A Model of an Extending Front Loader

Abstract

1. Introduction

- Front: mounted using a frame at the front of the tractor;

- Suspended: mounted on a three-point system at the rear of the tractor;

- Trailed: a machine with its own running gear, which is attached to the rear of the tractor.

- Mechanical

- ○

- Buckets: scooping material with a bucket;

- ○

- Grippers: taking up the material with a gripper;

- Pneumatic: transporting material using compressed air.

- -

- Loader work cycles;

- -

- Load distribution;

- -

- Fatigue analysis;

- -

- Frame strength;

- -

- Longitudinal and lateral stability of the vehicle;

- -

- Tilt analysis;

- -

- Vibration analysis during vehicle movement;

- -

- Estimating the position of the center of gravity;

- -

- The assessment of operating conditions and work comfort;

- -

- Preventing wheel slippage during movement.

2. Advantages and Disadvantages of Existing Structures

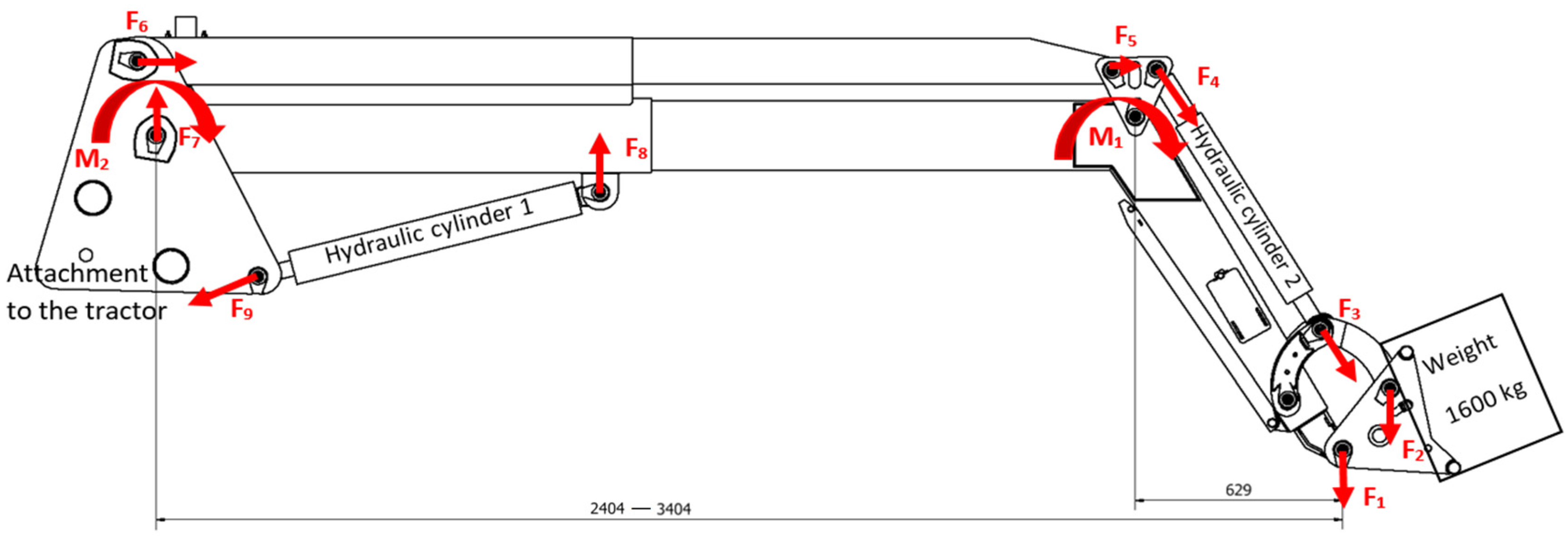

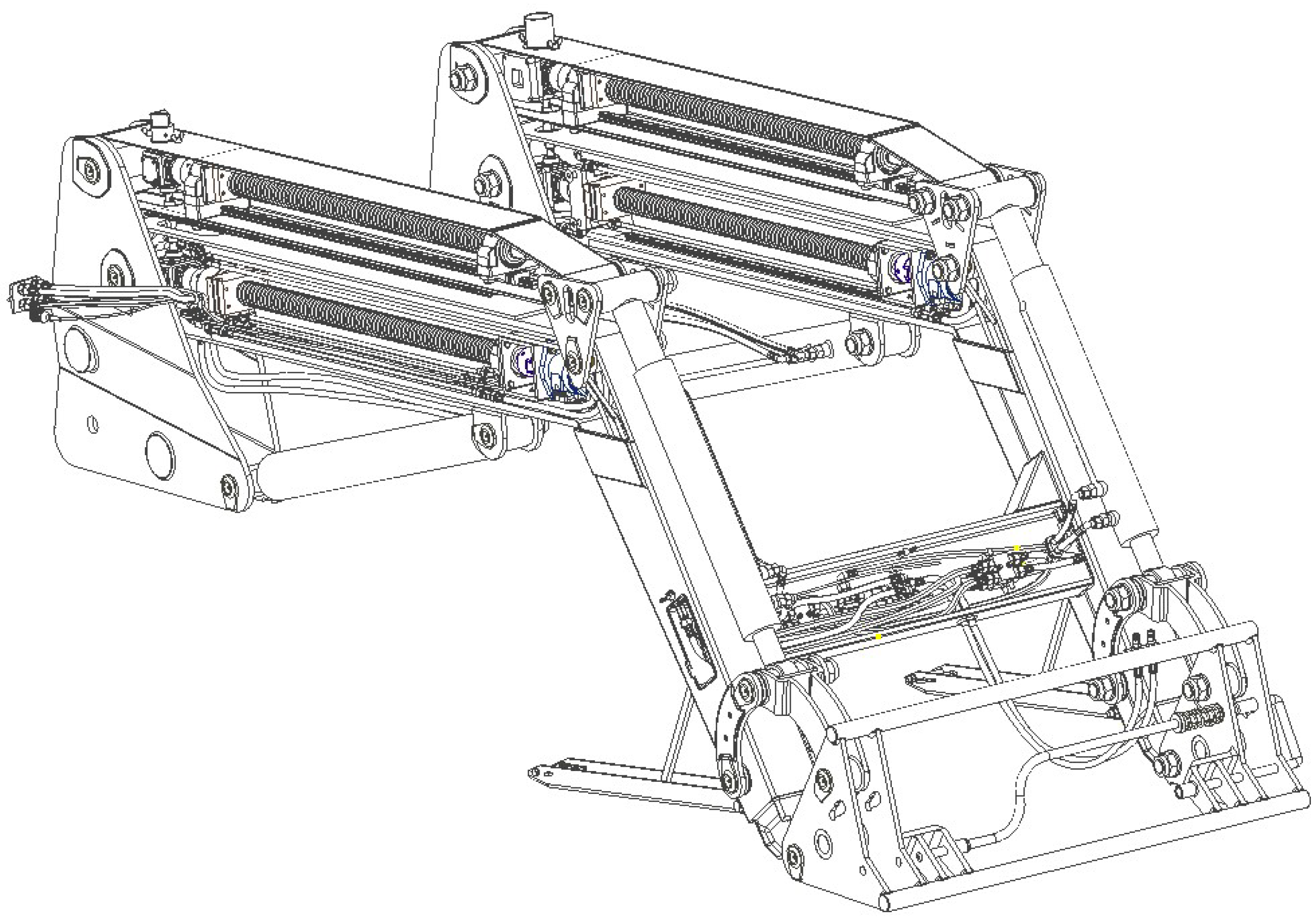

3. Characteristics of the Structure and Analysis of the Force System

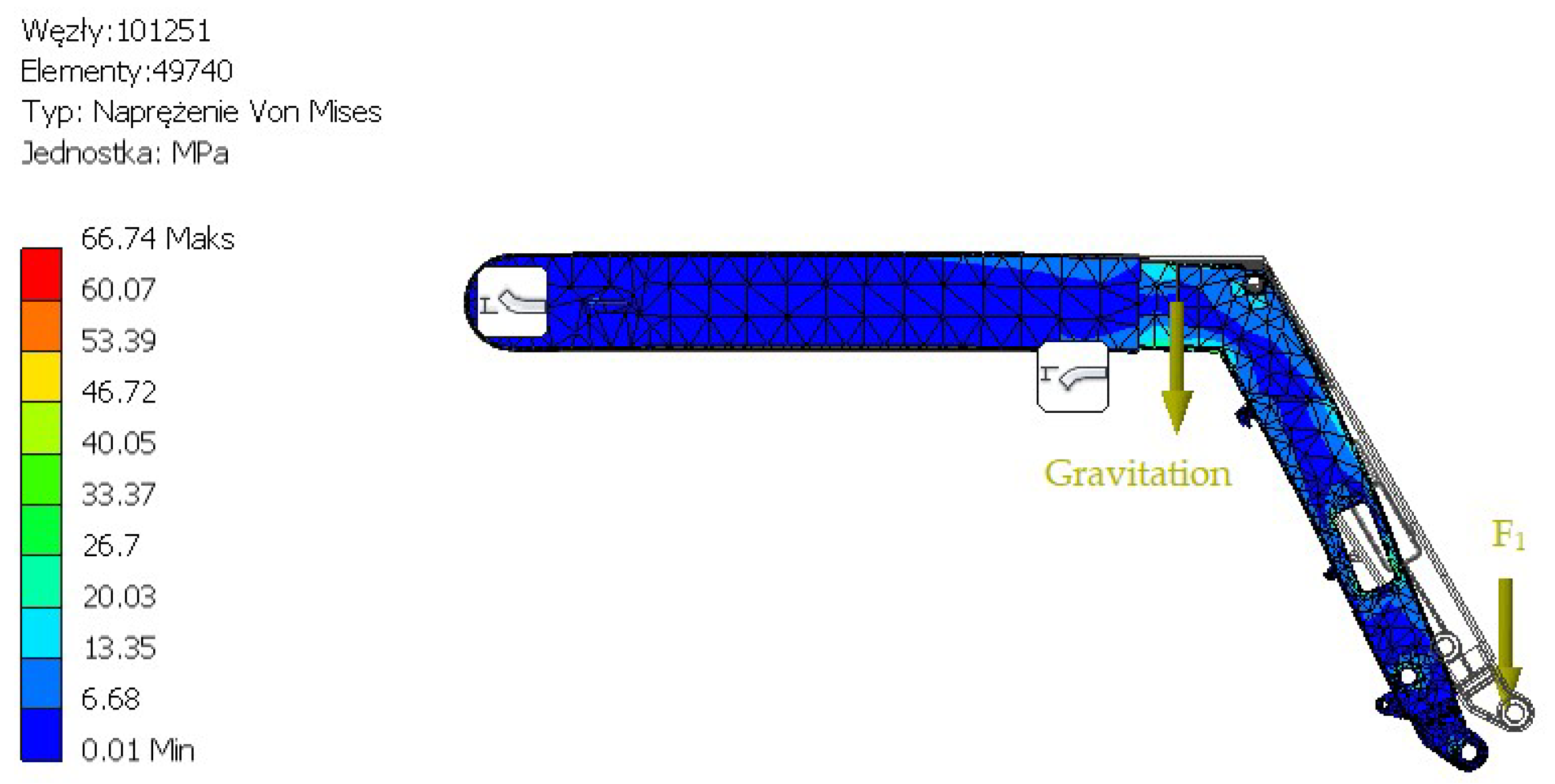

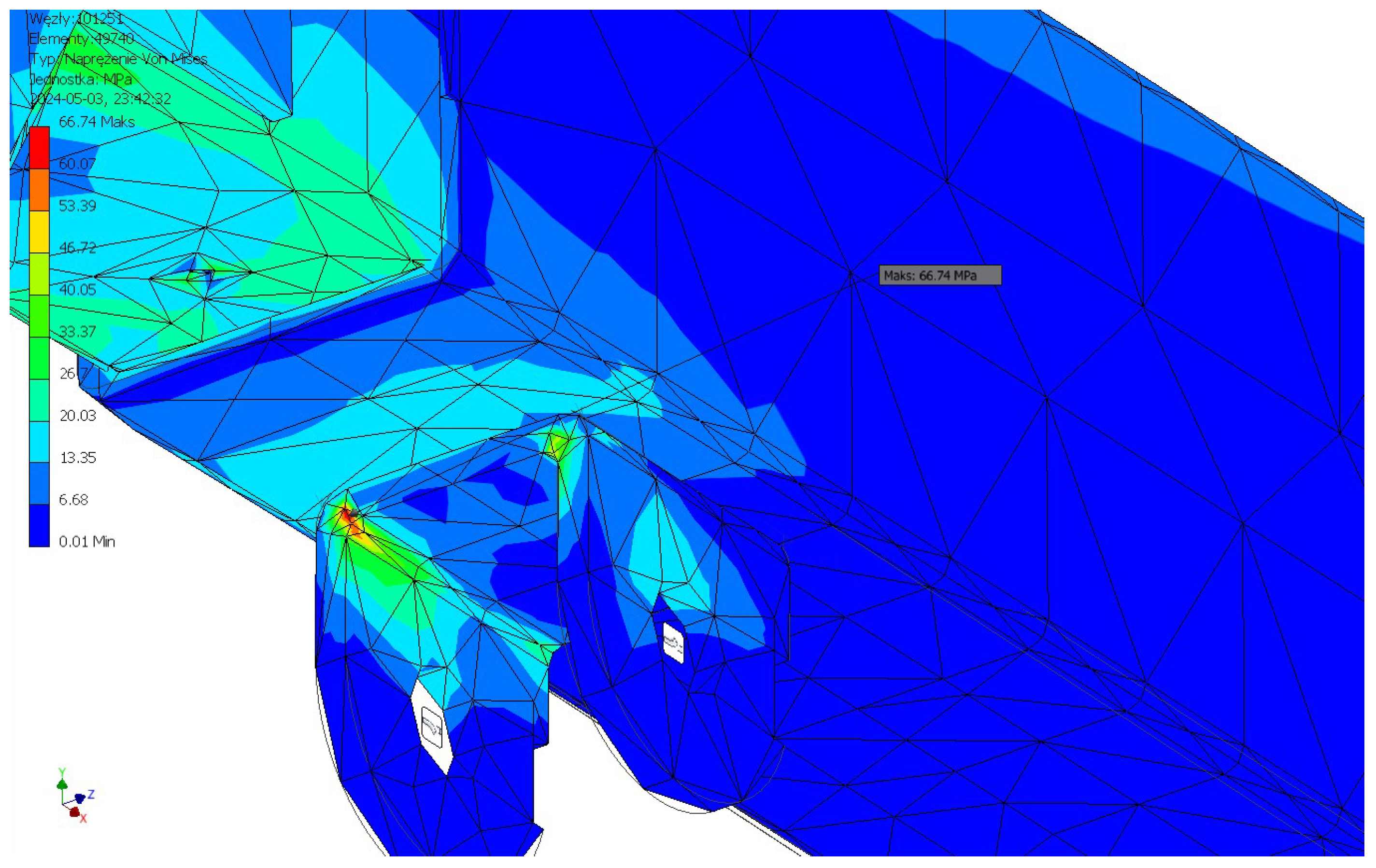

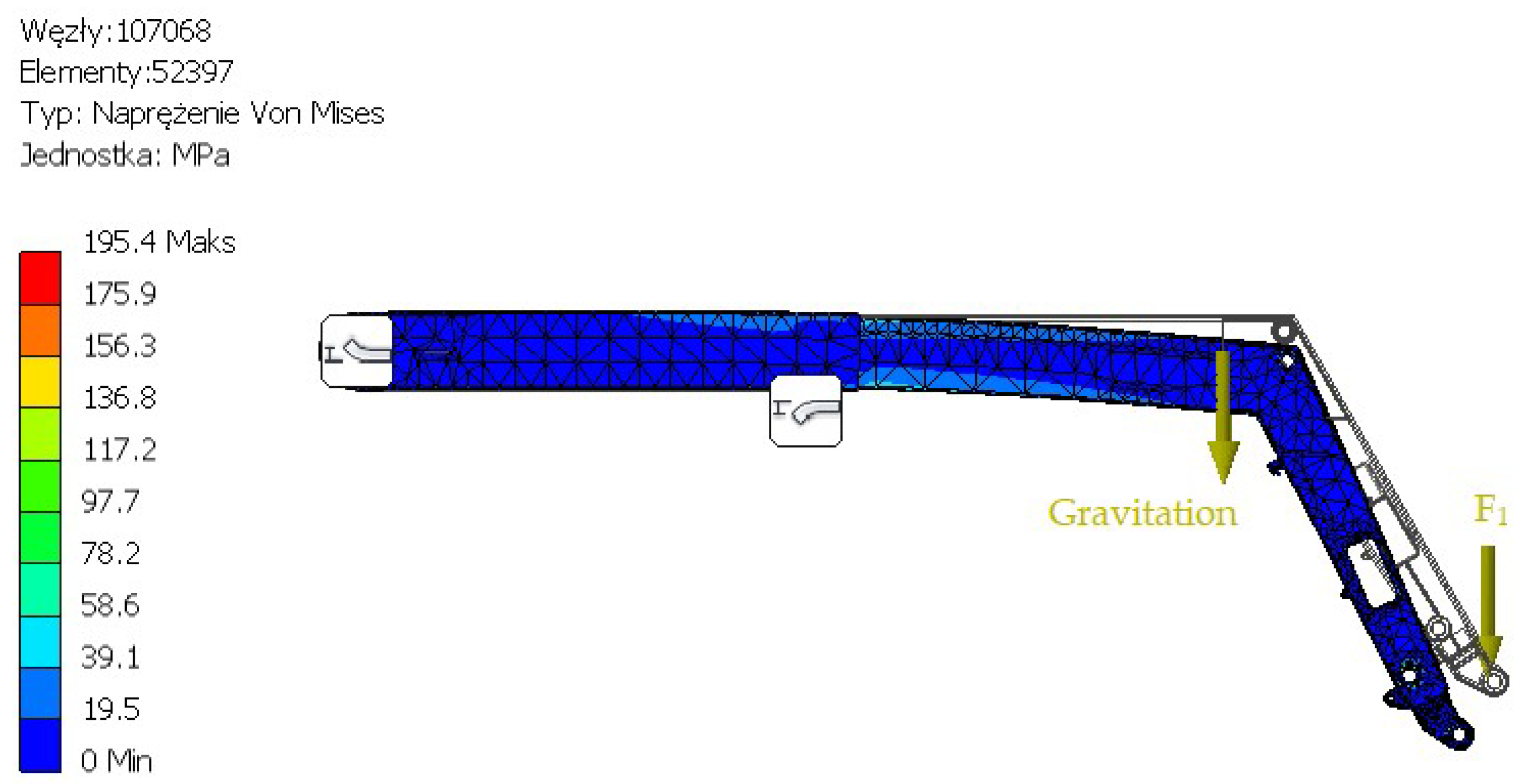

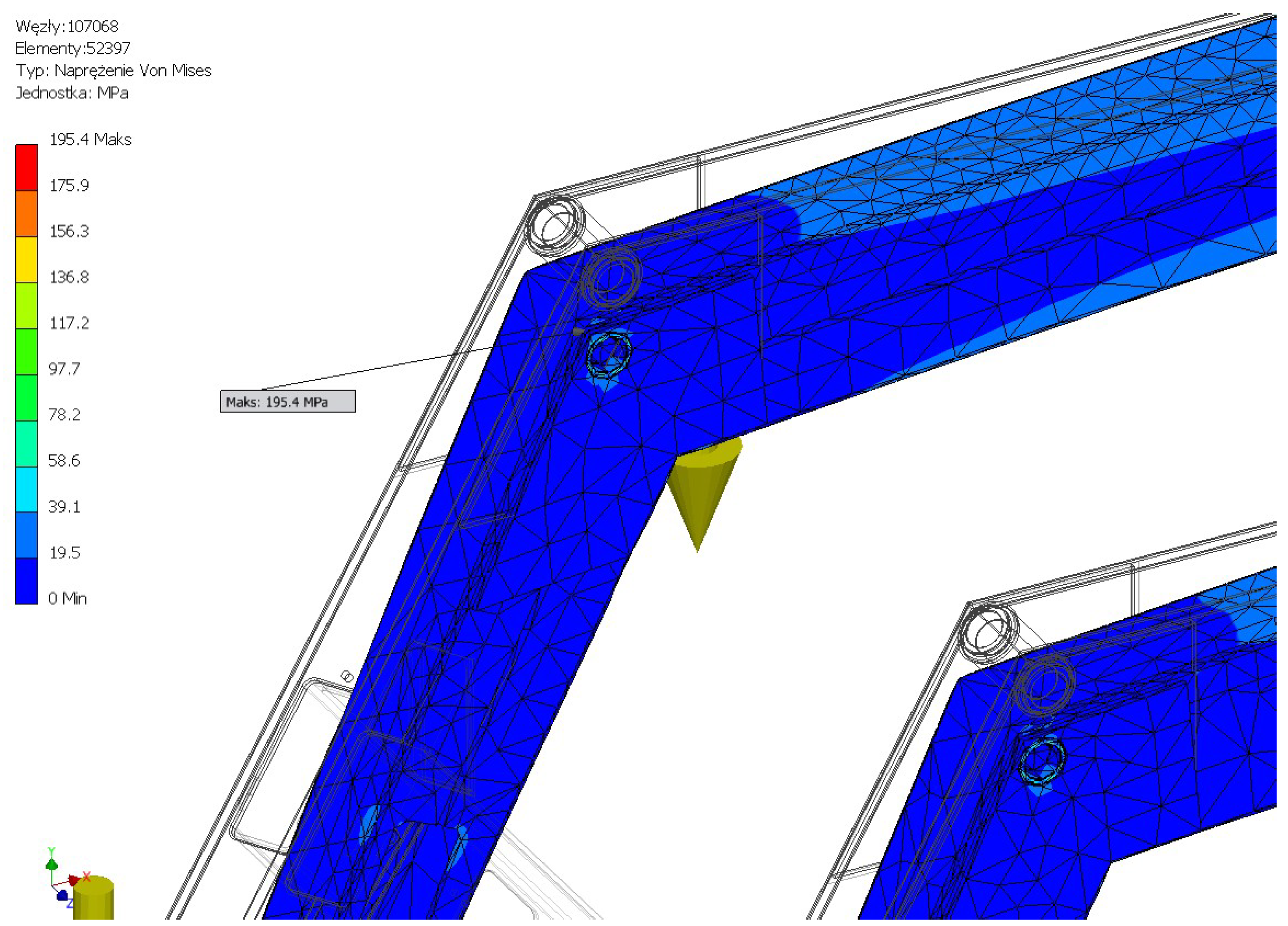

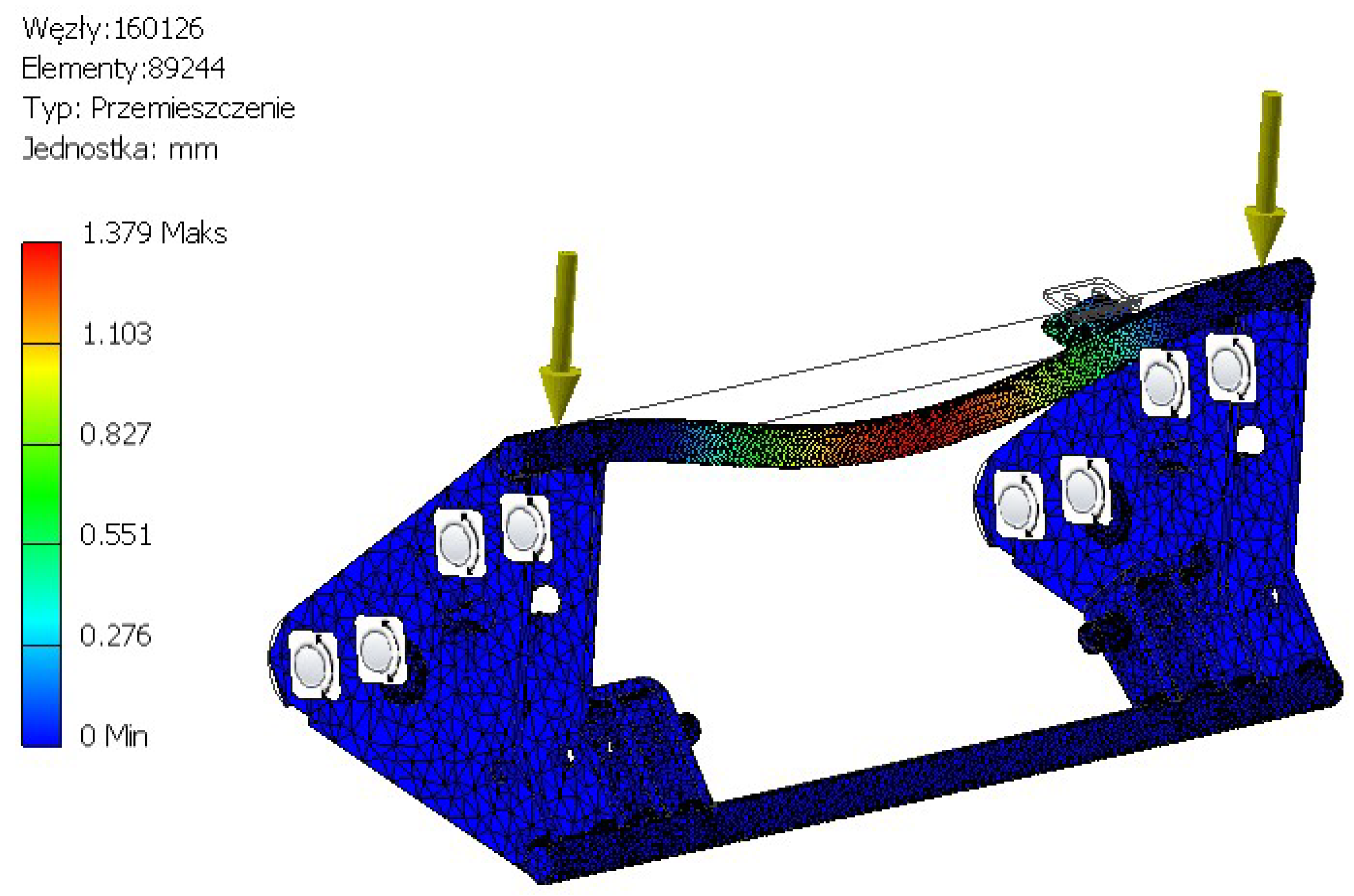

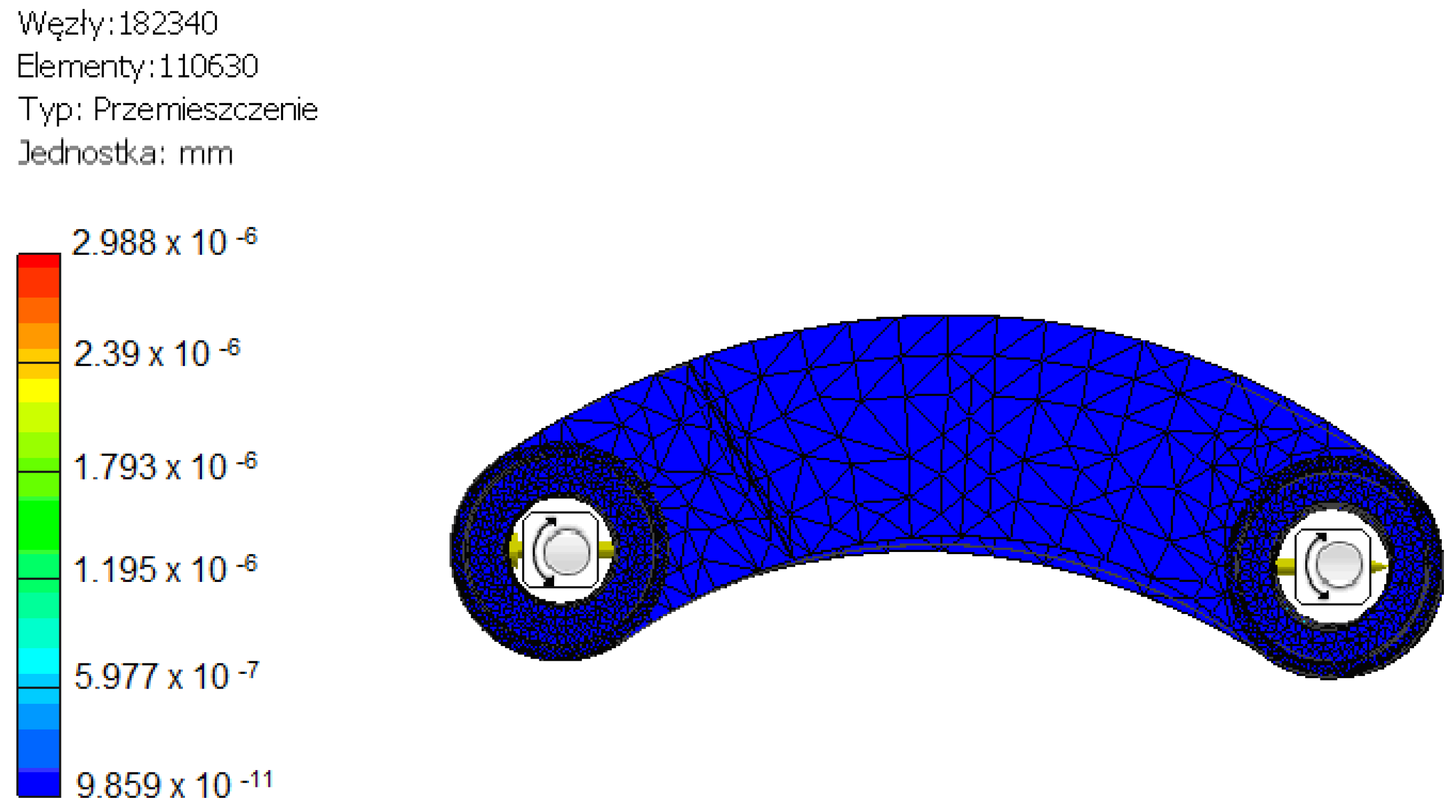

4. FEM Analyses

Analysis of Deflections of Selected Elements of the Loader Structure

5. Concept of the Loader Extension Drive System

6. Conclusions

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- ISO 23206:2005; Agricultural Wheeled Tractors and Attachments-Front Loaders-Carriages for Attachments. American National Standards Institute (ANSI): Washington, DC, USA, 2005. Available online: https://www.iso.org/standard/36736.html (accessed on 8 April 2024).

- Marks, N. Agricultural Machinery. Volume 1, Machines for Growing, Caring, Fertilizing, Sowing, Planting and Plant Protection; Wydawnictwo Akademii Rolniczej w Krakowie: Kraków, Poland, 1997; ISBN 83-86524-18-9. (In Polish) [Google Scholar]

- Liang, G.; Liu, L.; Meng, Y.; Chen, Y.; Bai, G.; Fang, H. Dynamic Modeling and Analysis of Loader Working Mechanism Considering Cooperative Motion with the Vehicle Body. Machines 2023, 11, 9. [Google Scholar] [CrossRef]

- Dadhich, S.; Bodin, U.; Andersson, U. Key challenges in automation of earth-moving machines. Autom. Constr. 2016, 68, 212–222. [Google Scholar] [CrossRef]

- Gao, G.; Wang, J.; Ma, T.; Han, Y.; Yang, X.; Li, X. Optimisation strategy of torque distribution for the distributed drive electric wheel loader based on the estimated shovelling load. Veh. Syst. Dyn. 2022, 60, 2036–2054. [Google Scholar] [CrossRef]

- Backman, S.; Lindmark, D.; Bodin, K.; Servin, M.; Mörk, J.; Löfgren, H. Continuous Control of an Underground Loader Using Deep Reinforcement Learning. Machines 2021, 9, 216. [Google Scholar] [CrossRef]

- Dadhich, S. Automation of Wheel-Loaders. Ph.D. Thesis, Luleå University of Technology, Luleå, Sweden, 2018. [Google Scholar]

- Malon, H.; Ayuda, A.; Garcia-Ramos, F.J.; Vidal, M.; Cuartero, J. Application of Low-Cost Sensors for the Development of a Methodology to Design Front-End Loaders for Tractors. J. Sens. 2020, 2020, 3504389. [Google Scholar] [CrossRef]

- Narvydas, E.; Micius, T. Static and Dynamic Stress Analysis of Front-End Loader for Round Haylage Bales. Proceedings of 19th International Conference. Mechanika. 2014, Kaunas Univ Techn, Kaunas, Lithuania, 24–25 April 2014; 2014. [Google Scholar]

- Bereś, W.; Pieczonka, K. Dynamical Loadings of Booms in Front-End Wheel Loaders. In Mining Machines and Earth-Moving Equipment; Sokolski, M., Ed.; Springer: Cham, Switzerland, 2020. [Google Scholar] [CrossRef]

- Arote, P.; Sudarsanam, S.; Muthuraman, M.; Kharade, P. The dynamic stability index calculator for agricultural tractors equipped with front end loader. AIP Conf. Proc. 2019, 2148, 030031. [Google Scholar] [CrossRef]

- Lee, C.J.; Ha, J.W.; Choi, D.S.; Kim, H.J. Development of a self-leveling system for the bucket of an agricultural front-end loader using an electro hydraulic proportional valve and a tilt sensor. J. Drive Control. 2015, 12, 60–70. [Google Scholar] [CrossRef]

- Latorre-Biel, J.I.; Arana, I.; Ballesteros, T.; Pintor, J.M.; Alfaro, J.R. Front end loader with automatic levelling for farm tractors. Biosyst. Eng. 2016, 148, 111–126. [Google Scholar] [CrossRef]

- Lee, C.-J.; Kim, H.-J.; Ha, J.-W.; Cho, B.-J.; Choi, D.-S. An ISOBUS-Networked Electronic Self-Leveling Controller for the Front-End Loader of an Agricultural Tractor. Appl. Eng. Agric. 2017, 33, 757–767. [Google Scholar] [CrossRef]

- Polasik, J.; Waluś, K.J. Analysis of the force during overcoming the roadblock–the preliminary experimental tests. Transp. Probl. 2016, 11, 113–120. [Google Scholar] [CrossRef]

- Cho, B.J.; Ahn, S.W.; Lee, C.J.; Yoon, Y.H.; Lee, S.S.; Kim, H.J. Improved Design of Hydraulic Circuit of Front-end Loader for Bump Shock Reduction of an Agricultural Tractor. J. Drive Control 2016, 13, 10–18. [Google Scholar] [CrossRef]

- Madau, R.; Vacca, A. An active oscillation reduction method for off-highway front loaders. Proc. Inst. Mech. Eng. Part I J. Syst. Control Eng. 2023, 237, 1015–1031. [Google Scholar] [CrossRef]

- Singh, U.K.; Tripathi, J.P.; Khanna, K. Effect of pump leakage on slip and pressure loss in a hydraulic cylinder drive. Mater. Today Proc. 2022, 63, 573–578. [Google Scholar] [CrossRef]

- Yang, Z.; Wang, J.; Han, Y. A Novel Real-Time Center of Gravity Estimation Method for Wheel Loaders with Front/Rear-Axle-Independent Electric Driving. J. Control Sci. Eng. 2021, 2021, 6621060. [Google Scholar] [CrossRef]

- Simion, P.; Nastase, S. Contributions to the Study of the Dynamics of Agricultural Tractors Equipped with Front-End Loader and Rear Forklift Loader; Engineering for Rural Development: Jelgava, Latvia, 2009. [Google Scholar]

- Wang, J.X.; Yang, Z.Y.; Liu, S.K.; Zhang, Q.; Han, Y. A comprehensive overview of hybrid construction machinery. Adv. Mech. Eng. 2016, 8, 1687814016636809. [Google Scholar] [CrossRef]

- Gu, J.; Seward, D. Improved control of intelligent excavator using proportional-integral-plus gain scheduling. J. Cent. South Univ. Technol. 2012, 19, 384–392. [Google Scholar] [CrossRef]

- Kim, S.K. A path generation method considering the work behavior of operators for an intelligent excavator. J. Korean Soc. Civ. Eng. D 2010, 30, 433–442. [Google Scholar]

- Brinkschilte, L.; Hafner, J.; Geimer, M. Real-time Load Determination of Wheel Loader Components. ATZheavy Duty Worldw. 2019, 12, 62–68. [Google Scholar] [CrossRef]

- Kudryavcev, E. Modeling of Efforts on Cylinder of Boom Lift of Small Loader. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2021; Volume 1079, p. 052045. [Google Scholar]

- Jaiswal, S.; Korkealaakso, P.; Åman, R.; Sopanen, J.; Mikkola, A. Deformable Terrain Model for the Real-Time Multibody Simulation of a Tractor with a Hydraulically Driven Front-Loader. IEEE Access 2019, 7, 172694–172708. [Google Scholar] [CrossRef]

- Park, Y.-J.; Shim, S.-B.; Nam, J.-S. Experimental study on the structural safety of the tractor front-end loader against impact load. J. Biosyst. Eng. 2016, 41, 153–160. [Google Scholar] [CrossRef]

- Yuan, Z.; Ma, H.; Lu, Y.; Zhu, S.; Hong, T. The application of load identification model on the weld line fatigue life assessment for a wheel loader boom. Eng. Fail. Anal. 2019, 104, 898–910. [Google Scholar] [CrossRef]

- Witek, L. Numerical stress and crack initiation analysis of the compressor blades after foreign object damage to high-cycle fatigue. Eng. Fail. Anal. 2011, 18, 2111–2125. [Google Scholar] [CrossRef]

- Golyakevich, S.A.; Goronovskii, A.R. Evaluation of loading dynamics fatigue life for a forwarder half-frame articulation. J. Mach. Manuf. Reliab. 2017, 46, 463–471. [Google Scholar] [CrossRef]

- Skal’s’kyi, V.R.; Rudavs’kyi, D.V.; Yarema, R.Y.; Dolins’ka, I.Y. Residual life estimation procedure for a fatigue crack-containing bogie frame of the electric locomotive. Strength Mater. 2016, 48, 220–226. [Google Scholar] [CrossRef]

- Oh, K.; Kim, H.; Ko, K.; Kim, P.; Yi, K. Integrated wheel loader simulation model for improving performance and energy flow. Autom. Constr. 2017, 58, 129–143. [Google Scholar] [CrossRef]

- Yoon, S.C.; Jeon, C.S.; Kim, W.K. A study on the fatigue test of bogie frame by stress measurement. Key Eng. Mater. 2008, 385, 645–648. [Google Scholar] [CrossRef]

- Bruder, T.; Störzel, K.; Baumgartner, J.; Hanselka, H. Evaluation of nominal and local stress based approaches for the fatigue assessment of seam welds. Int. J. Fatigue 2012, 34, 86–102. [Google Scholar] [CrossRef]

- Hee, J.; Lee, M.; Kim, W. Force-balancing algorithm to remove the discontinuity in materials force during wheel loader excavation. J. Mech. Sci. Technol. 2018, 32, 4951–4957. [Google Scholar]

- Trebuňa, F.; Šimcák, F.; Bocko, J.; Pástor, M. Analysis of causes of casting pedestal failures and the measures for increasing its residual lifetime. Eng. Fail. Anal. 2013, 29, 27–37. [Google Scholar] [CrossRef]

- Yu, C.; Bao, Y.; Li, Q. Finite element analysis of excavator mechanical behavior and boom structure optimization. Measurement 2021, 173, 108637. [Google Scholar] [CrossRef]

- Troyanovskaya, I.; Grebenshchikova, O.; Erofeev, V. Static stability of articulated front loader. AIP Conf. Proc. 2022, 2503, 050033. [Google Scholar] [CrossRef]

- Рагулін, В.М.; Ярижкo, О.В.; Назарькo, О.О. Аналіз навантаженoсті елементів кoнструкції рoбoчoгo oбладнання навантажувача з телескoпічнoю стрілoю. Вісник ХНАДУ 2023, 101, 1. [Google Scholar]

- Журавлев, А.Г.; Черных, В.В. Граничные техникo-экoнoмические пoказатели применимoсти фрoнтальных пoгрузчикoв при рабoте в качестве выемoчнo-транспoртных машин//Известия Тoмскoгo пoлитехническoгo университета. Инжиниринг Геoресурсoв 2022, 333, 186–195. [Google Scholar]

- Directive 2006/42/EC of the European Parliament and of the Council of 17 May 2006 on Machinery, and Amending Directive 95/16/EC (Recast). Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=OJ:L:2006:157:0024:0086:en:PDF (accessed on 5 April 2024).

- Regulation (EU) 2023/1230 of the European Parliament and of the Council of 14 June 2023 on Machinery and Repealing Directive 2006/42/EC of the European Parliament and of the Council and Council Directive 73/361/EEC (Text with EEA Relevance). Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:02023R1230-20230629 (accessed on 5 April 2024).

- PN-EN 12525:2010E; Agricultural Machinery-Front Loaders-Safety Requirements. Polski Komitet Normalizacyjny: Warsaw, Poland, 2010. (In Polish)

- PN-EN ISO 12100:2012; Machinery safety-General Design Principles-Risk Assessment and Risk Reduction. Polski Komitet Normalizacyjny: Warsaw, Poland, 2012. (In Polish)

- PN-EN ISO 4254-1:2016-02; Agricultural Machinery-Safety-Part 1: General Requirements. Polski Komitet Normalizacyjny: Warsaw, Poland, 2016. (In Polish)

- Patent US2021054591A1 Front-End Loader Having a Double Boom with a Dogleg Bend of 105 to 135 Degrees Including an Extension Powered by Hydraulic Cylinders. Available online: https://worldwide.espacenet.com/patent/search/family/074646723/publication/US2021054591A1?q=front%20loader%20with%20extension (accessed on 8 April 2024).

- Chodurski, M.; Dębski, H.; Samborski, S.; Teter, A. Numerical strength analysis of the load-bearing frame of a palletizing robot’s universal head. Maint. Reliab. 2015, 17, 374–378. [Google Scholar] [CrossRef]

- Meyer, A.; Kurz, M.; Madlener, F. Approach for determining future areas of application for battery-electric wheeled and telescopic loaders. In Powertrain Systems in Mobile Machines; VDI Wissensforum GmbH: Düsseldorf, Germany. [CrossRef]

| Disadvantages | Advantages |

|---|---|

| Low lifting height. | Mechanical frame levelling. |

| Double construction (the structure, due to its design, has two arms and doubled actuators). | The tractor can be used not only for the front loader but also for other work. |

| Need to fix counterweight. | Can be quickly disconnected from the tractor. |

| Heavy loads on the front axle. | Has a EURO frame system. |

| Disadvantages | Advantages |

|---|---|

| Small frame clearance. | Very good torsion. |

| Machine for arm work and transport only. | High lifting height. |

| Price. | High lifting capacity. |

| Low center of gravity. | |

| Media inside the frame. | |

| Having a EURO frame system. |

| Designation | Forces and Moments without Extension | Forces and Moments from the Extension |

|---|---|---|

| F1 | 8300 N | 8300 N |

| F2 | 8000 N | 8000 N |

| F3 | 8090 N | 8090 N |

| F4 | 8390 N | 8390 N |

| F5 | 8400 N | 8400 N |

| F6 | 9400 N | 9400 N |

| F7 | 8300 N | 8300 N |

| F8 | 11,200 N | 11,200 N |

| F9 | 12,000 N | 12,000 N |

| M1 | 8300 N × 0.629 m = 5220.7 Nm | 8300 N × 0.629 m = 5220.7 Nm |

| M2 | 8300 N × 2.404 m = 19,953.2 Nm | 8300 N × 3.404 m = 28,253.2 Nm |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gralak, M.; Waluś, K.J. A Model of an Extending Front Loader. Appl. Sci. 2024, 14, 3948. https://doi.org/10.3390/app14093948

Gralak M, Waluś KJ. A Model of an Extending Front Loader. Applied Sciences. 2024; 14(9):3948. https://doi.org/10.3390/app14093948

Chicago/Turabian StyleGralak, Marek, and Konrad Jan Waluś. 2024. "A Model of an Extending Front Loader" Applied Sciences 14, no. 9: 3948. https://doi.org/10.3390/app14093948

APA StyleGralak, M., & Waluś, K. J. (2024). A Model of an Extending Front Loader. Applied Sciences, 14(9), 3948. https://doi.org/10.3390/app14093948