Abstract

Since the beginning of spring 2022, successive landslides have occurred in the eastern pit slope of the Wolong Coal Mine in Qipanjing Town, Otog Banner, Inner Mongolia, which has adversely affected the mine’s production safety. This study aims to reveal the deformation patterns and failure mechanisms of landslides. Firstly, this study establishes the stratigraphic structure of the eastern pit slope of the Wolong Coal Mine using extensive field geological surveys combined with unmanned aerial vehicle photography, drilling, and comprehensive physical exploration techniques. Indoor geotechnical tests and microscopic experiments reveal that rock mass typically exhibits the characteristics of expansibility and water sensitivity. Moreover, the mechanical parameters of the rock mass were determined using a combination of the window sampling method, the Geological Strength Index, and the Hoek–Brown strength criterion estimation theory. Finally, this study consolidates the previously mentioned insights and employs FLAC3D (7.0) software to assess the stress–strain characteristics of the excavated slope. The results indicate that the deformation mode of the Wolong open pit coal mine is the toppling failure of soft-hard-interbedded anti-inclined layered rock slopes. The unloading effect and rock expansion-induced softening lead to stress concentration at the slope corners and more substantial deformation, thereby accelerating upper slope deformation. The deformation and destabilization process of landslides is categorized into four stages: the initial deformation stage, the development stage of lateral shear misalignment, the development stage of horizontal tensile-shear damage, and the slip surface development to the preslip stage. This research offers valuable references and engineering insights for future scientific investigations and the prevention of similar slope-related geological hazards.

1. Introduction

In recent years, due to the rapid growth of human engineering activities, the issue of slope instability has been on the rise annually. There is a common assumption that anti-dip slopes are inherently more stable, with shallower slip surfaces or a lower likelihood of mass sliding. In 1990, Brabb and Harrod provided a comprehensive overview of global landslide hazards, highlighting the widespread occurrence of toppling deformations worldwide [1]. Huang and Li conducted a statistical analysis of 200 major landslides in China dating back to 1900 [2]. Among these, landslides or deformation issues in anti-dip slopes comprise approximately one-third of the total number of cases. It is evident that studying and analyzing the instability and deformation mechanisms of anti-dip slopes is essential for timely prevention and control.

Owing to the perilous and unpredictable nature of anti-dip landslide events, scholars worldwide have undertaken numerous investigations. In early studies, the primary focus was on engineering geological descriptions [3,4,5,6]. In 1976, Goodman and Bray systematically examined the deformation and damage features of anti-dip slopes, classifying them into two groups: toppling and secondary toppling [7]. As the exploration of toppling deformation damage progressed, researchers initiated the examination of its deformation traits using physical experiments and numerical simulation methods. Adhikary and Dyskin [8] investigated and analyzed the deformation and damage mechanisms of anti-dip slopes using centrifugal simulation experiments. They also outlined the associated stability analysis methods. Numerical simulation has increasingly emerged as a vital tool for analyzing landslide deformation mechanisms, primarily because of the substantial costs and time needed for model test-based investigations. In 1995, Wu and Pollard [9] employed 3D analysis software to simulate and analyze the instability progression of an anticline slope in Japan. In 2009, Brideau and Stead [10] explored the impact of discontinuity orientation on the deformation mechanism of block topping, employing the discrete element software 3DEC. In 2013, Böhme et al. [11] conducted a thorough analysis of the destabilization mechanisms in rocky slopes in Stampa by integrating various analytical approaches. In May 2009, destabilization damage occurred during the construction of a road in northwestern Spain, which was numerically simulated by León Buendía et al. using the UDEC software to offer improved insights into the deformation damage features at the study site [12]. In 2016, Jiang et al. [13] applied a tension-weakening model in FLAC3D, using the Zhaogu No. 2 Mine as an example, considering the influence of fissures on the rock mass. Then, the deformation characteristics of the slope were analyzed, and the relationship between the fissure strength and the residual strength of the rock mass was established. In 2019, Zhan et al. [14] used the Xinyan landslide as a case study, uncovering the primary factors contributing to frequent landslides in the region via extensive indoor experiments, mineral analyses, and microstructural assessments. They also summarized the deformation and damage patterns. In 2020, Tao et al. [15] used the Changshanhao Coal Mine as an example to determine the destabilization damage mode of the anti-dip slopes by using field investigations, physical exploration, and comprehensive analysis of FLAC3D (5.0) and 3DEC (5.2) software.

Since the beginning of spring 2022, extensive deformation and damage have occurred on the eastern pit slope of the Wolong Coal Mine in Ordos City, Inner Mongolia, posing a serious threat to personnel safety during operation. In this study, a thorough field engineering geological investigation and analysis were conducted for the eastern slope of the Wolong Coal Mine. The geological structure of the slope and the characteristics of the rock mass were comprehensively ascertained using remote sensing interpretation, drilling, physical exploration, indoor mechanical experiments, and microscopic analyses. Subsequently, the stress–strain characteristics of the slope were examined using the finite difference software FLAC3D (6.0). On this basis, the damage patterns and deformation mechanisms of the eastern slope of Wolong Coal Mine were determined.

2. Study Area

2.1. Overview

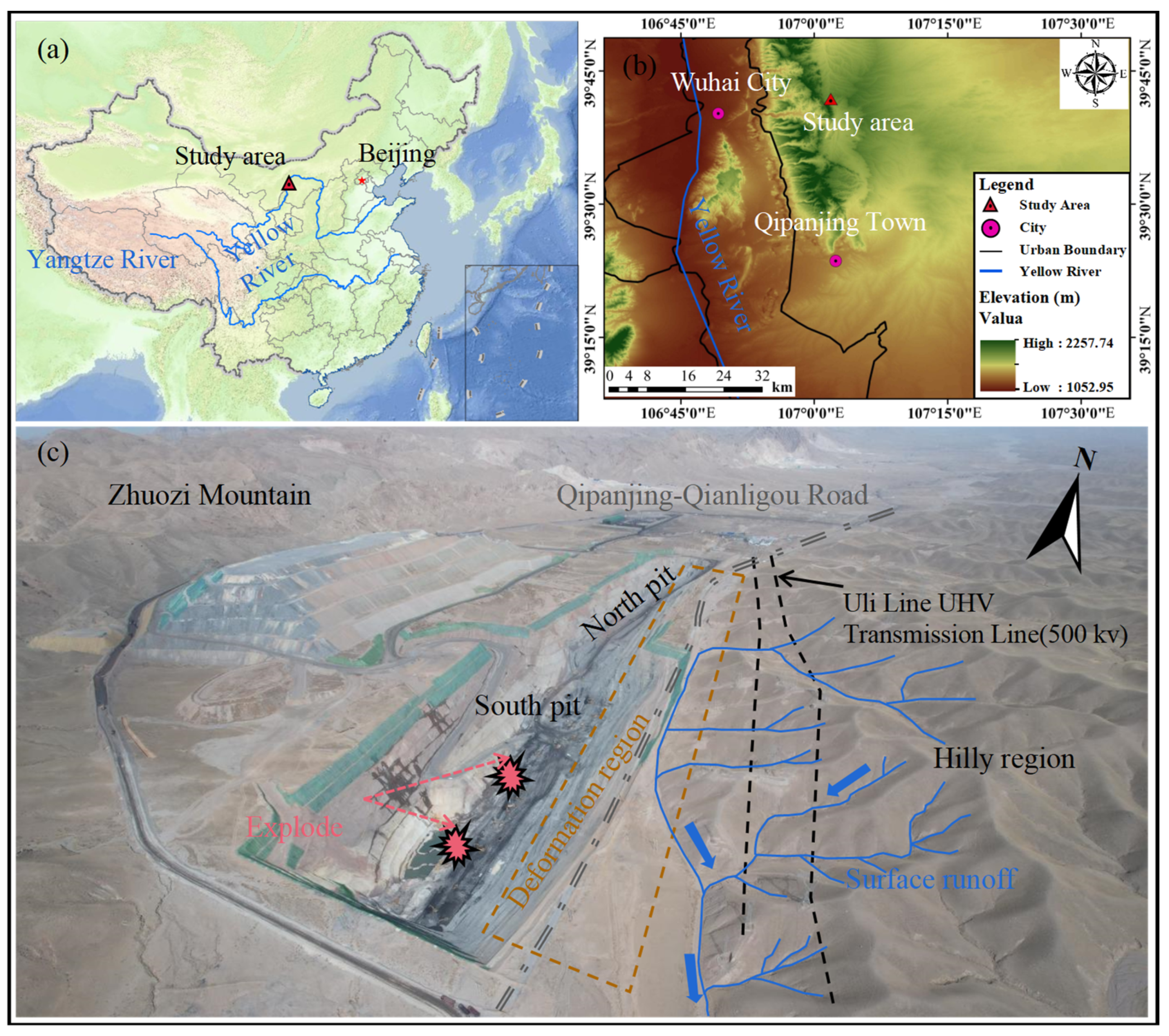

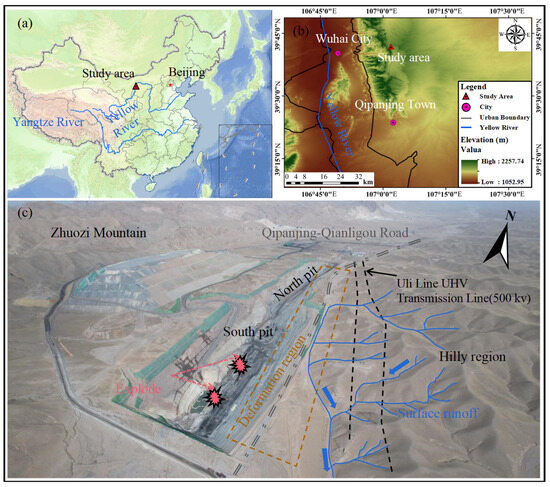

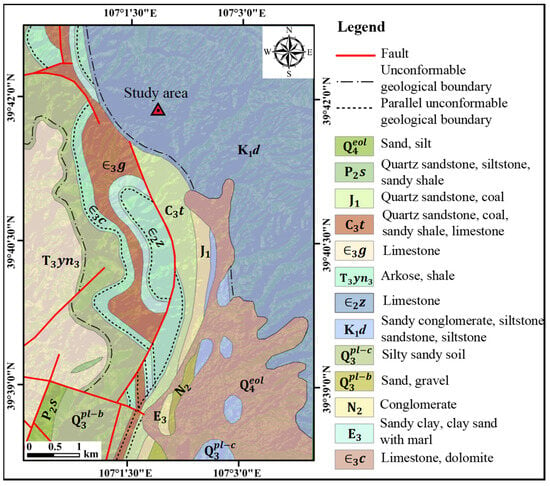

The study area is situated in Qipanjing Town, Otog Banner, Inner Mongolia, at the eastern base of the Zhuozi Mountain. It is bordered by the west edge of Zhuozi Mountain, where retrograde thrusting actions have shaped the peaks of an undulating mountain range. To the east, the landscape transitions into hilly areas (Figure 1a,b).

Figure 1.

Geological location of the Wolong open-pit coal mine. (a) Location of the study area; (b) Digital elevation model; (c) Panoramic view of open pit.

The Wolong Coal Mine’s open pit extends in a north–south direction, occupying the transitional zone between these two distinct geomorphic regions. The terrain is complex, with an elevation ranging from 1625 to 1640 m. Generally, the terrain exhibits a north–south gradient, with higher elevations in the north and lower elevations in the south. As of March 2023, the bottom elevation of the open pit reached 1545 m, resulting in a high and steep pit slope with a significant height difference exceeding 80 m. The pit slope angles range from 30 to 50 degrees, and the slope continues to deform, causing damage to adjacent roads and threatening the safety of the transmission line (Figure 1c).

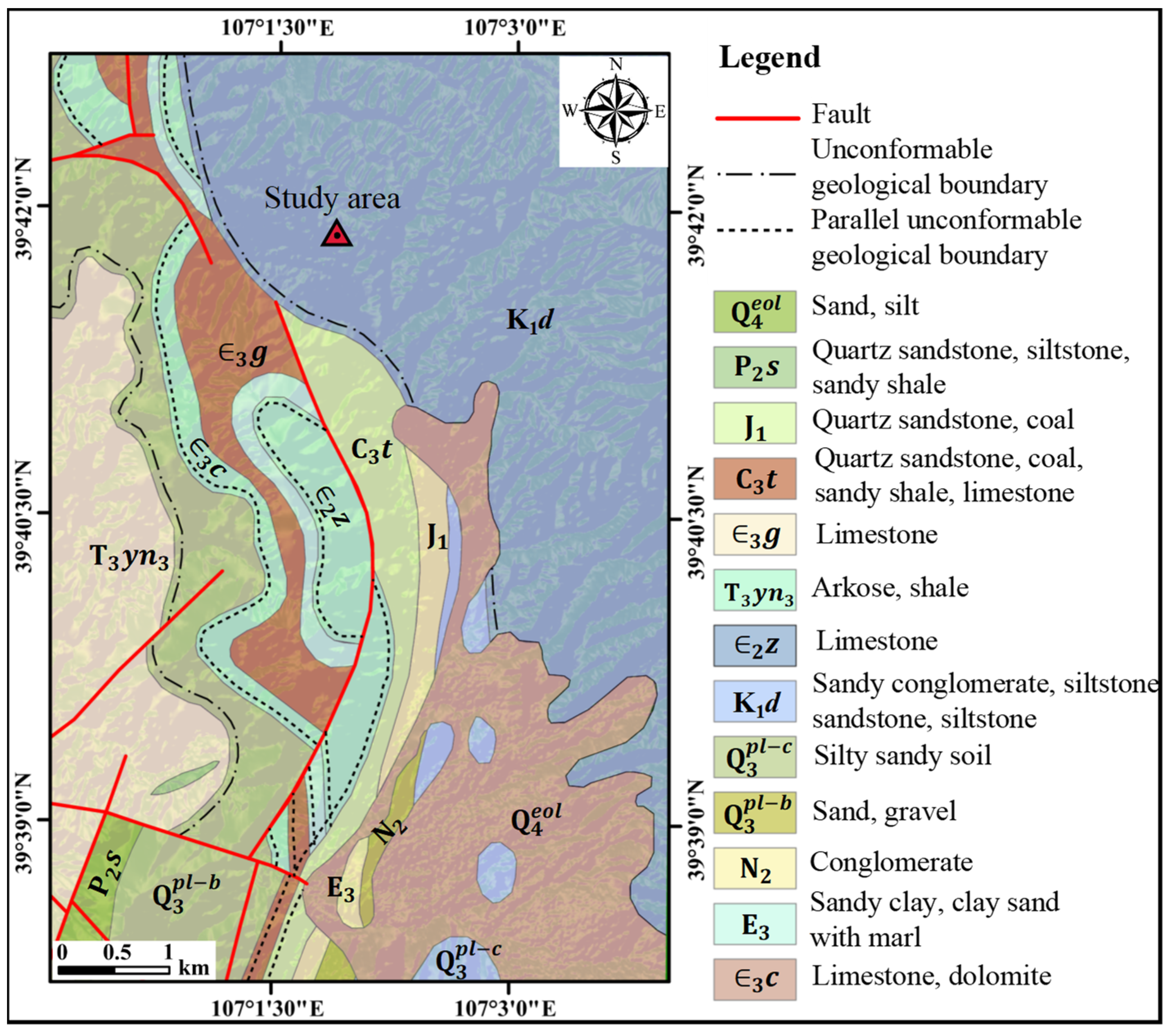

2.2. Geological Setting

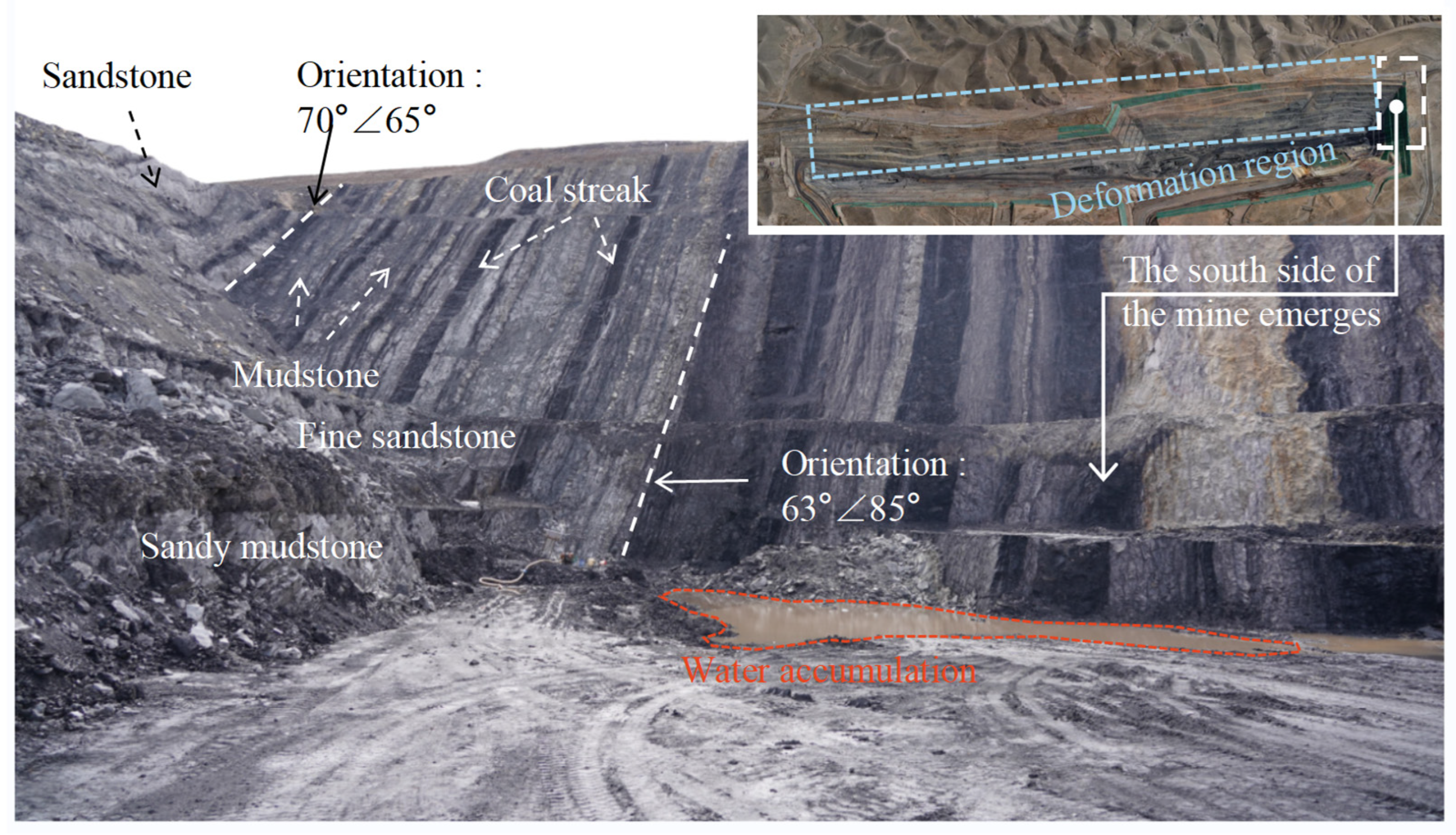

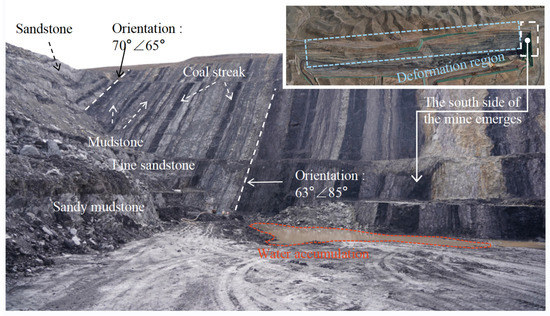

The study area is situated within the geological framework of the Zhuozi Mountain Coalfield, which has been influenced by the early Yanshan movement. The region’s tectonics exhibit a high degree of complexity, notably marked by strata inversion. Prominent fault formations are evident on the western side of the Zhuozi Mountain area, and the main structures include the Zhuozi Mountain Eastern Foothills Fault and the Zhuozi Mountain Anticline. The geological formation surrounding the mine area corresponds to the Damoguaihe Formation (K1d), characterized by a predominantly gray-white conglomerate, sandstone, siltstone, and mudstone layers interbedded with coal seams (Figure 2). As depicted in Figure 3, the southern pit slope reveals well-exposed strata, representing a classic example of an anti-dip rocky slope. These strata comprise a mix of sandstone and mudstone, along with sandy mudstone interbeddings that vary in hardness. The strike of the strata is predominantly north–south, with dip angles generally between 65–85°.

Figure 2.

Topographic and geological map.

Figure 3.

Stratigraphic structure of the Wolong open-pit coal mine.

2.3. Meteorology and Hydrology

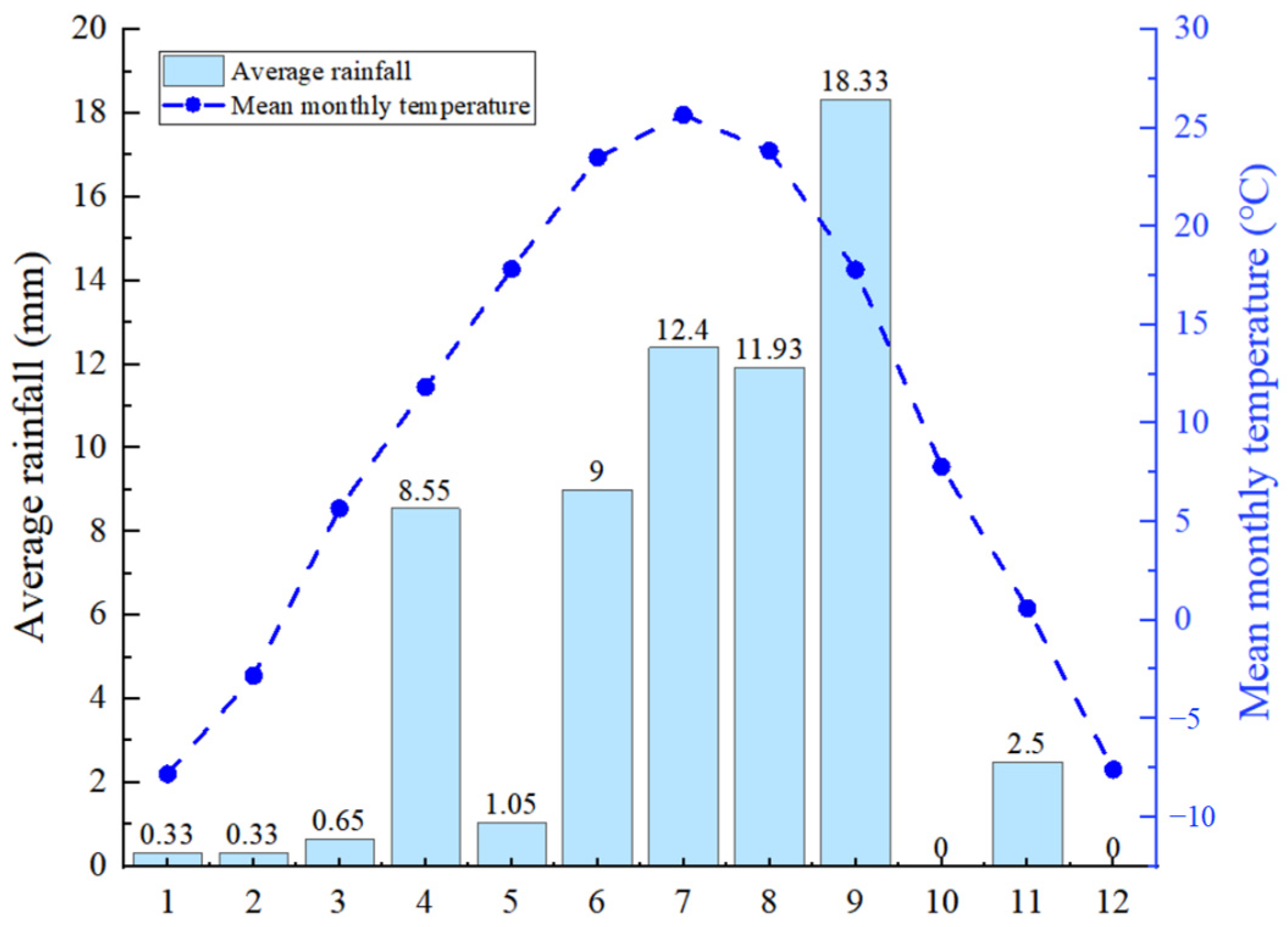

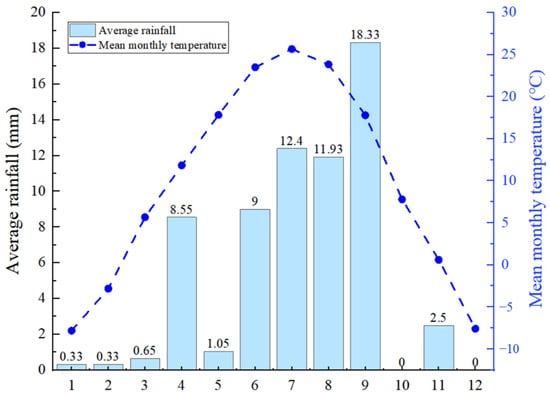

The study area is positioned on the northwestern periphery of the Ordos Plateau and experiences a temperate plateau continental climate. Based on data from the neighboring Wuhai meteorological station over the last five years, the region exhibits an annual average temperature of 10.1 °C, with a peak of 37 °C, a minimum of −16 °C, and an extreme low of −28 °C. The yearly average precipitation amounts to 218.6 mm, with the majority occurring during July, August, and September. Conversely, the annual average evaporation stands at 3025.1 mm (Figure 4). Notably, between January and March 2023, the mine site experienced numerous substantial snowfalls along with significant diurnal temperature fluctuations.

Figure 4.

Average monthly precipitation and average monthly temperature from 2018 to 2023.

As shown in Figure 1c, the eastern section of the mine site abuts a hilly terrain characterized by numerous sizable and smaller gullies and valleys. These gullies experience seasonal runoff, primarily during the rainy season when significant surface runoff occurs, albeit for a brief period. Following the rainy season, they tend to be dry and devoid of water.

2.4. Earthquake

Referring to China’s seismic ground motion parameter zonation map (GB18306-2015) [16], the earthquake’s basic intensity in the study area registers at the eighth degree. The peak ground shaking acceleration measures 0.20 m/s2, and the characteristic period of the ground shaking response spectrum stands at 0.40 s.

2.5. Status of Open-Pit Mining

As of March 2023, the north and south pits had been excavated to elevations of approximately 1580 and 1545 m, respectively. The overall slope of the pit slope had been steepened to 33 degrees. Detailed excavation data of the open pit are presented in Table 1.

Table 1.

Status of mine excavation (2023.03).

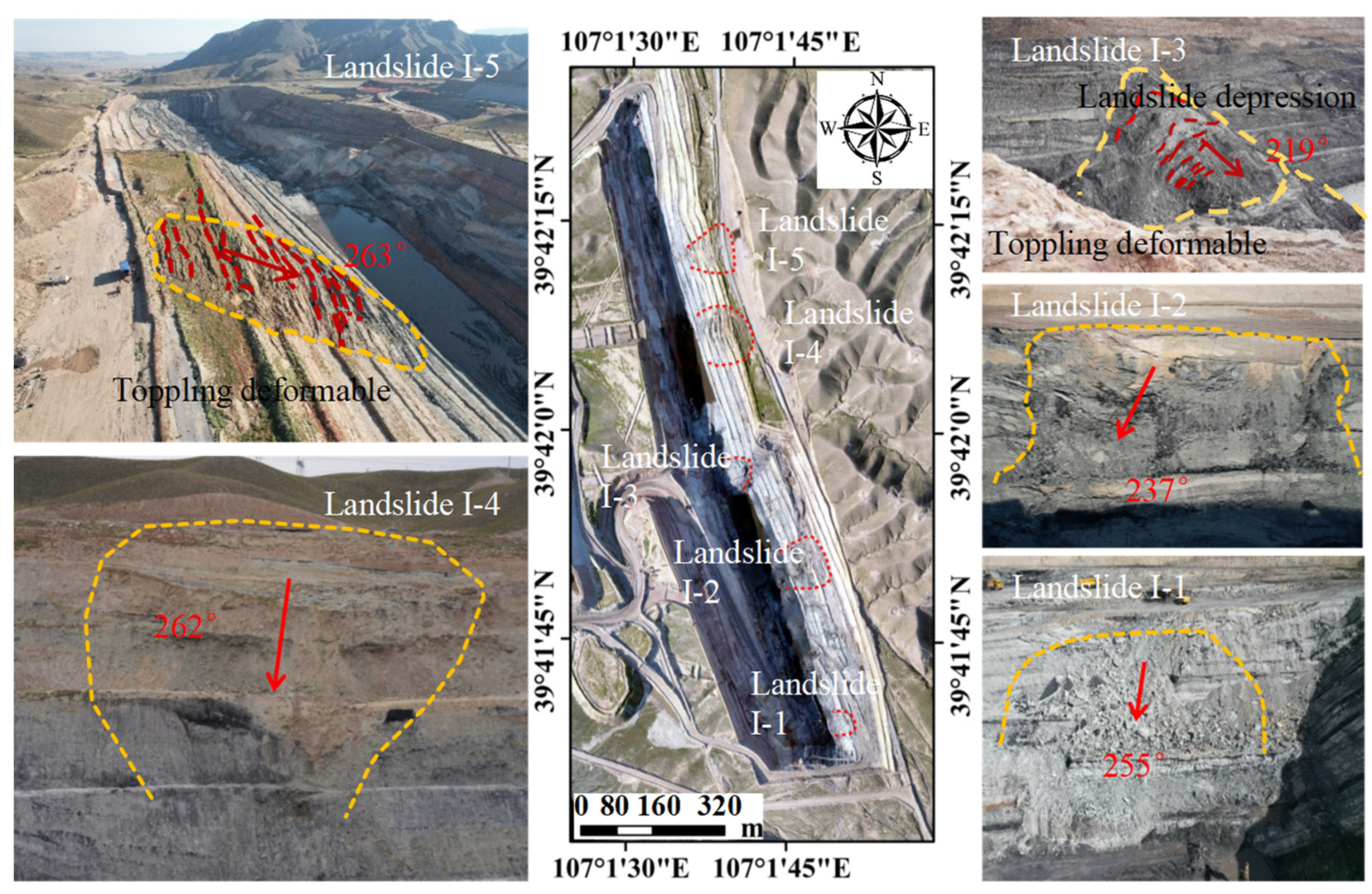

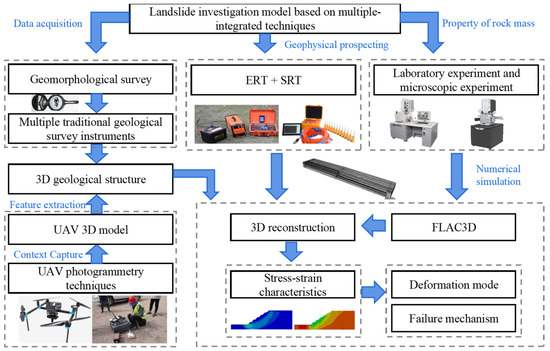

3. Data and Methodology

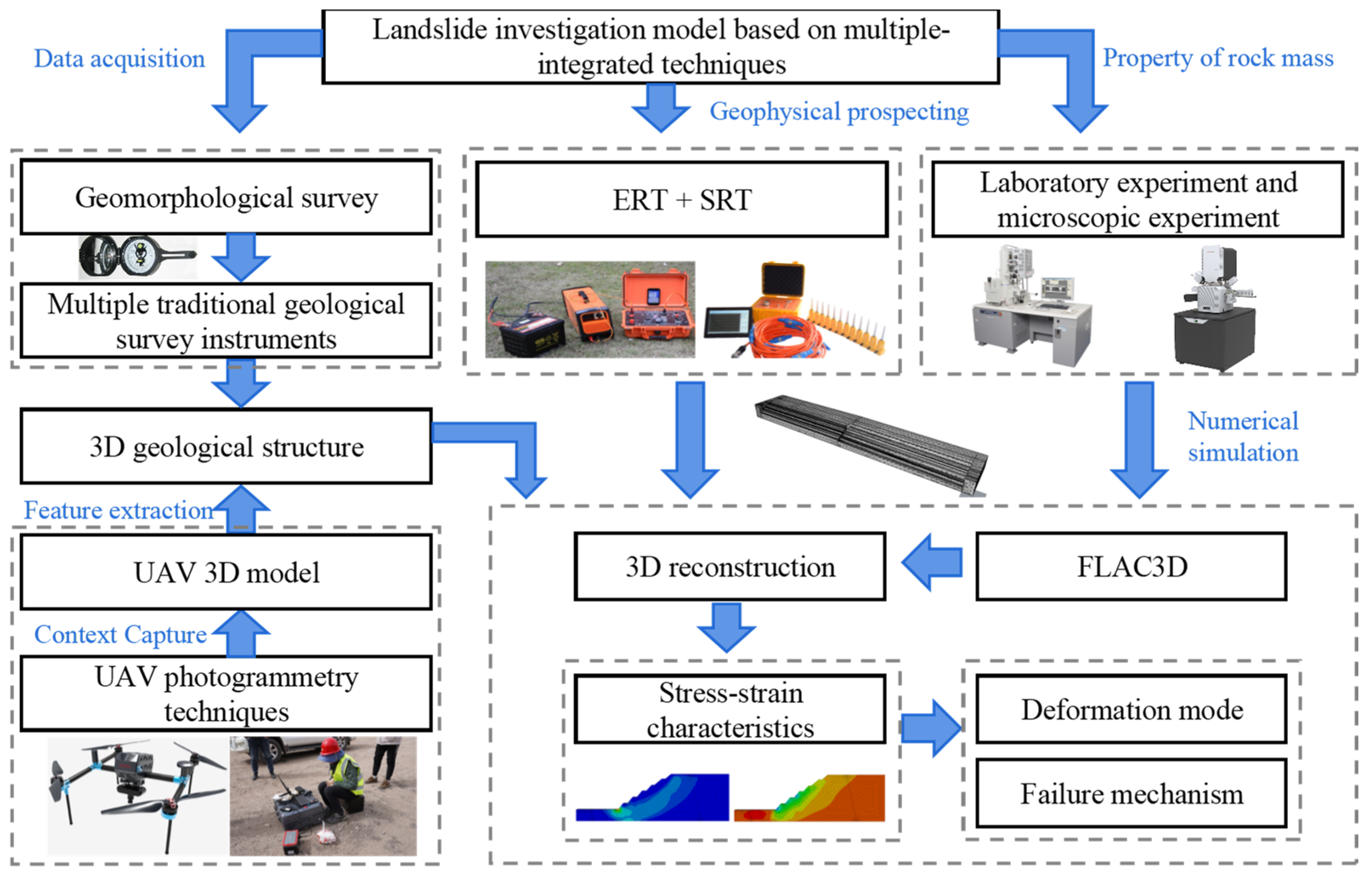

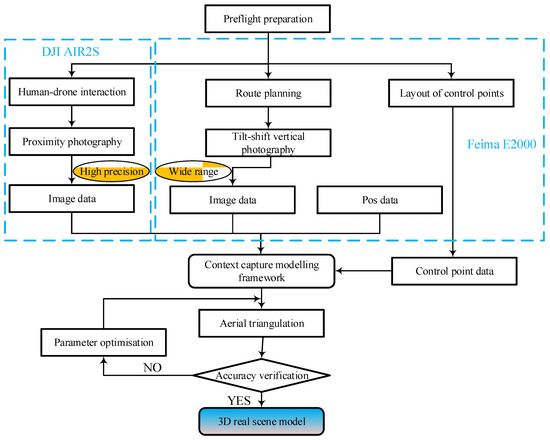

This study follows a comprehensive analysis approach, as outlined in Figure 5. The steps include (1) acquiring geological and geomorphological data of the mining area using on-site geological surveys; (2) interpreting landslide deformation features using multiperiod unmanned aerial vehicle (UAV) 3D models; (3) comprehensively determining the geological structure of the pit slope by combining physical exploration and drilling techniques; (4) conducting indoor physical-mechanical experiments and microscopic analyses to assess the geotechnical properties; and (5) employing FLAC3D for analyzing the stress–strain characteristics of the pit slope, followed by an assessment of the deformation patterns and damage mechanisms.

Figure 5.

Flow chart of multiple-integrated techniques for landslide investigations.

3.1. Geological and Geomorphological Survey

The field geological survey aims to gain insights into slope deformation and damage by examining the distribution, scale, and structural features of landslides. The first field geological survey was carried out in September 2022, and multiple slides have occurred in the study area. In March 2023, a follow-up geological survey was conducted as the trailing edge of the eastern pit slope on the southern side exhibited renewed and conspicuous deformation indications.

This field survey involved employing a 5 m standard tape measure alongside a geological compass to record orientation and fracture data at specific stratigraphic points. Furthermore, data concerning landslide features such as tension cracks, slope seepage, and geological formations within the study area were meticulously documented. This comprehensive geological investigation work has facilitated a preliminary identification of the stratigraphic distribution in the study area, laying the groundwork for the subsequent construction of a three-dimensional geological model.

3.2. UAV Photogrammetry Techniques

The advent and progression of modern technologies such as the Global Positioning System (GPS) and UAV photogrammetry have led to a rapid evolution of remote sensing imagery surveying methods [17]. Utilizing remote sensing interpretation techniques, valuable information regarding landslide deformation characteristics and surface cracks in the study area can be extracted from postprocessed image data [18]. Remote sensing and geographic information system (GIS) technologies enable the acquisition of high-resolution imagery data, providing precise insights into the deformation characteristics of landslide surfaces. These technologies also facilitate the analysis of spatial and temporal changes by incorporating multiperiod imagery data [19,20,21].

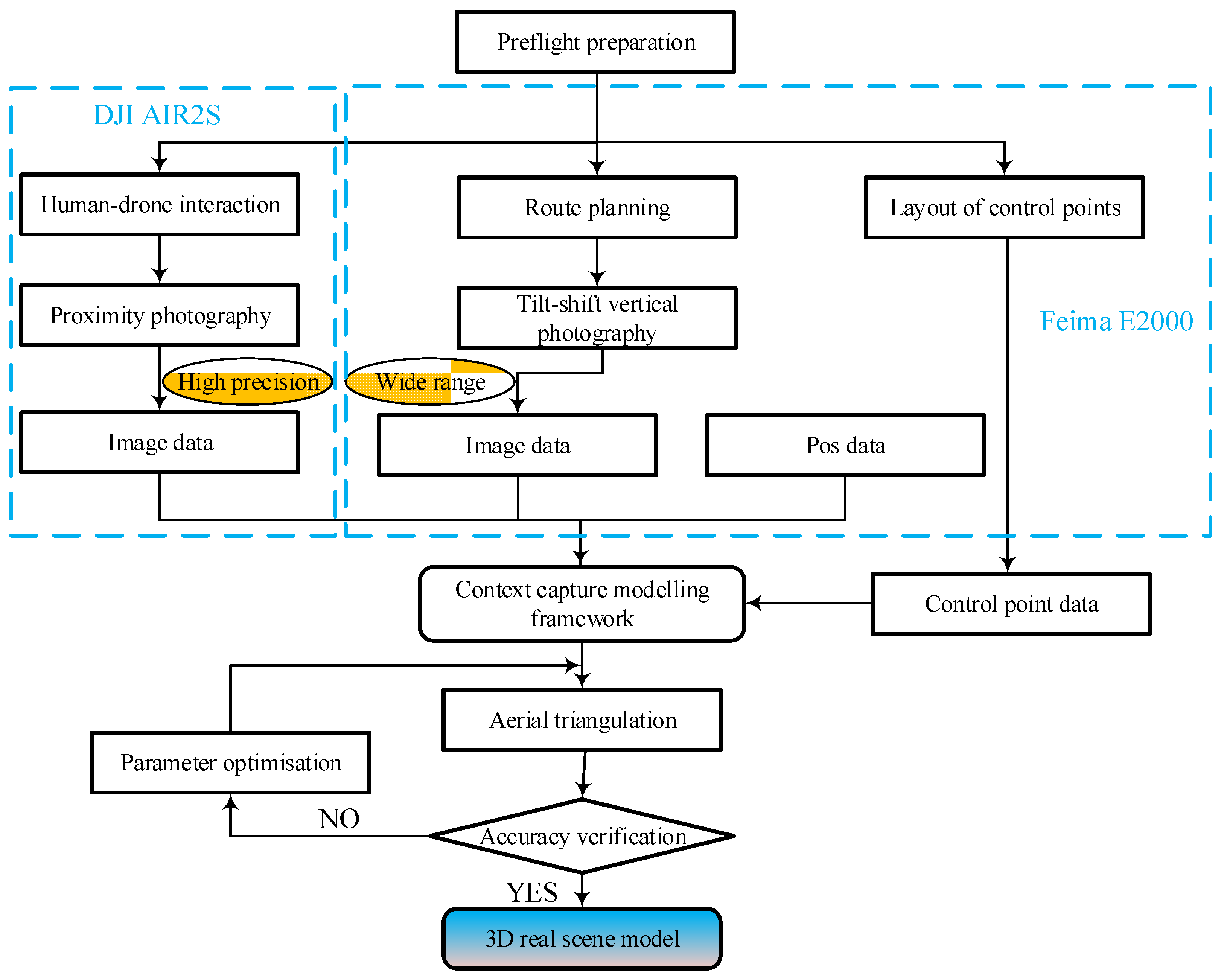

In this study, UAV remote sensing images were obtained in July 2022, October 2022, and March 2023. These datasets from the three time points served as the foundation for analyzing the progression of deformation characteristics in the pit slope of the Wolong Coal Mine. For the survey, aerial photographs of the study area were captured using a Feima E2000 UAV and a DJI AIR2S UAV. The Feima E2000 UAV and DJI AIR 2S UAV were respectively purchased from Feima Robotics in Shenzhen, Guangdong, and DJI Technology Co., Ltd. The DJI AIR2S UAV is manually controlled for close-range flights along the slope to capture image data of landslides in small areas, enabling the generation of high-precision three-dimensional images within localized areas. When utilizing the Feima E2000 UAV for mapping, specific parameters were established to enhance data quality during aerial photography, including an 80% heading overlap rate, a 70% side overlap rate, and a flight speed of 13.5 m/s. The image resolution (GSD, in cm) was calculated using Formula H = 36 × GSD, where H (in m) represents the flight altitude. Considering the undulating terrain in the survey area, a flight altitude of 220 m was selected. Hence, the resolution of the remote sensing image is 6.11 cm, providing accuracy at the centimeter level. Following image data collection, postprocessing was performed using Context Capture (CC) software (10.16.0.75). The modeling process was refined iteratively by incorporating control points to enhance accuracy. Ultimately, this process yields high-resolution orthophotos (DOM) and 3D reality scene models (Figure 6), meeting the specified accuracy criteria. Then, based on the UAV images and 3D models, the fissures and fractured rock mass at the trailing edge of the pit slope can be extracted, which facilitates a more in-depth analysis of the geological structure, stratigraphic relationships, and landslide deformation and damage mechanisms in the study area.

Figure 6.

3D model construction process based on UAV photogrammetry technology.

3.3. Integrated Geophysical Exploration Method

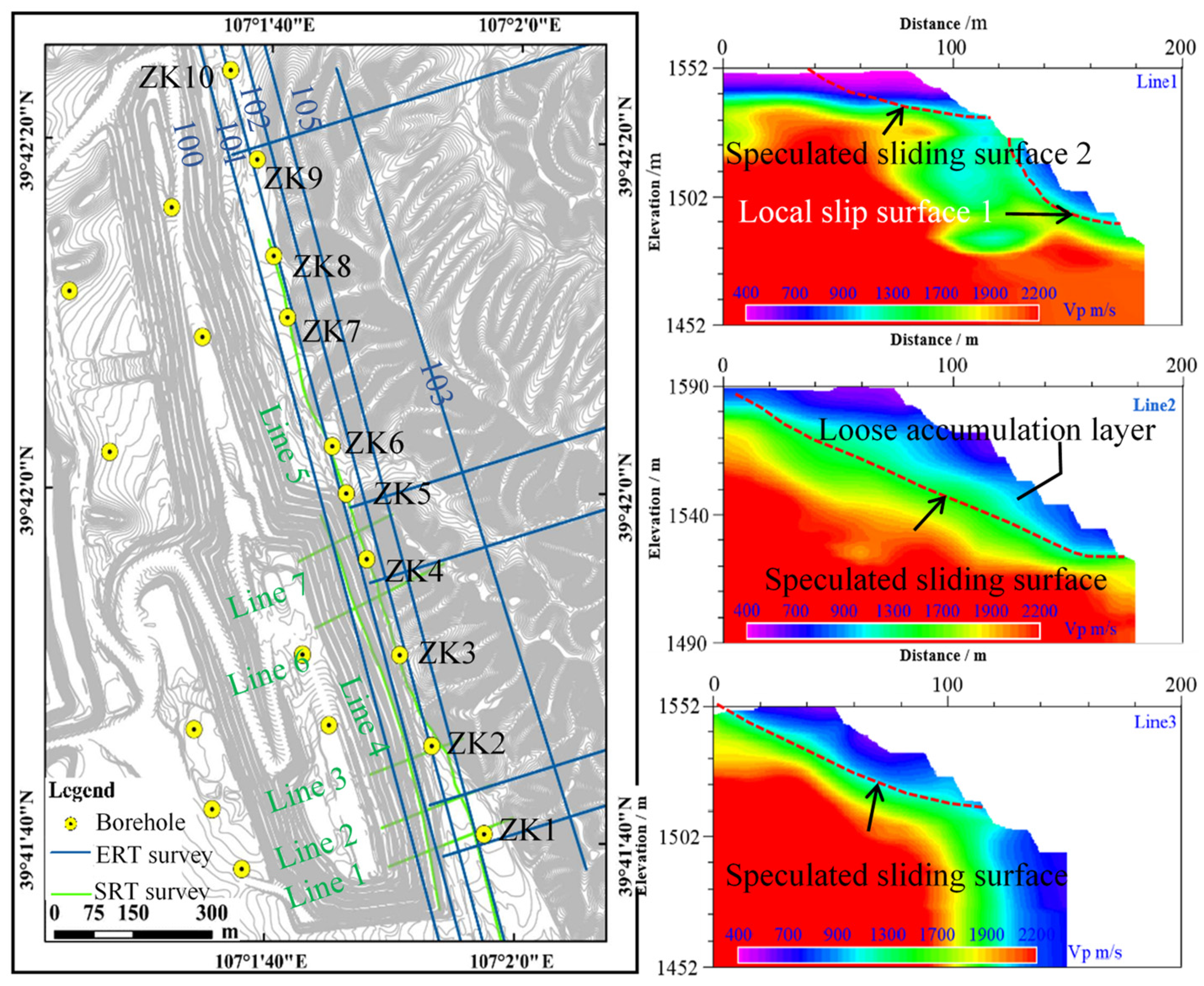

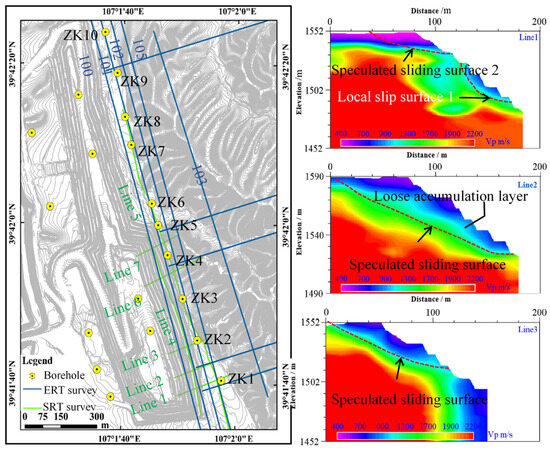

Typically, a single physical exploration method only provides insights into one specific physical property, leading to potential ambiguities in the interpretation results [22]. Hence, this paper employs the electrical resistivity tomography (ERT) method and seismic refraction tomography (SRT) method for a comprehensive analysis (Figure 7).

Figure 7.

Layout of engineering geophysical exploration and borehole and interpretation results by SRT survey.

3.3.1. ERT Survey

ERT generates an artificial electric field by applying electrical energy to electrodes inserted into the subsurface. It leverages the electrical disparities among rock layers to derive the apparent resistivity distribution of the subsurface medium, facilitating a dependable interpretation of the subsurface geological structure. Field measurements necessitate the simultaneous placement of multiple electrodes along the measurement line. These electrodes are subsequently linked to a programmable multielectrode converter, which is controlled by a program to enable rapid switching of a variety of pole distances, measuring points, and arrangements. This process allows for the collection of a substantial volume of data in a single operation [23,24].

The ERT analyses were conducted using a WDA-1 super digital DC resistivity meter from Chongqing Pentium Company, featuring 10 m spacing and 90 road stakes selected for the survey. As shown in Figure 7, survey line positions were determined using handheld GPS devices, covering a total mapping profile length of 15.99 km. To ensure an effective survey depth, the long profile underwent a mobile superposition measurement. Field-collected data underwent several operations, including bad point removal, format conversion, and inversion calculations. The ERT inversion software RES2DINV (5.0) was used to generate resistivity contour maps in this study. These ERT results, combined with geological survey data, were used for geological interpretation, and the interpretation map of the physical exploration results was created using ArcGIS (10.8.1) software.

3.3.2. SRT Survey

SRT involves the deliberate generation of seismic waves on the ground, which will change propagation direction when they encounter a velocity-dividing interface during their downward propagation. If the velocity of the lower medium is greater than that of the upper medium above and the angle of wave incidence equals the critical angle, the wave will be transformed to propagate along the interface, and refracted waves will be generated in the overlying medium. Then, ground-based instruments can collect these seismic data, which are subsequently subjected to computer postprocessing to produce interpreted images [25,26].

For data collection, the ANT-1C wireless intelligent node acquisition system from Earth Pulse Technology Co., Ltd. based in Beijing, China, was employed with a heavy hammering excitation method. The detection process utilized an encounter observation mode with a fixed receiving arrangement and a 4 m channel distance. Multiple coverage techniques were implemented to mitigate strong interference from heavy mechanical equipment within the pit. Each excitation point underwent 20 hammer strikes, leading to the completion of seven survey lines (Figure 8). In the digital processing phase, the raw seismic data underwent processing using the break-picking program to generate the first arrival file in *.bpk format. Subsequently, the first arrival files from multiple encounter observation systems were imported into the SIPQC program. The first arrival times were then allocated to each layer based on the refracted wave time-distance curve’s gradient. This process led to the creation of a measurement point-depth map, facilitating the calculation of wave velocities for each layer and determining the depth of the underground bedrock at each geophone location. Given the considerable dip in the stratigraphy of the study area, superimposed offsets were managed accordingly.

Figure 8.

Field workflow for SRT survey.

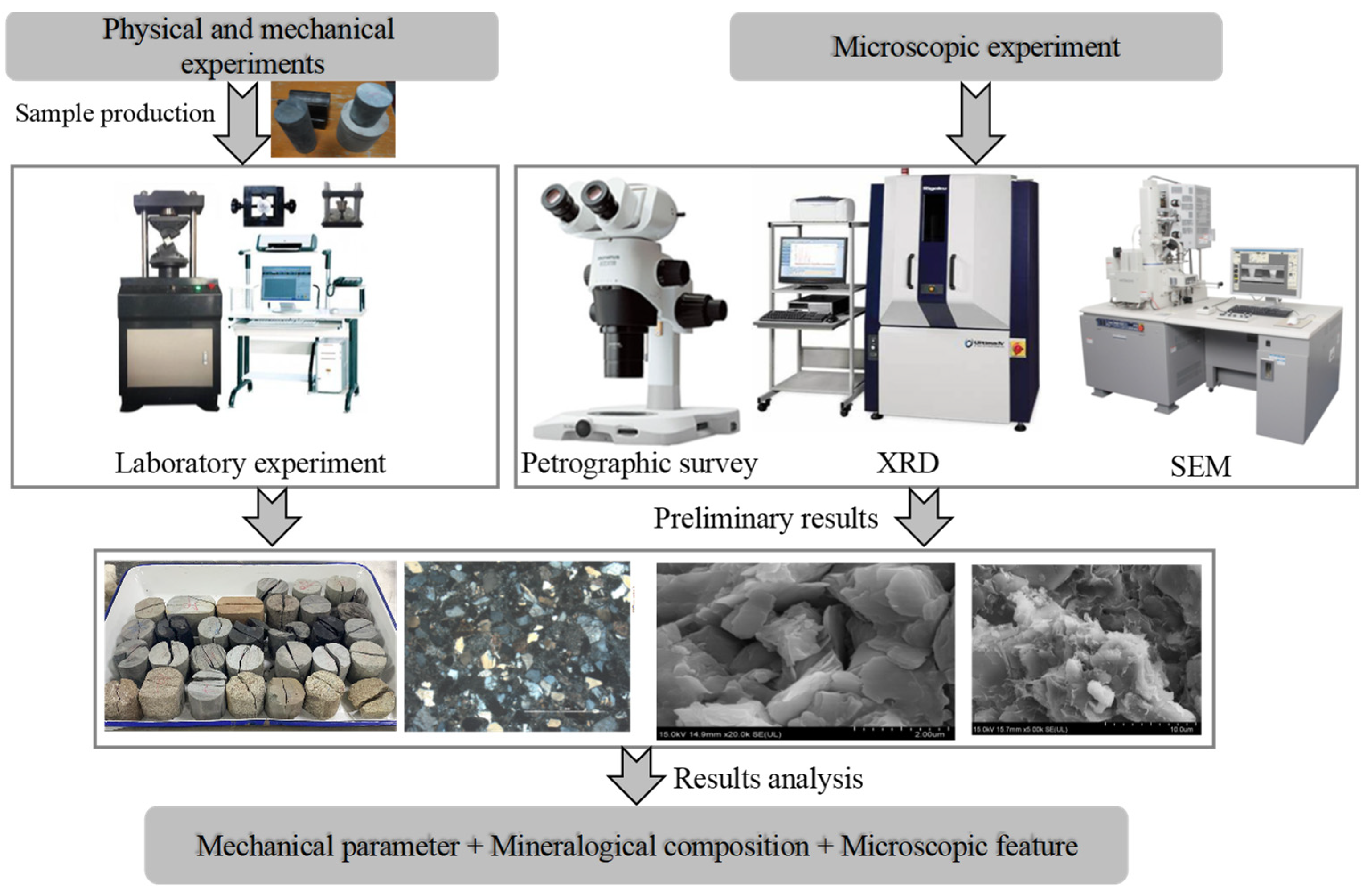

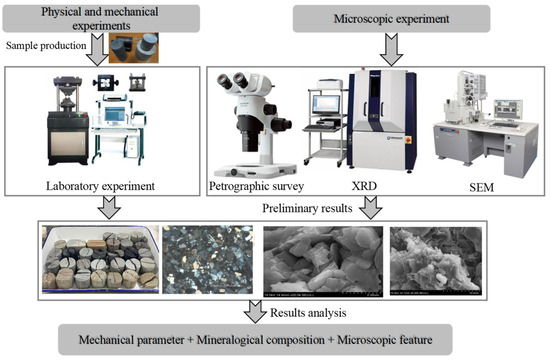

3.4. Laboratory Testing of Rock Masses

To investigate the physical and mechanical characteristics of the rock masses in the study area, various laboratory rock mechanics tests, rock thin section analysis, X-ray diffraction (XRD), and scanning electron microscopy (SEM) techniques were utilized (Figure 9).

Figure 9.

Flowchart of the laboratory testing of rock masses.

3.4.1. Laboratory Physical and Mechanical Tests

Rock samples were obtained from on-site cores, following the specifications outlined in the Standard for Geotechnical Test Methods (GB/T50123-2019) [27] and the Standard for Testing Methods for Engineering Rocks (GB/T 50266-2013) [28]. Subsequently, tests were conducted to determine the physical and mechanical properties of the specimens, including water content, natural density, particle density, water absorption, uniaxial compressive strength, tensile strength, shear strength, etc. A total of 30 groups of tests for rock physical parameters and 489 tests for mechanical parameters were carried out. Since the properties of rock masses are generally controlled by fractures and indoor experiments may not fully account for their influences, subsequent analyses will be combined with rock mass quality evaluation methods to ascertain rock mass parameters.

3.4.2. Rock Thin Section Analysis

Rock thin section analysis involves preparing rock specimens in the form of thin slices, translucent slices, or probe slices. Subsequently, under the guidance of crystal optics and mineralogy principles, a polarized microscope was used to examine the optical properties of minerals for mineral identification. In the context of the lithology of the study area, four samples were chosen for experimentation, and the observation positions and magnifications were carefully adjusted to ensure optimal results. An Olympus polarizing microscope was used for this purpose, and microscope images at 25×, 50×, and 100× magnifications were eventually obtained.

3.4.3. XRD Analysis

The fundamental principle of quantitative XRD analysis is based on X-rays irradiating a crystal and subsequently being scattered by electrons. This scattering process results in the emission of electromagnetic waves with the same frequency as the incident wave. These emitted waves are then processed to quantitatively analyze the mineral content [29]. In contrast to typical chemical and spectral analysis methods, XRD has the capability to measure the complete mineral composition of rocks rather than just the elemental composition. This method offers the advantages of simplicity in operation, cost-effectiveness in detection, and time efficiency.

The experimental instrument used was a Rigaku Ultima IV XRD from Rigaku, Tokyo, Japan. To minimize experimental errors, three samples from each lithology were chosen for testing, resulting in a total of 12 samples.

3.4.4. SEM Analysis

SEM bridges the gap between transmission electron microscopy and optical microscopy. This method involves scanning the sample with a high-voltage electron beam generated by an electron gun in a specific spatial and temporal order to stimulate various physical information. The information is then collected, processed, and imaged for the purpose of characterizing microscopic morphological features of samples [30,31]. The experiment utilized a Hitachi SU8010 Scanning Electron Microscope as the testing instrument in this study. Examining the microstructural characteristics of the observed samples can aid in the analysis of the factors and mechanisms contributing to pit slope deformation and damage.

3.5. Rock Mass Quality Evaluation

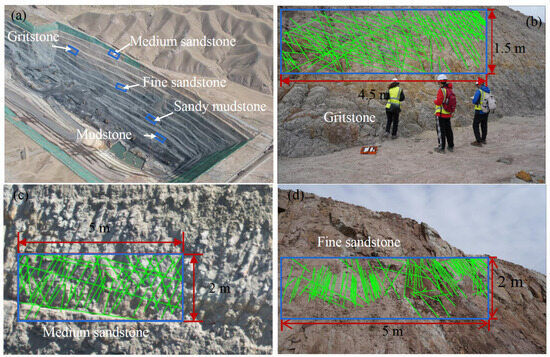

3.5.1. Fracture Data Collection

At present, the window sampling method is extensively employed in field surveys for collecting fissure data [32]. The window sampling method involves assessing the geometric attributes of all fracture features within a specified area of a natural outcrop or the exposed surface of an excavation in the same geological zone and describing the geological characteristics of each fracture according to the requirements of engineering geological criteria [33,34]. In addition, the model-based method proposed by Zhan et al. [35] was used to automatically identify fracture sets.

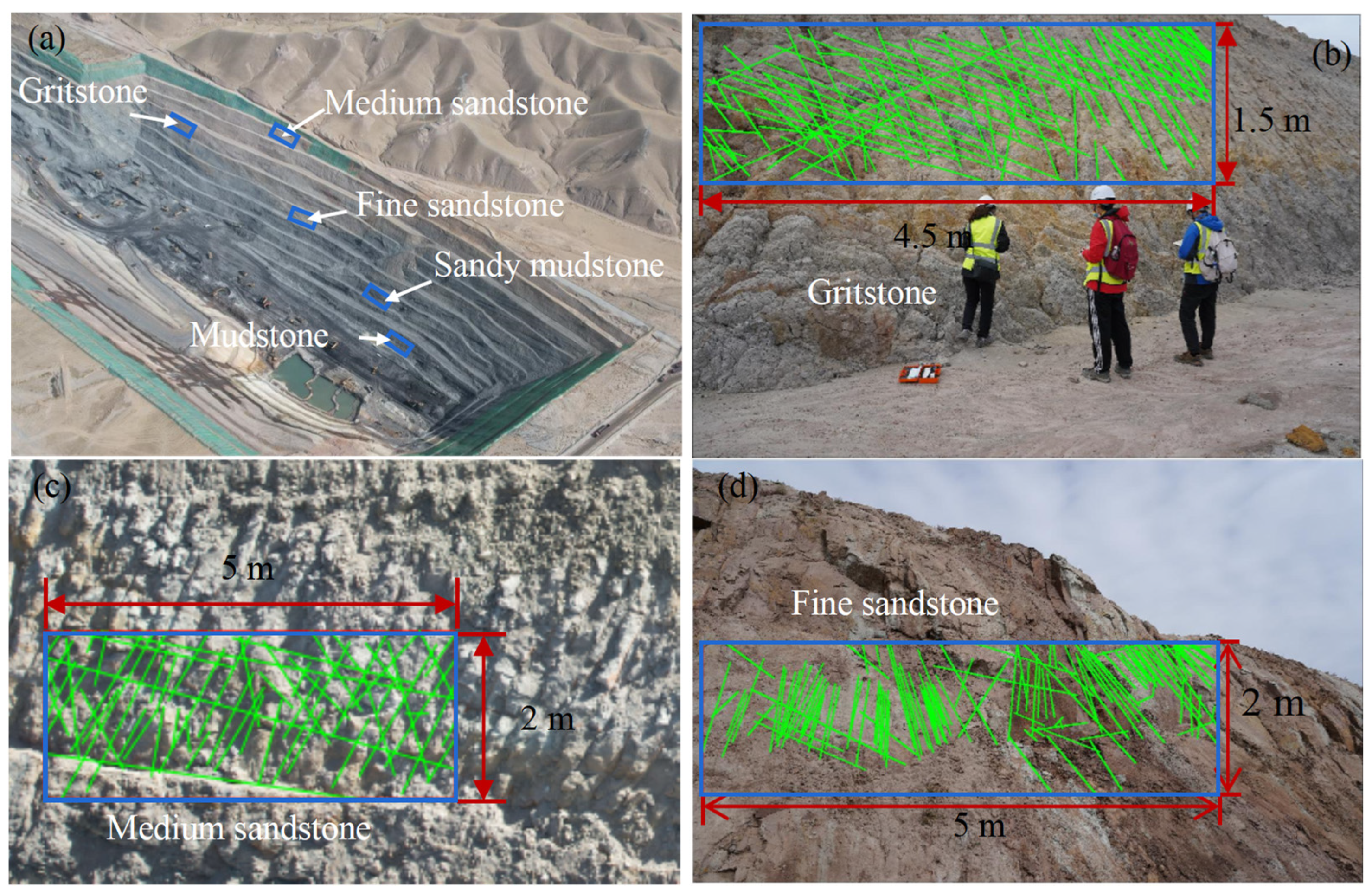

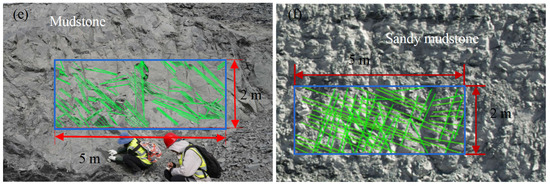

Due to challenging site conditions, acquiring direct measurements for all fracture data in some well-exposed rock faces can be difficult. In recent years, rapid advancements in remote sensing technology have significantly improved the accuracy of UAV 3D models, essentially meeting statistical requirements. Therefore, image data were captured using UAV and camera to construct 3D modes of sampling windows to carry out fracture mapping indoors. Finally, filed measurements were combined with in-door mapping to enhance the interpretation of fracture data (Figure 10b–f).

Figure 10.

(a) Distribution of fracture sampling windows; (b) Sampling window for gritstone; (c) Sampling window for medium sandstone; (d) Sampling window for fine sandstone; (e) Sampling window for mudstone; (f) Sampling window for sandy mudstone.

3.5.2. Rock Mass Quality Evaluation Based on Geological Strength Index (GSI)

Estimating rock mechanical parameters is a crucial step for subsequent numerical simulations of landslide deformation analysis. In this study, rock mass parameters are assessed using the GSI classification system along with the Hoek–Brown failure criterion. The generalized Hoek–Brown criterion is expressed as [36]:

where mb, s, and a are the rock mass material constants given by

where D represents the disturbance factor, which depends on the extent of disturbance caused by blast damage and stress relaxation, and mi is the Hoek–Brown constant.

Sonmez and Ulusay [37] introduced two parameters, namely, the structural rating (SR) and surface condition rating (SCR), which are based on the volumetric discontinuity frequency (Jv), to quantitatively estimate the GSI. In this study, the window sampling method was employed to collect fundamental parameters, and the values were computed using the following equation [38]:

where Si denotes the mean spacing of each fracture set, Nr represents the number of fractures, and A denotes the area of the sampling window.

Upon acquiring a GSI estimate, the mechanical parameters of rock masses were computed using the Hoek–Brown failure criterion [39]. Numerous studies have shown that the Hoek–Brown criterion followed by the rock mass can be approximated by a straight line when is satisfied. Then, the equivalent internal friction angle (φm) and the equivalent cohesion (Cm) of the Mohr–Coulomb criterion for damaged rock masses can be determined after a series of formula transformations [40]. The specific equations are as follows:

where .

In addition, when < 100 MPa, the deformation modulus of the rock mass can be estimated using the following equation:

when > 100 MPa, the following formula is used

3.6. Numerical Simulation

In this study, FLAC3D was employed for numerical simulations. This software utilizes the Lagrangian difference formulation for computations and is designed to model and analyze the mechanical response of a continuous three-dimensional medium, particularly focusing on reaching equilibrium or steady plastic flow. It is particularly well suited for addressing significant geotechnical engineering challenges, including rock excavation [41].

In accordance with the Mohr–Coulomb damage criterion, this simulation in FLAC3D requires the determination of two key material parameters: the deformation parameter and the strength parameter. The mechanical characteristics of the rock mass were ascertained using a combination of laboratory and field-based mechanical tests guided by the Hoek–Brown criterion. The deformation properties are described in terms of the bulk modulus (K) and shear modulus (G). The calculation equations are written as follows:

where E is the modulus of elasticity (MPa), and v is Poisson’s ratio.

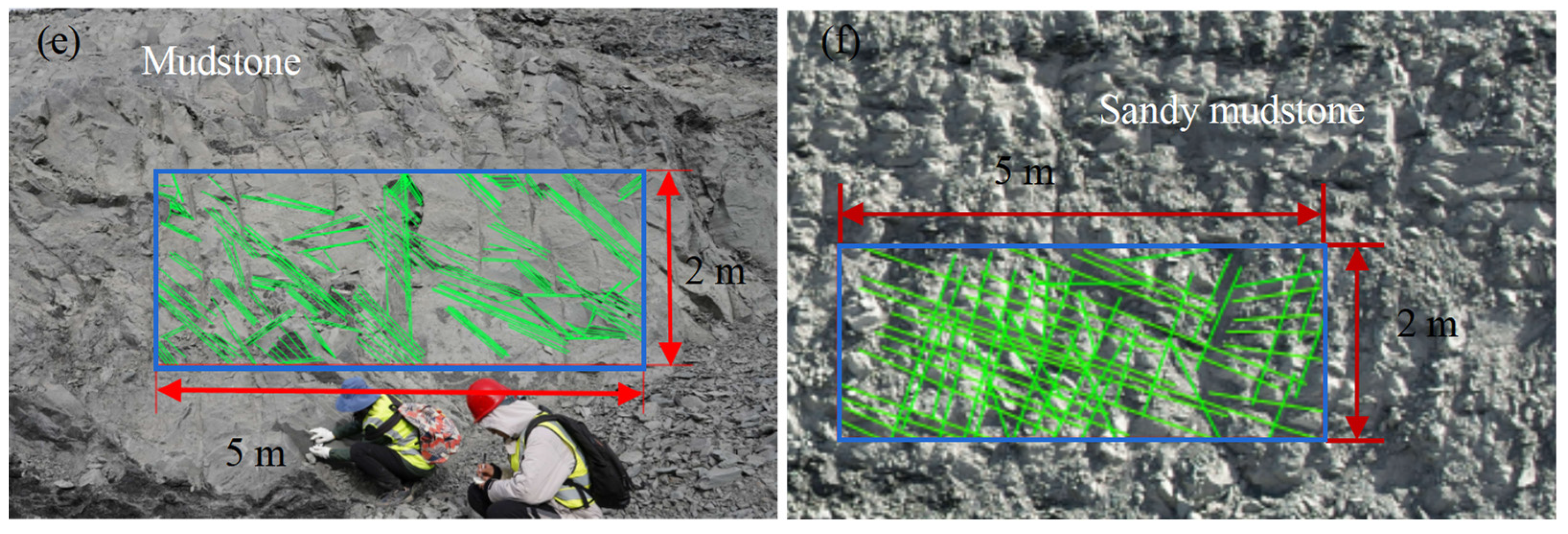

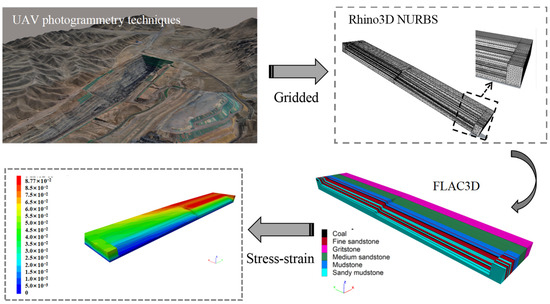

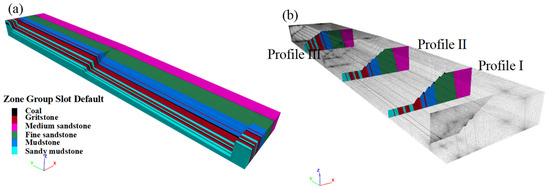

The 3D model used in the numerical simulation was constructed based on comprehensive data and then appropriately simplified to align with real-world conditions during the modeling process. This study employs Rhino software (6 SR10) for interactive modeling via the following steps (Figure 11): (1) Use UAV modeling software CC to generate 3D models and DEM data. Process this data in conjunction with ArcGIS software to create contour data. (2) Combine field knowledge to create a simplified 3D geological model using Rhino software and generate a grid using the Griddle plug-in. (3) Import the 3D model into FLAC3D, and perform a series of actions such as grouping, setting initial geostress, simulating excavation, and sequentially analyzing stress–strain.

Figure 11.

Numerical simulation process based on Rhinoceros software and FLAC3D software.

4. Results

4.1. Characteristics of Landslide Deformation

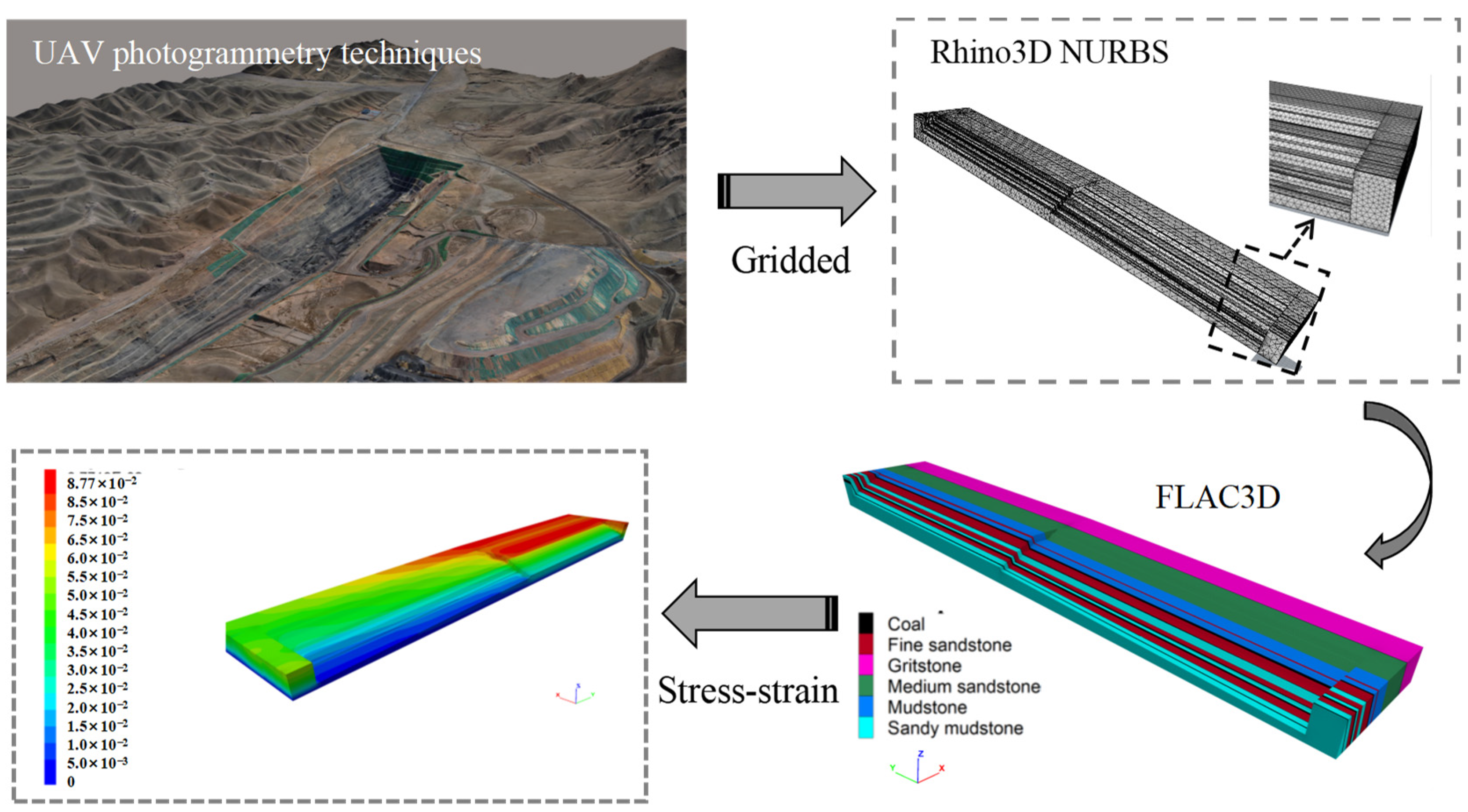

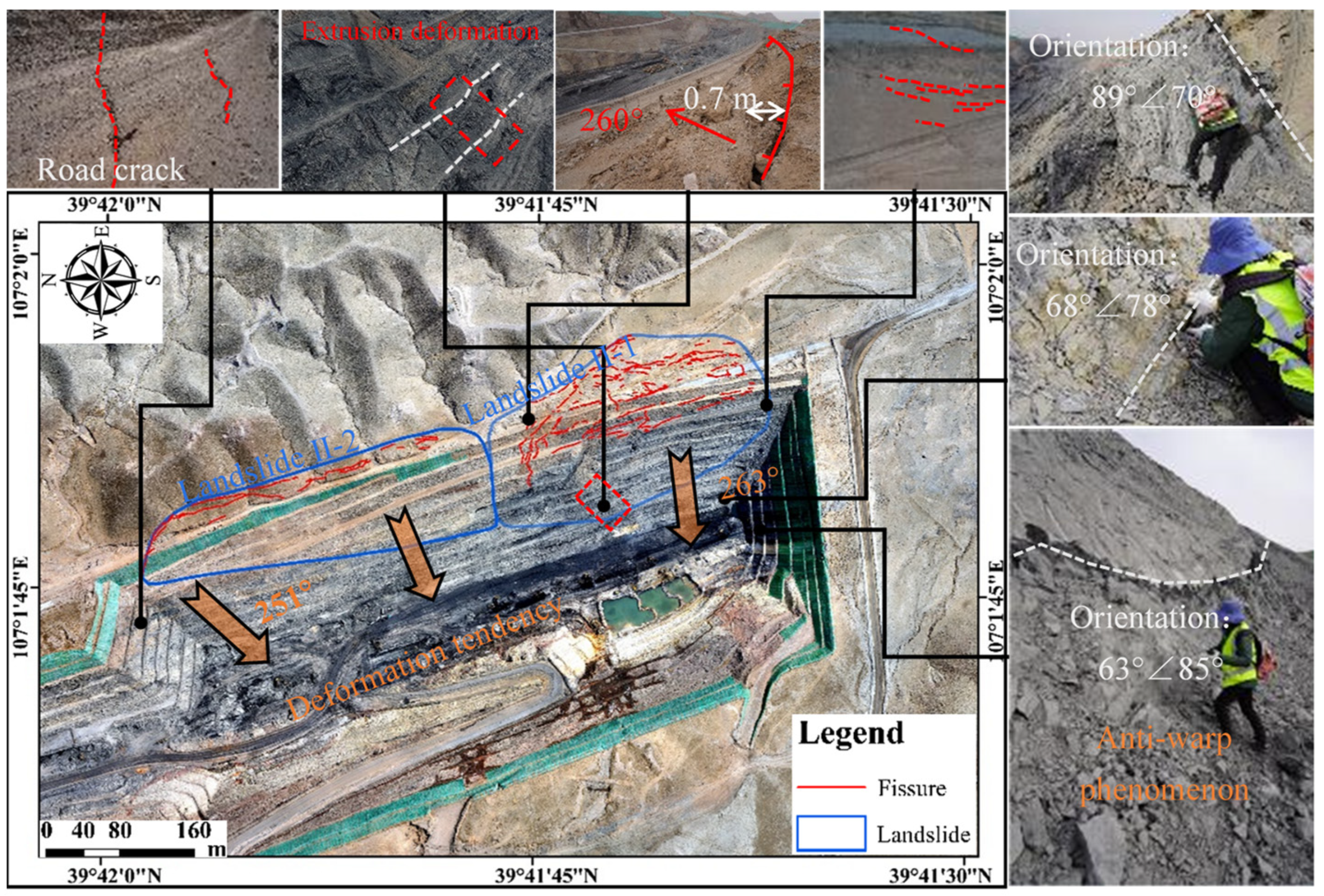

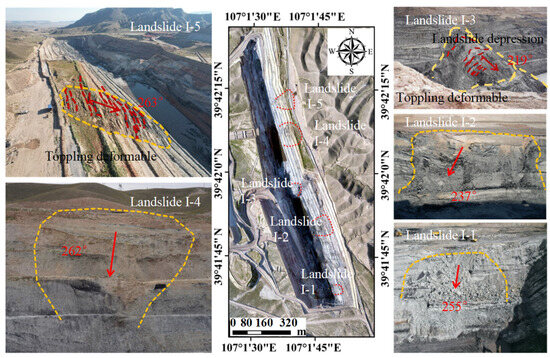

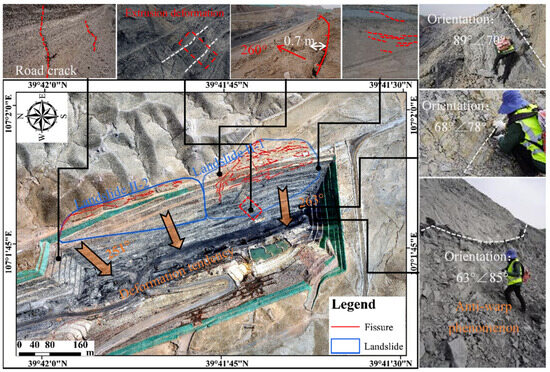

Multiperiod imagery of the study area was acquired using field geological surveys. Beginning with the observation of surface cracks in July 2022 and extending to September, a total of five landslides occurred on the eastern pit slope. All these landslides slide from east to west, with an approximate orthogonal projection area of 4.66 × 104 m2. Among them, three landslides on the south side of the eastern pit slope are centrally developed and relatively large in size. Detailed parameters for each landslide can be found in Table 2, and their distribution characteristics are illustrated in Figure 12.

Table 2.

Landslide parameters in the Wolong open-pit coal mine.

Figure 12.

Distribution map of landslide hazards (September 2022).

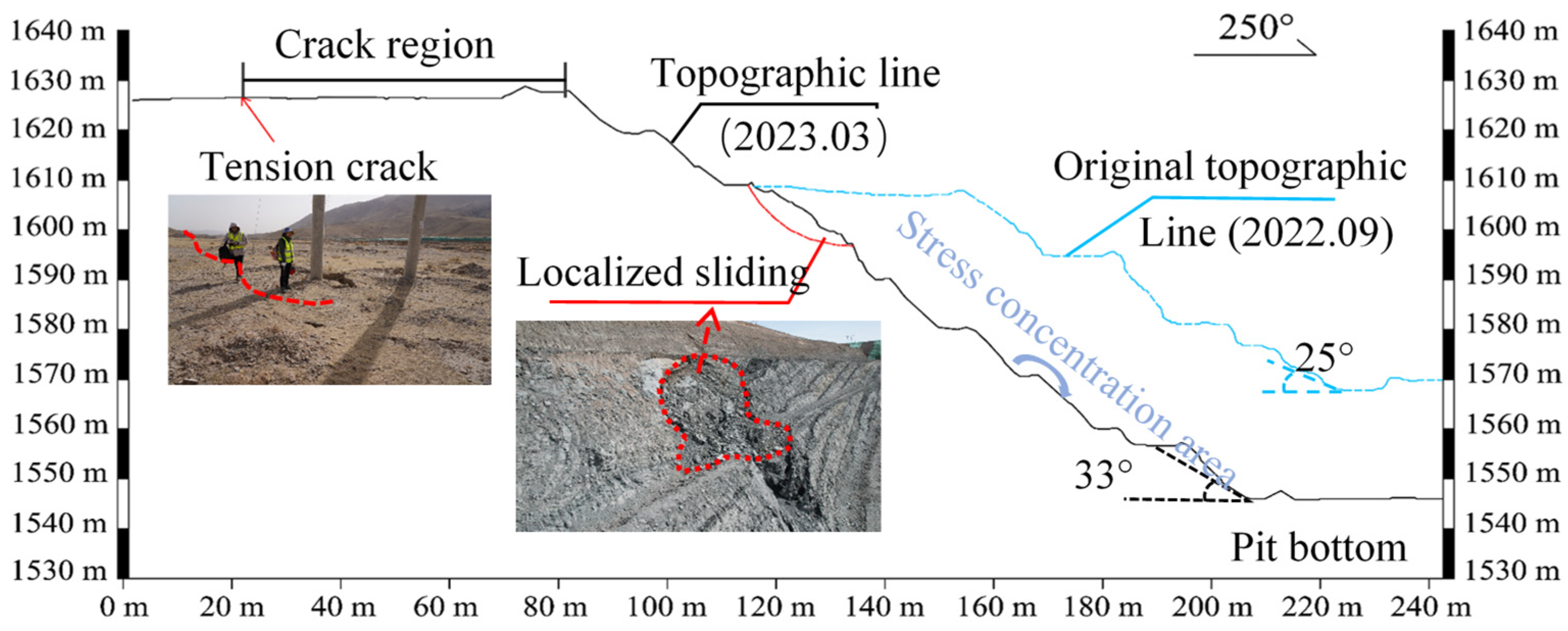

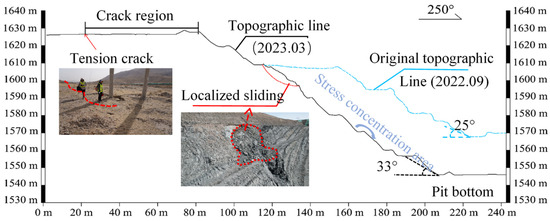

As of March 2023, the southern pit’s excavation had reached an elevation of 1548 m, resulting in the formation of a high and steep slope measuring approximately 83 m in height. As shown in Figure 13, this increase in mining depth has resulted in a significant change in overall slope angle, from 25° in September 2022 to 33°.

Figure 13.

Topographic line of the Wolong open-pit coal mine from September 2022 to March 2023.

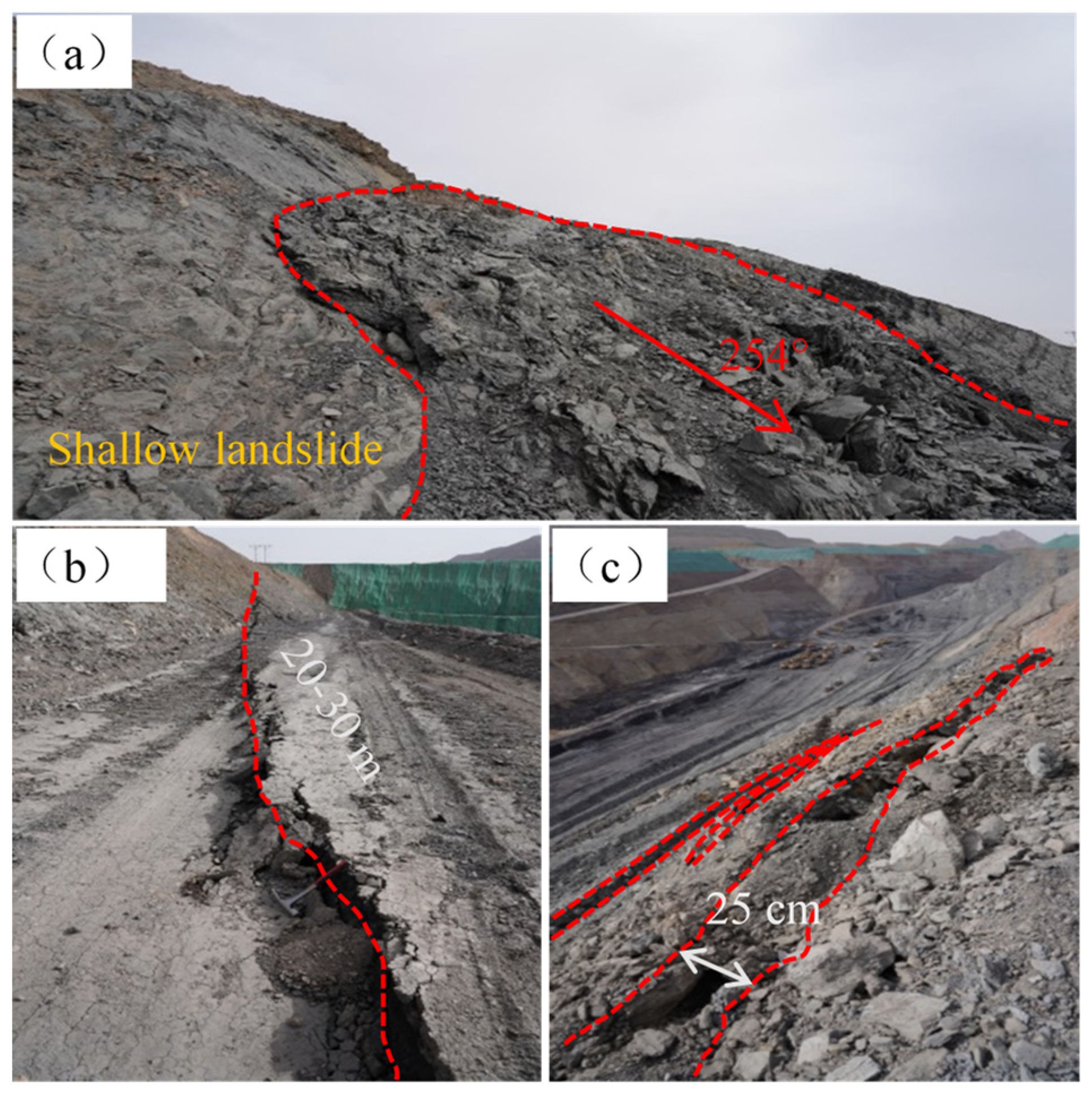

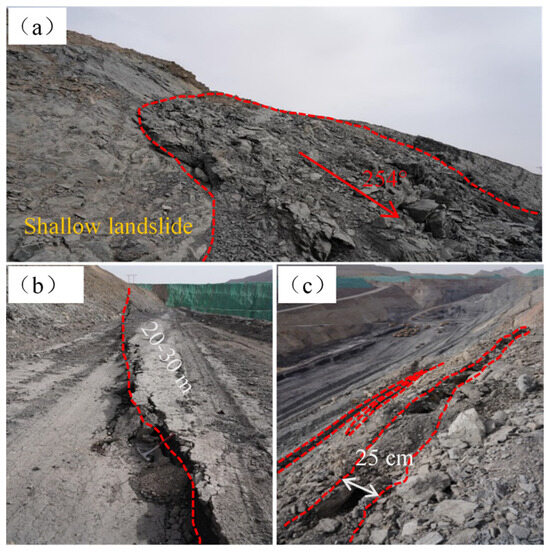

As the height of the eastern mining pit slope increases, stress concentration zones are generated due to stress redistribution near the slope surface. As shown in Figure 14, a total of 936 tensile fissures were developed in the tensile stress zone near the top of the eastern pit slope on the south side of the mining pit. Notably, the fissures at the trailing edge of the landslide II-1 exhibited more extensive development, causing slight misalignment at the upper platform edge and noticeable shear-induced bulging deformation in the lower portion. The orthographic projection area of the deformed bodies of landslides II-1 and II-2 is approximately 7.84 × 104 m2, and the deformation direction is approximately 263° (Figure 14). The strata in the landslide deformation zone exhibited a gradual decrease in dip, shifting from 85° at the bottom to 70° at the top. Additionally, the front edges of mining benches displayed signs of stratigraphic inversion, which is characterized by distinct features of flexural toppling failure (Figure 14 and Figure 15).

Figure 14.

Deformation development characteristics of the eastern pit slope (March 2023).

Figure 15.

Deformation characteristics of the pit slope: (a) Shallow landslide; (b,c) Tension fissure in the mining benches.

Due to continuous creep deformation, the central region of the pit slope has experienced severe deformation, leading to the development of small, shallow landslides. Tensile fissures, extending tens of meters upward to the slope’s peak, exhibit noticeable characteristics of inversion, particularly on the stepped-slope surface, as depicted in Figure 15.

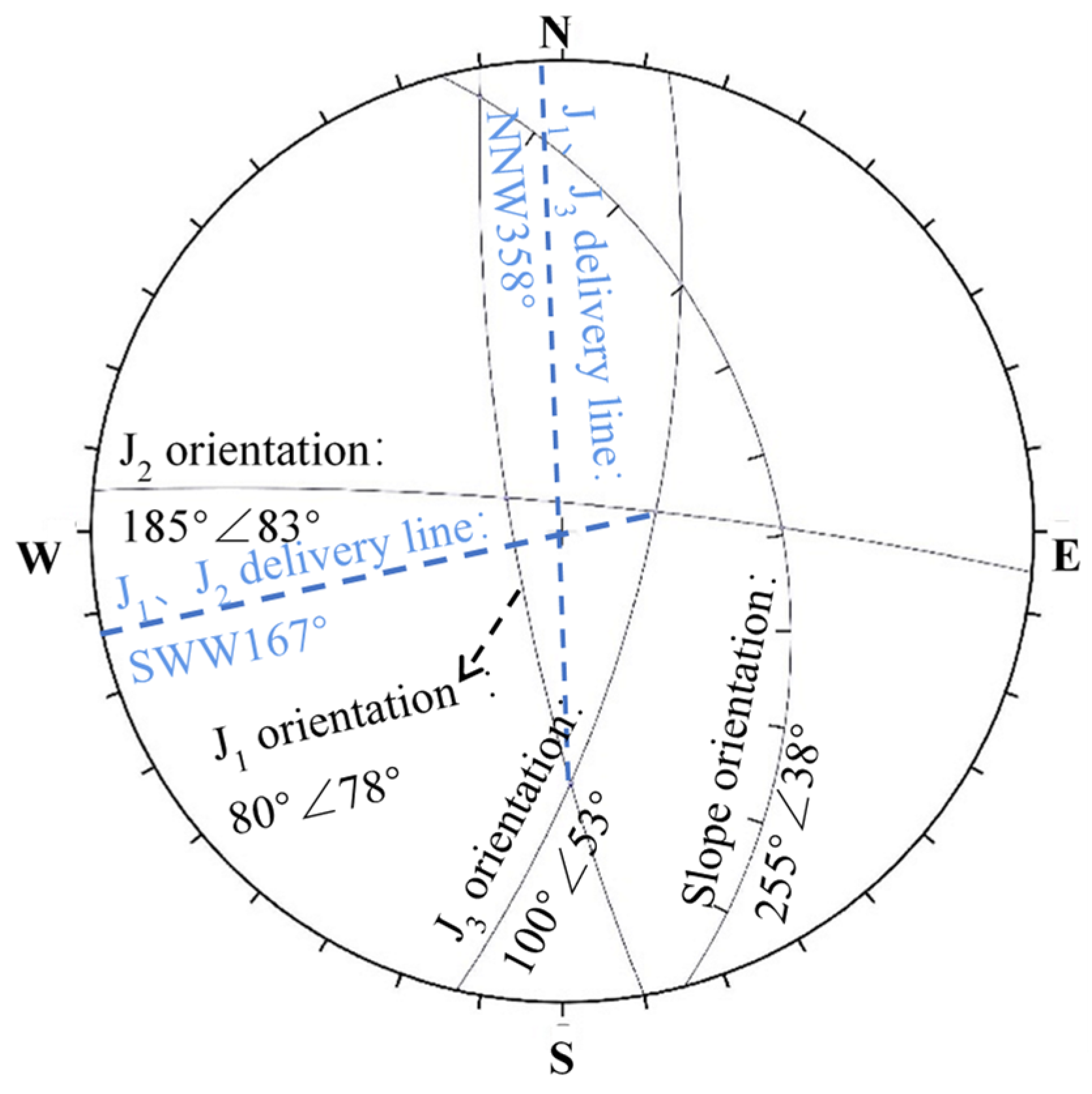

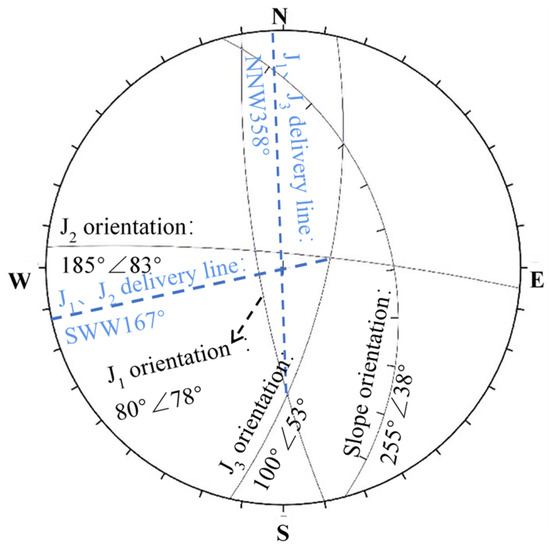

As illustrated in Figure 10, the window sampling method was employed to collect the fracture information within the exposed lithology of the pit slope. Then, utilizing the statistical findings of the mapping fracture data, a preliminary representation of the fractures was created, where J1 represents the bedding, and J2 and J3 denote the random fractures of the rock mass (Figure 16). The results show that the eastern pit slope of the Wolong open-pit coal mine belongs to an anti-inclined layered rock slope.

Figure 16.

Stereographic projection of the rock discontinuities in the Wolong open-pit coal mine.

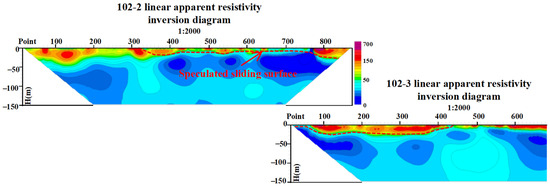

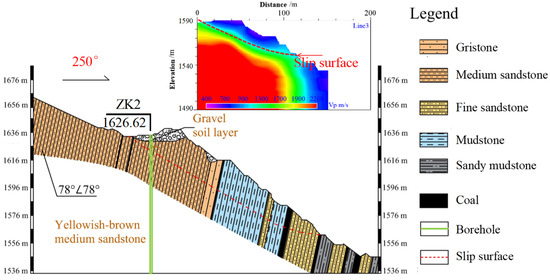

4.2. 3D Geological Structure Model of the Slope in the Mining Area

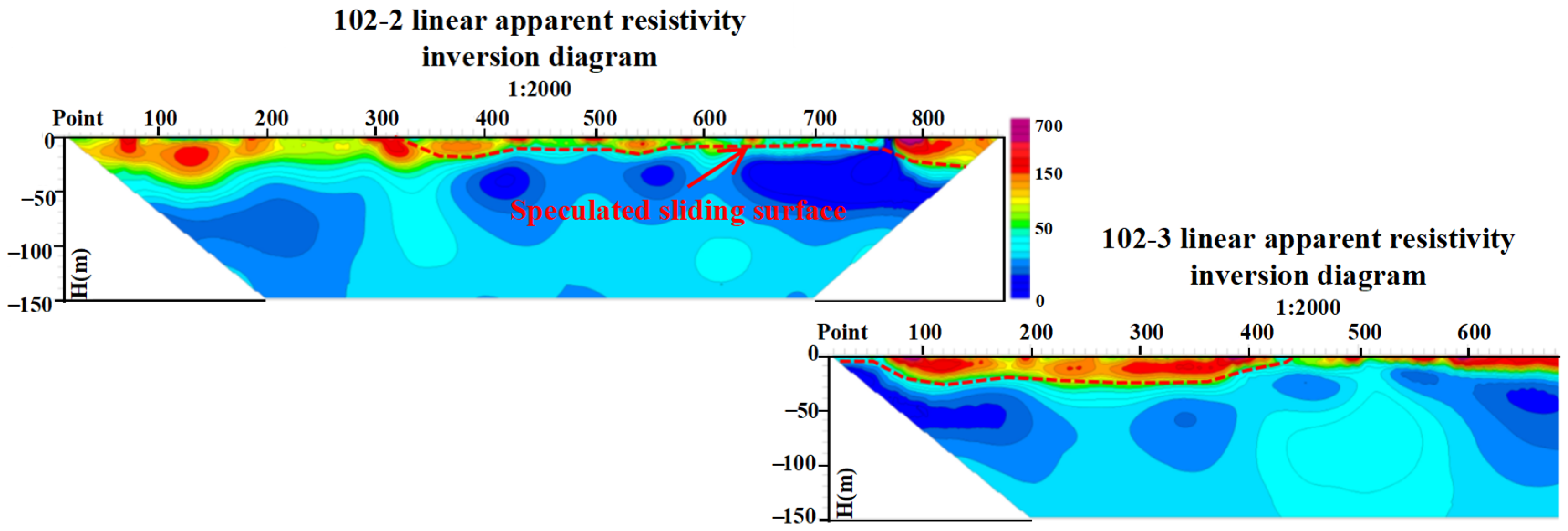

The field survey revealed that the predominant lithology in the study area comprises sandstone, mudstone, and sandy mudstone, as depicted in Figure 3. These rock formations exhibit a nearly north–south strike, and their dip angles are notably steep due to tectonic influences, ranging mostly between 65 and 85 degrees. As shown in Figure 17, the ERT results show that the resistivity of the upper part of the stratum in the study area ranges from 150 to 400 Ω·m (red), and the resistivity of the lower part changes abruptly, dropping to below 70 Ω·m (blue). By integrating the ERT results with borehole information, it was initially determined that the location of the potential sliding surface is located at the red-blue junction at a depth of between 55 and 75 m, with the prevalent stratigraphic lithology being primarily composed of mudstone and sandy mudstone.

Figure 17.

Inversion diagram of the apparent resistivity of Line 102 by the ERT method (see Figure 7 for profile locations).

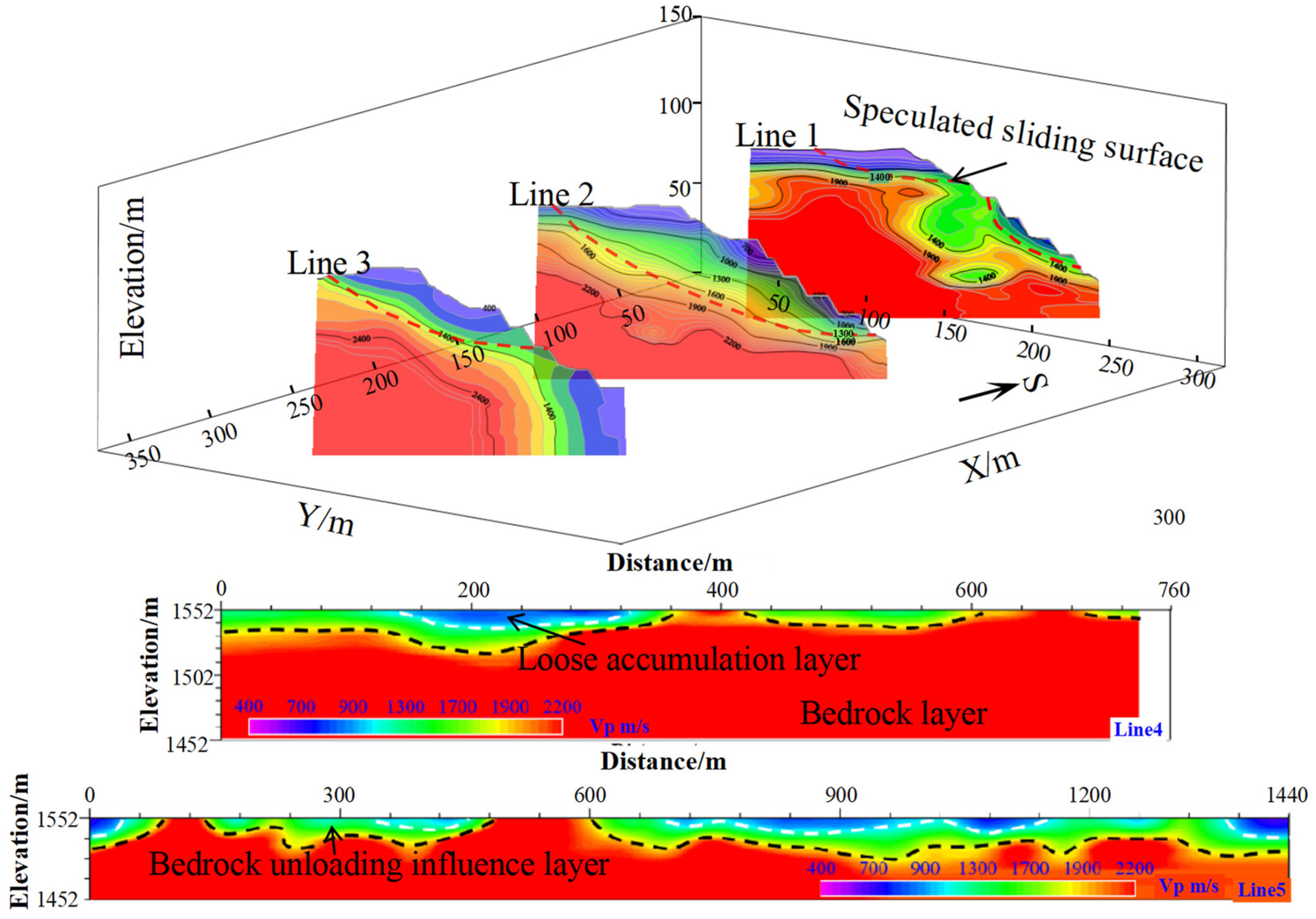

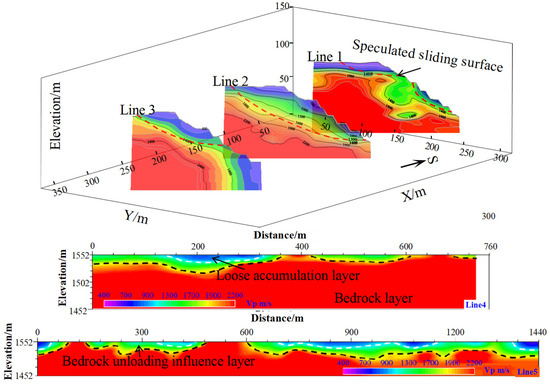

As shown in Figure 7 and Figure 18, the variation of compression wave velocity (Vp) from shallow to deep strata in the study area ranges from 400 to 2200 m/s, with obvious velocity stratification. This mainly reflects the velocity variation characteristics between the surface loose accumulation layer, the bedrock unloading influence layer, and the intact bedrock layer. The results show that wave velocities in the study area range from 400 m/s to 900 m/s in the loose accumulation layer (blue), from 900 m/s to 1900 m/s in the bedrock unloading influence layer (green), and rise above 1900 m/s in the intact bedrock layer (red).

Figure 18.

Interpretation results by the SRT method (see Figure 7 for profile locations).

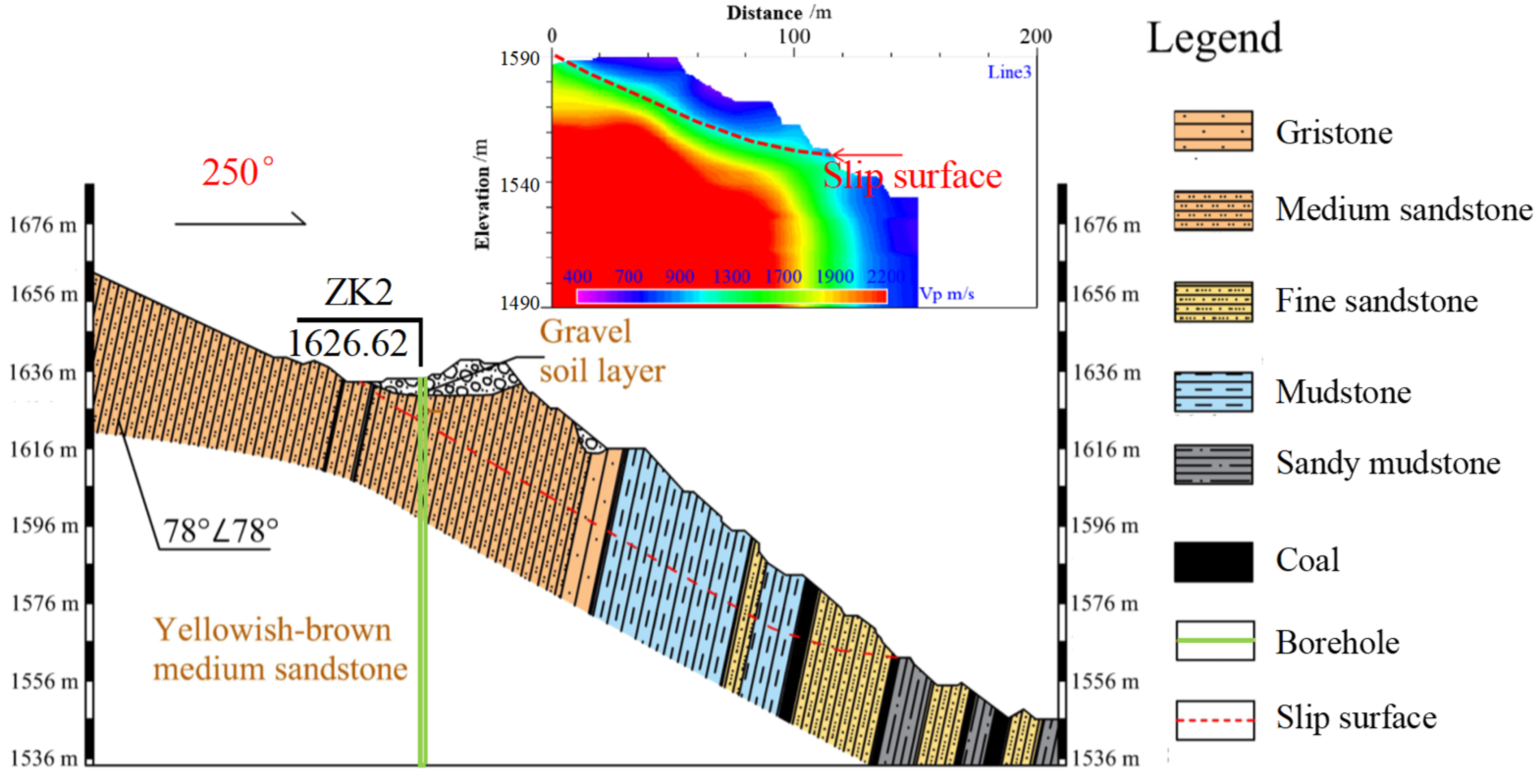

Finally, this study combined drilling, ERT, and SRT survey data (Figure 17 and Figure 18) to identify the geological structure of the pit slope and the surface morphology of the slip surface (Figure 7 and Figure 19).

Figure 19.

Typical geological profile of the eastern pit slope in the Wolong Coal Mine.

4.3. Laboratory Testing Results of the Rock Mass

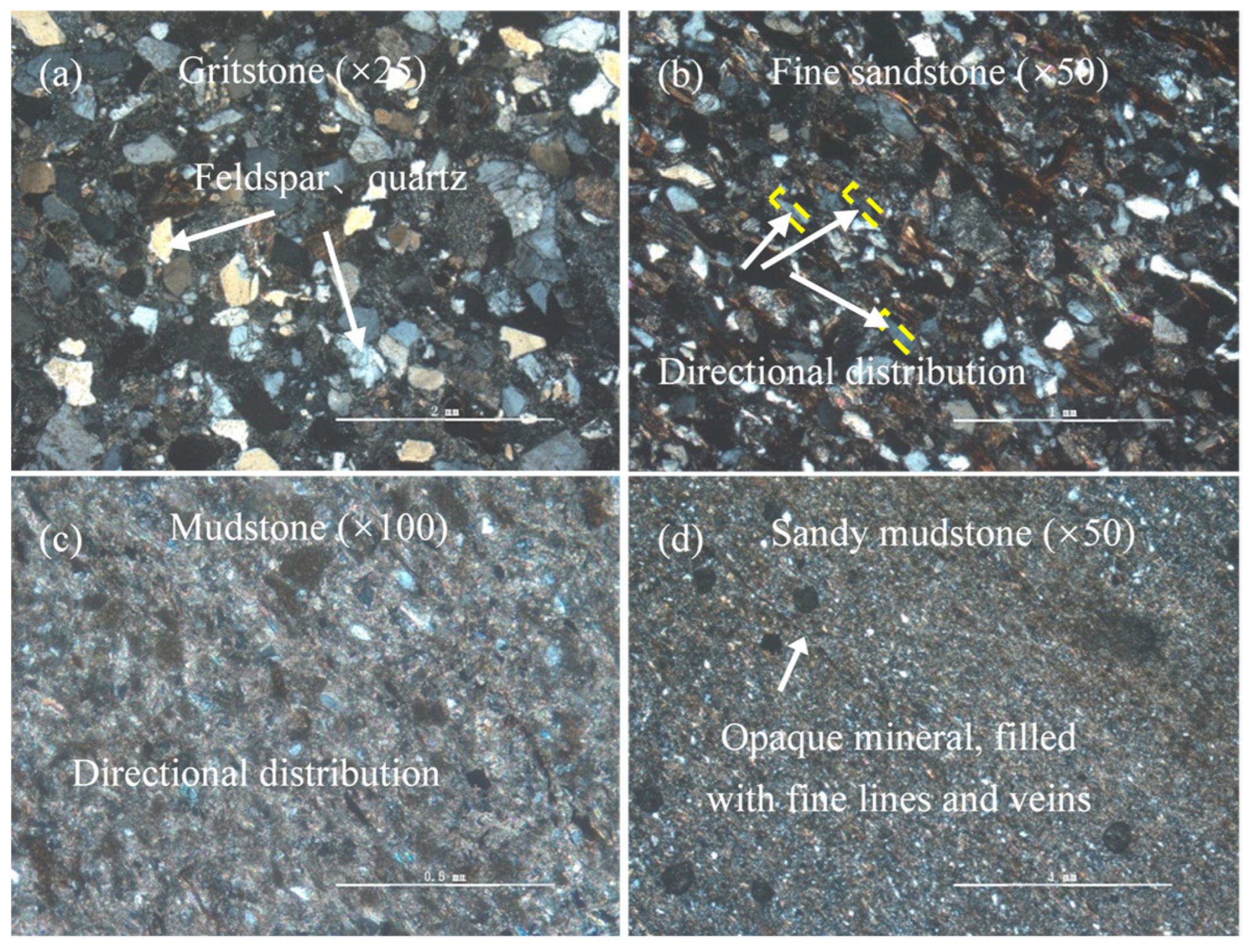

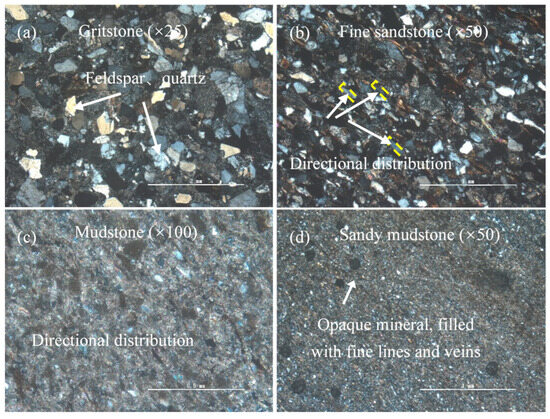

4.3.1. Results of Rock Thin Section Analysis

As shown in Figure 20a, the clasts within the gritstone exhibit a predominantly angular-subangular shape, poorly rounded, with grain sizes mostly ranging from 0.5–1.7 mm and moderate sorting. Moreover, the clasts predominantly maintain point-line contact with each other, with basal-porous cementation. In contrast, the grain size of clasts within the fine sandstone ranges from 0.1 to 0.25 mm, with good sorting and directional distribution (Figure 20b). The directional arrangement of clasts can also be observed in the mudstone (Figure 20c). As shown in Figure 20d, opaque minerals are primarily observed along fissures in thin lines and within vein fillings.

Figure 20.

Results of the rock thin section identification method for major lithologies: (a) Gritstone (×25); (b) Fine sandstone (×50); (c) Mudstone ×100; (d) Sandy mudstone (×50).

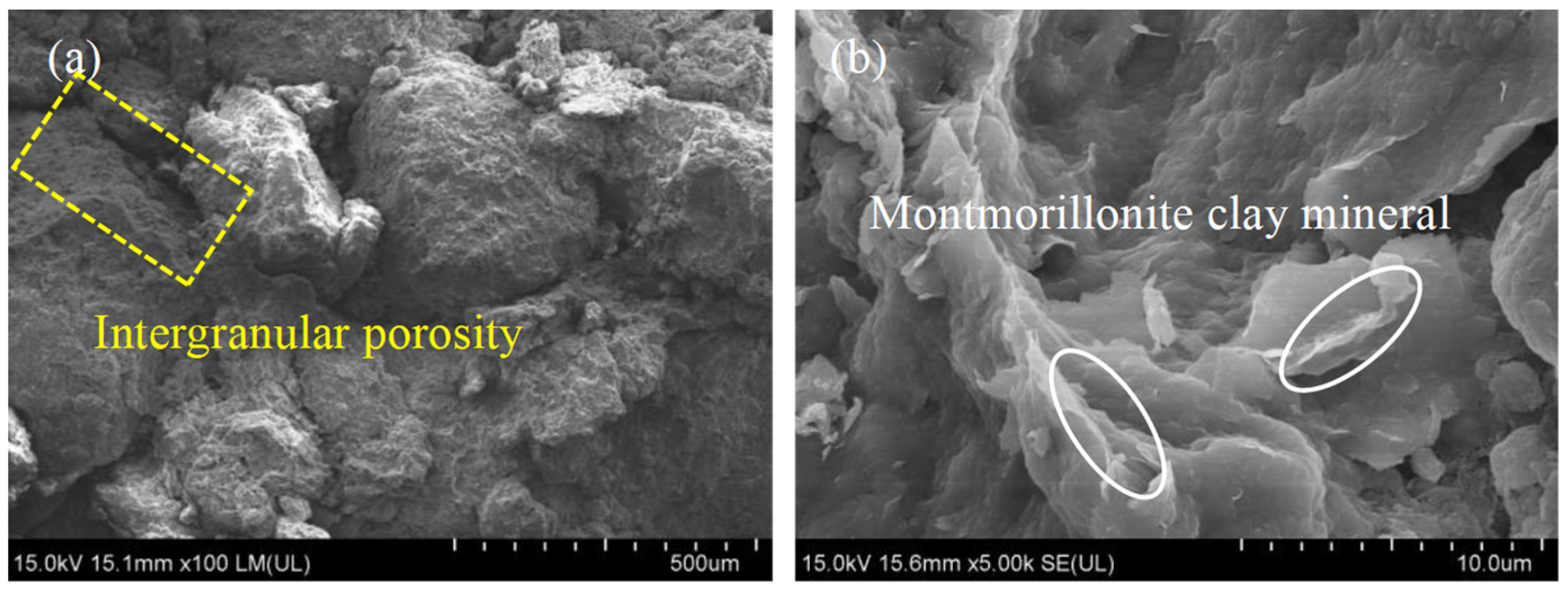

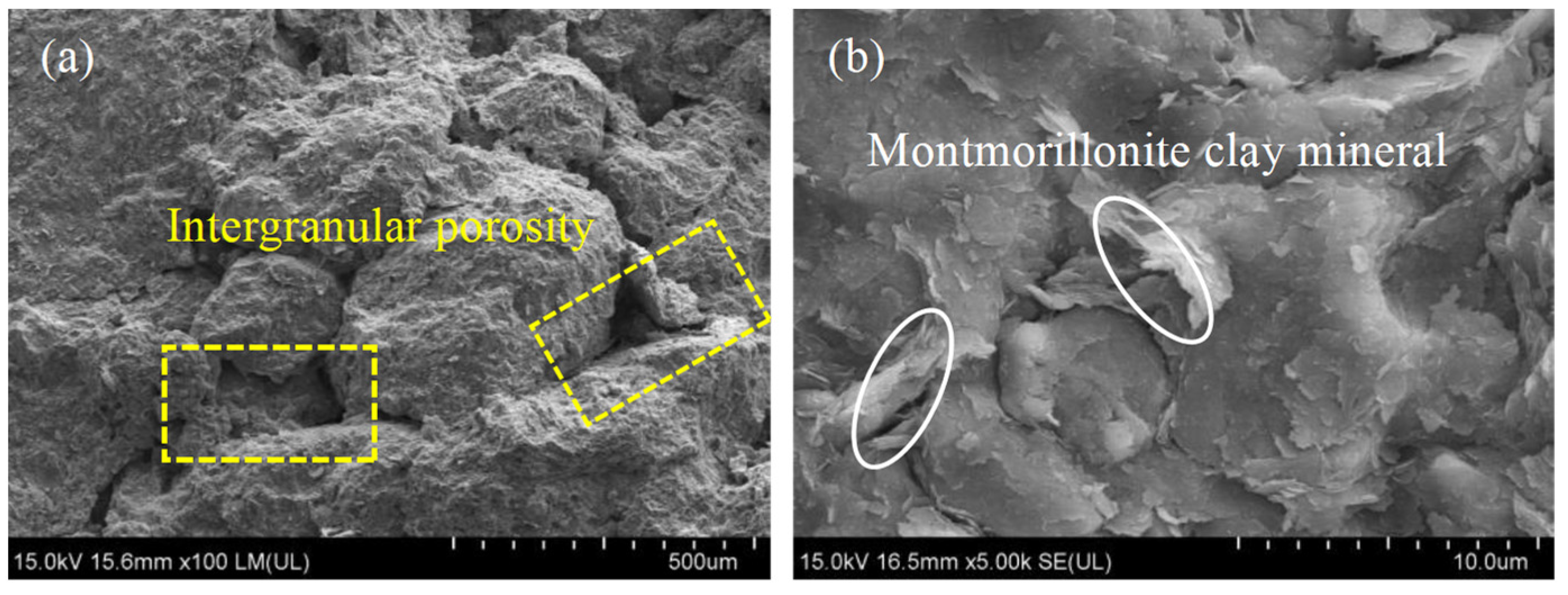

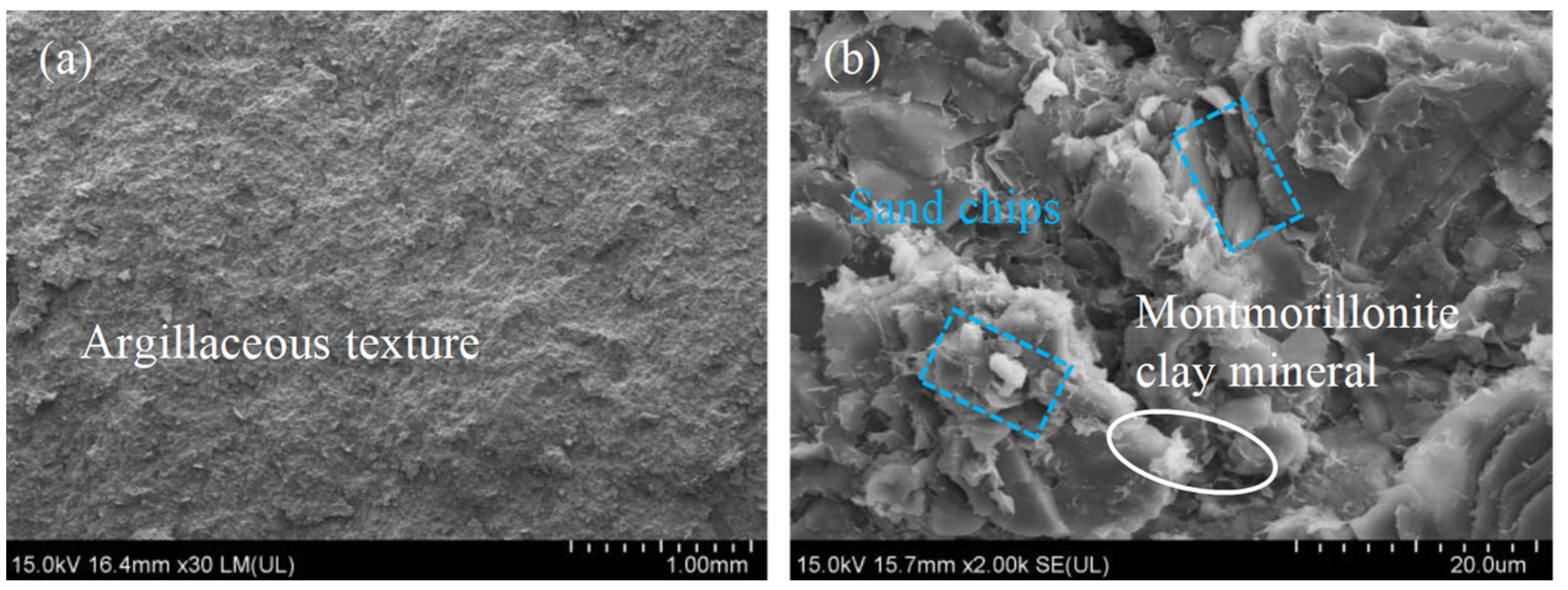

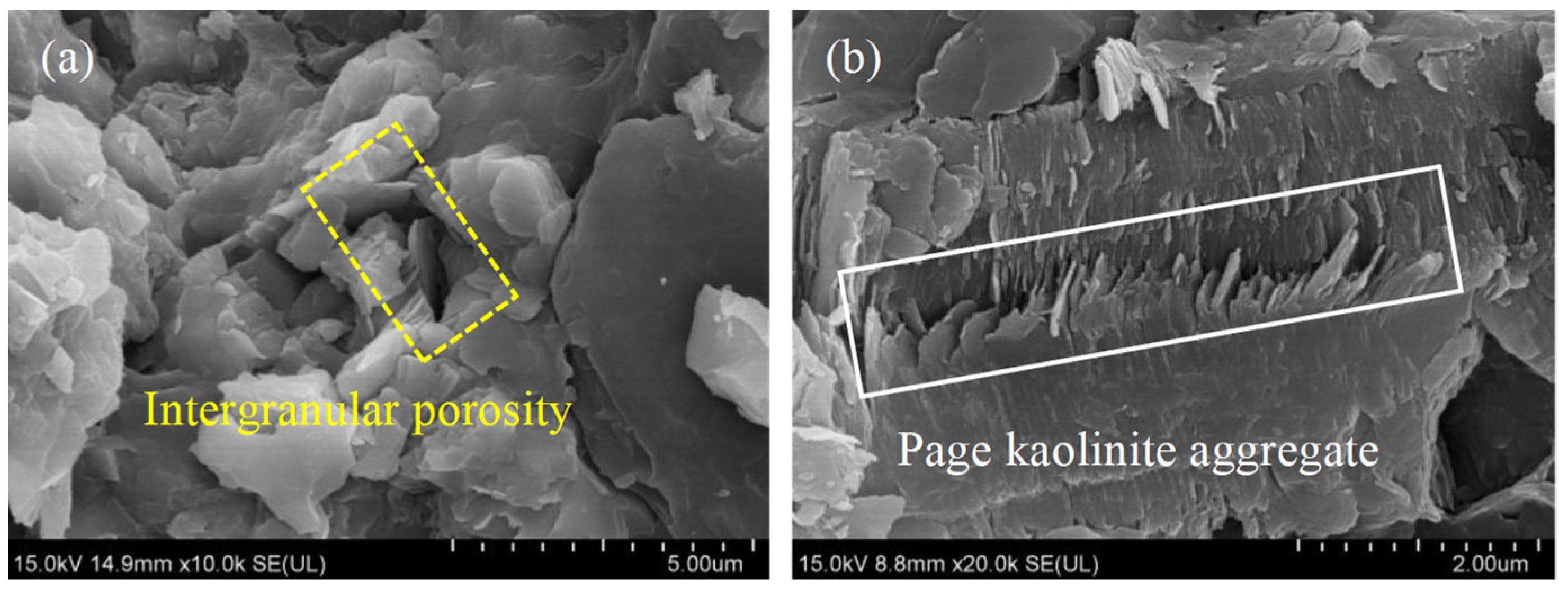

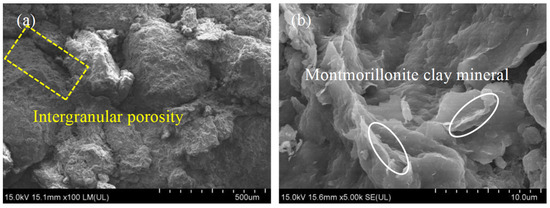

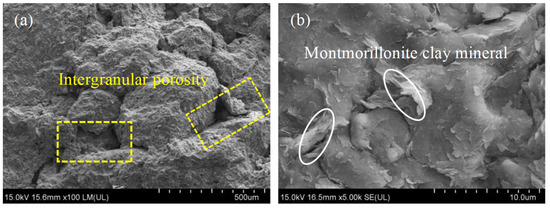

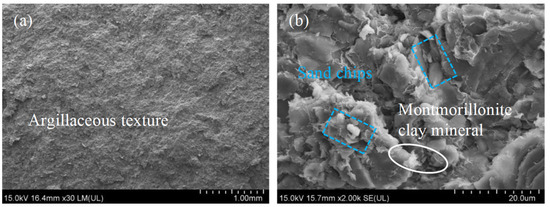

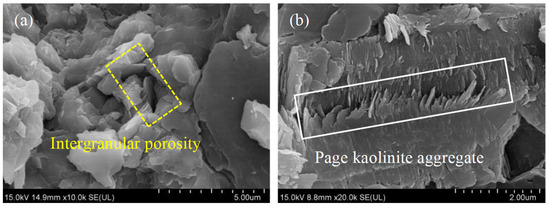

4.3.2. Results of SEM Analysis

As depicted in Figure 21 and Figure 22, the sandstones within the study area exhibit intergranular pores measuring approximately 20 to 100 μm. These pores are laden with mud, clay minerals, and other constituents. Clay minerals are affixed to the grain surfaces, often displaying characteristic lamellar and distorted edges. The micro-fissures developed in sandstone are natural reservoirs for infiltrating rainwater, and the sandstone is prone to cracking along these intergranular pores in the presence of water. The mudstone contains both sand clasts and clay minerals. The clay minerals exhibit warped, petal-like edges and the pore space primarily consists of intergranular pores (Figure 23). The mudstone matrix in the sandy mudstone in the study area is mainly composed of clay minerals and feldspar. The feldspar clasts exhibit obvious flat and straight disintegration surfaces, and the kaolinite aggregates in the clay minerals are flaky, with intergranular pores of approximately 100–200 μm. When magnified 20,000 times), the booklet-shaped, flaky kaolinite sheets are observed to exhibit face-to-face contact (Figure 24).

Figure 21.

Electron microscope image of gritstone: (a) ×100; (b) ×5000.

Figure 22.

Electron microscope image of fine sandstone: (a) ×100; (b) ×10,000.

Figure 23.

Electron microscope image of mudstone: (a) ×30; (b) ×10,000.

Figure 24.

Electron microscope image of sandy mudstone: (a) ×10,000; (b) ×20,000.

4.3.3. Results of XRD Analysis

Table 3 lists the mineral composition results of rock samples by the XRD analysis. The results reveal that the sandstone samples contain approximately 15.6% to 33.8% clay minerals, with montmorillonite and kaolinite being the predominant clay minerals. These two minerals collectively constitute a substantial relative content ranging from 79% to 96%. In comparison, the mudstone and sandy mudstone samples exhibit higher clay mineral contents, varying between 29.7% and 59.6%, with kaolinite and montmorillonite accounting for 58% to 85%. Notably, the rock samples in the study area consistently contain substantial quantities of clay minerals, particularly montmorillonite and kaolinite.

Table 3.

Analysis results of X-ray diffraction components.

4.3.4. Results of Laboratory Physical and Mechanical Tests

A variety of physical and mechanical tests were conducted on 120 rock samples, and the specific parameters are shown in Table 4. The uniaxial compressive strength experiments show that most of the rock samples in the study area are less than or equal to 30 MPa, which are soft rocks. The above results indicate that the mechanical properties of the rock samples in the study area are significantly reduced when exposed to water.

Table 4.

Results of laboratory physical and mechanical tests.

4.4. Rock Mass Structure Characterization

By grouping and statistically analyzing the fracture data obtained by the window sampling method (Figure 10), the basic parameters of the fractures of each lithology in the study area were obtained, including the number of fractures, orientation, and average spacing of each fracture set. The specific parameters are shown in Table 5. In the study area, two or three fracture sets are commonly developed in the rock mass, resulting in a relatively fractured rock mass structure.

Table 5.

Development characteristics of fractures of different lithologies in the study area.

By integrating the field geological understanding and the methodology in Section 3.5, the estimates of GSI, mi, D, mb, s, and a for typical lithologies in the study area are shown in Table 6. Then, the geomechanical properties of rock masses can be estimated by the GSI system using Equations (2)–(4), such as Mohr–Coulomb failure constants and rock mass deformation modulus (Table 7).

Table 6.

Parameters of generalized Hoek–Brown criterion for typical lithologies in the study area.

Table 7.

Geomechanical properties of rock masses estimated by GSI system.

4.5. Numerical Simulation Results of Slope Deformation and Failure

4.5.1. Model Construction

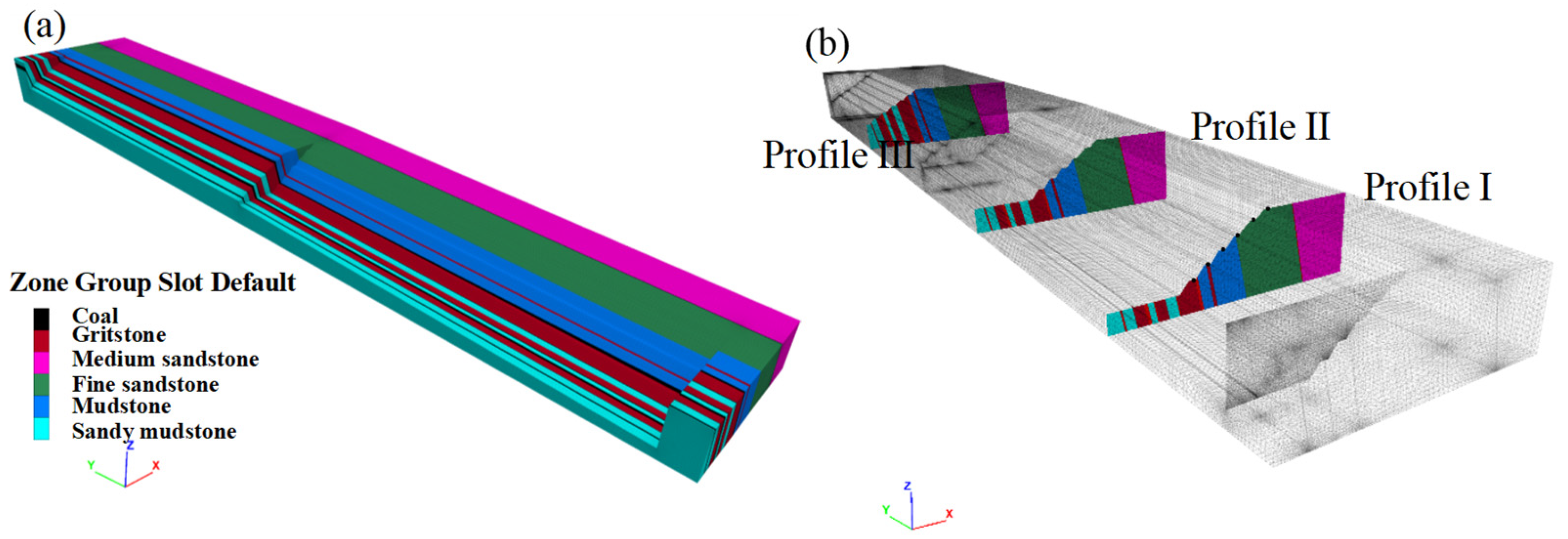

As shown in Figure 25a, a simplified 3D model for the eastern pit slope is first constructed with the mine excavation condition in October 2022 as the initial state. The 3D model uses an ideal elasto–plastic model with a Mohr–Coulomb yield criterion for the material. In the model, the x-axis direction is perpendicular to the slope strike, spanning a length of 266 m, while the y-axis is approximately parallel to the slope strike, extending over 1600 m. The z-axis direction has a length of 99 m. The resulting computational model consisted of a total of 2,648,727 zones and 481,045 grid points. Tetrahedral meshes are used to describe the behavior of the rock mass. The specific parameters used in the numerical model are shown in Table 4 and Table 7. After zeroing its displacement and velocity, the excavation operation is carried out to analyze the stress–strain characteristics of the mine post-excavation. Excavation operations were conducted in accordance with the actual construction operations, and the final model was excavated to the mining pit status in March 2023. To visually examine the stress–strain dynamics within the pit slope, three profiles were chosen for observation, as shown in Figure 25b.

Figure 25.

(a) A simplified 3D geological model used in FLAC3D; (b) Profile distribution map.

4.5.2. Displacement Analysis

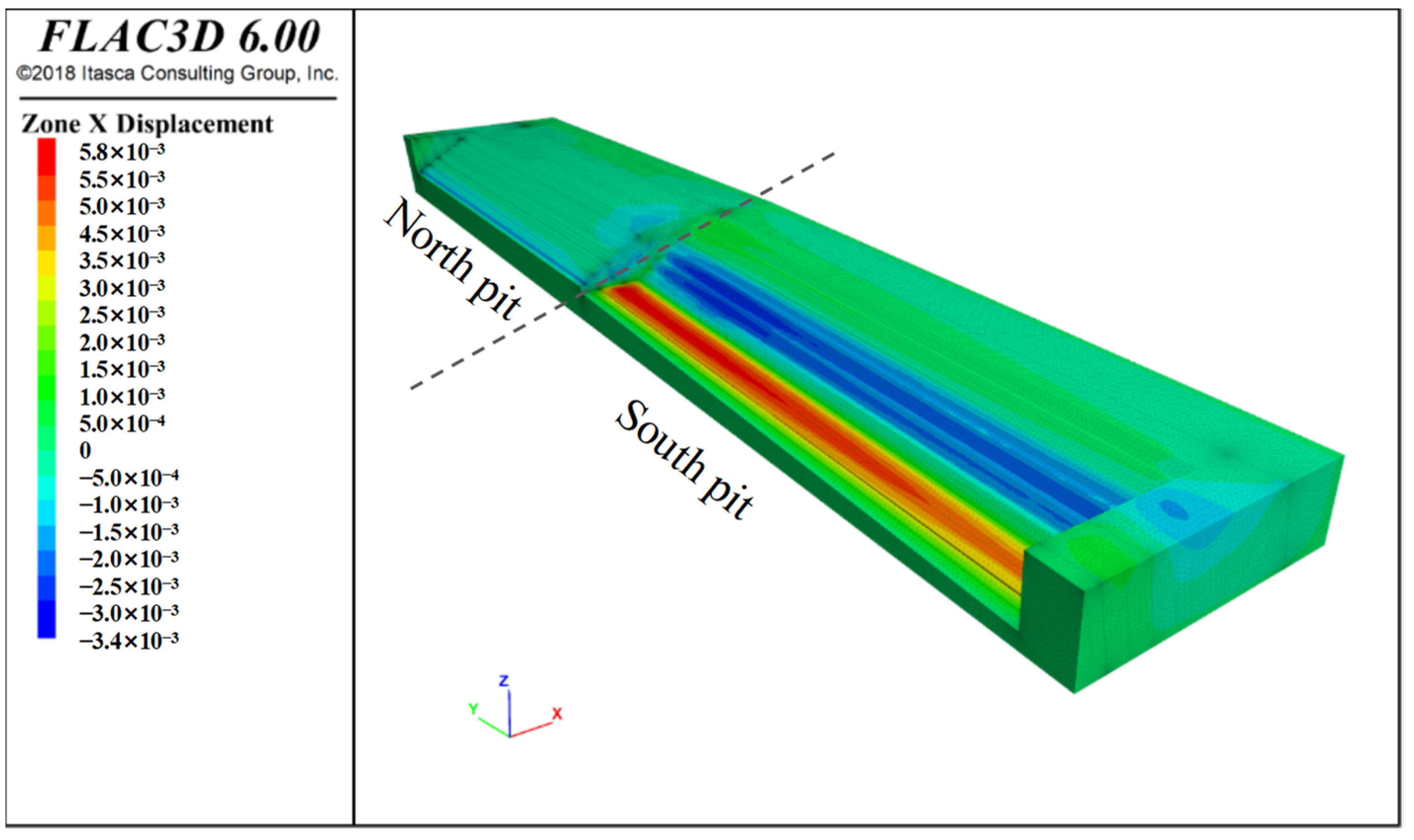

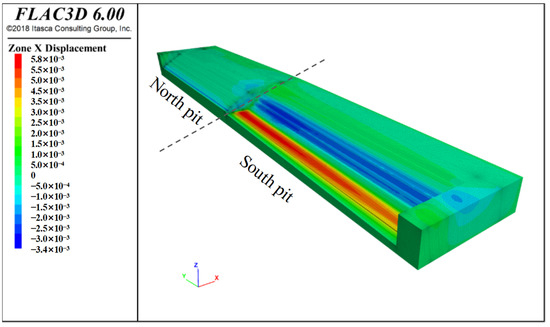

As depicted in Figure 26, influenced by the different excavation depths of the north and south sides of the open-pit mine, the high values of displacement on the north side are mainly concentrated near the foot of the slope, while the high values of displacement on the south side of the pit slope are mainly distributed in the middle and lower parts of the slope, with a broader area of impact.

Figure 26.

A simplified 3D geological model used in FLAC3D.

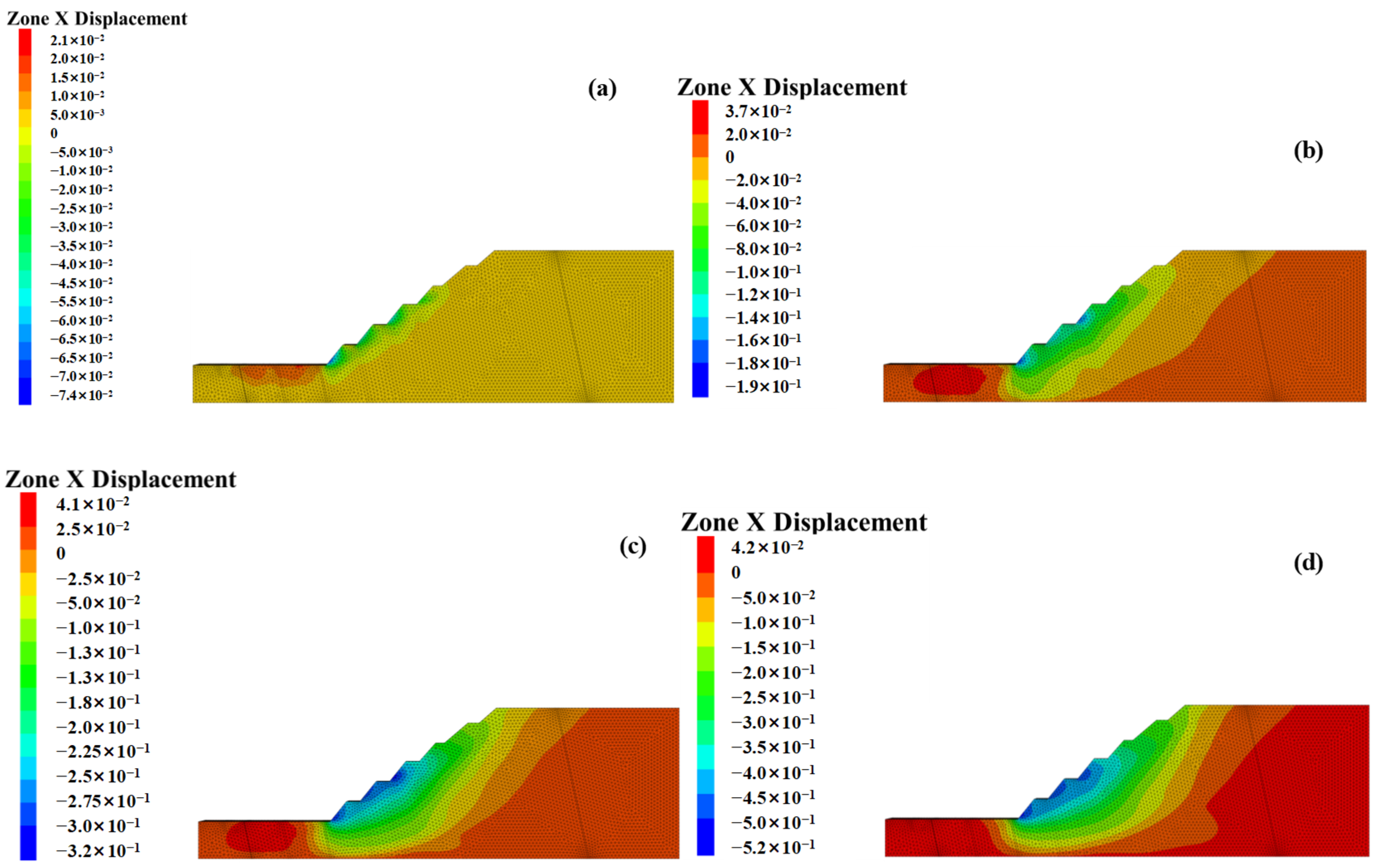

As depicted in Figure 27a, after the model was calculated for 100 steps, the shallow surface layer in the middle and lower parts of the slope exhibited minor deformation, inclining outward from the slope body. The displacement values ranged from 2.06 × 10–2–7.44 × 10–2 m. When the model reached 1000 steps, the areas of deformation began to extend to higher and deeper regions, resulting in a local step displacement and increased deformation reaching 1.89 × 10−1 m (Figure 27b). As the number of simulation steps increased, the displacement near the surface of the slope consistently grew, and the degree of deformation continued to escalate (Figure 27c,d).

Figure 27.

Displacement cloud of profile I in the x-direction: (a) 100 steps; (b) 1000 steps; (c) 2000 steps; (d) 3000 steps.

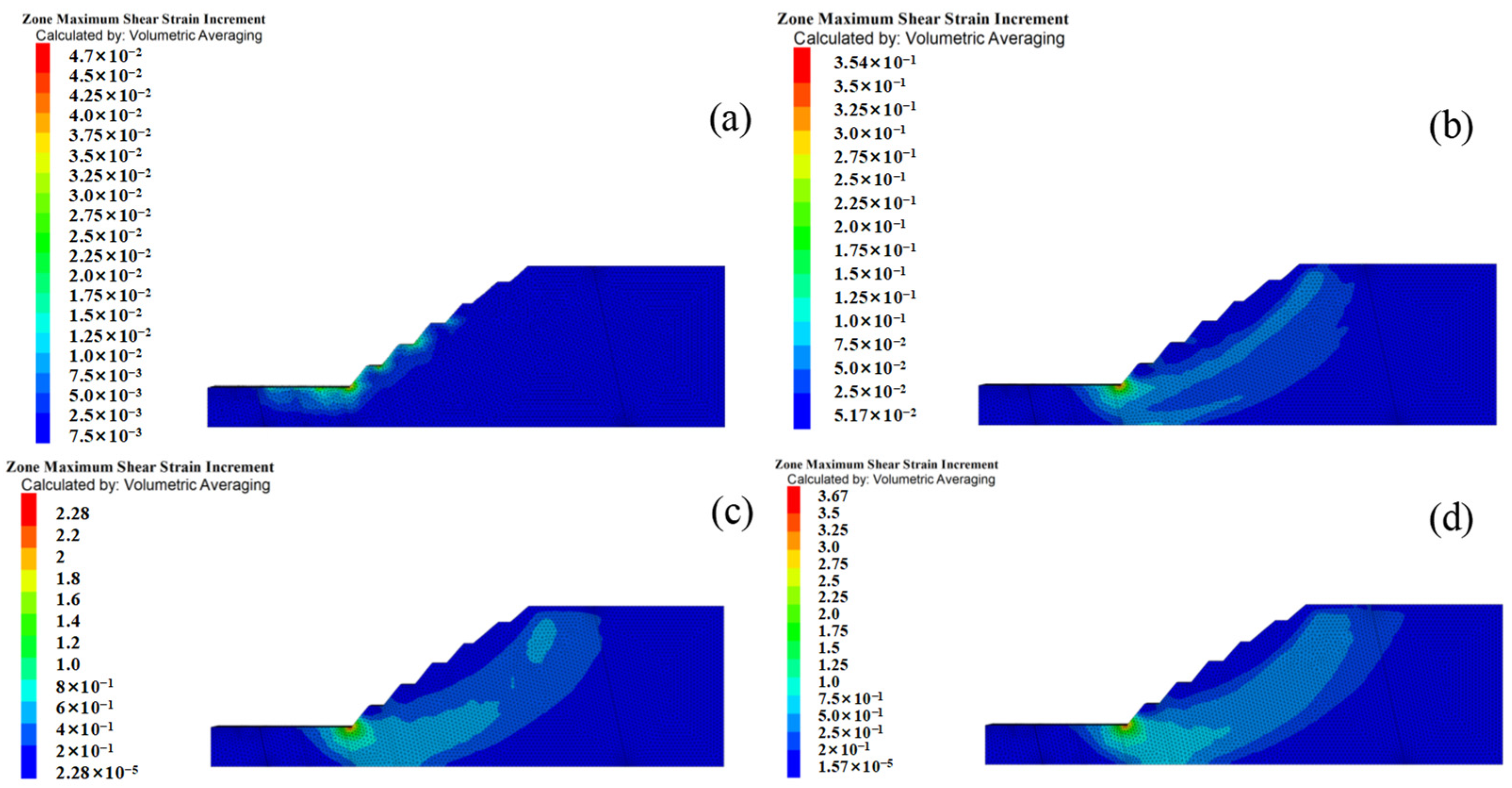

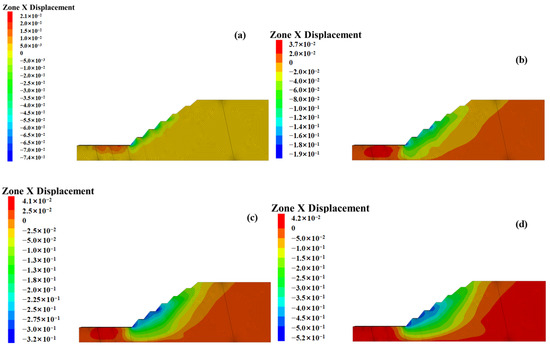

4.5.3. Shear Strain Distributions

Many engineering cases demonstrate that the magnitude of shear strain increments can be indicative of potential slip surfaces or locations of deformation damage [42,43]. Typically, zones with concentrated shear strain increments occur at the depth of the damage area on the slope. As illustrated in Figure 28a, the shear strain cloud map after 100 calculation steps reveals that the region with concentrated shear strain increments is situated within the middle and lower superficial layers of the pit slope, with the maximum value reaching 4.697 × 10−2. As the number of calculation steps increases, the region of concentrated shear stress shifts downward, and its impact area gradually expands. Simultaneously, the strain values consistently increase (Figure 28b–d). This progression signifies a gradual decrease in slope stability over time following excavation.

Figure 28.

Cloud map of the incremental shear strain in profile I: (a) 100 steps; (b) 1300 steps; (c) 2600 steps; (d) 3900 steps.

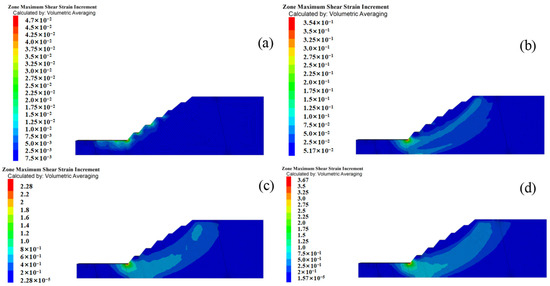

4.5.4. Dynamic Deformation Characteristics

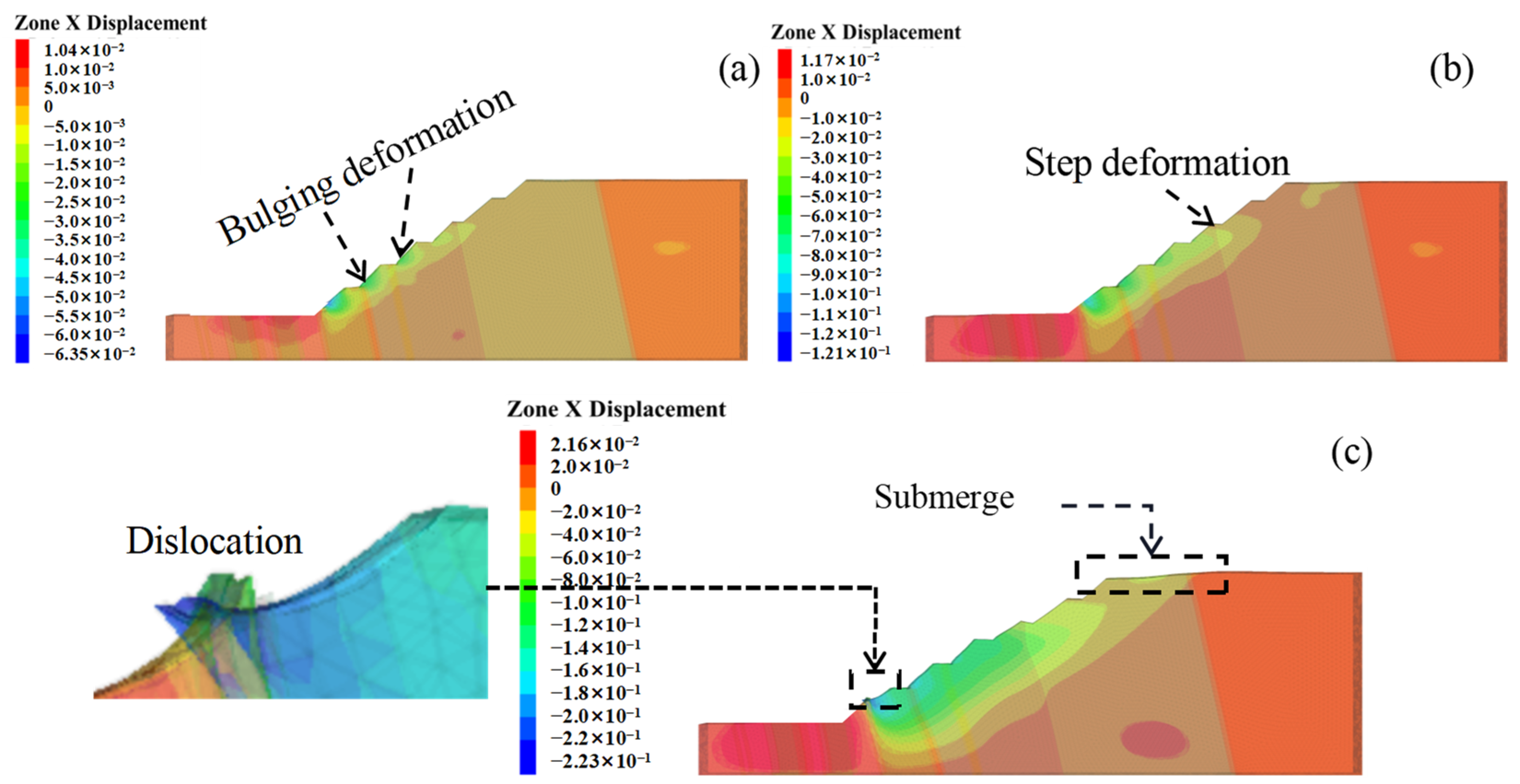

To visually examine the deformation and damage patterns within the model, we activated the large deformation parameters in FLAC3D for simulation. As depicted in Figure 29a, an initial small bulging deformation emerges at the simulated slope corner. As the simulation progresses, the displacement values gradually increase, and the step surface undergoes deformation, presenting a warping shape at the front end of the upper step of the slope body (Figure 29b). With ongoing calculations, the model’s deformation continues to intensify, involving deformation at the top and local stratigraphic misalignment near the slope’s corner, a characteristic pattern of buckling in steep terrain (Figure 29c).

Figure 29.

Deformation and failure characteristics of the model: (a) 100 steps; (b) 200 steps; (c) 500 steps.

An analysis of Figure 13, Figure 14 and Figure 15 shows that distinct extrusion and deformation features appear at the foot of the pit slope. Local shallow landslides manifest in the middle of the slope, with numerous tensile cracks developing at the slope’s summit and minor-scale misalignment occurring along the edge. Figure 29 illustrates that the deformation characteristics in this numerical simulation broadly align with those observed in the field, rendering the simulation process more plausible.

5. Discussion

5.1. Causes of Pit Slope Deformation and Failure

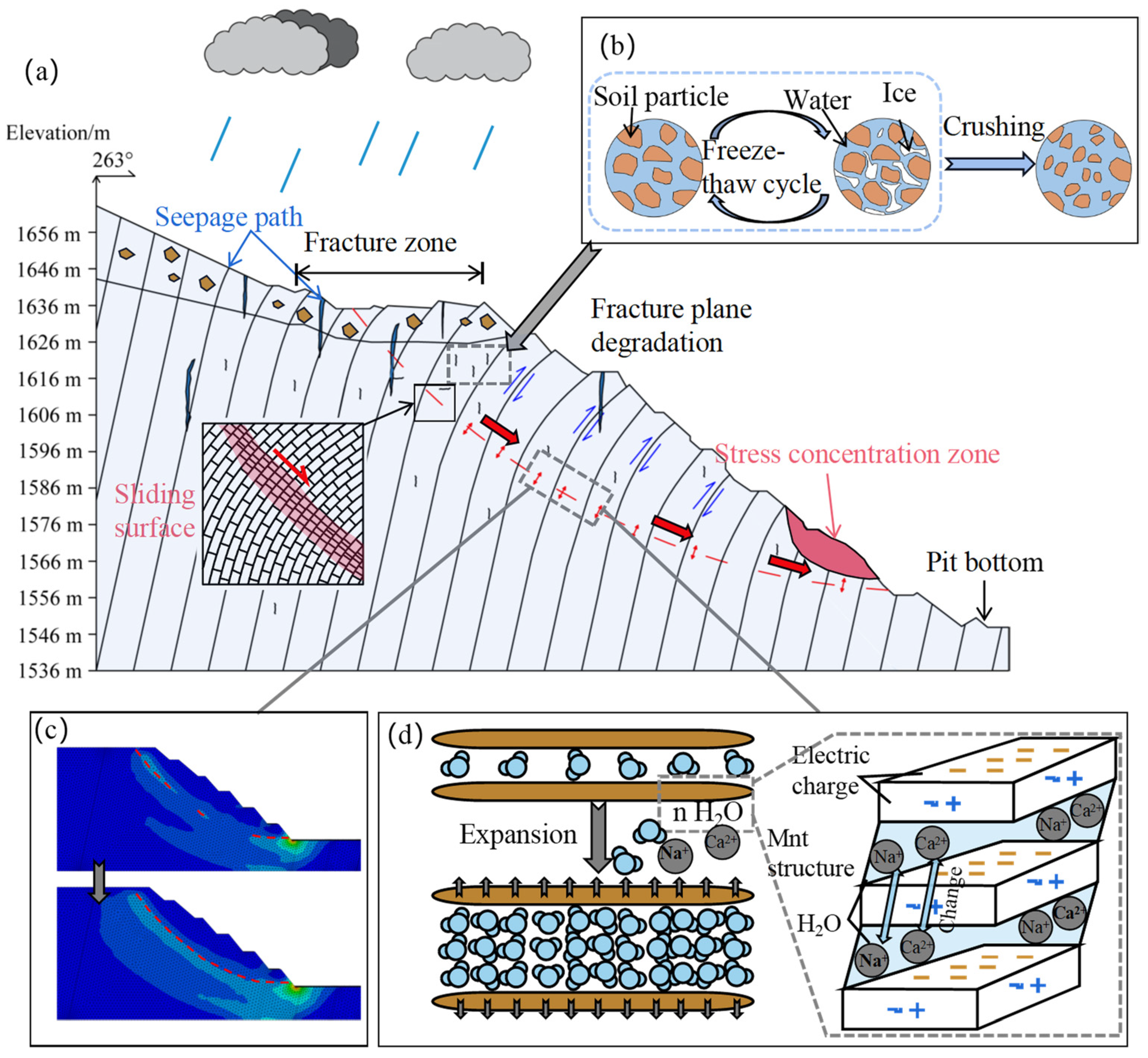

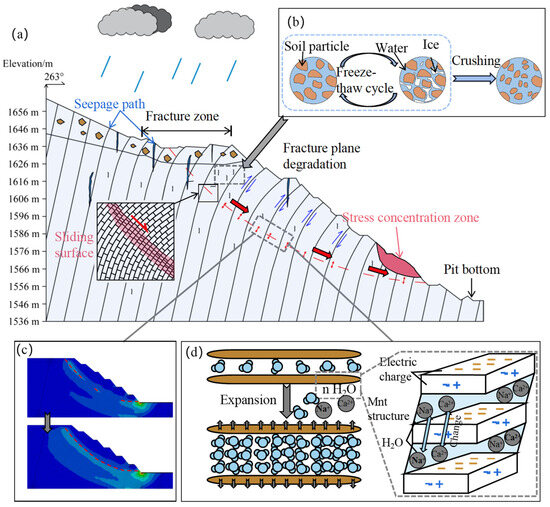

As depicted in Figure 30, slope deformation and failure are often the result of a combination of natural and contributing factors. Using thorough, in-depth field surveys and laboratory and on-site tests, the main instability factors of the eastern pit slope in the Wolong coal mine were identified. The following is detailed as follows:

Figure 30.

Deformation and failure mechanism of the eastern pit slope in Wolong Coal Mine. (a) Factors influencing slope deformation and failure; (b) Freeze–thaw cycles; (c) Variation in the shear strain increment; (d) Clay minerals expand and soften when exposed to water.

5.1.1. Topography and Geomorphology

Open-pit mining has created high, steep slopes in the study area with an impressive vertical elevation difference of approximately 83 m. The general slope gradient measures approximately 33°, with the slope of local mining benches exhibiting inclinations of up to 60°, as illustrated in Figure 13. These high, steep slopes create an environment conducive to slip deformations, and the existence of multiple strata interfaces serves as potential shear zones, thus heightening the likelihood of slope deformation and failure [44,45].

5.1.2. Stratigraphic Lithological Distribution

The eastern pit slope of the Wolong Coal Mine constitutes an anti-inclined layered rock slope, covered with 3~15 m loose Quaternary alluvial pebble-gravel soil layer at the top. The lower strata exhibit significant inclinations, facilitating the percolation of rainwater along the bedding surfaces. Figure 19 reveals that the upper part of the pit slope predominantly comprises medium- and coarse-grained sandstone, characterized by favorable geological properties. In contrast, the lower part consists mainly of sandy mudstone and mudstone interlayered with coal seams, which serve as softer and weaker interlayers. Therefore, the eastern pit slope as a whole constitutes a stratigraphic structure of an “upper-hard-and-lower-soft” two-layered configuration. The presence of weak interlayers reduces the strength of the surrounding structure [46]. Initially, the weaker middle and lower strata experience gradual deformation under the influence of gravity, with subsequent deformation extending to the upper strata as it intensifies.

5.1.3. Development Characteristics of Fractures

As described in Section 4.1, five local landslides occurred in the study area since spring 2022, which resulted in the deterioration of the rock mass structure in the adjacent area (Figure 12). As the depth of open-pit mining increases, the unloading effect and stress concentration phenomenon of the rock mass of the pit slope intensifies, resulting in reduced slope stability and continuous deformation.

As depicted in Figure 10 and Figure 16, multiple fracture sets developed in the study area, indicating that the integrity of the rock mass was damaged. The eastern pit slope displays three distinct sets of fractures, with wedge-shaped blocks created by the intersection of joints and bedding planes that tend to incline outward. These configurations are prone to extrusion under the influence of gravity, leading to instances of tilting and structural damage.

5.1.4. Geotechnical Properties of Rock Masses

As described in Section 4.3, it is evident that the mudstone and sandy mudstone constituting the pit slopes exhibit low strength. As indicated in Table 3, the specimens of rock masses contain significant proportions of clay minerals such as kaolinite and montmorillonite, rendering the rock more hydrophilic and prone to expansion. On a microscopic scale, numerous microcracks are present in the rock samples of the study area, and clay minerals are layered, resulting in an increased specific surface area for the rock masses. This, in turn, provides pathways and spaces for water infiltration (see Figure 21, Figure 22, Figure 23 and Figure 24). When exposed to water, the rock mass readily disintegrates and softens, leading to overall deformation and landslide susceptibility [47].

5.1.5. Precipitation and Freeze–Thaw Cycles

The arid and water scarcity in the study area is not favorable for plant growth, and the vegetation cover is extremely low (Figure 1). As outlined in Section 2.1, rainwater and ice meltwater follow the drainage path toward the southern side of the eastern pit slope in the Wolong Coal Mine (Figure 1). Under rainfall conditions, the topsoil is prone to runoff due to its poor water retention, and water seepage will further affect slope stability.

Freeze–thaw cycles are important triggers for the mass movement [48]. According to Section 2.3, the temperature in the study area is highly variable throughout the year, with peaks at 37 °C and extreme lows at −28 °C. The intense freeze–thaw cycles experienced by the rock mass of the pit slope have resulted in continued structural deterioration and reduced stability of the rock mass. Notably, the study area experiences significant temperature variations, with a pronounced impact from freeze–thaw cycles. Over numerous freezing and thawing cycles, the micro-fissures of rock masses are persistently subjected to microscopic freezing and swelling, leading to continuous damage. Concurrently, the fractures with the rock mass progressively deteriorate, resulting in a reduction in the slope body’s stability (Figure 30b,c).

5.1.6. Human Engineering Activities

As excavation proceeds, the pit slope is affected by gravitational forces, leading to an increase in stress at its corners and the disruption of the original stress equilibrium. To establish a new state of equilibrium, the slope’s stress is inevitably realigned along the direction of the critical surface to ensure slope stability. The expansion of the critical surface additionally undermines the rock mass’s ability to withstand lateral shear forces, thereby rendering the slope more susceptible to flexural toppling (Figure 27 and Figure 28). Simultaneously, the mine employs blasting operations to facilitate excavation. The seismic waves generated by blasting propagate throughout the rock mass, imposing supplementary vibratory forces on susceptible rock surfaces, thereby enlarging primary and tectonic fractures and generating secondary fractures (blast fissures). In summary, this exerts a compounding effect on the stability of the pit slopes (Figure 30a,c).

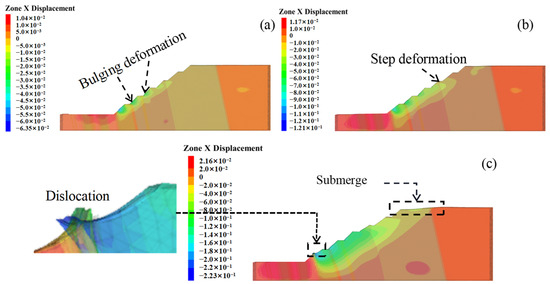

5.2. Deformation and Damage Pattern of the Pit Slope

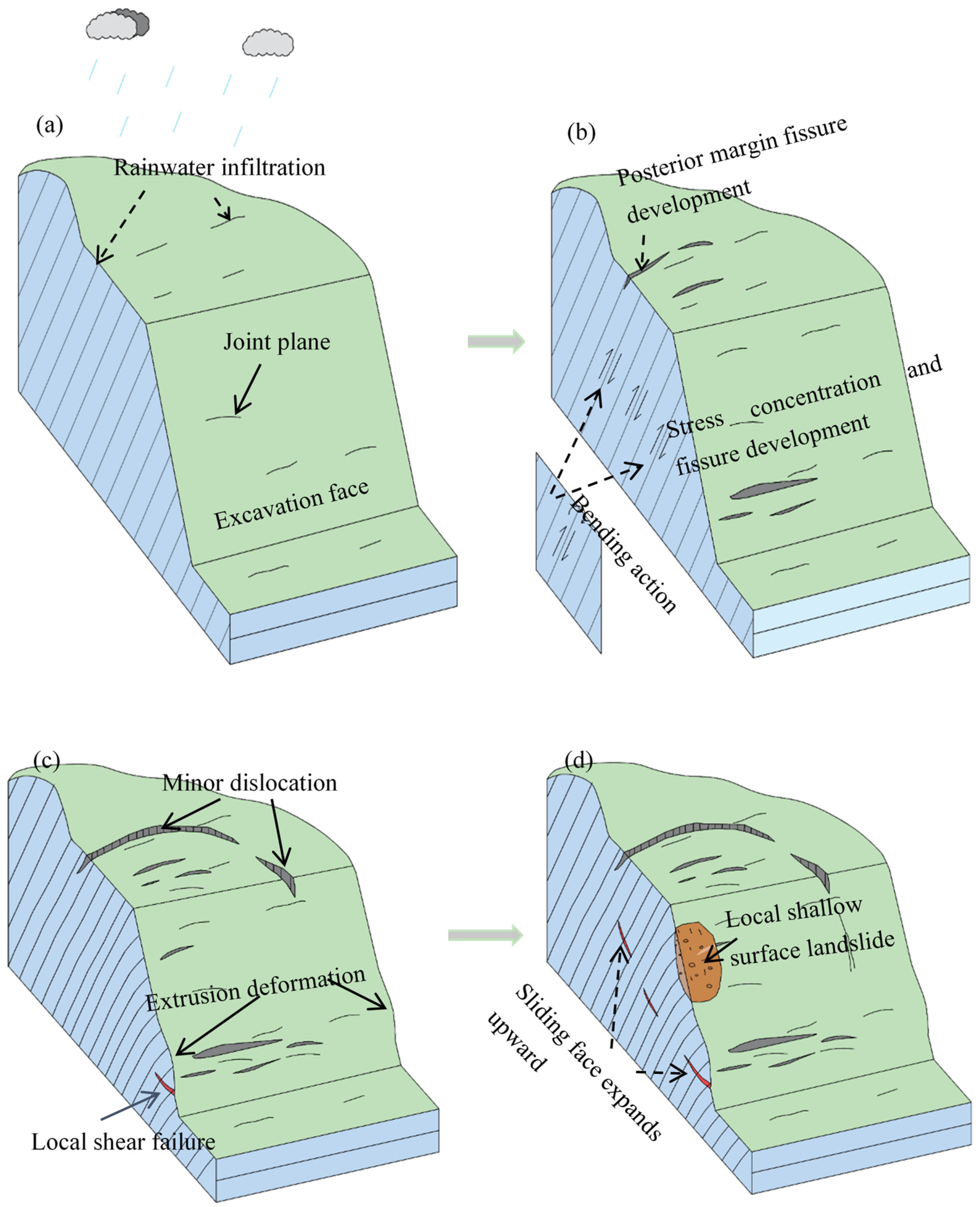

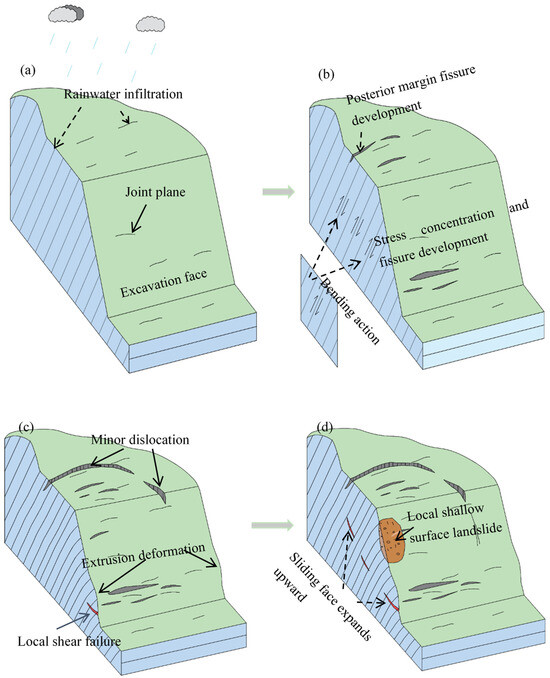

At present, the eastern pit slope of the Wolong Coal Mine has not yet formed an overall instability. Combining the field understanding and the numerical simulation results, it is determined that the instability and deformation process of the eastern pit slope of the Wolong Coal Mine can be divided into four stages (Figure 31). The specific description is as follows:

Figure 31.

Instability and failure process of the eastern pit slope in the Wolong Coal Mine: (a) The initial deformation stage; (b) The development stage of lateral shear misalignment; (c) The development stage of horizontal tensile-shear damage; (d) The slip surface development to preslip stage.

- (1)

- The initial deformation stage

As depicted in Section 4.1 and Section 4.2, the eastern pit slope belongs to a soft-hard-interbedded anti-inclined layered rock slope with a slope structure conducive to rainwater infiltration. Moreover, the rock mass of the pit slope features a high clay mineral content and significant microfracture development. Consequently, the mechanical properties of the rock mass deteriorate swiftly due to the influence of rainwater. Under the influence of artificial excavation, atmospheric rainfall, and other contributing factors, the surface water permeates along the bedding and joint surfaces. This heightened groundwater activity leads to the expansion of cracks, causing stress to concentrate in the lower section of the slope (Figure 31a).

- (2)

- The development stage of lateral shear misalignment

Due to rainwater infiltration, the integrity of the rock and soil body degrades rapidly, leading to a redistribution of internal stress within the pit slope. This is evident in the swift proliferation of fissures at the rear edge of the slope (Figure 14). Under the influence of the slope’s self-gravitational stress, the leading edge of the slope tilts toward the critical surface. Then, the lower rock mass is prone to shear slip misalignment, and the foot of the slope develops fissures due to stress concentration (Figure 31b).

- (3)

- The development stage of horizontal tensile-shear damage

Due to the further aggravation of the misalignment of bedding surfaces, flexural deformation of the pit slope occurs. Moreover, localized small-scale misalignment occurs at the trailing edge of the slope, and a slip surface starts to form at the upper part of the slope corner (Figure 31c).

- (4)

- The slip surface development to preslip stage

Due to the intensification of the flexural toppling deformation, shear forces within the layer become highly intense, causing the slip surface to expand further toward the upper part of the pit slope. This results in localized shallow landslides in the surface layer of loose rock and soil due to deformation (Figure 31d).

If the deformation activity intensifies further, instability and damage to the eastern pit slope will occur when the slip surface is fully penetrated.

5.3. Evolution Mechanism of the Slope Deformation and Failure in the Wolong Coal Mine

In the field investigation, it was found that the strata in the study area generally dip at 65° to 85°, indicating an anti-inclined layered rock slope (Figure 3). Under the combination action of freeze–thaw cycles, rainfall, and slope excavation, the layered rock mass began to flexural toppling in the downslope direction (Figure 30). As the degree of bending deformation of the entire slope increases, the rock mass at the base of the slope is the first to be damaged by the repetitive loading of the rock mass layer behind it, which in turn generates shear sliding relative to the bedrock. This provides space for significant deformation of the rock mass layer in the middle and rear of the pit slope to accumulate and flow downhill (Figure 14 and Figure 29). Under the unloading stress, prominent tensile cracks begin to form at the trailing edge of the pit slope’s summit. The rock mass in the middle and rear sections of the slope progressively experiences tensile damage due to bending, leading to an increased degree of tensile cracking in the rock at the summit. Concurrently, the cyclic freeze–thaw action induces microscopic frost damage, generating a cumulative effect that manifests as a reduction in the tensile strength of rock masses on a macroscopic scale. Moreover, this weakened area of tensile strength extends into the frozen rock mass at a certain depth, expediting the upward progression of the potential sliding surface until it intersects with the tension crack region at the trailing edge (Figure 31). This process drives the pit slope closer to a state of ultimate instability.

5.4. Disaster Prevention and Control Recommendations

As presented in Section 5.1, the analysis in this study highlights the susceptibility of the eastern pit slope to deformation and damage due to various factors. This study recommends the following measures to effectively secure the mine site:

- (1)

- Management measures such as slope cutting and anchor support are taken to attenuate the effects of slope weight forces or to increase the structural stability of slopes.

- (2)

- Geotextile fabric can be placed on the slope surface to cope with the upcoming rainy season. At the same time, ditching works could be carried out in the eastern watercourse to reduce the impact of surface water on the slope.

- (3)

- During and after the disaster management process, GPS receivers and ground-based SAR need to be arranged on the slope surface and nearby areas, and specialists need to be arranged to monitor the dynamics of the landslide and to grasp the deformation and displacement characteristics of the slope. If large deformation is monitored, timely feedback should be given to experts for safety assessment.

The research conducted herein establishes a scientific foundation for mine management in the context of soft-hard-interbedded anti-inclined layered rock slopes.

6. Conclusions

Using the eastern pit slope in the Wolong Coal Mine as a case study, this study employs diverse methodologies to conduct research on the deformation patterns and failure mechanism of soft-hard-interbedded anti-inclined layered rock slopes. The following main conclusions are drawn:

- (1)

- This study establishes a landslide investigation framework based on the integration of multiple techniques, including field investigations, remote sensing analysis, experimental analysis, integrated physical exploration methods, and three-dimensional numerical simulations, for elucidating slope deformation patterns and damage mechanisms.

- (2)

- In this study, a combination of field surveys, ERT surveys, and SRT analyses was employed to comprehensively determine the three-dimensional stratigraphic structure and characteristics of slip surfaces in the study area. The results indicate that the eastern pit slope is alternate layers of sandstone, mudstone, and sandy mudstone with an average stratigraphic dip angle of 78° ∠ 78°, which represents a typical soft-hard-interbedded anti-inclined layered rock slope. The potential slip surface is located at a deeper depth and is predominantly continuous, with a steeper upper part and a gentler lower section.

- (3)

- A combination of standard geotechnical tests, rock thin section analyses, SEM and XRD analyses was employed to characterize the rock mass properties. The results show that the rock masses in the study area exhibit low strength, with clay mineral contents from 15.6% to 33.8% in sandstone and mudstone and 29.7% to 59.6% in mudstone and sandy mudstone. Since high contents of clay minerals make the rock mass hydrophilic and expansive, rock masses are susceptible to softening and damage when exposed to water.

- (4)

- The numerical simulation results of FLAC3D show that following the pit slope excavation, the potential slip surface continuously expanded and extended upward, while stress accumulation concentrated predominantly at the slope’s corners. The soft rock layers in the middle and lower sections of the slope initially underwent bulging deformation. With the aggravation of deformation, the upper rock layers also unloaded and deformed to the free surface, showing a typical flexural toppling failure pattern.

- (5)

- We highlight the significant role of stratigraphic structure and rock hydrophilicity and expansivity in controlling the deformation of the eastern pit slope in the Wolong Coal Mine. Surface water retention, freeze–thaw cycles, and human-driven engineering activities are the main triggers of pit slope destabilization. The deformation and failure process of the eastern pit slope can be categorized into four stages: the initial deformation stage, the development stage of lateral shear misalignment, the development stage of horizontal tensile-shear damage, and the slip surface development to the preslip stage. The research presented herein offers valuable insights and engineering implications for the study of soft-hard-interbedded anti-inclined layered rock slopes, both locally and globally.

Author Contributions

Conceptualization: G.C. and J.Z.; Methodology: G.C. and Z.Y. (Zhaowei Yao); Formal analysis and investigation: Z.Y. (Zhaowei Yao) and G.C.; Writing—original draft preparation: G.C. and Z.Y. (Zhaoyue Yu); Writing—review and editing: P.C.; Resources: J.Z. and P.C.; Software and coding: Y.Y.; Validation: Z.Y. (Zhaoyue Yu); Supervision: J.Z., Z.Y. (Zhaoyue Yu). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China (Grant No. 42007269), the Young Talent Fund of Xi’an Association for Science and Technology (Grant No. 959202313094), and the Fundamental Research Funds for the Central Universities, CHD (Grant Nos. 300102263501 and 300102263401).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data will be made available on request.

Acknowledgments

We are very grateful to receive support from the Scientific·Innovation·Practice Project·of·Postgraduates·of·Chang’an·University (No. 300103723012).

Conflicts of Interest

Author Peng Cai was employed by the company Inner Mongolia Second Hydrogeology Engineering Geology Exploration Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Brabb, E.E.; Harrod, B.L. Landslides: Extent and economic significance. Can. Geotech. J. 1990, 27, 408. [Google Scholar]

- Huang, R.Q.; Li, W.L. Formation, distribution and risk control of landslides in China. J. Rock Mech. Geotech. Eng. 2011, 3, 97–116. [Google Scholar] [CrossRef]

- Caine, N. Toppling failures from alpine cliffs on ben Lomond, Tasmania. Earth Surf. Process. Landf. 1982, 7, 133–152. [Google Scholar] [CrossRef]

- Cruden, D.; Hu, X.Q. Topples on underdip slopes in the Highwood Pass, Alberta, Canada. Q. J. Eng. Geol. Hydrogeol. 1994, 27, 57–68. [Google Scholar] [CrossRef]

- Tamrakar, N.K.; Yokota, S.; Osaka, O. A toppled structure with sliding in the Siwalik Hills, midwestern Nepal. Eng. Geol. 2002, 64, 339–350. [Google Scholar] [CrossRef]

- Tu, X.B.; Dai, F.C.; Lu, X.J.; Zhong, H.Y. Toppling and stabilization of the intake slope for the Fengtan Hydropower Station enlargement project, Mid-South China. Eng. Geol. 2007, 91, 152–167. [Google Scholar] [CrossRef]

- Goodman, R.E.; Bray, J.W. Toppling of rock slopes. In Proceedings of the Specialty Conference on Rock Engineering for Foundations and Slopes, Boulder, CO, USA, 15–18 August 1976. [Google Scholar]

- Adhikary, D.P.; Dyskin, A.V. Modelling of progressive and instantaneous failures of foliated rock slopes. Rock Mech. Rock Eng. 2007, 40, 349–362. [Google Scholar] [CrossRef]

- Wu, H.Q.; Pollard, D. An experimental study of the relationship between joint spacing and layer thickness. J. Struct. Geol. 1995, 17, 887–905. [Google Scholar] [CrossRef]

- Brideau, M.A.; Stead, D. Controls on block toppling using a three-dimensional distinct element approach. Rock Mech. Rock Eng. 2009, 43, 241–260. [Google Scholar] [CrossRef]

- Böhme, M.; Hermanns, R.L.; Oppikofer, T.; Fischer, L.; Bunkholt, H.S.S.; Eiken, T.; Pedrazzini, A.; Derron, M.-H.; Jaboyedoff, M.; Blikra, L.H.; et al. Analyzing complex rock slope deformation at Stampa, western Norway, by integrating geomorphology, kinematics and numerical modeling. Eng. Geol. 2013, 154, 116–130. [Google Scholar] [CrossRef]

- León Buendía, C.; Santamaría Arias, J.; Alejano, L.; Giráldez, R. Analysis of a complex slope failure in a quartzite slope. In Proceedings of the ISRM European Symposium, Vigo, Spain, 27–29 May 2014. [Google Scholar]

- Jiang, L.S.; Sainoki, A.; Mitri, H.S.; Ma, N.; Liu, H.T.; Hao, Z. Influence of fracture-induced weakening on coal mine gateroad stability. Int. J. Rock Mech. Min. 2016, 88, 307–317. [Google Scholar] [CrossRef]

- Zhan, J.W.; Wang, Q.; Zhang, W.; Shangguan, Y.L.; Song, S.Y.; Chen, J.P. Soil-engineering properties and failure mechanisms of shallow landslides in soft-rock materials. Catena 2019, 181, 104093. [Google Scholar] [CrossRef]

- Tao, Z.G.; Zhu, C.; He, M.C.; Liu, K.M. Research on the safe mining depth of anti-dip bedding slope in Changshanhao Mine. Geomech. Geophys. Geo-Energy Geo-Res. 2020, 6, 36. [Google Scholar]

- GB18306-2015; Seismic Ground Motion Parameters Zonation Map of China. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Standards Press of China: Beijing, China, 2011.

- Cignetti, M.; Godone, D.; Wrzesniak, A.; Giordan, D. Structure from motion multisource application for landslide characterization and monitoring: The Champlas du Col Case study, Sestriere, North-Western Italy. Sensors 2019, 19, 2364. [Google Scholar] [CrossRef] [PubMed]

- Travelletti, J.; Delacourt, C.; Allemand, P.; Malet, J.P.; Schmittbuhl, J.; Toussaint, R.; Bastard, M. Correlation of multi-temporal ground-based optical images for landslide monitoring: Application, potential and limitations. ISPRS J. Photogramm. 2012, 70, 39–55. [Google Scholar] [CrossRef]

- Guzzetti, F.; Reichenbach, P.; Cardinali, M.; Galli, M.; Ardizzone, F. Probabilistic landslide hazard assessment at the basin scale. Geomorphology 2005, 72, 272–299. [Google Scholar] [CrossRef]

- Chacón, J.; Irigaray, C.; Fernández, T.; El Hamdouni, R. Engineering geology maps: Landslides and geographical information systems. Bull. Eng. Geol. Environ. 2006, 65, 341–411. [Google Scholar] [CrossRef]

- Zhan, J.W.; Yu, Z.Y.; Lv, Y.; Peng, J.B.; Song, S.Y.; Yao, Z.W. Rockfall hazard assessment in the Taihang Grand Canyon scenic area integrating regional-scale identification of potential rockfall sources. Remote Sens. 2022, 14, 3021. [Google Scholar] [CrossRef]

- Chen, W.J.; Liu, H.T.; Liu, J.M.; Sun, X.G.; Zeng, Q.D. Integrated geophysical exploration for the Longtoushan Ag-Pb-Zn deposit in the southeast of the Da Xing’an Ling mountains, Inner Mongolia, northern China. Explor. Geophys. 2010, 41, 279–288. [Google Scholar] [CrossRef]

- Uhlemann, S.; Wilkinson, P.B.; Maurer, H.; Wagner, F.M.; Johnson, T.C.; Chambers, J.E. Optimized survey design for electrical resistivity tomography: Combined optimization of measurement configuration and electrode placement. Geophys. J. Int. 2018, 214, 108–121. [Google Scholar] [CrossRef]

- Yannah, M.; Martens, K.; Van Camp, M.; Walraevens, K. Geophysical exploration of an old dumpsite in the perspective of enhanced landfill mining in Kermt area, Belgium. Bull. Eng. Geol. Environ. 2019, 78, 55–67. [Google Scholar] [CrossRef]

- Uhlemann, S.; Hagedorn, S.; Dashwood, B.; Maurer, H.; Gunn, D.; Dijkstra, T.; Chambers, J. Landslide characterization using P- and S-wave seismic refraction tomography-the importance of elastic moduli. J. Appl. Geophys. 2016, 134, 64–76. [Google Scholar] [CrossRef]

- Imani, P.; Tian, G.; Hadiloo, S.; El-Raouf, A.A. Application of combined electrical resistivity tomography (ERT) and seismic refraction tomography (SRT) methods to investigate Xiaoshan District landslide site: Hangzhou, China. J. Appl. Geophys. 2021, 184, 104236. [Google Scholar] [CrossRef]

- GB/T 50123-2019; Standard for Geotechnical Test Methods. Ministry of Housing and Urban-Rural Development of the People’s Republic of China and Standardization Administration of the People’s Republic of China. China Planning Press: Beijing, China, 2019.

- Schäbitz, M.; Janssen, C.; Wenk, H.R.; Wirth, R.; Schuck, B.; Wetzel, H.U.; Meng, X.; Dresen, G. Microstructures in landslides in northwest China-implications for creeping displacements? J. Struct. Geol. 2018, 106, 70–85. [Google Scholar] [CrossRef]

- GB/T 50266-2013; Standard for Test Methods of Engineering Rock Mass. Ministry of Housing and Urban-Rural Development of the People’s Republic of China. China Planning Press: Beijing, China, 2013.

- Weidinger, J.T.; Schramm, J.-M.; Nuschej, F. Ore mineralization causing slope failure in a high-altitude mountain crest—On the collapse of an 8000 m peak in Nepal. J. Asian Earth Sci. 2002, 21, 295–306. [Google Scholar] [CrossRef]

- Wang, G.; Suemine, A.; Schulz, W. Shear-rate-dependent strength control on the dynamics of rainfall-triggered landslides, Tokushima Prefecture, Japan. Earth Surf. Proc. Landf. 2010, 35, 407–416. [Google Scholar] [CrossRef]

- Zhan, J.W.; Eberhardt, E.; Han, X.D.; Pang, Y.M.; Chen, J.P. Robust estimation of fracture trace length distributions derived from underground mapping and long narrow sampling windows. Tunn. Undergr. Space Technol. 2022, 128, 104630. [Google Scholar] [CrossRef]

- Mauldon, M. Estimating mean fracture trace length and density from observations in convex windows. Rock Mech. Rock Eng. 1998, 31, 201–216. [Google Scholar] [CrossRef]

- Song, J.J.; Lee, C.I. Estimation of joint length distribution using window sampling. Int. J. Rock Mech. Min. 2001, 38, 519–528. [Google Scholar] [CrossRef]

- Zhan, J.W.; Chen, J.P.; Xu, P.H.; Zhang, W.; Han, X.D.; Zhou, X. Automatic identification of rock fracture sets using finite mixture models. Math. Geosci. 2017, 49, 1021–1056. [Google Scholar] [CrossRef]

- Hoek, E.; Brown, E.T. The Hoek–Brown failure criterion and GSI—2018 edition. J. Rock Mech. Geotech. 2019, 11, 445–463. [Google Scholar] [CrossRef]

- Sonmez, H.; Ulusay, R. Modifications to the geological strength index (GSI) and their applicability to stability of slopes. Int. J. Rock Mech. Min. 1999, 36, 743–760. [Google Scholar] [CrossRef]

- Palmstrom, A. Measurements of and correlations between block size and rock quality designation (RQD). Tunn. Undergr. Space Technol. 2005, 20, 362–377. [Google Scholar] [CrossRef]

- Hoek, E.; Carranza-Torres, C.; Corkum, B.; Hoek, E.; Carranza-Torres, C. Hoek-Brown failure criterion-2002 Edition. In Proceedings of the 5th North American Rock Mechanics Symposium, Toronto, ON, Canada, 7–10 July 2002. [Google Scholar]

- Hoek, E.; Brown, E.T. Practical estimates of rock mass strength. Int. J. Rock Mech. Min. 1997, 34, 1165–1186. [Google Scholar] [CrossRef]

- Longoni, L.; Papini, M.; Arosio, D.; Zanzi, L.; Brambilla, D. A new geological model for Spriana landslide. Bull. Eng. Geol. Environ. 2014, 73, 959–970. [Google Scholar] [CrossRef]

- Wang, Z.Y.; Zhang, W.G.; Gao, X.C.; Liu, H.; Böhlke, T. Stability analysis of soil slopes based on strain information. Acta Geotech. 2020, 15, 3121–3134. [Google Scholar] [CrossRef]

- Tu, J.Z.; Zhang, Y.L.; Mei, G.; Xu, N.X. Numerical investigation of progressive slope failure induced by sublevel caving mining using the finite difference method and adaptive local remeshing. Appl. Sci. 2021, 11, 3812. [Google Scholar] [CrossRef]

- Yu, J.L.; Zhao, J.J.; Yan, H.Y.; Lai, Q.Y.; Huang, R.Q.; Liu, X.W.; Li, Y.C. Deformation and failure of a high-steep slope induced by multi-layer coal mining. J. Mt. Sci.-Engl. 2020, 17, 2942–2960. [Google Scholar] [CrossRef]

- Li, S.L.; Qiu, C.; Huang, J.K.; Guo, X.P.; Hu, Y.C.; Mugahed, A.-S.Q.; Tan, J. Stability analysis of a high-steep dump slope under different rainfall conditions. Sustainability 2022, 14, 11148. [Google Scholar] [CrossRef]

- Rong, P.; Zuo, Y.J.; Lin, J.Y.; Chen, Q.G.; Zheng, L.L.; Jin, K.Y. Study of mechanical properties and failure characteristics of combined rock mass with weak interlayer. Geomech. Geophys. Geo-Energy Geo-Res. 2022, 8, 89. [Google Scholar] [CrossRef]

- Lu, J.K.; Xu, T.; Tang, X.H.; Heap, M.J.; Xu, J.J.; Yang, T.H.; Zhao, X. Nanoindentation-based characterization of micromechanical properties of greenish mudstone from deep Fushun West open-pit mine (Fushun city, China). Geomech. Geophys. Geo-Energy Geo-Res. 2022, 8, 59. [Google Scholar] [CrossRef]

- Mateos, R.M.; García-Moreno, I.; Azañón, J.M. Freeze–thaw cycles and rainfall as triggering factors of mass movements in a warm Mediterranean region: The case of the Tramuntana Range (Majorca, Spain). Landslides 2012, 9, 417–432. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).