Featured Application

Industrial application of temperature control in coal-based exothermic reactions.

Abstract

The control of steam drums, used to remove heat from Fischer–Tropsch synthesis or diethyl oxalate hydrogenation, is confronted with a challenge on controlling quality. The traditional proportional–integral–differential (PID) controllers with fixed parameters are dissatisfying upon deployment. The backward-propagation neural network (BPNN) self-tuning PID control algorithm was thus developed and implemented via a Python and KINGVIEW software combination. Application experiments showed that, in both setpoint control and step change control of the steam drum pressure, static deviation and the maximum error were less with the BPNN self-tuning PID controller, in comparison to the conventional PID controller. Moreover, it seemed that certain adaptations occurred to the nonlinear change in the reaction system, revealing that it was superior to the traditional PID controller. It is shown that the backward-propagation neural network will improve the control quality in boiling water drum systems for exothermic reactions. It can be predicted that the backward-propagation neural network is qualified for process condition control in the chemical industry.

1. Introduction

Exothermic catalytic reactions, such as Fischer–Tropsch synthesis (FTS) [1,2,3,4] and diethyl oxalate hydrogenation [5,6,7,8], have an important position in syngas conversion, which is primary to the utilization of biomass or coal resources. Diethyl oxalate hydrogenation and FTS are both strong exothermic reactions and the addition of hydrogen atoms to the molecule usually leads to the release of heat during the process. According to the previous study, the thermodynamic view reveals that FTS product deviation from ASF distribution occurs because the industrial FTS process is not generally in equilibrium except for only a few reactions, for example, the water–gas shift. However, according to thermodynamic analysis, the increase in temperature favors the hydrocarbon formation of short-chain, lower degree of unsaturation, or containing fewer oxygen atoms products, since the negative enthalpy change and Gibbs energy of all the FTS exothermic reactions in industrial conditions has a linear relationship with temperature [9]. Hence, the reaction temperature of FTS has a huge impact on the thermodynamically allowed products [10,11], which makes temperature control so crucial in this kind of chemical process.

From a kinetic point of view, exothermic reaction heat is beneficial to accelerate the reaction rate, though over-increasing the temperature may be detrimental to the exothermic reaction, namely the poor control of autogenous heat will lead to “T runaway” and make a mess of the process. Given the complex reaction characteristics of diethyl oxalate hydrogenation and FTS, the produced heats need to be removed promptly to avoid the buildup of heat and runaway of temperature in reactors. Therefore, the optimization of the process and improvement in operating conditions in the technical route of diethyl oxalate hydrogenation or FTS have been the focus of many researchers [5,7]. Moreover, their product contribution is sensitive to reaction temperature [3,12], which means large temperature fluctuations can negatively affect the yields of target products. To ensure the catalyst durability, guarantee thermo-mechanical reliability of the entire process, and dominate the product distribution, temperature fine control is particularly significant. Notably, some new materials have been tried to address the temperature control problem. For example, Ademola and Tadhg et al. used encapsulated phase change material (PCM) to optimize the thermal transmission of FTS reactors, possessing a shift in the C5+ selectivity [13]. However, these new materials cannot be economically utilized in industrial devices due to the difficulty of universal adaptation and the high cost. The intelligent control of coal-based exothermic reactions, especially the artificial intelligent control of temperature, is of great significance in scientific research and practical application.

Nevertheless, the heat generation rule is rather different and the enthalpy released from the exothermic reaction is an exponential function of temperature (Arrhenius principle), causing the temperature fluctuation in the reaction zone. It is urgent to improve temperature control accuracy. Fixed beds and slurry beds are common reactors used in the current industrial diethyl oxalate hydrogenation and FTS process; the temperature of fixed-bed reactors is generally controlled in the pressurized circulating boiling water system by adjusting the pressure of the steam drum. In essence, the steam generation of a reactor is like a steam boiler in a power plant. In the current production and simulation system, compared with the cooling method of cooling water heat transfer, the use of pressurized water for heat transfer is more conducive to the temperature of the reactor reaching a stable value and is conducive to improving the grade of energy utilization. Conventional steam drum control is a three-element controller generally deployed with PID controllers: feed-water flow, process level, and vapor flow [14]. PID control remains the majority of all control loops over decades and in decades to come in industrial process control because of its simple structure, easy implementation, and effective control of some industrial objects or processes. However, there are some limitations of conventional PID control [15]: (1) it is difficult to establish an accurate mathematical model when the controlled object has complex nonlinear characteristics; (2) the parameters of the controlled system in the industrial process control are unknown; and (3) the time-varying phenomenon of parameters or the non-negligible existence of random disturbances led by the changes in raw materials, environment, and working conditions raise considerable hardness for conventional PID control to carry out online parameter tuning, which is studied under the premise that the controlled object is linear. Hence, more sophisticated controlling strategies with error detection and abnormal behavior are urgently required to solve the problems including great inertia, long time delay, and strong nonlinearity in drum control.

Several advanced control strategies have been applied to steam generators in the serial communication industry to realize system health monitoring. Based on the triumph of intelligent control theory, the PID can be refined in various ways, like IMC (internal model control), DMC (dynamic matrix control), MPC (model predictive control), and fuzzy logic. Enrique Arriaga-de-Valle et al. [16] compared and discussed the performance of a boiler evaporator system controlled by a traditional PID strategy and fuzzy logic block, which brings some advantages to the previous three-element boiler feed–water controller; likewise, Mehmet [17] and Min Xu [14] acquired an improvement over the boiler drum level controller by embedding a cascade model predictive control scheme.

However, not all the prevalent smart control methods are suitable for drum pressure control. Generally, for real-world control problems, phenomenological and empirical models, like the IMC and MPC mentioned above, are available and the selection of these two categories is concerned mainly with the practical problems approached, available technology, and the goal of the simulations. These two models are based on the fundamental theory and simplification of a chemical process, which makes it difficult to develop an accurate model quantifying the phenomenology of unknown or partially unknown parameters. Moreover, numerous experimental records desired for expertise database establishment of expert control and rules determination of fuzzy control confines their implementation in the chemical control system, in spite of the fact that modeling of the controlled object is not demanded in these two control schemes. In this context, a neural network [18,19,20,21,22], capable of learning and adapting and thus providing good models, is a recommended tool, which is useful in the frequently encountered cases when researchers do not fully know the laws that govern the systems. In neural network modeling, there is no need for a good understanding of the process’s internal laws, like a “black box” [23]. Neural networks [24] with good modeling capabilities have been widespread in chemical processes and the applications will increase broadly and continuously, such as sensor data analysis, fault detection, and nonlinear process identification. Three different types of neural networks (MLP, recurrent, and probabilistic) are applied by Banjanovic [25] to solve the problem of anomaly detection, confirming that neural network-based data-driven modeling has the potential to be integrated into real-time health monitoring systems of thermal power plants. Xiaocen Xue [26] utilized a radial basis function neural network (RBFNN) for the FTS slurry reactor control and modeling, successfully predicting the reactor temperature. Favorable control equality was reached by the introduction of a neural network and different air–water loop configurations as well [27,28,29]. In addition, the neural network is an integral part of predictive control, inverse-model-based control, and adaptive control methods [24].

The goal of the research is to build a backward-propagation neural network-based PID controller that will be used to solve the control challenge of a coal-based exothermic reaction, for instance, diethyl oxalate hydrogenation or FTS; on the basis of the status of the steam drum control layout, the smart control theories were recommended to address the drum control in diethyl oxalate hydrogenation. We make an attempt in this paper to apply a neural network to the simulation of steam heat transition in a designed fixed-bed reactor system. The control process is performed via the SIEMENS Module, KINGVIEW 6.6 SP2 and Python 3.7.0 software, and executive devices. Still, the PID controller and OPC technique also settled the foundation of the theory of this paper.

2. The Pressure Control Configurations Design

This section is involved in the design of a fixed bed reactor experimental device with pressurized circulating water. The device is based on the understanding of traditional PID controllers and neural network self-tuning PID control algorithms.

2.1. The PID Control Mechanism with a Backward-Propagation Neural Network

The principle of traditional PID controllers, especially the control principle of digital PID, is deeply studied and analyzed. The digital PID is divided into position PID and incremental PID. It can be seen that the control output of position PID is related to the calculation results of each step and the previous results need to be accumulated. However, it has a great influence on the subsequent calculation results and the calculation amount is large when the previous calculation results have errors. However, the control output of each step for incremental PID is only related to the calculation results of the previous step. The previous disoperation has little effect on the subsequent calculation results and the calculation amount is smaller than that of the position PID control. The incremental PID is picked in this paper.

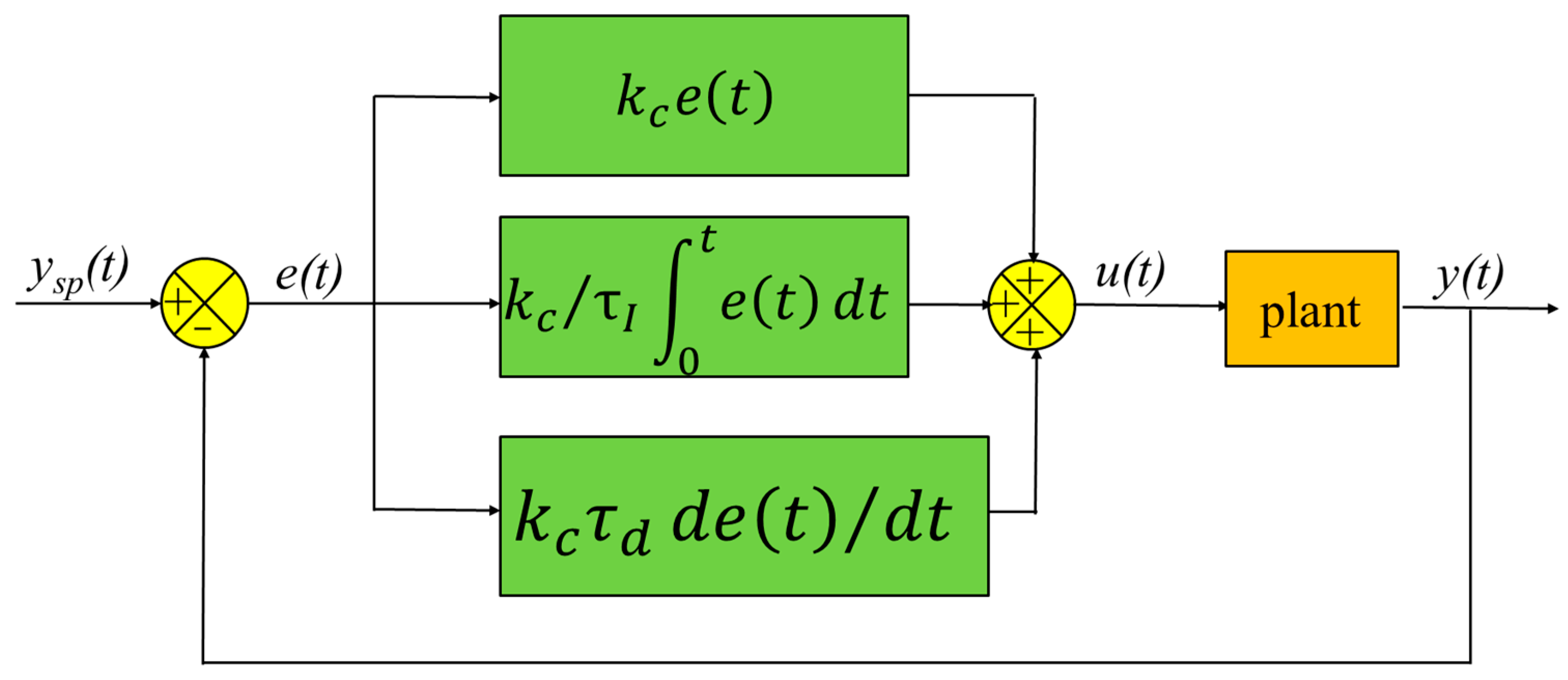

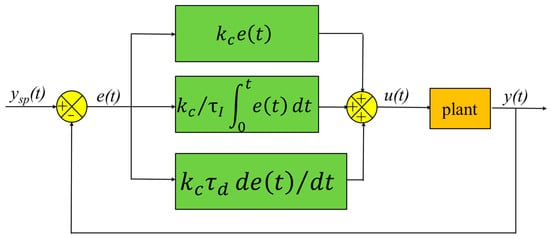

The incremental ubiquitous PID algorithm (shown in Figure 1) we adopted is as Equations (1) and (2), whereas the ysp(t) = process value of the controlled variable, y(t) = setting value of the controlled variable, e(t) = real-time error, u0 = initial output, kc = the proportional coefficient, τI = integral time constant, and τd = derivative time constant. As a kind of sampling control, sampling and processing of computer control proceeds at short intervals; thus, continuous PID algorithms cannot be applied in actual control system before discretization. Incremental digital PID algorithms focus on the augmentation of the last controlled variable, which reduces negative effects of the past maloperation. The incremental PID algorithms are depicted as in Equation (3), where k = the sampling instant.

Figure 1.

The structure of the PID algorithm (“+” and ”−” is the sign of operation).

At the same time, aiming at the tuning method of PID parameters, we analyze the structure and principle of neural network control algorithm and take the BP neural network control algorithm as the PID parameter tuning method in this paper, in order to improve the control quality of PID to drum pressure, so as to improve the temperature control accuracy of the Fischer–Tropsch synthesis reactor.

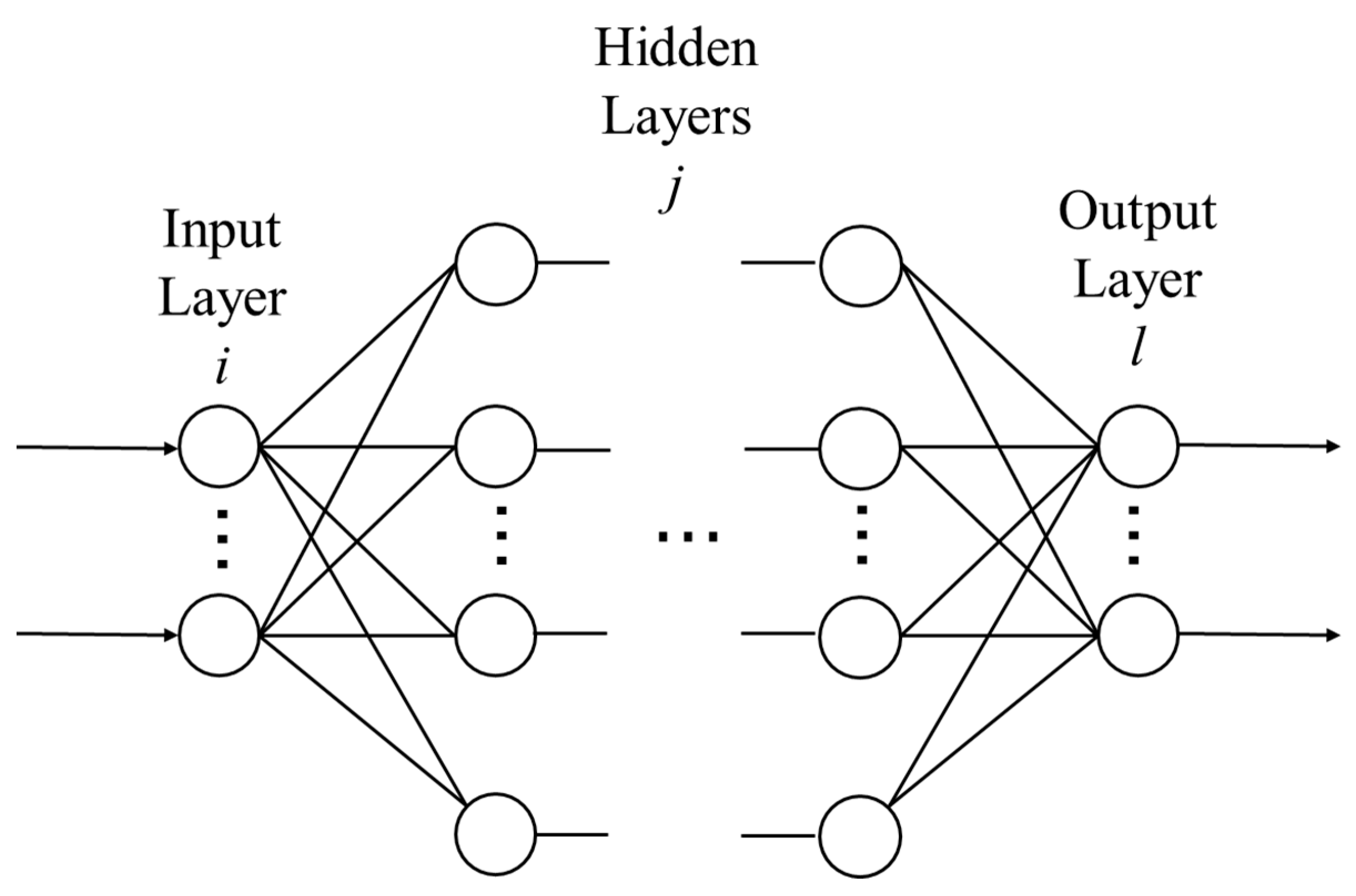

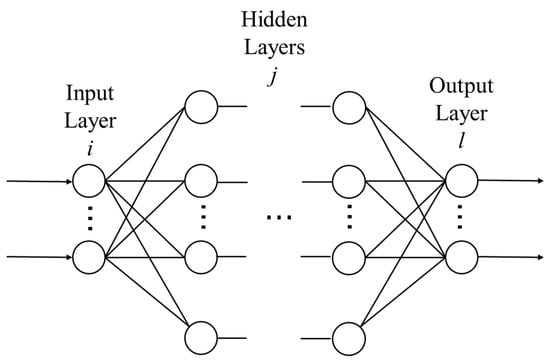

The backward-propagation neural network (BPNN) has excellent capacity of self-learning, self-tuning, self-adaptation, and paralleled distributed processing, robustness, and fault tolerance, which can deal with complicated nonlinear control systems. There are three-layer (or more) neurons in the backward-propagation neural network (BPNN, as is Figure 2), including the inter-connected but inner-unconnected input layer, hidden layers, and output layers. The neuron activation values of the input layer are transmitted from the input layer to the output layer through hidden layers, the neurons of output layer capturing the input response; this procedure is referred to as forward information transmitting. If the actual output of the network does not fall within the expected error range, the error in the output is used as feedback sent from the output layer to the input layer in the reverse direction to adjust the connection weights at the neurons/nodes in each layer; this procedure is referred to as backward error correction transmission or backward propagation. With this kind of backward error correction transmission ongoing, the precision of network response to input information continuously rises [30,31].

Figure 2.

The structure of the BP neural network (i, j and l are used for marking the input layer, hidden layers and output layer respectively).

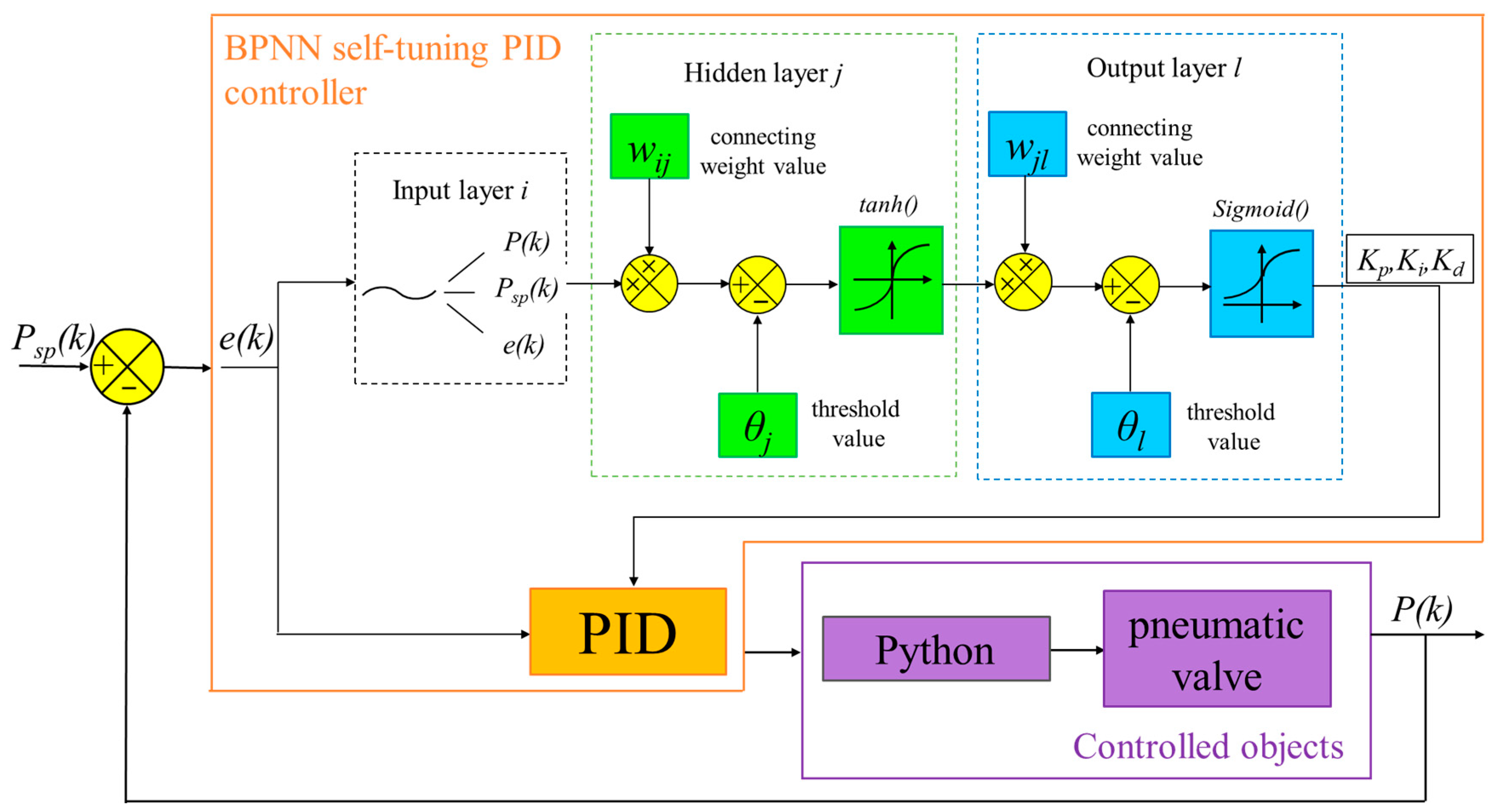

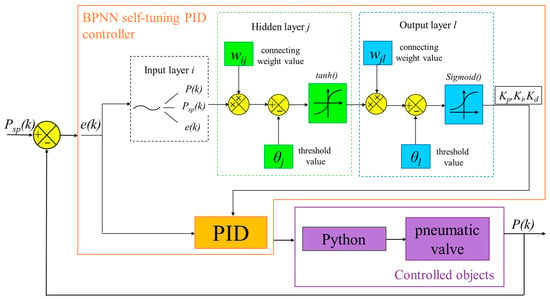

The detail of the BPNN self-tuning PID controller is described in Figure 3. After setpoint Psp(k), process value P(k) and control deviation e(k) are entered and BPNN control algorithms are used to self-adjust Kp, Ki, and Kd online. Self-tuned parameters are assigned to input incremental PID algorithms; hence, drum pressure control with the PID controller is realized.

Figure 3.

The control loop configuration of a BPNN self-tuning PID controller (“+”, ”−” and ”×” is the sign of operation).

2.2. Practical Impletion of the PID Controller with BPNN Self-Tuning

In order to realize the traditional PID and BP neural network self-tuning PID controller to control things, it is necessary to complete the traditional PID and BP neural network self-tuning PID program in Python; through the data exchange between Python and KINGVIEW, the data exchange between the two software is realized. At the same time, the communication between the host computer and other hardware in the control system is realized by means of KINGVIEW.

Hardware connection and software communication came first in controller impletion. The pressure sensors were connected physically to the PC via the SIEMENS gathering module, which is packed with Python. Then, the SIEMENS output module linked up the PC and pneumatic valve, delivering an actuating signal from Python.

Communication between Python and KINGVIEW is faced with a tough challenge, some other data exchange agreements have been employed, for example, the dynamic data exchange (DDE) method. The object linking and embedding (OLE) for process control (OPC) technology brings a broad communication opportunity among industrial devices, control systems, and management software and it acts as the common interface for mutual communication of the various types of data from technological processes [32,33,34,35]. OPC technology consists of servers and clients and clients are able to take real-time information from servers and respond in time, which is convenient and simple.

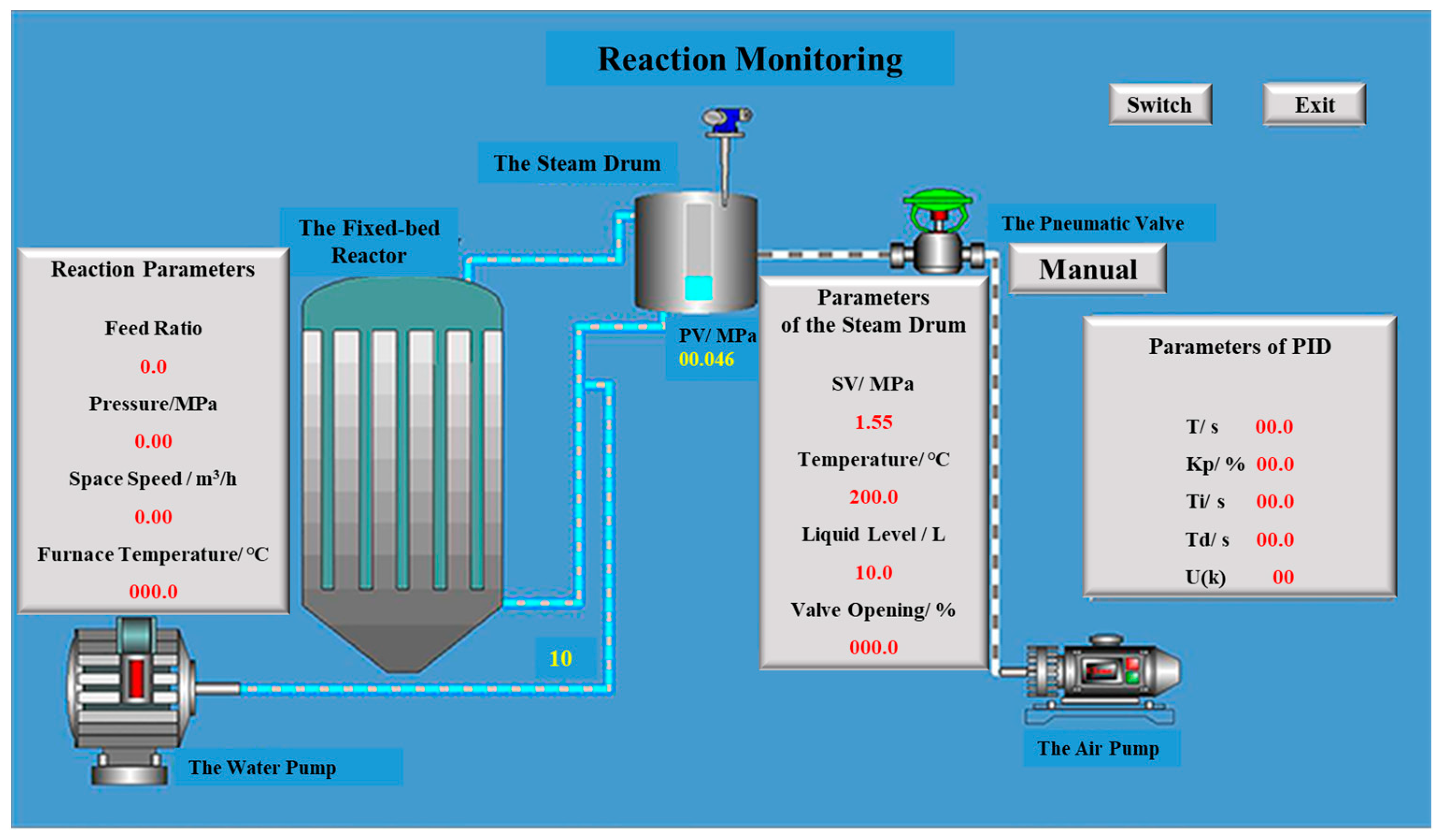

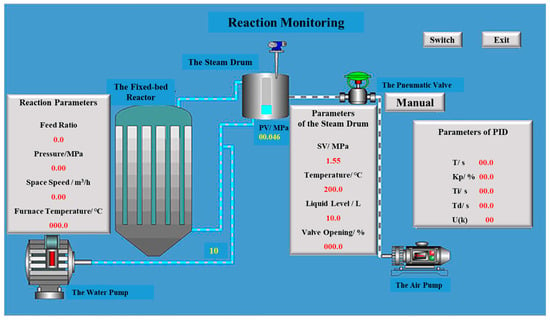

KINGVIEW software, the OPC client, serves as monitoring information for reactors and heat exchange systems. As shown in Figure 4, we set variables in KINGVIEW corresponding to different status parameters, such as the pressure and liquid level of the steam drum, several control factors of the PID algorithm, and buttons sending instructions to the valve. Circumstances on the other end of OPC communication are much harder due to the flexibility of Python, which reversely accounts for the fact that we use Python for related programming and PID calculation rather than KINGVIEW. In Python, the OPC server, connection to KINGVIEW, can be accomplished through the program codes. The algorithm programs of conventional PID and BPNN self-tuning PID are also completed in Python (see the Supplementary Materials).

Figure 4.

The schematic diagram of the control layout design in KINGVIEW.

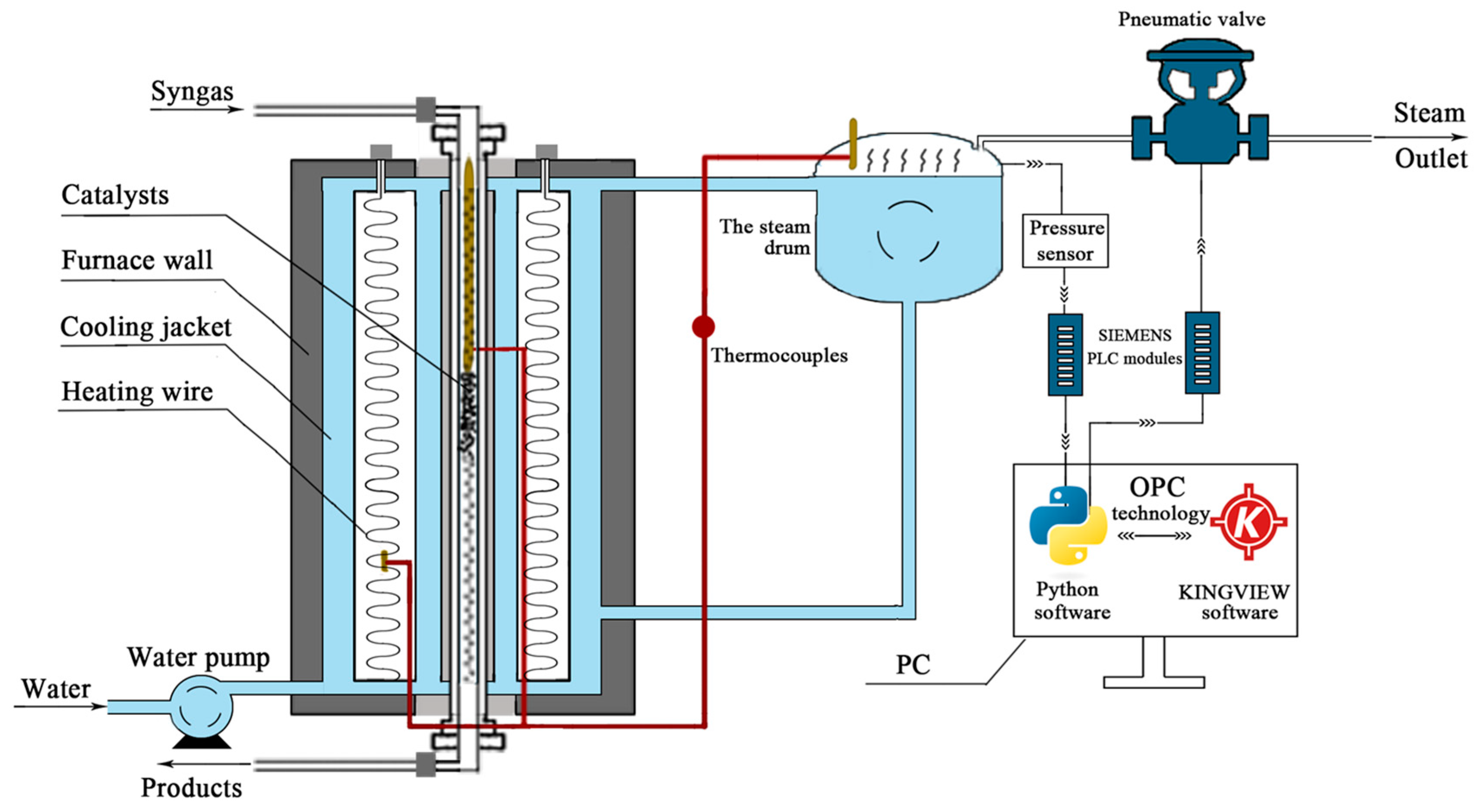

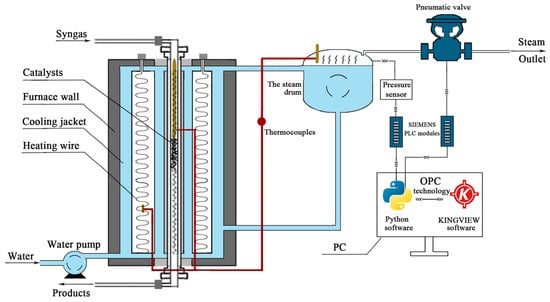

2.3. Pressure Control System

Because the existing fixed bed reactor in the laboratory has a small amount of catalyst loading and limited reaction heat production, it is difficult to meet the needs of this experiment, so it is necessary to design a reactor close to practical production. A water jacket encircled the fixed-bed reactor, which is extensively applied in chemical catalytic reactions conduction [14,15,24,36], especially the diethyl oxalate hydrogenation and FTS, is designed and constructed (Figure 5), with pressurized circulating water with a steam drum serving as the heat exchange medium. A stainless-steel tube for the thermocouple is put in the middle of the fixed bed reactor and the determination of the temperature at different positions of the reactor can be realized by adjusting the height of the thermocouple in the reactor. Thermocouples are also installed at the inlet and outlet of the electric heating furnace, steam drum, and reactor to monitor the temperature at the corresponding position. The circulating steam–water mixture is pressurized into the jacket by entering a drum with an inner diameter of 300 mm and a height of 500 mm. Thermal insulation cotton is wrapped around the electric heating furnace, water circulation pipeline, and steam drum to reduce heat loss. An electric heating wire with a power of 2000 W is installed on the periphery of the water jacket.

Figure 5.

The schematic diagram of fixed-bed reactor control configurations.

Having analyzed the heat transfer characteristics of FTS, we employed an electrically heated furnace of the fixed-bed reactor as a simulation of reaction exotherm, inspecting the control equality of the PID controller with fixed and BPNN auto-tuning parameters. Our control configuration consists of a PC and basic controllers, such as a pressure sensor (PS), PLC, and pneumatic valve with electrical regulators. By the programmed PLC-data reading function, Python captures the real-time steam-drum pressure signal from the sensor via the SIEMENS PLC analog-input module. The pressure data is reported and displayed in KINGVIEW by the OPC technology between Python and KINGVIEW. Next, Python carries out PID calculations based on the setting parameters of KINGVIEW and delivers control signals to the SIEMENS PLC analog-output module successively and the pneumatic valve lastly, which is turned up when the measured pressure of the drum is above the setpoint. Thereupon, drum pressure remains stable, as well as the temperature of the drum and reactor.

3. Result and Discussion of the Simulation Study

To test the control quality of the BPNN self-tuning PID controller, we conducted a series of experiments, including setpoint tracking for drum pressure and the response to large variations in setpoint. Otherwise, the wattage of the electrically heated furnace was altered to promote system disturbance, aimed at examining the performance of constant value control. All the experiments above are for the purpose of accumulating profound basic applications.

Distinguished from traditional PID controllers with empirical fixed arguments, the biggest advantage of BPNN lies in the correction of PID parameters without delay. The initial value of the PID control algorithm is not important because the goal of the PID controller is to maintain stability between a given input and a set value. To increase experimental significance, at the beginning of experiments by the attenuation curve method, we adjusted the coefficients to the appropriate level (Kp = 10, Ki = 100, Kd = 50) according to the previous setting value in our lab, which are usually determined by a trial-and-error method and can also be adjusted by experience of informed experts and PID tuning software.

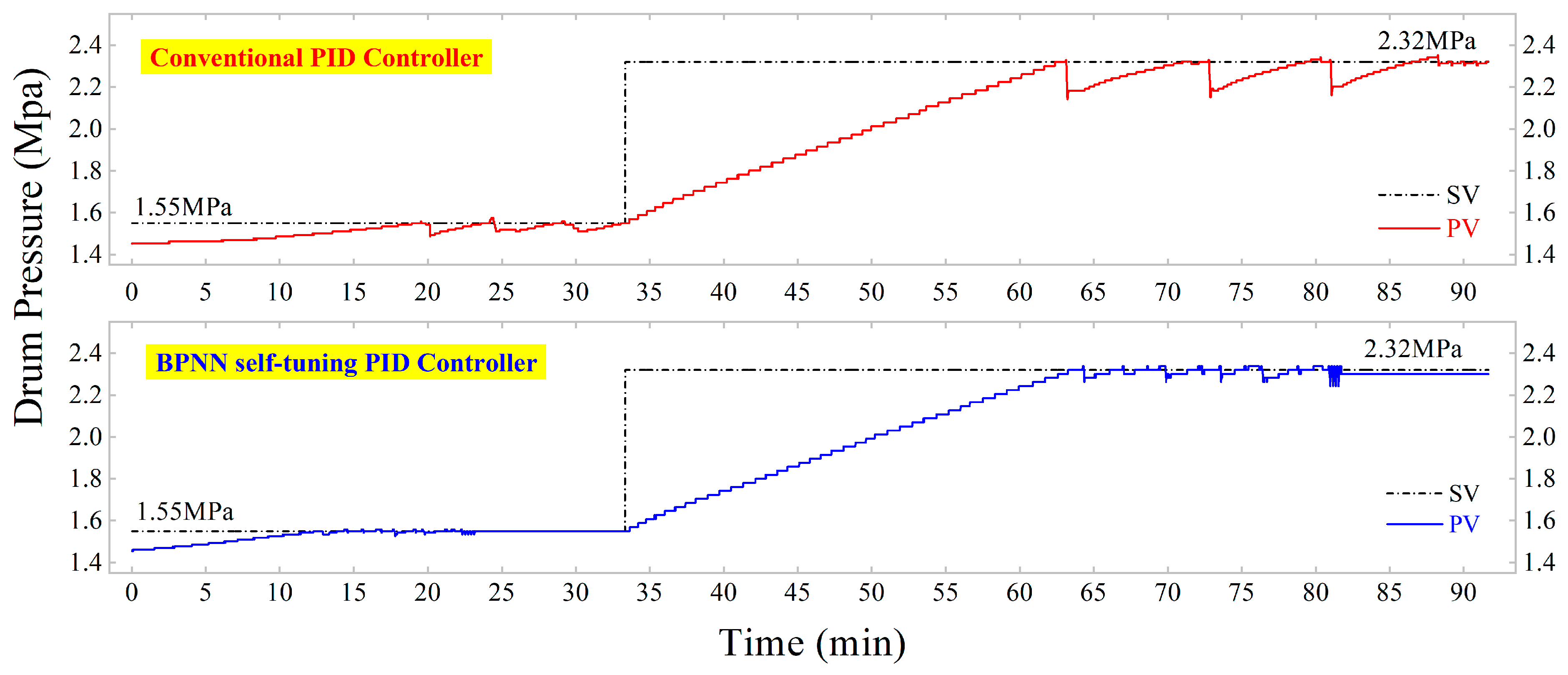

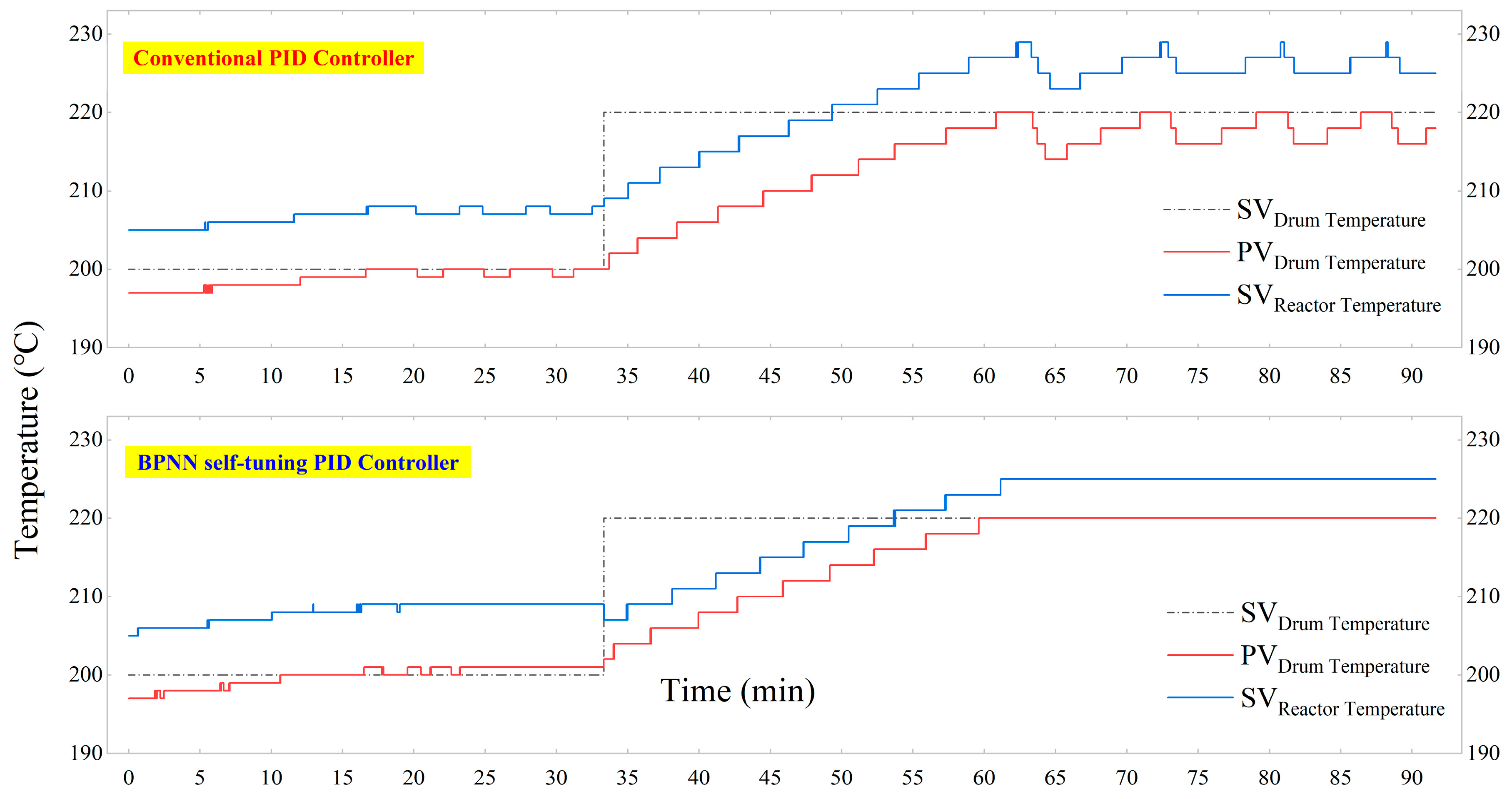

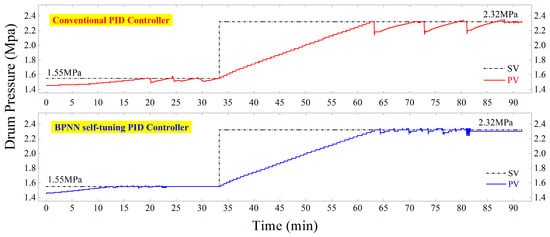

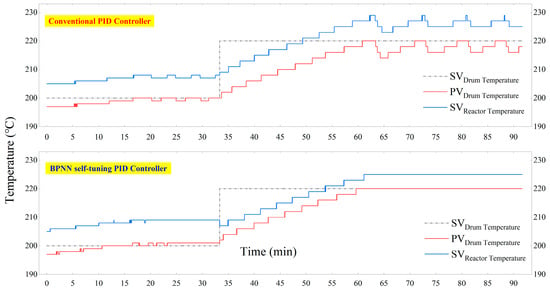

3.1. Setpoint Tracking of the PID Pressure Control

In general, only constant setpoint control tests are performed to inspect system stability. However, the FTS reactor system is nonlinear and time-varying, thus the pressure setpoint is supposed to be shifted in a wide range to verify the response power of the control system. The initial pressure value of the setpoint tracking tests was 1.55 MPa, reset to 2.32 MPa a while after the pressure settled out; corresponding water boiling points of 200 °C and 220 °C are eligible for heterogeneous reaction, such as FTS and diethyl oxalate hydrogenation. The two-kind-PID-controlled drum pressure, drum temperature, and reactor temperature were recorded in real-time in KINGVIEW as Figure 6 and Figure 7. Both dynamic and steady-state controls were researched in this study.

Figure 6.

The real-time curves of drum pressure control over two controllers.

Figure 7.

The real-time curves of drum and reactor temperature over two controllers.

As Figure 6 represents, the static misalignment of conventional PID is −0.1 MPa~+0.01 MPa as we set 1.55 MPa, much more than that of BPNN self-tuned PID, −0.03 MPa~+0.01 MPa. Having adjusted the pressure set value to 2.32 MPa later, the former static error of PID grew between −0.15 MPa and +0.01 MPa, BPNN self-tuning PID remaining unchanged though. Consequently, the fixed value control performance of BPNN self-tuned PID controllers is significantly superior to traditional ones. The step change from 1.55 MPa to 2.32 MPa, embodiment of strong nonlinearity and time-varying nature, enabled BPNN self-tuning PID controllers to display the control power well, which has shown better robust ability.

Simultaneously, we also observed the real-time temperature alteration of the steam drum as shown in Figure 7. The BPNN self-tuning drum temperature held a steady and final short swing of less than 1 °C (as opposed to more than 3 °C in conventional PID control) due to the powerful pressure control; the temperature with altered pressure stayed constant and had no residuals, which proved a stronger control quality of BPNN. During the control process of BPNN, continual readjustment of the PID parameters allowed greater adaptability to the system instability. Along with tended stable pressure, the PID factors converged to the actual definite value through end-to-end adaptive tuning.

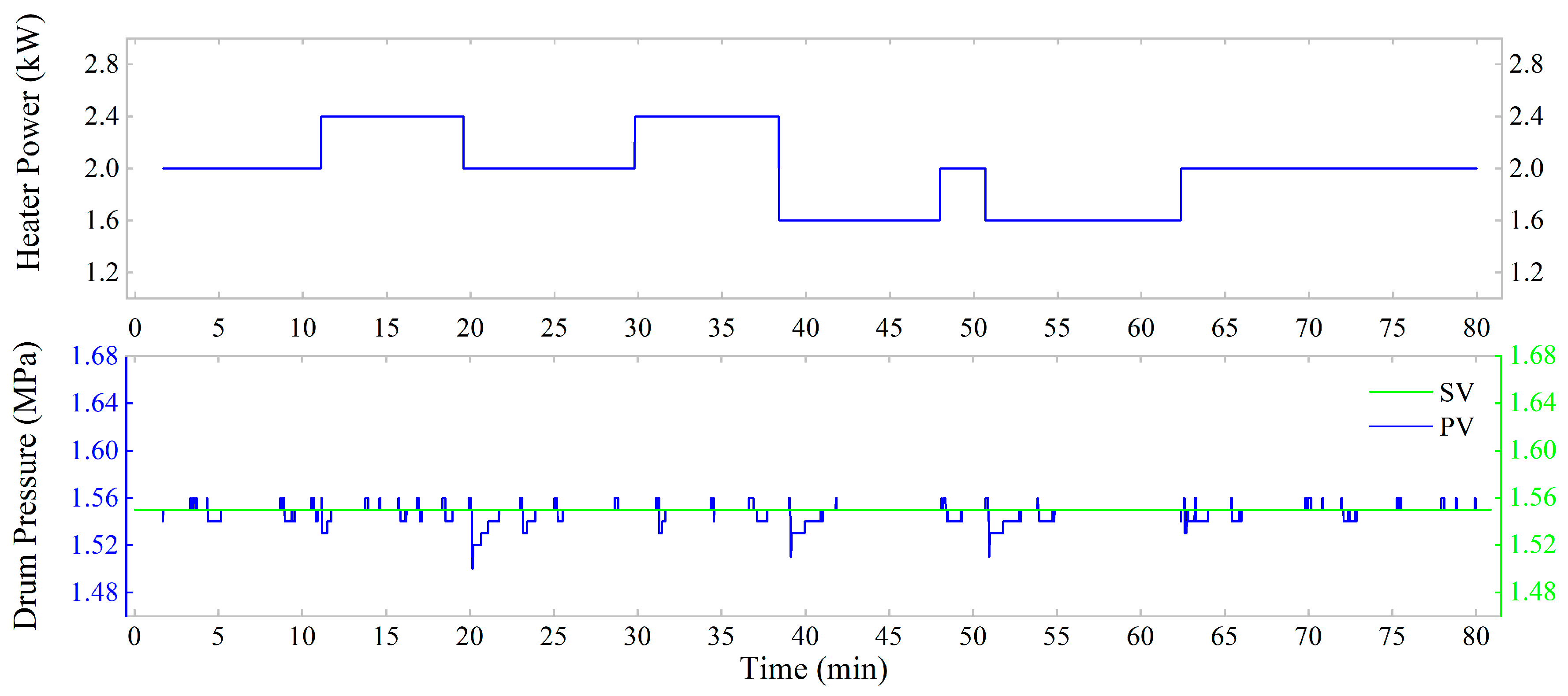

3.2. The Resistance to System Disturbance of BPNN Self-Tuning PID Controller

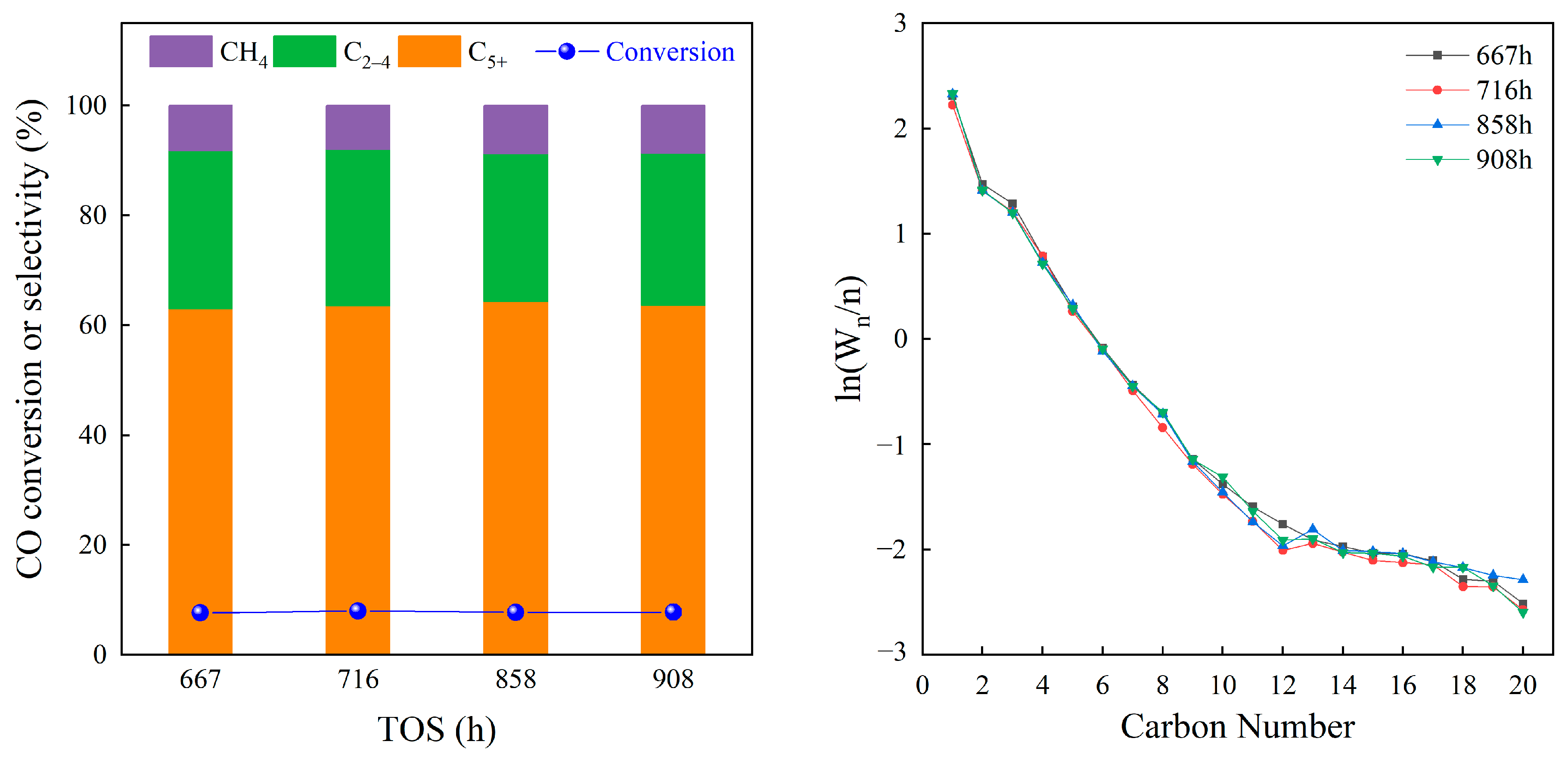

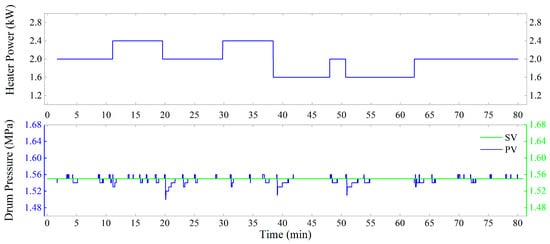

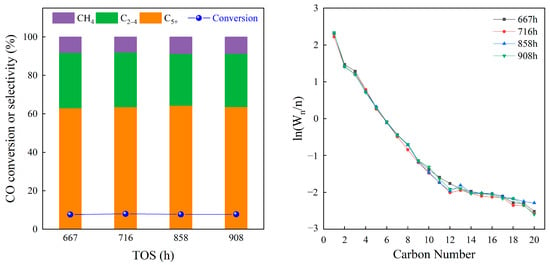

Lots of process conditions can upset the diethyl oxalate hydrogenation and FTS reactor system [37,38], including fluctuation in flow rate, the feed ratio, and the failure of recycling. Those will lead to hotspot shifts and heat rises and falls. In this study, the heat power was regulated from time to time as a simulation of system disturbance; the control quality and adaptive ability remain to be further seen in Figure 8, which demonstrated a tracking response to furnace power of BPNN self-tuned controller when the drum pressure setpoint was 1.55 MPa. Obvious deviations could be observed between the measured and setting pressures of the drum each time system turbulence arose. BPNN self-tuning parameters led to smooth control, short response time in the transient process, and little error, which moreover highlighted great adaptability. A case of FTS product distribution of TOS (time on stream) = 667–908 h over an iron-based catalyst is shown in Figure 9 when the BPNN self-tuning PID controller is employed in the fixed-bed reactor of this paper. It can be observed that the catalyst activity and product selectivity are particularly stable after the reaction lasts for a long time. Other than this case, the BPNN self-tuning PID controller is also effectively applied to several research works of colleagues, such as the evaluation of the Mn-Fe/ZrO2 FTS catalyst [39] and Ni catalysts for the hydrogenation of diethyl oxalate [40].

Figure 8.

BPNN self-tuning PID controller real-time curves when altering heater power.

Figure 9.

The product distribution of FTS using BPNN self-tuning PID controllers.

4. Conclusions

A steam boiler pressure controller is designed on the basis of BPNN-PID strategy using Python and KINGVIEW software in order to tackle the notorious exothermic reactions like FTS or oxalate hydrogenation. We carried out a series of control experiments of the steam drum in a fixed-bed reactor, employing two kinds of PID controllers, showing great improvement in control quality with the BPNN self-tuning controller.

Firstly, when pressure setpoints were shifted in a wide range from 1.55 MPa to 2.32 MPa, upon the emulation of large time-varying nonlinearity in practical reaction processes, such as diethyl oxalate hydrogenation and FTS, better control results were attained within BPNN by adjusting PID parameters online to match up the system uncertainty, which the conventional PID controller failed to do so. Varying with pressure, the BPNN-controlled drum temperature also responded instantly and was more stable and this could herald the quick stabilization of reactor temperature in future applications.

Next, considering the presence of disturbance in the practical temperature-control process, simulated adaptive experiments of system fluctuation were performed by changing the power of generating heat. BPNN self-tuning controller showed short disorder time, little static error, and effective control. The desired product distribution of diethyl oxalate hydrogenation and FTS can also be predictably obtained.

For the purpose of precise control of fixed-bed reactors, we developed the BPNN self-tuning controller, which showed excellent control performance. BPNN algorithms can make online adjustments to compensate for time-varying research variables, revealing better adaptivity to nonlinear chemical reactions; further application of BPNN can be predicted in the industrial process of diethyl oxalate hydrogenation process and FTS. However, BPNN also carries deficiency in itself (noticeably less theoretical support on selecting hidden layer numbers) and forecasting reactions is also strained for BPNN. In addition to BPNN, a prediction mechanism can be brought in modeling the reactors for diethyl oxalate hydrogenation and FTS, boosting the control accuracy of exothermic reactions.

Supplementary Materials

The following supporting information can be downloaded at: https://www.mdpi.com/article/10.3390/app14073052/s1.

Author Contributions

Conceptualization, J.C.; Methodology, J.L.; Software, Z.Z.; Formal analysis, J.L.; Investigation, J.L.; Data curation, J.L.; Writing—original draft, J.L.; Supervision, J.C. and J.Z.; Project administration, J.C.; Funding acquisition, J.C. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the National Key Research and Development Program of China (No. 2023YFB4103304), with special thanks to the Chinese Academy of Sciences Strategic Pioneer Special Fund for a grant to support in situ experiments (XDA29030402).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The raw data supporting the conclusions of this article will be made available by the authors upon request.

Acknowledgments

All of the authors would like to thank Liang Wen and Zhikui Jiang for the cooperation between the Institute of Coal Chemistry and the China Shenhua Coal to Liquid Chemical Co., Ltd. (Beijing, China).

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Stamenic, M.; Dikic, V.; Mandic, M.; Todic, B.; Bukur, D.B.; Nikacevic, N.M. Multiscale and Multiphase Model of Fixed-Bed Reactors for Fischer-Tropsch Synthesis: Optimization Study. Ind. Eng. Chem. Res. 2018, 57, 3149–3162. [Google Scholar] [CrossRef]

- Todic, B.; Ma, W.P.; Jacobs, G.; Davis, B.H.; Bukur, D.B. Effect of process conditions on the product distribution of Fischer-Tropsch synthesis over a Re-promoted cobalt-alumina catalyst using a stirred tank slurry reactor. J. Catal. 2014, 311, 325–338. [Google Scholar] [CrossRef]

- Van der Laan, G.P.; Beenackers, A. Kinetics and selectivity of the Fischer-Tropsch synthesis: A literature review. Catal. Rev.-Sci. Eng. 1999, 41, 255–318. [Google Scholar] [CrossRef]

- Okeson, T.J.; Keyvanloo, K.; Lawson, J.S.; Argyle, M.D.; Hecker, W.C. On the kinetics and mechanism of Fischer Tropsch synthesis on a highly active iron catalyst supported on silica-stabilized alumina. Catal. Today 2016, 261, 67–74. [Google Scholar] [CrossRef]

- Rohman, F.S.; Muhammad, D.; Zahan, K.A.; Aziz, N.; Murat, M.N. Differential Evolution-Based Optimization in Dimethyl Oxalate Hydrogenation. Chem. Eng. Technol. 2023, 46, 2487–2496. [Google Scholar] [CrossRef]

- Yin, S.; Zhu, L.J.; Wang, X.L.; Liu, Y.Y.; Wang, S.R. The influence mechanism of solvent on the hydrogenation of dimethyl oxalate. Chin. J. Chem. Eng. 2019, 27, 386–390. [Google Scholar] [CrossRef]

- Li, S.M.; Wang, Y.; Zhang, J.; Wang, S.P.; Xu, Y.; Zhao, Y.J.; Ma, X.B. Kinetics Study of Hydrogenation of Dimethyl Oxalate over Cu/SiO2 Catalyst. Ind. Eng. Chem. Res. 2015, 54, 1243–1250. [Google Scholar] [CrossRef]

- Rohman, F.S.; Sulaiman, S.H.S.; Aziz, N. Modelling and simulation of hydrogenation of dimethyl oxalate in ethylene glycol production. In Proceedings of the 5th International Conference of Chemical Engineering and Industrial Biotechnology (ICCEIB), City Univ Hong Kong, ELECTR NETWORK, Kuala Lumpur, Malaysia, 9–11 August 2020. [Google Scholar]

- Marques, F.H.; Guirardello, R. Gibbs energy minimization with cubic equation of state and Henry’s law to calculate thermodynamic equilibrium of Fischer-Tropsch synthesis. Fluid. Phase Equilibr. 2019, 502, 112290. [Google Scholar] [CrossRef]

- Zhu, H.-K.; Song, G.-L.; Li, Z.-H. Computational study on thermodynamic properties of Fischer-Tropsch synthesis process. Chin. J. Chem. Phys. 2019, 32, 586–596. [Google Scholar] [CrossRef]

- Lu, X.J.; Hildebrandt, D.; Liu, X.Y.; Glasser, D. A Thermodynamic Approach to Olefin Product Distribution in Fischer-Tropsch Synthesis. Ind. Eng. Chem. Res. 2012, 51, 16544–16551. [Google Scholar] [CrossRef]

- Todic, B.; Nowicki, L.; Nikacevic, N.; Bukur, D.B. Fischer-Tropsch synthesis product selectivity over an industrial iron-based catalyst: Effect of process conditions. Catal. Today 2016, 261, 28–39. [Google Scholar] [CrossRef]

- Odunsi, A.O.; O’Donovan, T.S.; Reay, D.A. Temperature stabilisation in Fischer–Tropsch reactors using phase change material (PCM). Appl. Therm. Eng. 2016, 93, 1377–1393. [Google Scholar] [CrossRef]

- Xu, M.; Li, S.; Cai, W. Cascade generalized predictive control strategy for boiler drum level. ISA Trans. 2005, 44, 399–411. [Google Scholar] [CrossRef] [PubMed]

- Bequette, B.W. Nonlinear control of chemical process—A review. Ind. Eng. Chem. Res. 1991, 30, 1391–1413. [Google Scholar] [CrossRef]

- Arriaga de Valle, E.D.A. Modeling and Simulation of a Fuzzy Supervisory Controller for an Industrial Boiler. Simulation 2016, 82, 841–850. [Google Scholar] [CrossRef]

- Mercangöz, M.; Doyle, F.J., III. Distributed model predictive control of an experimental four-tank system. J. Process Contr. 2007, 17, 297–308. [Google Scholar] [CrossRef]

- Wang, T.; Gao, H.; Qiu, J. A Combined Adaptive Neural Network and Nonlinear Model Predictive Control for Multirate Networked Industrial Process Control. IEEE Trans. Neur. Net. Lear. 2016, 27, 416–425. [Google Scholar] [CrossRef] [PubMed]

- Hosen, M.A.; Hussain, M.A.; Mjalli, F.S. Control of polystyrene batch reactors using neural network based model predictive control (NNMPC): An experimental investigation. Control. Eng. Pract. 2011, 19, 454–467. [Google Scholar] [CrossRef]

- Guo, X.L.; Wang, T.; Fu, H.; Guo, Y.X.; Li, J.Z. Ice-Jam Forecasting during River Breakup Based on Neural Network Theory. J. Cold Reg. Eng. 2018, 32, 04018010. [Google Scholar] [CrossRef]

- Surendran, S.; Kumar, V. Neural Network Based PI Controller Parameter Calculation on a Boiler Drum Level System. Procedia Technol. 2016, 24, 1616–1622. [Google Scholar] [CrossRef]

- Kamesh, R.; Rani, K.Y. Nonlinear control strategies based on Adaptive ANN models: Multi-product semi-batch polymerization reactor case study. Chem. Eng. Res. Des. 2017, 121, 255–274. [Google Scholar] [CrossRef]

- Pirdashti, M.; Curteanu, S.; Kamangar, M.H.; Hassim, M.H.; Khatami, M.A. Artificial neural networks: Applications in chemical engineering. Rev. Chem. Eng. 2013, 29, 205–239. [Google Scholar] [CrossRef]

- Hussain, M.A. Review of the applications of neural networks in chemical process control–simulation and online implementation. Artif. Intell. Eng. 1999, 13, 55–68. [Google Scholar] [CrossRef]

- Banjanovic-Mehmedovic, L.; Hajdarevic, A.; Kantardzic, M.; Mehmedovic, F.; Dzananovic, I. Neural network-based data-driven modelling of anomaly detection in thermal power plant. Automatika 2017, 58, 69–79. [Google Scholar] [CrossRef]

- Xue, X.; Xiang, W.; Lu, J. Modeling and Control of Industrial Fischer-Tropsch Synthesis Slurry Reactor Using Artificial Neural Networks. J. Chem. Eng. Jpn. 2014, 47, 887–892. [Google Scholar] [CrossRef]

- Bagul, R.K.; Pilkhwal, D.S.; Vijayan, P.K.; Joshi, J.B. Air Water Loop for investigation of flow dynamics in a steam drum: Carryover experiments and CFD simulation. Nucl. Eng. Des. 2018, 333, 145–160. [Google Scholar] [CrossRef]

- Gaikwad, A.J.; Vijayan, P.K.; Iyer, K.; Bhartiya, S.; Kumar, R.; Lele, H.G.; Ghosh, A.K.; Kushwaha, H.S.; Sinha, R.K. Effect of Loop Configuration on Steam Drum Level Control for a Multiple Drum Interconnected Loops Pressure Tube Type Boiling Water Reactor. IEEE Trans. Nucl. Sci. 2009, 56, 3712–3725. [Google Scholar] [CrossRef]

- Gaikwad, A.J.; Vijayan, P.K.; Bhartiya, S.; Kumar, R.; Lele, H.G.; Vaze, K.K. Selection of Steam Drum Level Control Method for Multiple Drum Interacting Loops Pressure Tube-Type BWR. IEEE Trans. Nucl. Sci. 2011, 58, 479–489. [Google Scholar] [CrossRef]

- Sadeghi, B.H.M. A BP-neural network predictor model for plastic injection molding process. J. Mater. Process. Technol. 2000, 103, 411–416. [Google Scholar] [CrossRef]

- Xia, D.Z.; Kong, L.; Hu, Y.W.; Ni, P.Z. Silicon microgyroscope temperature prediction and control system based on BP neural network and Fuzzy-PID control method. Meas. Sci. Technol. 2015, 26, 025101. [Google Scholar] [CrossRef]

- Mahmoud, M.S.; Sabih, M.; Elshafei, M. Using OPC technology to support the study of advanced process control. ISA Trans. 2015, 55, 155–167. [Google Scholar] [CrossRef] [PubMed]

- Aydogmus, O. A web-based educational tool using programmable logic controller-connected MATLAB-OPC server. Int. J. Electr. Eng. Educ. 2015, 52, 71–80. [Google Scholar] [CrossRef]

- Persin, S.; Tovornik, B.; Muskinja, N. OPC-driven data exchange between MATLAB and PLC-controlled system. Int. J. Electr. Eng. Educ. 2003, 19, 586–592. [Google Scholar]

- Cao, J.; Ye, Q.; Li, P. Resistance Furnace Temperature Control System Based on OPC and MATLAB. Meas. Control 2015, 48, 60–64. [Google Scholar] [CrossRef]

- Rafalimanana, A.; Cabassud, M.; Le Lann, M.V.; Casamatta, G. Adaptive control of a multipurpose and flexible semi-batch and pilot plant reactor. Comput. Chem. Eng. 1992, 16, 837–848. [Google Scholar] [CrossRef]

- Mandić, M.; Dikić, V.; Petkovska, M.; Todić, B.; Bukur, D.B.; Nikačević, N.M. Dynamic analysis of millimetre-scale fixed bed reactors for Fischer-Tropsch synthesis. Chem. Eng. Sci. 2018, 192, 434–447. [Google Scholar] [CrossRef]

- Li, D.; Li, Z.; Gao, Z.; Jin, Q. Active Disturbance Rejection-Based High-Precision Temperature Control of a Semibatch Emulsion Polymerization Reactor. Ind. Eng. Chem. Res. 2014, 53, 3210–3221. [Google Scholar] [CrossRef]

- Zhang, W.; Zhang, H.; Abbas, M.; Zhang, J.; Huang, Z.; Kawi, S.; Chen, J. Eco-friendly solid-state synthesis of Na-promoted Mn-Fe/ZrO2 catalyst for Fischer-Tropsch synthesis. Fuel 2024, 363, 131013. [Google Scholar] [CrossRef]

- Xue, Q.; Jiang, Z.; Wang, C.; Kan, X.; Wang, J.; Chen, J. Modulation of supported Ni catalysts with phosphorus for the hydrogenation of diethyl oxalate to ethyl glycolate. New J. Chem. 2024, 48, 3089–3099. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).