A Comprehensive Analysis of Environmental Emissions from Trenchless CIPP and Excavation Technologies for Sanitary Sewers

Abstract

1. Introduction and Background

2. Cured-in-Place Pipe

3. Excavation Technologies

4. Greenhouse Gas Emissions

5. Data Collection for GHG Emissions

5.1. Carbon Footprint

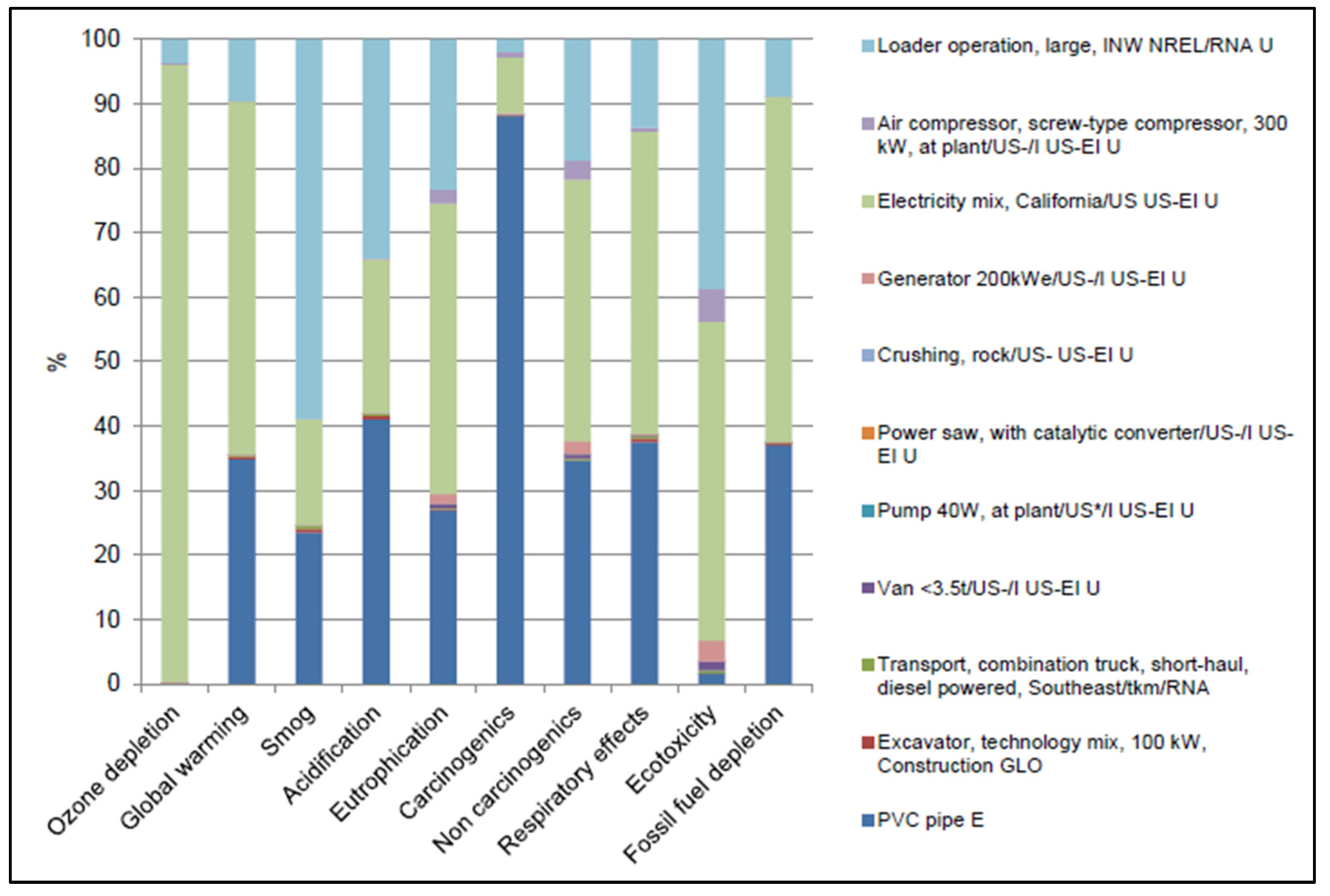

5.2. Case Study

5.3. Ecological Impact Assessment

6. SimaPro Software

7. Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts

- Ozone depletion (kg CFC-11 equivalents);

- Global warming (kg CO2 equivalents);

- Smog (kg O3 equivalents);

- Acidification (kg SO2 equivalents);

- Eutrophication (kg N equivalents);

- Carcinogenics (Comparative Toxic Units for morbidity);

- Non-carcinogenics (CTUh);

- Respiratory effects (kg particulate matter 2.5 equivalents);

- Ecotoxicity (CTUs for aquatic toxicity and fossil fuel depletion in MJ).

8. Comparative Review of CIPP and ET

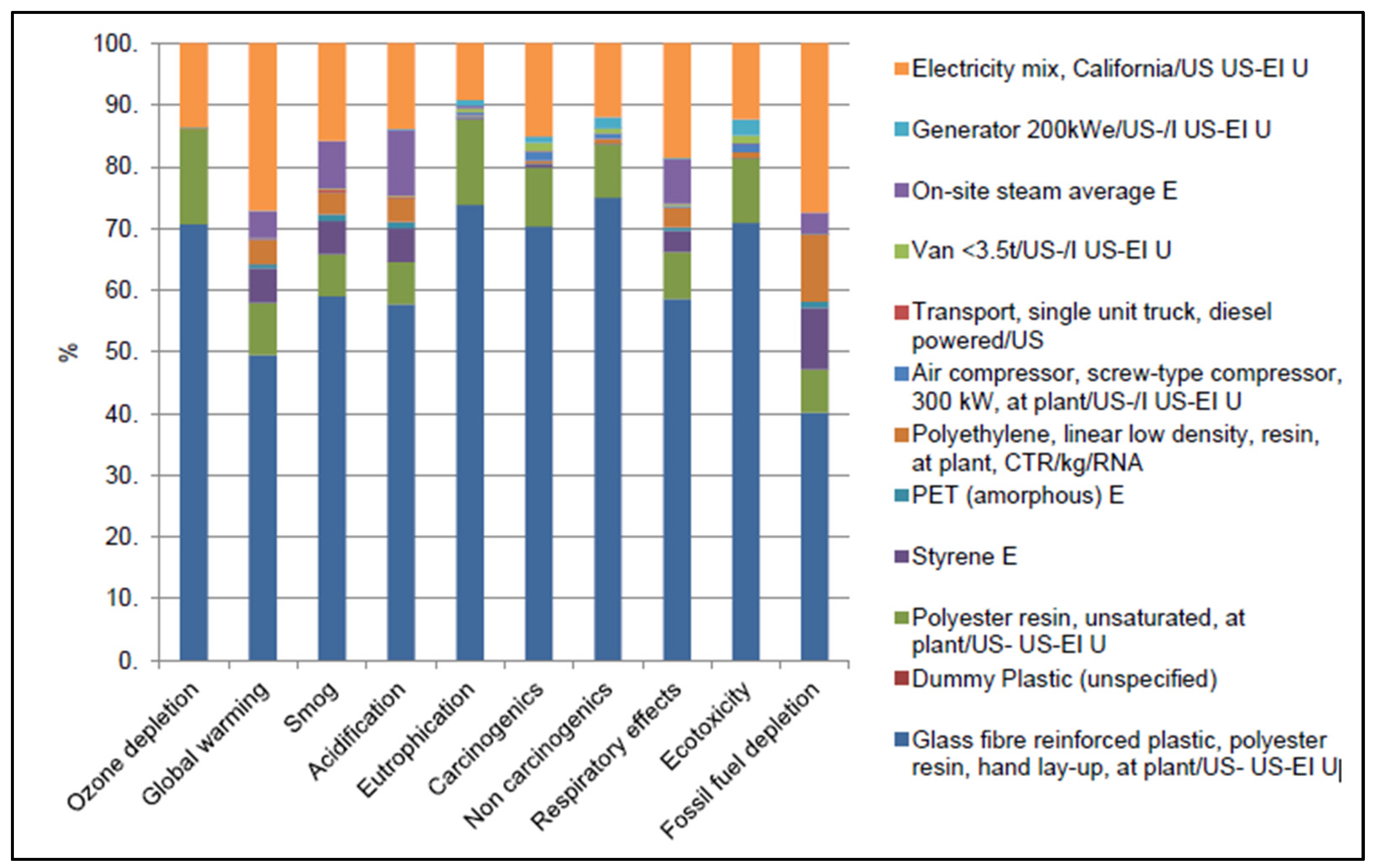

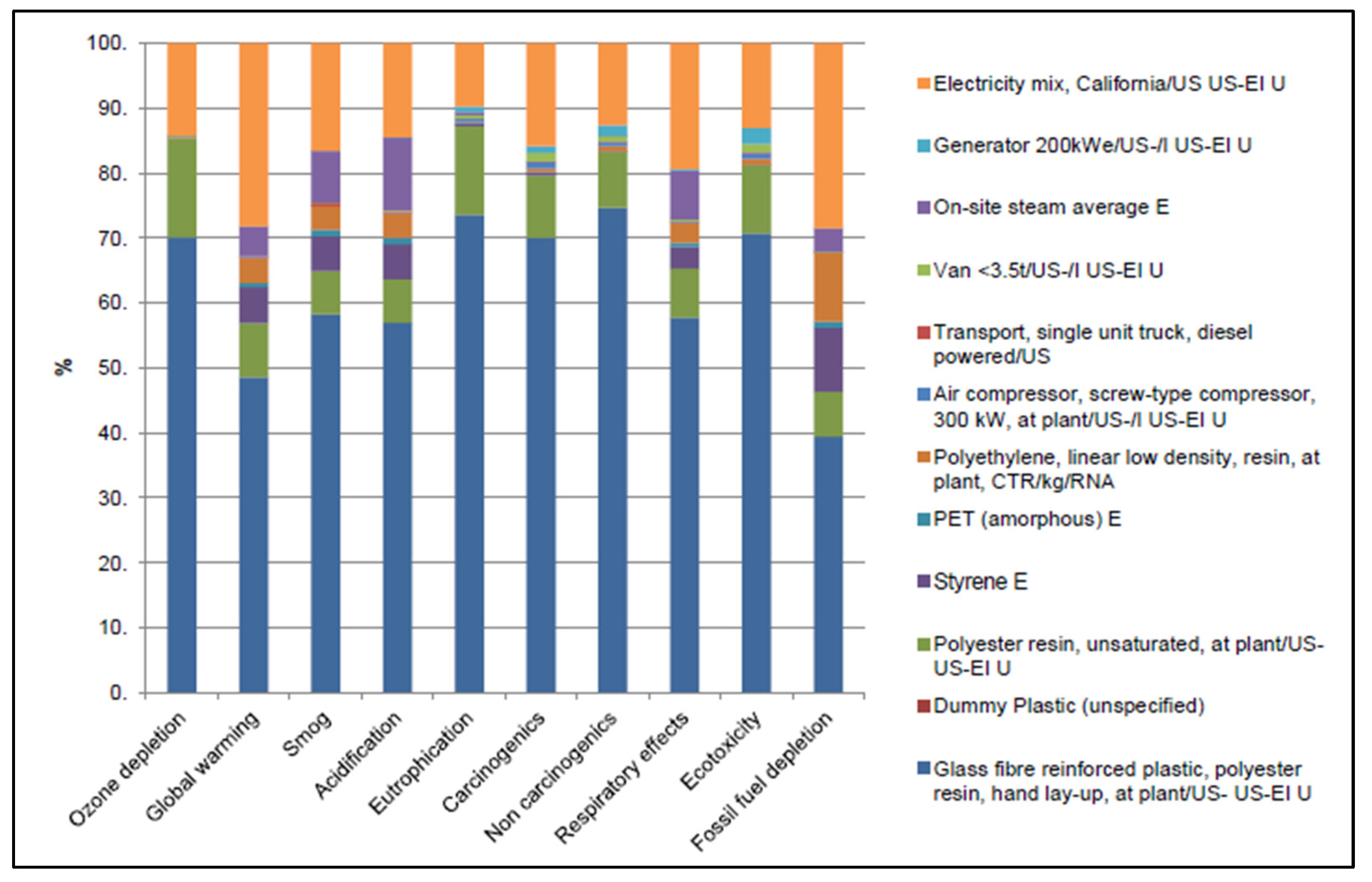

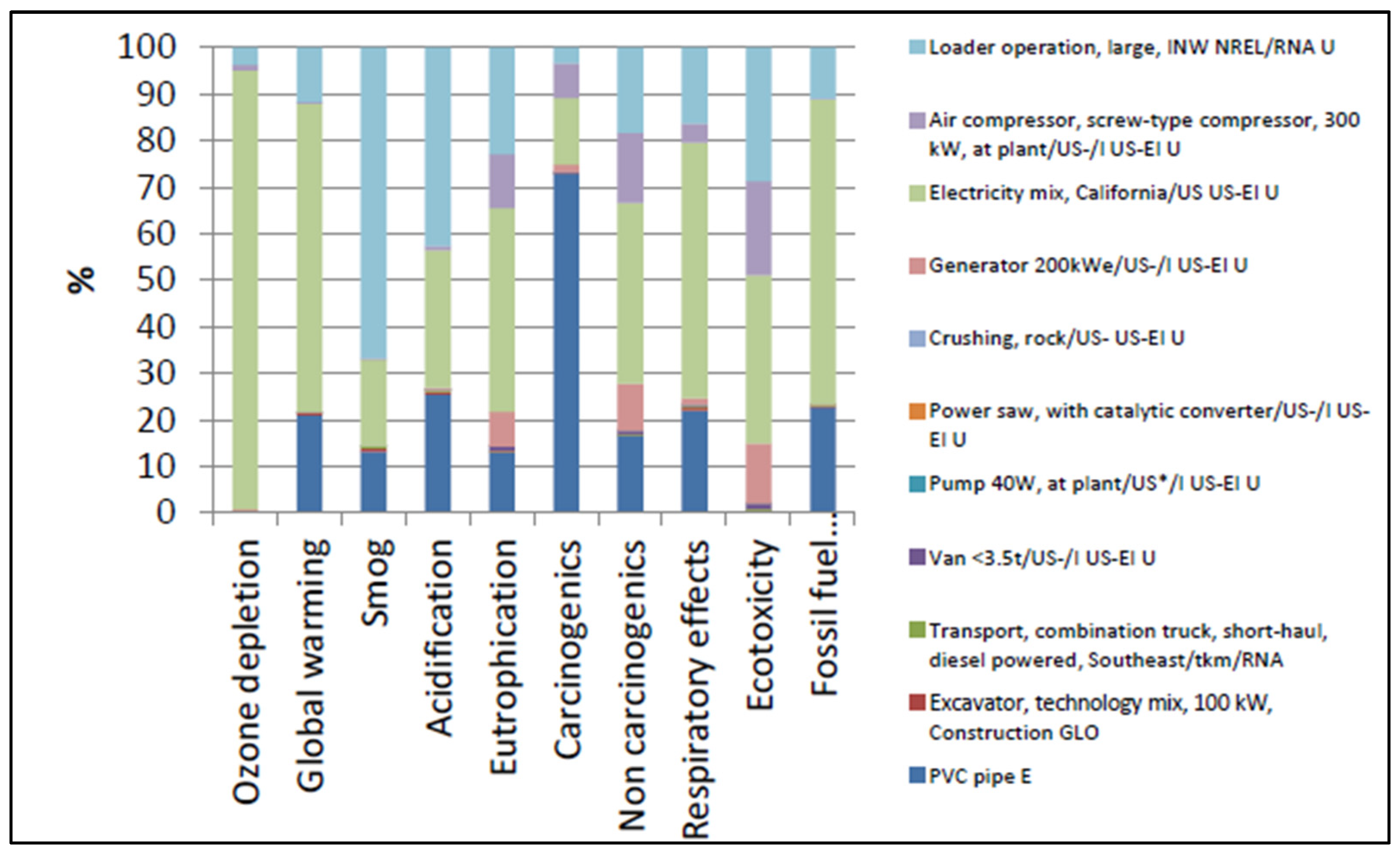

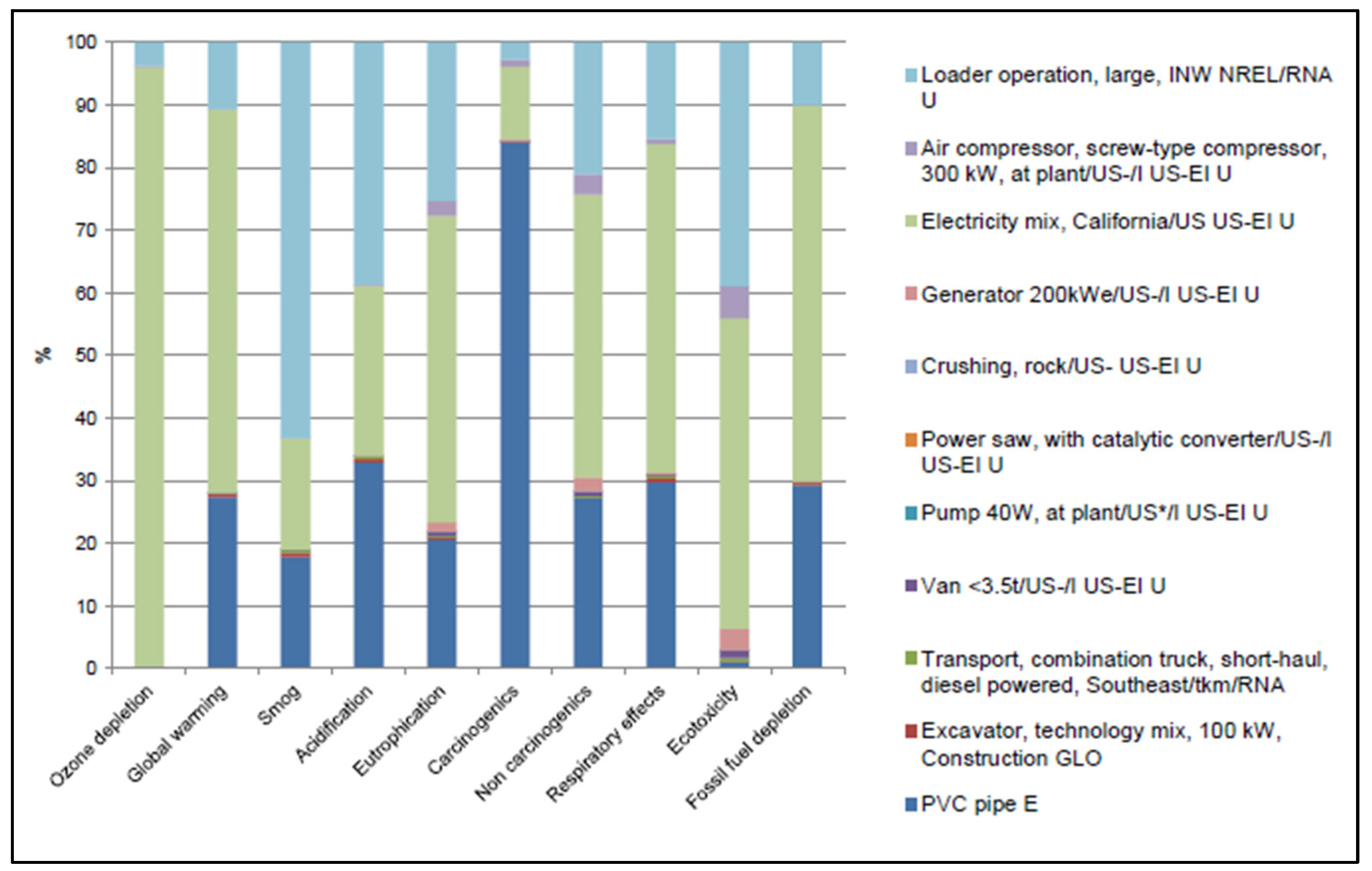

8.1. Emissions from CIPP and ET

8.2. Ecological Impact Assessment Processes for CIPP and ET

9. Discussion and Conclusions

10. Future Research Recommendations

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- ASCE. A Comprehensive Assessment of America’s Infrastructure. 2021. Available online: https://wastewater-infrastructure/ (accessed on 2 November 2024).

- Ariaratnam, S.T.; Sihabuddin, S.S. Comparison of Emitted Emissions Between Trenchless Pipe Replacement and Open Cut Utility Construction. J. Green Build. 2009, 4, 126–140. [Google Scholar] [CrossRef]

- Pipe Spy Inc. What Are Trenchless Sewer Pipe Repair Methods? 2024. Available online: https://www.pipespy.com/blog/what-are-trenchless-sewer-pipe-repair-methods (accessed on 20 May 2024).

- Kaushal, V. Comparison of Environmental and Social Costs of Trenchless Cured-in-Place Pipe Renewal Method with Open-Cut Pipeline Replacement for Sanitary Sewers. Ph.D. Thesis, Department of Civil Engineering, University of Texas, Arlington, TX, USA, 2019. [Google Scholar]

- Fu, G.; Shannon, B.; Rathnayaka, S.; Deo, R.; Kodikara, J. State of the Art Literature Review on CIPP Liners; CRC Project: Smart Lining for Pipe and Infrastructure; Monash University: Melbourne, VIC, Australia, 2020. [Google Scholar]

- Chadalawada, R. Innovative Trenchless Technologies for Installing Underground Fiber Optic Cables are Improving Efficiency while Minimizing Environmental Impact. Eur. J. Adv. Eng. Technol. 2024, 11, 85–98. [Google Scholar]

- Tabor, M.; Newman, D.; Whelton, A. Stormwater Chemical Contamination Caused by Cured-in-Place Pipe (CIPP) Infrastructure Rehabilitation Activities. J. Environ. Sci. Technol. 2014, 58, 10938–10947. [Google Scholar] [CrossRef]

- Alsadi, A.A.; Matthews, J.C. Evaluation of Carbon Footprint of Pipeline Materials during Installation, Operation, and Disposal Phases. J. Pipeline Syst. Eng. Pract. 2020, 11, 04020005. [Google Scholar] [CrossRef]

- Alsadi, A. Evaluation of Carbon Footprints During the Life-Cycle of Four Different Pipe Materials. Ph.D. Thesis, Department of Civil Engineering, Louisiana Tech University, Ruston, LA, USA, 2019. [Google Scholar]

- USESPA. Tool for Reduction and Assessment of Chemicals and Other Environmental Impacts (TRACI). 2024. Available online: https://www.epa.gov/traci (accessed on 25 October 2024).

- Parvez, J. Life Cycle Assessment of PVC Water and Sewer Pipe and Comparative Sustainability Analysis of Pipe Materials. Proc. Water Environ. Fed. 2018, 2018, 5493–5518. [Google Scholar] [CrossRef]

- Ajdari, E. Volatile Organic Compound (VOC) Emission During Cured-in-Place-Pipe (CIPP) Sewer Pipe Rehabilitation. Ph.D. Thesis, Department of Civil Engineering, University of New Orleans, New Orleans, LA, USA, 2016. [Google Scholar]

- Das, S. Evaluation of Cured-in-Place Pipe Lining Installations. Master’s Thesis, University of Alberta, Edmonton, AB, Canada, 2016. [Google Scholar]

- Ra, K. Chemicals Released from In-Situ Pipe Lining Installations: Current Practices and Water Quality Impacts. Master’s Thesis, Purdue University, West Lafayette, IN, USA, 2017. [Google Scholar]

- Kaushal, V.; Najafi, M. Comparative Assessment of Environmental Impacts from Open-Cut Pipeline Replacement and Trenchless Cured-in-Place Pipe Renewal Method for Sanitary Sewers. Infrastructures 2020, 5, 48. [Google Scholar] [CrossRef]

- Donaldson, B.M. Environmental Implications of Cured-in-Place Pipe Rehabilitation Technology. Transp. Res. Rec. 2009, 2123, 172–179. [Google Scholar] [CrossRef]

- Kampbell, E. Understanding Environmental Implications of CIPP Rehab Technology. Rehabilitation Technology, Underground Technology Cutting Edge Technical Information for Utility Construction and Rehabilitation; FHWA/VTRC 08-R16. 2009. Available online: https://undergroundinfrastructure.com/magazine/2009/april-2009-vol-64-no-4/features/understanding-environmental-implications-of-cipp-rehab-technology (accessed on 22 January 2025).

- Kamat, S.M. Comparison of Dust Generation from Open Cut and Trenchless Technology Methods for Utility Construction. Master’s Thesis, The University of Texas, Arlington, TX, USA, 2011. [Google Scholar]

- Penders, S.; Melendrez, D. Environmental Effects of Cured-in-Place Pipe Repairs. Caltrans Division of Research and Innovation-Preliminary Investigation; CTC & Associates LLC: Lincoln, NE, USA, 2012. [Google Scholar]

- Berglund, D. Life Cycle Assessment Comparison of CIPP-Lining and Traditional Pipe Replacement. Master’s Thesis, Royal Institute of Technology (KTH), Stockholm, Sweden, 2015. [Google Scholar]

- Berglund, D.; Kharazmi, P.; Miliutenko, S.; Björk, F.; Malmqvist, T. Comparative life-cycle assessment for renovation methods of waste water sewerage systems for apartment buildings. J. Build. Eng. 2018, 19, 98–108. [Google Scholar] [CrossRef]

- Sendesi, S.M.T.; Noh, Y.; Nuruddin, M.; Boor, B.E.; Howarter, J.A.; Youngblood, J.P.; Jafvert, C.T.; Whelton, A.J. An emerging mobile air pollution source: Outdoor plastic liner manufacturing sites discharge VOCs into urban and rural areas. Environ. Sci. Process. Impacts 2020, 22, 1828–1841. [Google Scholar] [CrossRef]

- Sendesi, S.M. Improving Worker Safety and Environmental Protection by Understanding Chemical Emissions from Plastic Composites During Manufacture and Use. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2021. [Google Scholar]

- Noh, Y.; Boor, B.E.; Shannahan, J.H.; Troy, C.D.; Jafvert, C.T.; Whelton, A.J. Emergency responder and public health considerations for plastic sewer lining chemical waste exposures in indoor environments. J. Hazard. Mater. 2021, 422, 126832. [Google Scholar] [CrossRef]

- Matthews, E.; Kraft, J.; Hossain, G.; Bednar, A.; Laber, C.; Alam, S.; Manzur, T.; Matthews, J.; Howell, J.; Eklund, S. Air Quality Dispersion Modelling to Evaluate CIPP Installation Styrene Emissions. Int. J. Environ. Res. Public Health 2022, 19, 13800. [Google Scholar] [CrossRef] [PubMed]

- Bavilinezhad, S.; Elledge, W.; Kaynak, B.; Najafi, M.; Kaushal, V.; Hamidzadeh, P. Equipment and Methods for Measuring Volatile Organic Compound Emissions During CIPP Renewal. In Proceedings of the NASTT No Dig 2024 Conference, Providence, RI, USA, 14–18 April 2024. [Google Scholar]

- Loss, A.; Toniolo, S.; Mazzi, A.; Manzardo, A.; Scipioni, A. LCA comparison of traditional open cut and pipe bursting systems for relining water pipelines. Resour. Conserv. Recycl. 2018, 128, 458–469. [Google Scholar] [CrossRef]

- Joshi, A. A Carbon Dioxide Comparison of Open Cut and Pipe Bursting. Master’s Thesis, College of Technology, Architecture, and Applied Engineering, Bowling Green State University, Bowling Green, OH, USA, 2012. [Google Scholar]

- Tavakoli, R.; Najafi, M.; Tabesh, A.; Ashoori, T. Comparison of Carbon Footprint of Trenchless and Open-Cut Methods for Underground Freight Transportation. In Pipelines 2017; ASCE: Reston, VA, USA, 2017. [Google Scholar] [CrossRef]

- Onsarigo, L.; Atalah, A.; Roudebush, W. An Introduction to Environmental Value Engineering (EVE) and the EVE Assessment of Horizontal Directional Drilling (HDD) versus Open-Cut Construction. In Pipelines 2014: From Underground to the Forefront of Innovation and Sustainability; American Society of Civil Engineers: Reston, VA, USA, 2014. [Google Scholar] [CrossRef]

- Kaushal, V.; Najafi, M.; Serajiantehrani, R. Environmental Impacts of Conventional Open-Cut Pipeline Installation and Trenchless Technology Methods: State-of-the-Art Review. J. Pipeline Syst. Eng. Pract. 2020, 11, 03120001. [Google Scholar] [CrossRef]

- Sihabuddin, S.; Ariaratnam, S.T. Quantification of carbon footprint on underground utility projects. In Proceedings of the Construction Research Congress 2009: Building a Sustainable Future, ASCE, Reston, VA, USA, 5–7 April 2009; pp. 618–627. [Google Scholar]

- Mohit, S.; Monfared, M.A.N.; Kang, C.; Bayat, A. Comparative study of greenhouse gas emissions from hand tunneling and pilot tube method underground construction methods. J. Green Build. 2017, 12, 54–69. [Google Scholar] [CrossRef]

- USEPA. Exhaust and Crankcase Emission Factors for Nonroad Engine Modelling Compression Ignition; EPA-420-R-10-018; USEPA: Washington, DC, USA, 2010. [Google Scholar]

- USEPA. Median Life, Annual Activity, and Load Factor Values for Nonroad Engine Emissions Modeling; EPA-420-R-10-016; USEPA: Washington, DC, USA, 2010. [Google Scholar]

- Latake, P.T.; Pawar, P.; Ranveer, A.C. The greenhouse effect and its impacts on environment. Int. J. Innov. Res. Creat. Technol. 2015, 1, 333–337. [Google Scholar]

- Rudolph, L.; Harrison, C. A Physician’s Guide to Climate Change, Health and Equity; Public Health Institute: Oakland, CA, USA, 2016. [Google Scholar]

- ASCE. Guidelines for the Sustainable Design of Pipelines; ASCE: Reston, VA, USA, 2019. [Google Scholar]

- Pandey, D.; Agrawal, M.; Pandey, J.S. Carbon footprint: Current methods of estimation. Environ. Monit. Assess. 2010, 178, 135–160. [Google Scholar] [CrossRef]

- Dimaranan, B.V. Global Trade, Assistance, and Production: The GTA P6 Database; Center for Global Trade Analysis: West Lafayette, IN, USA, 2006. [Google Scholar]

- USCCTP (US Climate Change Technology Program). Technology Options for Near and Long-Term Future; USCCTP: Washington, DC, USA, 2005. [Google Scholar]

- Haag, A. Earth Monitoring: The crucial measurement. Nature 2007, 450, 785–786. [Google Scholar] [CrossRef]

- Gurney, K.R.; Mendoza, D.L.; Zhou, Y.; Fischer, M.L.; Miller, C.C.; Geethakumar, S.; Can, S.d.l.R.d. High Resolution Fossil Fuel Combustion CO2 Emission Fluxes for the United States. Environ. Sci. Technol. 2009, 43, 5535–5541. [Google Scholar] [CrossRef]

- Chilana, L. Carbon Footprint Analysis of a Large Diameter Water Transmission Pipeline Installation. Master’s Thesis, The University of Texas, Arlington, TX, USA, 2011. Available online: https://mavmatrix.uta.edu/civilengineering_theses/62 (accessed on 10 December 2024).

- Patel, J. Green sky thinking. Environ. Bus. 2006, 122, 32. [Google Scholar]

- Wiedmann, T.; Minx, J. A Definition of Carbon Footprint; ISAUK Research Rep. No. 07-01; ISAUK Research & Consulting: Durham, UK, 2007. [Google Scholar]

- Kelly, L.M.; Shepson, P.B.; Strim, B.P.; Karion, A.; Sweeney, C.; Gurney, K.R. Aircraft-based measurements of the carbon footprint of Indianapolis. Environ. Sci. Technol. 2009, 43, 7816–7823. [Google Scholar] [CrossRef]

- Carbon Trust. Carbon Footprinting: An Introduction for Organizations. London: Carbon Trust. CE Delft. Handbook Environmental Prices; Carbon Trust: London, UK, 2007. [Google Scholar]

- EPLCA. Life Cycle Assessment (LCA). 2007. Available online: https://eplca.jrc.ec.europa.eu/lifecycleassessment.html (accessed on 2 November 2024).

- Chilana, L.; Bhatt, A.H.; Najafi, M.; Sattler, M. Comparison of carbon footprints of steel versus concrete pipelines for water transmission. J. Air Waste Manag. Assoc. 2016, 66, 518–527. [Google Scholar] [CrossRef] [PubMed]

- ISO 14040:2006; Environmental Management—Life Cycle Assessment—Principles and Framework. International Organization for Standardization (ISO): Geneva, Switzerland, 2006.

- Pre-Sustainability. LCA Software for Informed Change-Makers. 2016. Available online: https://network.simapro.com/pre/ (accessed on 16 November 2024).

- Jung, Y.J.; Sinha, S.K. Evaluation of Trenchless Technology Methods for Municipal Infrastructure System. J. Infrastruct. Syst. 2007, 13, 144–156. [Google Scholar] [CrossRef]

- Rehan, R.; Knight, M. Do Trenchless Pipeline Construction Methods Reduce Greenhouse Gas Emission? University of Waterloo: Waterloo, ON, Canada, 2007. [Google Scholar]

- Woodroffe, N.J.; Ariaratnam, S.T. Cost and Risk Evaluation for Horizontal Directional Drilling versus Open Cut in an Urban Environment. Pract. Period. Struct. Des. Constr. 2008, 13, 85–92. [Google Scholar] [CrossRef]

- Donaldson, B. Water Quality Implications of Culvert Repair Options: Vinyl Ester Based and Ultraviolet Cured-in-Place Pipe Liners; Virginia Center for Transportation Innovation & Research: Richmond, VA, USA, 2012. [Google Scholar]

- Currier, B. Water Quality of Flow Through Cured-in-Place Pipe (CIPP); Final Report; Office of Water Programs, California State University: Sacramento, CA, USA, 2017. [Google Scholar]

- Sendesi, S.M.T.; Ra, K.; Conkling, E.N.; Boor, B.E.; Nuruddin, M.; Howarter, J.A.; Youngblood, J.P.; Kobos, L.M.; Shannahan, J.H.; Jafvert, C.T.; et al. Worksite Chemical Air Emissions and Worker Exposure During Sanitary Sewer and Stormwater Pipe Rehabilitation Using Cured-in-Place-Pipe (CIPP). Environ. Sci. Technol. Lett. 2017, 4, 325–333. [Google Scholar] [CrossRef]

- Monfared, M.A.N. Comparison of Trenchless Technologies and Open Cut Methods in New Residential Land Development. Master’s Thesis, Department of Civil Engineering, University of Alberta, Edmonton, AB, Canada, 2018. [Google Scholar]

- Knight, M.A.; Ioannidis, M.A.; Salim, F.; Górecki, T.; Pivin, D. Health Risks Assessment from Cured-in-Place Pipe Lining Fugitive Styrene Emissions in Laterals. J. Pipeline Syst. Eng. Pract. 2022, 14, 04022056. [Google Scholar] [CrossRef]

- Chorazy, T.; Hlavínek, P.; Raček, J.; Pietrucha-Urbanik, K.; Tchórzewska-Cieślak, B.; Keprdová, Š.; Dufek, Z. Comparison of Trenchless and Excavation Technologies in the Restoration of a Sewage Network and Their Carbon Footprints. Resources 2024, 13, 12. [Google Scholar] [CrossRef]

| Author(s) | Year | Impact Parameter(s) | Focused Area Method | Analysis Method Used | Key Findings | Research Gaps |

|---|---|---|---|---|---|---|

| Jung and Sinha [53] | 2007 | Worker Safety, Human Toxicity, Dust Generation, Land Deterioration, Aquatic Toxicity | CIPP | Sewer Scanner and Evaluation Technology |

|

|

| Rehan and Knight [54] | 2007 | Carbon Emissions | ET | Traffic Control Plan, RS Means | CIPP significantly reduces CO2 emissions. Case studies show a 78–100% reduction in greenhouse gas emissions. |

|

| Woodroffe and Arairatnam [55] | 2008 | Worker Safety, Human Toxicity, Land Deterioration | ET | Interviewing Various Contractors |

|

|

| Arairatnam and Sihabuddin [2] | 2009 | Carbon Emissions, Non-Styrene Emissions | ET | e-Calc Emission Calculator Tool | ET generates 77% more greenhouse gases and 80% more pollutants. |

|

| Kampbell [17] | 2009 | Styrene Emissions, Aquatic Toxicity | CIPP | Sample Collection at CIPP Installation Sites, Styrene Concentration Monitoring |

|

|

| Donaldson [16] | 2009 | Styrene Emissions, Uncured Resin | CIPP | Water Samples Taken at 7 CIPP Installation Sites, Observations Taken over the Course of 1 Year. |

|

|

| Kamat [18] | 2011 | Dust Generation | CIPP, ET | Personal Exposure Sampler |

|

|

| Donaldson [56] | 2012 | Aquatic Toxicity, Styrene Emissions, Non-Styrene Emissions | CIPP | Flowing Water Test, Immersion Test of Liner Section |

|

|

| Joshi [28] | 2012 | Carbon Emissions | ET | RS Means | Total CO2 emissions from ET are higher than those from pipe bursting technology. |

|

| Penders and Melendrez [19] | 2012 | Styrene Emissions, Aquatic Toxicity, Human Toxicity | CIPP | Survey and Interviews by the Department of Transportation (DOT) of Virginia |

|

|

| Onsarigo et al. [30] | 2014 | Environmental Impact, Land Deterioration | ET | EVE | ET has a 66.2% higher environmental impact as compared to HDD. |

|

| Tabor et al. [7] | 2014 | Styrene Emissions, Non-Styrene Emissions | CIPP | Sample Collection, Water Quality Analysis, Solid-Phase Microextraction (SPME) GC−MS, Liquid–Liquid Extraction (LLE) GC-MS, Daphnia Magna Toxicity Testing, Statistical Analysis |

| Environmental monitoring is mainly focused on styrene. There should be additional research to study the implications of non-styrene compounds. |

| Berglund [20] | 2015 | Ozone Depletion, Human Toxicity, Dust Generation, Land Deterioration, Aquatic Toxicity | CIPP, ET | LCA through SimaPro modelling, ReCiPe(H) Midpoint Impact Assessment |

|

|

| Ajdari [12] | 2016 | Volatile Organic Compound (VOC) Emissions, Carbon Emissions, Other Emissions | CIPP, ET | Method 8260B for Chemical Analysis | The CO2 equivalent generated as GHG emissions were higher from ETs than those from CIPP. |

|

| Currier [57] | 2017 | VOC Emissions, Styrene Emissions, Aquatic Toxicity | CIPP | Field and Simulation Field Water Quality Tests, Sample Collection |

|

|

| Ra [14] | 2017 | VOC Emissions, Styrene Emissions, Other Emissions | CIPP | Dimensions, Imaging and Thermogravimetry analysis |

|

|

| Sendesi et al. [58] | 2017 | Styrene Emissions, Other Emissions | CIPP | Photoionization Detectors (PIDs), GC-MS, Thermogravimetric Analysis (TGA), Different Scanning Calorimetry (DSC), Proton NMR Spectroscopy |

|

|

| Tavakoli et al. [55] | 2017 | Carbon Emissions | ET | Carbon Footprint Analysis using Statistical Data | Carbon footprint produced by ET is very high. | Parameters other than carbon emissions must be considered to assess the overall ecological impact of the method. |

| Berglund et al. [21] | 2018 | Ozone Depletion, Human Toxicity, Dust Generation, Land Deterioration, Aquatic Toxicity | CIPP, ET | LCA through SimaPro modelling, ReCiPe(H) Midpoint Impact Assessment | CIPP method is more environmentally friendly due to lower ecological impacts. | Aspects related to impact on workers and occupants’ health due to dust and the process itself were not considered. |

| Loss et al. [27] | 2018 | Ozone Depletion, Human Toxicity, Dust Generation, Land Deterioration, Aquatic Toxicity | ET | LCA through SimaPro modelling, ReCiPe 2008 H/H Europe Midpoint Impact Assessment |

|

|

| Monfared [59] | 2018 | Carbon Emissions, Other Emissions | ET | Emission Factor | GHG emissions produced by ET are high due to longer project durations and greater resource allocation. |

|

| Kaushal [4] | 2019 | Ozone Depletion, Human Toxicity, Land Deterioration, Aquatic Toxicity | CIPP, ET | LCA through SimaPro modelling, TRACI 2.1 Impact Assessment Tool |

|

|

| Kaushal and Najafi [15] | 2020 | Ozone Depletion, Human Toxicity, Land Deterioration, Aquatic Toxicity | CIPP, ET | LCA through SimaPro modelling, TRACI 2.1 Impact Assessment Tool |

|

|

| Kaushal et al. [31] | 2020 | Carbon Emissions | ET | Literature Review, Emission Factor |

|

|

| Sendesi et al. [22] | 2020 | Styrene Emissions, VOC Emissions, Other Emissions | CIPP | Sample Collection, Chemical Air Monitoring |

|

|

| Sendesi [23] | 2021 | Styrene Emissions, VOC Emissions, Other Emissions, Human Toxicity, Uncured Resin | CIPP | PIDs, GC-MS, Thermogravimetric Analysis (TGA), Different Scanning Calorimetry (DSC), Proton NMR Spectroscopy | Styrene emissions, VOCs, and hazardous compounds were detected through uncured resin residue from CIPP. |

|

| Knight et al. [60] | 2022 | Styrene Emissions, VOC Emissions, Human Toxicity | CIPP | Field Study using PIDs, Waterloo Membrane Samplers, Styrene Analytical Risk Assessment Model, WMS |

|

|

| Noh et al. [24] | 2022 | Styrene Emissions | CIPP | Pressure Calculation, Chemical Air Contamination and Decontamination Model |

|

|

| Matthews et al. [25] | 2022 | Styrene Emissions, Human Toxicity | CIPP | Field Measurements, AERMOD Modelling System |

|

|

| Bavilinezhad et al. [26] | 2024 | VOC Emissions | CIPP | PIDs, Summa Canisters, Passive Worker Samplers, Method 18 PUF/XAD Cartridges, Portable GC-MS unit |

| Further research should include different resin types and curing methods. |

| Chorazy et al. [61] | 2024 | Carbon Emissions | ET | Field Study, Emissions Equation | ET has a high carbon footprint value of 24.29 metric tons of CO2 eq. |

|

| Impact Category | Unit | Glass Fiber-Reinforced Plastic | Dummy Plastic | Polyester Resin | Styrene E | PET (Amorphous) | Polyethylene (Linear Low-Density, Resin, at Plant, CTR/kg/RNA) * | Total Emissions |

|---|---|---|---|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | 0.00768 | N/A | 0.00169 | N/A | N/A | 2.85 × 10−5 | 0.0109 |

| Global warming | kg CO2 eq | 1.11 × 105 | N/A | 1.91 × 104 | 1.28 × 104 | 1.57 × 103 | 8.91 × 103 | 2.24 × 105 |

| Smog | kg O3 eq | 4.75 × 103 | N/A | 542 | 433 | 89 | 287 | 8.015 × 103 |

| Acidification | kg SO3 eq | 408 | N/A | 48.4 | 38.6 | 7.265 | 27.357 | 706 |

| Eutrophication | kg N eq | 172 | N/A | 31.7 | 0.911 | 0.23 | 0.541 | 230 |

| Carcinogenics | CTUh | 0.00364 | N/A | 0.000499 | 2.85 × 10−6 | 4.015 × 10−6 | 2.34 × 10−5 | 0.00525 |

| Non-carcinogenics | CTUh | 0.0238 | N/A | 0.00273 | 2.38 × 10−6 | 1.15 × 10−6 | 0.000246 | 0.0318 |

| Respiratory effects | kg PM2.5 eq | 30.11 | N/A | 3.918 | 1.746 | 0.317 | 1.616 | 51.31 |

| Ecotoxicity | CTUe | 3.27 × 105 | N/A | 4.86 × 104 | 474 | 58.88 | 4.19 × 103 | 4.64 × 105 |

| Fossil fuel depletion | MJ surplus | 1.91 × 105 | N/A | 3.44 × 104 | 4.8 × 104 | 4.84 × 103 | 5.23 × 104 | 4.81 × 105 |

| Impact Category | Unit | Glass Fiber-Reinforced Plastic | Dummy Plastic | Polyester Resin | Styrene E | PET (Amorphous) | Polyethylene (Linear Low-Density, Resin, at Plant, CTR/kg/RNA) * | Total Emissions |

|---|---|---|---|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | 0.00206 | N/A | 0.0004515 | N/A | N/A | 7.82 × 10−6 | 0.00289 |

| Global warming | kg CO2 eq | 3.01 × 104 | N/A | 5.131 × 103 | 3.42 × 103 | 422 | 2.43 × 103 | 5.57 × 104 |

| Smog | kg O3 eq | 1.27 × 103 | N/A | 149 | 116 | 23.8 | 77.91 | 2.079 × 103 |

| Acidification | kg SO2 eq | 113 | N/A | 13.31 | 10.57 | 1.95 | 7.45 | 182 |

| Eutrophication | kg N eq | 46.225 | N/A | 8.62 | 0.247 | 0.0597 | 0.145 | 61.14 |

| Carcinogenics | CTUh | 0.000996 | N/A | 0.000133 | 7.9 × 10−6 | 1.15 × 10−6 | 6.39 × 10−6 | 0.00134 |

| Non-carcinogenics | CTUh | 0.00641 | N/A | 0.000744 | 6.44 × 10−6 | 3.28 × 10−7 | 6.75 × 10−5 | 0.00833 |

| Respiratory effects | kg PM2.5 eq | 8.173 | N/A | 1.069 | 0.472 | 0.083 | 0.433 | 13.26 |

| Ecotoxicity | CTUe | 8.876 × 104 | N/A | 1.31 × 104 | 129 | 18 | 1.15 × 103 | 1.25 × 105 |

| Fossil fuel depletion | MJ surplus | 5.24 × 104 | N/A | 9.24 × 103 | 1.32 × 104 | 1.31 × 103 | 1.6 × 104 | 1.23 × 105 |

| Impact Category | Unit | Glass Fiber-Reinforced Plastic | Dummy Plastic | Polyester Resin | Styrene E | PET (Amorphous) | Polyethylene (Linear Low-Density, Resin, at Plant, CTR/kg/RNA) * | Total Emissions |

|---|---|---|---|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | 0.00153 | N/A | 0.000332 | N/A | N/A | 5.656 × 10−6 | 0.00221 |

| Global warming | kg CO2 eq | 2.24 × 104 | N/A | 3.79 × 103 | 2.517 × 103 | 311 | 1.77 × 103 | 4.545 × 104 |

| Smog | kg O3 eq | 941 | N/A | 110 | 86.72 | 17.6 | 57.29 | 1.62 × 103 |

| Acidification | kg SO2 eq | 81.25 | N/A | 9.615 | 7.75 | 1.44 | 5.44 | 141 |

| Eutrophication | kg N eq | 33.81 | N/A | 6.31 | 0.182 | 0.0447 | 0.106 | 46.15 |

| Carcinogenics | CTUh | 0.000735 | N/A | 9.87 × 10−5 | 5.67 × 10−6 | 8.06 × 10−8 | 4.68 × 10−6 | 0.00107 |

| Non-carcinogenics | CTUh | 0.00471 | N/A | 0.000542 | 4.78 × 10−6 | 2.44 × 10−7 | 4.96 × 10−5 | 0.0063 |

| Respiratory effects | kg PM2.5 eq | 5.97 | N/A | 0.78 | 0.345 | 0.0632 | 0.324 | 10.43 |

| Ecotoxicity | CTUe | 6.52 × 104 | N/A | 9.68 × 103 | 94.46 | 11.78 | 818 | 9.21 × 104 |

| Fossil fuel depletion | MJ surplus | 3.867 × 104 | N/A | 6.78 × 103 | 9.58 × 103 | 967 | 1.025 × 104 | 9.74 × 104 |

| Impact Category | Unit | PVC Pipe E | Excavator | Total Emissions |

|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | N/A | 2.167 × 10−6 | 0.00347 |

| Global warming | kg CO2 eq | 4.278 × 104 | 987 | 2.035 × 105 |

| Smog | kg O3 eq | 2.014 × 103 | 98.7 | 1.52 × 104 |

| Acidification | kg SO2 eq | 187 | 4.656 | 735 |

| Eutrophication | kg N eq | 14 | 0.265 | 108 |

| Carcinogenics | CTUh | 0.00885 | 5.12 × 10−7 | 0.01225 |

| Non-carcinogenics | CTUh | 0.00357 | 3.14 × 10−6 | 0.0216 |

| Respiratory effects | kg PM2.5 eq | 8.49 | 0.256 | 38.25 |

| Ecotoxicity | CTUe | 2.04 × 103 | 31.89 | 3.53 × 105 |

| Fossil fuel depletion | MJ surplus | 1.01 × 105 | 1.95 × 103 | 4.49 × 105 |

| Impact Category | Unit | PVC Pipe E | Excavator | Total Emissions |

|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | N/A | 1.49 × 10−7 | 0.000231 |

| Global warming | kg CO2 eq | 4.13 × 103 | 67.18 | 1.52 × 104 |

| Smog | kg O3 eq | 192 | 6.9 | 1.07 × 103 |

| Acidification | kg SO3 eq | 17.81 | 0.317 | 54.41 |

| Eutrophication | kg N eq | 1.34 | 0.018 | 6.53 |

| Carcinogenics | CTUh | 0.000851 | 3.51 × 10−8 | 0.00103 |

| Non-carcinogenics | CTUh | 0.000344 | 2.14 × 10−7 | 0.00126 |

| Respiratory effects | kg PM2.5 eq | 0.811 | 0.0172 | 2.73 |

| Ecotoxicity | CTUe | 198 | 2.17 | 1.72 × 104 |

| Fossil fuel depletion | MJ surplus | 9.65 × 103 | 133 | 3.31 × 104 |

| Impact Category | Unit | PVC Pipe E | Excavator | Total Emissions |

|---|---|---|---|---|

| Ozone depletion | kg CFC-11 eq | N/A | 1.47 × 10−7 | 0.000231 |

| Global warming | kg CO2 eq | 5.83 × 103 | 67.1 | 1.69 × 104 |

| Smog | kg O3 eq | 275 | 6.5 | 1.15 × 103 |

| Acidification | kg SO2 eq | 25.25 | 0.318 | 61.87 |

| Eutrophication | kg N eq | 1.91 | 0.0181 | 7.05 |

| Carcinogenics | CTUh | 0.0013 | 3.47 × 10−8 | 0.00136 |

| Non-carcinogenics | CTUh | 0.000485 | 2.115 × 10−7 | 0.0016 |

| Respiratory effects | kg PM2.5 eq | 1.17 | 0.0174 | 3.07 |

| Ecotoxicity | CTUe | 281 | 2.16 | 1.72 × 104 |

| Fossil fuel depletion | MJ surplus | 1.378 × 104 | 133 | 3.71 × 104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Karkhanis, E.; Kaushal, V.; Thakre, G.; Najafi, M. A Comprehensive Analysis of Environmental Emissions from Trenchless CIPP and Excavation Technologies for Sanitary Sewers. Appl. Sci. 2025, 15, 1268. https://doi.org/10.3390/app15031268

Karkhanis E, Kaushal V, Thakre G, Najafi M. A Comprehensive Analysis of Environmental Emissions from Trenchless CIPP and Excavation Technologies for Sanitary Sewers. Applied Sciences. 2025; 15(3):1268. https://doi.org/10.3390/app15031268

Chicago/Turabian StyleKarkhanis, Eesha, Vinayak Kaushal, Gayatri Thakre, and Mohammad Najafi. 2025. "A Comprehensive Analysis of Environmental Emissions from Trenchless CIPP and Excavation Technologies for Sanitary Sewers" Applied Sciences 15, no. 3: 1268. https://doi.org/10.3390/app15031268

APA StyleKarkhanis, E., Kaushal, V., Thakre, G., & Najafi, M. (2025). A Comprehensive Analysis of Environmental Emissions from Trenchless CIPP and Excavation Technologies for Sanitary Sewers. Applied Sciences, 15(3), 1268. https://doi.org/10.3390/app15031268