Signal-Centric Framework Based on Probability of Detection for Real-Time Reliability of Concrete Damage Inspection

Abstract

1. Introduction

2. Methodology

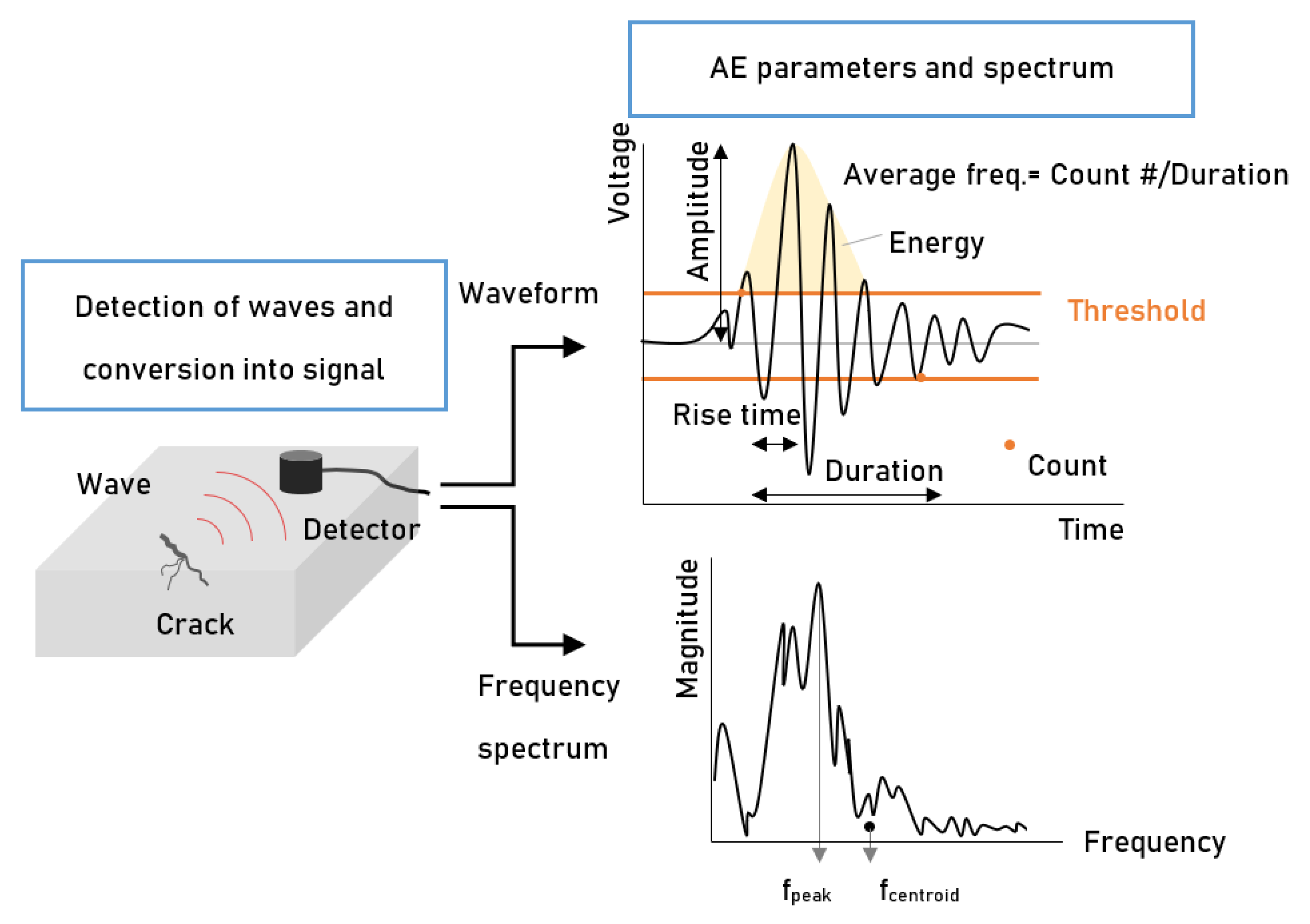

2.1. AE Technique as a Passive NDT

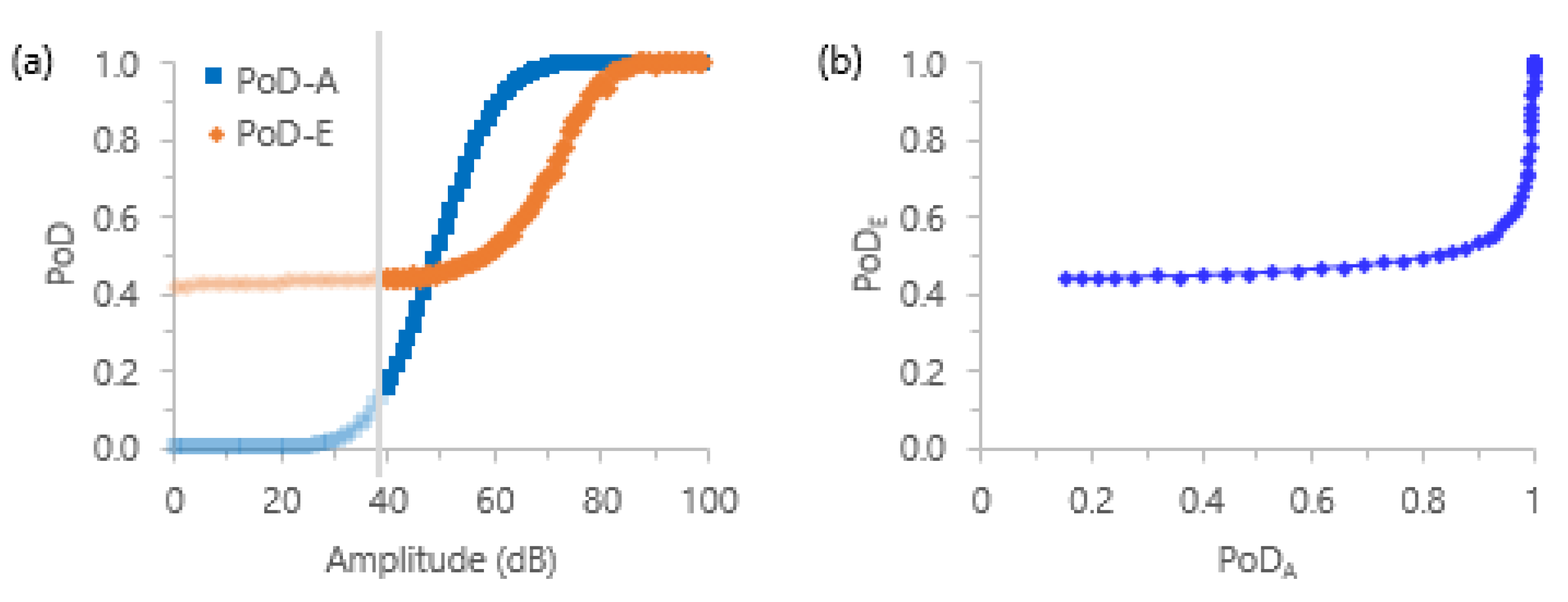

2.2. PoD Concept for Passive Signals

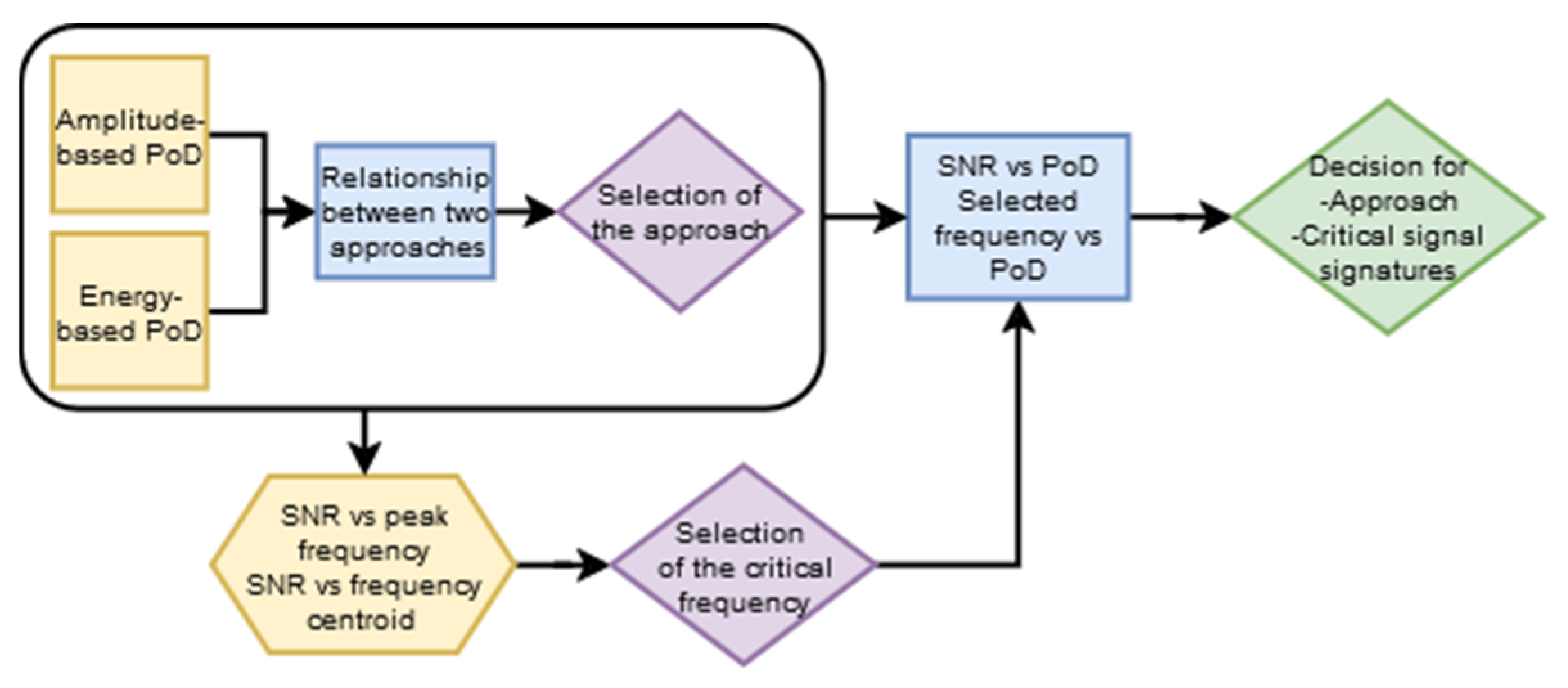

2.3. Basis Algorithm for the Framework

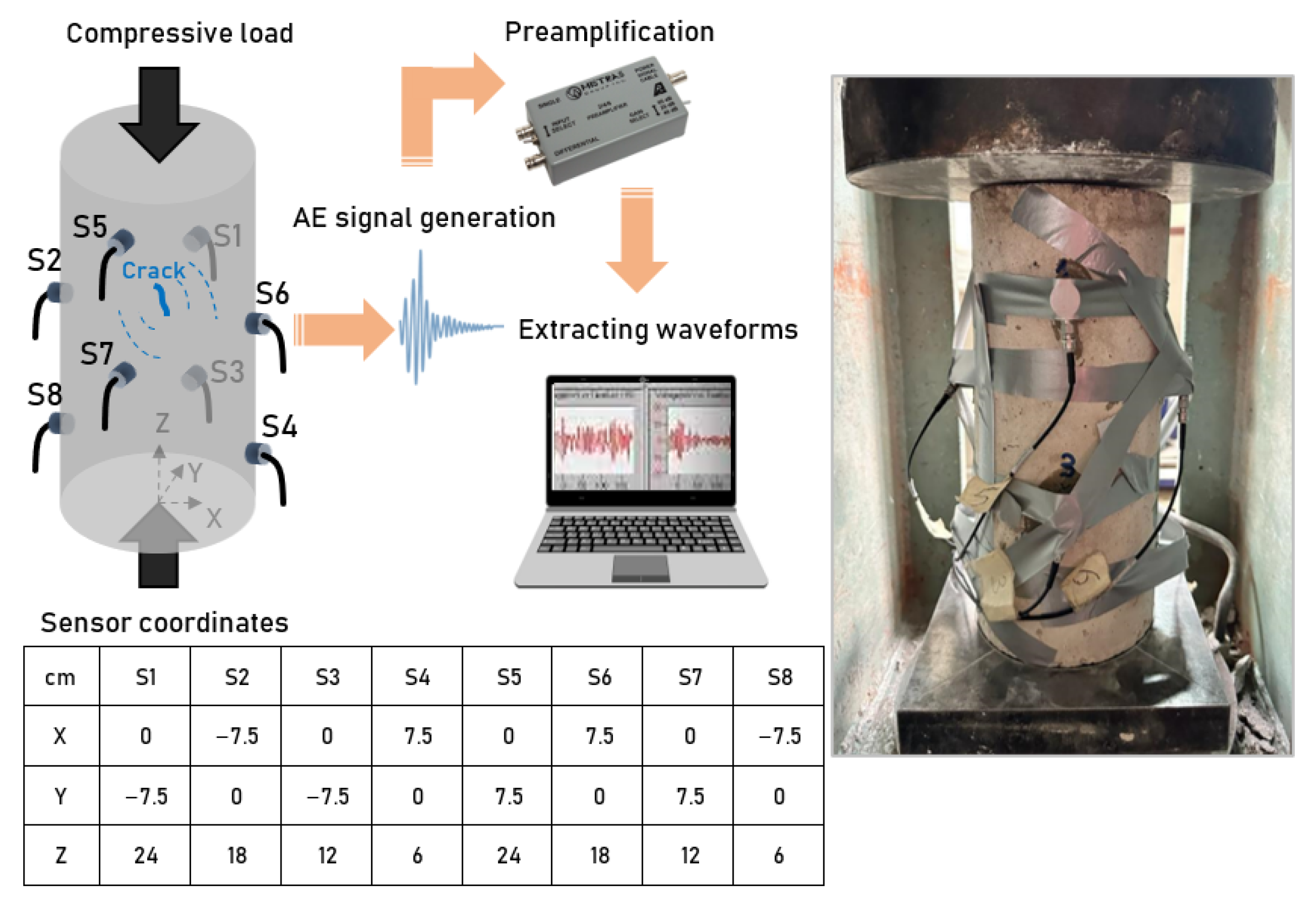

3. Experimental Procedure

3.1. Materials and Test Setup

3.2. Processing of AE Data

4. Results and Discussion

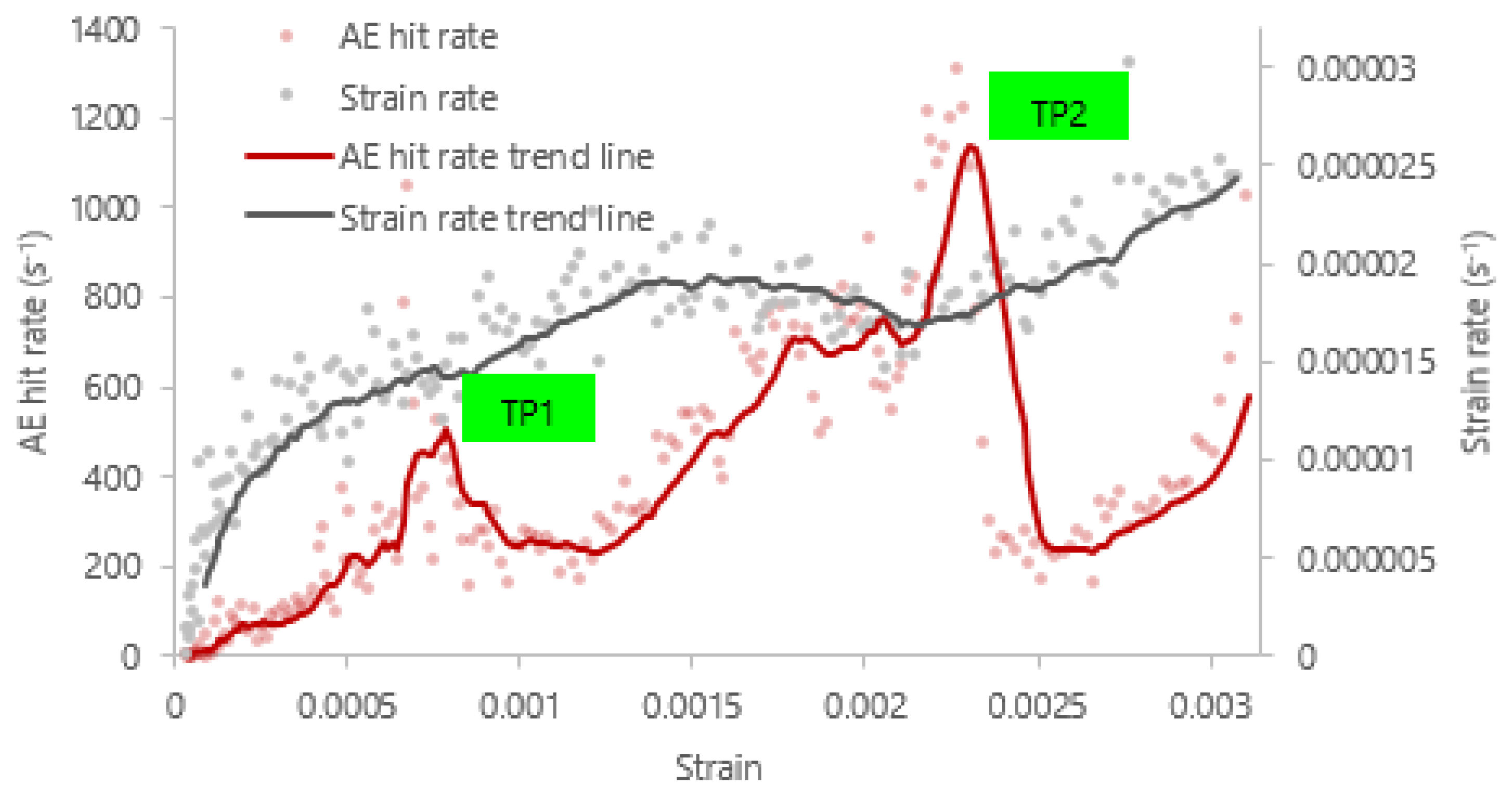

4.1. Joint Evaluation of the Signal Response and Concrete Behavior

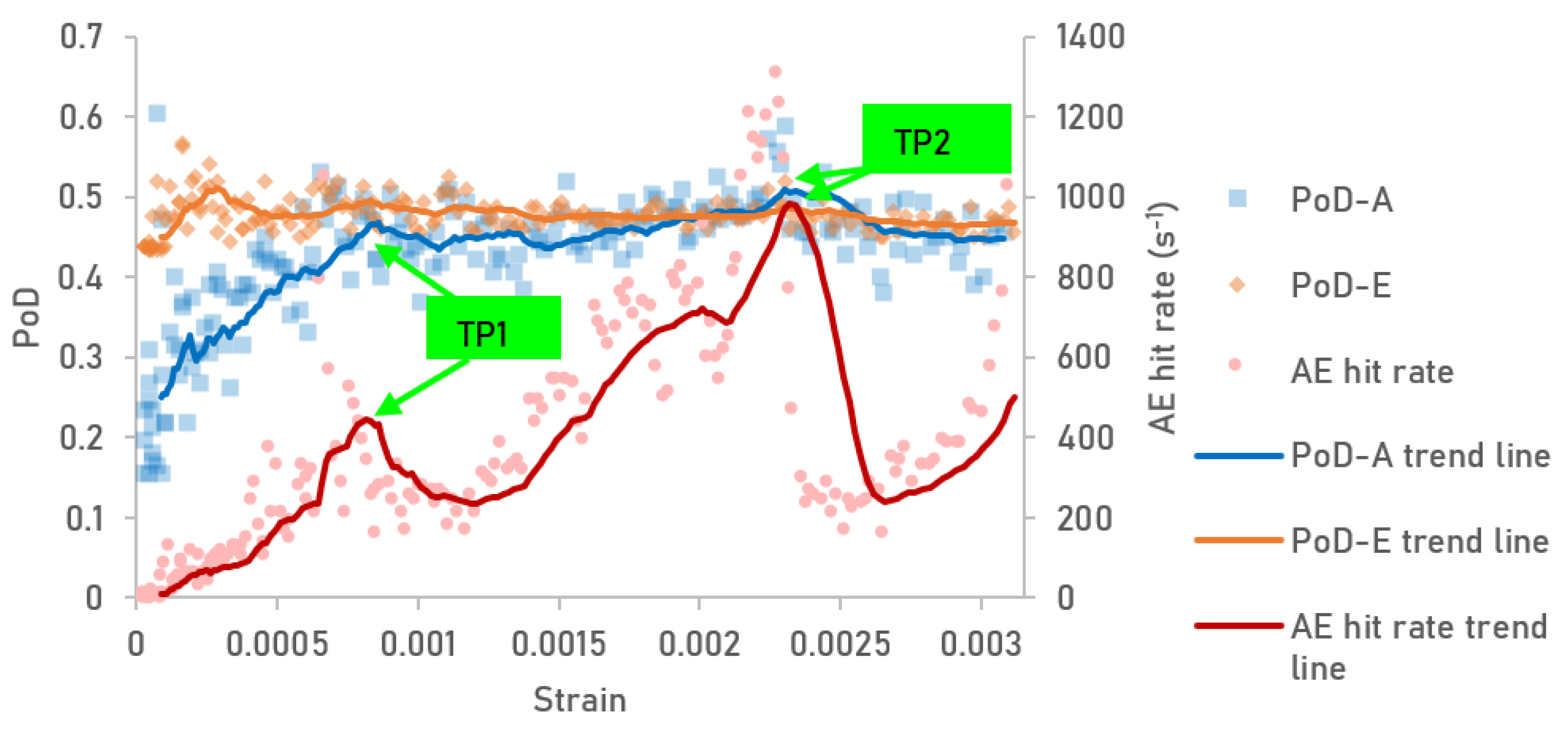

4.2. Strain-Driven Comparison of PoDA and PoDE

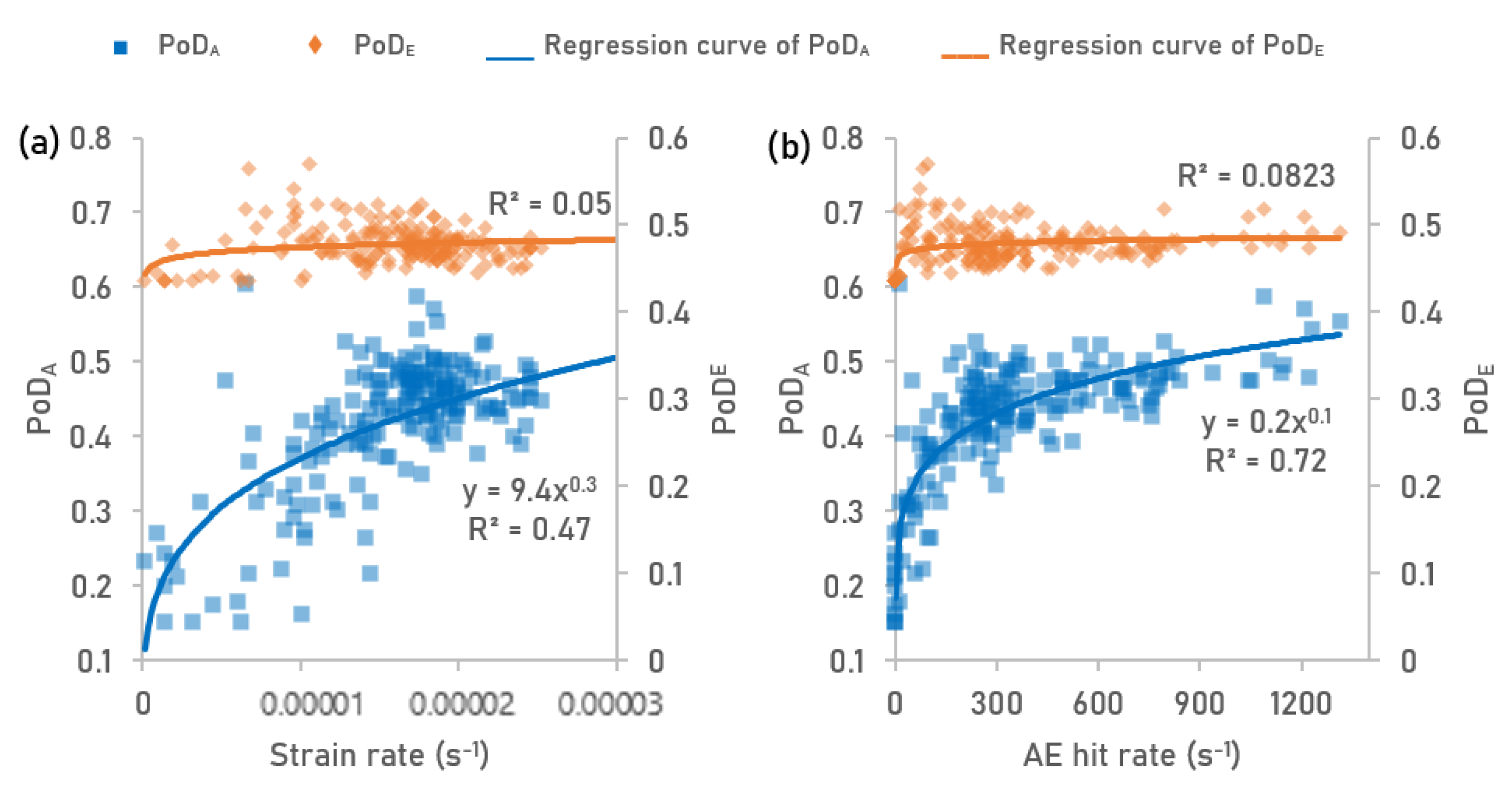

4.3. Correlations of Signal Signatures with PODA and PODE

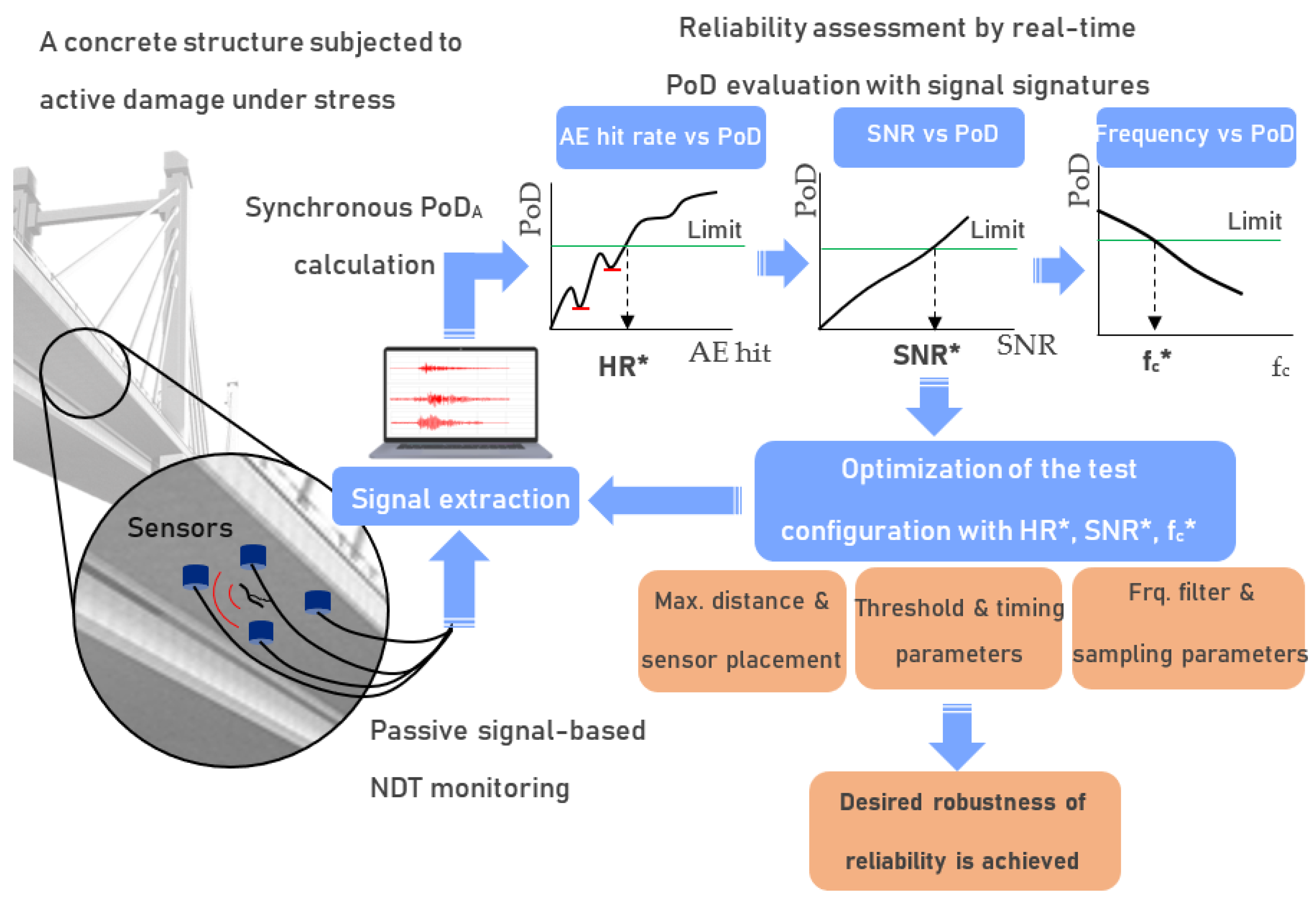

5. Signal-Centric Framework for Real-Time Inspection Reliability

- The acquisition system is configured with a sensor placement scheme considering the maximum distance between sensors due to attenuation, an amplitude threshold level to eliminate noise-related signals, digital and analog filters based on frequency, timing parameters (peak definition time, hit definition time, and hit lockout time), and data logging features (pre-trigger and sampling frequency). It is important to note that all these parameters are also related to the AE hit rate, in addition to the mechanical processes of concrete, and they need to be reconfigured to enhance the detectability of the technique and, thus, the reliability of the inspection.

- During the real-time monitoring of damages using this test setup on the structure, waveforms and FFT spectra of the signals captured by the sensors and their features are acquired.

- The synchronous amplitude-based PoD approach is applied to the amplitude distribution of the accumulated activities, and the instantaneous PoDA is calculated due to its effectiveness, as discussed in previous sections.

- The AE hit rate of the same accumulated AE activities is calculated and correlated with PoDA values. The dip point of the AE hit rate vs. PoD curve is considered a warning, indicating a decrease in detectability. This curve indicates to the user the AE hit rate (HR*) that needs to be achieved to reach the desired PoD limit. SNR and frequency centroid of the signals are calculated and correlated with PoDA values, and their trend also indicates the required minimum SNR (SNR*) and maximum frequency centroid (fc*).

- To provide the required AE hit rate, SNR, and frequency centroid for the minimum desired PoD of the technique, the test configuration is optimized by changing the sensor placement or type (broadband or different resonance frequency), threshold level, frequency filter, timing, and sampling parameters.

- By continuing real-time PoD calculation with monitoring PoD variations with respect to the suggested signal signatures, this methodology is adaptable to the need for reorganization until the desired robustness of reliability is achieved.

6. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Basu, S.; Thirumalaiselvi, A.; Sasmal, S.; Kundu, T. Nonlinear ultrasonics-based technique for monitoring damage progression in reinforced concrete structures. Ultrasonics 2024, 115, 106472. [Google Scholar] [CrossRef] [PubMed]

- Di Mucci, V.M.; Cardellicchio, A.; Ruggieri, S.; Nettis, A.; Renò, V.; Uva, G. Artificial intelligence in structural health management of existing bridges. Autom. Constr. 2024, 167, 105719. [Google Scholar] [CrossRef]

- Berrocal, C.G.; Fernandez, I.; Rempling, R. Crack monitoring in reinforced concrete beams by distributed optical fiber sensors. Struct. Infrastruct. Eng. 2020, 17, 124–139. [Google Scholar] [CrossRef]

- Grosse, C.U.; Ohtsu, M. Acoustic Emission Testing, Basics for Research—Applications in Civil Engineering, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Verstrynge, E.; Van Steen, C.; Vandecruys, E.; Wevers, M. Steel corrosion damage monitoring in reinforced concrete structures with the acoustic emission technique: A review. Constr. Build. Mater. 2022, 349, 128732. [Google Scholar] [CrossRef]

- Li, D.; Nie, J.-H.; Wang, H.; Yan, J.-B.; Hu, C.-X.; Shen, P. Damage location, quantification and characterization of steel-concrete composite beams using acoustic emission. Eng. Struct. 2023, 283, 115866. [Google Scholar] [CrossRef]

- Barile, C.; Casavola, C.; Pappalettera, G.; Vimalathithan, P.K. Damage characterization in composite materials using acoustic emission signal-based and parameter-based data. Compos. Part. B Eng. 2019, 178, 107469. [Google Scholar] [CrossRef]

- Ohtsu, M.; Mori, K.; Kawasaki, Y. Corrosion process and mechanisms of corrosion-induced cracks in reinforced concrete identified by AE analysis. Strain 2011, 47, 179–186. [Google Scholar] [CrossRef]

- Rather, A.I.; Mirgal, P.; Banerjee, S.; Laskar, A. Application of acoustic emission as damage assessment technique for performance evaluation of concrete structures: A review. Pract. Period. Struct. Des. 2023, 28, 03123003. [Google Scholar] [CrossRef]

- Van Steen, C.; Pahlavan, L.; Verstrynge, E. Smart aggregates for acoustic emission monitoring of concrete cracking and reinforcement corrosion. Constr. Build. Mater. 2024, 443, 137644. [Google Scholar] [CrossRef]

- Thirumalaiselvi, A.; Sasmal, S. Machine learning-based acoustic emission technique for corrosion-induced damage monitoring in reinforced concrete structures. Eng. Appl. Artif. Intel. 2024, 137, 109121. [Google Scholar] [CrossRef]

- ASTM E1316; Standard Terminology for NDT. ASTM International: West Conshohocken, PA, USA, 2002.

- Burud, N.B.; Kishen, J.M.C. Response based damage assessment using acoustic emission energy for plain concrete. Constr. Build. Mater. 2021, 269, 121241. [Google Scholar] [CrossRef]

- Liu, K.; Wulan, T.; Yao, Y.; Bian, M.; Bao, Y. Assessment of damage evolution of concrete beams strengthened with BFRP sheets with acoustic emission and unsupervised machine learning. Eng. Struct. 2024, 300, 117228. [Google Scholar] [CrossRef]

- Tayfur, S.; Alver, N.; Türk, E.; Menteşoğlu, M.; Ercan, E. Failure Behavior of CFRP-Strengthened Reinforced Concrete Beam–Column Joints under Reversed-Cyclic Lateral Loading: Mechanical and Acoustic Emission Observations. Struct. Eng. Int. 2024, 34, 141–152. [Google Scholar] [CrossRef]

- Tayfur, S.; Alver, N. A 3D parameter correction technique for damage assessment of structural reinforced concrete beams by acoustic emission. Constr. Build. Mater. 2019, 215, 148–161. [Google Scholar] [CrossRef]

- Aggelis, D.G.; Shiotani, T. Effect of size of inhomogeneity on the surface wave attenuation in cementitious media. J. Mater. Civ. Eng. 2012, 24, 1097–1102. [Google Scholar] [CrossRef]

- Livitsanos, G.; Shetty, N.; Hündgen, D.; Verstrynge, E.; Wevers, M.; Hemelrijck, V.; Aggelis, D.G. Acoustic emission characteristics of fracture modes in masonry materials. Constr. Build. Mater. 2018, 162, 914–922. [Google Scholar] [CrossRef]

- Boniface, A.; Saliba, J.; Sbartaï, Z.M.; Ranaivomanana, N.; Balayssac, J.P. Evaluation of the acoustic emission 3D localisation accuracy for the mechanical damage monitoring in concrete. Eng. Frac. Mech. 2020, 223, 106742. [Google Scholar] [CrossRef]

- Mirgal, P.; Pal, J.; Banerjee, S. Online acoustic emission source localization in concrete structures using iterative and evolutionary algorithms. Ultrasonics 2020, 108, 106211. [Google Scholar] [CrossRef]

- Tayfur, S.; Alver, N. Consideration of Heterogeneity in Three Dimensional Source Localization Algorithm in AE; Acoustic Emission Working Group, AEWG-62: Chicago, IL, USA, 2020. [Google Scholar]

- Tayfur, S.; Zhang, T.; Mahdi, M.; Issa, M.; Ozevin, D. Cluster-based sensor selection framework for acoustic emission source localization in concrete. Measurement 2023, 219, 113293. [Google Scholar] [CrossRef]

- Ono, K. Current understanding of mechanisms of acoustic emission. J. Strain Anal. Eng. Des. 2005, 40, 1–15. [Google Scholar] [CrossRef]

- Agletdinov, E.; Pomponi, E.; Merson, D.; Vinogradov, A. A novel Bayesian approach to acoustic emission data analysis. Ultrasonics 2016, 72, 89–94. [Google Scholar] [CrossRef] [PubMed]

- Rentala, V.K.; Kanzler, D.; Fuchs, P. POD Evaluation: The Key Performance Indicator for NDE 4.0. J. Nondestruct. Eval. 2022, 41, 20. [Google Scholar] [CrossRef]

- Georgiou, G.A. Probability of Detection (PoD) Curves Derivation, applications and limitations. Insight Non-Destruct Test. Cond. Monit. 2006, 49, 409–414. [Google Scholar] [CrossRef]

- NASA-STD-5009; Mike Suits. Nondestructive Evaluation Requirements for Fracture Critical Metallic Components. NASA: Washington, DC, USA, 2008.

- Rummel, W.D.; Matzkanin, G.A. Nondestructive Evaluation (NDE) Capabilities Data Book; Nondestructive Testing Information Analysis Center: Austin, TX, USA, 1997. [Google Scholar]

- Lee, D.; Kwon, K. Dynamic Bayesian network model for comprehensive risk analysis of fatigue-critical structural details. Reliab. Eng. Syst. Saf. 2023, 229, 108834. [Google Scholar] [CrossRef]

- Schmid, S.; Reinhardt, J.; Grosse, C.U. Spatial and temporal deep learning for defect detection with lock-in thermography. NDT E Int. 2024, 143, 03063. [Google Scholar] [CrossRef]

- Ali, M.S.S.A.; Rajagopal, P. Probability of Detection (PoD) Curves Based on Weibull Statistics. J. Nondestruct. Eval. 2018, 37, 1–13. [Google Scholar]

- Pollock, A. Probability of detection for acoustic emission. J. Acous Emis. 2017, 25, 231–237. [Google Scholar]

- Diakhate, M.; Bastidas-Arteaga, E.; Pitti, R.M.; Schoefs, F. Cluster analysis of acoustic emission activity within wood material: Towards a real-time monitoring of crack tip propagation. Eng. Fract. Mech. 2017, 180, 254–267. [Google Scholar] [CrossRef]

- Sause, M.G.R.; Linscheid, F.F.; Wiehler, M. An experimentally accessible probability of detection model for acoustic emission measurements. J. Nondestruct. Eval. 2018, 37, 17. [Google Scholar] [CrossRef]

- Rastegaev, I.A.; Yasnikov, I.S.; Rastegaeva, I.I.; Agletdinov, E.A.; Merson, D.L. Evaluating the Probability of Detecting Acoustic Emission Signals Using the Amplitude Discrimination Method with a Low Signal-to-Noise Ratio. Russ. J. Nondestruct. Test. 2022, 58, 157–166. [Google Scholar] [CrossRef]

- Niri, E.D.; Farhidzadeh, A.; Salamone, S. Adaptive multisensor data fusion for acoustic emission source localization in noisy environment. Struct. Health Monit. 2013, 12, 59–77. [Google Scholar] [CrossRef]

- Barat, V.; Marchenkov, A.; Ivanov, V.; Bardakov, V.; Elizarov, S.; Machikhin, A. Empirical Approach to Defect Detection Probability by Acoustic Emission Testing. Appl. Sci. 2021, 11, 9429. [Google Scholar] [CrossRef]

- Ozevin, D.; Zhang, L. The probability of detection for acoustic emission to assess the crack growth in steel structures. In Proceedings of the International Conference on Structural Health Monitoring of Intelligent Infrastructure, Porto, Portugal, 30 June–2 July 2021. ISSN 2564-3738. [Google Scholar]

- Oh, T.M.; Kim, M.K.; Lee, J.W.; Kim, H.; Kim, M.J. Experimental Investigation on Effective Distances of Acoustic Emission in Concrete Structures. Appl. Sci. 2020, 10, 6051. [Google Scholar] [CrossRef]

- Wu, X.; Yan, Q.; Hedayat, A.; Wang, X. The influence law of concrete aggregate particle size on acoustic emission wave attenuation. Sci. Rep. 2021, 11, 22685. [Google Scholar] [CrossRef]

- Sun, X.; Fan, S.; Liu, C. Attenuation characteristics of concrete using smart aggregate transducers: Experiments and numerical simulations of P-wave propagation. J. Intell. Mater. Syst. Struct. 2024, 35, 556–572. [Google Scholar] [CrossRef]

- Li, S.-L.; Hou, S.-T.; Wu, G.-M.; Sun, W.-C.; Jiang, N. Damage pattern recognition of concrete hollow slab with analysis of different AE monitoring positions. Appl. Acous. 2024, 219, 109916. [Google Scholar] [CrossRef]

- Dai, J.; Liu, J.; Zhou, L.; He, X. Crack Pattern Recognition Based on Acoustic Emission Waveform Features. Rock. Mech. Rock. Eng. 2023, 56, 1063–1076. [Google Scholar] [CrossRef]

- Tayfur, S.; Alver, N. Attenuation and frequency characteristics of acoustic waves in steel and synthetic fiber-reinforced concrete: 3D-pct and unsupervised pattern recognition. Appl. Sci. 2022, 12, 12976. [Google Scholar] [CrossRef]

- Deresse, N.E.; Van Steen, C.; Soete, J.; Sarem, M.; Vanhulst, J.; Wevers, M.; François, S.; Verstrynge, E. Fracture mode analysis of cementitious mortars by simultaneous application of 4D-XCT and acoustic emission technique. Constr. Build. Mater. 2024, 419, 135486. [Google Scholar] [CrossRef]

- Silva, R.R.d.; Padu, G.X.d. Nondestructive inspection reliability: State of the art. In Nondestructive Testing Methods and New Applications; InTech: Hong Kong, 2012; pp. 1–22. [Google Scholar]

- Gagar, D.; Foote, P.; Irving, P.E. Effects of loading and sample geometry on acoustic emission generation during fatigue crack growth: Implications for structural health monitoring. Int. J. Fatigue 2015, 81, 117–127. [Google Scholar] [CrossRef]

- Prakash, N.; Nieberl, D.; Mayer, M.; Schuster, A. Learning defects from aircraft NDT data. NDT E Int. 2023, 138, 102885. [Google Scholar] [CrossRef]

- Mazzatura, I.; Casas, J.R.; Salvatore, W.; Caprili, S. Reliability of ultrasonic tomography in detecting grouting defects in post-tensioned structures by PoD curves. Eng. Struct. 2024, 302, 117352. [Google Scholar] [CrossRef]

- Kwon, K.; Frangopol, D.M. Bridge fatigue assessment and management using reliability-based crack growth and probability of detection models. Probabilistic Eng. Mech. 2011, 26, 471–480. [Google Scholar] [CrossRef]

- ASTM C39/C39M-21; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- ASTM E 976; Standard Guide for Determining the Reproducibility of Acoustic Emission Sensor Response. ASTM International: West Conshohocken, PA, USA, 2015.

- Tinkey, B.V.; Fowler, T.J.; Klingner, R.E. Nondestructive Testing of Prestressed Bridge Girders with Distributed Damage; Research Report 1857-2; Center for Transportation Research, The University of Texas at Austin: Austin, TX, USA, 2020. [Google Scholar]

- Aggelis, D.G. Classification of cracking mode in concrete by acoustic emission parameters. Mech. Res. Comm. 2011, 38, 153–157. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tayfur, S. Signal-Centric Framework Based on Probability of Detection for Real-Time Reliability of Concrete Damage Inspection. Appl. Sci. 2025, 15, 18. https://doi.org/10.3390/app15010018

Tayfur S. Signal-Centric Framework Based on Probability of Detection for Real-Time Reliability of Concrete Damage Inspection. Applied Sciences. 2025; 15(1):18. https://doi.org/10.3390/app15010018

Chicago/Turabian StyleTayfur, Sena. 2025. "Signal-Centric Framework Based on Probability of Detection for Real-Time Reliability of Concrete Damage Inspection" Applied Sciences 15, no. 1: 18. https://doi.org/10.3390/app15010018

APA StyleTayfur, S. (2025). Signal-Centric Framework Based on Probability of Detection for Real-Time Reliability of Concrete Damage Inspection. Applied Sciences, 15(1), 18. https://doi.org/10.3390/app15010018