Assessment of the Baking Properties of Rye Flour Based on the Polysaccharide Content and Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

2.2.1. Starch Content of Rye Flour Samples and Its Properties

Starch Content, Falling Number and Amylograph Properties

Thermal Properties of Rye Flour Samples

2.2.2. Pentosan Content and Swelling Curve Parameter

2.2.3. Baking Procedure

2.2.4. Statistical Analysis

3. Results

3.1. The Parameters Related to the Starch–Amylolytic Complex

3.1.1. Starch Content and Falling Number

3.1.2. Amylograph Properties

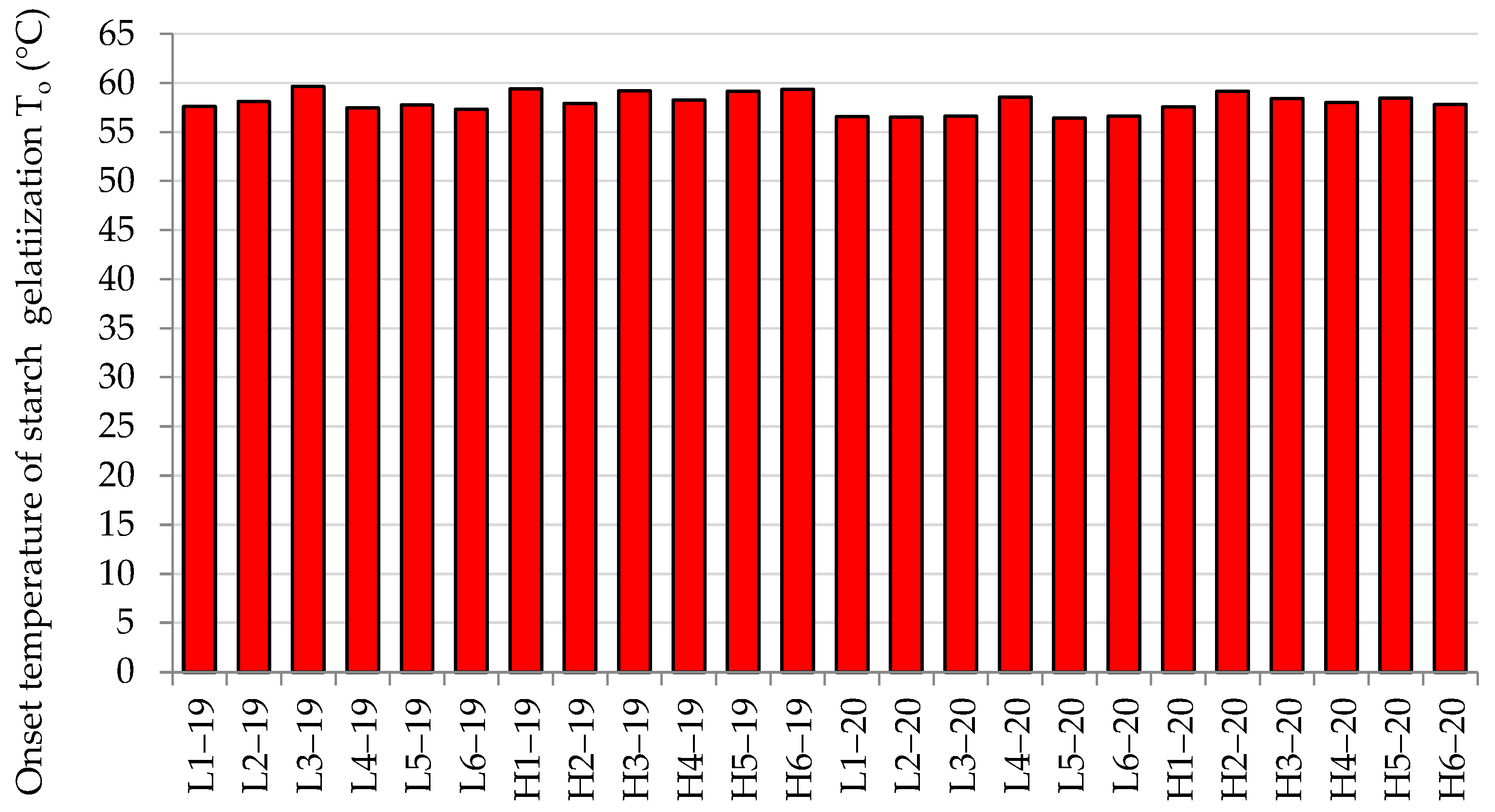

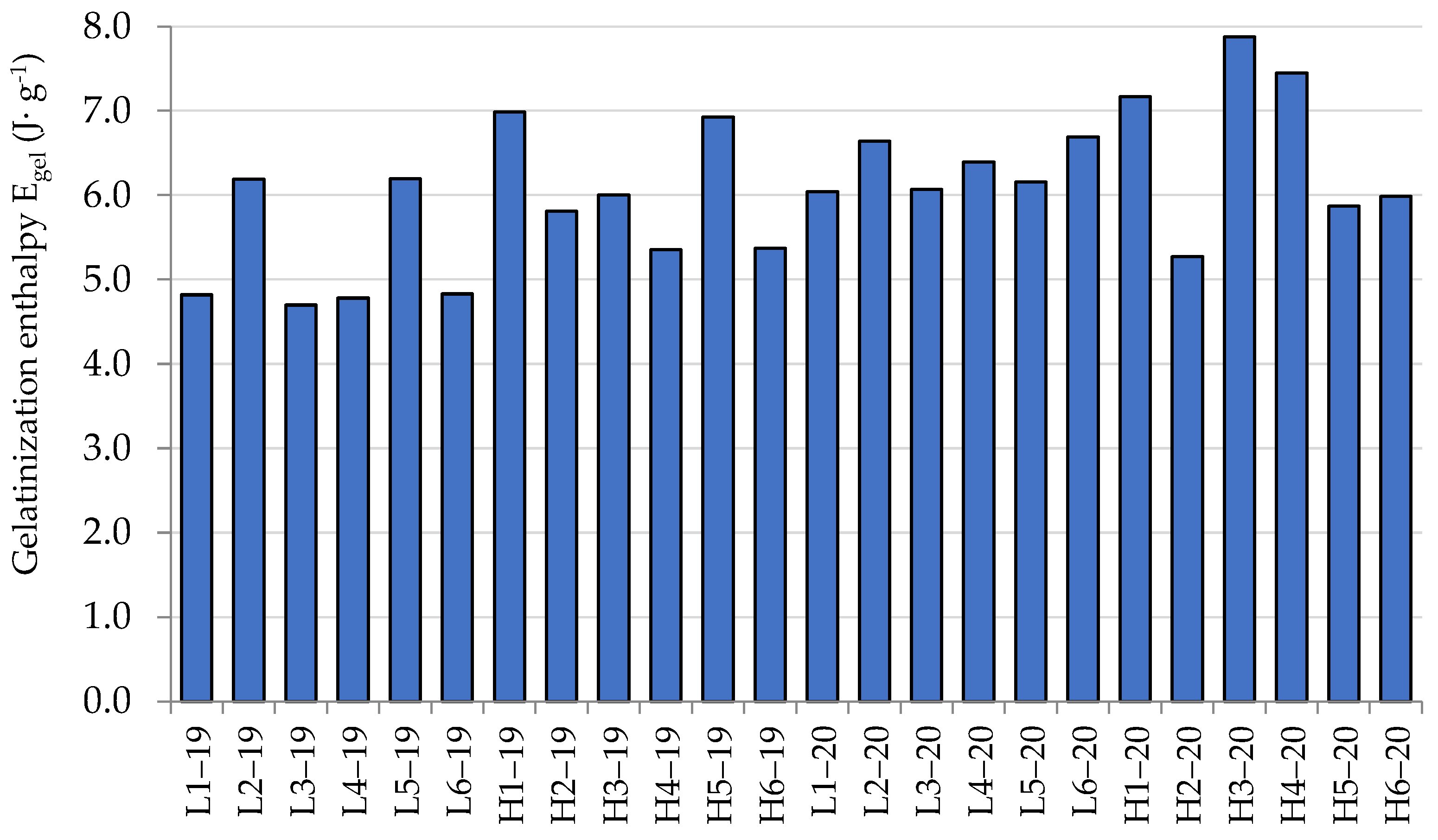

3.1.3. Differential Scanning Calorimetry (DSC)

3.2. The Parameters Related to the Pentosan–Pentosanolytic Complex

3.2.1. Pentosan Content

3.2.2. Swelling Curve Parameters

3.3. Bread Characteristic

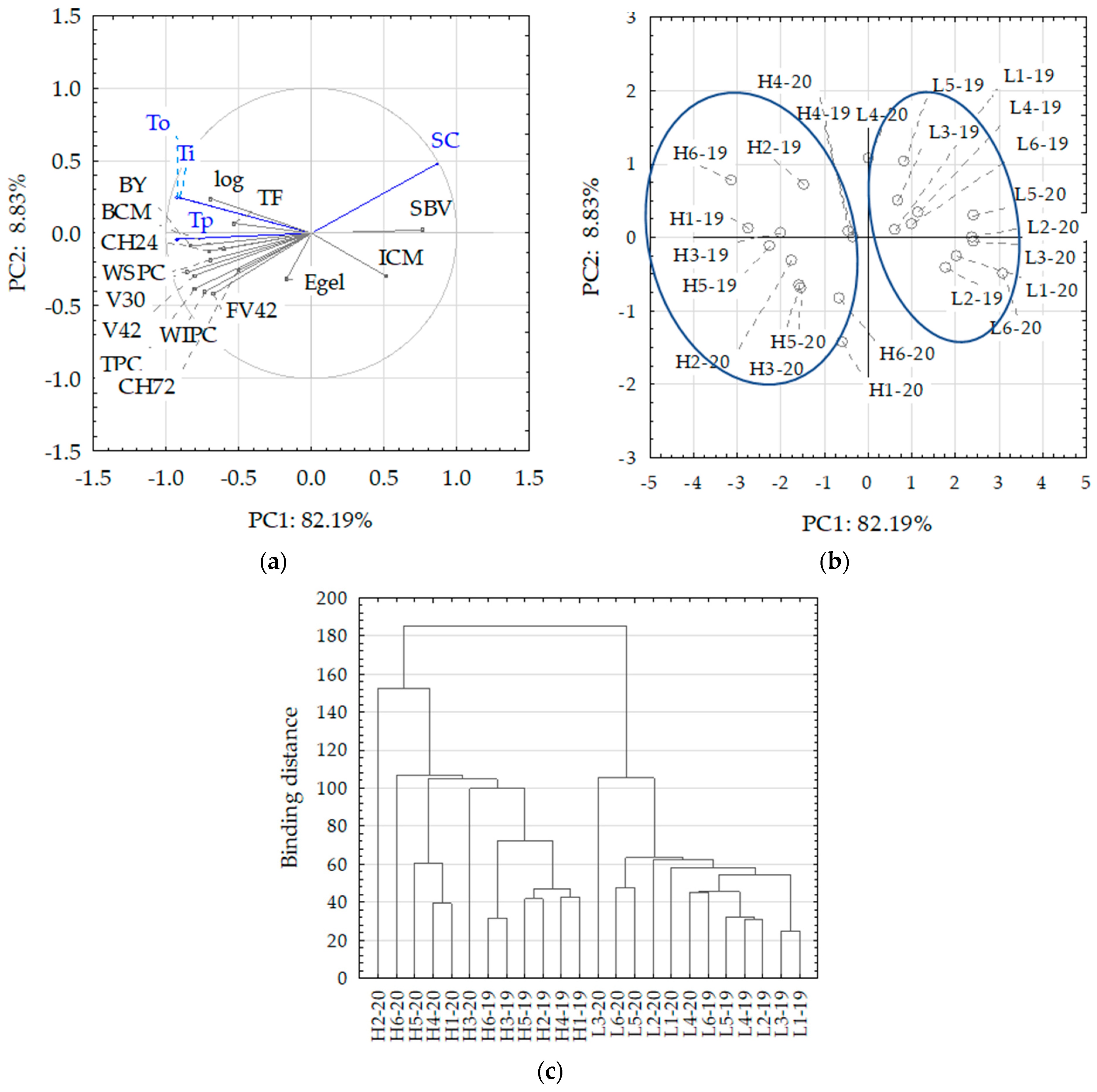

3.4. Comprehensive Assessment of the Baking Quality of Flour Using Principal Component Analysis (PCA)

4. Conclusions

Practical Application

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Poutanen, K.; Katina, K.; Heiniö, R.-L. Rye. In Bakery Products Science and Technology; Zhou, W., Hui, Y.H., De Leyn, I., Pagani, M.A., Rosell, C.M., Selman, J.D., Therdthai, N., Eds.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014; pp. 75–87. [Google Scholar]

- Gräber, S. Influence of enzyme treatment on the rheology of rye doughs. Nahr. Food 1999, 43, 249–252. [Google Scholar] [CrossRef]

- Arendt, K.; Ryan Liam, A.M.; Fabio, D.B. Impact of sourdough on the texture of bread. Food Microbiol. 2007, 24, 165–174. [Google Scholar] [CrossRef] [PubMed]

- Bucsella, B.; Molnár, D.; Harasztos, A.H.; Tömösközi, S. Comparison of the rheological and end-product properties of an industrial aleurone-rich wheat flour, whole grain wheat and rye flour. J. Cereal Sci. 2016, 69, 40–48. [Google Scholar] [CrossRef]

- Drakos, A.; Malindretoi, K.; Mandala, I. Protein isolation from jet milled rye flours differing in practicle size. Food Bioprod. Process. 2017, 104, 13–18. [Google Scholar] [CrossRef]

- Beck, M.; Jekle, M.; Selmair, P.L.; Koehler, P.; Becker, T. Rheological properties and baking performance of rye dough as affected by transglutaminase. J. Cereal Sci. 2011, 54, 29–36. [Google Scholar] [CrossRef]

- Michalska, A.; Ceglińska, A.; Zieliński, H. Bioactive compounds in rye flours with different extraction rates. Eur. Food Res. Technol. 2007, 225, 545–551. [Google Scholar] [CrossRef]

- Verwimp, T.; Courtin, C.M.; Delcour, J.A. Rye constituents and their impact on rye processing. In Food Biochemistry and Food Processing, 2nd ed.; Simpson, B.K., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2012; pp. 654–672. [Google Scholar] [CrossRef]

- Stępniewska, S.; Cacak-Pietrzak, G.; Szafrańska, A.; Ostrowska-Ligęza, E.; Dariusz, D. Assessment of the starch-amylolytic complex of rye flours by traditional methods and modern one. Materials 2021, 14, 7603. [Google Scholar] [CrossRef] [PubMed]

- Bieniek, A.; Buksa, K. The influence of arabinoxylans on the properties of wheat bread baked using the postponed baking method. Molecules 2024, 29, 904. [Google Scholar] [CrossRef]

- Izydorczyk, M.S.; Biliaderis, C.G. Cereal arabinoxylans: Advances in structure and physicochemical properties. Carbohydr. Polym. 1995, 28, 33–48. [Google Scholar] [CrossRef]

- Cyran, M.; Cygankiewicz, A. Variability in the content of water-extractable and water-unextractable non-starch polysaccharides in rye flour and their relationship to baking quality parameters. Cereal Res. Commun. 2004, 32, 143–150. [Google Scholar] [CrossRef]

- Jaekel, L.Z.; Silva, C.B.; Steel, C.; Change, Y.K. Influence of xylanase addition on the characteristics of loaf bread prepared with white flour or whole grain wheat flour. Cienc. Tecnol. Alime. 2012, 32, 844–849. [Google Scholar] [CrossRef]

- Fadel, A.; Ashworth, J.; Plunkett, A.; Mahmoud, A.M.; Ranneh, Y.; Li, W. Improving the extractability of arabinoxylans and the molecular weight of wheat endosperm using extrusion processing. J. Cereal Sci. 2018, 84, 55–61. [Google Scholar] [CrossRef]

- Cyran, M.R.; Dynkowska, W.M. Mode of endosperm and wholemeal arabinoxylans solubilisation during rye breadmaking: Genotypic diversity in level, substitution degree and macromolecular characteristics. Food Chem. 2014, 145, 356–364. [Google Scholar] [CrossRef] [PubMed]

- Dziki, D. Rye flour and rye bran: New perspectives for use. Processes 2022, 10, 293. [Google Scholar] [CrossRef]

- Cleemput, G.; Roels, S.P.; Van Oort, M.; Grobet, P.J.; Delcour, J.A. Heterogeneity in the structure of water-soluble arabinoxylans in European wheat flour of variable bread-making quality. Cereal Chem. 1993, 70, 324–329. [Google Scholar]

- Biliaderis, C.G.; Izydorczyk, M.S.; Rattan, O. Effect of arabinoxylans on bread-making quality of wheat flours. Food Chem. 1995, 53, 165–171. [Google Scholar] [CrossRef]

- Fabritius, M.; Gates, F.; Salovaara, H.; Auto, K. Structural changes in insoluble cell walls in wholemeal rye doughs. LWT-Food Sci. Technol. 1997, 30, 367–372. [Google Scholar] [CrossRef]

- He, H.; Hoseney, R.C. Gas retention of different cereal flour. Cereal Chem. 1991, 68, 334–336. [Google Scholar]

- Izydorczyk, M.S.; Biliaderis, C.G. Effect of molecular size on physical properties of wheat arabinoxylans. J. Agric. Food Chem. 1992, 40, 581–588. [Google Scholar] [CrossRef]

- Vinkx, C.J.A.; Delcour, J.A. Rye (Secale cereal L.) arabinoxylans: A critical review. J. Cereal Sci. 1996, 24, 1–14. [Google Scholar] [CrossRef]

- Kühn, M.C.; Grosch, W. Baking functionality of reconstituted rye flours having different nonstarchy polysaccharide and starch contents. Cereal Chem. 1989, 66, 149–154. [Google Scholar]

- Bushuk, W. Rye: Production, Chemistry and Technology, 2nd ed.; AACC: St. Paul, MN, USA, 2001. [Google Scholar]

- Stępniewska, S.; Słowik, E.; Cacak-Pietrzak, G.; Romankiewicz, D.; Szafrańska, A.; Dziki, D. Prediction of rye flour baking quality based on parameters of swelling curve. Eur. Food Res. Technol. 2018, 244, 989–997. [Google Scholar] [CrossRef]

- ISO 10520:1997; Native Starch—Determination of Starch Content—Ewers Polarimetric Method. ISO: Geneva, Switzerland, 1997.

- ISO 3093:2009; Wheat, Rye and Their Flours, Durum Wheat and Durum Wheat Semolina—Determination of the Falling Number according to Hagberg-Perten. ISO: Geneva, Switzerland, 2009.

- ISO 7973:1992; Cereals and Milled Cereal Products—Determination of the Viscosity of Flour—Method Using an Amylograph. ISO: Geneva, Switzerland, 1992.

- Hashimoto, S.; Shogren, M.D.; Pomeranz, Y. Cereal pentosans. Their estimation and significance. I. Pentosans in wheat and milled wheat products. Cereal Chem. 1987, 64, 30–34. [Google Scholar]

- Drews, E. Quellkurven von Roggenmahlprodukten. Die Muehle 1971, 108, 723–724. [Google Scholar]

- Michalska, A.; Zieliński, H. Effect of flour extraction rate on bioactive compounds content of two rye varieties. Polish J. Food Nutr. Sci. 2006, 15/56, 297–303. [Google Scholar]

- Gómez, M.; Pardo, J.; Oliete, B.; Caballero, P.A. Effect of the milling process on quality characteristics of rye flour. J. Sci. Food Agric. 2009, 89, 470–476. [Google Scholar] [CrossRef]

- Ratnayake, W.S.; Jackson, D.S. Gelatinization and solubility of corn starch during heating in excess water: New insights. J. Agric. Food Chem. 2006, 54, 3712–3716. [Google Scholar] [CrossRef] [PubMed]

- Blazek, J.; Copeland, L. Pasting and swelling properties of wheat flour and starch in relation to amylose content. Carbohydr. Polym. 2008, 71, 380–387. [Google Scholar] [CrossRef]

- Lin, P.Y.; Czajkowska, Z. Role of phosphorius in viscosity, gelatinization and retrogradation of starch. Cereal Chem. 1998, 75, 705–709. [Google Scholar] [CrossRef]

- Jane, J.; Chen, Y.Y.; Lee, L.F.; McPherson, A.E.; Wong, K.S.; Radosavljevic, M.; Kasemsuwan, T. Effect of amylopectin branch chain length and amylose content on the gelatinization and pasting properties of starch. Cereal Chem. 1999, 76, 629–637. [Google Scholar] [CrossRef]

- Makowska, A.; Szwengiel, A.; Kubiak, P.; Tomaszewska-Gras, J. Characteristics and structure of starch isolated from triticale. Starch-Stärke 2014, 66, 895–902. [Google Scholar] [CrossRef]

- Weipert, D. Processing performance of rye as compared to wheat. Cereal Foods World 1997, 42, 706–712. [Google Scholar]

- Kaur, P.; Sandhu, K.S.; Purewal, S.S.; Bhatia, A. Physicochemical, morphological, thermal, pasting and tablet making properties along with drug releasing potential of rye (Secale cereale) starch: A report broadening its commercial uses. J. Food Meas. Charact. 2023, 17, 1985–1996. [Google Scholar] [CrossRef]

- Fredriksson, H.; Silverio, J.; Andersson, R.; Eliasson, A.-C.; Åman, P. The influence of amylose and amylopectin characteristics on gelatinization and retrogradation properties of different starches. Carbohydr. Polym. 1998, 35, 119–134. [Google Scholar] [CrossRef]

- Elgadir, M.A.; Bakar, J.; Zaidul, R.; Abdul Rahman, R.; Abbas, K.A.; Hashim, D.M.; Karim, R. Thermal behavior of selected starches in presence of other food ingredients studied by differential scanning calorimetery (DSC)—Review. Compr. Rev. Food Sci. Food Saf. 2009, 8, 195–201. [Google Scholar] [CrossRef] [PubMed]

- Sasaki, T. Effect of wheat characteristics on the gelatinization, retrogradation and gelation properties. JARQ 2005, 39, 253–260. [Google Scholar] [CrossRef]

- Liu, H.; Yu, L.; Xie, F.; Chen, L. Gelatinization of corn starch with different amylose/amylopectin content. Carbohydr. Polym. 2006, 65, 357–363. [Google Scholar] [CrossRef]

- Chen, P.; Liu, X.; Zhang, X.; Sangwan, P.; Yu, L. Phase transition of waxy and normal wheat starch granules during gelatinization. Int. J. Polym. Sci. 2015, 2015, 397128. [Google Scholar] [CrossRef]

- Kaur, M.; Singh, N. Studies on functional, thermal and pasting properties of flours from different chickpea (Cicer arietinum L.) cultivars. Food Chem. 2005, 91, 403–411. [Google Scholar] [CrossRef]

- Gomand, S.V.; Verwimp, T.; Goesaert, H.; Delcour, J.A. Structural and physicochemical characterization of rye starch. Carbohydr. Res. 2011, 346, 2727–2735. [Google Scholar] [CrossRef]

- Banu, I. Baking quality of rye flour. Bull. USAMV-CN 2007, 63, 488–492. [Google Scholar] [CrossRef]

- Stępniewska, S.; Hassoon, W.H.; Szafrańska, A.; Cacak-Pietrzak, G.; Dziki, D. Procedures for breadmaking quality assessment of rye wholemeal flour. Foods 2019, 8, 331. [Google Scholar] [CrossRef] [PubMed]

- Tester, R.F.; Sommerville, M.D. The effect of non-starch polysaccharides on the extent of gelatinization, swelling and α-amylase hydrolysis of maize and wheat starches. Food Hydrocoll. 2003, 17, 41–54. [Google Scholar] [CrossRef]

- Arif, S.; Ali, T.M.; Afzal, Q.; Ahmed, M.; Siddiqui, A.J.; Hasnain, A. Effect of pentosans addition on pasting properties of flours of eight hard white spring wheat cultivars. J. Food Sci. Technol. 2014, 51, 1066–1075. [Google Scholar] [CrossRef] [PubMed]

- Harasztos, H.; Balzazs, G.; Csöke, P.N.; D’Amico, S.; Schönlechner, R.; Tömösközi, S. How arabinoxylans modify gluten and starch related wheat flour characteristics. Acta Aliment. 2016, 45, 215–223. [Google Scholar] [CrossRef]

- Santos, D.M.J.; Gama, A.C.; Lopes da Silva, J.A. A rheological study of wheat starch-water-soluble pentosans mixtures under hydrothermal gelling conditions. J. Food Sci. 2002, 67, 3372–3380. [Google Scholar] [CrossRef]

- Grossmann, I.; Koehler, P. Fractionation-reconstitution studies on determine the functional properties of rye flour constituents. J. Cereal Sci. 2016, 70, 1–8. [Google Scholar] [CrossRef]

- Gudmundsson, M.; Eliasson, A.-C. Thermal and viscous of rye starch extracted from different varieties. Cereal Chem. 1991, 68, 172–177. [Google Scholar]

- Revanappa, S.B.; Nandini, C.D.; Salimath, P.V. Structural characterization of pentosans from hemicellulose B of wheat varieties with varying chapatti-making quality. Food Chem. 2010, 119, 27–33. [Google Scholar] [CrossRef]

- Banu, I. The evaluation of the quality rye flours on the basis of the biochemical and rheological indices. J. Agroaliment. Process. Technol. 2006, 12, 291–298. [Google Scholar]

- Czubaszek, A.; Wojciechowicz-Budzisz, A.; Spychaj, R.; Kawka-Rygielska, J. Baking properties of flour and nutritional value of rye bread with brewer’s spent grain. LWT-Food Sci. Technol. 2021, 150, 111955. [Google Scholar] [CrossRef]

- Autio, K.; Flander, L.; Heinonen, R.; Kinnunen, A. Comparison off small and large deformation measurements of whole meal rye doughs. Cereal Chem. 1999, 76, 912–914. [Google Scholar] [CrossRef]

- Cyran, M.R.; Ceglińska, A. Genetic variation in the extract viscosity of rye (Secale cereale L.) bread made from endosperm and wholemeal flour: Impact of high-molecular weight arabinoxylans, starch and protein. J. Sci. Food Agric. 2011, 91, 469–479. [Google Scholar] [CrossRef] [PubMed]

- Hemalatha, M.S.; Manohar, R.S.; Salimath, P.V.; Prasada Rao, U.J.S. Effect of added arabinoxylans isolated from good and poor chapatti making wheat varieties on rheological properties of dough and chapatti making quality. Food Sci. Nutr. 2013, 4, 884–892. [Google Scholar] [CrossRef]

- Autio, K.; Härkönen, H.; Parkkonen, T.; Frigård, T.; Poutanen, K.; Siika-Aho, M.; Åman, P. Effect of purified endo-β-xylanase and endo-β-glucanase on the structural and baking characteristics of rye doughs. LWT-Food Sci. Technol. 1996, 29, 18–27. [Google Scholar] [CrossRef]

- Meeus, Y.; Janssen, F.; Wouters, A.G.B.; Delcour, J.A.; Moldenaers, P. The role of arabinoxylan in determining the non-linear and linear rheology of bread doughs made from blends of wheat (Triticum aestivum L.) and rye (Secale cereale L.) flour. Food Hydrocoll. 2021, 120, 106990. [Google Scholar] [CrossRef]

- Courtin, C.M.; Delcour, J.A. Arabinoxylans and endoxylanases in wheat flour bread making. J. Cereal Sci. 2002, 35, 225–243. [Google Scholar] [CrossRef]

- Li, W.; Hu, H.; Wang, Q.; Brennan, C.S. Molecular features of wheat endosperm arabinoxylans inclusion in functional bread. Foods 2013, 2, 225–237. [Google Scholar] [CrossRef] [PubMed]

- Harris, A.D.; Ramalingam, C. Xylanases and its application in food industry: A review. J. Exp. Sci. 2010, 7, 1–11. [Google Scholar]

- Dornez, E.; Gebruers, K.; Wiame, S.; Delcour, J.A.; Courtin, C.M. Insight into the distribution of arabinoxylans, endoxylanases, and endoxylanases inhibitors in industrial wheat roller mill streams. J. Agric. Food Chem. 2006, 54, 8521–8529. [Google Scholar] [CrossRef]

- Salmenkallio-Marttila, M.; Hovinen, S. Enzyme activities, dietary fibre components and rheological properties of wholemeal flours from rye cultivars grown in Finland. J. Sci. Food Agric. 2005, 85, 1350–1356. [Google Scholar] [CrossRef]

- Pejcz, E.; Spychaj, R.; Gil, Z. Technological methods for reducing the content of fructan in rye bread. Eur. Food Res. Technol. 2020, 246, 1839–1846. [Google Scholar] [CrossRef]

- Buksa, K.; Nowotna, A.; Praznik, W.; Gambuś, H.; Ziobro, R.; Krawontka, J. The role of pentosans and starch in baking of wholemeal rye bread. Food Res. Int. 2010, 43, 2045–2051. [Google Scholar] [CrossRef]

| Ingredient | Quantity |

|---|---|

| Rye flour | 1000 g * |

| Salt | 15 g |

| Yeast | 30 g |

| Lactic acid 88% | 8 cm3 |

| Water | To obtain the appropriate dough yield ** |

| Parameter, Code/Factor | Flour | Interaction | |

|---|---|---|---|

| Type (A) | Year Production (B) | A × B | |

| Parameter related to starch–amylolytic complex | |||

| Starch content, ST | 165.55 ** | 0.49 | 1.08 |

| Falling number, FN | 3.00 | 0.46 | 0.16 |

| Amylograph parameters | |||

| Maximum peak viscosity, APV | 5.07 * | 0.68 | 0.48 |

| Initial temperature, TI | 27.98 ** | 4.96 * | 0.70 |

| Final temperature, TF | 3.76 | 0.00 | 0.06 |

| DSC parameters | |||

| Onset temperature, To | 37.15 ** | 7.17 * | 1.11 |

| Peak temperature, Tp | 43.22 ** | 11.64 ** | 3.28 |

| Conclusion temperature, Tc | 5.46 * | 30.05 ** | 15.55 ** |

| Gelatinization enthalpy, Egel | 3.49 | 7.26 * | 0.77 |

| Parameters related to pentosan content | |||

| Total content, TPC | 152.78 ** | 0.06 | 5.81 * |

| Water insoluble, WSPC | 26.03 ** | 0.53 | 3.25 |

| Water soluble, WIPC | 84.24 ** | 0.20 | 10.23 ** |

| Swelling curve parameters | |||

| Initial viscosity at 30 °C, V30 | 146.23 ** | 0.54 | 0.04 |

| Viscosity at 42 °C, V42 | 93.07 ** | 0.09 | 0.09 |

| Viscosity at 42 °C for 30 min, FV42 | 86.89 ** | 10.01 ** | 0.00 |

| Logarithmic decrease of viscosity at 42 °C, log | 20.67 ** | 59.79 ** | 1.32 |

| Bread quality parameters | |||

| Bread yield, BY | 70.76 ** | 10.17 ** | 3.03 |

| Specific bread volume, SBV | 16.70 ** | 2.26 | 0.14 |

| Bread crumb moisture, BCM | 18.92 ** | 0.88 | 1.60 |

| Hardness after 24 h, CH24 | 17.32 ** | 0.80 | 0.21 |

| Hardness after 72 h, CH72 | 8.44 ** | 0.89 | 0.05 |

| Hardness increase for 48 h, ICM | 10.30 ** | 39.81 ** | 5.15 * |

| Quality Parameter | Range | Flour Type | Year of Production | ||

|---|---|---|---|---|---|

| Low Extract | High Extract | 2019 | 2020 | ||

| Starch content (% d.m.) ST | 52.2–68.7 | 66.4 ± 1.5 a | 55.0 ± 2.7 b | 61.0 ± 5.8 a | 60.4 ± 6.8 a |

| Falling number (s), FN | 200–324 | 242 ± 32 a | 224 ± 14 a | 236 ± 30 a | 230 ± 21 a |

| Amylograph parameters | |||||

| Maximum peak viscosity (AU), APV | 410–940 | 579 ± 144 a | 478 ± 64 b | 510 ± 148 a | 547 ± 88 a |

| Initial temperature of starch gelatinization (°C), TI | 50.5–58.0 | 53.1 ± 0.9 b | 54.7 ± 1.2 a | 54.2 ± 1.0 a | 53.5 ± 1.0 a |

| Final temperature of starch gelatinization (°C), TF | 67.5–83.0 | 72.2 ± 3.7 a | 70.0 ± 1.6 a | 71.1 ± 3.8 a | 71.1 ± 2.1 a |

| DSC parameters | |||||

| Onset temperature of starch gelatinization (°C), To | 56.4–59.8 | 57.1 ± 1.0 b | 58.7 ± 0.7 a | 58.2 ± 0.8 a | 57.5 ± 1.0 a |

| Peak temperature of starch gelatinization (°C), Tp | 57.6–65.3 | 62.7 ± 0.9 b | 64.4 ± 0.5 a | 64.0 ± 0.7 a | 63.1 ± 1.3 a |

| Conclusion temperature of starch gelatinization (°C), Tc | 69.2–76.6 | 72.9 ± 2.4 a | 74.0 ± 1.3 b | 74.7 ±1.2 a | 72.2 ± 1.8 b |

| Gelatinization enthalpy (J·g−1), Egel | 4.7–7.9 | 5.8 ± 0.8 a | 6.4 ± 0.9 b | 5.7 ± 0.8 b | 6.5 ± 0.7 a |

| Quality Parameter | Range | Flour Type | Year of Production | ||

|---|---|---|---|---|---|

| Low Extract | High Extract | 2019 | 2020 | ||

| TPC (% d.m.) | 4.57–9.61 | 5.92 ± 0.62 b | 8.67 ± 0.58 a | 7.26 ± 1.17 a | 7.32 ± 1.82 a |

| WSPC (% d.m.) | 3.14–4.74 | 3.53 ± 0.16 b | 4.17 ± 0.43 a | 3.89 ± 0.48 a | 3.80 ± 0.44 a |

| WIPC (% d.m.) | 0.89–5.29 | 2.38 ± 0.71 b | 4.47 ± 0.62 a | 3.78 ± 0.83 a | 3.48 ± 1.57 a |

| Swelling curve parameters | |||||

| V30 (AU) | 175–700 | 223 ± 34 b | 540 ± 81 a | 391 ± 177 a | 372 ± 180 a |

| V42 (AU) | 145–600 | 191 ± 37 b | 435 ± 76 a | 309 ± 139 a | 317 ± 146 a |

| FV42 | 95–385 | 142 ± 41 b | 280 ± 46 a | 187 ± 75 b | 235 ± 86 a |

| (logV42 − logFV42)·1000 | 41–261 | 136 ± 62 b | 190 ± 48 a | 208 ± 30 a | 117 ± 49 b |

| Quality Parameter | Range | Flour Type | Year of Production | ||

|---|---|---|---|---|---|

| Low Extract | High Extract | 2019 | 2020 | ||

| Bread yield (%) | 145–156 | 148 ± 2 b | 153 ± 2 a | 151 ± 3 b | 149 ± 2 a |

| Specific bread volume (cm3/100 g) | 152–233 | 193 ± 7 a | 171 ± 13 b | 178 ± 12 a | 186 ± 21 a |

| Bread crumb moisture (%) | 45.3–51.0 | 46.4 ± 0.6 b | 48.4 ± 1.5 a | 47.6 ± 1.6 a | 47.2 ± 1.5 a |

| CH24 (N) | 37.8–90.7 | 45.1 ± 5.1 b | 66.1 ± 16 a | 57.9 ± 13.5 a | 53.3 ± 18.1 a |

| CH72 (N) | 54.1–115.0 | 63.1 ± 6.1 b | 79.2 ± 17.8 a | 68.6 ± 9.8 a | 73.8 ± 19.0 a |

| CH72 − CH24 (N) | 3.9–29.0 | 18.0 ± 5.6 a | 13.1 ± 7.4 b | 10.7 ± 5.2 b | 20.4 ± 4.7 a |

| Parameters | FN | TI | APV | To | Egel | TPC | WSPC | WIPC | V30 | V42 | FV42 | Log | BY | SBV | BCM | CH24 | CH72 | ICM |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| SC | NS | −0.634 * | NS | −0.690 * | NS | −0.895 * | −0.734 * | −0.828 * | −0.895 * | −0.871 * | −0.834 * | −0.434 | −0.795 * | 0.676 * | −0.581 * | −0.689 * | −0.584 * | NS |

| FN | NS | 0.761 * | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | |

| TI | −0.447 | 0.824 * | NS | 0.567 * | 0.586 * | 0.562 * | 0.684 * | 0.636 * | 0.510 | 0.592 * | 0.759 * | −0.729 * | 0.474 | 0.611 * | 0.404 | −0.520 * | ||

| APV | NS | NS | −0.429 | NS | −0.454 | NS | NS | NS | NS | NS | NS | NS | NS | NS | NS | |||

| To | NS | 0.671 * | 0.663 * | 0.582 * | 0.786 * | 0.744 * | 0.589 * | 0.714 * | 0.759 * | −0.664 * | 0.592 * | 0.648 * | 0.425 | −0.563 * | ||||

| Egel | NS | NS | NS | NS | NS | NS | NS | NS | NS | 0.435 | NS | NS | NS | |||||

| TPC | 0.674 * | 0.971 * | 0.886 * | 0.861 * | 0.823 * | 0.436 | 0.786 * | −0.660 * | 0.531 * | 0.681 * | 0.615 * | NS | ||||||

| WSPC | 0.485 | 0.852 * | 0.858 * | 0.756 * | 0.516 | 0.610 * | −0.732 * | 0.423 | 0.790 * | 0.642 * | −0.409 | |||||||

| WIPC | 0.773 * | 0.740 * | 0.724 * | NS | 0.737 * | −0.549 * | 0.493 | 0.551 * | 0.521 | NS | ||||||||

| V30 | 0.988 * | 0.909 * | 0.563 * | 0.780 * | −0.746 * | 0.591 * | 0.796 * | 0.658 * | NS | |||||||||

| V42 | 0.951 * | 0.478 | 0.716 * | −0.726 * | 0.535 | 0.792 * | 0.692 * | NS | ||||||||||

| FV42 | NS | 0.599 * | −0.589 * | 0.486 | 0.658 * | 0.662 * | NS | |||||||||||

| Log | 0.562 * | −0.664 * | NS | 0.605 * | NS | −0.743 | ||||||||||||

| BY | −0.636 * | 0.653 * | 0.644 * | 0.425 | −0.552 * | |||||||||||||

| SBV | NS | −0.865 * | −0.737 * | NS | ||||||||||||||

| BCM | NS | NS | −0.495 | |||||||||||||||

| CH24 | 0.905 * | NS | ||||||||||||||||

| CH72 | NS |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Stępniewska, S.; Cacak-Pietrzak, G.; Szafrańska, A.; Ostrowska-Ligęza, E.; Salamon, A.; Kowalska, H. Assessment of the Baking Properties of Rye Flour Based on the Polysaccharide Content and Properties. Appl. Sci. 2024, 14, 2772. https://doi.org/10.3390/app14072772

Stępniewska S, Cacak-Pietrzak G, Szafrańska A, Ostrowska-Ligęza E, Salamon A, Kowalska H. Assessment of the Baking Properties of Rye Flour Based on the Polysaccharide Content and Properties. Applied Sciences. 2024; 14(7):2772. https://doi.org/10.3390/app14072772

Chicago/Turabian StyleStępniewska, Sylwia, Grażyna Cacak-Pietrzak, Anna Szafrańska, Ewa Ostrowska-Ligęza, Agnieszka Salamon, and Hanna Kowalska. 2024. "Assessment of the Baking Properties of Rye Flour Based on the Polysaccharide Content and Properties" Applied Sciences 14, no. 7: 2772. https://doi.org/10.3390/app14072772