Design and Experiment of Variable-Spray System Based on Deep Learning

Abstract

1. Introduction

2. Materials and Methods

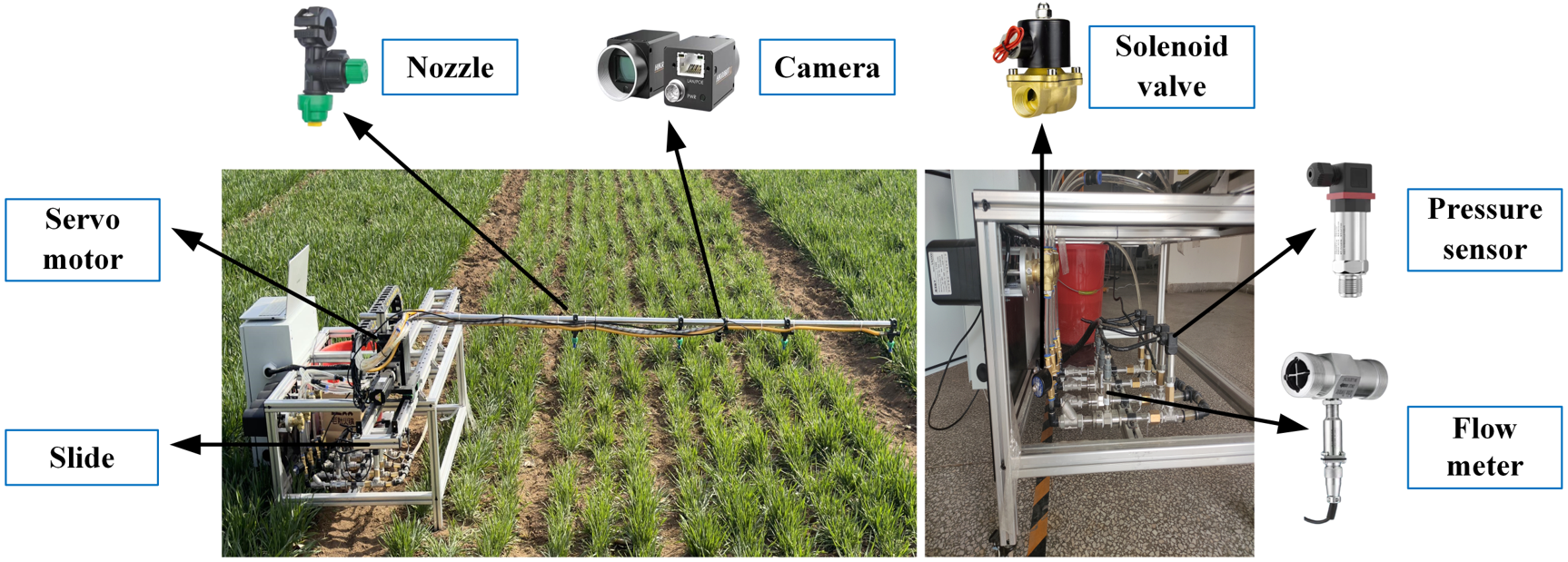

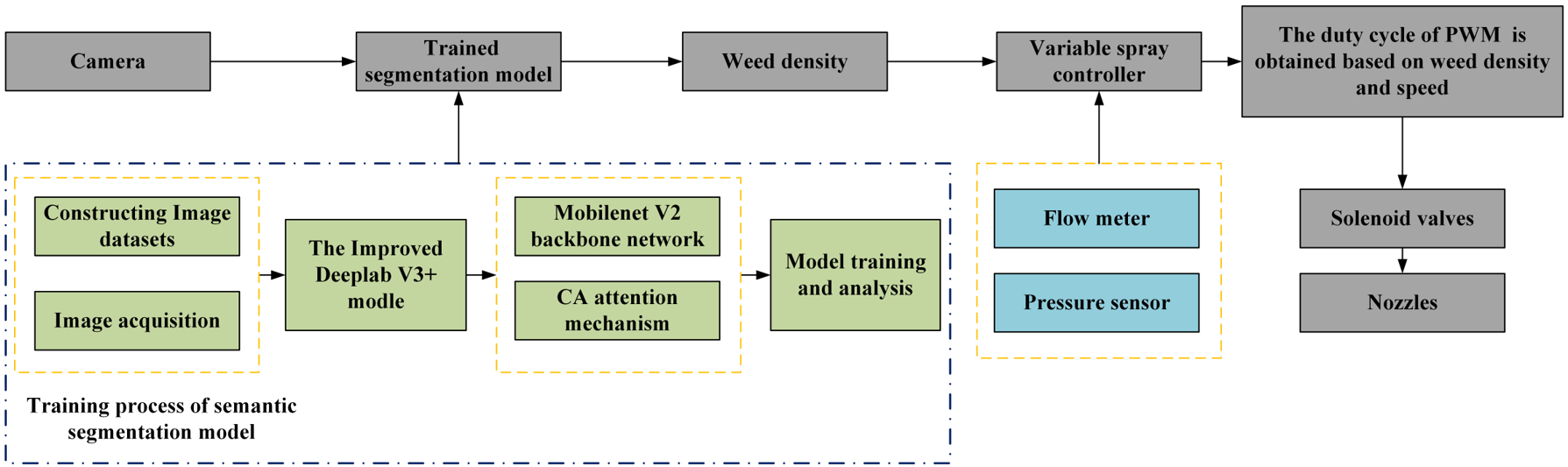

2.1. Variable-Spray System for Wheat Weeds

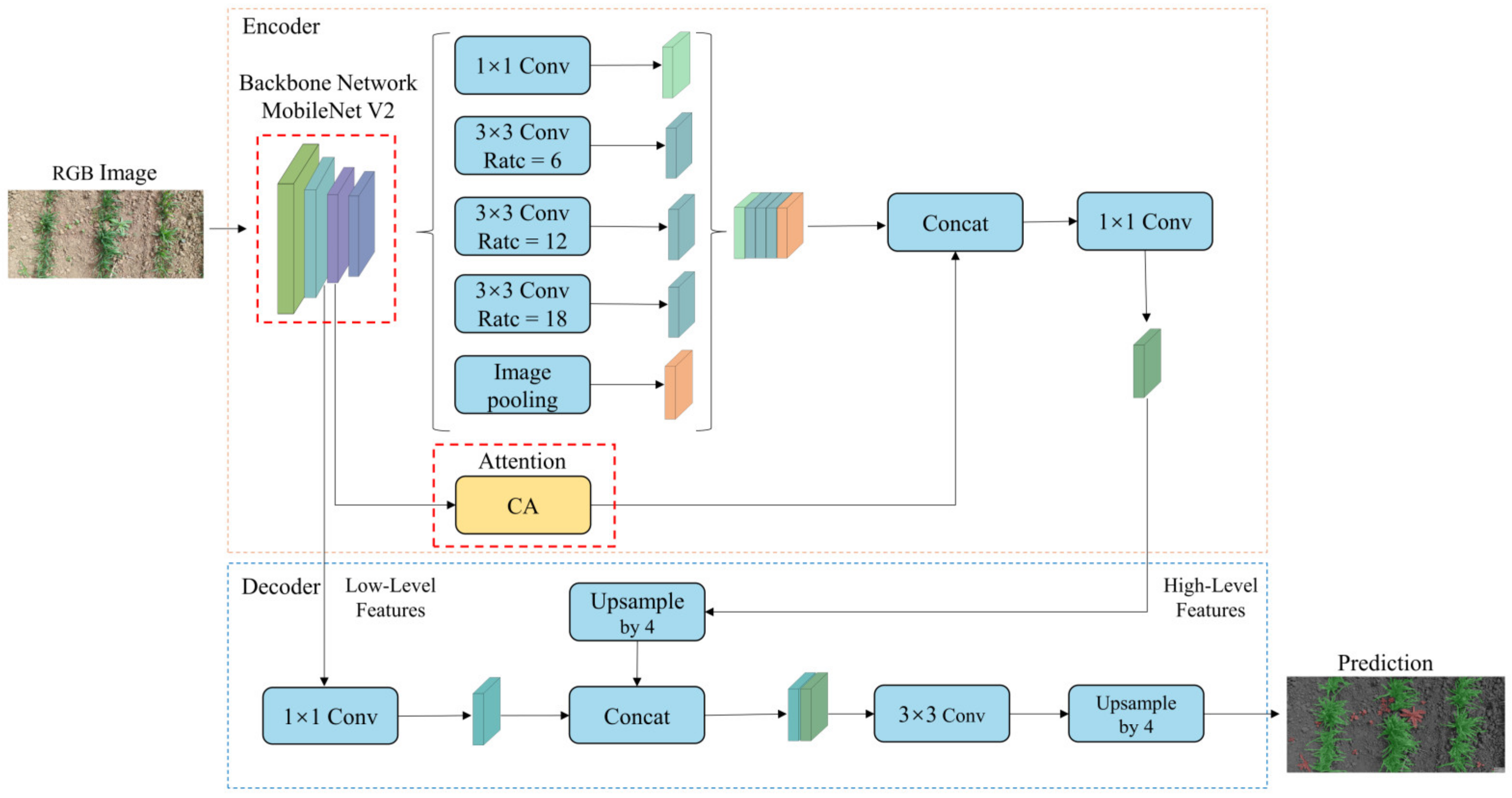

2.2. Semantic Segmentation Model for Wheat Weeds Based on DeepLab V3+

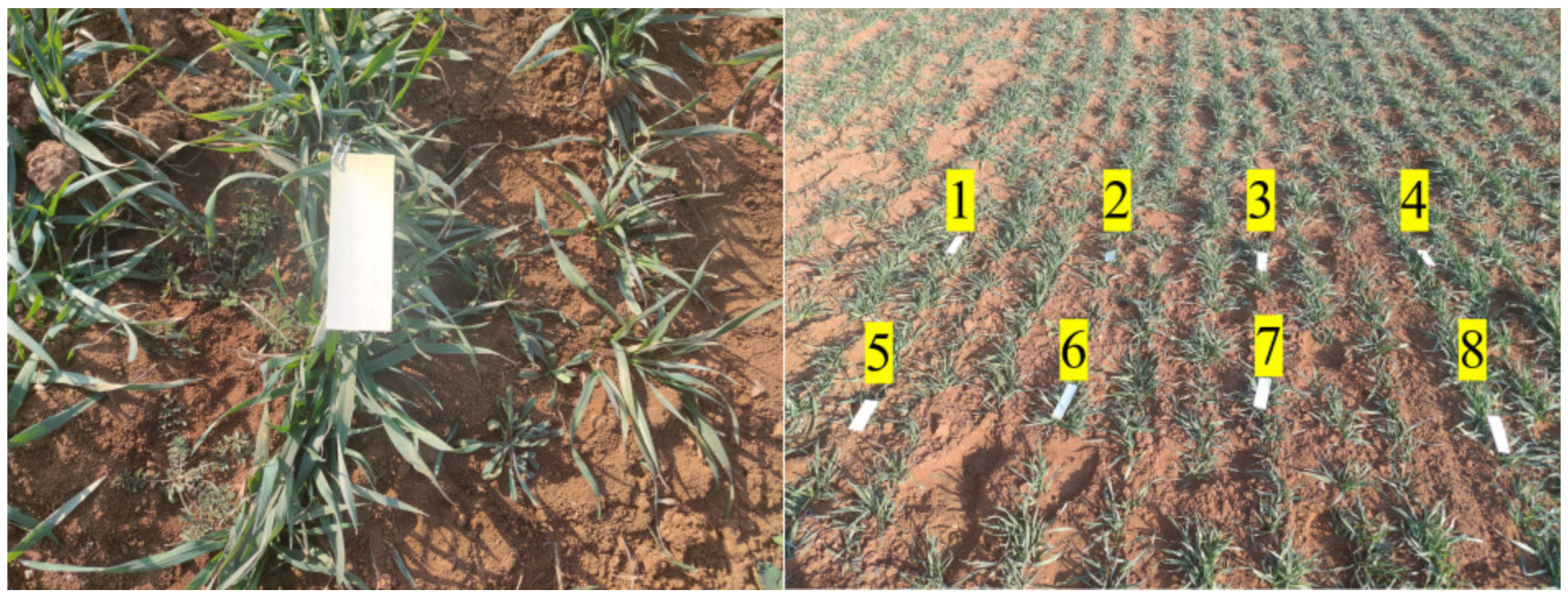

2.2.1. Data Acquisition

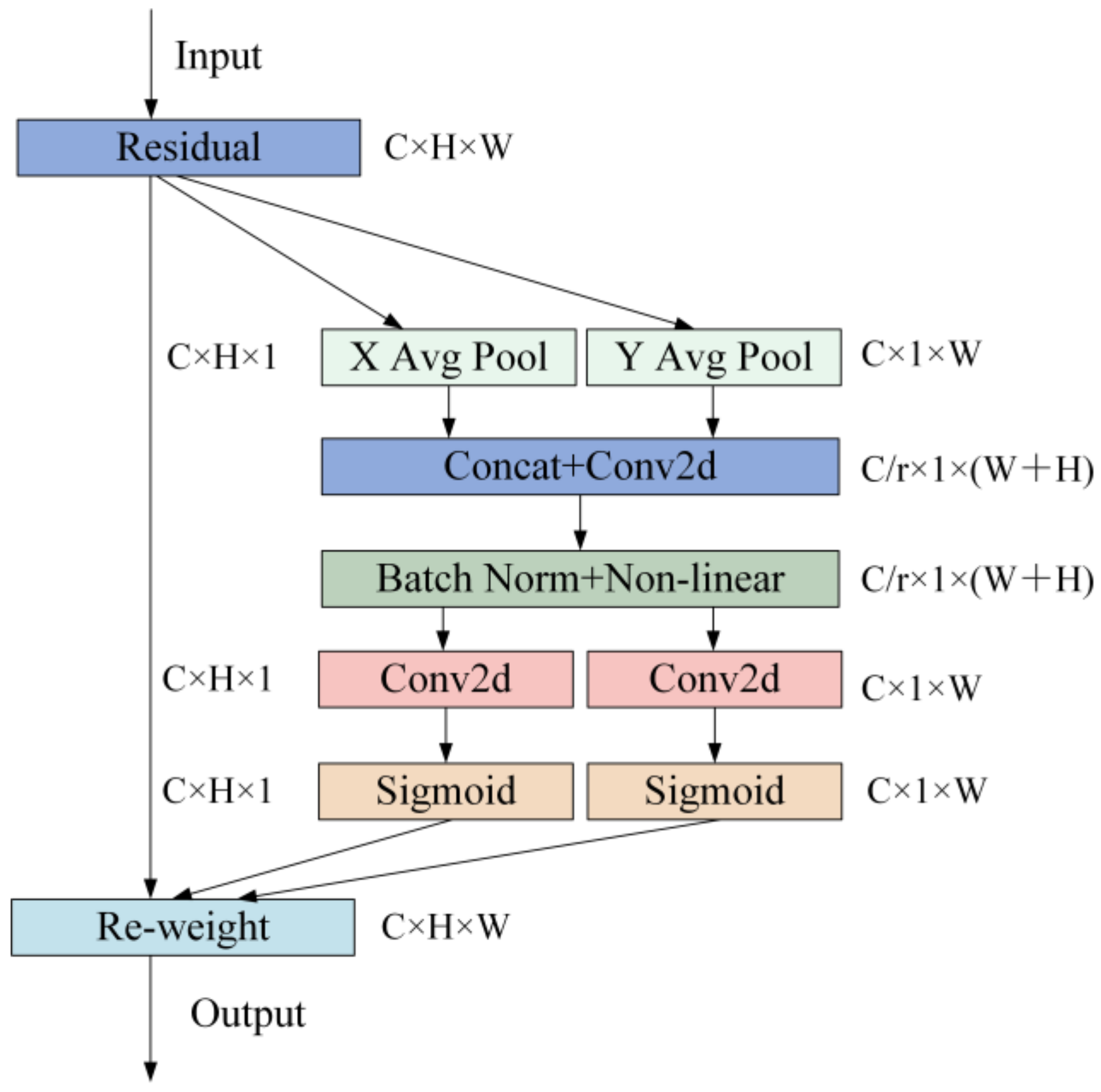

2.2.2. Improved DeepLab V3+ Segmentation Model

2.2.3. Model Training Environment and Parameter Setting

2.2.4. Segmentation Performance Evaluation Index

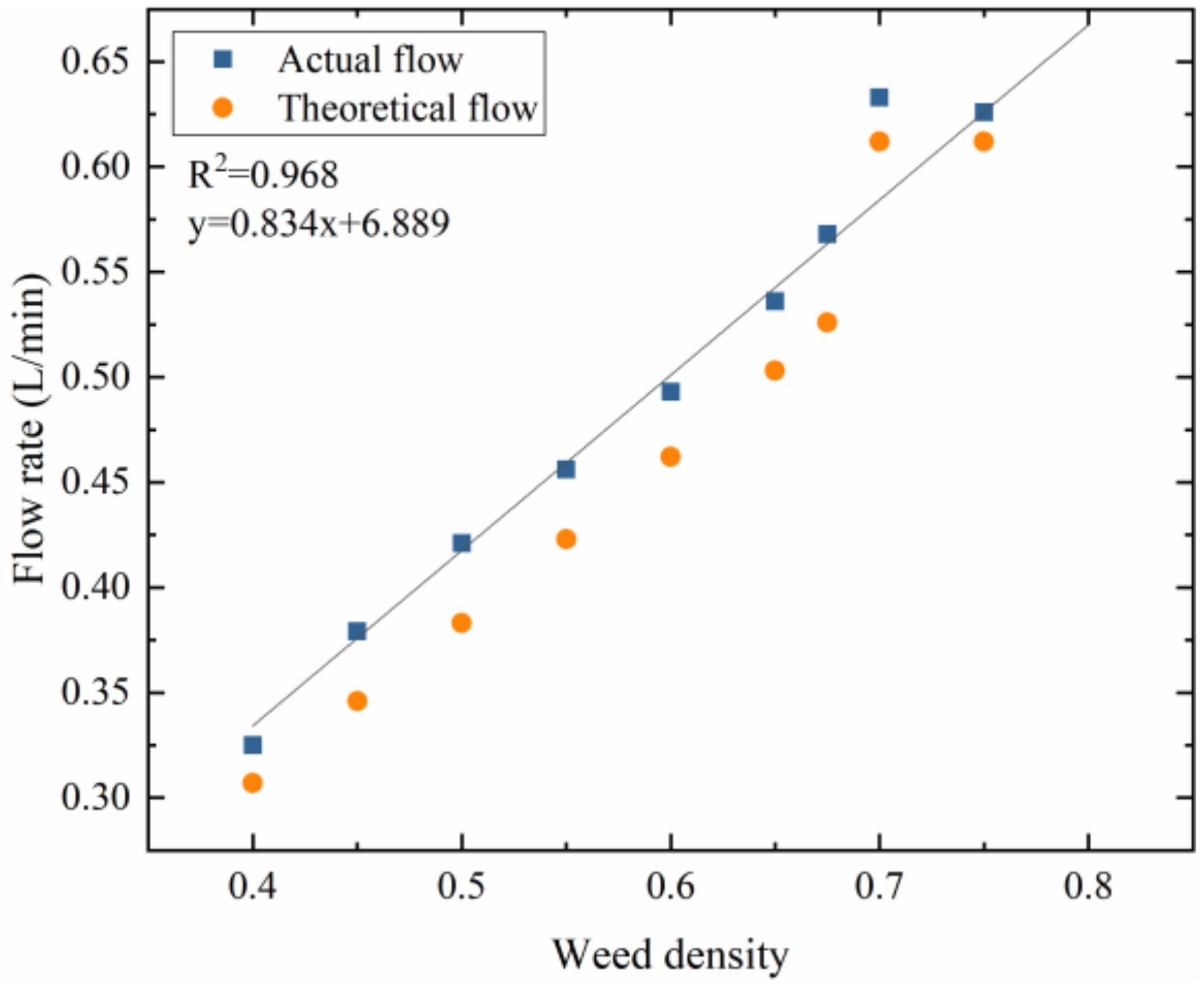

2.3. Variable-Spray Regulation Decision

- (1)

- Calculation method of weed density.

- (2)

- The impact of weed density on the flow rate.

- (3)

- The impact of speed on flow rate.

- (4)

- Nozzle-flow duty-cycle flow curve.

- (5)

- Spray-rating decision model.

2.4. Experimental Design and Methodology

2.4.1. System Performance Verification Tests

2.4.2. Variable-Spray Experiment

- (1)

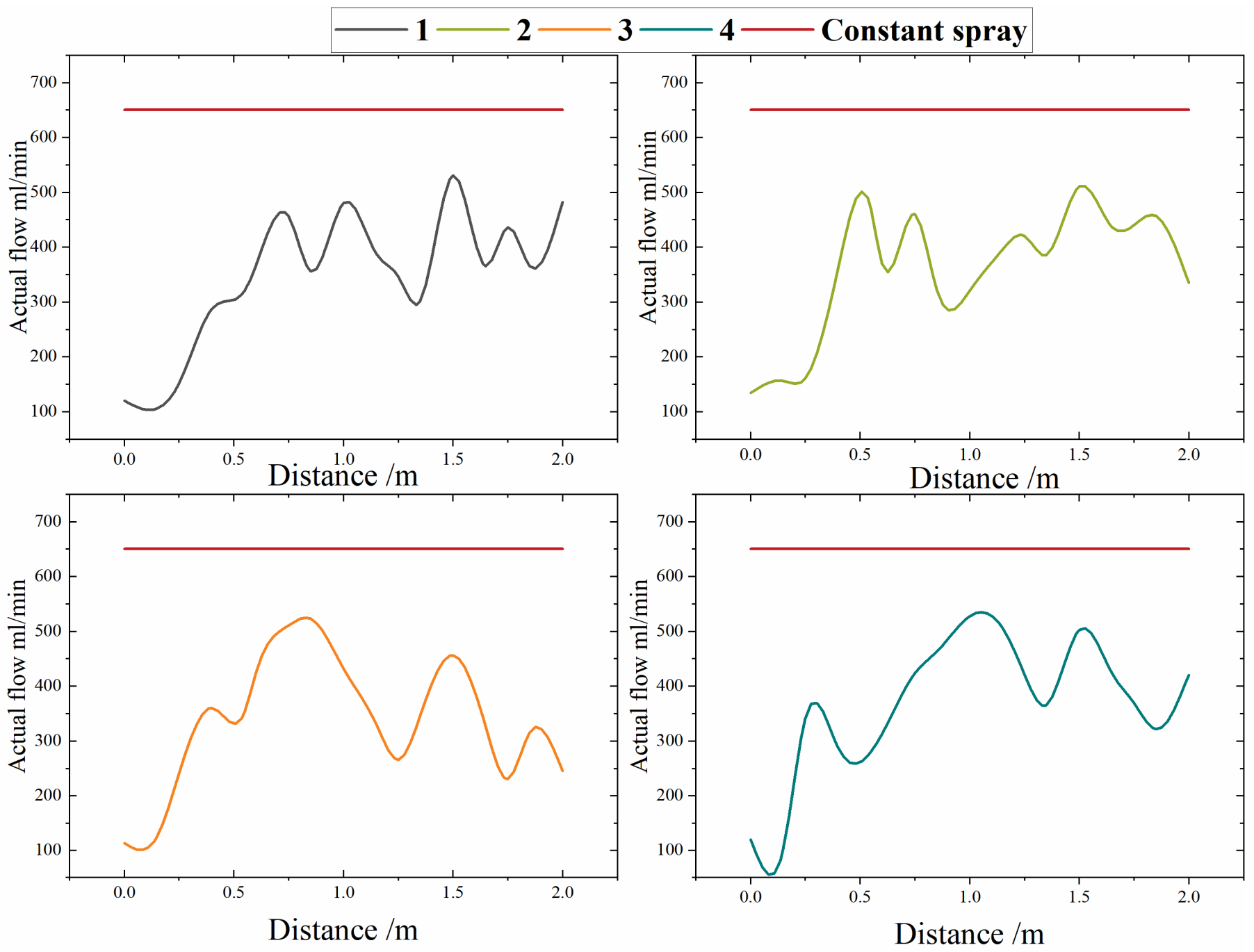

- In the pre-test, the optimal spray speed of the test stand was 1 m/s Therefore, the speed of the spray test was set to 1 m/s and the travel distance was 2 m. Firstly, the test stand conducted three constant spray tests at a speed of 1 m/s. After completing the constant spray experiment, three variable-spray experiments were performed at the same speed.

- (2)

- Variable-spray experiments were conducted at speeds of 0.5 m/s, 1 m/s, and 1.5 m/s, and three variable-spray experiments were conducted at the same speed, resulting in a total of nine variable-spray experiments.

3. Results and Discussion

3.1. Analysis of Segmentation Models

3.1.1. Performance Analysis of Different Models

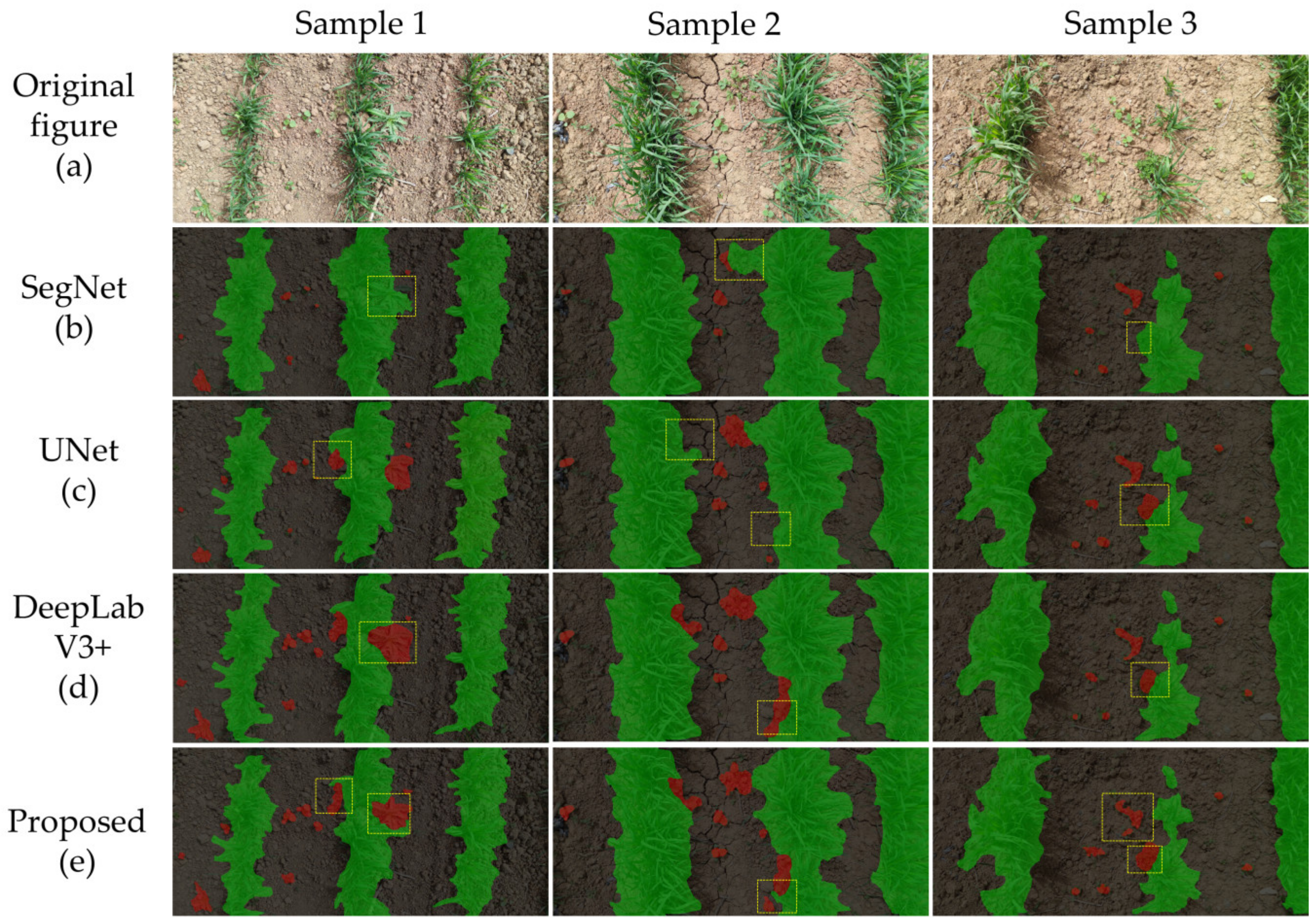

3.1.2. Analysis of Segmentation Results from Different Models

3.2. System Performance Test Results and Analysis

3.3. Variable-Spray Experiment Results

3.3.1. Comparative Analysis of Variable-Spray and Constant-Spray Test Results

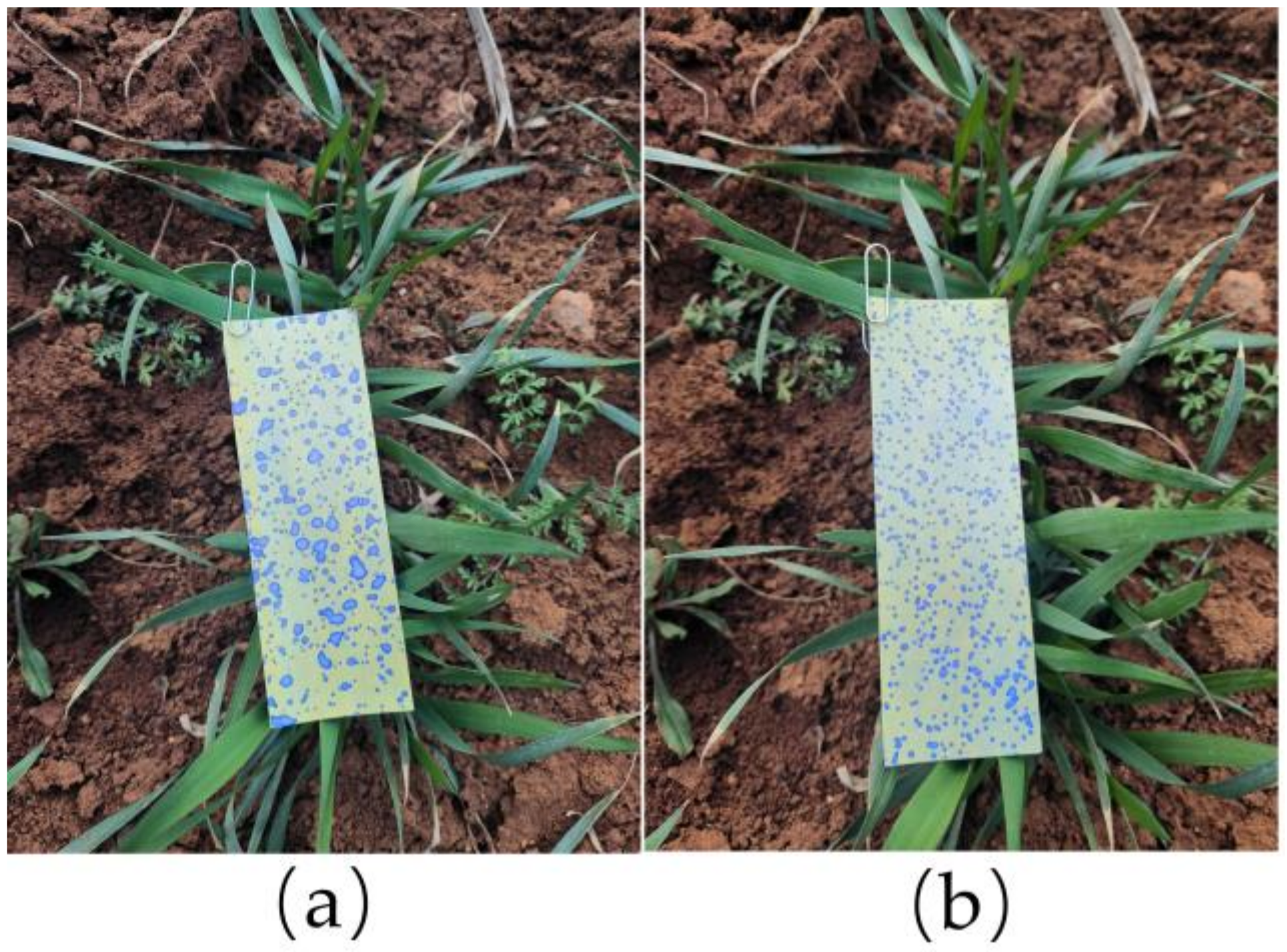

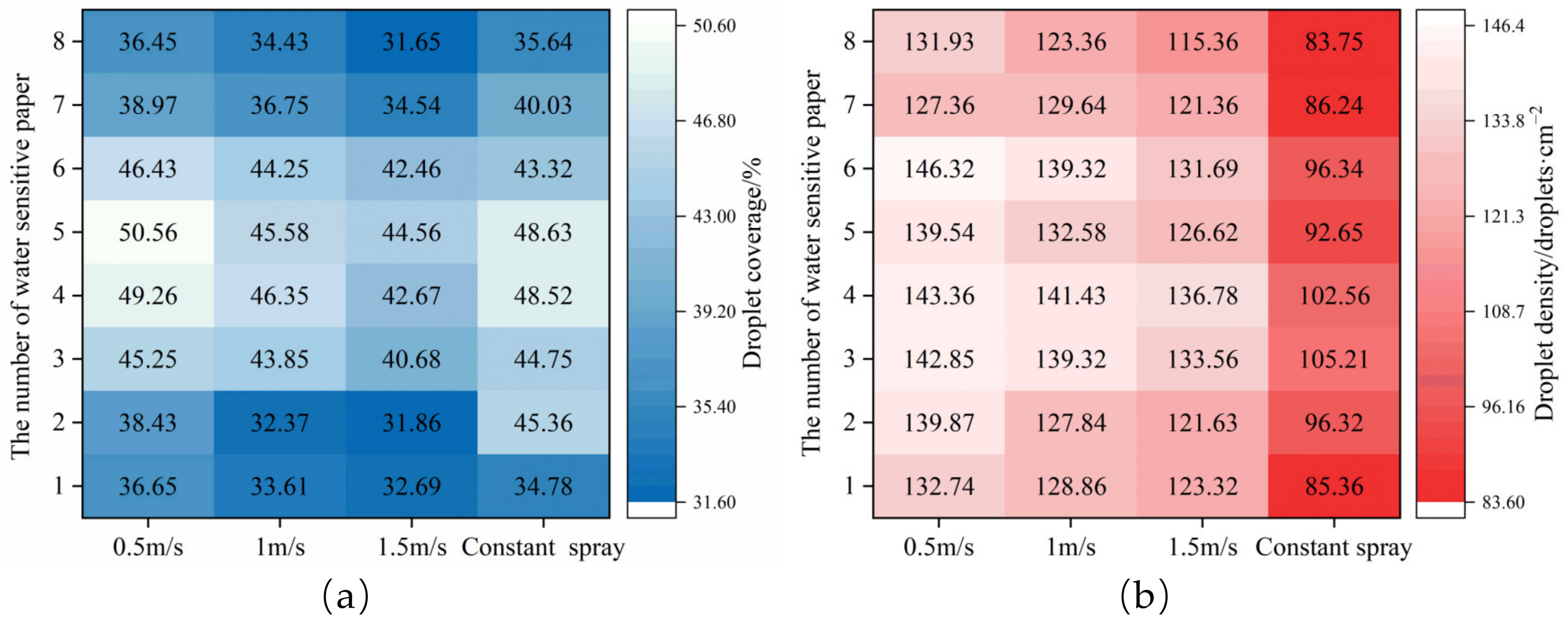

3.3.2. Analysis of Spray Droplet Deposition Effect

4. Conclusions

- (1)

- The overall parameter count and computational load were reduced by the improved model, and the accuracy of image segmentation was enhanced. By substituting the original Xception backbone network with the lightweight MobileNet V2 network and integrating the CA attention mechanism module, the results indicated that the MIoU and MPA of the modified model were 73.34% and 80.76%, respectively, with a single-image segmentation time of 0.09 s.

- (2)

- Within a certain distance, the atomization parameters of droplets sprayed at the same speed by constant and variable spraying were compared. The results indicated that variable spraying can refine droplet diameter and increase droplet density. The median volume diameter decreased by 138.13 μm, and the droplet density increased by 38.87 droplets/cm2, with an average drug-saving rate of 46.3%.

- (3)

- By utilizing PWM variable-spraying technology, online variable spraying was achieved for different weed densities and speeds. At the same speed, the average droplet-coverage rate in sparse-weed areas decreased by 13.98% compared to dense areas. Under the same plant density, the average coverage rate at a forward speed of 0.5 m/s increased by 2.91% and 6.59% compared with 1 m/s and 1.5 m/s, respectively. The results indicated that, under the standards of spraying, the spray system can automatically adjust the spray volume based on different travel speeds and weed densities, exhibiting excellent spray performance.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hamuda, E.; Glavin, M.; Jones, E. A Survey of Image Processing Techniques for Plant Extraction and Segmentation in the Field. Comput. Electron. Agric. 2016, 125, 184–199. [Google Scholar] [CrossRef]

- Christensen, S.; Søgaard, H.T.; Kudsk, P.; Nørremark, M.; Lund, I.; Nadimi, E.S.; Jørgensen, R. Site-Specific Weed Control Technologies. Weed Res. 2009, 49, 233–241. [Google Scholar] [CrossRef]

- Veeranampalayam Sivakumar, A.N.; Li, J.; Scott, S.; Psota, E.; Jhala, A.J.; Luck, J.D.; Shi, Y. Comparison of Object Detection and Patch-Based Classification Deep Learning Models on Mid-to Late-Season Weed Detection in UAV Imagery. Remote Sens. 2020, 12, 2136. [Google Scholar] [CrossRef]

- Wang, A.; Zhang, W.; Wei, X. A Review on Weed Detection Using Ground-Based Machine Vision and Image Processing Techniques. Comput. Electron. Agric. 2019, 158, 226–240. [Google Scholar] [CrossRef]

- Shaner, D.L.; Beckie, H.J. The Future for Weed Control and Technology. Pest Manag. Sci. 2014, 70, 1329–1339. [Google Scholar] [CrossRef]

- Lechenet, M.; Dessaint, F.; Py, G.; Makowski, D.; Munier-Jolain, N. Reducing Pesticide Use While Preserving Crop Productivity and Profitability on Arable Farms. Nat. Plants 2017, 3, 17008. [Google Scholar] [CrossRef] [PubMed]

- Green, J.M. Current State of Herbicides in Herbicide-Resistant Crops. Pest Manag. Sci. 2014, 70, 1351–1357. [Google Scholar] [CrossRef] [PubMed]

- Myers, J.P.; Antoniou, M.N.; Blumberg, B.; Carroll, L.; Colborn, T.; Everett, L.G.; Hansen, M.; Landrigan, P.J.; Lanphear, B.P.; Mesnage, R.; et al. Concerns over Use of Glyphosate-Based Herbicides and Risks Associated with Exposures: A Consensus Statement. Environ. Health 2016, 15, 19. [Google Scholar] [CrossRef]

- Gerhards, R.; Sökefeld, M.; Timmermann, C.; Kühbauch, W.; Williams, M.M. Site-Specific Weed Control in Maize, Sugar Beet, Winter Wheat, and Winter Barley. Precis. Agric. 2002, 3, 25–35. [Google Scholar] [CrossRef]

- Wen, S.; Zhang, Q.; Deng, J.; Lan, Y.; Yin, X.; Shan, J. Design and Experiment of a Variable Spray System for Unmanned Aerial Vehicles Based on PID and PWM Control. Appl. Sci. 2018, 8, 2482. [Google Scholar] [CrossRef]

- Xiongkui, H. Research Progress and Developmental Recommendations on Precision Spraying Technology and Equipment in China. Smart Agric. 2020, 2, 133. [Google Scholar]

- Nackley, L.L.; Warneke, B.; Fessler, L.; Pscheidt, J.W.; Lockwood, D.; Wright, W.C.; Sun, X.; Fulcher, A. Variable-Rate Spray Technology Optimizes Pesticide Application by Adjusting for Seasonal Shifts in Deciduous Perennial Crops. HortTechnology 2021, 31, 479–489. [Google Scholar] [CrossRef]

- Abbas, I.; Liu, J.; Faheem, M.; Noor, R.S.; Shaikh, S.A.; Solangi, K.A.; Raza, S.M. Different Sensor Based Intelligent Spraying Systems in Agriculture. Sens. Actuators Phys. 2020, 316, 112265. [Google Scholar] [CrossRef]

- Hussain, N.; Farooque, A.A.; Schumann, A.W.; McKenzie-Gopsill, A.; Esau, T.; Abbas, F.; Acharya, B.; Zaman, Q. Design and Development of a Smart Variable Rate Sprayer Using Deep Learning. Remote Sens. 2020, 12, 4091. [Google Scholar] [CrossRef]

- Zhao, D.J.; Zhang, B.; Wang, X.L.; Guo, H.H.; Xu, S.B. Automatic Target of Indoor Spray Robot Based on Image Moments. Trans. CSAM 2016, 47, 22–29. [Google Scholar]

- de Castro, A.I.; Jurado-Expósito, M.; Peña-Barragán, J.M.; López-Granados, F. Airborne Multi-Spectral Imagery for Mapping Cruciferous Weeds in Cereal and Legume Crops. Precis. Agric. 2012, 13, 302–321. [Google Scholar] [CrossRef]

- Xu, Y.L.; Bao, J.L.; Fu, D.P.; Zhu, C.Y. Design and Experiment of Variable Spraying System based on Multiple Combined Nozzles. Trans. CSAE 2016, 32, 47–54. [Google Scholar]

- Partel, V.; Kakarla, S.C.; Ampatzidis, Y. Development and Evaluation of a Low-Cost and Smart Technology for Precision Weed Management Utilizing Artificial Intelligence. Comput. Electron. Agric. 2019, 157, 339–350. [Google Scholar] [CrossRef]

- Chen, L.-C.; Papandreou, G.; Schroff, F.; Adam, H. Rethinking Atrous Convolution for Semantic Image Segmentation. arXiv 2017, arXiv:1706.05587. [Google Scholar]

- Chollet, F. Xception: Deep Learning with Depthwise Separable Convolution. In Proceedings of the 2017 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 1251–1258. [Google Scholar]

- Diab, A.; Kashef, R.; Shaker, A. Deep Learning for LiDAR Point Cloud Classification in Remote Sensing. Sensors 2022, 22, 7868. [Google Scholar] [CrossRef]

- Baheti, B.; Innani, S.; Gajre, S.; Talbar, S. Semantic Scene Segmentation in Unstructured Environment with Modified DeepLabV3+. Pattern Recognit. Lett. 2020, 138, 223–229. [Google Scholar] [CrossRef]

- Liu, H.; Jiang, J.B.; Shen, Y.; Jia, W.D.; Zeng, X.; Zhuang, Z.Z. Multi-category Segmentation of Orchard Scene Based on Improved DeepLab V3+. Trans. CSAM 2022, 53, 255–261. [Google Scholar]

- Peng, H.; Xue, C.; Shao, Y.; Chen, K.; Xiong, J.; Xie, Z.; Zhang, L. Semantic Segmentation of Litchi Branches Using DeepLabV3+ Model. IEEE Access 2020, 8, 164546–164555. [Google Scholar] [CrossRef]

- Cai, C.; Tan, J.; Zhang, P.; Ye, Y.; Zhang, J. Determining Strawberries’ Varying Maturity Levels by Utilizing Image Segmentation Methods of Improved DeepLabV3+. Agronomy 2022, 12, 1875. [Google Scholar] [CrossRef]

- Sandler, M.; Howard, A.; Zhu, M.; Zhmoginov, A.; Chen, L.-C. Mobilenetv2: Inverted Residuals and Linear Bottlenecks. In Proceedings of the 2018 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Salt Lake City, UT, USA, 18–23 June 2018; pp. 4510–4520. [Google Scholar]

- Targ, S.; Almeida, D.; Lyman, K. Resnet in Resnet: Generalizing Residual Architectures. arXiv 2016, arXiv:1603.08029. [Google Scholar]

- Hou, Q.; Zhou, D.; Feng, J. Coordinate Attention for Efficient Mobile Network Design. In Proceedings of the 2021 IEEE/CVF Conference on Computer Vision and Pattern Recognition (CVPR), Nashville, TN, USA, 20–25 June 2021; pp. 13708–13717. [Google Scholar]

- Liu, K.; Peng, L.; Tang, S. Underwater Object Detection Using TC-YOLO with Attention Mechanisms. Sensors 2023, 23, 2567. [Google Scholar] [CrossRef]

- Giles, D. Pulse Width Modulation for Nozzle Flow Control: Principles, Development and Status of the Technology. Asp. Appl. Biol. 2020, 144, 59–66. [Google Scholar]

- Wei, X.H.; Yu, D.Z.; Bai, J.; Jiang, S. Static Spray Deposition Distribution Characteristics of PWM-based Intermittently Spraying System. Trans. CSAE 2013, 29, 19–24. [Google Scholar]

- Yan, C.; Xu, L.; Yuan, Q.; Ma, S.; Niu, C.; Zhao, S. Design and Experiments of Vineyard Variable Spraying Control System Based on Binocular Vision. Trans. CSAE 2021, 37, 13–22. [Google Scholar]

| Model | IoU/% | MIoU/% | MPA /% | Segmentation Time/s | ||

|---|---|---|---|---|---|---|

| Background | Wheat | Weed | ||||

| SegNet | 80.56 | 70.23 | 41.36 | 64.05 | 71.53 | 0.15 |

| UNet | 81.24 | 71.41 | 50.36 | 67.57 | 74.32 | 0.13 |

| DeepLab V3+ | 83.38 | 73.44 | 53.12 | 69.98 | 77.34 | 0.12 |

| Proposed | 84.87 | 77.28 | 57.87 | 73.34 | 80.76 | 0.09 |

| Spraying Modes | VMD/μm | Droplet Density /(Droplets/cm2) | Coverage/% | Deposition Rate /(μL·cm−2) |

|---|---|---|---|---|

| Constant spray | 284.49 | 102.56 | 48.52 | 2.36 |

| Variable spray | 146.36 | 141.43 | 46.35 | 2.17 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, Z.; Ding, L.; Ji, J.; Jin, X.; Feng, Z.; Hao, M. Design and Experiment of Variable-Spray System Based on Deep Learning. Appl. Sci. 2024, 14, 3330. https://doi.org/10.3390/app14083330

He Z, Ding L, Ji J, Jin X, Feng Z, Hao M. Design and Experiment of Variable-Spray System Based on Deep Learning. Applied Sciences. 2024; 14(8):3330. https://doi.org/10.3390/app14083330

Chicago/Turabian StyleHe, Zhitao, Laiyu Ding, Jiangtao Ji, Xin Jin, Zihua Feng, and Maochuan Hao. 2024. "Design and Experiment of Variable-Spray System Based on Deep Learning" Applied Sciences 14, no. 8: 3330. https://doi.org/10.3390/app14083330

APA StyleHe, Z., Ding, L., Ji, J., Jin, X., Feng, Z., & Hao, M. (2024). Design and Experiment of Variable-Spray System Based on Deep Learning. Applied Sciences, 14(8), 3330. https://doi.org/10.3390/app14083330