New Fat Bases in Model Emulsion Systems in Physicochemical and Consumer Evaluation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Research Material

2.2. Preparation of Research Material

2.2.1. Treatment of Mutton Tallow

2.2.2. Procedure for the Enzymatic Modification of the Fatty Blends of Mutton Tallow and Hemp Seed Oil

2.2.3. Parameters and Procedure for Producing Emulsion Systems

2.3. Methods

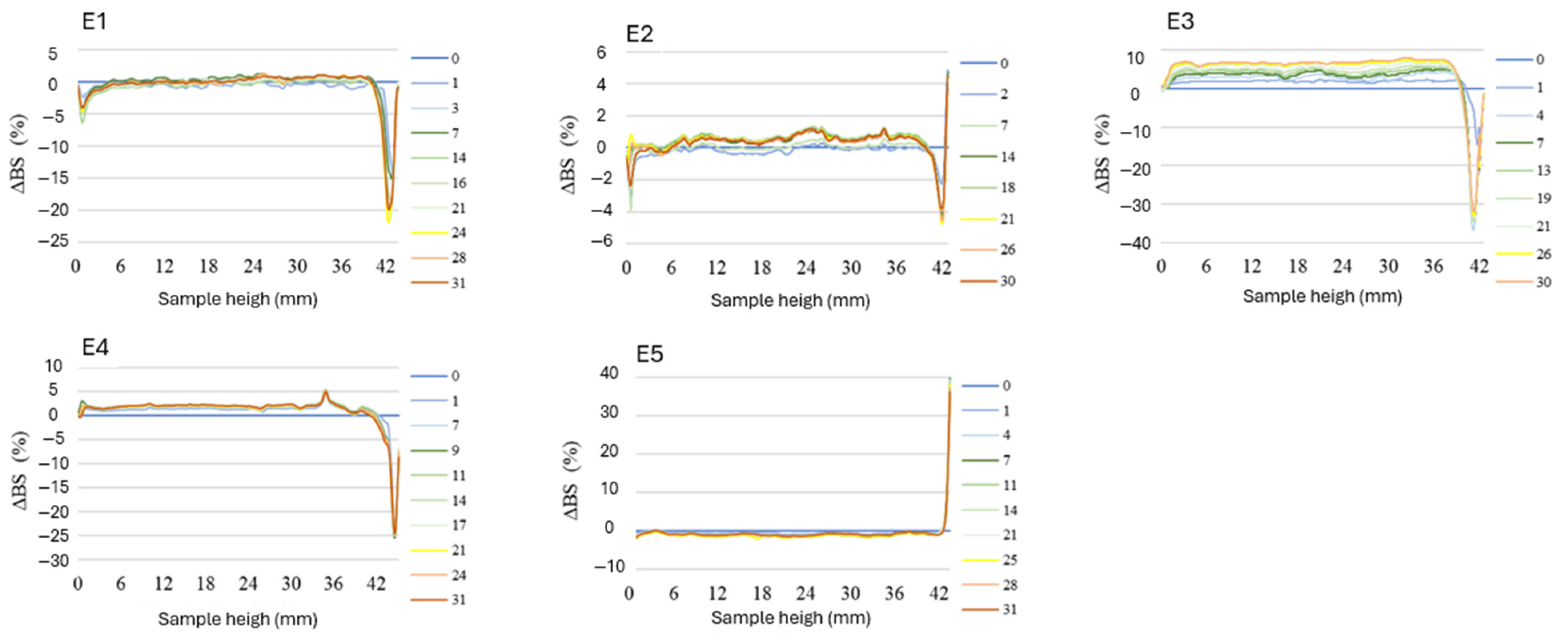

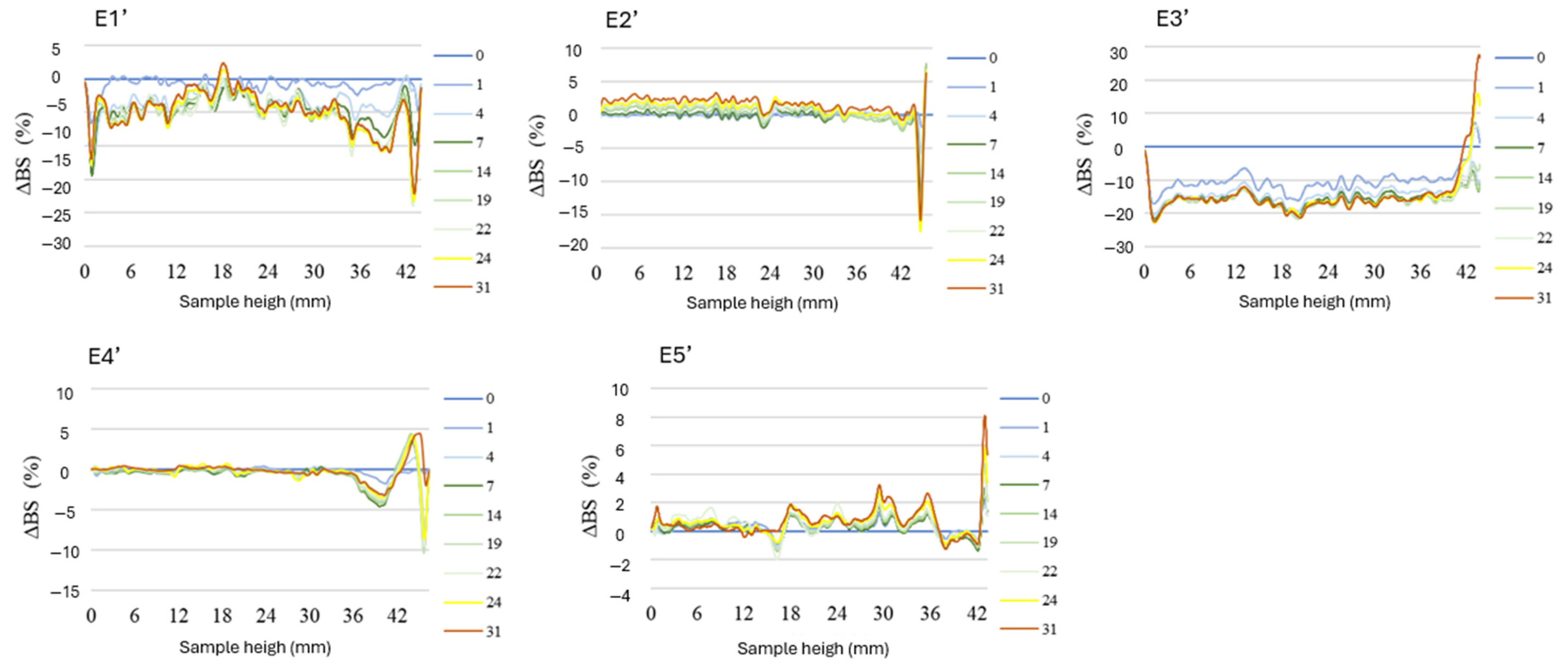

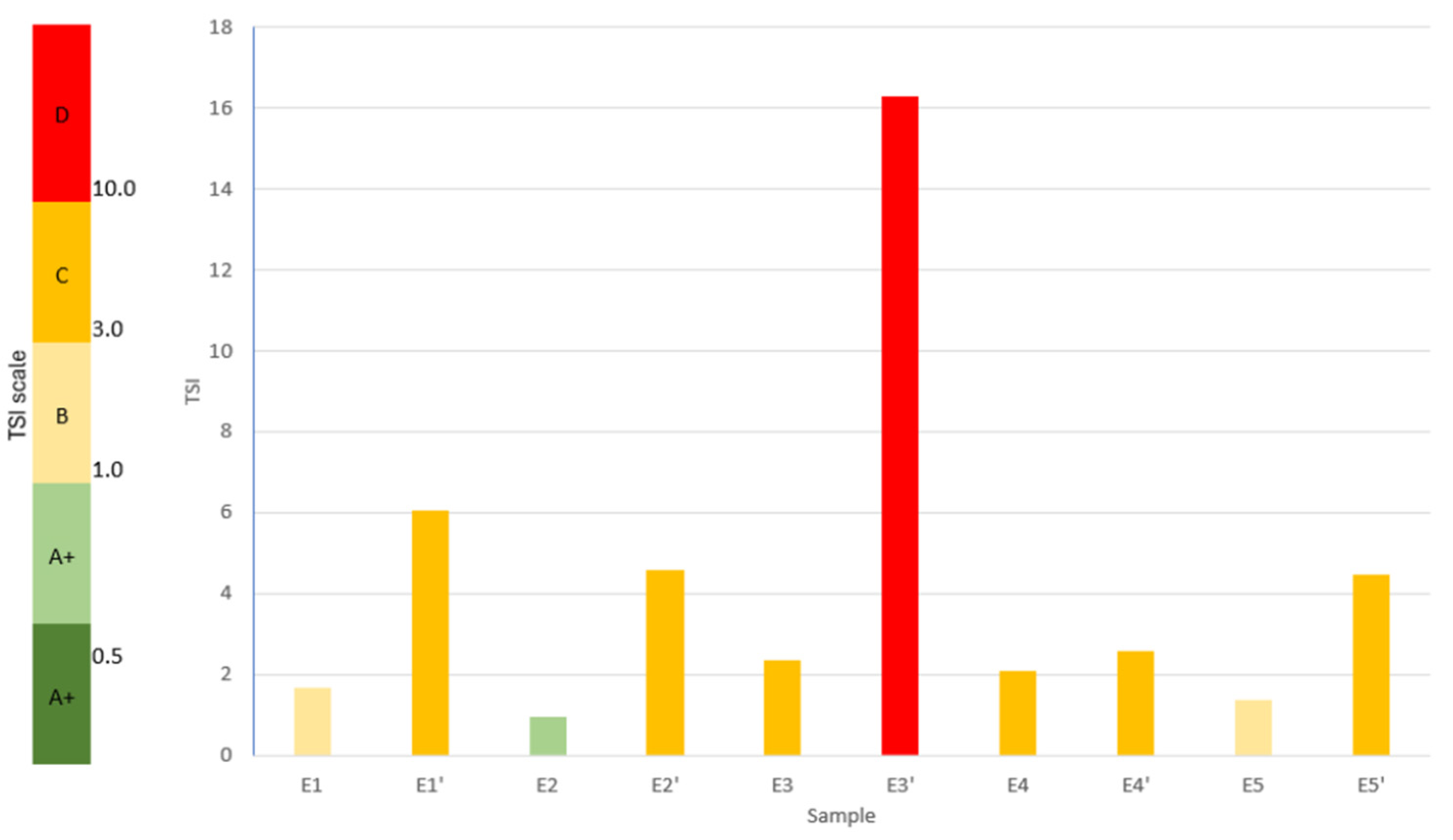

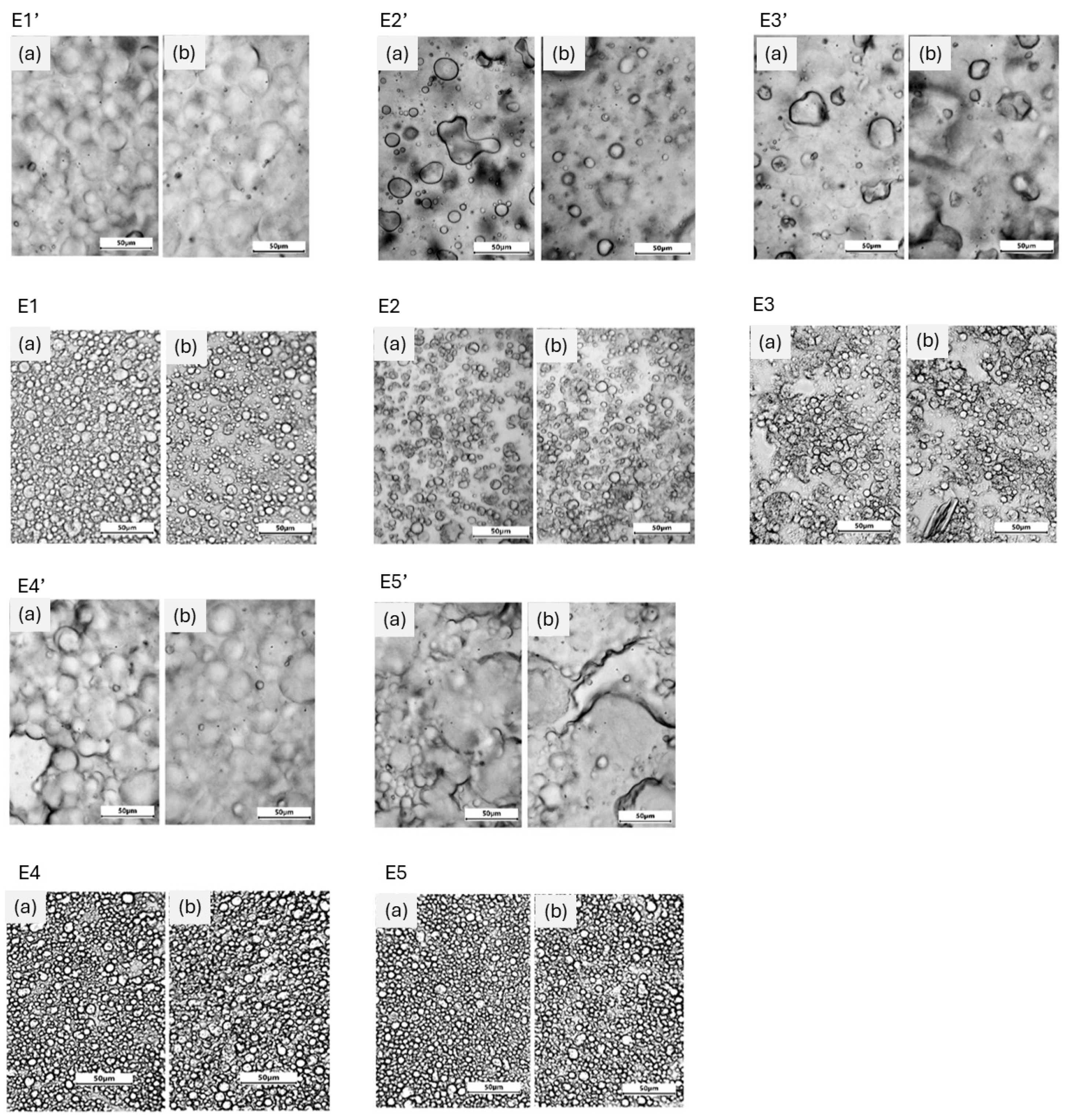

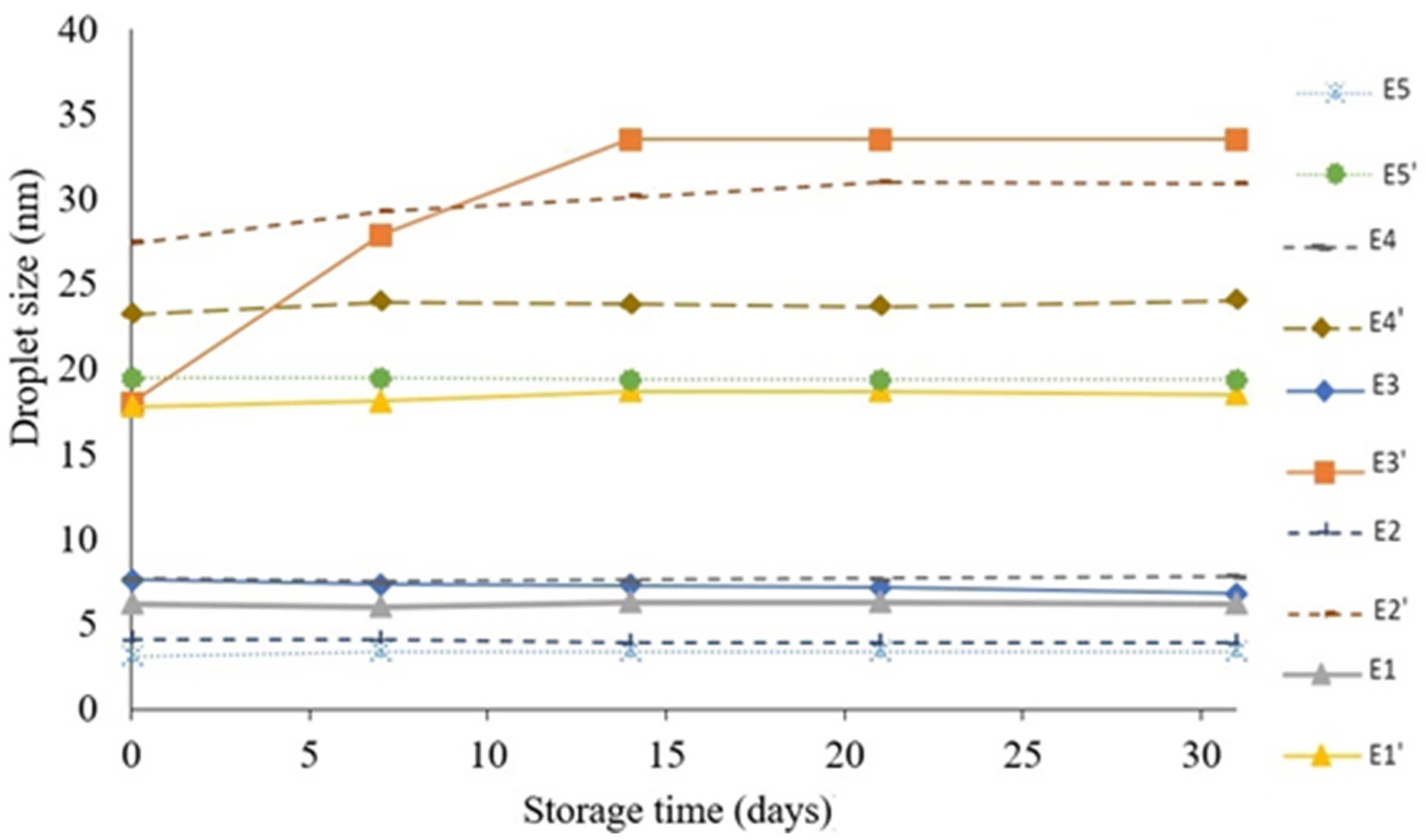

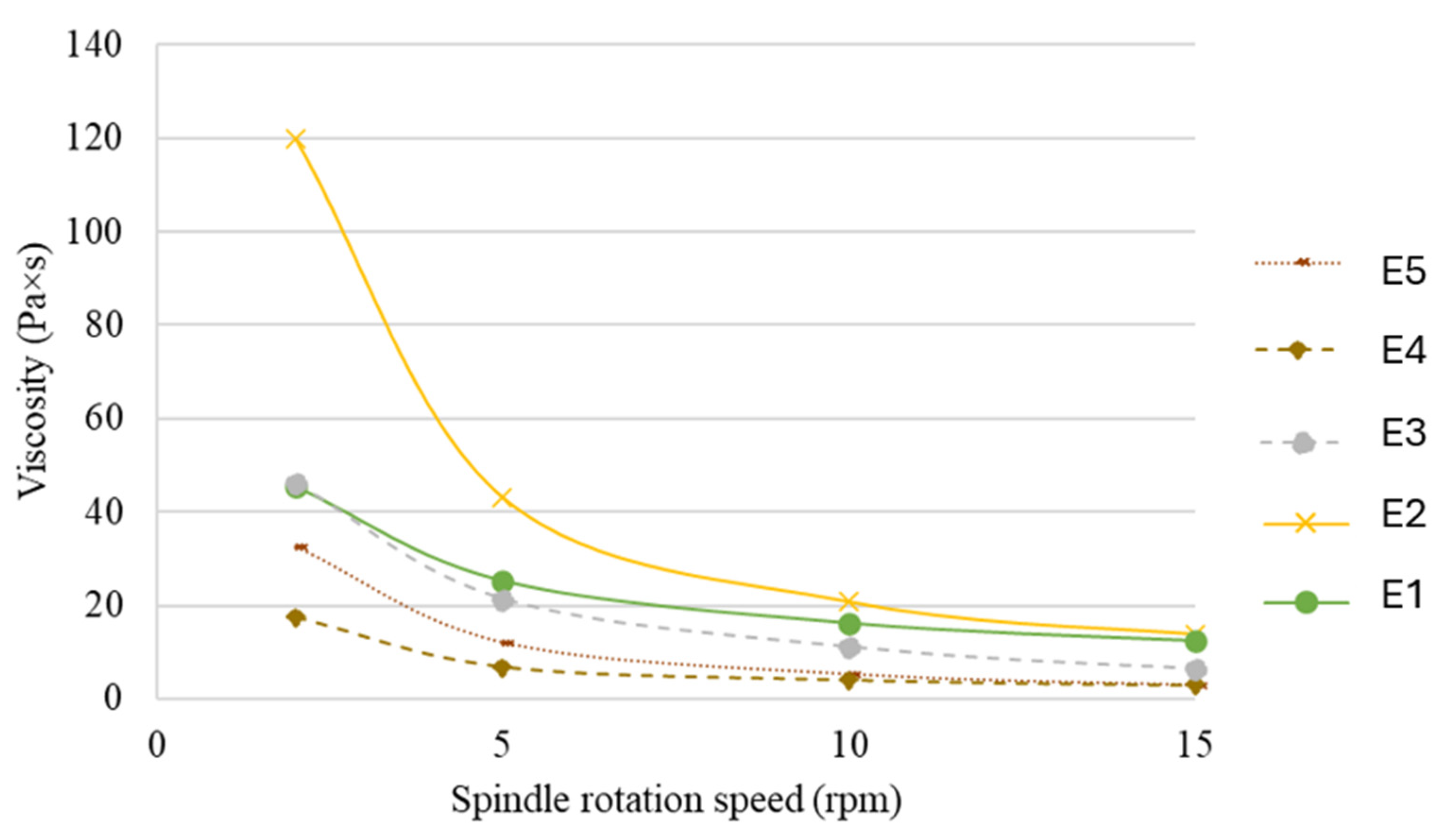

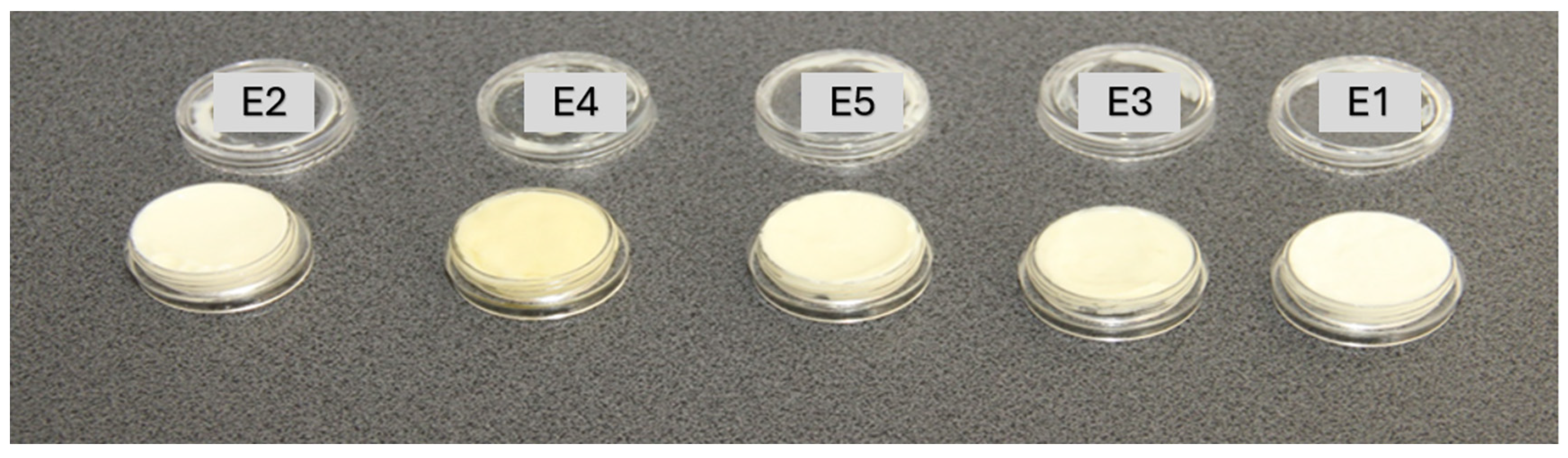

2.3.1. Evaluation of Processes Occurring in Emulsions during Storage and Microstructure Evaluation of Emulsion Systems

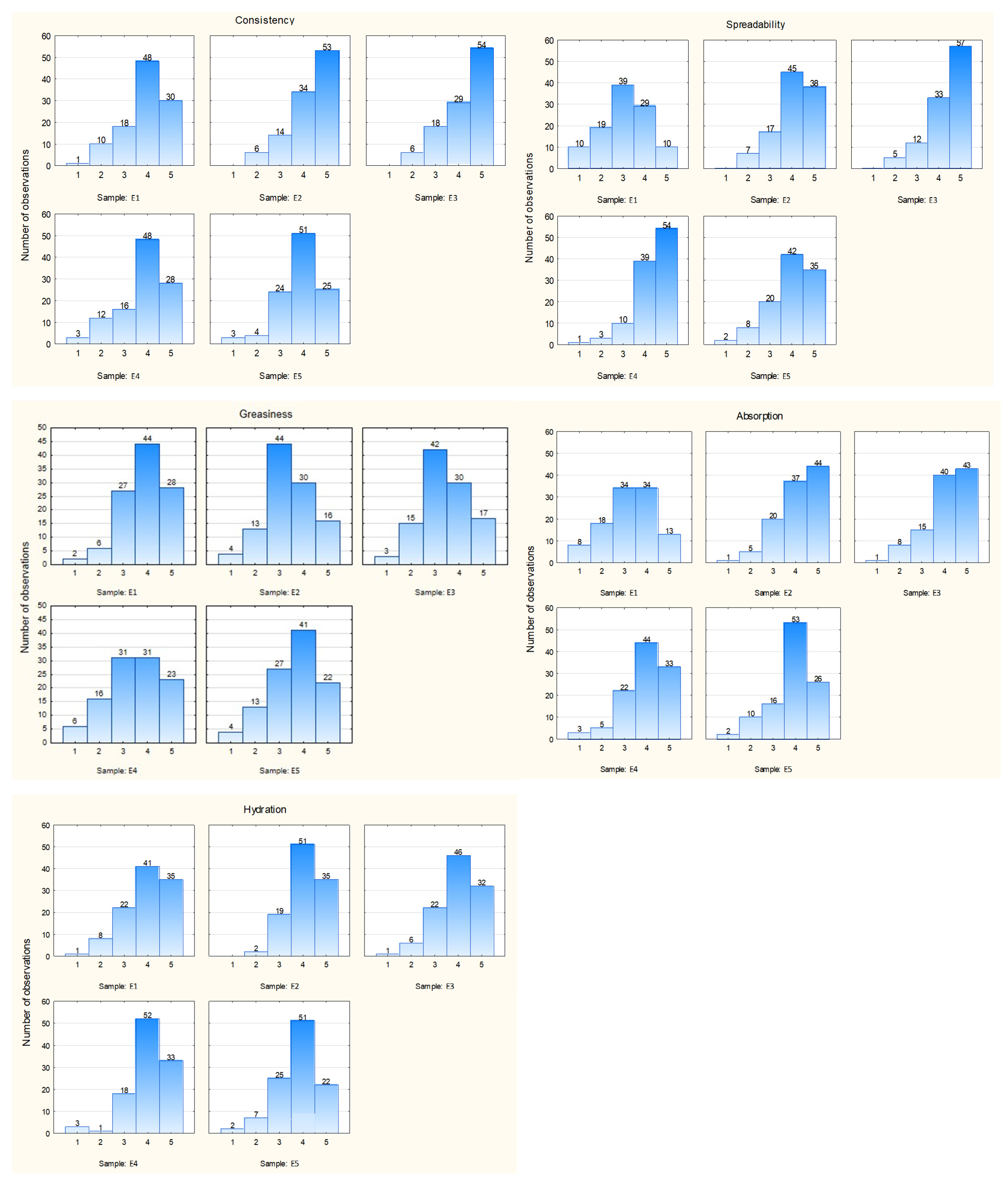

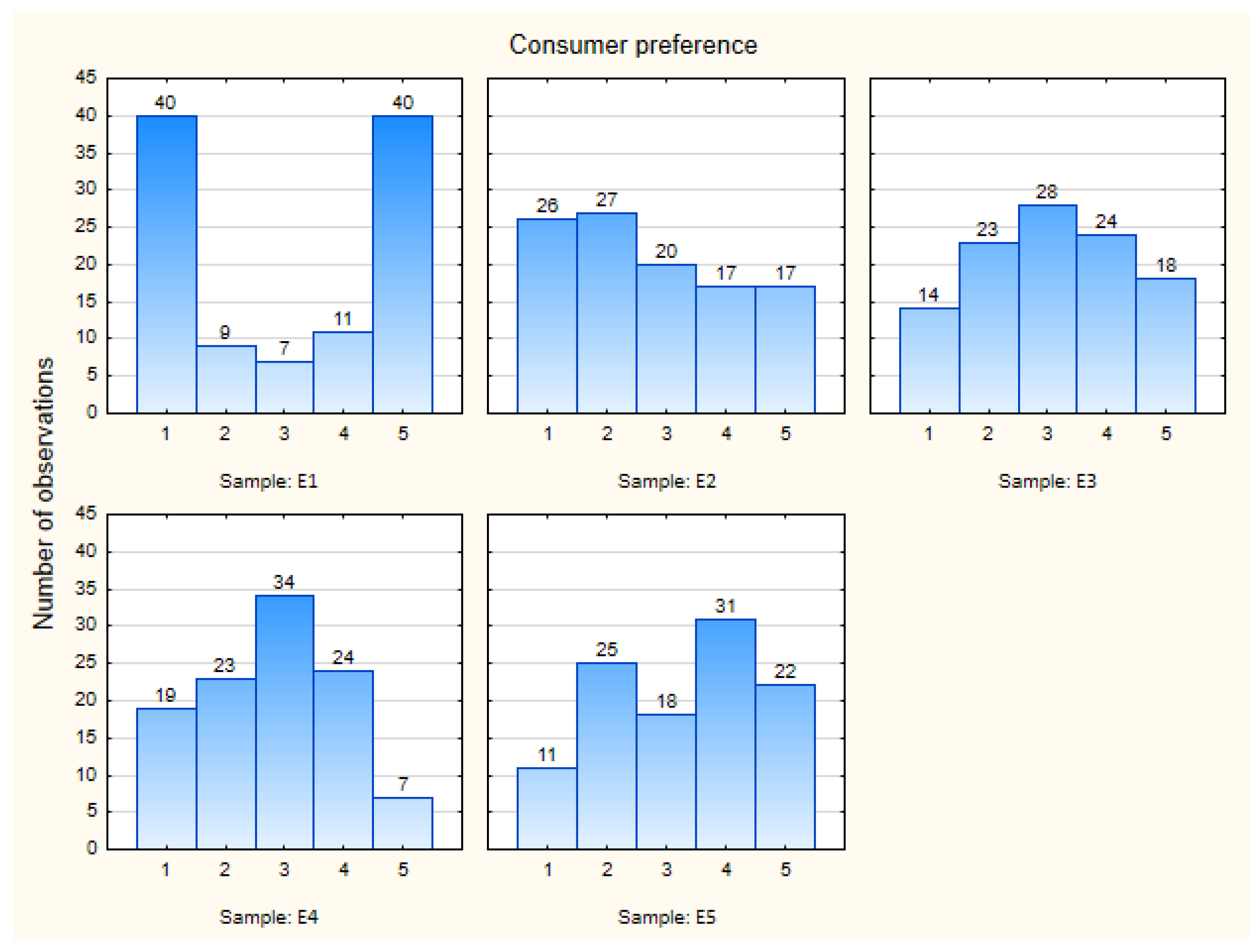

2.3.2. Consumer Evaluation of Emulsions

2.3.3. Statistical Analysis of the Results

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Korać, R.; Krajišnik, D.; Milić, J. Sensory and instrumental characterization of fast inverting oil-in-water emulsions for cosmetic application. Int. J. Cosmet. Sci. 2016, 38, 246–256. [Google Scholar] [CrossRef] [PubMed]

- Calixto, L.S.; Maia Campos, P.M.B.G. Physical-Mechanical characterization of cosmetic formulations and correlation between instrumental measurements and sensorial properties. Int. J. Cosmet. Sci. 2017, 39, 527–534. [Google Scholar] [CrossRef] [PubMed]

- Terescenco, D.; Hadj Benali, L.; Canivet, F.; Benoit le Gelebart, M.; Hucher, N.; Gore, E.; Picard, C. Bio-sourced polymers in cosmetic emulsions: A hidden potential of the alginates as thickeners and gelling agents. Int. J. Cosmet. Sci. 2021, 43, 573–587. [Google Scholar] [CrossRef] [PubMed]

- Niu, F.; Zhao, M.; Tu, W.; Li, Z.; Gao, Y.; Du, Y.; Pan, W. Fabrication and stability of W/O/W emulsions stabilized by gum arabic and polyglycerol polyricinoleate. J. Sci. Food Agric. 2024, 104, 797–808. [Google Scholar] [CrossRef] [PubMed]

- Xiao, A.; Yang, Y.; Liu, X.; Shen, C.; Meng, Q. Formulation of rhamnolipid-containing cosmetics without sulfate surfactants: A rheology and stability study. J. Surfactants Deterg. Early View. 2024. [Google Scholar] [CrossRef]

- Talavera, M.; Chambers IV, E. Using sensory sciences help products succeed. Br. Food J. 2017, 119, 2130–2144. [Google Scholar] [CrossRef]

- Martins, V.B.; Bordim, J.; Bom, G.A.P.; Carvalho, J.G.D.S.; Parabocz, C.R.B.; Mitterer Daltoé, M.L. Consumer profiling techniques for cosmetic formulation definition. J. Sens. Stud. 2020, 35, e12557. [Google Scholar] [CrossRef]

- Arrieta-Escobar, J.A.; Camargo, M.; Morel, L.; Bernardo, F.P.; Orjuela, A.; Wendling, L. Design of formulated products integrating heuristic knowledge and consumer assessment. AIChE J. 2021, 67, e17117. [Google Scholar] [CrossRef]

- Kowalska, M.; Woźniak, M. Proposal of New Emulsion Systems Containing Hydroxypropylmethylcellulose as a Viscosity Modifier and Diacylglycerols from Mutton Tallow and Hemp Seed Oil. Appl. Sci. 2023, 13, 10289. [Google Scholar] [CrossRef]

- Stone, H.; Bleibaum, R.N.; Thomas, H.A. Sensory Evaluation Practices, 4th ed.; Elsevier: Amsterdam, The Netherlands, 2012; Available online: https://shop.elsevier.com/books/sensory-evaluation-practices/stone/978-0-12-382086-0 (accessed on 9 February 2024).

- Rogers, L. Sensory Panel Management. A Practical Handbook for Recruitment, Training and Performance; A Volume in Woodhead Publishing Series in Food Science, Technology and Nutrition; Woodhead Publishing: Cambridge, MA, USA, 2018; ISBN 978-0-08-101001-3. [Google Scholar]

- ISO 11136; Sensory Analysis—Methodology—General Guidance for Conducting Hedonic Tests with Consumers in a Controlled Area. ISO: Geneva, Switzerland, 2014. Available online: http://www.iso.org/cms/render/live/en/sites/isoorg/contents/data/standard/05/01/50125.html (accessed on 23 April 2019).

- Kovács, A.; Erős, I.; Csóka, I. Optimization and development of stable w/o/w cosmetic multiple emulsions by means of the Quality by Design approach. Int. J. Cosmet. Sci. 2016, 38, 128–138. [Google Scholar] [CrossRef] [PubMed]

- Celia, C.; Trapasso, E.; Cosco, D.; Paolino, D.; Fresta, M. Turbiscan lab expert analysis of the stability of ethosomes and ultradeformable liposomes containing a bilayer fluidizing agent. Colloids Surf. B Biointerfaces 2009, 72, 155–160. [Google Scholar] [CrossRef] [PubMed]

- Domian, E.; Brynda-Kopytowska, A.; Oleksza, K. Rheological properties and physical stability of o/w emulsions stabilized by OSA starch with trehalose. Food Hydrocoll. 2015, 44, 49–58. [Google Scholar] [CrossRef]

- Zhu, T.; Zhao, Y.; Zong, M.; Li, B.; Zhang, X.; Wu, H. Improvement of physical properties of palm stearin and soybean oil blends by enzymatic interesterification and their application in fast frozen food. RSC Adv. 2017, 7, 34435–34441. [Google Scholar] [CrossRef]

- Szakiel, J.; Turek, P. Sensoryczna ocena jakości kosmetycznych produktów nawilżających przeznaczonych do pielęgnacji skóry rąk. Zesz. Nauk. Uniw. Ekon. Krakowie 2019, 6, 239–252. [Google Scholar] [CrossRef]

- Bombol, M.; Dąbrowska, A. Zachowania konsumentów na rynku produktów żywnościowych. Handel. Wewn. 2006, 24, 31. [Google Scholar]

| Trade Name | Texture Modifier | Manufacturer | Symbol |

|---|---|---|---|

| NA | Carboxymethylcellulose | Barentz International BV (Hoofddorp, The Netherlands) | CMC |

| Methocel 40-0101 | Hydroxypropyl methylcellulose | Dow (Midland, MI, USA) | HPMC |

| Rheocare XGN | Xanthan gum | BASF (Ludwigshafen, Germany) | XG |

| Actigum VSX 20 | Xanthan gum and scleroglucan | Cargill (Krefeld, Germany) | XGSG |

| Vivapur CS 032 XV | Xanthan gum and microcrystalline cellulose | J. Rettenmaier & Söhne (Rosenberg, Germany) | XGCM |

| Emulsion Symbol | Type of Fatty Phase | Texture Modifier Content % w/w | Texture Modifier Type | Emulsifier Content % w/w * | Type of Emulsifier |

|---|---|---|---|---|---|

| E1/E1’ | T1/T1’ | 0.6 | HPMC | 7.4 | DAG and MAG produced during interesterification/hydrolysis of mutton tallow and hemp seed oil blends |

| E2/E2’ | T2T2’ | XGSC | 7.2 | ||

| E3/E3’ | T2/T2’ | CMC | 7.4 | ||

| E4/E4’ | T3T3’ | XGMCC | 7.4 | ||

| E5/E5’ | T3/T3’ | XG | 7.4 |

| General Composition of the Emulsion | |

|---|---|

Fatty phase:

| 30% w/w |

Water phase:

| 70% w/w 0.6 or 0.8 or 1.0% w/w up to 100 g q.s. |

| Phase temperature before homogenisation | |

| Water phase | 50–55 °C |

| Fatty phase | 50–55 °C |

| Homogenisation parameters | |

| Type of homogenization | mechanical |

| Homogenization time | 4 min |

| Speed of rotation | 18,500 rpm |

| E1 | E2 | E3 | E4 | E5 | |

|---|---|---|---|---|---|

| E1 | - | 0.054 | 0.092 | 1.000 | 1.000 |

| E2 | 0.054 | - | 1.000 | 0.013 | 0.011 |

| E3 | 0.092 | 1.000 | - | 0.023 | 0.020 |

| E4 | 1.000 | 0.013 | 0.023 | - | 1.000 |

| E5 | 1.000 | 0.011 | 0.020 | 1.000 | - |

| E1 | E2 | E3 | E4 | E5 | |

|---|---|---|---|---|---|

| E1 | - | 0.000 | 0.000 | 0.000 | 0.000 |

| E2 | 0.000 | - | 0.349 | 0.390 | 1.000 |

| E3 | 0.000 | 0.349 | - | 1.000 | 0.042 |

| E4 | 0.000 | 0.390 | 1.000 | - | 0.049 |

| E5 | 0.000 | 1.000 | 0.042 | 0.049 | - |

| E1 | E2 | E3 | E4 | E5 | |

|---|---|---|---|---|---|

| E1 | - | 0.012 | 0.017 | 0.128 | 1.000 |

| E2 | 0.012 | - | 1.000 | 1.000 | 0.933 |

| E3 | 0.017 | 1.000 | - | 1.000 | 1.000 |

| E4 | 0.128 | 1.000 | 1.000 | - | 1.000 |

| E5 | 1.000 | 0.933 | 1.000 | 1.000 | - |

| E1 | E2 | E3 | E4 | E5 | |

|---|---|---|---|---|---|

| E1 | - | 0.000 | 0.000 | 0.000 | 0.001 |

| E2 | 0.000 | - | 1.000 | 1.000 | 0.691 |

| E3 | 0.000 | 1.000 | - | 1.000 | 0.759 |

| E4 | 0.000 | 1.000 | 1.000 | - | 1.000 |

| E5 | 0.001 | 0.691 | 0.759 | 1.000 | - |

| E1 | E2 | E3 | E4 | E5 | |

|---|---|---|---|---|---|

| E1 | - | 1.000 | 1.000 | 1.000 | 1.000 |

| E2 | 1.000 | - | 1.000 | 1.000 | 0.185 |

| E3 | 1.000 | 1.000 | - | 1.000 | 1.000 |

| E4 | 1.000 | 1.000 | 1.000 | - | 0.428 |

| E5 | 1.000 | 0.185 | 1.000 | 0.428 | - |

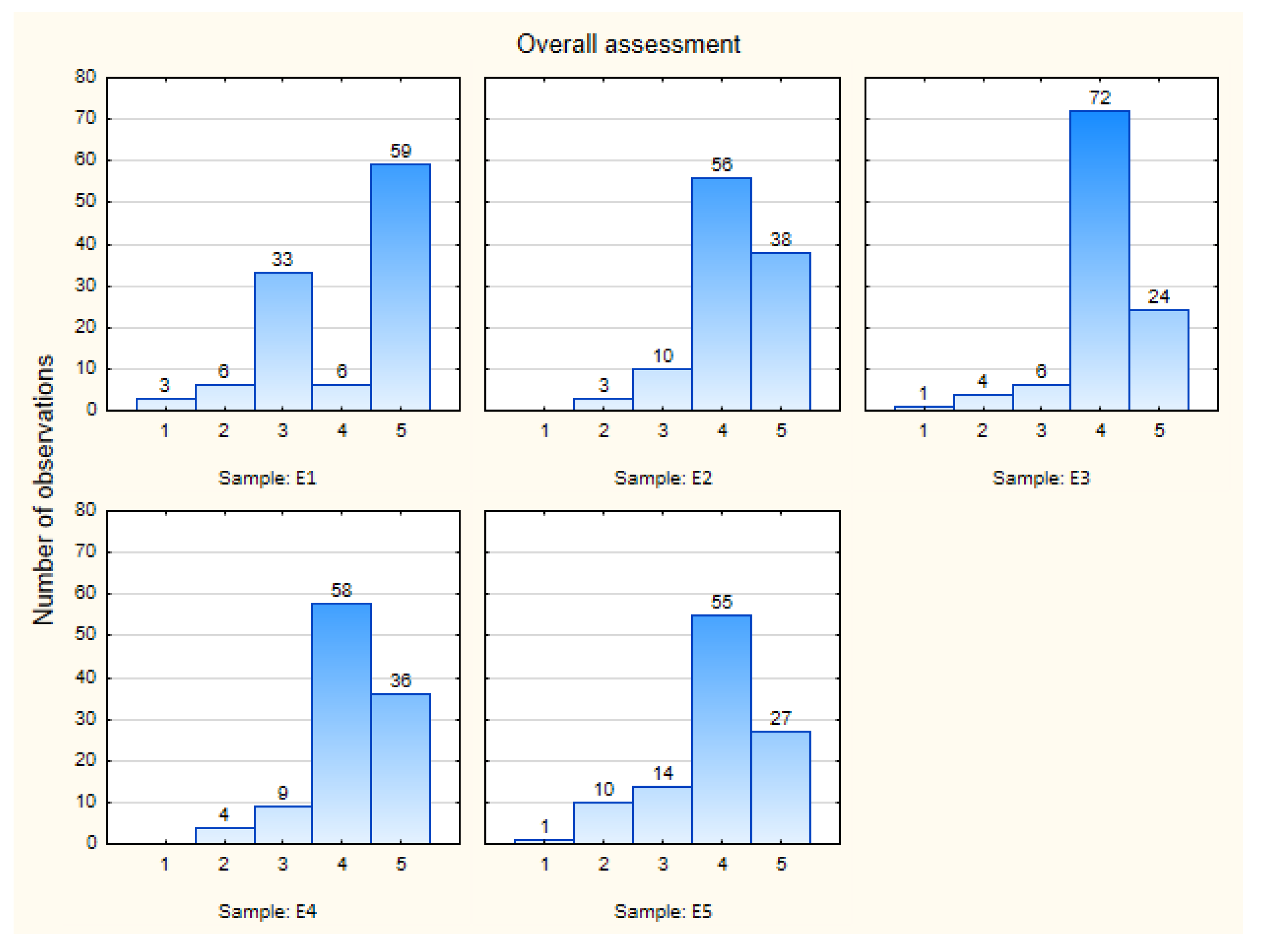

| Emulsion System | Overall Assessment (Mean ± Standard Deviation) |

|---|---|

| E1 | 4.0 a ± 1.2 |

| E2 | 4.2 a ± 0.7 |

| E3 | 4.2 a ± 0.7 |

| E4 | 4.1 a ± 0.7 |

| E5 | 3.9 a ± 0.9 |

| E1 | E2 | E3 | E4 | E5 | |

|---|---|---|---|---|---|

| E1 | - | 1.000 | 1.000 | 1.000 | 1.000 |

| E2 | 1.000 | - | 1.000 | 1.000 | 0.160 |

| E3 | 1.000 | 1.000 | - | 0.787 | 0.079 |

| E4 | 1.000 | 1.000 | 0.787 | - | 1.000 |

| E5 | 1.000 | 0.160 | 0.079 | 1.000 | - |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kowalska, M.; Woźniak, M.; Turek, P.; Żbikowska, A. New Fat Bases in Model Emulsion Systems in Physicochemical and Consumer Evaluation. Appl. Sci. 2024, 14, 3553. https://doi.org/10.3390/app14093553

Kowalska M, Woźniak M, Turek P, Żbikowska A. New Fat Bases in Model Emulsion Systems in Physicochemical and Consumer Evaluation. Applied Sciences. 2024; 14(9):3553. https://doi.org/10.3390/app14093553

Chicago/Turabian StyleKowalska, Małgorzata, Magdalena Woźniak, Paweł Turek, and Anna Żbikowska. 2024. "New Fat Bases in Model Emulsion Systems in Physicochemical and Consumer Evaluation" Applied Sciences 14, no. 9: 3553. https://doi.org/10.3390/app14093553

APA StyleKowalska, M., Woźniak, M., Turek, P., & Żbikowska, A. (2024). New Fat Bases in Model Emulsion Systems in Physicochemical and Consumer Evaluation. Applied Sciences, 14(9), 3553. https://doi.org/10.3390/app14093553