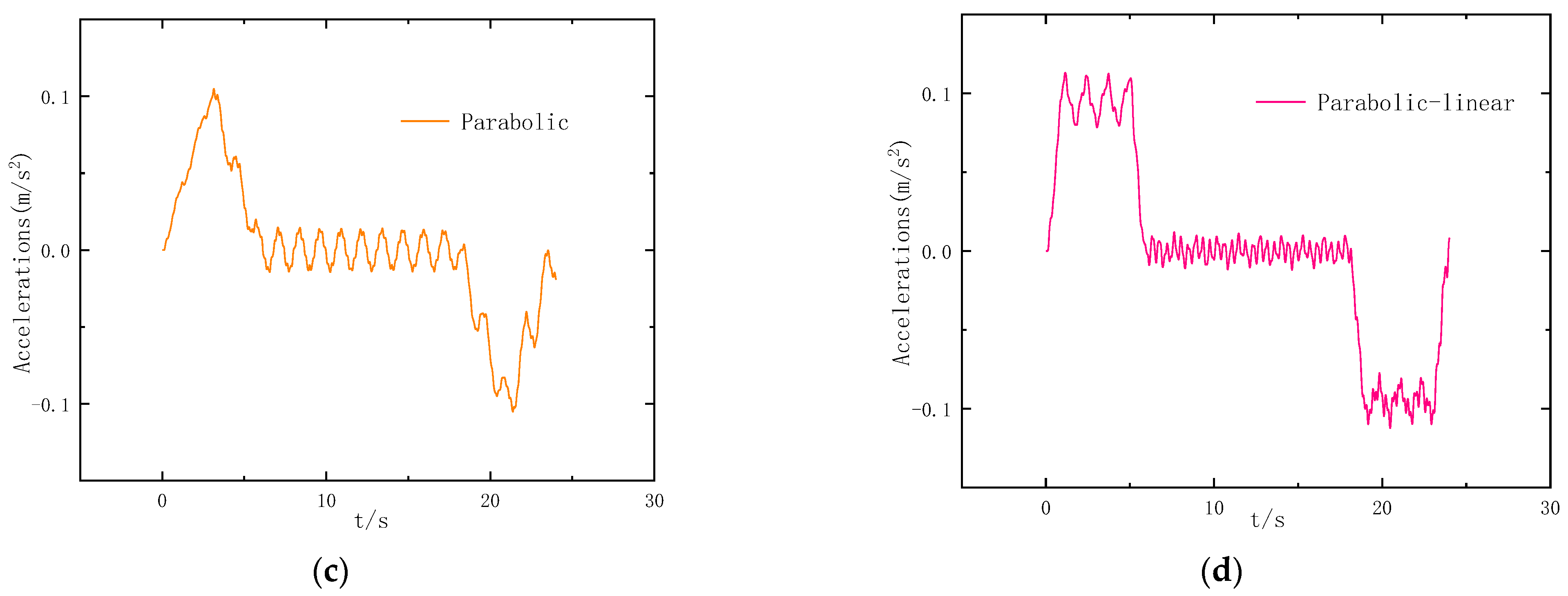

4.2. Impact of Control Strategies on Elevator Operation

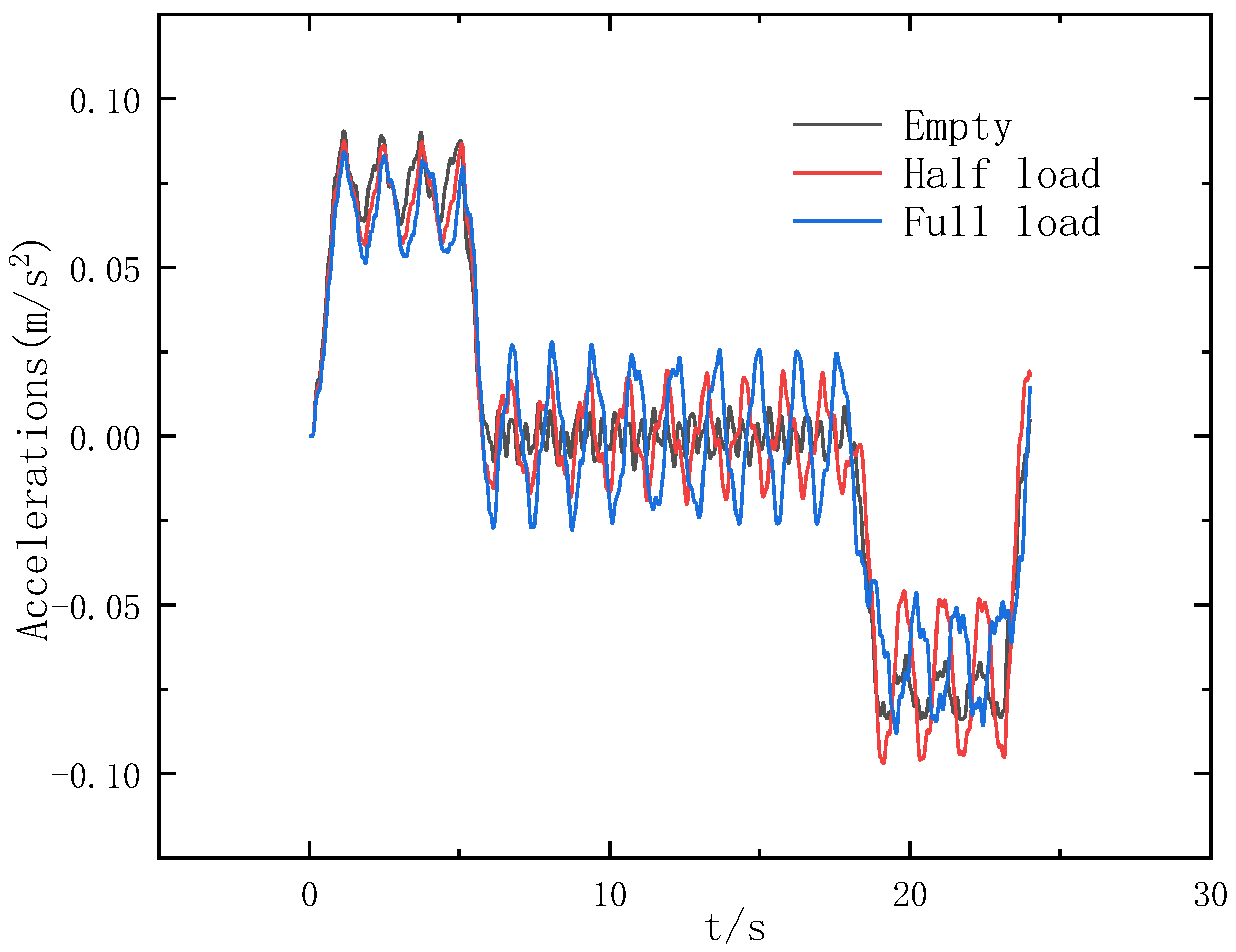

4.3. Effect of Load on Elevator Response

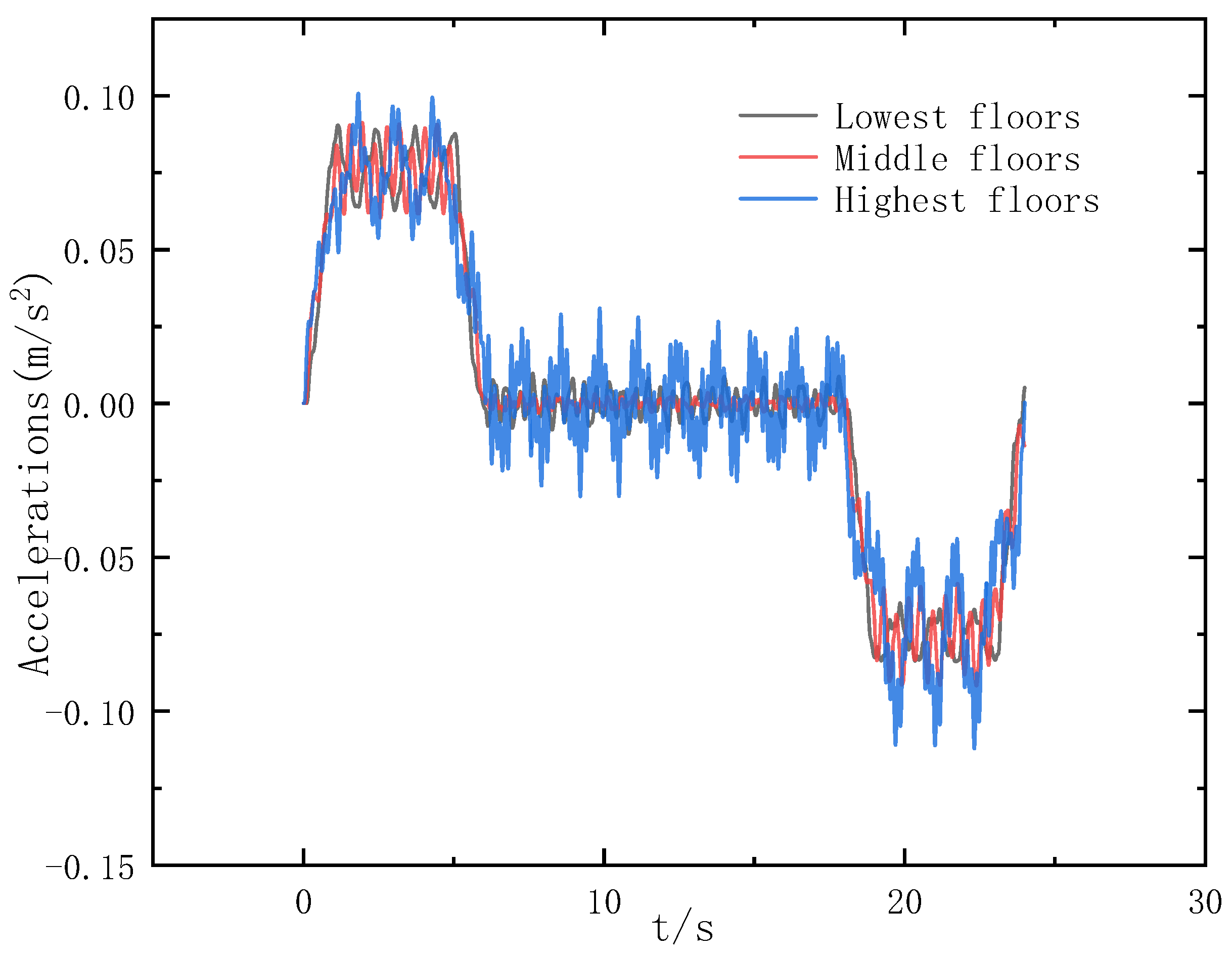

4.4. Effect of Car Position Height on Elevator Response

5. Conclusions

- This paper introduces a novel approach to analyze elevator system dynamics by dividing it into eight subsystems, developing a dynamics model for each and then integrating them based on shared degrees of freedom, providing an efficient and adaptable methodology. The time-domain calculation of the model employs stepwise integration, utilizing the variable-step fourth-order Runge–Kutta method. Comparison of the calculation results with experimental data confirms the feasibility of the model for time-domain analysis.

- This paper introduces a novel computational approach for handling the non-linear aspects of elevator dynamics. The linear and non-linear systems are separated during modeling, updating only the non-linear part in the numerical solution. This method circumvents the need for re-establishing the dynamics model, streamlining the computational process.

- With varying car heights, the length of each wire rope section fluctuates, consequently significantly altering the natural frequency of the elevator system. Specifically, when the car is positioned centrally, the first-order natural frequency of the elevator increases, leading to a reduction in its vibration response.

- Among the four common elevator control strategies, the triangle and trapezoidal control strategies result in significant elevator vibration response due to their abrupt initial and braking acceleration, rendering them unsuitable for high-speed elevators. Conversely, the parabolic and parabolic–linear control strategies exhibit minimal vibration responses, accompanied by gentle acceleration and deceleration. Hence, the parabolic–linear control strategy emerges as the preferable operational law for high-speed elevators.

- The load variation significantly impacts the elevator’s time-domain response, notably evident during the uniform speed phase. The elevator’s vibration response increases and the natural frequency diminishes with an increasing load during operation at a uniform speed. Conversely, the vibration response remains similar across different loads during the acceleration phase. In the deceleration phase, no load results in the lowest response fluctuations, while a half load exhibits the most significant fluctuations.

- The elevator’s vibration response is influenced by the changing mechanical properties of the wire rope at different car heights. During acceleration, the highest-level car exhibits the largest vibration response, while those at middle and lowest levels are similar. In the uniform speed phase, the highest-level car experiences larger vibration responses compared to those at the middle and lowest levels, with the middle-level car exhibiting the smallest response. Similarly, during deceleration, the highest-level car displays a greater vibration response than the middle- and lowest-level cars.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhang, Q.; Yang, Z.; Wang, C.; Yang, Y.; Zhang, R. Intelligent control of active shock absorber for high-speed elevator car. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 3804–3815. [Google Scholar] [CrossRef]

- Roberts, R. Control of high-rise/high-speed elevators. In Proceedings of the American Control Conference, Philadelphia, PA, USA, 26 June 1998; pp. 3440–3444. [Google Scholar]

- Yu, Y. Research on Vibration Characteristics of High-Speed Traction Elevator Mechanical System. Master’s Thesis, Shandong University of Architecture, Jinan, China, 2015. [Google Scholar]

- Peng, Q.; Jiang, A.; Yuan, H.; Huang, G.; He, S.; Li, S. Study on Theoretical Model and Test Method of Vertical Vibration of Elevator Traction System. Math. Probl. Eng. 2020, 2020, 8518024. [Google Scholar] [CrossRef]

- Peng, Q.F.; Xu, P.; Yuan, H.; Ma, H.X.; Xue, J.H.; He, Z.Y.; Li, S.Q. Analysis of Vibration Monitoring Data of Flexible Suspension Lifting Structure Based on Time-Varying Theory. Sensors 2020, 20, 6586. [Google Scholar] [CrossRef] [PubMed]

- Li, D.; Sun, G. Study on vertical time-varying vibration characteristics of traction-driven elevator. Mech. Eng. Autom. 2022, 1–12. [Google Scholar]

- Xu, P.; Peng, Q.F.; Jin, F.S.; Xia, F.; Xue, J.H.; Yuan, H.; Li, S.Q. Experimental study on damping characteristics of elevator traction system. Adv. Mech. Eng. 2022, 14, 168781322210854. [Google Scholar] [CrossRef]

- Dokic, R.; Vladic, J.; Kljajin, M.; Jovailovic, V.; Markovic, G.; Karakasic, M. Dynamic Modelling, Experimental Identification and Computer Simulations of Non-Stationary Vibration in High-Speed Elevators. Stroj. Vestn. J. Mech. Eng. 2021, 67, 287–301. [Google Scholar]

- Shi, R.D.; Zhang, Q.; Zhang, R.J.; He, Q.; Liu, L.X. Analysis of the horizontal vibration response under gas-solid coupling throughout the entire high-speed elevator operating process. J. Vib. Control 2023, 29, 4455–4465. [Google Scholar] [CrossRef]

- Du, X.Q.; Mei, D.Q.; Chen, Z.C. Research on the vertical dynamics of high-speed elevator system—Art. no. 60400V. In Proceedings of the 3rd International Conference on Mechatronics and Information Technology (ICMIT 05), Chongqing, China, 20–23 September 2005; p. V400. [Google Scholar]

- Song, D.L.; Zhang, P.; Wang, Y.H.; Du, C.H.; Lu, X.M.; Liu, K. Horizontal dynamic modeling and vibration characteristic analysis for nonlinear coupling systems of high-speed elevators and guide rails. J. Mech. Sci. Technol. 2023, 37, 643–653. [Google Scholar] [CrossRef]

- Zubik-Kowal, B. Dynamic Iterations for Nonlinear Systems Applied in Population Dynamics. In Proceedings of the 21st European Conference on Mathematics for Industry, ECMI, Wuppertal, Germany, 13–15 April 2021; pp. 91–97. [Google Scholar]

- Qiu, L.M.; He, C.; Yi, G.D.; Zhang, S.Y.; Wang, Y.; Rao, Y.; Zhang, L.C. Energy-Based Vibration Modeling and Solution of High-Speed Elevators Considering the Multi-Direction Coupling Property. Energies 2020, 13, 4812. [Google Scholar] [CrossRef]

- Tusset, A.M.; Fuziki, M.E.K.; Lenzi, G.G.; Santos, G.P.D.; Balthazar, J.M.; Brasil, R. Non-linear Energy Sink Applied in the Vibration Suppression of a High-Speed Elevator System and Energy Harvesting. J. Vib. Eng. Technol. 2023, 11, 2819–2830. [Google Scholar] [CrossRef]

- Liu, S.C.; Wu, J.D.; Li, S.; He, D.Y.; Ji, Y.L. Multi-degree-of-freedom dynamic response calculation and experimental validation of a new type of vibrating relaxation screen. Vib. Shock 2023, 42, 48–54. [Google Scholar]

- Qiu, C.J.; Zhang, L.X.; Li, M.H.; Zhang, P.P.; Zheng, X. Elevator Fault Diagnosis Method Based on IAO-XGBoost under Unbalanced Samples. Appl. Sci. 2023, 13, 10968. [Google Scholar] [CrossRef]

- Wang, N.G.; Cao, G.H.; Wang, L.; Lu, Y.; Zhu, Z.C. Modelling and control of flexible guided lifting system with output constraints and unknown input hysteresis. J. Vib. Control 2020, 26, 112–128. [Google Scholar] [CrossRef]

- Han, J. Intrinsic Characterization and Dynamic Response of Mechanical Vibration System of Traction Elevator. South Agric. Mach. 2021, 52, 3. [Google Scholar]

- Fu, W.J.; Zhu, C.M.; Zhang, C.Y. Dynamic modeling and simulation analysis of a single winding elevator. J. Syst. Simul. 2005, 17, 635–638. [Google Scholar]

- Lonkwic, P. Influence of friction drive lift gears construction on the length of braking distance. Chin. J. Mech. Eng. 2015, 28, 363–368. [Google Scholar] [CrossRef]

- Peng, Q.F.; Xu, P.; Li, Y.K.; Yuan, H.; Xue, Z.N.; Yang, J.C. Experiment Research on Emergency Stop Vibrations of Key Components in the Friction Vertical Lifting System. Shock Vib. 2022, 2022, 7816270. [Google Scholar] [CrossRef]

| Elevator Parameter | Unit | Numeric |

|---|---|---|

| Racking girder quality | kg | 198.45 |

| Equivalent mass of traction device | kg | 2835 |

| Carriage quality | kg | 2282 |

| Car mass | kg | 1805 |

| Counterweight mass | kg | 4887.4 |

| Compensation system quality | kg | 1260 |

| Moment of inertia of the traction sheave | kg·m2 | 50 |

| Compensating wheel moment of inertia | kg·m2 | 51.5 |

| Stiffness of the upper vibration isolation rubber of the traction unit | N/m | 1.6 107 4 |

| Stiffness of vibration isolation rubber underneath the traction unit | N/m | 2.7 107 4 |

| Car side rope head taper sleeve spring stiffness | N/m | 2.72 105 15 |

| Anti-vibration rubber stiffness of car bottom | N/m | 9.8 105 |

| Counterweight side rope head taper sleeve spring stiffness | N/m | 2.72 10515 |

| Number of ropes | roots | 15 |

| Traction rope line density | kg/m | 0.494 |

| Cross-sectional area of the rope | m2 | 1.210−5 |

| Young’s modulus of traction rope | N/m−2 | 1.1761011 |

| Number of compensating ropes | roots | 7 |

| Compensating rope density | kg/m | 0.878 |

| Young’s modulus of compensating rope | N/m−2 | 9.81010 |

| Compensating rope cross-sectional area | m2 | 1.610−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tian, Z.; He, H.; Zhou, Y. Modeling and Numerical Computation of the Longitudinal Non-Linear Dynamics of High-Speed Elevators. Appl. Sci. 2024, 14, 1821. https://doi.org/10.3390/app14051821

Tian Z, He H, Zhou Y. Modeling and Numerical Computation of the Longitudinal Non-Linear Dynamics of High-Speed Elevators. Applied Sciences. 2024; 14(5):1821. https://doi.org/10.3390/app14051821

Chicago/Turabian StyleTian, Zhongxu, Hang He, and You Zhou. 2024. "Modeling and Numerical Computation of the Longitudinal Non-Linear Dynamics of High-Speed Elevators" Applied Sciences 14, no. 5: 1821. https://doi.org/10.3390/app14051821

APA StyleTian, Z., He, H., & Zhou, Y. (2024). Modeling and Numerical Computation of the Longitudinal Non-Linear Dynamics of High-Speed Elevators. Applied Sciences, 14(5), 1821. https://doi.org/10.3390/app14051821