Impact of Laser Cavity Configurations and Pump Radiation Parameters on the Characteristics of High-Energy Yellow Raman Lasers Based on Potassium Gadolinium Tungstate Crystals

Abstract

:1. Introduction

2. Experimental Part

3. Results and Discussion

3.1. Energy Characteristics

- -

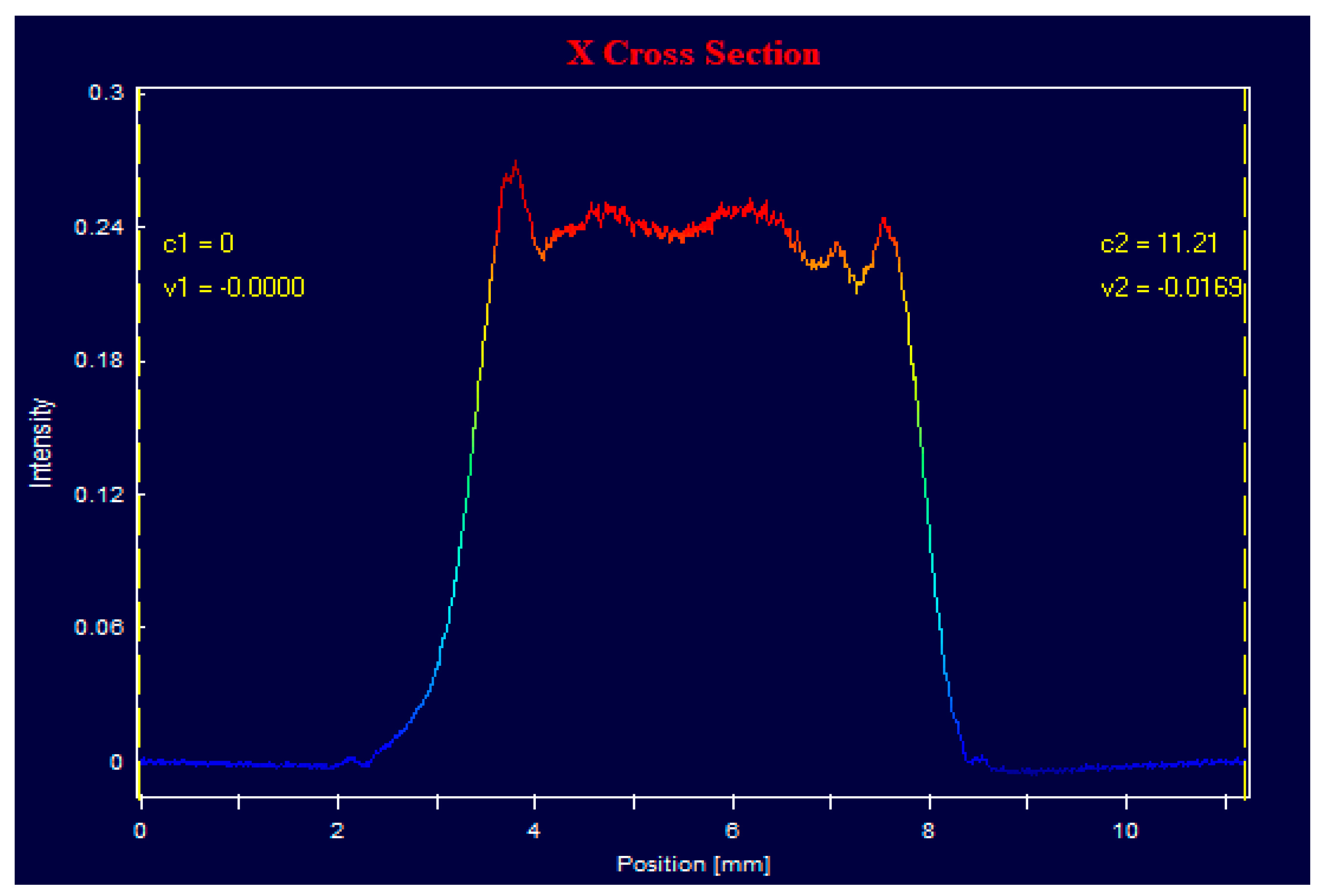

- The appearance of a negative lens in low-energy lasers, when the spot size is ~0.2 mm, leads to the distortion of Stokes generation in the TEM00 mode, which results in an increase in diffraction losses and worsening of the overlap with the pump beam;

- -

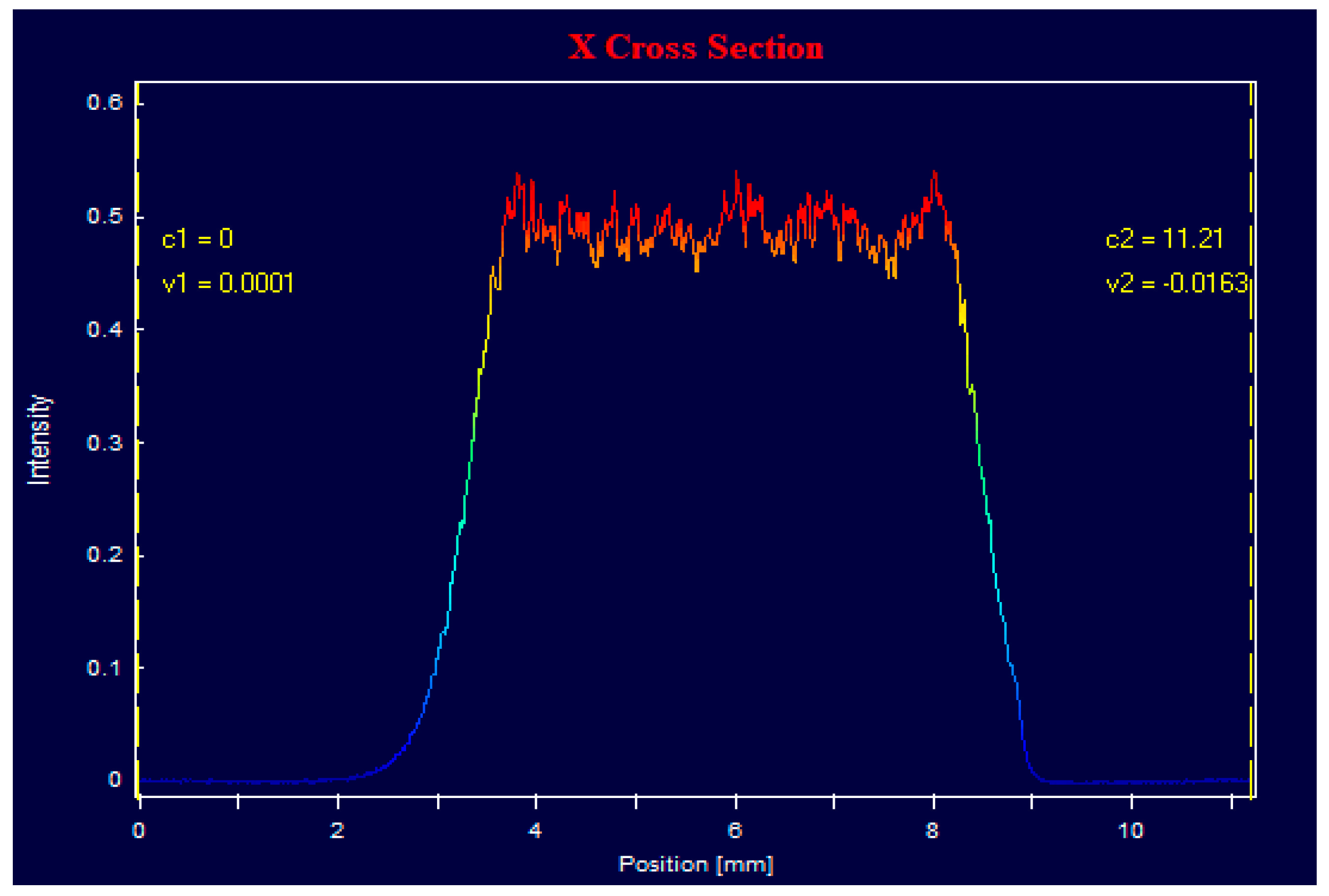

- In high-energy lasers, the efficiency has a low sensitivity to the increase in diffraction losses due to a high gain. A negative lens (or the negative curvature of laser mirrors) does not reduce the uniformity of the Stokes transversal distribution or the overlap with the pump beam (see next paragraph).

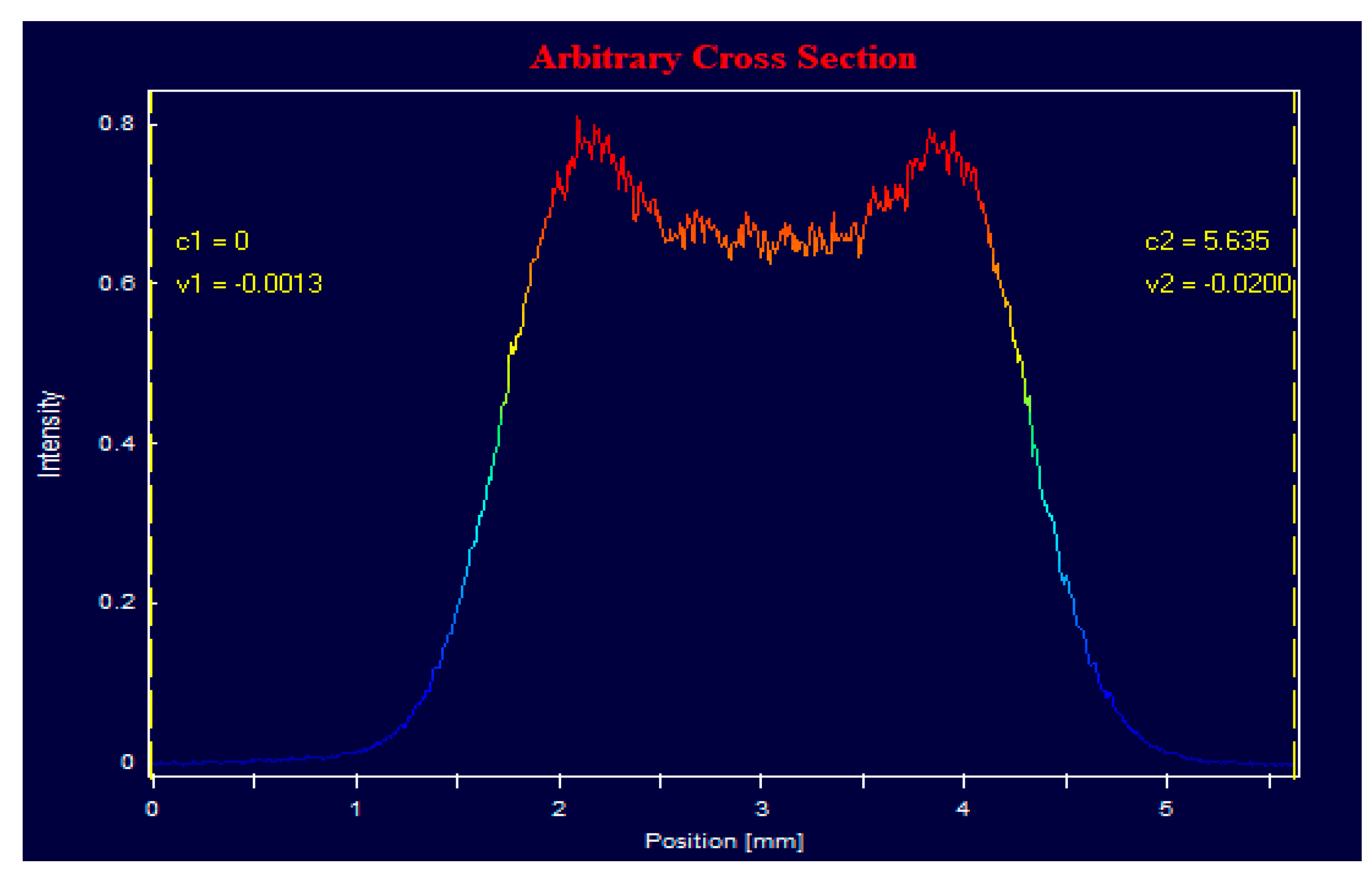

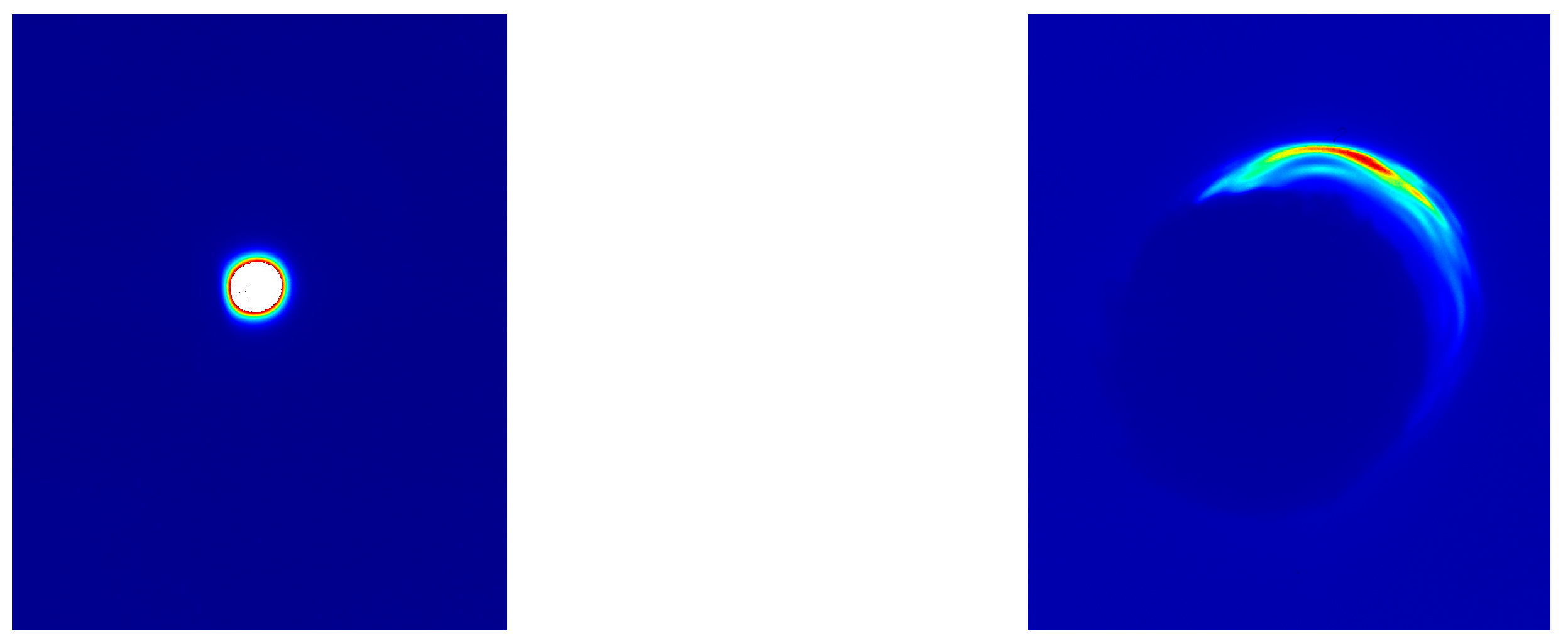

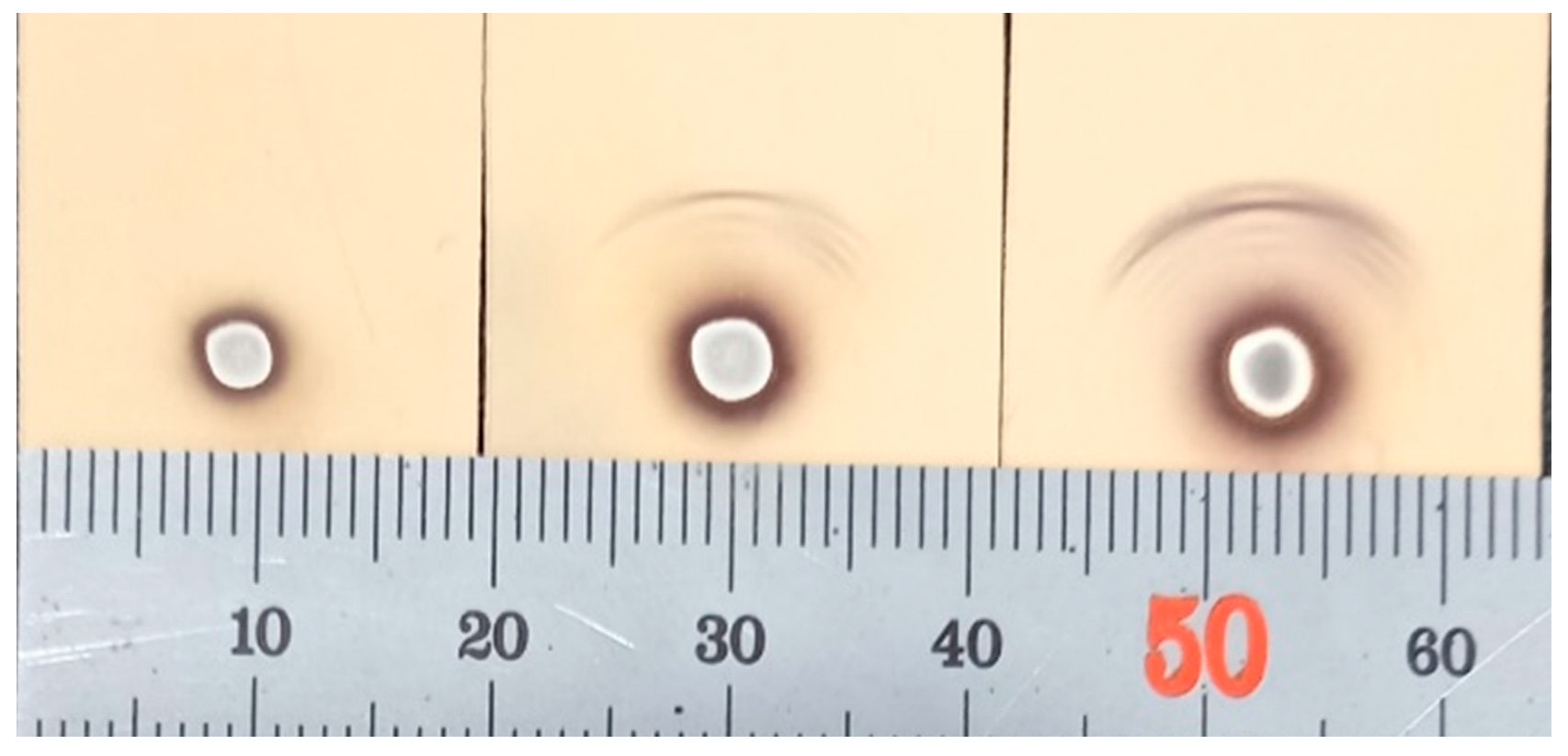

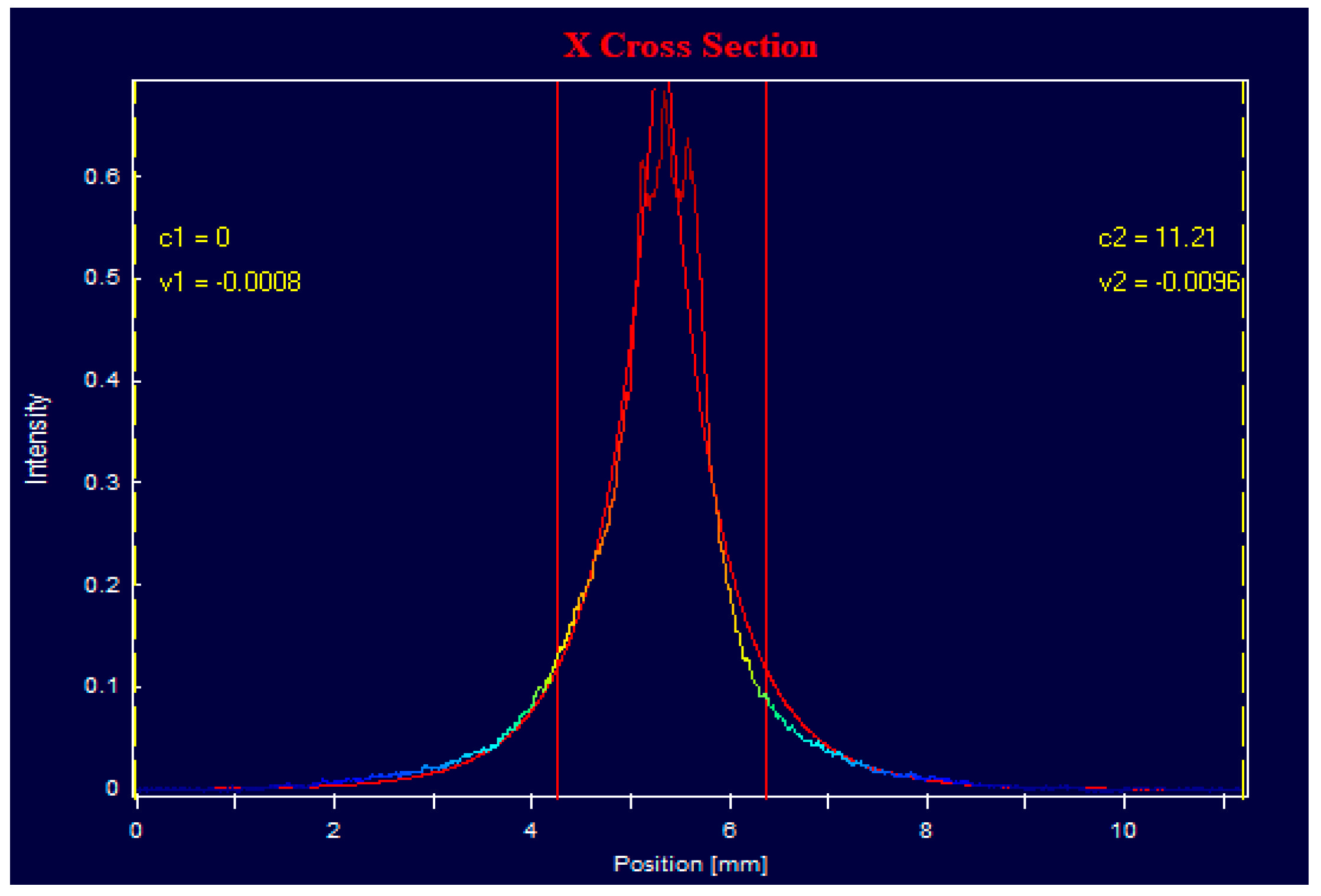

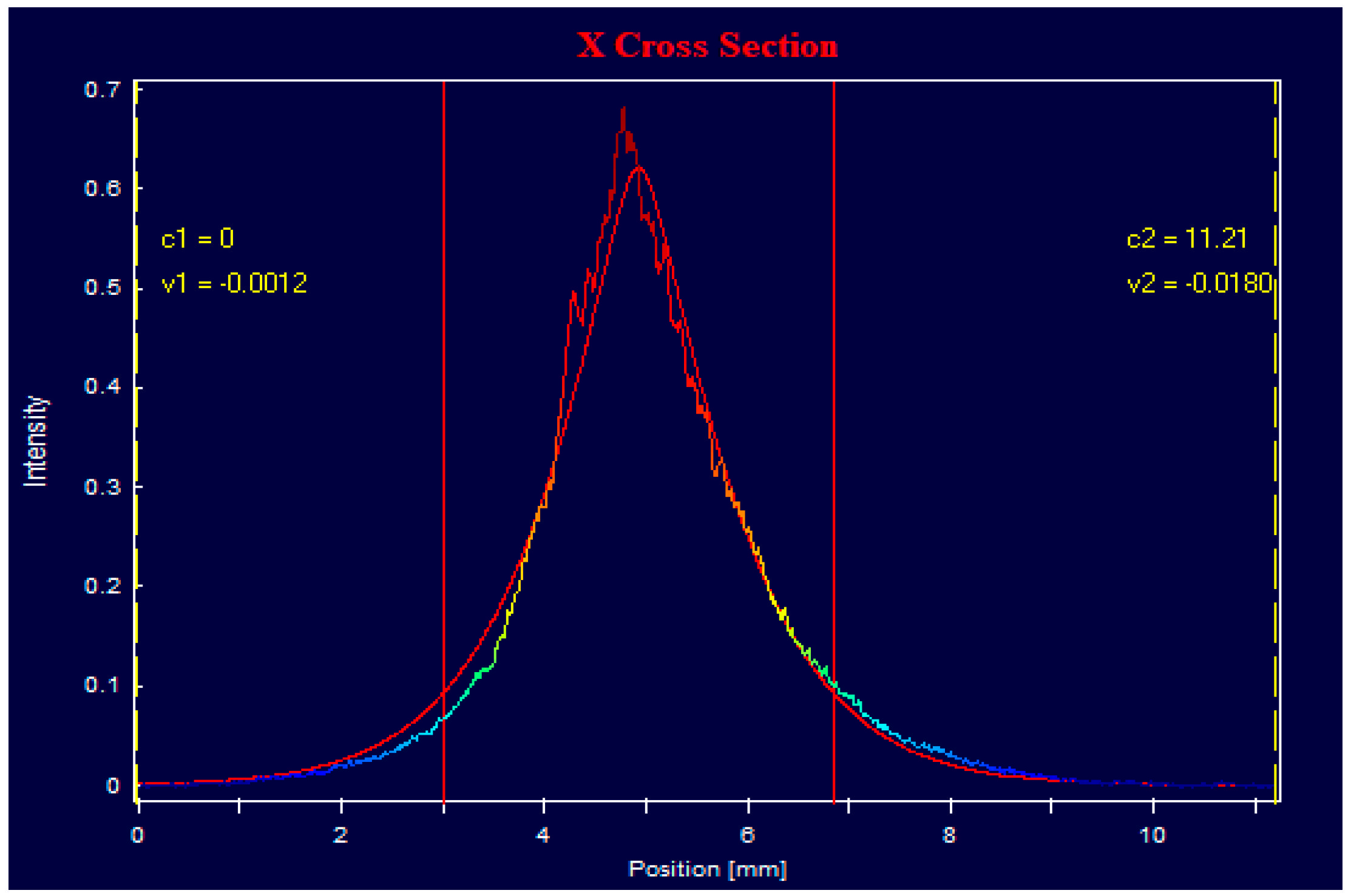

3.2. Near Field Uniformity

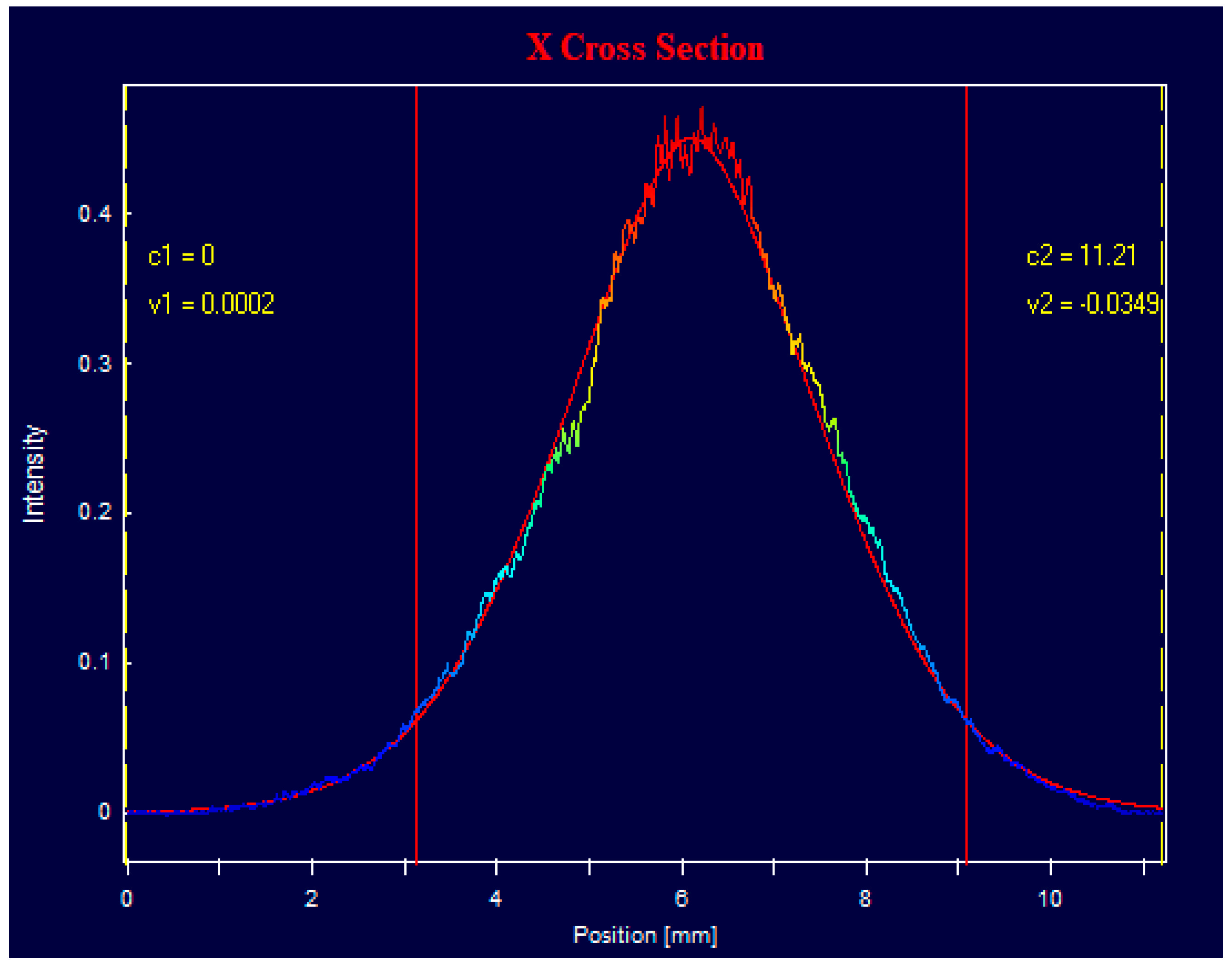

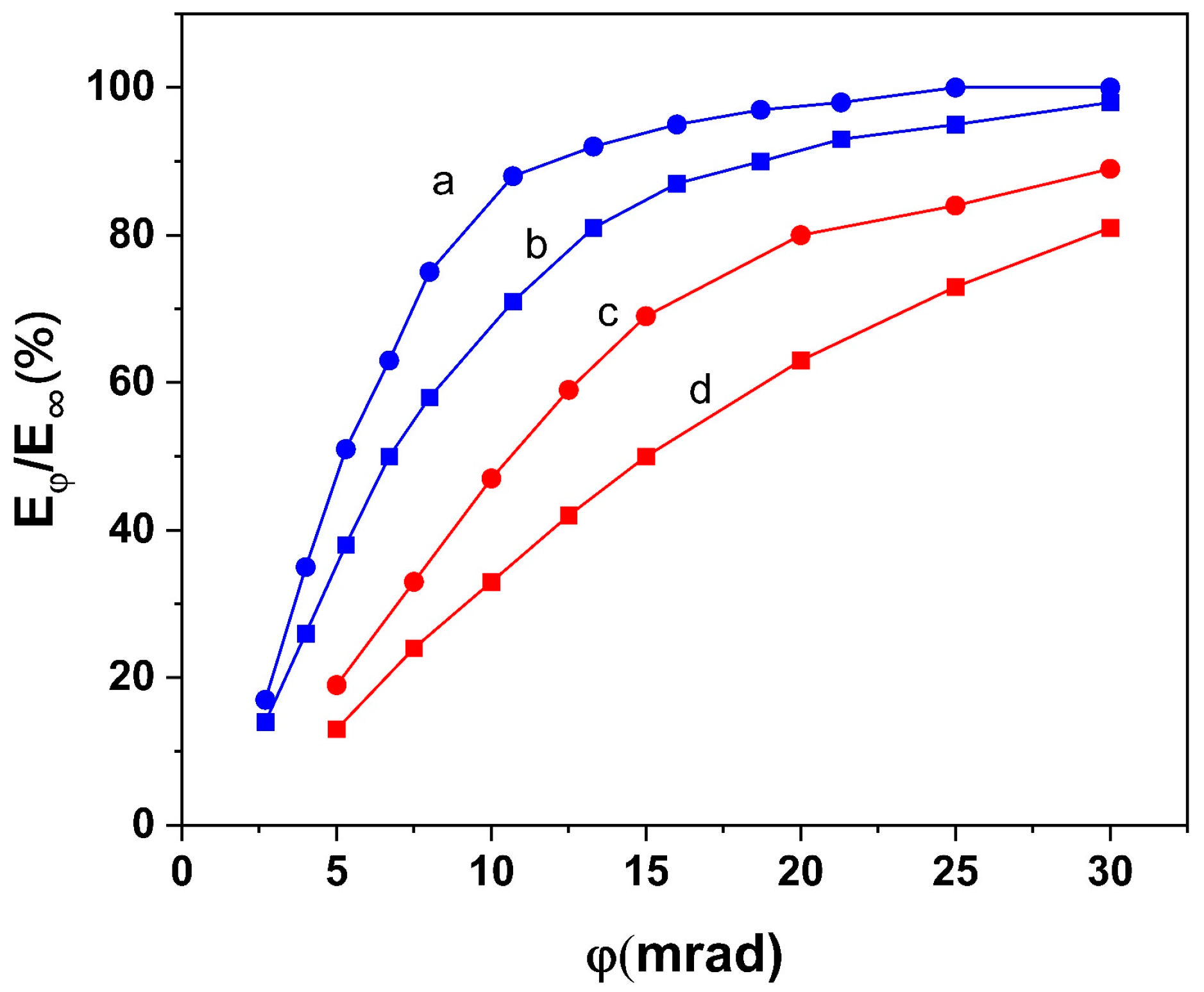

3.3. Angular Characteristics

3.3.1. Laser with a Flat Cavity

3.3.2. Lasers with an Unstable Cavity

4. Conclusions

- The largest energy efficiency of KGW Raman lasers can be obtained with the use of a flat cavity. A slightly lower energy efficiency is observed with unstable cavities. Worse energy characteristics are obtained when using stable spherical cavities. The energy efficiency reduces with a reduction in the resonator mirror’s radius of curvature. This is explained by the worse lateral overlap between the pump radiation and Stokes radiation, because the spatial distribution of the Stokes radiation depends on the cavity configuration.

- The best angular characteristics (lowest angular divergence) are obtained using unstable resonators. Lasers with flat cavities have a 2–3 times larger angular divergence, and worse characteristics are obtained with stable spherical cavities. We can conclude that stable spherical cavities in high-energy Raman lasers have no advantages, and there is no practical interest in their application.

- A reduction in the mirror’s curvature in unstable-cavity lasers leads to a better angular divergence. At the same time, the energy efficiency is reduced. Thus, for a given laser application, optimization of the mirror’s curvature is required.

- An increase in pump intensity leads to an increase in the angular energy divergence in lasers with all types of resonators. However, in lasers with flat cavities, the angular size of the core remains almost unchanged, and the angular energy divergence increases mainly due to wing growth. In lasers with unstable cavities, this process requires additional study.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, P.; Ding, X.; Guo, J.; Zhang, H.; Qui, H.; Shang, Y.; Song, Z.; Wang, W.; Wang, C.; Liu, G.; et al. Research progress in crystalline Raman yellow lasers. Opt. Laser Technol. 2024, 169, 110072. [Google Scholar] [CrossRef]

- Cai, Y.; Ding, J.; Bai, Z.; Qi, Y.; Wang, Y.; Lu, Z. Recent progress in yellow laser: Principles, status and perspectives. Opt. Laser Technol. 2022, 152, 108113. [Google Scholar] [CrossRef]

- Pask, H.; Piper, J. Raman Lasers. In Handbook of Solid-State Lasers; Denker, B., Shklovsky, E., Eds.; Woodhead Publishing Limited: Cambridge, UK, 2013; pp. 493–524. [Google Scholar]

- Tarasov, A.; Chu, H. Wavelength conversion of multi-joule energy 532 nm pulse bursts via a potassium gadolinium tungstate Raman laser. Appl. Sci. 2023, 13, 10195. [Google Scholar] [CrossRef]

- Karpukhin, S.; Stepanov, A. Stimulated emission from the cavity under SRS in Ba(NO3)2, NaNO3 and CaCO3 crystals. Sov. J. Quantum Electron. 1986, 16, 1027–1031. [Google Scholar] [CrossRef]

- Basiev, T.; Danileiko, Y.; Doroshenko, M.; Osiko, V.; Fedin, A.; Gavrilov, A.; Smetanin, S. Powerful BaWO4 Raman laser pumped by a self-phase-conjugated Nd: YAG and Nd: GGG lasers. In Proceedings of the Advanced Solid-State Photonics 2004, Santa Fe, NM, USA, 1–4 February 2004; OSA: Washington, DC, USA, 2004. Paper TuB11. [Google Scholar]

- Ermolenkov, V.; Lisinetskii, V.; Mishkel, Y.; Grabchikov, A.; Chaikovskii, A.; Orlovich, V. A radiation source based on a solid-state Raman laser for diagnosing tropospheric ozone. Opt. Zhurnal 2005, 72, 39–44. [Google Scholar] [CrossRef]

- Chulkov, R.; Lisinetskii, V.; Lux, O.; Rhee, H.; Shrader, S.; Eichler, H.; Orlovich, V. Thermal aberrations and high-power frequency conversion in a barium nitrate Raman laser. Appl. Phys. B 2012, 106, 867–875. [Google Scholar] [CrossRef]

- Lv, X.; Chen, J.; Peng, Y.; Long, Y.; Liu, G.; Leng, Y. Investigation of high-energy extracavity Raman laser oscillator and single-pass Raman generator based on potassium gadolinium tungstate (KGW) crystal. Opt. Laser Technol. 2021, 140, 10723. [Google Scholar] [CrossRef]

- McKay, A.; Kitzler, O.; Mildren, R. High power tungstate-crystal Raman laser operating in the strong thermal lensing regime. Opt. Express 2014, 22, 707–715. [Google Scholar] [CrossRef] [PubMed]

- Spence, D. Spectral effects of stimulated Raman scattering in crystals. Prog. Quant. Electron. 2017, 51, 1–45. [Google Scholar] [CrossRef]

- Anan’ev, Y. Laser Resonators and the Beam Divergence Problem; Adam Higler: Bristol, PA, USA; New York, NY, USA, 1992. [Google Scholar]

- Sabella, A.; Spence, D.; Mildren, R. Pump-probe measurements of the Raman gain coefficient in crystals using multi-longitudinandal-mode beams. IEEE J. Quant. Electron. 2015, 51, 1000108. [Google Scholar] [CrossRef]

- McKay, A.; Kitzler, O.; Mildren, R. Thermal lens evolution and compensation in a high power KGW Raman laser. Opt. Express 2014, 22, 6707–6718. [Google Scholar] [CrossRef] [PubMed]

- Basiev, T.; Osiko, V.; Prokhorov, A.; Dianov, E. Crystalline and fiber Raman lasers. In Solid-State Mid-Infrared Laser Sources; Sorokina, I., Vodopyanov, K., Eds.; Springer: Berlin/Heidelberg, Germany, 2003; Volume 89, pp. 351–400. [Google Scholar]

- Tarasov, A.; Chu, H. The impact of pump light spatial modulation on the angular distribution of gain-switched sub-nanosecond Ti: Sapphire laser radiation. Opt. Express 2019, 27, 16250–16257. [Google Scholar] [CrossRef] [PubMed]

- Hodgson, N.; Weber, H. Laser Resonators and Beam Propagation; Springer: New York, NY, USA, 2005. [Google Scholar]

- Murray, J.; Austin, W.; Powell, R. Intracavity Raman conversion and Raman beam cleanup. Opt. Mater. 1999, 11, 353–371. [Google Scholar] [CrossRef]

- Basiev, T.; Smetanin, S.; Shurygin, A.; Fedin, A. Parametric coupling of frequency components at stimulated Raman scattering in solids. Uspekhi Fiz. Nauk 2010, 180, 639–646. [Google Scholar] [CrossRef]

- Zverev, P.; Murray, J.; Powell, R.; Reeves, R.; Basiev, T. Stimulated Raman scattering of picosecond pulses in barium nitrate crystals. Opt. Communs 1993, 97, 59–64. [Google Scholar] [CrossRef]

- Cerny, P.; Jelinkova, H.; Miyagi, M.; Basiev, T.; Zverev, P. Efficient picosecond Raman lasers on BaWO4 and KGd(WO4)2 tungstate crystals emitting in 1.15–1.18 μm spectral region. In Solid State Lasers XI—Proceedings of the High-Power Lasers and Applications, San Jose, CA, USA, 20–25 January 2002; Scheps, R., Ed.; SPIE: Bellingham, WA, USA, 2002; Volume 4630, pp. 108–118. [Google Scholar]

| Pump Mirror Curvature | I532 = 120 MW/cm2 | I532 = 220 MW/cm2 | I532 = 350 MW/cm2 |

|---|---|---|---|

| Flat | 43 | 54 | 57 |

| Convex, R = 2000 mm | 36 | 49 | 53 |

| Convex, R = 750 mm | 32 | 44 | 47 |

| Concave, R = 1000 mm | 25 | 30 | 31 |

| Concave, R = 500 mm | 11 | 16 | 19 |

| Pump Mirror | I532 = 120 MW/cm2 | I532 = 220 MW/cm2 | I532 = 350 MW/cm2 |

|---|---|---|---|

| Flat | 41 | 61 | 67 |

| Convex, R = 2000 mm | 40 | 60 | 64 |

| Convex, R = 750 mm | 37 | 58 | 62 |

| Concave, R = 2000 mm | 14 | 31 | 39 |

| Concave, R = 1000 mm | 5 | 17 | 34 |

| Concave, R = 500 mm | 4 | 14 | 20 |

| Pump Mirror | Flat | Convex, R2000 mm | Convex, R750 mm | Concave, R1000 mm | Concave, R500 mm |

|---|---|---|---|---|---|

| ITH, MW/cm2 | 45 | 50 | 50 | 72 | 110 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tarasov, A.; Chu, H. Impact of Laser Cavity Configurations and Pump Radiation Parameters on the Characteristics of High-Energy Yellow Raman Lasers Based on Potassium Gadolinium Tungstate Crystals. Appl. Sci. 2024, 14, 2412. https://doi.org/10.3390/app14062412

Tarasov A, Chu H. Impact of Laser Cavity Configurations and Pump Radiation Parameters on the Characteristics of High-Energy Yellow Raman Lasers Based on Potassium Gadolinium Tungstate Crystals. Applied Sciences. 2024; 14(6):2412. https://doi.org/10.3390/app14062412

Chicago/Turabian StyleTarasov, Aleksandr, and Hong Chu. 2024. "Impact of Laser Cavity Configurations and Pump Radiation Parameters on the Characteristics of High-Energy Yellow Raman Lasers Based on Potassium Gadolinium Tungstate Crystals" Applied Sciences 14, no. 6: 2412. https://doi.org/10.3390/app14062412