Experimental Study on the Relationship between Time-Varying Uplift Displacement and Grout Diffusion in Sand

Abstract

:1. Introduction

2. Experimental Design

2.1. Experimental Materials

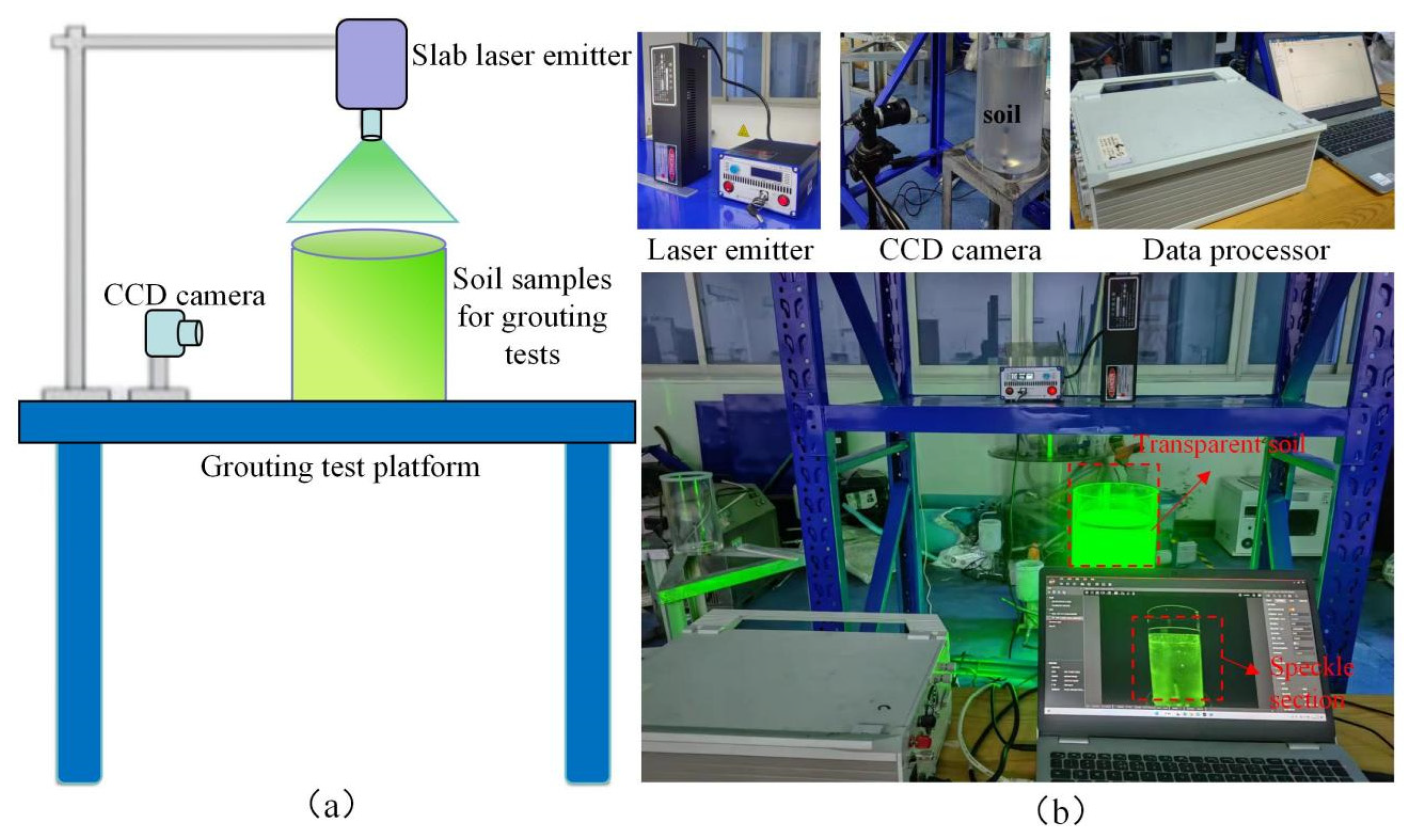

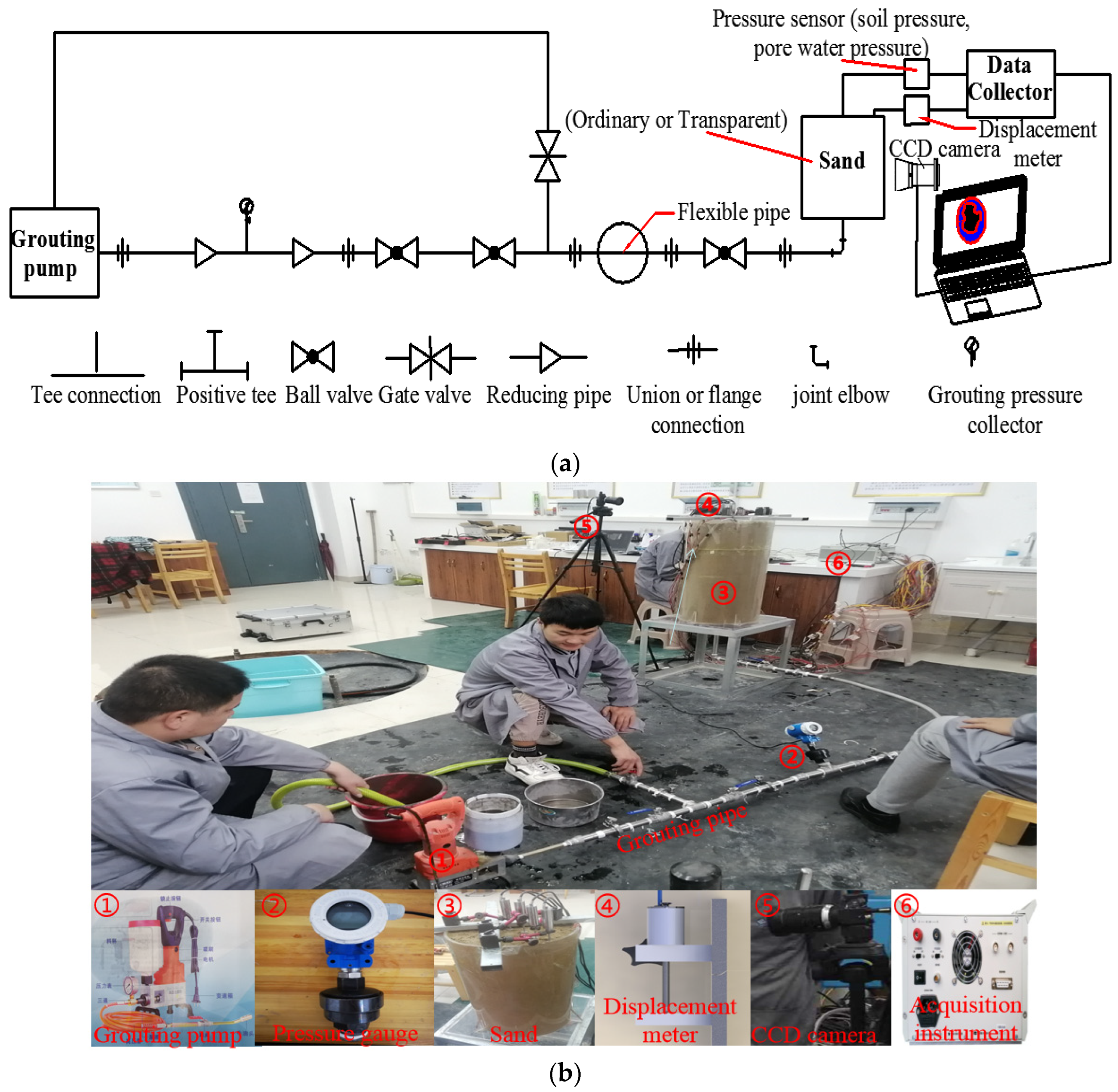

2.2. Experimental Equipment

3. Results and Discussion

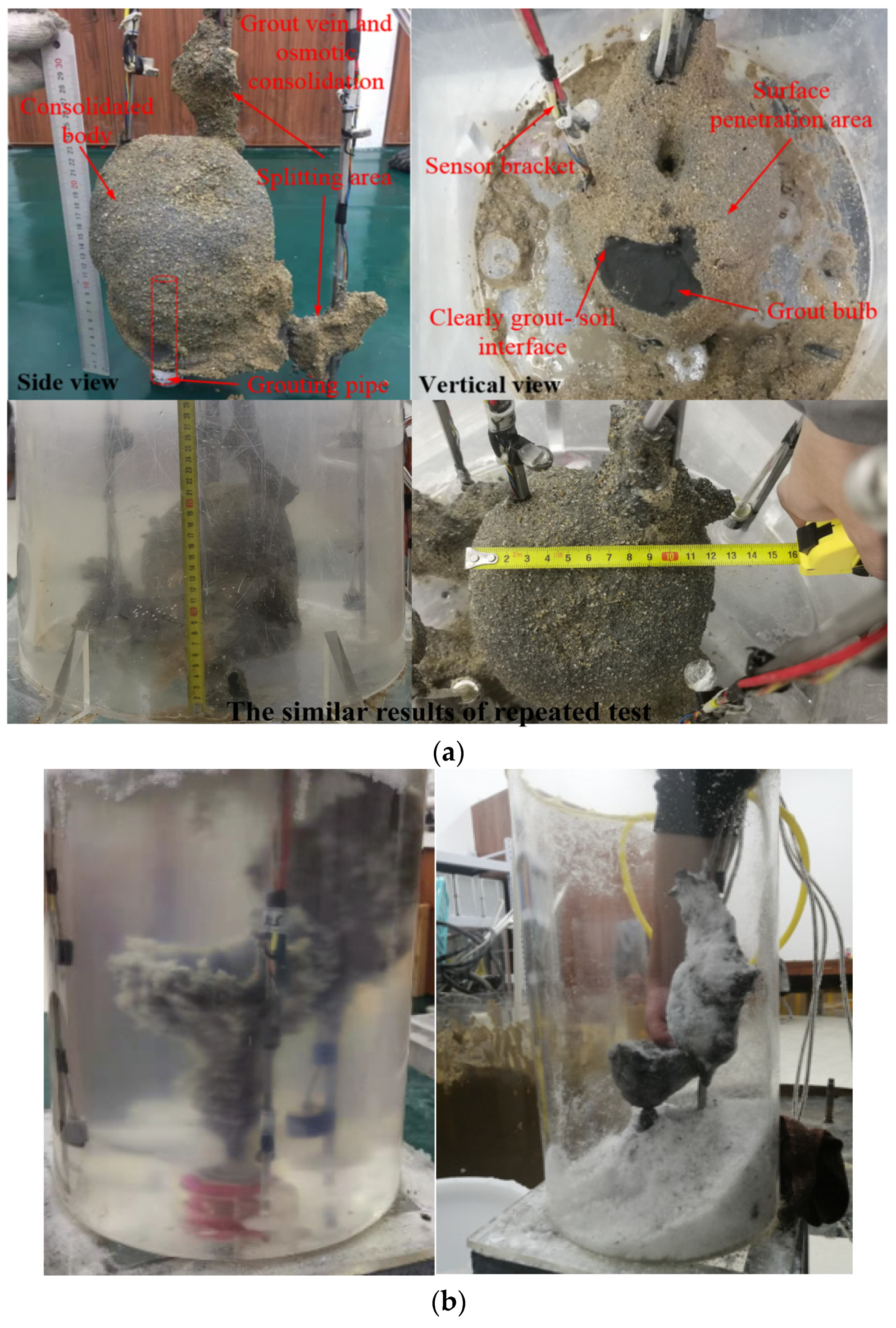

3.1. Consolidated Body in Two Kinds of Soil

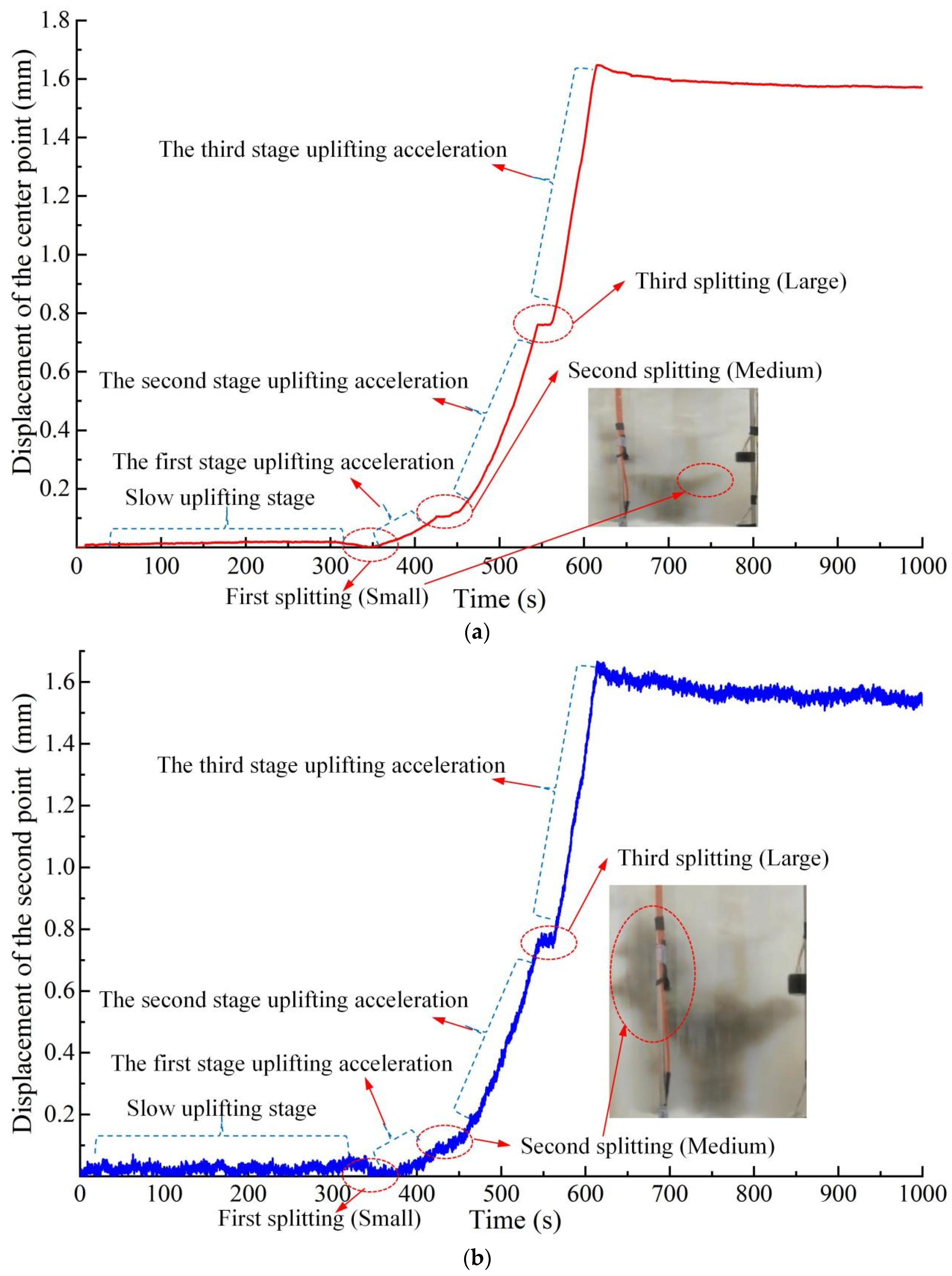

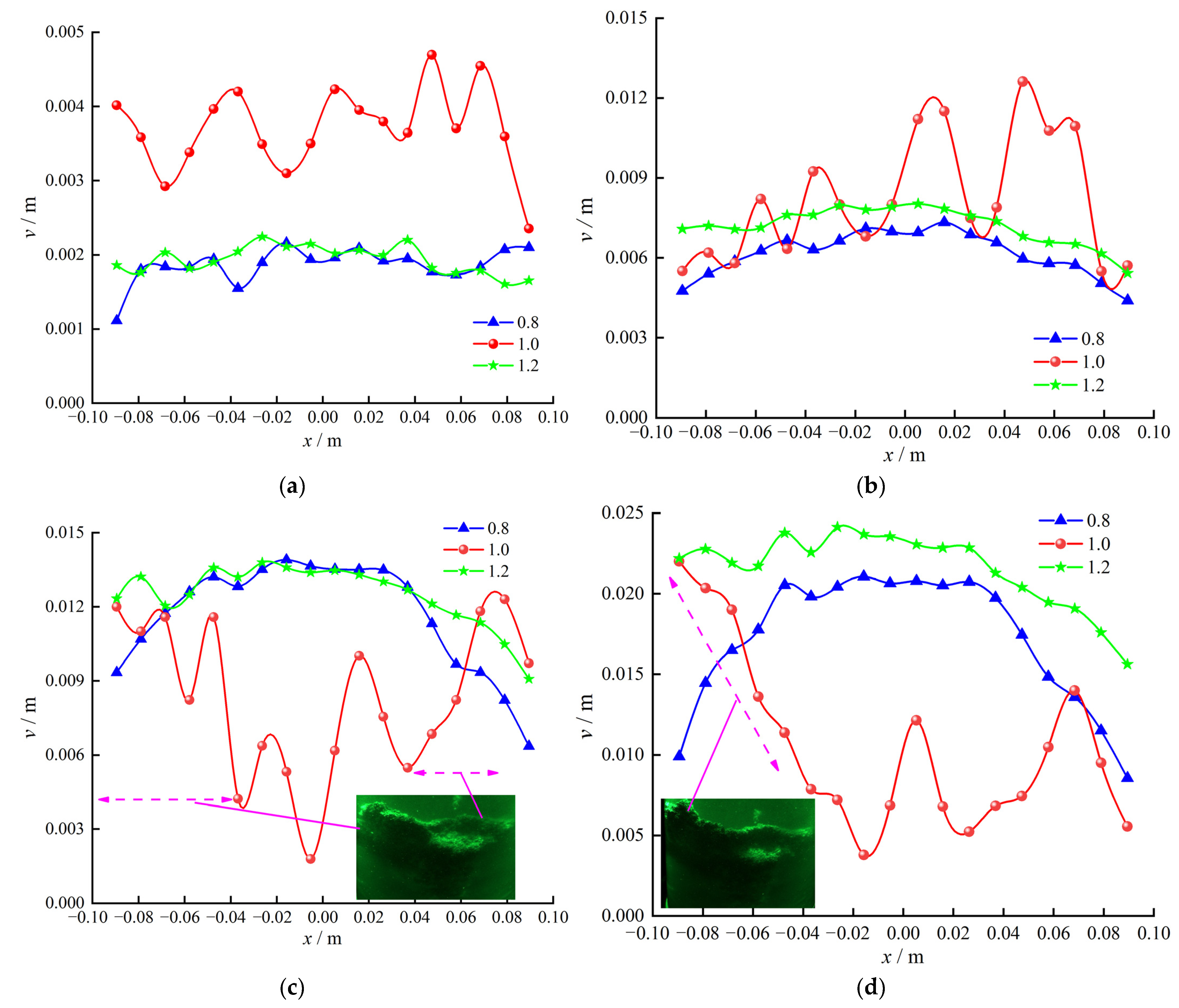

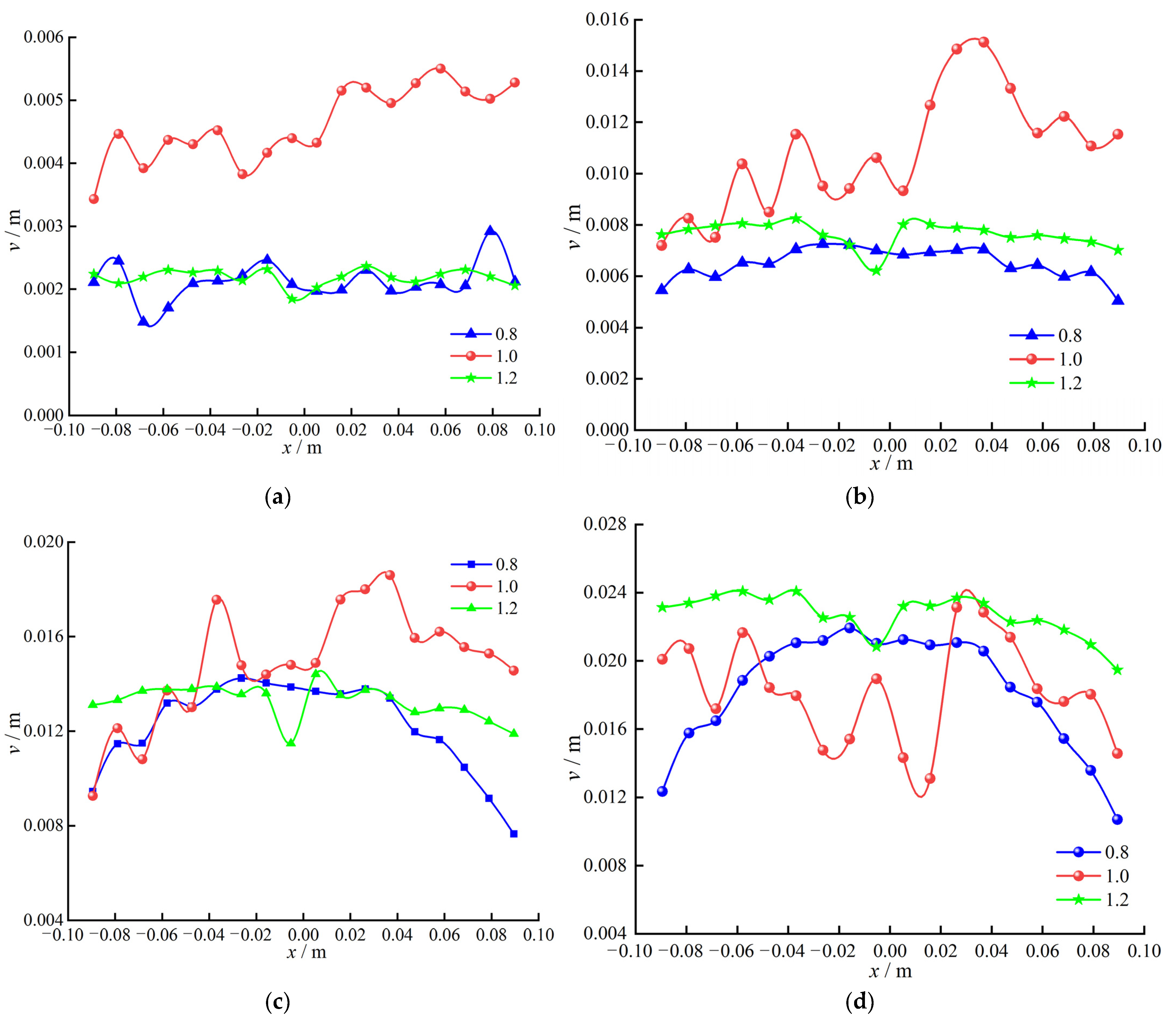

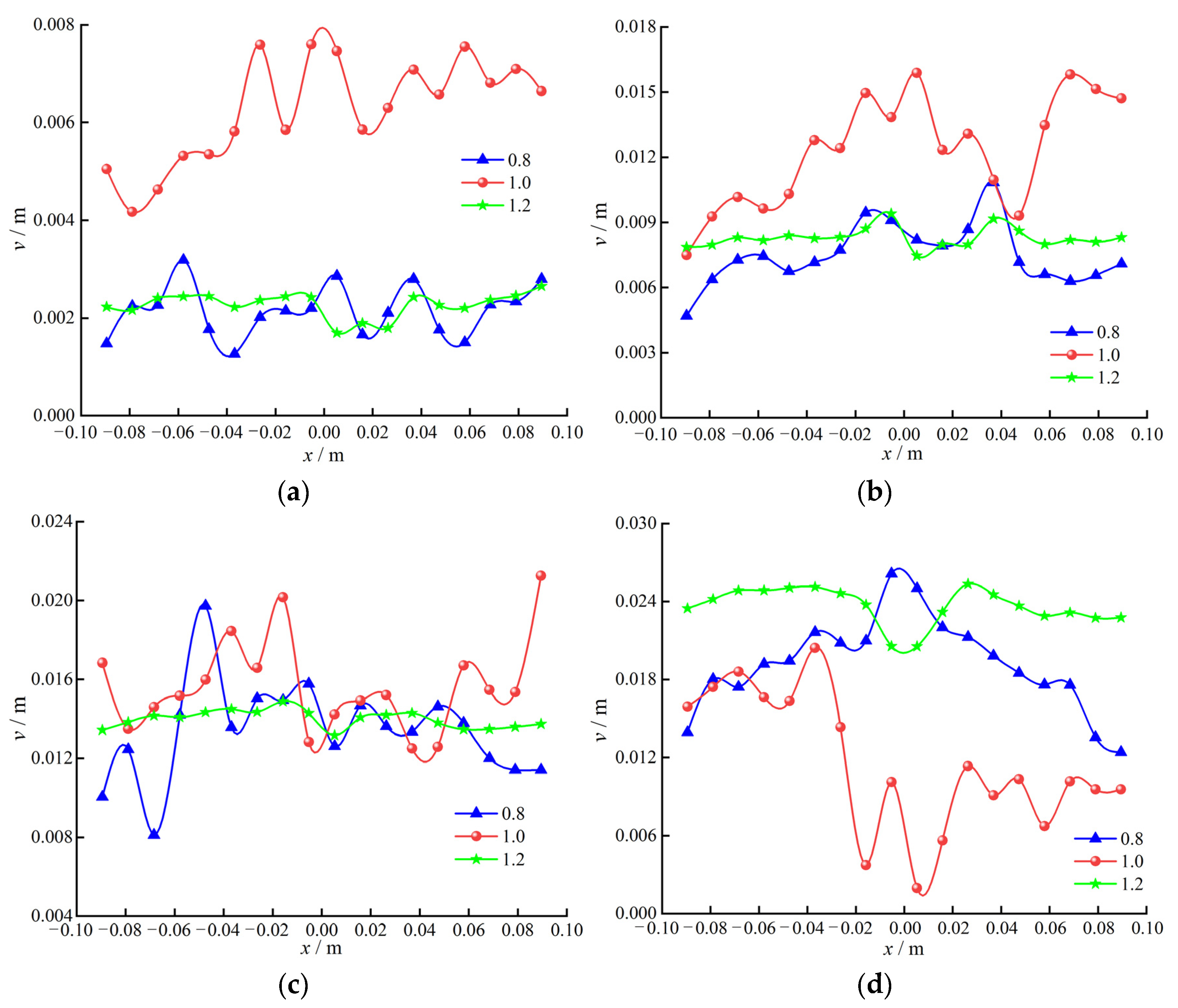

3.2. The Change in Uplift Displacement in Two Kinds of Soil

3.3. Analysis of Dynamic Deformation Characteristics of Transparent Sand Particles in Grouting Process

4. Conclusions

- (1)

- During non-steady-pressure grouting, at lower grouting pressures, grout primarily permeates through the sand, resulting in the formation of spherical grout bodies. As the grouting pressure increases, the compaction effect of the grout in the sand gradually becomes dominant, compacting the surrounding soil. With a continued increase in grouting pressure, the sand undergoes splitting, and the grout rapidly fills the cracks. During the initial stages of fracturing, there is permeation and compaction around the cracks. As the grouting pressure continues to increase, the pressure within the cracks gradually rises, promoting crack propagation. Additionally, as the grouting pressure increases, the grout pockets expand, leading to the formation of new cracks.

- (2)

- When compaction is predominant, the grouting pressure curve exhibits a smooth characteristic, whereas during low-pressure permeation, the grouting pressure curve is non-smooth. A sharp decrease in grouting pressure occurs when grouting fracturing happens, followed by an increase in grouting pressure that exceeds the rate of decrease. Each segment has distinct features in terms of its starting and ending points on the graph, showing a concave tip on the pressure curve.

- (3)

- The changes in surface displacement induced by grouting also exhibit noticeable characteristics. The curves of grouting pressure and surface displacement show good consistency with grouting time, displaying a gradual increase followed by rapid growth. The characteristics of surface uplift displacement curves are generally consistent, all undergoing three developmental stages: a slow increase stage, an accelerated increase stage, and a stable increase stage. The diffusion mode and direction of grout have a direct impact on the deformation characteristics of the overlying sand.

- (4)

- The uplift displacement curve exhibits a characteristic “step-like” growth pattern, with an increase in speed after each step, indicating distinct stage-wise features in the surface displacement curve with increasing grouting time. Visualized grouting experiments reflect good consistency in the effects of grouting pressure, grout diffusion, and their corresponding uplift displacement. For the grout with w/c = 0.8, the deformation overall shows a symmetrical distribution pattern of “higher in the middle, lower on the sides”. The distribution of vertical displacement along the horizontal direction for w/c = 0.8 and 1.2 tends to become horizontal with decreasing depth. The diffusion direction of the grout with w/c = 1.0 varies, leading to a fluctuating dynamic deformation pattern resembling “ripples” in the transparent sand.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, H.X.; Deng, C.; Chen, W. The effect of magnetization conditions on the stability of cement grout. Case Stud. Constr. Mater. 2022, 16, e01016. [Google Scholar] [CrossRef]

- Hu, H.X.; Deng, C. Effect of magnetized water on the stability and consolidation compressive strength of cement grout. Materials 2021, 14, 275. [Google Scholar] [CrossRef]

- Marwan, A.; Zhou, M.M.; Abdelrehim, M.Z.; Meschke, G. Optimization of artificial ground freezing in tunneling in the presence of seepage flow. Comput. Geotech. 2016, 75, 112–125. [Google Scholar] [CrossRef]

- García Calvo, J.L.; Pedrosa, F.; Carballosa, P.; Revuelta, D. Evaluation of the sealing effectiveness of expansive cement grouts through a novel water penetration test. Constr. Build. Mater. 2020, 251, 118974. [Google Scholar] [CrossRef]

- Stempkowska, A.; Wójcik, Ł.; Ostrowski, K.A.; Gawenda, T. Low-energy clay-cement slurries find application as waterproofing membranes for limiting the migration of contaminants-Case studies in Poland. Energies 2023, 16, 230. [Google Scholar] [CrossRef]

- Boschi, K.; Prisco, C.G.D.; Grassi, D.; Modoni, G.; Salvatore, E. Nanosilica grout permeation in sand: Experimental investigation and modeling. J. Geotech. Geoenviron. Eng. 2024, 150. [Google Scholar] [CrossRef]

- Li, D.; Li, X.; Hu, Y.; Zhang, S.; Mei, C.; Wu, H.; Sun, X.; Fu, Y. Study on dispersion of cement grout in sand considering filtration effect through the EDTA titration test. Geofluids 2020, 2020, 6620979. [Google Scholar] [CrossRef]

- Ding, W.; Duan, C.; Zhang, Q. Experimental and numerical study on a grouting diffusion model of a single rough fracture in rock mass. Appl. Sci. 2020, 10, 7041. [Google Scholar] [CrossRef]

- Jiang, D.; Cheng, X.; Luan, H.; Wang, T.; Zhang, M.; Hao, R. Experimental investigation on the law of grout diffusion in fractured porous rock mass and its application. Processes 2018, 6, 191. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, Q.; Zhang, L.; Peng, F.; Li, Z.; Weng, X. Model test on segmental grouting diffusion process in muddy fault of tunnel engineering. Geofluids 2020, 2020, 6698011. [Google Scholar] [CrossRef]

- Li, P.; Zhang, Q.; Zhang, X.; Li, S.; Li, X.; Zuo, J. Grouting diffusion characteristics in faults considering the interaction of multiple grouting. Int. J. Geomech. 2017, 17, 04016117. [Google Scholar] [CrossRef]

- Soga, K.; Au SK, A.; Jafari, M.R.; Bolton, M.D. Laboratory investigation of multiple grout injections into clay. Géotechnique 2004, 54, 81–90. [Google Scholar] [CrossRef]

- Zhang, J.; Li, S.C.; Li, Z.F.; Yang, L.; Zhang, Q.S.; Wang, K.; Qi, Y.H.; Du, J.; Li, H.T. Effect of particle size distribution on the grout diffusion pattern in completely and strongly weathered granite. Indian Geotech. J. 2019, 50, 531–539. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Q.; Li, Z.; Wang, H. Test on compaction reinforcement effect of sand. Adv. Mater. Sci. Eng. 2020, 2020, 3685619. [Google Scholar] [CrossRef]

- Bezuijen, A.; Grotenhuis, R.T.; Tol, A.V.; Bosch, J.W.; Haasnoot, J.K. Analytical model for fracture grouting in sand. J. Geotech. Geoenviron. Eng. 2011, 137, 611–620. [Google Scholar] [CrossRef]

- Guo, Y.X.; Zhang, Q.S.; Zhang, L.Z.; Liu, R.T.; Chen, X.; Liu, Y.K. Experimental study on groutability of sand layer concerning permeation grouting. Adv. Mater. Sci. Eng. 2021, 2021, 6698263. [Google Scholar] [CrossRef]

- Li, Z.P.; Zhang, L.Z.; Chu, Y.T.; Zhang, Q. Research on influence of water-cement ratio on reinforcement effect for permeation grouting in sand layer. Adv. Mater. Sci. Eng. 2020, 2020 (Suppl. S1), 5329627. [Google Scholar] [CrossRef]

- Guo, C.C.; Hu, D.P.; Wang, F.M. Diffusion behavior of polymer grouting materials in sand and gravel. Soil Mech. Found. Eng. 2021, 57, 440–444. [Google Scholar] [CrossRef]

- Li, Z.C.; Wang, G.H.; Li, J.; Lv, Z. Experimental study on vacuum grouting in silty sand stratum. Math. Probl. Eng. 2020, 2020, 2689059. [Google Scholar] [CrossRef]

- Wang, D.; Sui, W. Grout diffusion characteristics during chemical grouting in a deep water-bearing sand layer. Int. J. Min. Sci. Technol. 2012, 22, 589–593. [Google Scholar] [CrossRef]

- Yang, J.Y.; Cheng, Y.H.; Chen, W.C. Experimental study on diffusion law of post-grouting slurry in sandy soi. Adv. Civ. Eng. 2019, 2019, 3493942. [Google Scholar]

- Kleinlugtenbelt, R.; Bezuijen, A.; van Tol, A.F. Model tests on compensation grouting. Tunn. Undergr. Space Technol. 2006, 21, 435–436. [Google Scholar] [CrossRef]

- Hu, H.X.; Gan, B.Q.; Deng, C.; Xie, Z.; Lu, Y.; Cai, Y. Experimental study on the efect of water-cement ratios on the difusion behavior of sand soil grouting. Bull. Eng. Geol. Environ. 2024, 83, 80. [Google Scholar] [CrossRef]

- Hu, H.X.; Lu, Y.F.; Deng, C.; Gan, B.; Xie, Z.; Cai, Y.; Chu, A. Experimental study on grout-soil interaction effects in sandy soil under different water-to-cement ratios. Buildings 2024, 14, 947. [Google Scholar] [CrossRef]

- Li, M.T.; Zhang, X.; Li, S.C.; Zhang, Q.; Zuo, J.; Lan, X. Grouting lifting numerical methods based on numerical simulation and model experiment. J. Harbin Inst. Technol. 2019, 51, 159. [Google Scholar] [CrossRef]

| Specific Surface Area (m2/kg) | 3 d Flexural Strength (MPa) | 3 d Compressive Strength (MPa) | 28 d Compressive Strength (MPa) | Initial Setting Time (min) | Final Setting Time (min) | |

|---|---|---|---|---|---|---|

| P·O 42.5 | 356 | 5.4 | 27.8 | 49.6 | 176 | 232 |

| Standard | ≥300 | ≥3.5 | ≥17.0 | ≥42.5 | ≥45 | ≤600 |

| Item | Grouting Parameters | Sand Sample Parameters | |||||

|---|---|---|---|---|---|---|---|

| Grouting Pressure (MPa) | Grouting Volume (L) | Water– Cement Ratio | Moisture Condition | Void Ratio | Permeability Coefficient (10−4 cm/s) | Internal Friction Angle (°) | |

| Value | 0~0.5 | 2.66~3.12 | 0.8/1.0/1.2 | Saturation | 0.73–0.75 | 2.01~2.05 | 33.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, H.-X.; Cao, W.; Deng, C.; Lu, Y.-F. Experimental Study on the Relationship between Time-Varying Uplift Displacement and Grout Diffusion in Sand. Appl. Sci. 2024, 14, 3922. https://doi.org/10.3390/app14093922

Hu H-X, Cao W, Deng C, Lu Y-F. Experimental Study on the Relationship between Time-Varying Uplift Displacement and Grout Diffusion in Sand. Applied Sciences. 2024; 14(9):3922. https://doi.org/10.3390/app14093922

Chicago/Turabian StyleHu, Huan-Xiao, Wei Cao, Chao Deng, and Yu-Fan Lu. 2024. "Experimental Study on the Relationship between Time-Varying Uplift Displacement and Grout Diffusion in Sand" Applied Sciences 14, no. 9: 3922. https://doi.org/10.3390/app14093922

APA StyleHu, H.-X., Cao, W., Deng, C., & Lu, Y.-F. (2024). Experimental Study on the Relationship between Time-Varying Uplift Displacement and Grout Diffusion in Sand. Applied Sciences, 14(9), 3922. https://doi.org/10.3390/app14093922