Investigation of Steep Waste Dump Slope Stability of Iron Ore Mine—A Case Study

Abstract

1. Introduction

2. Materials and Methods

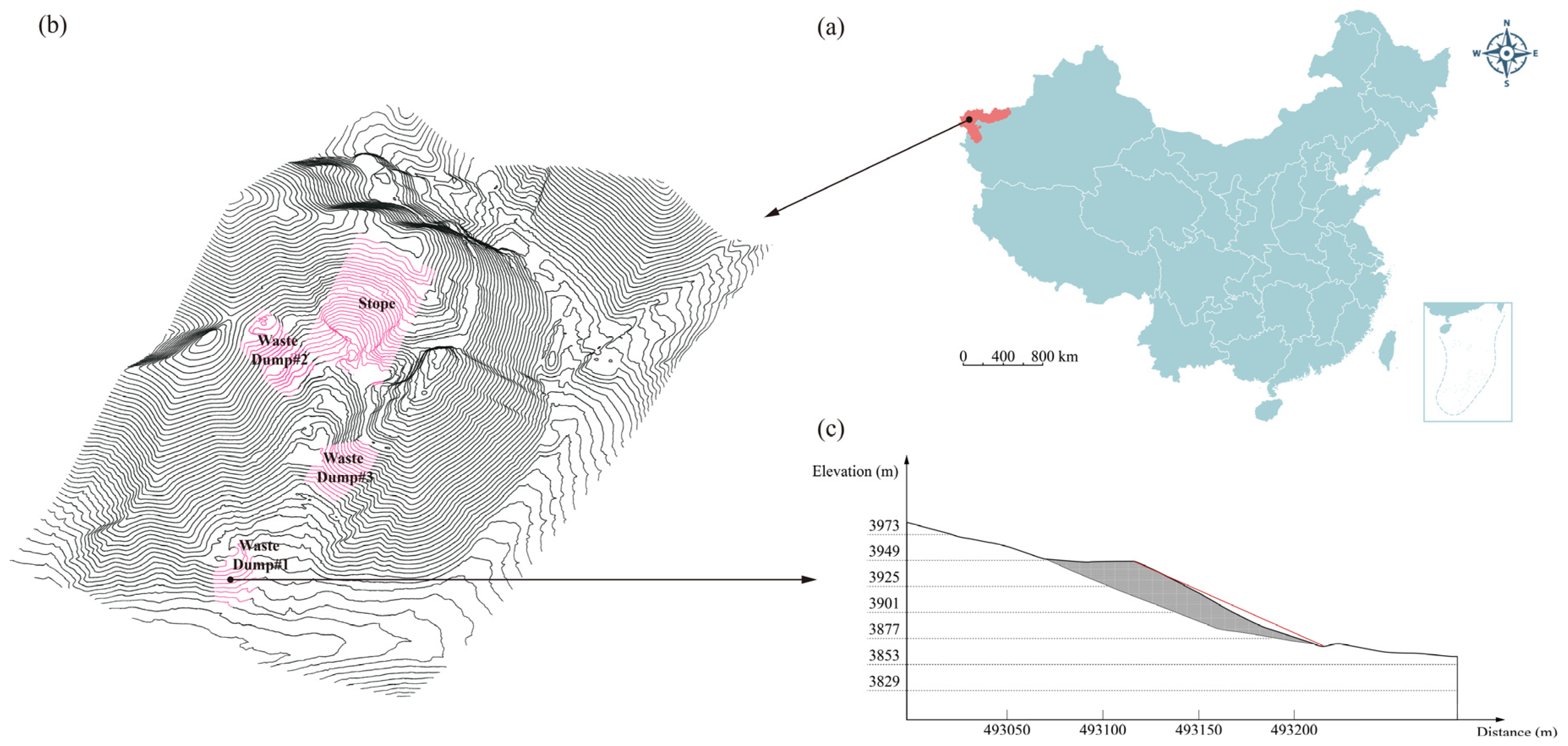

2.1. Iron Mine Location Data and Slope Morphology

2.2. Sample Collection and Preparation

2.2.1. Soil Sampling

2.2.2. Soil Sample Preparation

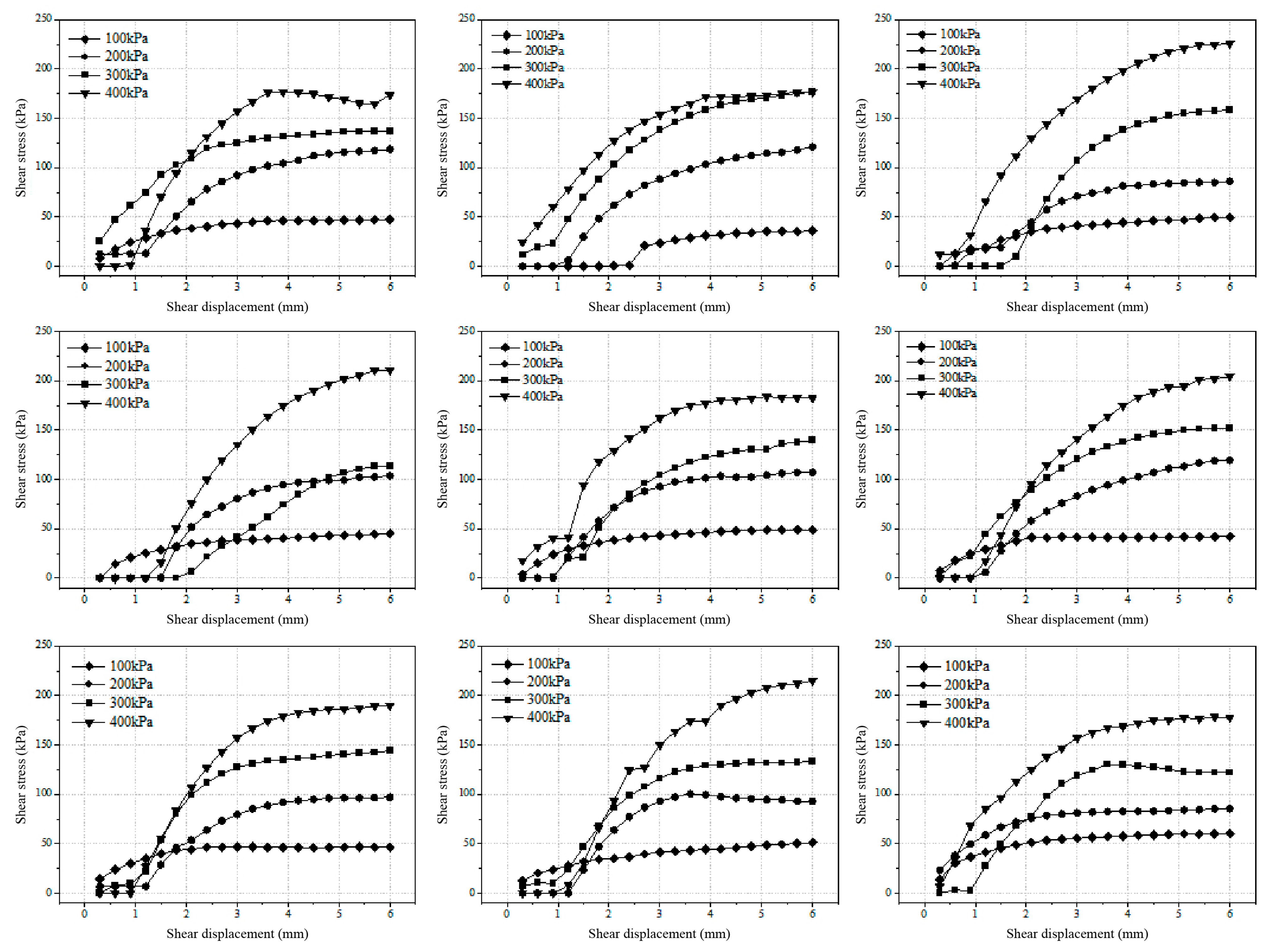

2.3. Direct Shear Test

2.3.1. Test Parameter Setting

- Vertical (normal) stress: maximum 400 kPa;

- Pressure levels: 100, 200, 300, and 400 kPa;

- Bar ratio: 1:12;

- Shear boxes: 4;

- Horizontal shear force: maximum 1.2 kN;

- Specimen size with square cross-sections: 30 cm2 × 2 cm (H);

- Loading rates: 2.4, 0.8, 0.1, and 0.02 mm/min.

2.3.2. Experimental Procedure of Direct Shear Test

- Sorting of the test results:

- Calculate the shear stress and shear displacement for each sample per the following formulations:τ = CR,where τ denotes the shear stress in kPa, ΔL represents the shear displacement (unit: 0.01 mm), and C is the correction factor of the load cell (unit: kPa/0.01 mm). In addition, R denotes the load cell micrometer reading in 0.01 mm, ΔL′ represents the shear displacement for one revolution of the rotating wheel in 0.001 mm, and n is the number of rotations.ΔL = ΔL’(n − R)

- Plot the shear stress in terms of the shear displacement and then determine the peak or stable value on the relationship curve as the shear strength of the soil;

- Calculate the cohesion and the internal friction angle of the soil using the relationship.

2.4. Slope Stability Analysis

- The discharge material (in the present case study, Ziluoyi Iron Mine, Waste Dump#1) is both homogenous and isotropic;

- No sizeable cracks exist in the main spatial domain of the discharge material;

- In the mechanical modeling of the problem, the quartz schist medium underneath the discharge material is assumed to be rigid;

- The mechanical strength of the discharge material obeys the Mohr–Coulomb criterion;

- The failure surface entirely takes place inside the discharge material, which possesses a lower strength than the underlying quartz schist domain.

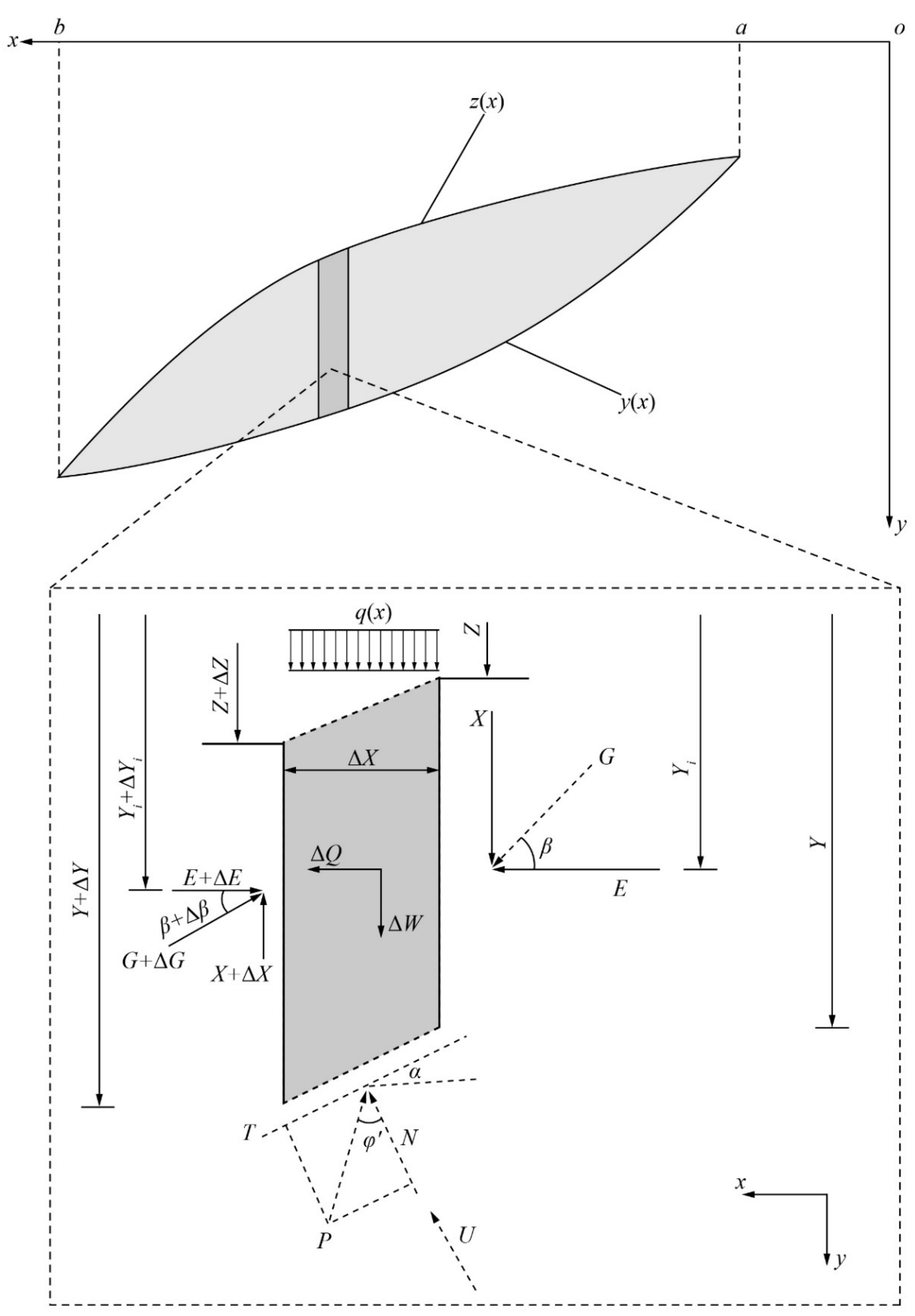

2.4.1. Morgenstern–Price Method

2.4.2. Discrete Element-Based Numerical Simulation

3. Results and Discussion

3.1. Slope Profile of Waste Dump#1

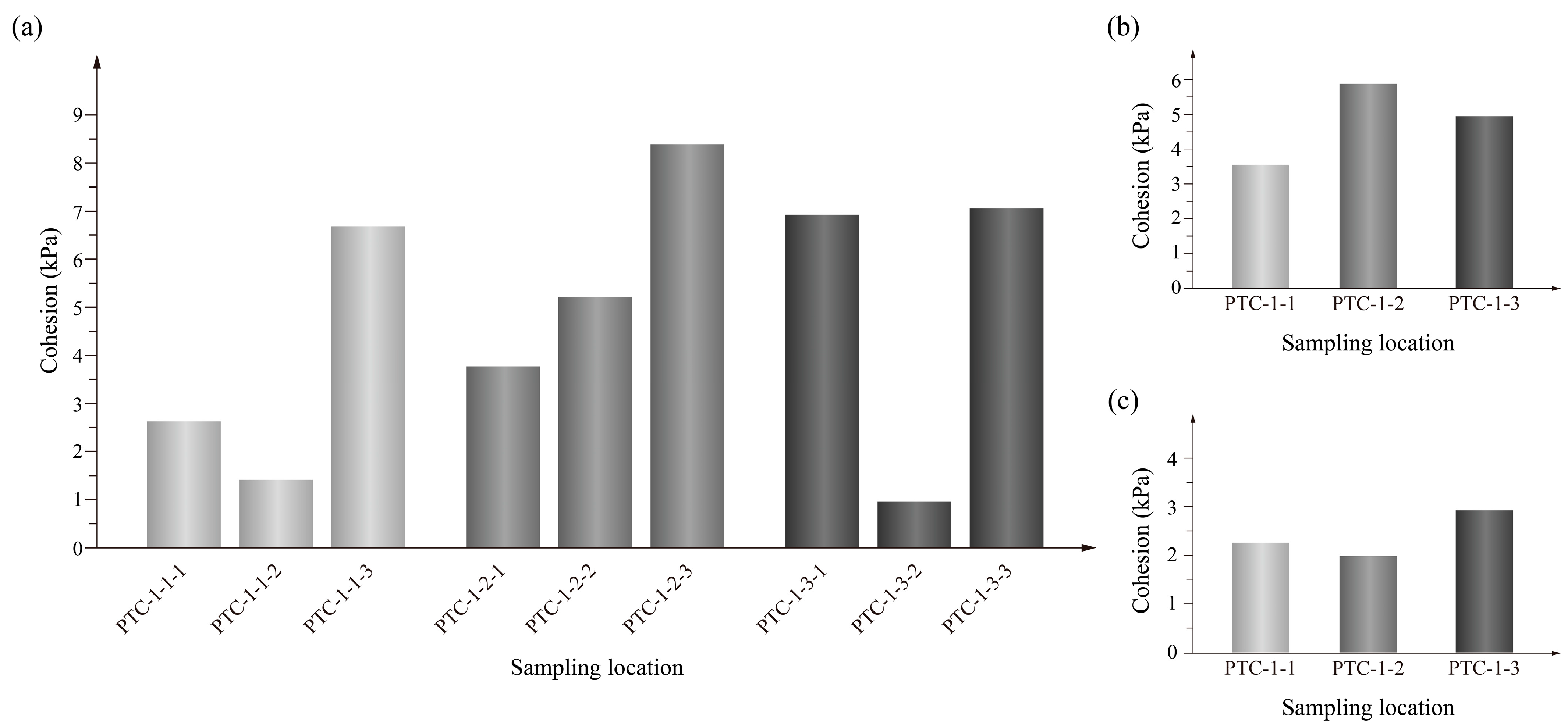

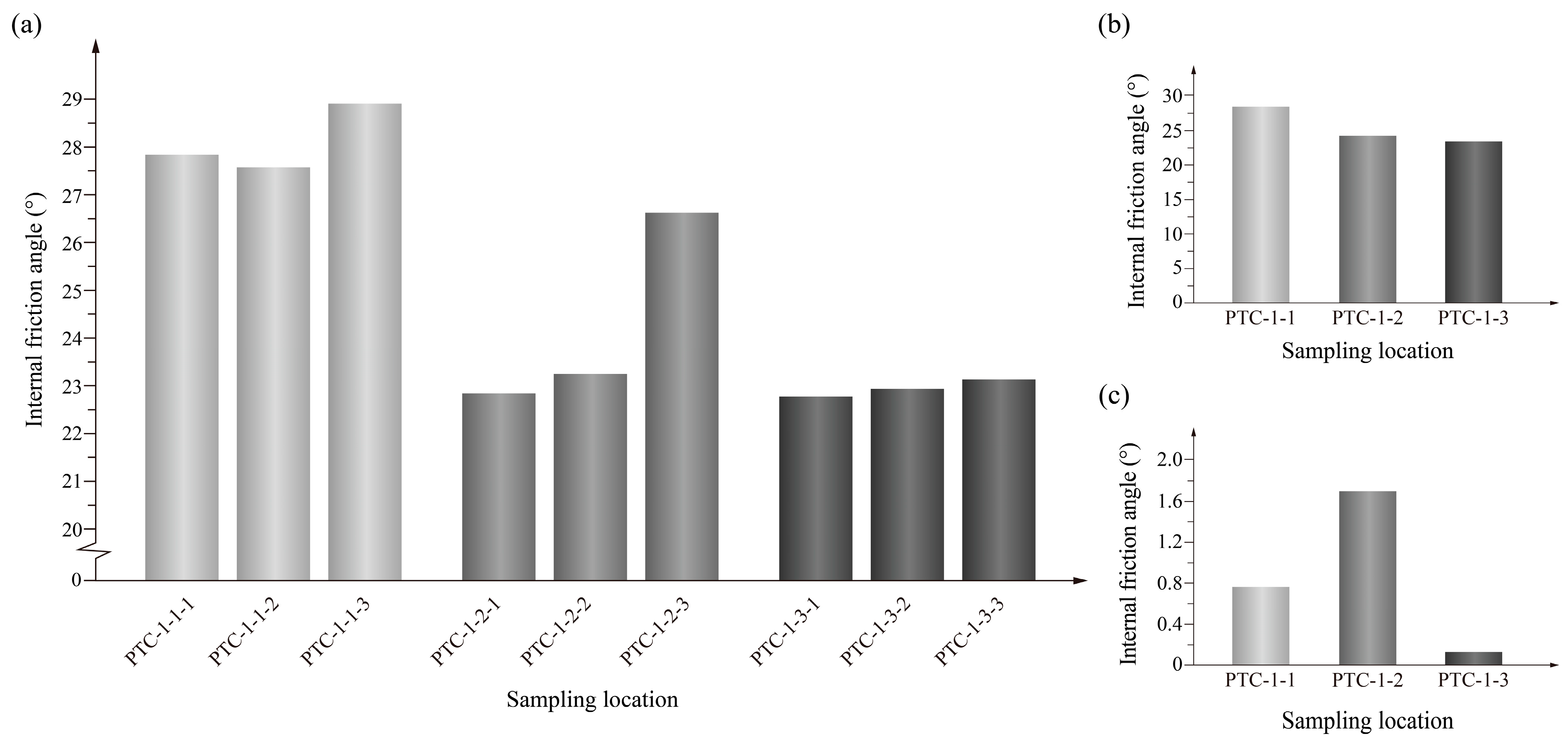

3.2. Experimental Findings

3.3. GEO-SLOPE Calculation Results

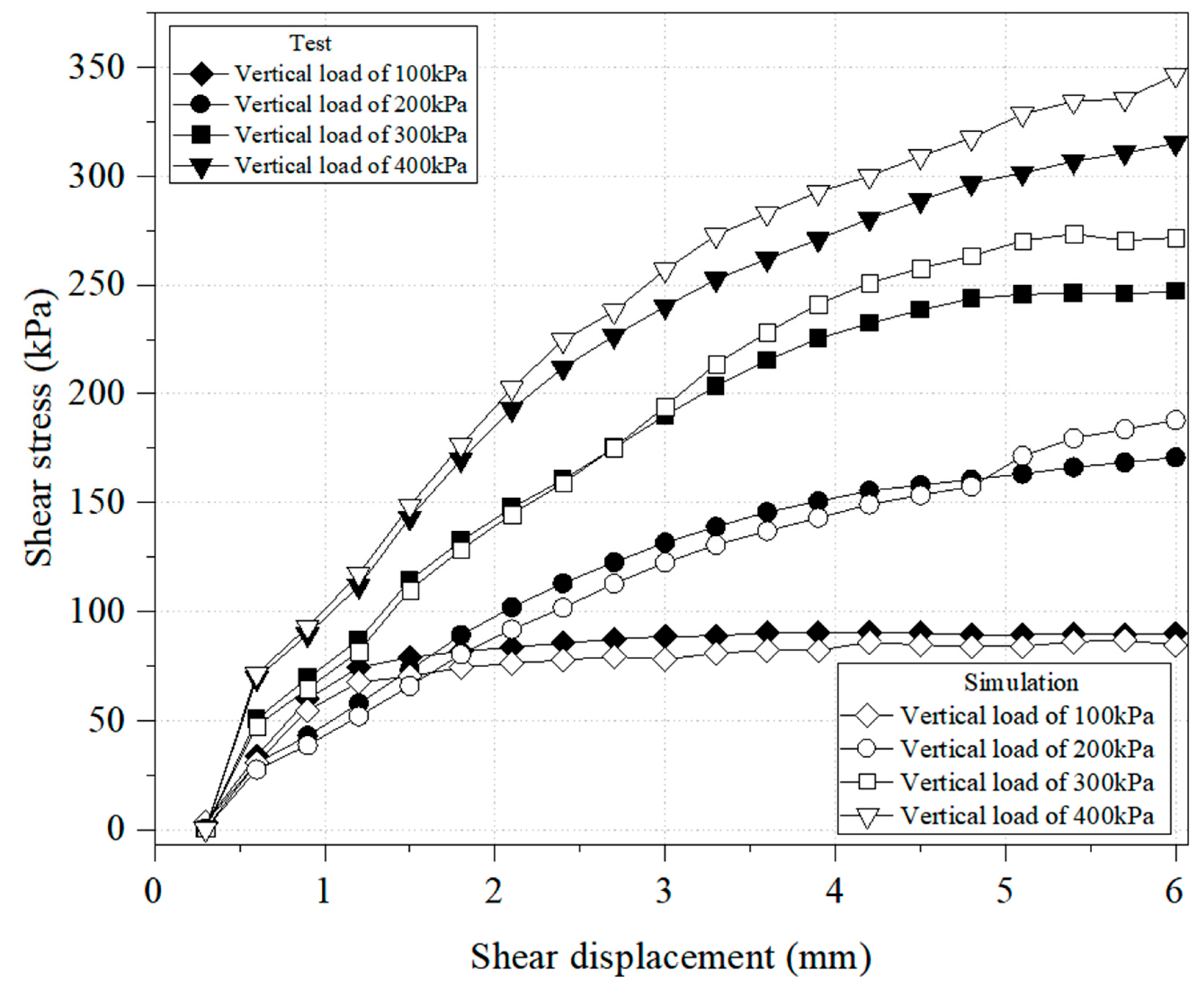

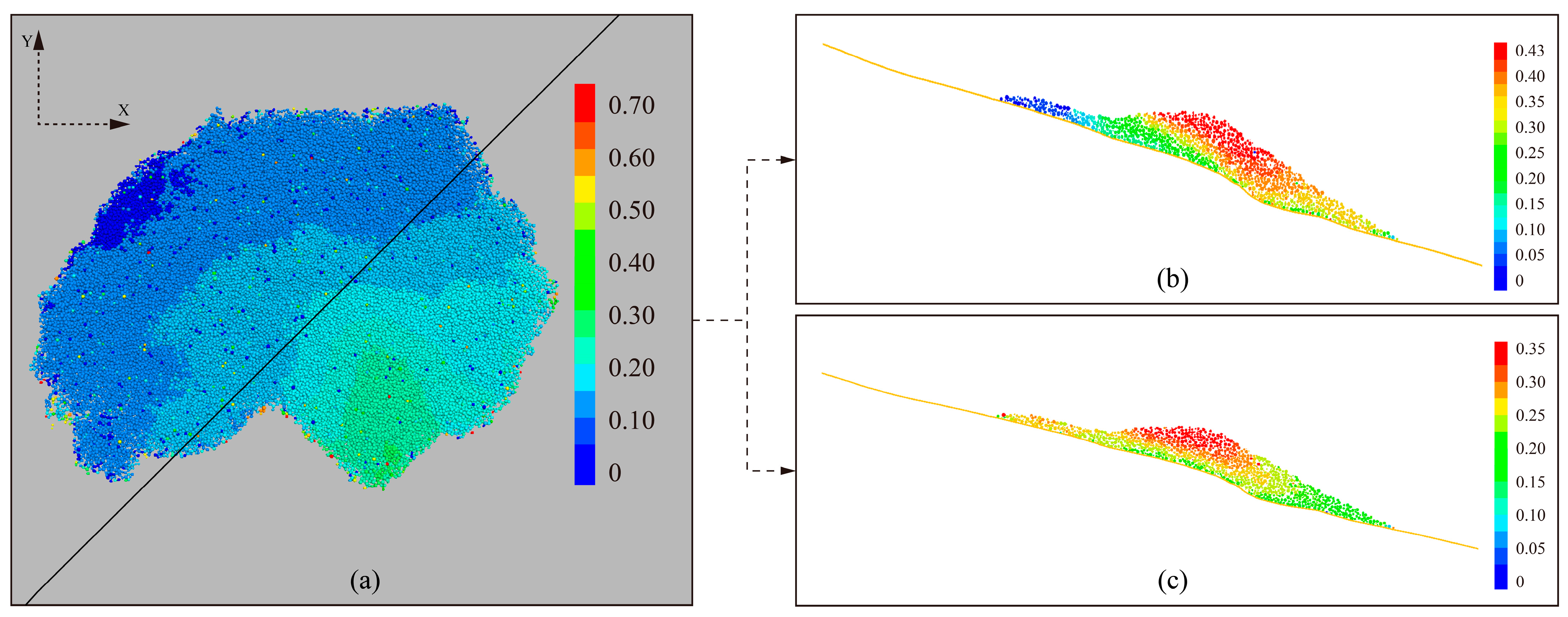

3.4. Capabilities of the PFC Particle Flow in Capturing Both Mechanical Behavior and Response

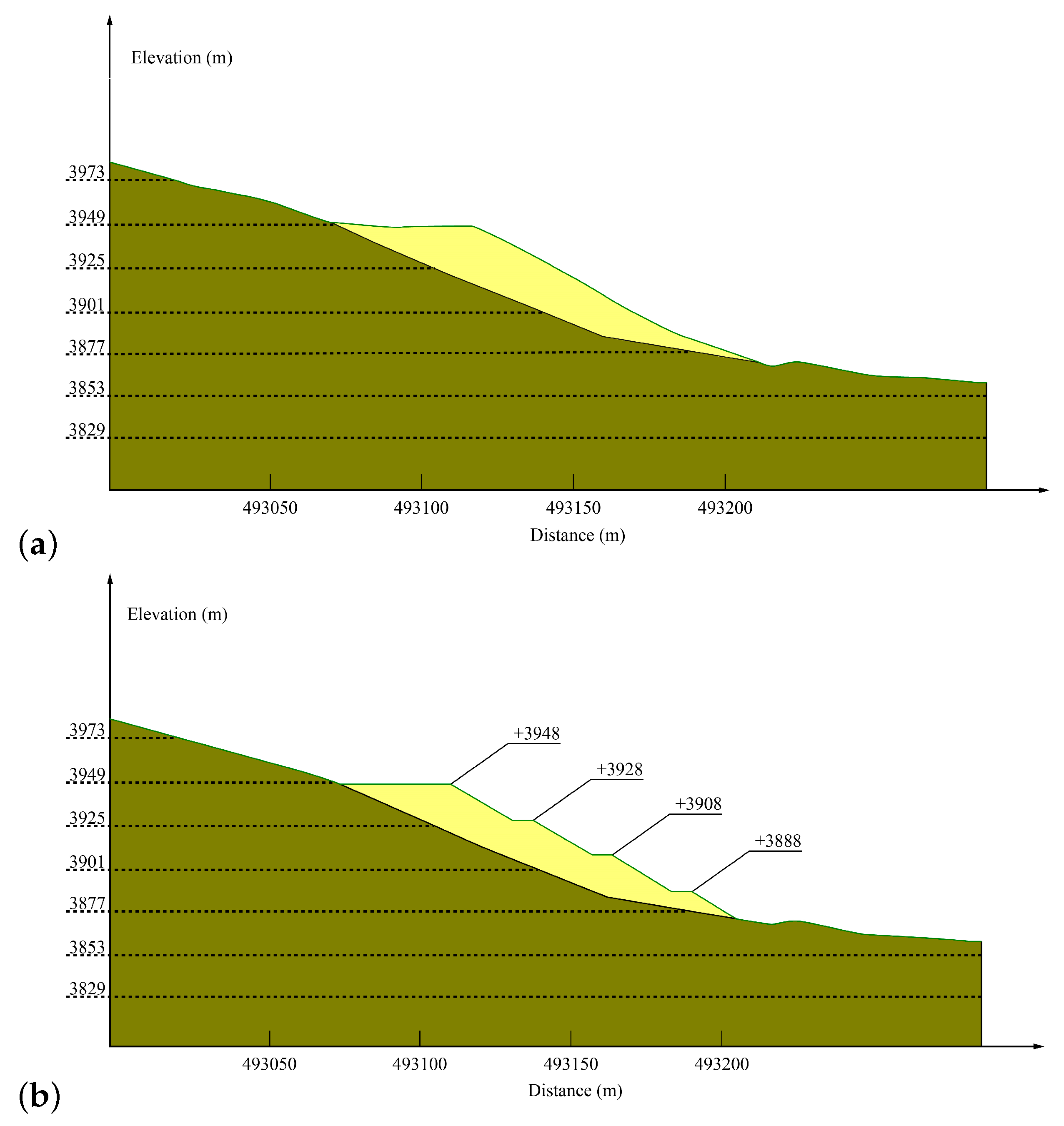

3.5. Slope Rectification

- The safety platform is constructed in a top-down manner through controlled material dumping. Initially, level the dumpling line +3948 m within 10 m and clear the slope of any loose stones, large blocks, and other debris to ensure the safety of the excavation work.

- Construct the safety platform +3938 moving from north to south. The width of the safety platform +3938 is 10 to 12 m. After that, remove unstable loose soil and debris at +3938 m and +3948 m slopes.

- Gradually lower the safety platform +3938 to create the safety platform +3928 m, while adhering to a 30° slope angle. This is accomplished with leveling, resulting in a final 10 m wide +3928 m safety platform.

- Construct the safety platform +3918 from north to south. Clear any unstable loose soil and debris on the slope from +3918 m to +3928 m.

- Level the safety platform +3918 by lowering it to the safety platform +3908 m along the slope angle of 30°, thereby establishing a safety platform with a width of 10 m +3908 m.

- Repeat the same procedure to form the +3898 m platform, which is subsequently lowered to form the +3888 m safety platform.

- During the formation of safety platforms +3908 m and +3888 m, a part of the space may require additional tailings to fill any gaps. The decision on this matter will be made according to the actual conditions during construction on site.

3.5.1. GEO-SLOPE Stability Calculation after Rectification

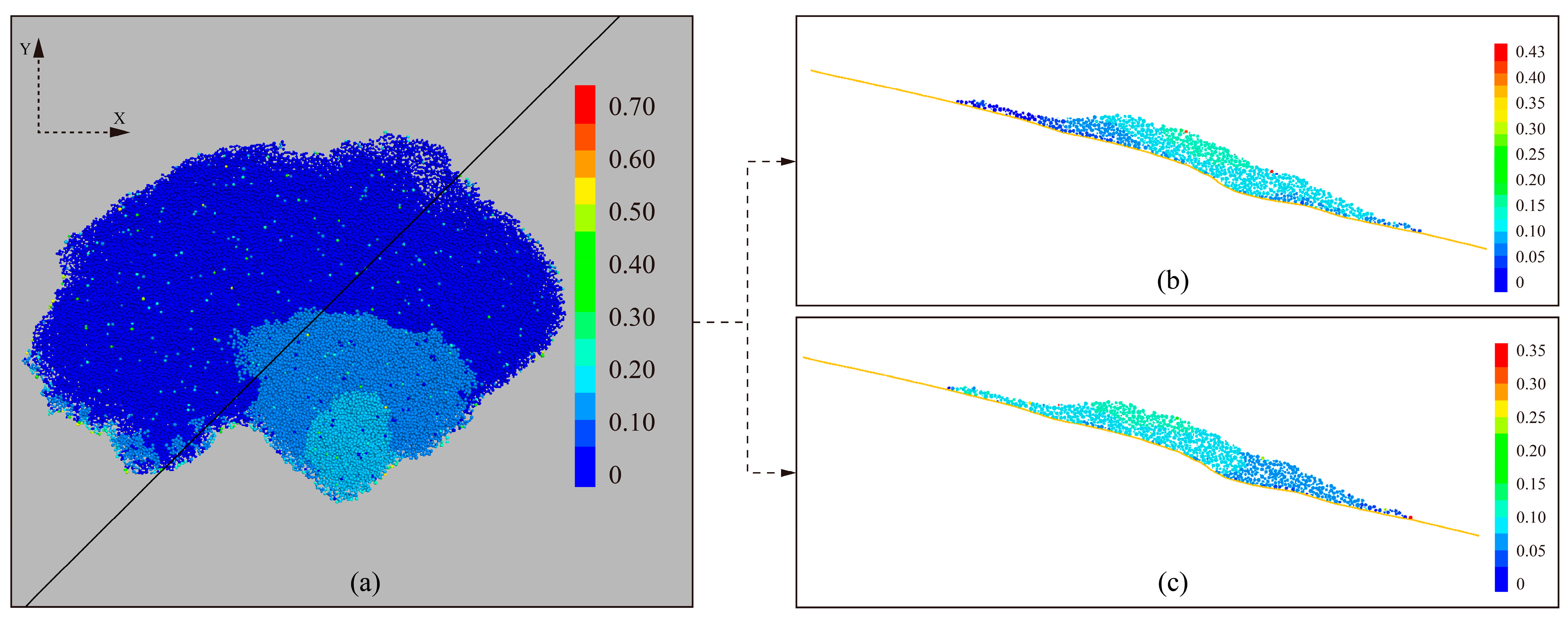

3.5.2. PFC Numerical Simulation of the Rectified Slope Displacement

4. Conclusions

- The open-pit mine of Ziluoyi has a slope with a height of 78 m and an angle of 25°, with a base slope angle of 22°, and has a significant step. According to the GB50421-2018 “Standard for Waste Dump Design of Nonferrous Metal Mines”, this type of slope is classified as a Grade 3 waste dump. For such slopes, the safety factor ranges from 1.15 to 1.20, as per GB50421-2018;

- The direct shear tests on soil samples taken from the dump site revealed the following key mechanical parameters: an average cohesion of 4.80 kPa and an average internal friction angle of 25.63°. However, the GEO-SLOPE calculations based on the Morgenstern–Price approach indicated that the actual slope stability factor of 1.047 does not meet the required stability criteria. To resolve this critical concern, appropriate rectification procedures including the construction of safety platforms, relocation, and removal of unstable soil were implemented. These modifications to the understudy slope improved the overall slope stability factor to 1.219 and were in line with safety standards;

- The efficiency of the PFC-based model in rational capturing the mechanical strength behavior of soil in the presence of various vertical stresses was demonstrated by comparing it with the experimental results. The obtained results are indicative of the fact that such a mode is capable of fairly precise capturing of the experimentally observed shear stress-shear displacement with a relative error lower than 6% in most cases.

- Subsequently, the PFC simulations were utilized to model the slope morphology and particle displacement before and after rectification. The obtained results reveal that through the application of the post-rectification, the area of sliding and the proportion of sliding particles were substantially reduced by 25%, with a 41.8% reduction in sliding volume. These results demonstrate the effectiveness of the slope remediation measures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sazid, M.; Singh, T.N.; Saharan, M.R. Risk analysis of mine dump slope stability—A case study. Min. Eng. J. 2012, 12, 11–15. [Google Scholar]

- Xu, X.-Z.; Guo, W.-Z.; Liu, Y.-K.; Ma, J.-Z.; Wang, W.-L.; Zhang, H.-W.; Gao, H. Landslides on the Loess Plateau of China: A latest statistics together with a close look. Nat. Hazards 2017, 86, 1393–1403. [Google Scholar] [CrossRef]

- Juang, C.H.; Dijkstra, T.; Wasowski, J.; Meng, X. Loess geohazards research in China: Advances and challenges for mega engineering projects. Eng. Geol. 2019, 251, 1–10. [Google Scholar] [CrossRef]

- Spooner, I.; Batterson, M.; Catto, N.; Liverman, D.; Broster, B.; Kearns, K.; Isenor, F.; MacAskill, W. Slope failure hazard in the Atlantic provinces: A review. Atl. Geol. 2013, 49, 1–14. [Google Scholar] [CrossRef]

- Itoh, K.; Timpong, S.; Toyosawa, Y. Case history of labor accident due to slope failure during slope excavation and its countermeasure work. In Proceedings of the International Conference on Case Histories in Geotechnical Engineering, Chicago, IL, USA, 11–16 August 2008; Volume 15. Available online: https://scholarsmine.mst.edu/icchge/6icchge/session02/15 (accessed on 10 March 2024).

- Evans, S.G. Fatal landslides and landslide risk in Canada 1. In Landslide Risk Assessment; Routledge: London, UK, 2018; pp. 185–196. [Google Scholar]

- Guzzetti, F. Landslide fatalities and the evaluation of landslide risk in Italy. Eng. Geol. 2000, 58, 89–107. [Google Scholar] [CrossRef]

- Sarkar, K.; Sazid, M.; Khandelwal, M.; Singh, T.N. Stability analysis of soil slope in Luhri area, Himachal Pradesh. Min. Eng. J. 2009, 10, 21–27. [Google Scholar]

- Sazid, M. Finite element analysis of road cut slopes using Hoek & Brown failure criterion. Int. J. Earth Sci. Eng. 2012, 5, 1100–1109. [Google Scholar]

- Gupte, S.S. Optimisation of internal dump capacity and stability analysis in a coal mine—A case study. In Proceedings of the First Asia Pacific Slope Stability in Mining Conference, Brisbane, Australia, 6–8 September 2016; Australian Centre for Geomechanics: Crawley, Australia, 2016; pp. 557–570. [Google Scholar]

- Singh, P.K.; Kainthola, A.; Singh, T.N. A distinct element modeling approach towards rockfall analysis. J. Eng. Geol. 2015, 40, 119129. [Google Scholar]

- Yang, T.H.; Zhang, F.C.; Yu, Q.L.; Cai, M.F.; Li, H.Z. Research situation of open-pit mining high and steep slope stability and its developing trend. Rock Soil Mech. 2011, 32, 1437–1451. [Google Scholar]

- Liu, J.; Cheng, Z.H.; Ji, D.X.; Zhang, X.D.; Ma, P.C.; Li, M.Y. Damage mechanism research on high slope stability of open-pit mine based on strength reduction method. Met. Mine 2018, 9, 74–78. [Google Scholar]

- Huang, X.; Zhang, X.H.; Xue, L.; Niu, J.R.; Wang, Y.Y. Stability evaluation on the high slope at dumping site of Jinduicheng Open Pit mine. Chin. J. Geol. Hazard Control 2010, 21, 40–43. [Google Scholar]

- Du, X.; Chai, J. Stability evaluation of medium soft soil pile slope based on limit equilibrium method and finite element method. Mathematics 2022, 10, 3709. [Google Scholar] [CrossRef]

- Ji, Z.Y.; Zhang, H.S.; Wang, G.H. Review of characteristics of open-pit mines slope and landslide key control technology. Site Investig. Sci. Technol. 2011, 6, 24–28. [Google Scholar]

- Shen, L.; Wang, J.G.; Ji, Y.S.; Li, G.Z.; Zhang, T.W. Safety analysis and application of rock deformation for high slope. Coal Sci. Technol. 2005, 33, 64–67. [Google Scholar]

- Zi, J.P.; Zhu, L.Q.; Zhang, D.W.; Wang, H.F. Stability analysis of open-pit mining slope in Heishan Iron Mine. Express Inf. Min. Ind. 2008, 8, 74–76. [Google Scholar]

- Ao, Z.; Wang, Z.; Zhou, W.; Qiao, Y.; Wahab, A.; Yang, Z.; Nie, S.; Liu, Z.; Zhu, L. CFD simulation based ventilation and dust reduction strategy for large scale enclosed spaces in open pit coal mines—A case of coal shed. Sustainability 2023, 15, 11651. [Google Scholar] [CrossRef]

- Li, S.; Liu, J.; Jiang, Z. Study on the basic characteristics and mechanical model of toppling and sliding deformable. Hydrogeol. Eng. Geol. 2000, 2, 20–22. [Google Scholar]

- Chen, F. Application of direct shear test in stability analysis of tailings ponds. New Technol. New Prod. China 2019, 12, 80–81. [Google Scholar]

- Ding, X.; Ao, Z.; Li, X.; Xiao, S.; Wu, M.; Xing, B.; Ge, R.; Zhang, D. The mechanism of plugging open-pit mine cannon holes and the modification of plugging materials. Sustainability 2023, 15, 4257. [Google Scholar] [CrossRef]

- Cai, Y.J.; Pei, S.H.; Ding, R.F. The influence of direct fast shear test conditions on shear strength. West—China Explor. Eng. 2003, 12, 40–42. [Google Scholar]

- Dahri, M.W.; Zhou, M.; Liu, Z. Prediction of shear strength for granular material under the effect of liquid-powder binder using a PSO-RBF neural network model. Particul. Sci. Technol. 2023, 41, 896–903. [Google Scholar] [CrossRef]

- Shen, Z.; Ao, Z.; Wang, Z.; Yang, Y. Study on crust-shaped dust suppressant in non-disturbance area of open-pit coal mine—A case study. Int. J. Environ. Res. Public Health 2023, 20, 934. [Google Scholar] [CrossRef]

- Tian, R.X.; Jiao, H.G. Application status and analysis of discrete element software PFC in mining engineering. Min. Metall. 2011, 20, 79–82. [Google Scholar]

- He, X.W.; Liu, Z.; Liao, B.; Wang, C.C. Stability analysis of jointed rock slopes based on discrete element method. Rock Soil Mech. 2011, 32, 2199–2204. [Google Scholar]

- Gao, Z.; Wang, S.; Yin, H.; Zhao, Q.; Vladimr, P.; Li, Y. Estimation of Shear strength parameters considering joint roughness: A stability case analysis of bedding rock slopes in an open-pit mine. Appl. Sci. 2023, 13, 5730. [Google Scholar] [CrossRef]

- Peng, B.; Chen, Y.M.; Yuan, L.W. Stability analysis of slope stability of No. 2 open pit in Maanshan Iron Mine based on PFC2D. Min. Eng. 2014, 35, 37–40. [Google Scholar]

- Tian, Y.; Jiskani, I.M.; Lu, X.; Zhou, W.; Liu, F.; Zhang, C.; Cai, Q. Control mechanism of end-slope deformation in open pit mine based on discrete-continuous coupling method. Comput. Part. Mech. 2023, 10, 951–963. [Google Scholar] [CrossRef]

- Tian, Y.; Zhou, W.; Jiskani, I.M.; Cai, Q.; Li, Z.; Lu, X. Stability analysis of varying height waste dump in open-pit mine under particle size gradation and reconstruction effect of waste materials. Int. J. Min. Reclam. Environ. 2022, 36, 587–604. [Google Scholar] [CrossRef]

- Zhang, T.; Yu, L.; Peng, Y.; Jing, H.; Su, H.; Wei, J. Effect of the mineral spatial distribution heterogeneity on the tensile strength of granite: Insights from PFC3D-GBM numerical analysis. J. Rock Mech. Geotech. Eng. 2023, 15, 1144–1160. [Google Scholar] [CrossRef]

- Cong, Y.; Liu, H.; Wang, X.; Guo, D.; Han, L.; Zhao, Y.; Zou, L. The influence of cross-section shape on failure of rock surrounding the main tunnel in a water-sealed cavern. Sustainability 2023, 15, 424. [Google Scholar] [CrossRef]

- Jiang, S.; Li, J.; Zhang, S.; Gu, Q.; Lu, C.; Liu, H. Landslide risk prediction by using GBRT algorithm: Application of artificial intelligence in disaster prevention of energy mining. Process Saf. Environ. Prot. 2022, 166, 384–392. [Google Scholar] [CrossRef]

- Zhang, W.F.; Ren, F.H.; Guo, Q.F.; Pan, J.L.; Liu, W.S. Analysis on slope stability of inner dump in Heshangqiao iron mine under rainfall. Met. Mine 2022, 5, 205–211. [Google Scholar]

- Ma, L.J.; Sheng, J.L. Stability analysis and reliability study of dump slope under rainfall infiltration. Ind. Miner. Process. 2019, 48, 67–71. [Google Scholar]

- Lin, B.X. Stability analysis of dump slope: Taking Zijinshan open-pit mine as an example. Mob. Inf. Syst. 2022, 2022, 9009528. [Google Scholar] [CrossRef]

- Lan, Y. Stability analysis and treatment of high and steep slope in open-pit dump based on numerical simulation. Min. Res. Dev. 2023, 43, 77–82. [Google Scholar]

- Zhang, L.; Chen, Z.; Nian, G.; Bao, M.; Zhou, Z. Base friction testing methodology for the deformation of rock masses caused by mining in an open-pit slope. Measurement 2023, 206, 112235. [Google Scholar] [CrossRef]

- Wang, M.; Li, X.; Yang, S.; Teng, L.; Chen, Q.; Jiang, S. Research on deformation and fracture characteristics of the fractured rock mass under coupling of heavy rainfall infiltration and mining unloading. Front. Earth Sci. 2022, 9, 792038. [Google Scholar] [CrossRef]

- Wang, J.; Chen, C. Stability analysis of slope at a disused waste dump by two-wedge model. Int. J. Min. Reclam. Environ. 2017, 31, 575–588. [Google Scholar] [CrossRef]

- Ansari, T.A.; Singh, H.K.; Sazid, M.; Singh, H.O.; Singh, T.N.; Singh, K.H.; Zhou, H. Evaluation of various modes of fracture toughness (Mode I, II, and I + II) in Indian limestone based on ae parameters. In CAJG 2020: Selected Studies in Geotechnics, Geo-informatics and Remote Sensing, Proceedings of the 3rd Conference of the Arabian Journal of Geosciences, Sousse, Tunisia, 2–5 November 2020; Springer Nature: Cham, Switzerland, 2020; pp. 169–173. [Google Scholar] [CrossRef]

- Chen, Y.; Tang, Y.; Cao, R.; Sun, S.; Zha, W.; Lin, H. Failure mode of parallel-fractured rock-like sample with different inclinations. Theor. Appl. Fract. Mech. 2023, 127, 104053. [Google Scholar] [CrossRef]

- ASTM D422–63e2 2007; Standard Test Method for Particle-Size Analysis of Soils. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D2217–85 1998; Standard Practice for Wet Preparation of Soil Samples for Particle-Size Analysis and Determination of Soil Constants (Withdrawn 2007). ASTM International: West Conshohocken, PA, USA, 1998.

- ASTM D4318–10e1 2010; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2010.

- ASTM D3080-11 2011; Standard for Test Method for Direct Shear Test of Soils under Consolidated Drained Conditions. ASTM International: West Conshohocken, PA, USA, 2011.

- Fellenius, W. Calculation of the stability of earth dams. In Transactions 2nd Congress on Large Dams; U.S. Government Printing Office: Washington, DC, USA, 1936; Volume 4, pp. 445–462. [Google Scholar]

- Taylor, D.W. Stability of earth slopes. J. Boston Soc. Civ. Eng. 1937, 24, 197–246. [Google Scholar]

- Khurram, M.; Mufti, R.A.; Bhutta, M.U.; Habib, Y.; Ahmed, A.; Afzal, N. A numerical approach to calculate creep in roller follower valve train basing on friction and lubrication modeling. Trans. Can. Soc. Mech. Eng. 2015, 39, 805–818. [Google Scholar] [CrossRef]

- GB50421-2018; Standard for Waste Dump Design of Nonferrous Metal Mines. China National Standard: Beijing, China, 2018.

- Nanehkaran, Y.A.; Licai, Z.; Chengyong, J.; Chen, J.; Anwar, S.; Azarafza, M.; Derakhshani, R. Comparative analysis for slope stability by using machine learning methods. Appl. Sci. 2023, 13, 1555. [Google Scholar] [CrossRef]

- Du, H.; Du, S.; Li, W. Probabilistic time series forecasting with deep non-linear state space models. CAAI Trans. Intell. Technol. 2023, 8, 3–13. [Google Scholar] [CrossRef]

- Cao, H.; Wu, Y.; Bao, Y.; Feng, X.; Wan, S.; Qian, C. UTrans-Net: A model for short-term precipitation prediction. Artif. Intell. Appl. 2023, 1, 106–113. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Y.; Gao, X.; Gong, D.; Guo, Y.; Gao, K.; Zhang, W. An embedded vertical-federated feature selection algorithm based on particle swarm optimisation. CAAI Trans. Intell. Technol. 2023, 8, 734–754. [Google Scholar] [CrossRef]

- Katkade, S.N.; Bagal, V.C.; Manza, R.R.; Yannawar, P.L. Advances in real-time object detection and information retrieval: A Review. Artif. Intell. Appl. 2023, 1, 139–144. [Google Scholar] [CrossRef]

- Ahangari Nanehkaran, Y.; Pusatli, T.; Chengyong, J.; Chen, J.; Cemiloglu, A.; Azarafza, M.; Derakhshani, R. Application of machine learning techniques for the estimation of the safety factor in slope stability analysis. Water 2022, 14, 3743. [Google Scholar] [CrossRef]

- Remmelzwaal, L. An AI-based early fire detection system utilizing HD cameras and real-time image analysis. Artif. Intell. Appl. 2023. [Google Scholar] [CrossRef]

- Wang, W.; Sun, Y.; Li, K.; Wang, J.; He, C.; Sun, D. Fully Bayesian analysis of the relevance vector machine classification for imbalanced data problem. CAAI Trans. Intell. Technol. 2023, 8, 192–205. [Google Scholar] [CrossRef]

- Moayedi, H.; Tien Bui, D.; Kalantar, B.; Kok Foong, L. Machine-learning-based classification approaches toward recognizing slope stability failure. Appl. Sci. 2019, 9, 4638. [Google Scholar] [CrossRef]

| Instrument | Model and Main Parameter | Manufacturer |

|---|---|---|

| JYS200 Soil Sieve | JYS200 | Hebei Zhongyi Weichuang Testing Instrument Co., Ltd., Cangzhou, China |

| Electronic Balance | YT2204 | Shenzhen Xinlangpu Electronic Technology Co., Ltd., Shenzhen, China |

| ZJ Strain-controlled Direct Shear Apparatus | ZJ | Nanjing Soil Instrument Factory Co., Ltd., Nanjing, China |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, Z.; Liu, X.; Qian, W.; Ding, X.; Ao, Z.; Zhang, Z.; Jiskani, I.M.; Tian, Y.; Xing, B.; Wahab, A. Investigation of Steep Waste Dump Slope Stability of Iron Ore Mine—A Case Study. Appl. Sci. 2024, 14, 3430. https://doi.org/10.3390/app14083430

Yang Z, Liu X, Qian W, Ding X, Ao Z, Zhang Z, Jiskani IM, Tian Y, Xing B, Wahab A. Investigation of Steep Waste Dump Slope Stability of Iron Ore Mine—A Case Study. Applied Sciences. 2024; 14(8):3430. https://doi.org/10.3390/app14083430

Chicago/Turabian StyleYang, Zhongao, Xin Liu, Weimin Qian, Xiaohua Ding, Zhongchen Ao, Zhiyuan Zhang, Izhar Mithal Jiskani, Ya Tian, Bokang Xing, and Abdoul Wahab. 2024. "Investigation of Steep Waste Dump Slope Stability of Iron Ore Mine—A Case Study" Applied Sciences 14, no. 8: 3430. https://doi.org/10.3390/app14083430

APA StyleYang, Z., Liu, X., Qian, W., Ding, X., Ao, Z., Zhang, Z., Jiskani, I. M., Tian, Y., Xing, B., & Wahab, A. (2024). Investigation of Steep Waste Dump Slope Stability of Iron Ore Mine—A Case Study. Applied Sciences, 14(8), 3430. https://doi.org/10.3390/app14083430