Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations

Abstract

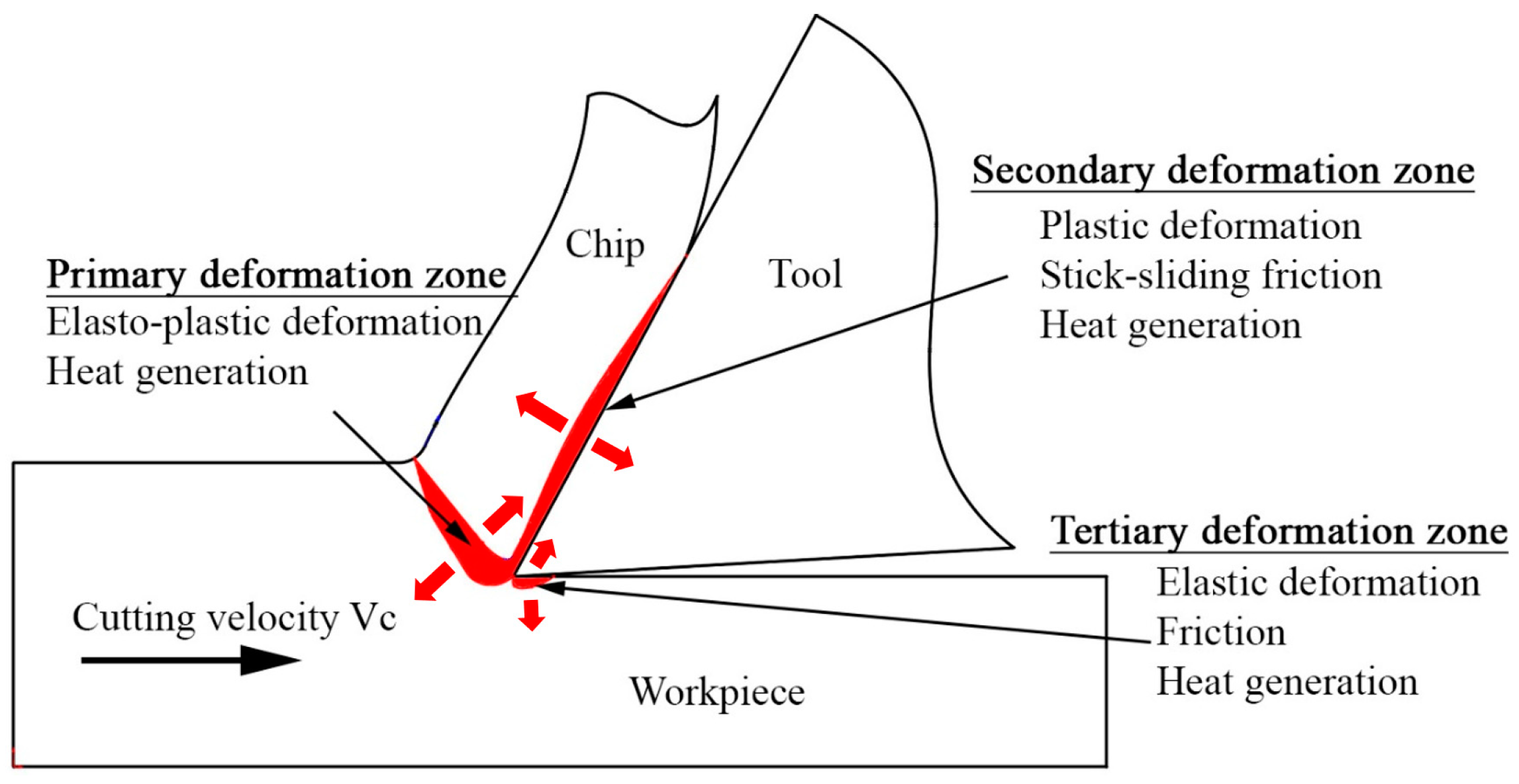

:1. Introduction

2. Materials and Methods

2.1. The CCD Experimental Design

2.2. Analysis of Tool Geometry in Hard Turning

- -

- The portion of the nose radius involved in the cutting process:

- -

- Local rake angle:

- -

- Local undeformed chip thickness:

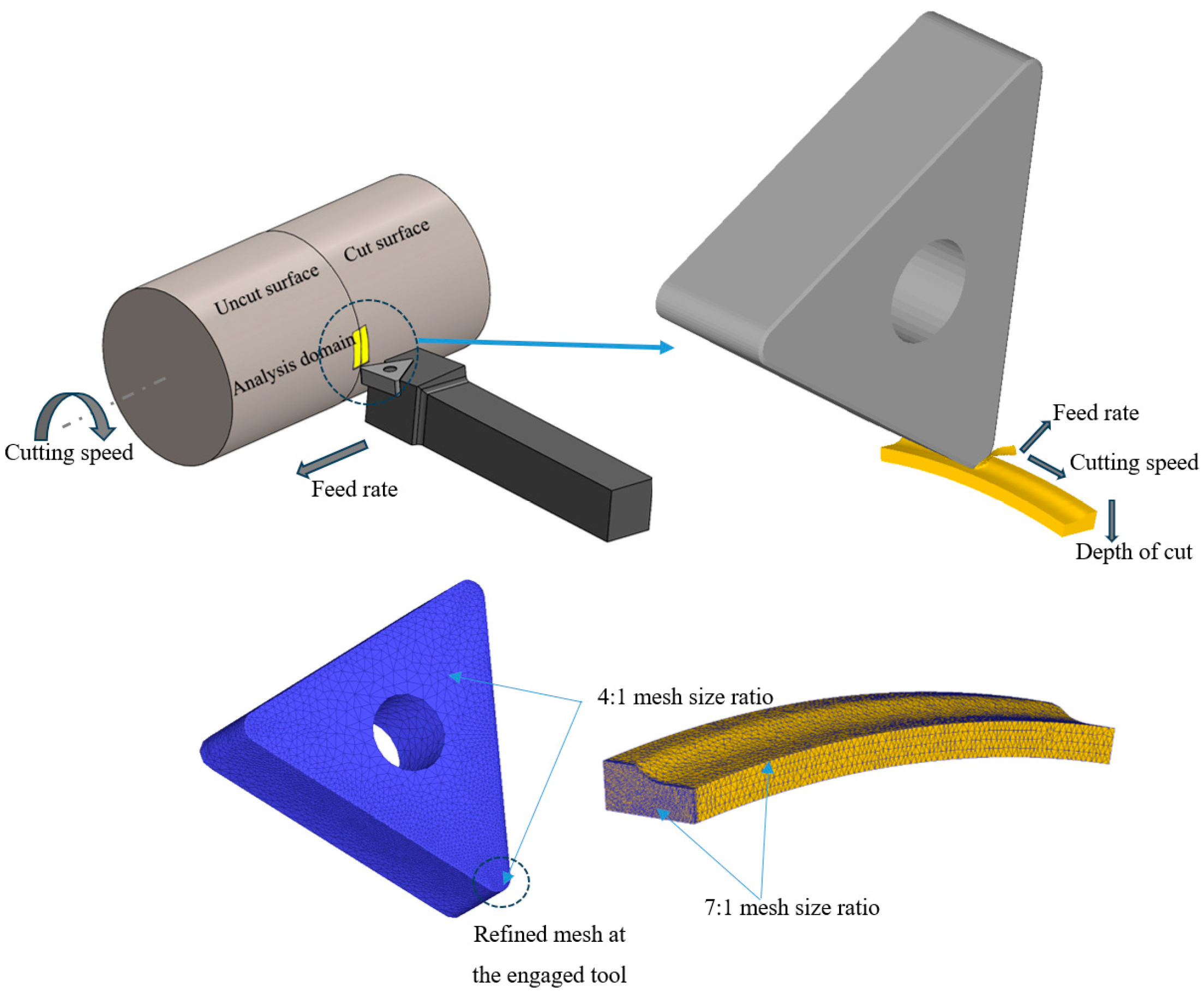

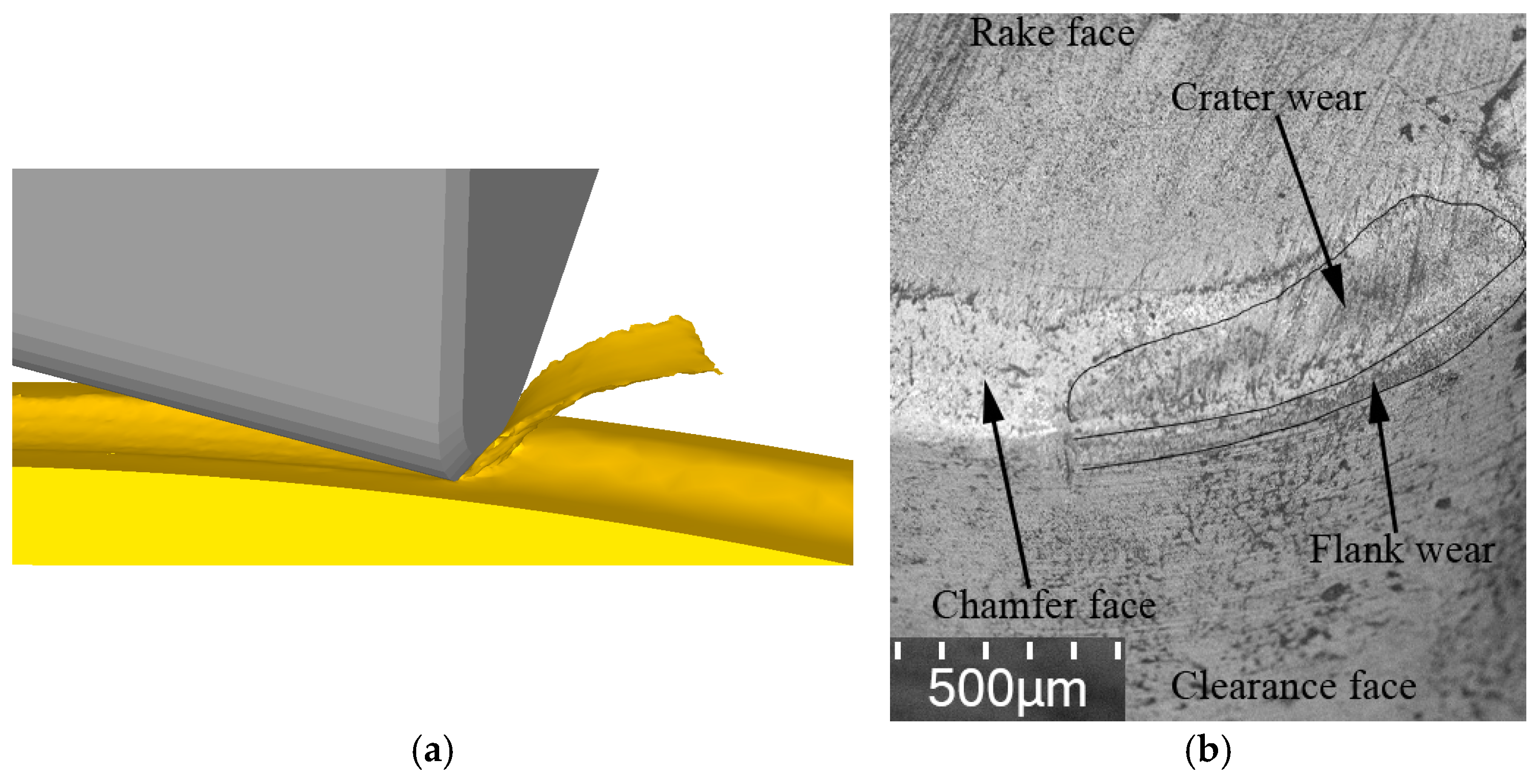

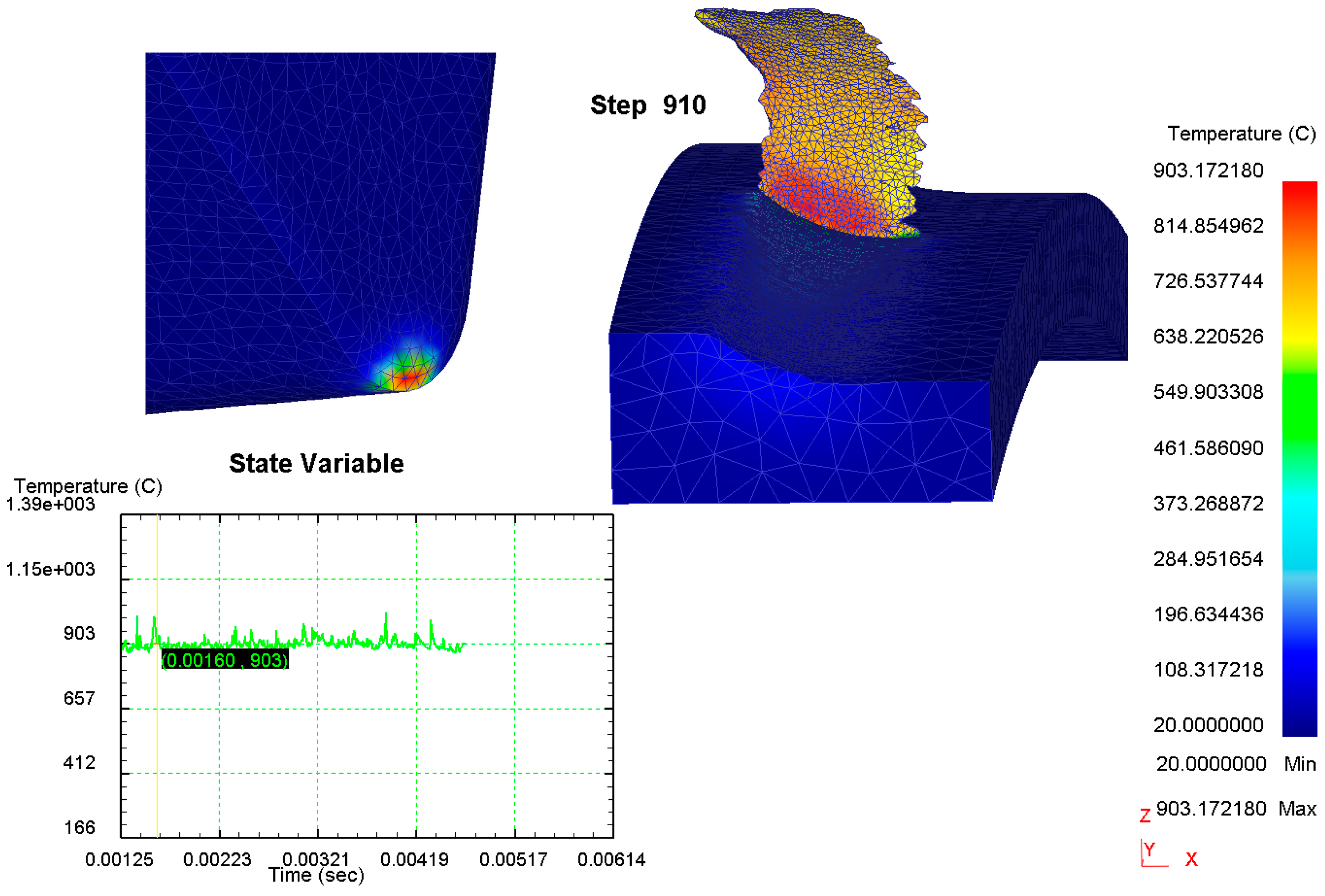

2.3. FEM Simulation

2.4. Experimental Procedure

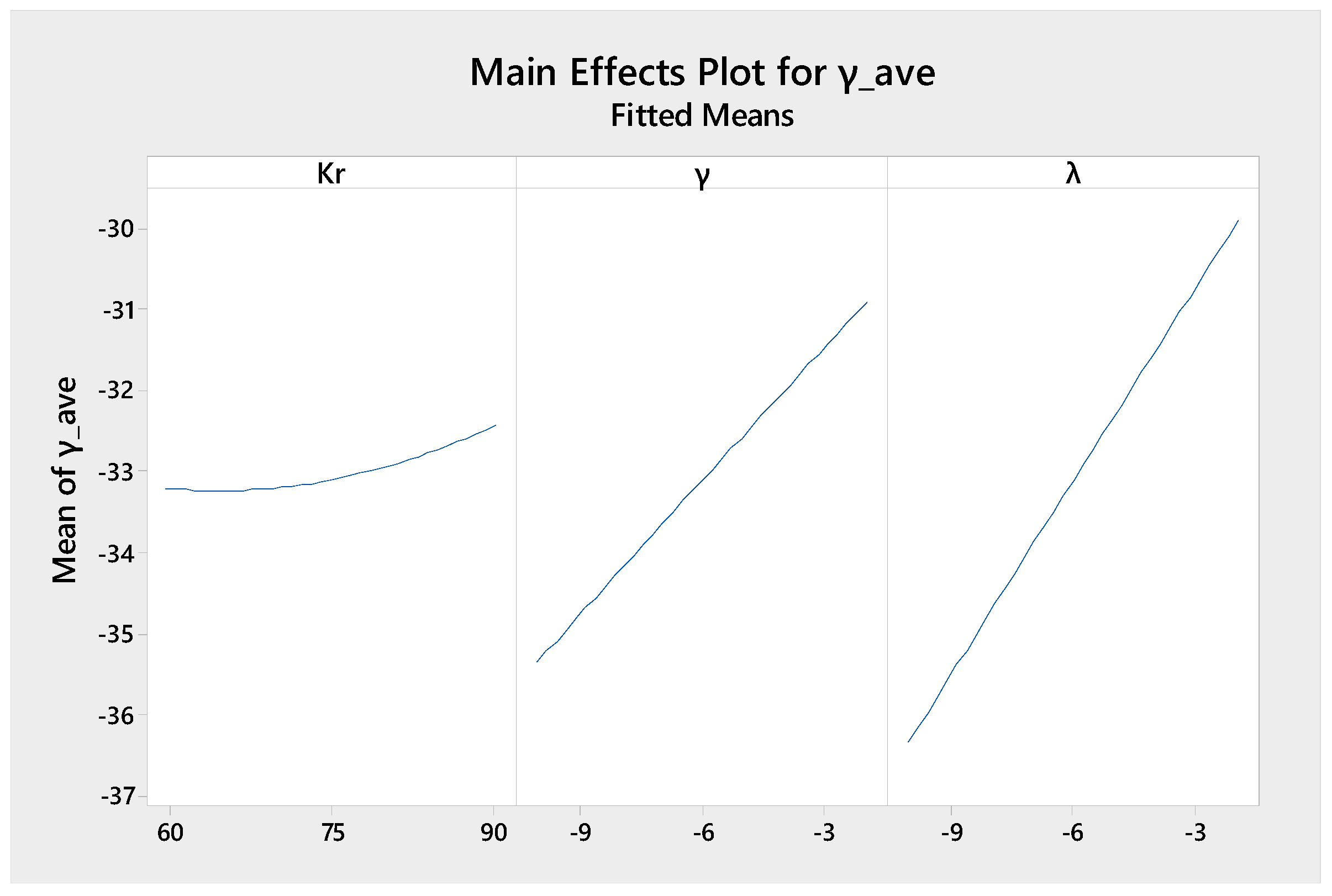

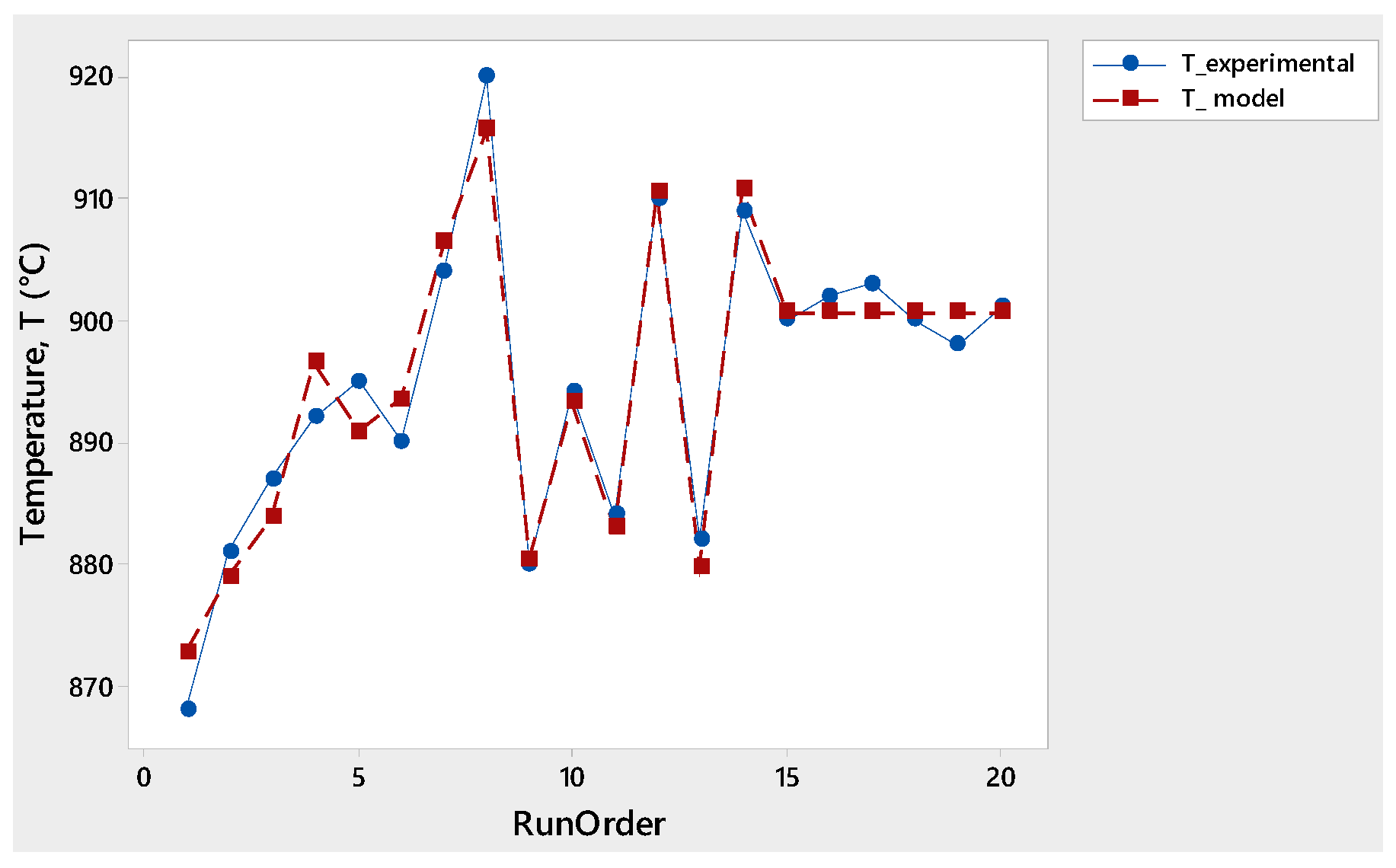

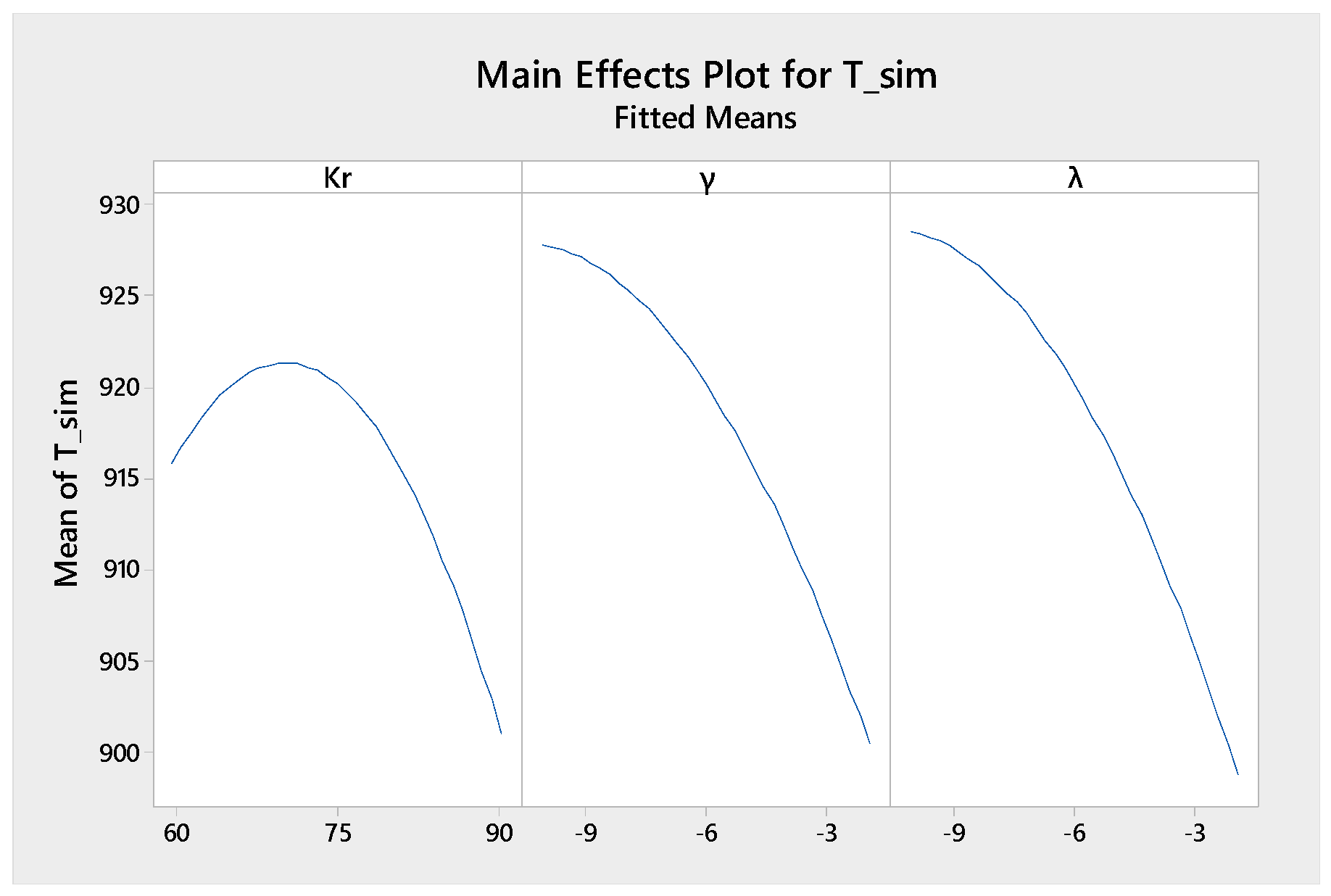

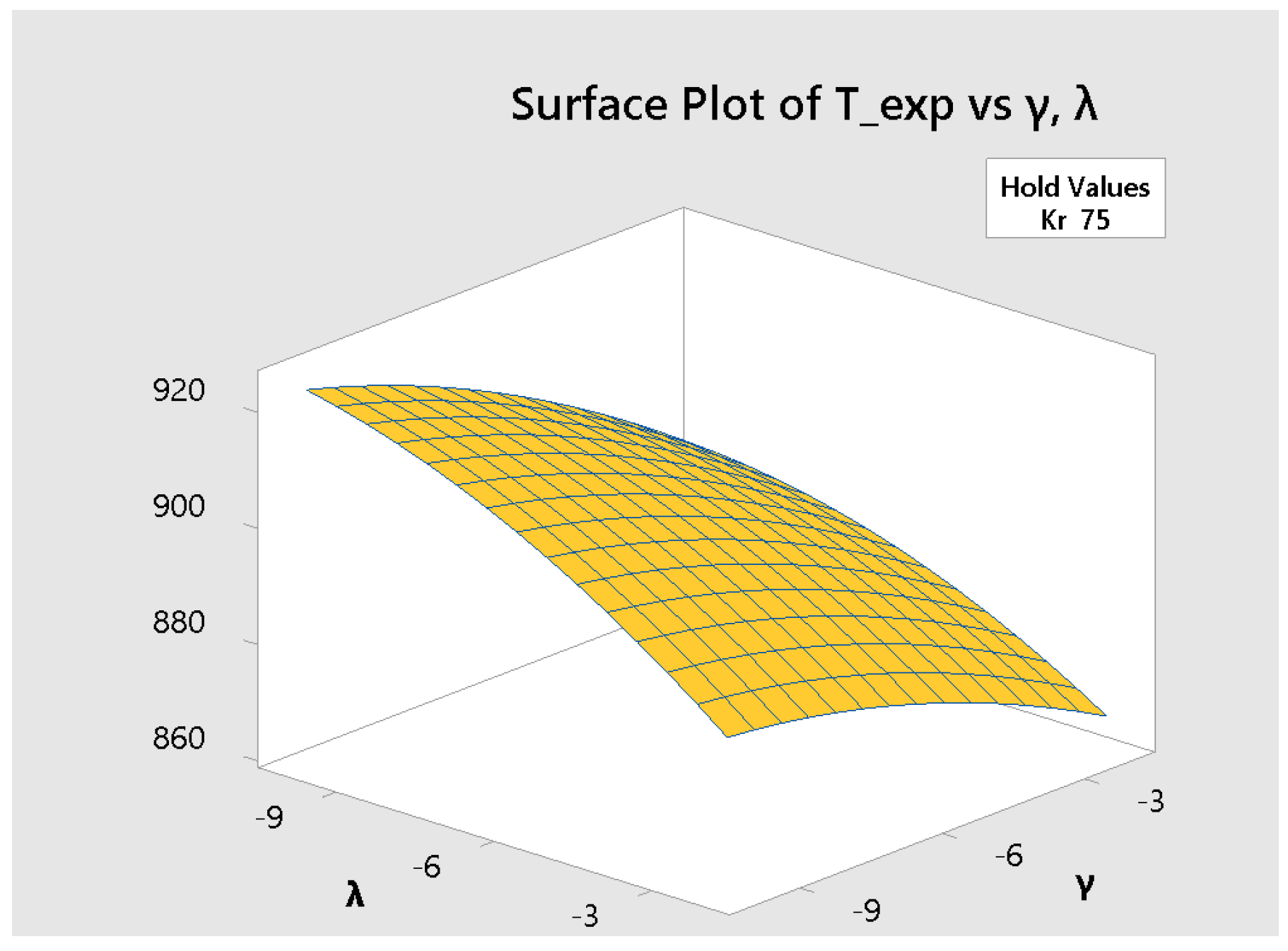

3. Results and Discussion

4. Conclusions

- -

- The cutting temperature from the experiment and the simulation results have consistent values, reaching about 900 °C. The difference in the experiment and simulation results is small—approximately 2%.

- -

- Only the tool-nose radius cuts during the hard-turning operation, and the chip makes contact with the cutting edge’s chamfered face. At each cutting point, the local tool-geometry parameters and the thickness of the undeformed chip change, and the local rake angle becomes noticeably negative.

- -

- Increasing the negative rake angle and negative inclination angle improves the local negative rake angle of the cutting-edge elements at the tool-nose radius during the hard-turning process, accounting for 65.84% and 31.43%, respectively.

- -

- The most significant factor influencing cutting temperature is the inclination angle, which accounts for 40.75% of the total variability. The rake angle has a smaller effect, accounting for 32.39% of the total variability, and the cutting-edge angle accounts for 7.03%.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Haq, A.N.; Tamizharasan, T. Investigation of the effects of cooling in hard turning operations. Int. J. Adv. Manuf. Technol. 2006, 30, 808–816. [Google Scholar]

- Abukhshim, N.A.; Mativenga, P.T.; Sheikh, M.A. Heat generation and temperature prediction in metal cutting: A review and implications for high-speed machining. Int. J. Mach. Tools Manuf. 2006, 46, 782–800. [Google Scholar] [CrossRef]

- Silva, M.B.; Wallbank, J. Cutting temperature: Prediction and measurement methods—A review. J. Mater. Process. Technol. 1999, 88, 195–202. [Google Scholar] [CrossRef]

- Hao, G.; Liu, Z. The heat partition into cutting tool at tool-chip contact interface during cutting process: A review. Int. J. Adv. Manuf. Technol. 2020, 108, 393–411. [Google Scholar] [CrossRef]

- Bhirud, N.L.; Gawande, R.R. Measurement and prediction of cutting temperatures during dry milling: Review and discussions. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 5135–5158. [Google Scholar] [CrossRef]

- Grzesik, W. Heat in metal cutting. In Advanced Machining Processes of Metallic Materials; Elsevier: Amsterdam, The Netherlands, 2017; pp. 163–182. [Google Scholar]

- Trent, E.M.; Wright, P.K. Heat in metal cutting. In Metal Cutting; Butterworth-Heinemann: Oxford, UK, 2000; pp. 97–131. [Google Scholar]

- Wang, Y.; Wang, Z.; Ni, P.; Wang, D.; Lu, Y.; Lu, H.; Guo, S.; Chen, Z. Experimental and numerical study on regulation of cutting temperature during the circular sawing of 45 steel. Coatings 2023, 13, 758. [Google Scholar] [CrossRef]

- Puls, H.; Klocke, F.; Veselovac, D. FEM-based prediction of heat partition in dry metal cutting of AISI 1045. Int. J. Adv. Manuf. Technol. 2016, 86, 737–745. [Google Scholar] [CrossRef]

- Davim, J.P. Machining of Hard Materials; Springer: London, UK, 2011. [Google Scholar]

- Dessoly, V.; Melkote, S.N.; Lescalier, C. Modeling and verification of cutting tool temperature in rotary tool turning of hardened steels. Int. J. Mach. Tools Manuf. 2004, 44, 1463–1470. [Google Scholar] [CrossRef]

- Diniz, A.E.; Oliveira, A.J. Hard turning of interrupted surfaces using CBN tool. J. Mater. Process. Technol. 2008, 195, 275–281. [Google Scholar] [CrossRef]

- Grezesik, W. Influence of tool wear on surface roughness in HT using differently shaped ceramic tools. Wear 2008, 265, 327–335. [Google Scholar] [CrossRef]

- Bartarya, G.; Choudhury, S.K. State of the art in hard turning. Int. J. Mach. Tools Manuf. 2012, 53, 1–14. [Google Scholar] [CrossRef]

- Lazoglu, I.; Altintas, Y. Prediction of tool and chip temperature in continuous and interrupted machining. Int. J. Mach. Tools Manuf. 2002, 42, 1011–1022. [Google Scholar] [CrossRef]

- Mathivanan, A.; Sudeshkumar, M.P.; Ramadoss, R.; Ezilarasan, C.; Raju, G.; Jayaseelan, V. Finite element simulation and regression modeling of machining attributes on turning AISI 304 stainless steel. Manuf. Rev. 2021, 8, 24. [Google Scholar] [CrossRef]

- Liu, Z.; Yue, C.; Li, X.; Liu, X.; Liang, S.Y.; Wang, L. Research on tool wear based on 3D FEM simulation for milling process. J. Manuf. Mater. Process. 2020, 4, 121. [Google Scholar] [CrossRef]

- Elsadek, A.A.; Gaafer, A.M.; Mohamed, S.S. Prediction and optimization of cutting temperature on hard turning. SN Appl. Sci. 2020, 2, 540. [Google Scholar] [CrossRef]

- Abrão, A.M.; Aspinwall, D.K.; Wise, M.H.L. Tool Life and Workpiece Surface Integrity Evaluations when Machining Hardened AISI H13 and AISI E52100 Steels with Conventional Ceramic and PCBN Tool Materials; Society of Manufacturing Engineers: Southfield, MI, USA, 1995; pp. 1–7. [Google Scholar]

- Santhanakrishnan, M.; Sivasakthivel, P.S.; Sudhakaran, R. Modeling of geometrical and machining parameters on temperature rise while machining Al 6351 using response surface methodology and genetic algorithm. J. Braz. Soc. Mech. Sci. Eng. 2017, 39, 487–496. [Google Scholar] [CrossRef]

- Xu, D.; Ding, L.; Liu, Y.; Zhou, J.; Liao, Z. Investigation of the Influence of Tool Rake Angles on Machining of Inconel 718. J. Manuf. Mater. Process. 2021, 5, 100. [Google Scholar] [CrossRef]

- Saglam, H.; Unsacar, F.; Yaldiz, S. Investigation of the effect of rake angle and approaching angle on main cutting force and tool tip temperature. Int. J. Mach. Tools Manuf. 2006, 46, 132–141. [Google Scholar] [CrossRef]

- Shah, D.; Bhavsar, S. Effect of tool nose radius and machining parameters on cutting force, cutting temperature and surface roughness—An experimental study of Ti-6Al-4V (ELI). Mater. Today Proc. 2020, 22, 1977–1986. [Google Scholar] [CrossRef]

- Dutta, S.; Narala, S.K.R. Effect of tool nose radius in turning of novel Mg alloy. Mater. Today Proc. 2021, 38, 2675–2679. [Google Scholar] [CrossRef]

- Duc, P.M.; Dai, M.D.; Giang, L.H. Modeling and optimizing the effects of insert angles on hard turning performance. Math. Probl. Eng. 2021, 2021, 9924427. [Google Scholar] [CrossRef]

- Tzotzis, A.; Garcia-Hernandez, C.; Talón, J.L.H.; Kyratsis, P. Influence of the nose radius on the machining forces induced during AISI-4140 hard turning: A CAD-based and 3D FEM approach. Micromachines 2020, 11, 798. [Google Scholar] [CrossRef] [PubMed]

- Tzotzis, A.; Garcia-Hernandez, C.; Talón, J.L.H.; Kyratsis, P. 3D FE Modelling of machining forces during AISI 4140 hard turning. Strojniški Vestn. J. Mech. Eng. 2020, 66, 467–478. [Google Scholar] [CrossRef]

- Haglund, A.J.; Kishawy, H.A.; Rogers, R.J. An exploration of friction models for the chip-tool interface using an Arbitrary Lagrangian-Eulerian finite element model. Wear 2008, 265, 452–460. [Google Scholar] [CrossRef]

- Zhang, S.; Li, B.; Li, J.; Man, J. Effects of constitutive model parameters on finite element simulation process for hard milling of AISI H13 steel. MM Sci. J. 2021, 2021, 5234–5240. [Google Scholar] [CrossRef]

- Davies, M.; Ueda, T.; M’Saoubi, R.; Mullany, B.; Cooke, A. On the measurement of temperature in material removal processes. CIRP Ann. 2007, 56, 581–604. [Google Scholar] [CrossRef]

- Weng, J.; Saelzer, J.; Berger, S.; Zhuang, K.; Bagherzadeh, A.; Budak, E.; Biermann, D. Analytical and experimental investigations of rake face temperature considering temperature-dependent thermal properties. J. Mater. Process. Technol. 2023, 314, 117905. [Google Scholar] [CrossRef]

- Guimaraes, B.M.P.; Fernandes, C.M.D.S.; de Figueiredo, D.A.; da Silva, F.S.C.P.; Miranda, M.G.M. Cutting temperature measurement and prediction in machining processes: Comprehensive review and future perspectives. Int. J. Adv. Manuf. Technol. 2022, 120, 2849–2878. [Google Scholar] [CrossRef]

- Hao, G.; Tang, A.; Zhang, Z.; Xing, H.; Xu, N.; Duan, R. Finite element simulation of orthogonal cutting of H13-hardened steel to evaluate the influence of coatings on cutting temperature. Coatings 2024, 14, 293. [Google Scholar] [CrossRef]

| Tool-Geometry Parameter | Unit | Levels | ||||

|---|---|---|---|---|---|---|

| −α | −1 | 0 | +1 | +α | ||

| Kr | (°) | 60 | 66 | 75 | 84 | 90 |

| γ | (°) | −2 | −3.6 | −6 | −8.4 | −10 |

| λ | (°) | −2 | −3.6 | −6 | −8.4 | −10 |

| No. | Factors | No. | Factors | ||||

|---|---|---|---|---|---|---|---|

| Kr | γ | λ | Kr | γ | λ | ||

| 1 | +1 | −1 | −1 | 11 | 0 | −α | 0 |

| 2 | −1 | −1 | −1 | 12 | 0 | +α | 0 |

| 3 | +1 | +1 | −1 | 13 | 0 | 0 | −α |

| 4 | −1 | +1 | −1 | 14 | 0 | 0 | +α |

| 5 | +1 | −1 | +1 | 15 | 0 | 0 | 0 |

| 6 | −1 | −1 | +1 | 16 | 0 | 0 | 0 |

| 7 | +1 | +1 | +1 | 17 | 0 | 0 | 0 |

| 8 | −1 | +1 | +1 | 18 | 0 | 0 | 0 |

| 9 | +α | 0 | 0 | 19 | 0 | 0 | 0 |

| 10 | −α | 0 | 0 | 20 | 0 | 0 | 0 |

| Cutting Speed v (m/min) | Feed Rate f (mm/rev) | Depth of Cut dw (mm) |

|---|---|---|

| 150 | 0.08 | 0.2 |

| A (MPa) | B (MPa) | n | C | m | (1/s) | (°C) | (°C) |

|---|---|---|---|---|---|---|---|

| 908.54 | 321.39 | 0.278 | 0.028 | 1.18 | 1.0 | 27 | 1475 |

| Thermo-Mechanical Properties | AISI H13 | Ceramic Tool | TiN Coating |

|---|---|---|---|

| Young’s Modulus (GPa) | 211 | 145 | - |

| Poisson ratio | 0.28 | 0.22 | 0.25 |

| Density (kg/m3) | 7800 | 3500 | 4650 |

| Thermal conductivity (W/m·°C) | 37 | 24 | 23.5 |

| Hardness (HV) | 544 | - | 2300 |

| No. | Cutting-Edge Angle Kr (°) | Rake Angle γ (°) | Inclination Angle λ (°) | Average Local Rake Angle γ_ave (°) | Simulated Temperature T_sim (°C) | Experimental Temperature T_exp (°C) |

|---|---|---|---|---|---|---|

| 1 | 84 | −3.6 | −3.6 | −29.7 | 888 | 868 |

| 2 | 66 | −3.6 | −3.6 | −30 | 900 | 881 |

| 3 | 84 | −8.4 | −3.6 | −31.7 | 905 | 887 |

| 4 | 66 | −8.4 | −3.6 | −33.2 | 914 | 892 |

| 5 | 84 | −3.6 | −8.4 | −33.9 | 912 | 895 |

| 6 | 66 | −3.6 | −8.4 | −33.3 | 911 | 890 |

| 7 | 84 | −8.4 | −8.4 | −35.9 | 922 | 904 |

| 8 | 66 | −8.4 | −8.4 | −36.5 | 939 | 920 |

| 9 | 90 | −6.0 | −6.0 | −32.4 | 903 | 880 |

| 10 | 60 | −6.0 | −6.0 | −33.2 | 916 | 894 |

| 11 | 75 | −2.0 | −6.0 | −30.9 | 903 | 884 |

| 12 | 75 | −10.0 | −6.0 | −35.3 | 927 | 910 |

| 13 | 75 | −6.0 | −2.0 | −29.9 | 902 | 882 |

| 14 | 75 | −6.0 | −10.0 | −36.3 | 927 | 909 |

| 15 | 75 | −6.0 | −6.0 | −33.1 | 919 | 900 |

| 16 | 75 | −6.0 | −6.0 | −33.1 | 922 | 902 |

| 17 | 75 | −6.0 | −6.0 | −33.1 | 921 | 903 |

| 18 | 75 | −6.0 | −6.0 | −33.1 | 920 | 900 |

| 19 | 75 | −6.0 | −6.0 | −33.1 | 919 | 898 |

| 20 | 75 | −6.0 | −6.0 | −33.1 | 920 | 901 |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Model | 9 | 73.7959 | 99.98% | 73.7959 | 8.1995 | 6783.94 | 0.000 |

| Linear | 3 | 72.5213 | 98.26% | 72.5213 | 24.1738 | 20,000.32 | 0.000 |

| Kr | 1 | 0.7243 | 0.98% | 0.7243 | 0.7243 | 599.22 | 0.000 |

| γ | 1 | 23.1987 | 31.43% | 23.1987 | 23.1987 | 19,193.58 | 0.000 |

| λ | 1 | 48.5984 | 65.84% | 48.5984 | 48.5984 | 40,208.15 | 0.000 |

| Square | 3 | 0.1496 | 0.20% | 0.1496 | 0.0499 | 41.26 | 0.000 |

| 1 | 0.1483 | 0.20% | 0.1426 | 0.1426 | 118.01 | 0.000 | |

| γ | 1 | 0.0006 | 0.00% | 0.0007 | 0.0007 | 0.60 | 0.458 |

| λ | 1 | 0.0007 | 0.00% | 0.0007 | 0.0007 | 0.60 | 0.458 |

| 2-Way Interaction | 3 | 1.1250 | 1.52% | 1.1250 | 0.3750 | 310.26 | 0.000 |

| γ | 1 | 0.7200 | 0.98% | 0.7200 | 0.7200 | 595.70 | 0.000 |

| λ | 1 | 0.4050 | 0.55% | 0.4050 | 0.4050 | 335.08 | 0.000 |

| λ | 1 | 0.0000 | 0.00% | 0.0000 | 0.0000 | 0.00 | 1.000 |

| Error | 10 | 0.0121 | 0.02% | 0.0121 | 0.0012 | ||

| Lack-of-Fit | 5 | 0.0121 | 0.02% | 0.0121 | 0.0024 | ||

| Pure Error | 5 | 0.0000 | 0.00% | 0.0000 | 0.0000 | ||

| Total | 19 | 73.8080 | 100.00% |

| Source | DF | Seq SS | Contribution | Adj SS | Adj MS | F-Value | p-Value |

|---|---|---|---|---|---|---|---|

| Model | 9 | 2736.17 | 95.20% | 2736.17 | 304.02 | 22.06 | 0.000 |

| Linear | 3 | 2304.11 | 80.17% | 2304.11 | 768.04 | 55.72 | 0.000 |

| Kr | 1 | 202.04 | 7.03% | 202.04 | 202.04 | 14.66 | 0.003 |

| γ | 1 | 930.89 | 32.39% | 930.89 | 930.89 | 67.54 | 0.000 |

| λ | 1 | 1171.18 | 40.75% | 1171.18 | 1171.18 | 84.97 | 0.000 |

| Square | 3 | 394.68 | 13.73% | 394.68 | 131.56 | 9.55 | 0.003 |

| 1 | 319.34 | 11.11% | 352.95 | 352.95 | 25.61 | 0.000 | |

| γ | 1 | 21.68 | 0.75% | 28.12 | 28.12 | 2.04 | 0.184 |

| λ | 1 | 53.67 | 1.87% | 53.67 | 53.67 | 3.89 | 0.077 |

| 2-Way Interaction | 3 | 37.38 | 1.30% | 37.38 | 12.46 | 0.90 | 0.473 |

| γ | 1 | 21.13 | 0.74% | 21.12 | 21.12 | 1.53 | 0.244 |

| λ | 1 | 6.12 | 0.21% | 6.12 | 6.12 | 0.44 | 0.520 |

| λ | 1 | 10.13 | 0.35% | 10.13 | 10.13 | 0.73 | 0.411 |

| Error | 10 | 137.83 | 4.80% | 137.83 | 13.78 | ||

| Lack-of-Fit | 5 | 122.49 | 4.26% | 122.49 | 24.50 | 7.99 | 0.020 |

| Pure Error | 5 | 15.33 | 0.53% | 15.33 | 3.07 | ||

| Total | 19 | 2874.00 | 100.00% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Minh Duc, P.; Hieu Giang, L.; Nguyen, V.T. Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations. Appl. Sci. 2025, 15, 983. https://doi.org/10.3390/app15020983

Minh Duc P, Hieu Giang L, Nguyen VT. Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations. Applied Sciences. 2025; 15(2):983. https://doi.org/10.3390/app15020983

Chicago/Turabian StyleMinh Duc, Pham, Le Hieu Giang, and Van Thuc Nguyen. 2025. "Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations" Applied Sciences 15, no. 2: 983. https://doi.org/10.3390/app15020983

APA StyleMinh Duc, P., Hieu Giang, L., & Nguyen, V. T. (2025). Analyzing Cutting Temperature in Hard-Turning Technique with Standard Inserts Through Both Simulation and Experimental Investigations. Applied Sciences, 15(2), 983. https://doi.org/10.3390/app15020983