Review of Manufacturing Processes and Vibro-Acoustic Assessments of Composite and Alternative Materials for Musical Instruments

Abstract

:1. Introduction

2. Manufacturing Processes of Musical Instruments Made of Composites and Alternative Materials

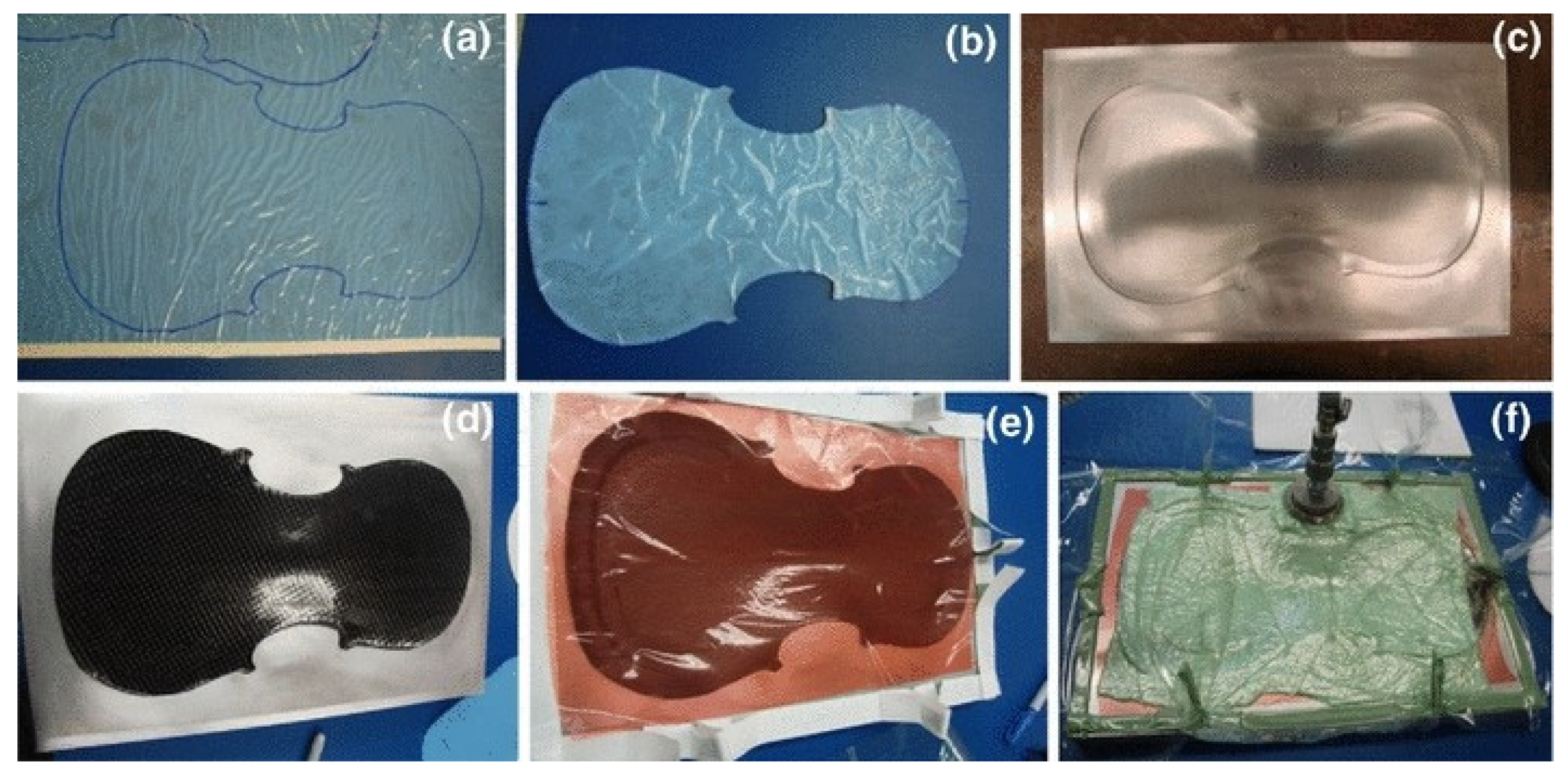

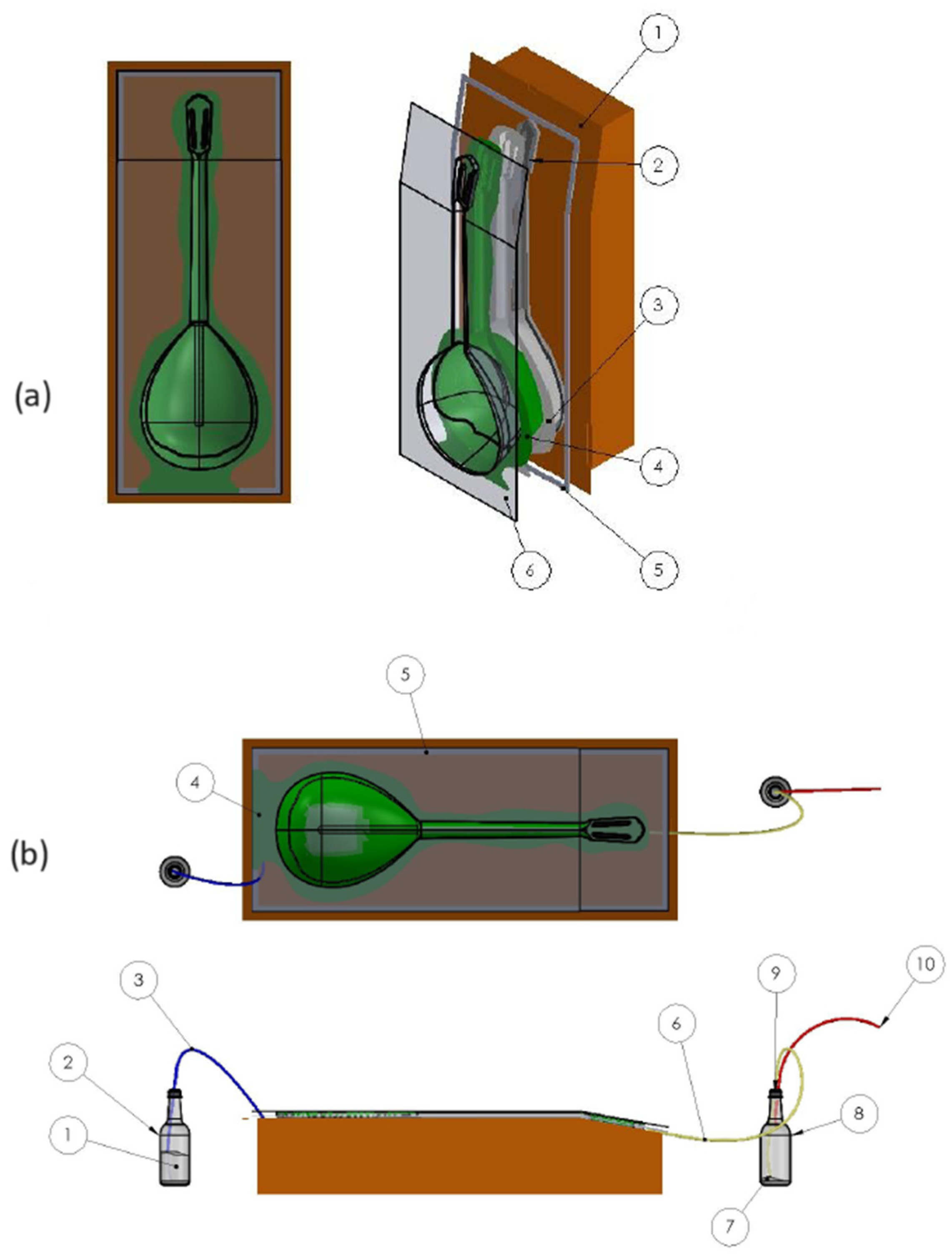

2.1. Composites in Musical Instrument Manufacturing

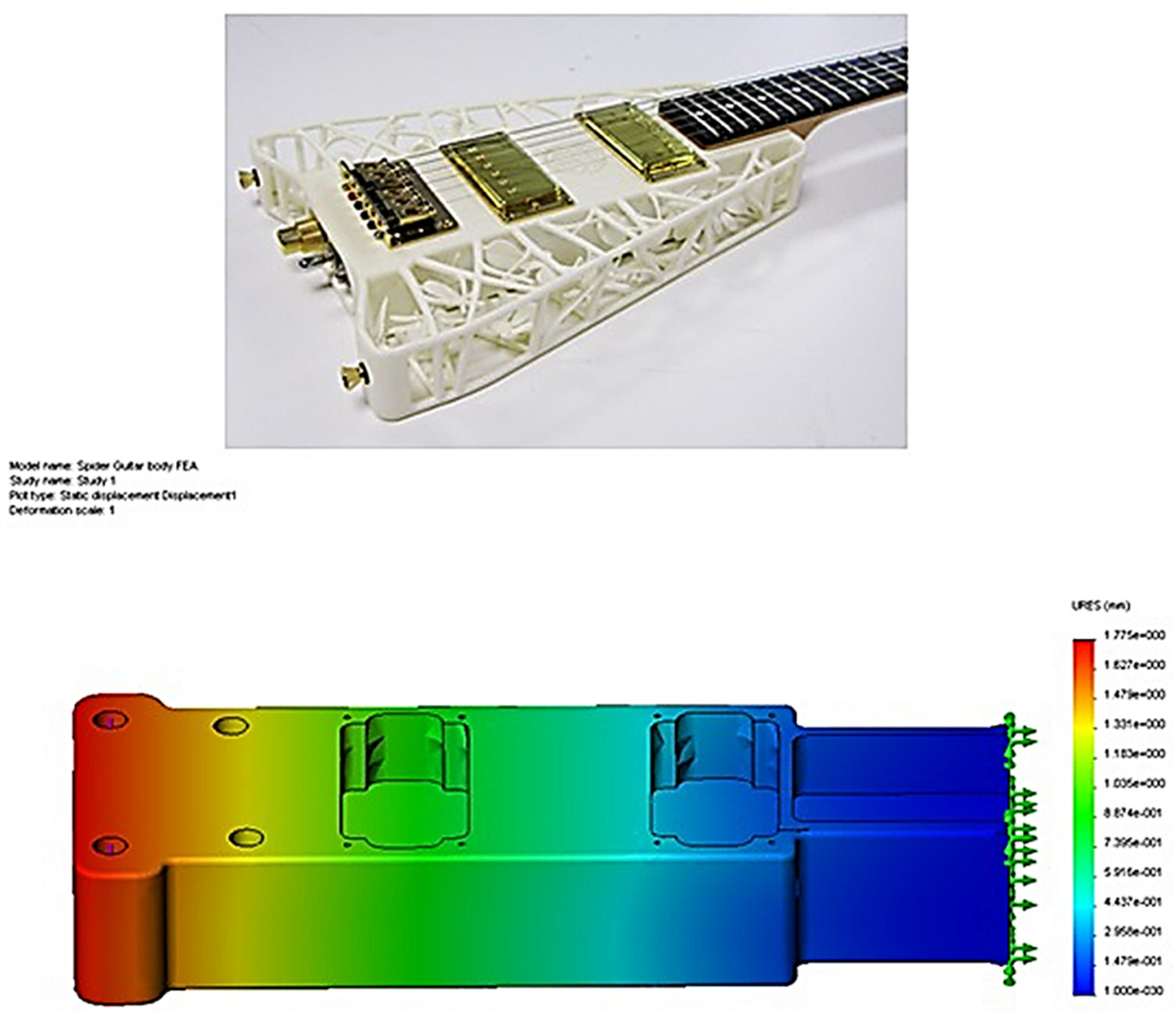

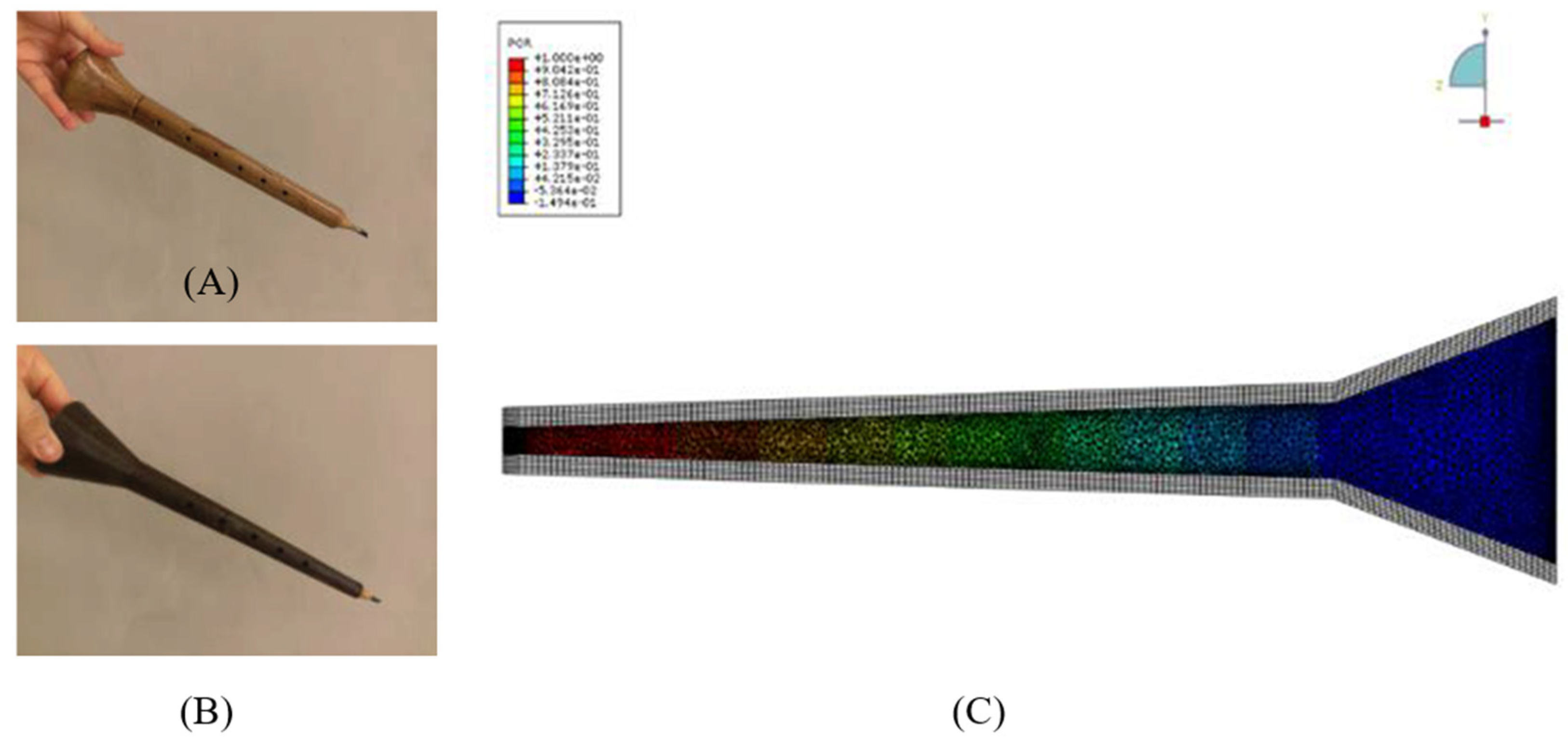

2.2. Three-Dimensional Printing in Musical Instrument Manufacturing

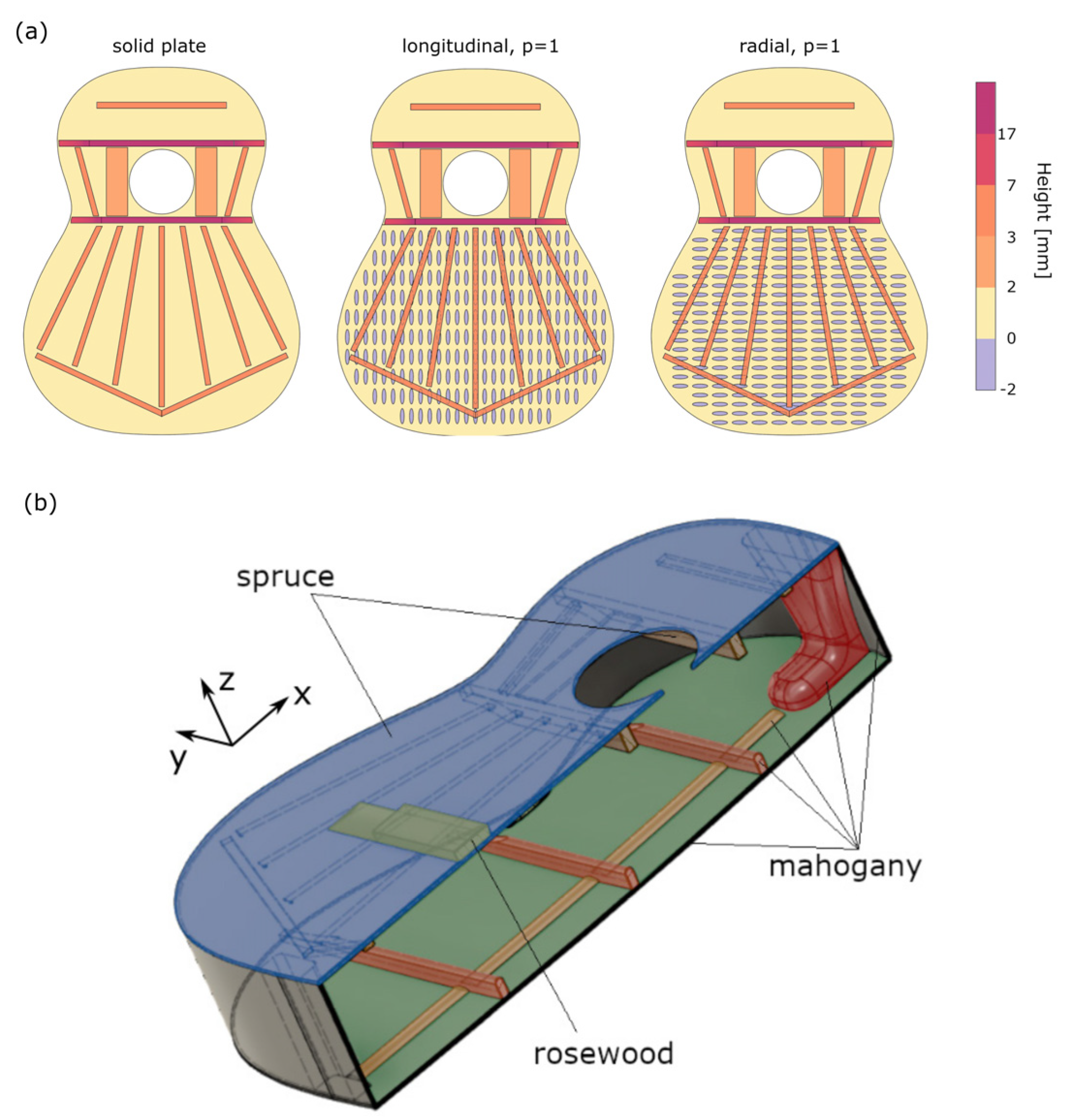

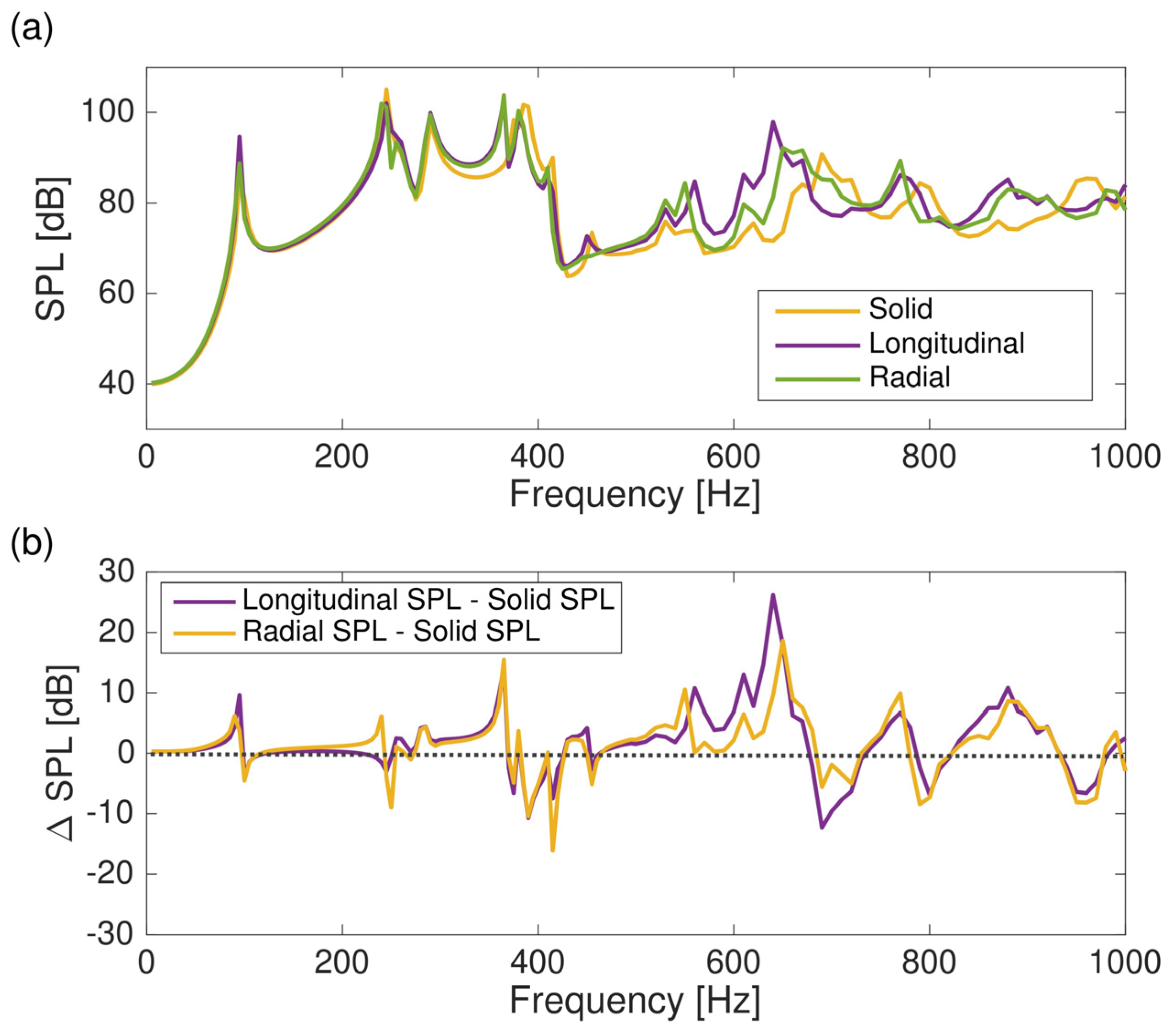

2.3. Metamaterials in Musical Instrument Manufacturing

3. Vibro-Acoustic Analysis and Assessment of Musical Instruments Made of Composites and Alternative Materials

3.1. Experimental and Numerical Methods for Musical Instrument Vibroacoustic Studies

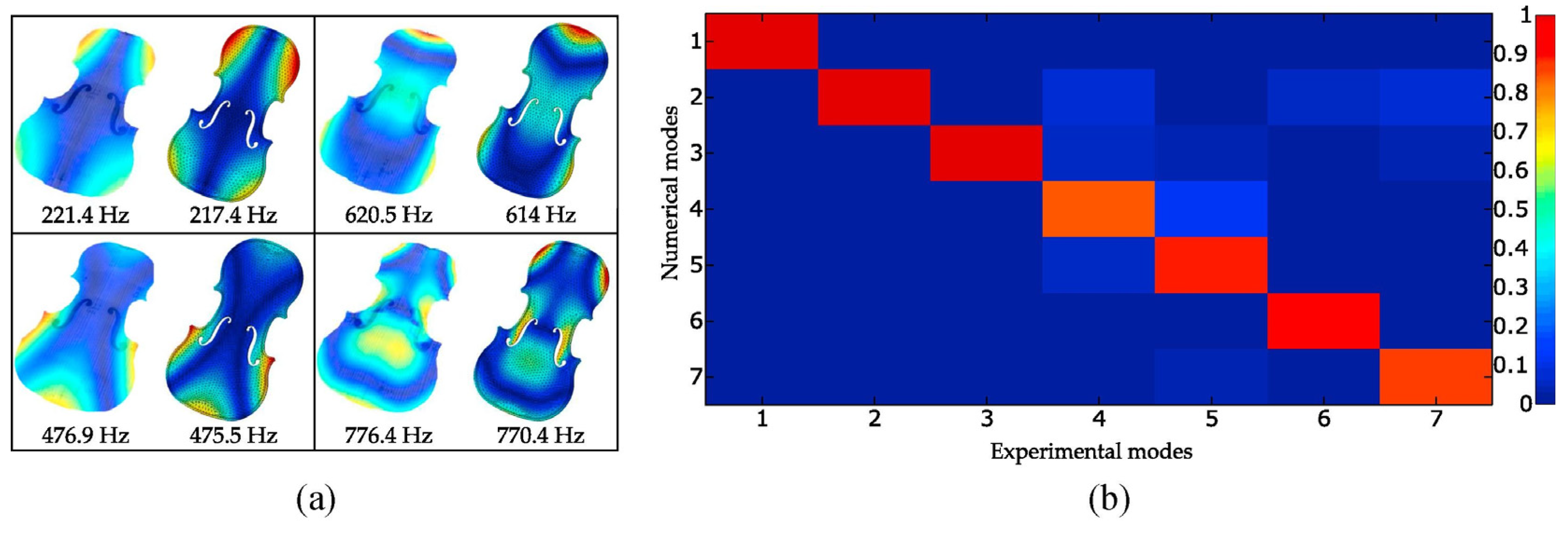

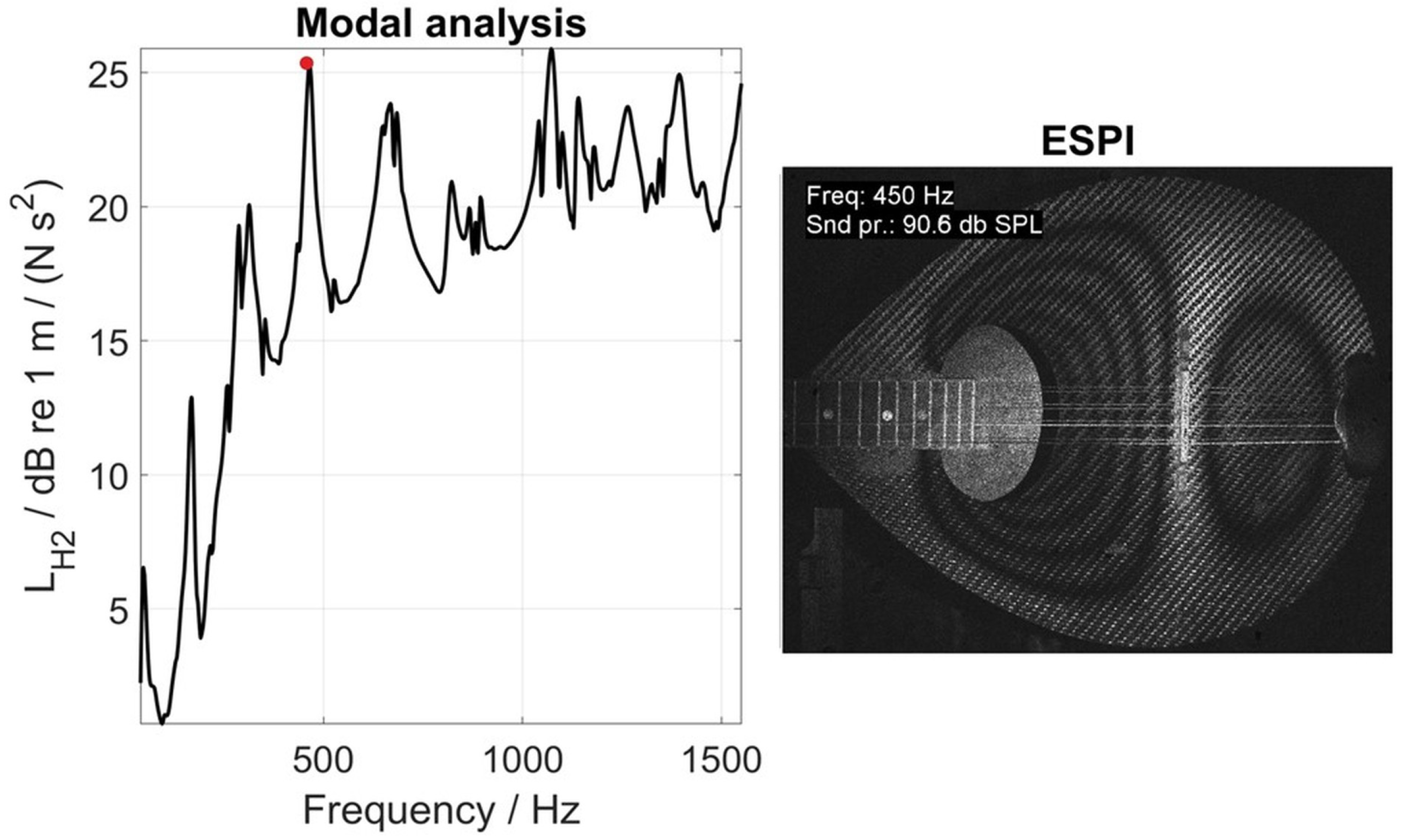

3.1.1. Vibro-Acoustic Assessments of Musical Instruments with Composites

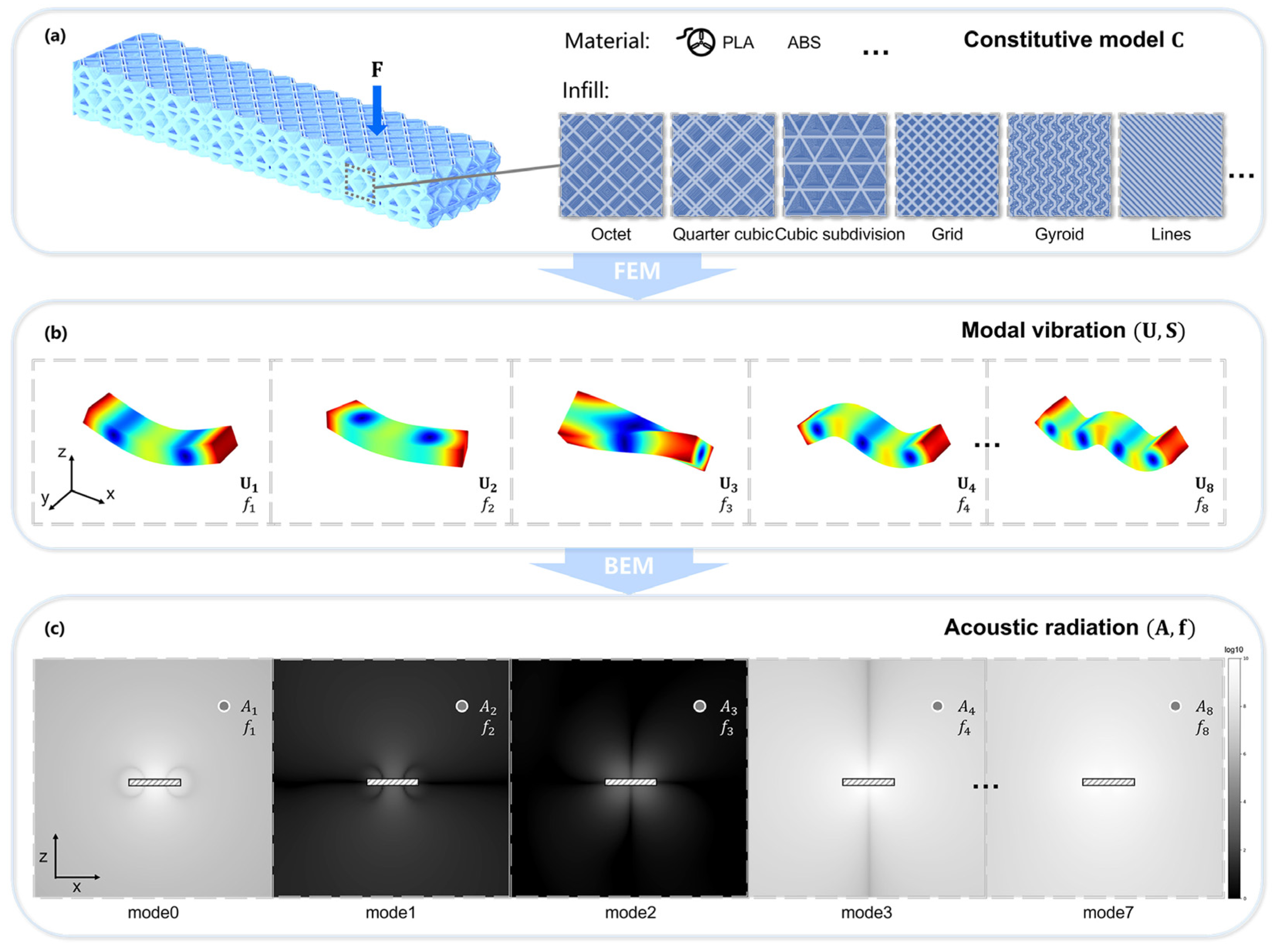

3.1.2. Vibro-Acoustic Assessments of 3D-printed Musical Instruments

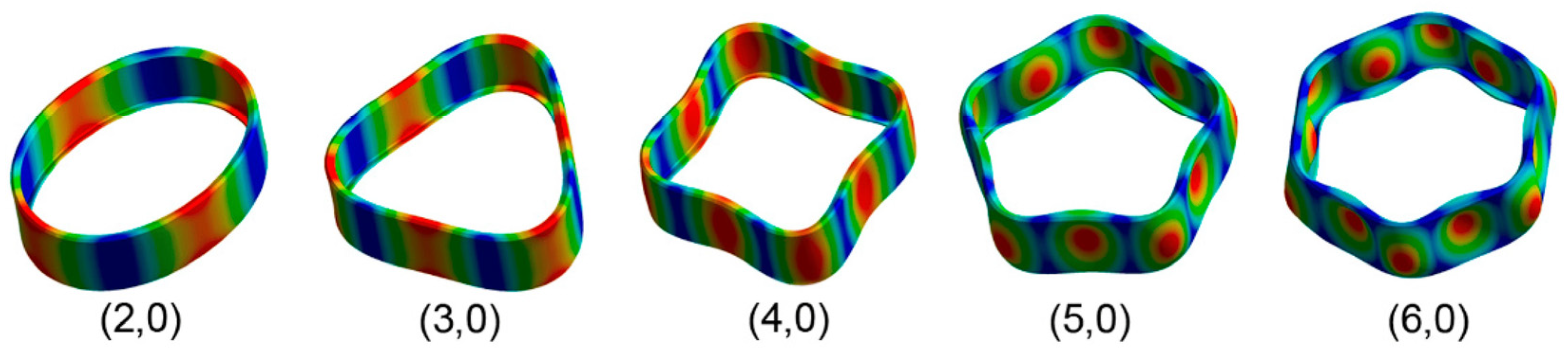

3.1.3. Vibro-Acoustic Assessments of Musical Instruments with Metamaterials

4. Concluding Remarks

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bucur, V. A Review on Acoustics of Wood as a Tool for Quality Assessment. Forests 2023, 14, 1545. [Google Scholar] [CrossRef]

- Bremaud, I. What do we know on “resonance wood” properties? Selective review and ongoing research. In Proceedings of the Meetings on Acoustics 2012, Nantes, France, 23–27 April 2012. [Google Scholar]

- Damodaran, A.; Lessard, L.; Babu, A.S. An Overview of Fibre-Reinforced Composites for Musical Instrument Soundboards. Acoust. Aust. 2015, 43, 117–122. [Google Scholar] [CrossRef]

- Bucur, V. Composite Materials for Musical Instruments. In Handbook of Materials for String Musical Instruments; Springer: Cham, Switzerland, 2016; Chapter 18. [Google Scholar]

- Kantaros, A.; Diegel, O. 3D printing technology in musical instrument research: Reviewing the potential. Rapid Prototyp. J. 2018, 24, 1511–1523. [Google Scholar] [CrossRef]

- Krushynska, A.O.; Torrent, D.; Aragón, A.M.; Ardito, R.; Bilal, O.R.; Bonello, B.; Bosia, F.; Chen, Y.; Christensen, J.; Colombi, A.; et al. Emerging topics in nanophononics and elastic, acoustic, and mechanical metamaterials: An overview. Nanophotonics 2023, 12, 659–686. [Google Scholar] [CrossRef]

- Hout, S.A. Advanced Manufacturing Operations Technologies: Principles, Applications, and Design Correlations in Chemical Engineering Fields of Practice; CRC Press: Boca Raton, FL, USA, 2023. [Google Scholar]

- Krimpenis, A.A.; Chrysikos, M. 3D parametric design and CNC manufacturing of custom solid wood electric guitars using CAD/CAM technology. Wood Mater. Sci. Eng. 2019, 14, 66–80. [Google Scholar] [CrossRef]

- Lee, K. Principles of CAD/CAM/CAE Systems, 1st ed.; Pearson: London, UK, 1999. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Vijay, N.; Rajkumara, V.; Bhattacharjee, P. Assessment of Composite Waste Disposal in Aerospace Industries. Procedia Environ. Sci. 2016, 35, 563–570. [Google Scholar] [CrossRef]

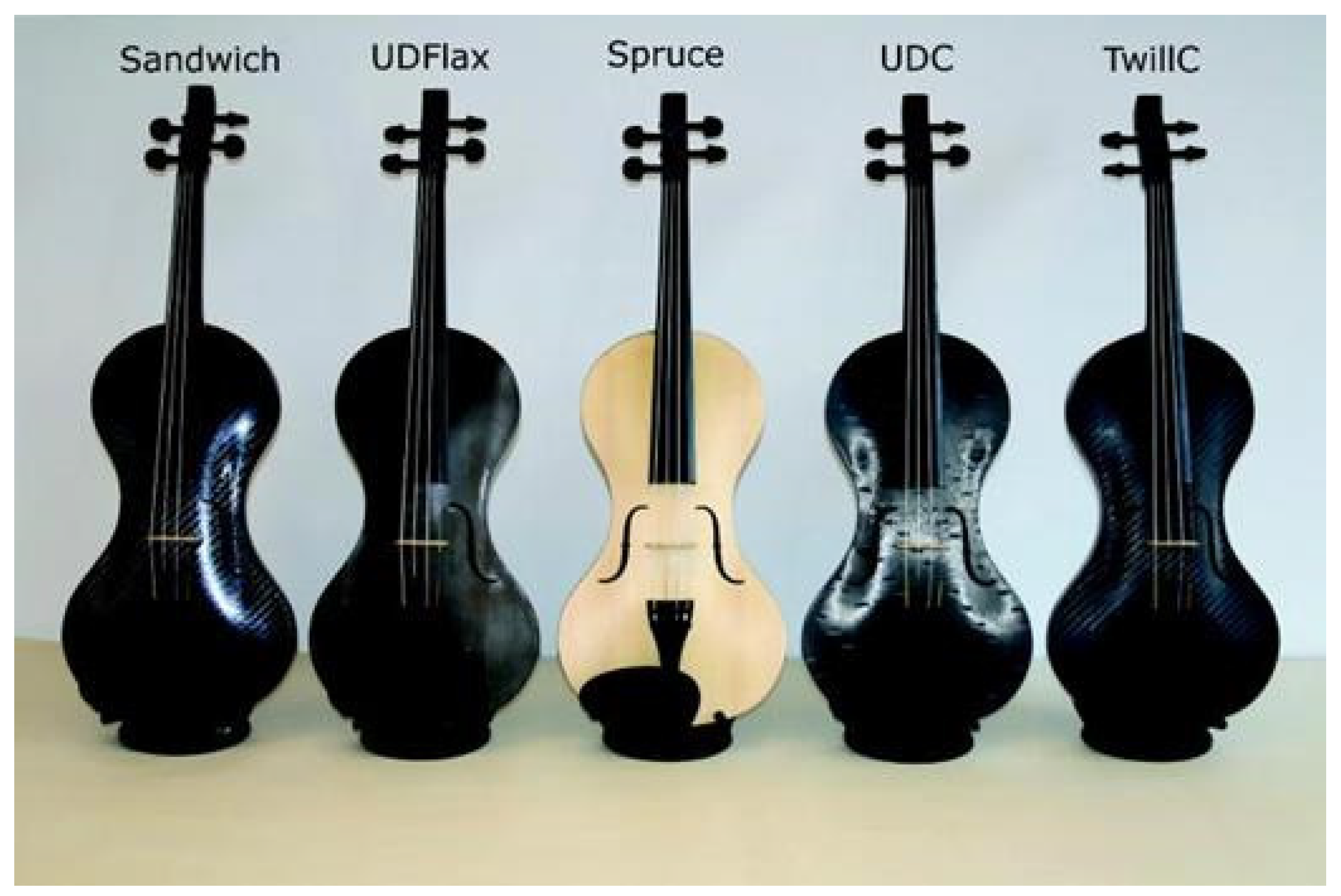

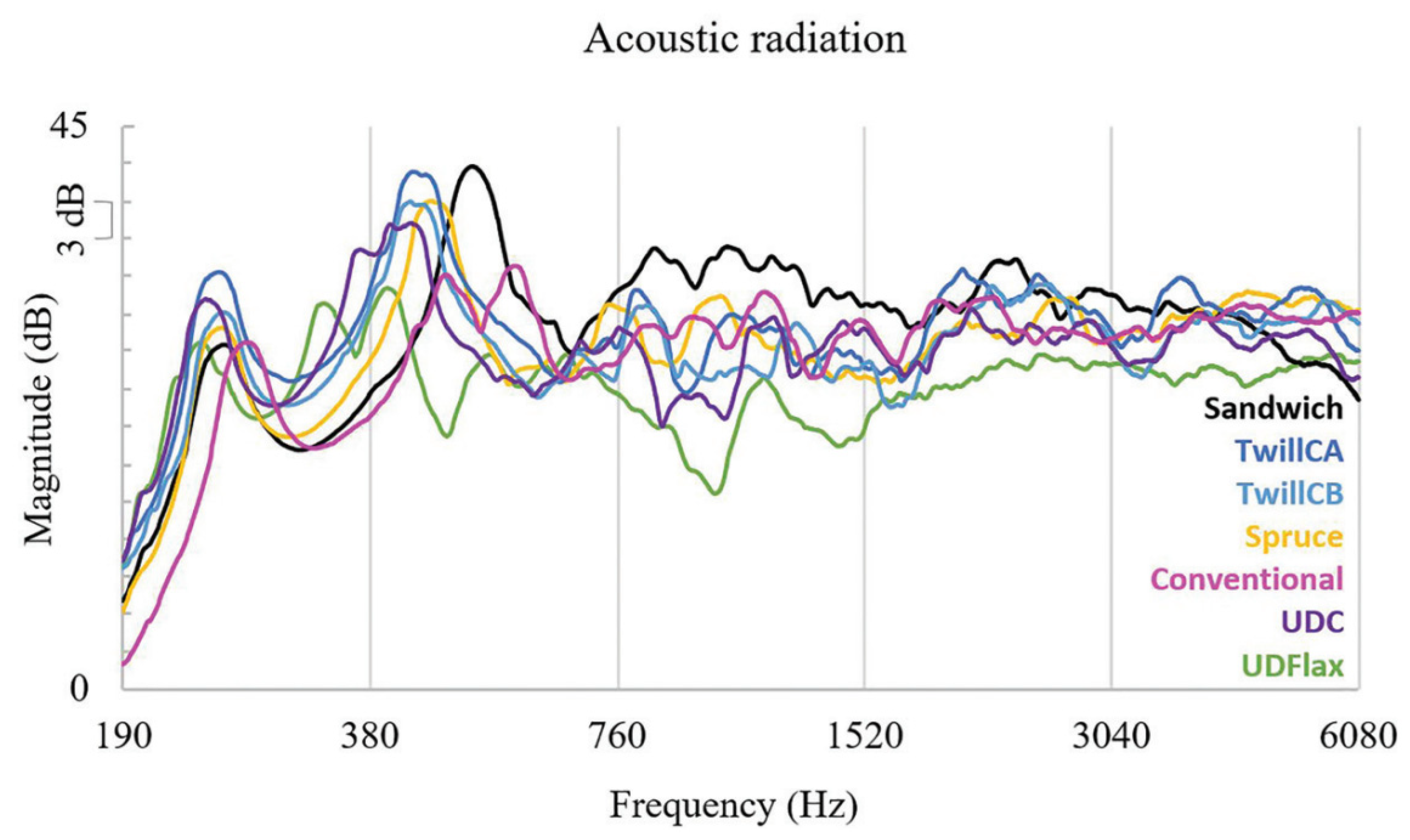

- Duerinck, T.; Verberkmoes, G.; Fritz, C.; Leman, M.; Nijs, L.; Kersemans, M.; Van Paepegem, W. Listener evaluations of violins made from composites. J. Acoust. Soc. Am. 2020, 147, 2647–2655. [Google Scholar] [CrossRef] [PubMed]

- Zambrano, M.; Vergara, M.; Burgos, J.L.; Trejo, J. Comparison of the acoustic performance of wooden violins and carbon fiber reinforced polymer violins through a modal study by finite elements method and effective masses. Open J. Eng. 2022, 1, 011036. [Google Scholar] [CrossRef]

- Ono, T.; Miyakoshi, S.; Watanabe, U. Acoustic characteristics of unidirectionally fiber-reinforced polyurethane foam composites for musical instrument soundboards. Acoust. Sci. Technol. 2002, 23, 135–142. [Google Scholar] [CrossRef]

- Ono, T.; Isomura, D. Acoustic characteristics of carbon fiber-reinforced synthetic wood for musical instrument soundboards. Acoust. Sci. Technol. 2004, 25, 475–477. [Google Scholar] [CrossRef]

- Ibáñez-Arnal, M.; Doménech-Ballester, L.; Sánchez-López, F. Manufacturing and structural features with respect to the modal behavior of a carbon fiber-reinforced epoxy drum shell. Materials 2019, 12, 4069. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z.H.; Li, J.H. Carbon fiber material in musical instrument making. Mater. Des. 2016, 80, 60–64. [Google Scholar] [CrossRef]

- Webb, S. Carbon-Fiber Cellos No Longer Playing Second-Fiddle to Wooden Instruments. 2009. Available online: http://www.scientificamerican.com/article/carbon-fiber-cellos (accessed on 5 February 2024).

- Luis and Clark Carbon Fiber Instruments. Available online: https://luisandclark.com (accessed on 5 February 2024).

- Klos Carbon Fiber Guitars. Available online: https://klosguitars.com (accessed on 5 February 2024).

- Rasch Drums. Available online: www.raschdrums.com (accessed on 5 February 2024).

- Boganyi Piano. Available online: http://www.boganyi-piano.com (accessed on 5 February 2024).

- Brezas, S.; Katsipis, M.; Orphanos, Y.; Kaselouris, E.; Kechrakos, K.; Kefaloyannis, N.; Papadaki, H.; Sarantis-Karamesinis, A.; Petrakis, S.; Theodorakis, I.; et al. An integrated method for the vibroacoustic evaluation of a carbon fiber bouzouki. Appl. Sci. 2023, 13, 4585. [Google Scholar] [CrossRef]

- Albrecht, W.; Fuchs, H.; Kittelmann, W. (Eds.) Introduction to Nonwovens. In Nonwoven Fabrics: Raw Materials, Manufacture, Applications, Characteristics, Testing Processes; John Wiley & Sons: Hoboken, NJ, USA, 2002; pp. 1–12. [Google Scholar]

- Majumdar, A. Principles of Woven Fabric Manufacturing; Taylor & Francis INC International Concepts: Milton Park, UK, 2016. [Google Scholar]

- Pedgley, O.; Norman, E.; Armstrong, R. Materials-inspired innovation for acoustic guitar. METU J. Fac. Archit. 2009, 26, 157–175. [Google Scholar]

- Mennig, G.; Stoeckhert, K. Mold-Making Handbook; Hanser Publications: Munich, Germany, 2013. [Google Scholar]

- Phillips, S.; Lessard, L. Application of natural fiber composites to musical instrument top plates. J. Compos. Mater. 2011, 46, 145–154. [Google Scholar] [CrossRef]

- Damodaran, A.; Mansour, H.; Lessard, L.; Scavone, G.; Babu, A.S. Application of composite materials to the chenda, an Indian percussion instrument. Appl. Acoust. 2015, 88, 1–5. [Google Scholar] [CrossRef]

- Mold Construction Guide. Available online: https://www.fibreglast.com/product/mold-construction (accessed on 5 February 2024).

- Callister, W.D., Jr.; Retwisch, D.G. Composite materials. In Materials Science and Engineering: An Introduction, 10th ed.; Wiley: Hoboken, NJ, USA, 2018; pp. 564–606. [Google Scholar]

- Ibáñez-Arnal, M.; Doménech-Ballester, L.; Sánchez-López, F. A study of the dynamic response of carbon fiber reinforced epoxy (CFRE) prepregs for musical instrument manufacturing. Appl. Sci. 2019, 9, 4615. [Google Scholar] [CrossRef]

- Acet, R.C.; Khosroshahi, F.S. Sound performance investigation of composite materials for the soundbox of a membrane musical instrument. In Proceedings of the ICSV 22, Florence, Italy, 12–16 July 2015. [Google Scholar]

- Berman, B. 3-D printing: The new industrial revolution. Bus. Horiz. 2012, 55, 155–162. [Google Scholar] [CrossRef]

- Depoorter, B.; Raus, B. Who’s afraid of 3D printing? B.U. J. Sci. Technol. Law 2019, 25, 60–99. [Google Scholar]

- Michon, R.; Chafey, C.; Granzow, J. 3D Printing and Physical Modeling of Musical Instruments: Casting the Net. In Proceedings of the Sound and Music Computing Conference 2018, Limassol, Cyprus, 4–7 July 2018. [Google Scholar]

- Savan, J.; Simian, R. CAD modelling and 3D printing for musical instrument research: The Renaissance cornett as a case study. Early Music 2014, 42, 537–544. [Google Scholar] [CrossRef]

- Kumar, M.B.; Sathiya, P. Methods and materials for additive manufacturing: A critical review on advancements and challenges. Thin-Walled Struct. 2021, 159, 107228. [Google Scholar] [CrossRef]

- Shahrubudin, N.; Lee, T.C.; Ramlan, R. An Overview on 3D Printing Technology: Technological, Materials, and Applications. Procedia Manuf. 2019, 35, 1286–1296. [Google Scholar] [CrossRef]

- Iftekar, S.F.; Aabid, A.; Amir, A.; Baig, M. Advancements and Limitations in 3D Printing Materials and Technologies: A Critical Review. Polymers 2023, 15, 2519. [Google Scholar] [CrossRef] [PubMed]

- Cottrell, S.; Howell, J. Reproducing musical instrument components from manufacturers’ technical drawings using 3D printing: Boosey & Hawkes as a case study. J. New Music Res. 2019, 48, 449–457. [Google Scholar]

- Frischling, E.B.; Dollins, C.; O’Grady, J.; Scruton, M. Design, Analysis, and 3D Print a Musical Instrument. Bachelor’s Thesis, Worcester Polytechnic Institute, Worcester, MA, USA, 2022. [Google Scholar]

- Simian, R. 3D-Printed Musical Instruments: Lessons Learned from Five Case Studies. Music Sci. 2023, 6, 1–16. [Google Scholar] [CrossRef]

- Zoran, A. The 3D Printed Flute: Digital Fabrication and Design of Musical Instruments. J. New Music Res. 2011, 40, 379–387. [Google Scholar] [CrossRef]

- Kokkinos, A.; Portan, D.V.; Saridaki, X.; Katerelos, D.T.G. Experimental and Numerical Approach in the Acoustical Behaviour of Kefalonian Traditional Instruments Made from Different Materials. Int. J. Sci. Res. 2020, 9, 607–617. [Google Scholar]

- Kolomiets, A.; Grobman, Y.J.; Popov, V.V.; Strokin, E.; Senchikhin, G.; Tarazi, E. The titanium 3D-printed flute: New prospects of additive manufacturing for musical wind instruments design. J. New Music Res. 2021, 50, 1–17. [Google Scholar] [CrossRef]

- Burgos-Pintos, Á.; Fernández-Zacarías, F.; Mayuet, P.F.; Hernández-Molina, R.; Rodríguez-Parada, L. Influence of 3D Printing Direction in PLA Acoustic Guitars on Vibration Response. Polymers 2023, 15, 4710. [Google Scholar] [CrossRef]

- Cavdir, D.B. Digital Manufacturing for Musical Applications: A Survey of Current Status and Future Outlook. In Proceedings of the 16th Sound and Music Computing Conference (SMC2019), Malaga, Spain, 28–31 May 2019. [Google Scholar]

- Evans, E.; McComb, C. The problem with printing pitch: Challenges in designing 3D printed claves. Rapid Prototyp. J. 2023, 29, 145–156. [Google Scholar] [CrossRef]

- De Maio, U.; Greco, F.; Luciano, R.; Sgambitterra, G.; Pranno, A. Microstructural design for elastic wave attenuation in 3D printed nacre-like bioinspired metamaterials lightened with hollow platelets. Mech. Res. Commun. 2023, 128, 104045. [Google Scholar] [CrossRef]

- De Maio, U.; Greco, F.; Nevone Blasi, P.; Pranno, A.; Sgambitterra, G. Elastic wave propagation control in porous and finitely deformed locally resonant nacre-like metamaterials. Materials 2024, 17, 705. [Google Scholar] [CrossRef]

- Lu, Y.; Huang, G.-Y.; Wang, Y.-F.; Wang, Y.-S. A mechanical model for elastic wave propagation in nacre-like materials with brick-and-mortar microstructures. J. Appl. Mech. 2022, 89, 091002. [Google Scholar] [CrossRef]

- Le Ferrand, H. Could bio-inspired nacre-like ceramics be suitable to fabricate musical instruments? Music Sci. 2022, 5, 1–14. [Google Scholar] [CrossRef]

- Jackson, C.M. Sustainability Models for 3D Printed Woodwinds. In Proceedings of the 2017 IEEE Conference on Technologies for Sustainability (SusTech), Phoenix, AZ, USA, 12–14 November 2017. [Google Scholar]

- Bader, R.; Fischer, J.L.; Münster, M.; Kontopidis, P. Metamaterials in Musical Acoustics: A modified frame drum. J. Acoust. Soc. Am. 2019, 145, 3086–3094. [Google Scholar] [CrossRef] [PubMed]

- Bader, R.; Fischer, J.L.; Münster, M.; Kontopidis, P. Metamaterials in Musical Instruments. In Proceedings of the ISMA, Detmold, Germany, 13–17 September 2019. [Google Scholar]

- Lercari, M.; Gonzalez, S.; Espinoza, C.; Longo, G.; Antonacci, F.; Sarti, A. Using Mechanical Metamaterials in Guitar Top Plates: A Numerical Study. Appl. Sci. 2022, 12, 8619. [Google Scholar] [CrossRef]

- Yeha, M.-K.; Lin, C.-M. Bending strength of sandwich beams with nanocomposites core. Adv. Mat. Res. 2009, 79–82, 577–580. [Google Scholar]

- Ono, T.; Okuda, A. Acoustic characteristics of guitars with a top board of carbon fiber-reinforced composites. Acoust. Sci. Technol. 2007, 28, 442–443. [Google Scholar] [CrossRef]

- Duerinck, T.; Segers, J.; Skrodzka, E.; Verberkmoes, G.; Leman, M.; Van Paepegem, W.; Kersemans, M. Experimental comparison of various excitation and acquisition techniques for modal analysis of violins. Appl. Acoust. 2021, 177, 107942. [Google Scholar] [CrossRef]

- Plath, N.; Linke, S.; Mores, R. On the angle-dependent vibrational behavior of fiber composite plates and its implications for musical instrument making. J. Acoust. Soc. Am. 2022, 151, 1956–1970. [Google Scholar] [CrossRef]

- Rodriguez, R.; Arteaga, E.; Rangel, D.; Salazar, R.; Vargas, S.; Estevez, M. Mechanical, chemical and acoustic properties of new hybrid ceramic-polymer varnishes for musical instruments. J. Non Cryst. Solids 2009, 355, 132–140. [Google Scholar] [CrossRef]

- Viala, R.; Placet, V.; Cogan, S. Identification of the anisotropic elastic and damping properties of complex shape composite parts using an inverse method based on finite element model updating and 3D velocity fields measurements (FEMU-3DVF): Application to bio-based composite violin soundboards. Compos. Part A Appl. Sci. 2018, 106, 91–103. [Google Scholar]

- Hughes, J.R. The Finite Element Method: Linear Static and Dynamic Finite Element Analysis; Dover Publications: Mineola, NY, USA, 1987. [Google Scholar]

- Kaselouris, E.; Bakarezos, M.; Tatarakis, M.; Papadogiannis, N.A.; Dimitriou, V. A Review of Finite Element Studies in String Musical Instruments. Acoustics 2022, 4, 183–202. [Google Scholar] [CrossRef]

- Dimitriou, V. Adaptive Finite Elements and Related Meshes. Doctoral Dissertation, National Technical University of Athens, School of Mechanical Engineering, Athens, Greece, August 2004. (In Greek). [Google Scholar]

- Bilbao, S. Conclusion and perspectives. In Numerical Sound Synthesis: Finite Difference Schemes and Simulation in Musical Acoustics; John Wiley & Sons: Hoboken, NJ, USA, 2009; pp. 386–388. [Google Scholar]

- Bader, R. Computational Mechanics of the Classical Guitar; Springer: Berlin/Heidelberg, Germany, 2005. [Google Scholar]

- Moosrainer, M.; Fleischer, H. Application of BEM and FEM to musical instruments. In Boundary Elements in Acoustics; Advances and Applications Series; WIT Press: Southampton, UK, 2000. [Google Scholar]

- Brooke, M.; Richardson, B.E. Numerical modeling of guitar radiation fields using boundary elements. J. Acoust. Soc. Am. 1991, 89, 1878. [Google Scholar] [CrossRef]

- Lu, Y. Comparison of Finite Element Method and Modal Analysis of Violin Top Plate. Master’s Thesis, McGill University, Montréal, QC, Canada, 2013. [Google Scholar]

- Kaselouris, E.; Orphanos, Y.; Bakarezos, M.; Tatarakis, M.; Papadogiannis, N.A.; Dimitriou, V. Influence of the plate thickness and material properties on the violin top plate modes. In Proceedings of the INTER-NOISE 2021, Washington, DC, USA, 1–4 August 2021. [Google Scholar]

- Kaselouris, E.; Alexandraki, C.; Bakarezos, M.; Tatarakis, M.; Papadogiannis, N.A.; Dimitriou, V. A detailed FEM Study on the Vibro-acoustic Behaviour of Crash and Splash Musical Cymbals. Int. J. Circuits Syst. Signal Process. 2022, 16, 948–955. [Google Scholar] [CrossRef]

- Ibañez, M.; Muñoz, E.; Domenech, L.; Cortés, E.; Sánchez, F.; García, J.A. On the influence of mechanical and processing characterization on the vibro-acoustic response of lcm and pre-impregnated composite laminates. In Proceedings of the 13th International Conference on Flow Processes in Composite Materials, Kioto, Japan, 6–9 July 2016. [Google Scholar]

- Schelleng, J.C. The violin as a circuit. J. Acoust. Soc. Am. 1963, 35, 326–338. [Google Scholar] [CrossRef]

- Haines, D.W.; Chang, N. Application of graphite composites in musical instruments. Newsl. Catgut Acoust. Soc. 1975, 23, 13–15. [Google Scholar]

- Dominy, J.; Killingback, P. The development of a carbon fibre violin. In Proceedings of the ICCM 17, Edinburgh, UK, 27–31 July 2009. [Google Scholar]

- Roest, M. Design of a Composite Guitar. Master’s Thesis, Delft University of Technology, Delft, The Netherlands, 17 August 2016. [Google Scholar]

- Probert, S.M. Design, Manufacture, and Analysis of a Carbon Fiber Epoxy Composite Acoustic Guitar. Master’s Thesis, University of Washington, Seattle, WA, USA, 2007. [Google Scholar]

- Zhong, S.; Punpongsanon, P.; Iwai, D.; Sato, K. Estimation of fused-filament-fabrication structural vibro-acoustic performance by modal impact sound. Comput. Graph. 2023, 115, 137–147. [Google Scholar] [CrossRef]

- Alfarisi, N.A.; Santos, G.N.; Norcahyo, R.; Sentanuhady, J.; Azizah, N.; Muflikhun, M.A. Model optimization and performance evaluation of hand cranked music box base structure manufactured via 3D printing. Heliyon 2021, 7, e08432. [Google Scholar] [CrossRef]

- Mulholland, R.; Perry, I.; Geng, Y.; Perkins, E. Keyboard technology: A 3D printed piano action and self-tuning controller. In Proceedings of the 26th International Congress on Sound & Vibration, Montreal, QC, Canada, 7–11 July 2019. [Google Scholar]

- ODD Guitars. Available online: www.oddguitars.com (accessed on 5 February 2024).

- Rodríguez, J.C.; del Rey, R.; Peydro, M.A.; Alba, J.; Gámez, J.L. Design, Manufacturing and Acoustic Assessment of Polymer Mouthpieces for Trombones. Polymers 2023, 15, 1667. [Google Scholar] [CrossRef]

- Durability of Photopolymers in 3D Printing. Available online: https://www.jellypipe.com/en/blog-news/durability-of-photopolymers-in-3d-printing/ (accessed on 2 March 2024).

- Espinoza, C.; Arancibia, A.; Cartes, G.; Falcón, C. New materials, new sounds: How metamaterials can change the timbre of musical instruments. In Proceedings of the 2nd International Conference on Timbre, Thessaloniki, Greece, 3–4 September 2020. [Google Scholar]

- Espinoza, C.; Arancibia, A.; Cartes, G.; Falcón, C. Seeking for spectral manipulation of the sound of musical instruments using metamaterials. In Proceedings of the 15th International Audio Mostly Conference, Graz, Austria, 15–17 September 2020. [Google Scholar]

- Gonzalez, S.; Chacra, E.; Carreño, C.; Espinoza, C. Wooden mechanical metamaterials: Towards tunable wood plates. Mater. Des. 2022, 221, 110952. [Google Scholar] [CrossRef]

- Kaleris, K.; Kaniolakis-Kaloudis, E.; Aravantinos-Zafeiris, N.; Katerelos, D.; Dimitriou, V.; Bakarezos, M.; Tatarakis, M.; Mourjopoulos, J.; Papadogiannis, N.A. Characterizing acoustic metamaterials using laser-plasma sound sources. Nat. Commun. Mater. 2024. under review. [Google Scholar]

- Kaleris, K.; Orphanos, Y.; Petrakis, S.; Bakarezos, M.; Tatarakis, M.; Mourjopoulos, J.; Papadogiannis, N.A. Laser-plasma sound sources in atmospheric air: A systematic experimental study. J. Sound Vib. 2023, 570, 118000. [Google Scholar] [CrossRef]

- Kaleris, K.; Orphanos, Y.; Bakarezos, M.; Dimitriou, V.; Tatarakis, M.; Mourjopoulos, J.; Papadogiannis, N.A. On the correlation of light and sound radiation following laser-induced breakdown in air. J. Phys. D Appl. Phys. 2020, 53, 435207. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Brezas, S.; Katsipis, M.; Kaleris, K.; Papadaki, H.; Katerelos, D.T.G.; Papadogiannis, N.A.; Bakarezos, M.; Dimitriou, V.; Kaselouris, E. Review of Manufacturing Processes and Vibro-Acoustic Assessments of Composite and Alternative Materials for Musical Instruments. Appl. Sci. 2024, 14, 2293. https://doi.org/10.3390/app14062293

Brezas S, Katsipis M, Kaleris K, Papadaki H, Katerelos DTG, Papadogiannis NA, Bakarezos M, Dimitriou V, Kaselouris E. Review of Manufacturing Processes and Vibro-Acoustic Assessments of Composite and Alternative Materials for Musical Instruments. Applied Sciences. 2024; 14(6):2293. https://doi.org/10.3390/app14062293

Chicago/Turabian StyleBrezas, Spyros, Markos Katsipis, Konstantinos Kaleris, Helen Papadaki, Dionysios T. G. Katerelos, Nektarios A. Papadogiannis, Makis Bakarezos, Vasilis Dimitriou, and Evaggelos Kaselouris. 2024. "Review of Manufacturing Processes and Vibro-Acoustic Assessments of Composite and Alternative Materials for Musical Instruments" Applied Sciences 14, no. 6: 2293. https://doi.org/10.3390/app14062293

APA StyleBrezas, S., Katsipis, M., Kaleris, K., Papadaki, H., Katerelos, D. T. G., Papadogiannis, N. A., Bakarezos, M., Dimitriou, V., & Kaselouris, E. (2024). Review of Manufacturing Processes and Vibro-Acoustic Assessments of Composite and Alternative Materials for Musical Instruments. Applied Sciences, 14(6), 2293. https://doi.org/10.3390/app14062293