Monitoring and Improving Aircraft Maintenance Processes Using IT Systems

Abstract

1. Introduction

1.1. Review of Existing Research

1.2. Unsolved Problems

1.3. Goal, Subject, and Scope of This Study

2. The Importance of Supervising and Modeling the Maintenance Process

- Reliability;

- Maintainability;

- Providing support.

- DMT—the duration of the maintenance task;

- m(τ)—is a function of the probability density of the duration of the maintenance task.

- Designing a technical facility;

- Designing the technique and organization of servicing an object with a shaped susceptibility to servicing.

3. Analysis of the Research Object Maintenance Process

3.1. Airworthiness of Research Object

- C—A/C on the records [pcs.];

- D—airworthy A/C [pcs.];

- X—A/C not counted for airworthiness [pcs.];

- F—airworthiness [%].

- max(F)—the highest recorded percentage airworthiness of the M-346 aircraft in 2018-2020.

3.2. Analysis of the Duration of Periodic Maintenance of the M-346 Aircraft

3.3. Conclusions from the Analysis

4. Data Acquisition Tool—IT System Design

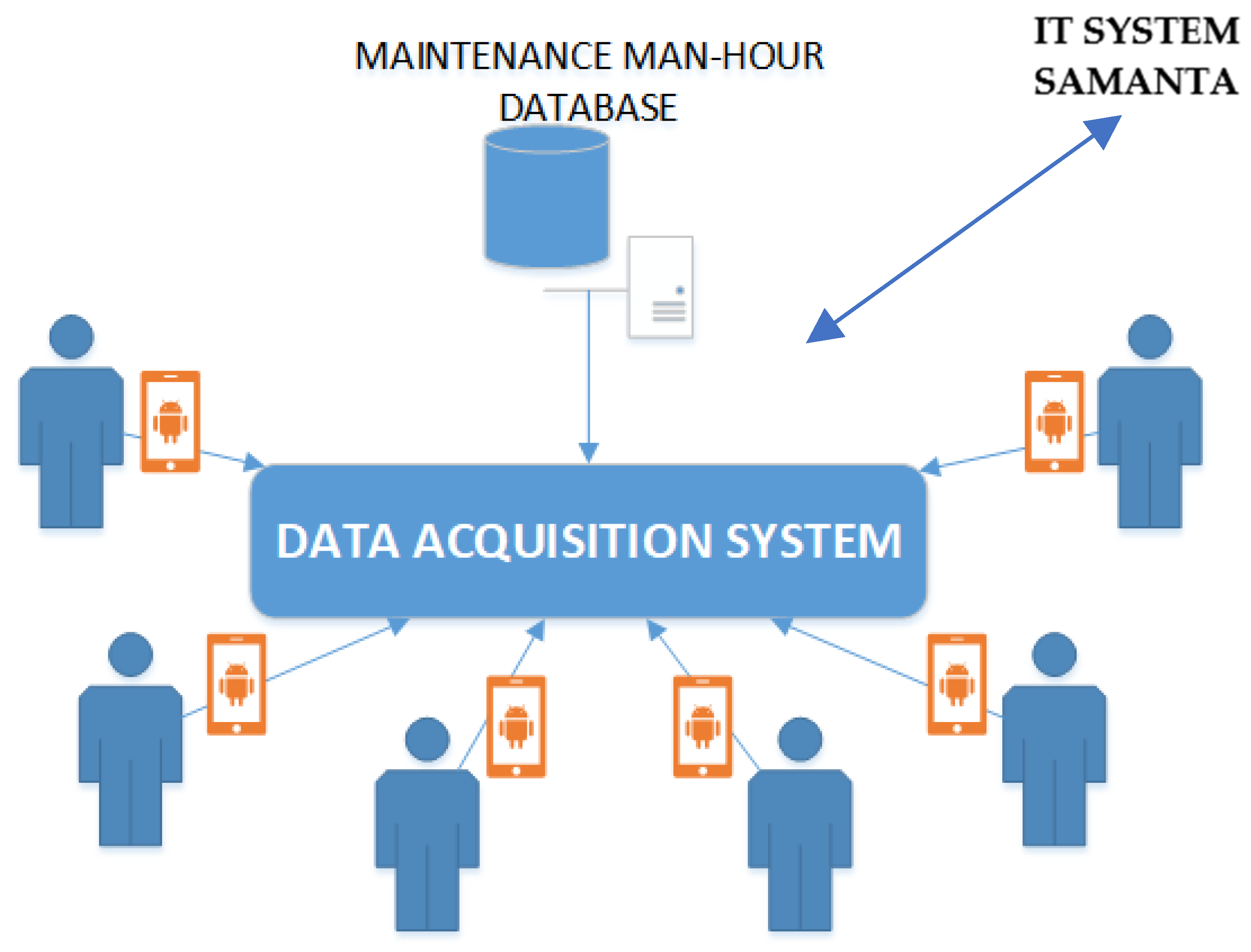

4.1. The Idea of an IT System for Monitoring the Service Process

- Replacing paper registration documentation of aircraft with their digital version;

- Using a mobile device to record the activities performed during services;

- Collecting information enabling the performance of optimization analyses;

- Using the IT systems currently in use, extending them with the above-mentioned functionalities, e.g., the IT system Samanta.

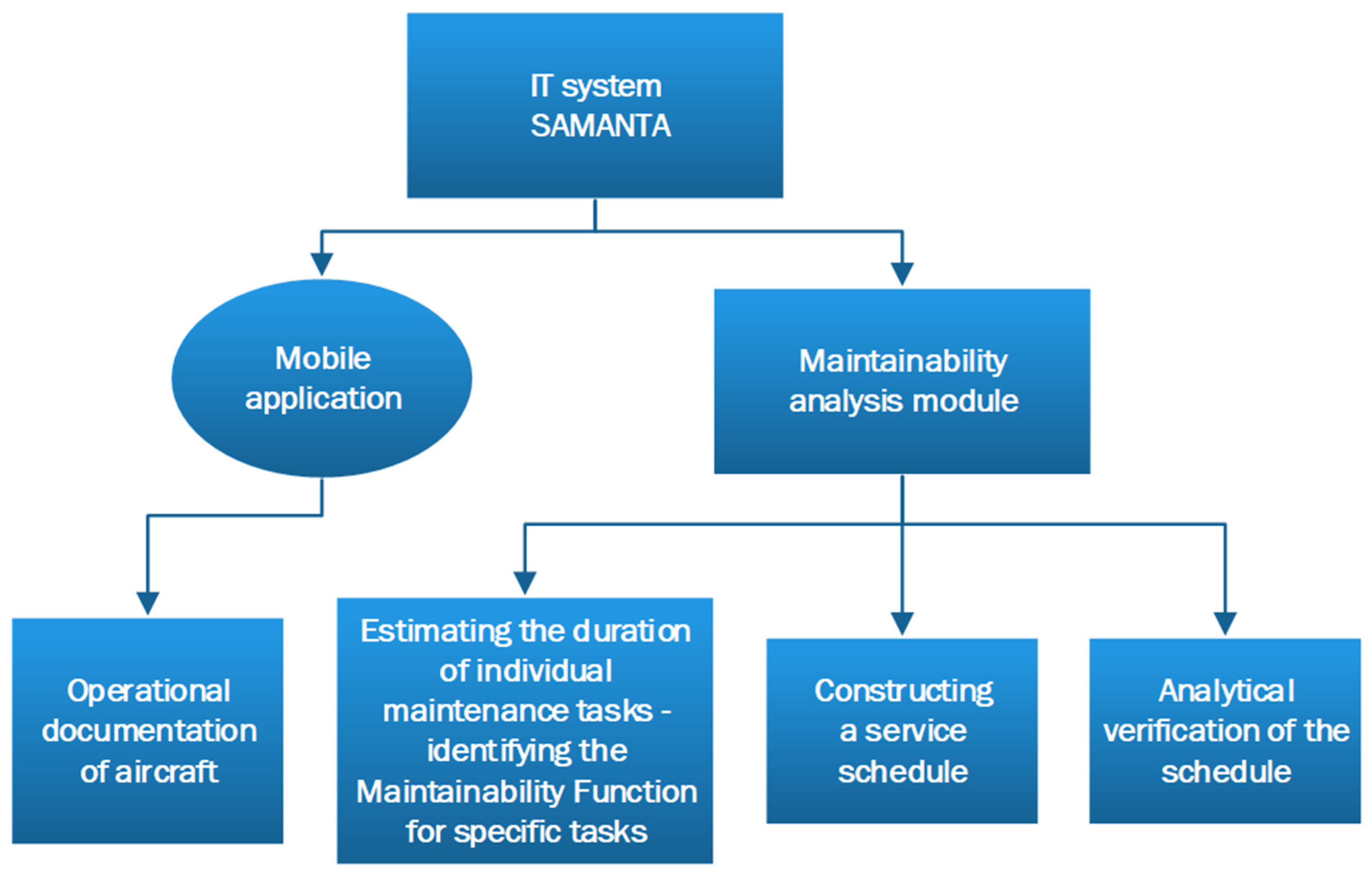

- A mobile application that replaces traditional AMCs, allowing the real-time recording of maintenance tasks and their durations, improving data accuracy, and reducing manual errors.

- Maintainability Analysis Module: This module processes task data to estimate maintainability functions, optimize service schedules, and verify their reliability through advanced analytical tools.

- Enhanced Integration: The system links maintenance data with operational documentation, ensuring synchronized and updated records.

- Task-level data recording and real-time documentation;

- Predictive maintainability analysis for optimizing schedules;

- Mobile integration for efficient field operations.

4.2. Maintainability Analysis Module

4.2.1. Data Acquisition Model

- Probability Distribution of Task Durations: For each task Ti, the duration Di is modeled as a random variable. The probability distribution function (PDF) fDi(d) is estimated from the collected data:where Kh is a kernel function (e.g., Gaussian) with bandwidth h, used for nonparametric density estimation.

- Cumulative Distribution Function (CDF): The CDF FDi(d) is defined as follows:

- Expected Duration E[Di]: The expected task duration is

4.2.2. Task Scheduling Optimization

- Objective Function:where σ(Ti) represents the sequence or priority of task Ti.

- Constraints: Tasks dependent on preceding tasks:

4.2.3. Reliability Assessment

- Maintainability Function :where t is the time threshold for task completion.

- Variance of Task Duration: Variance helps in identifying bottlenecks.

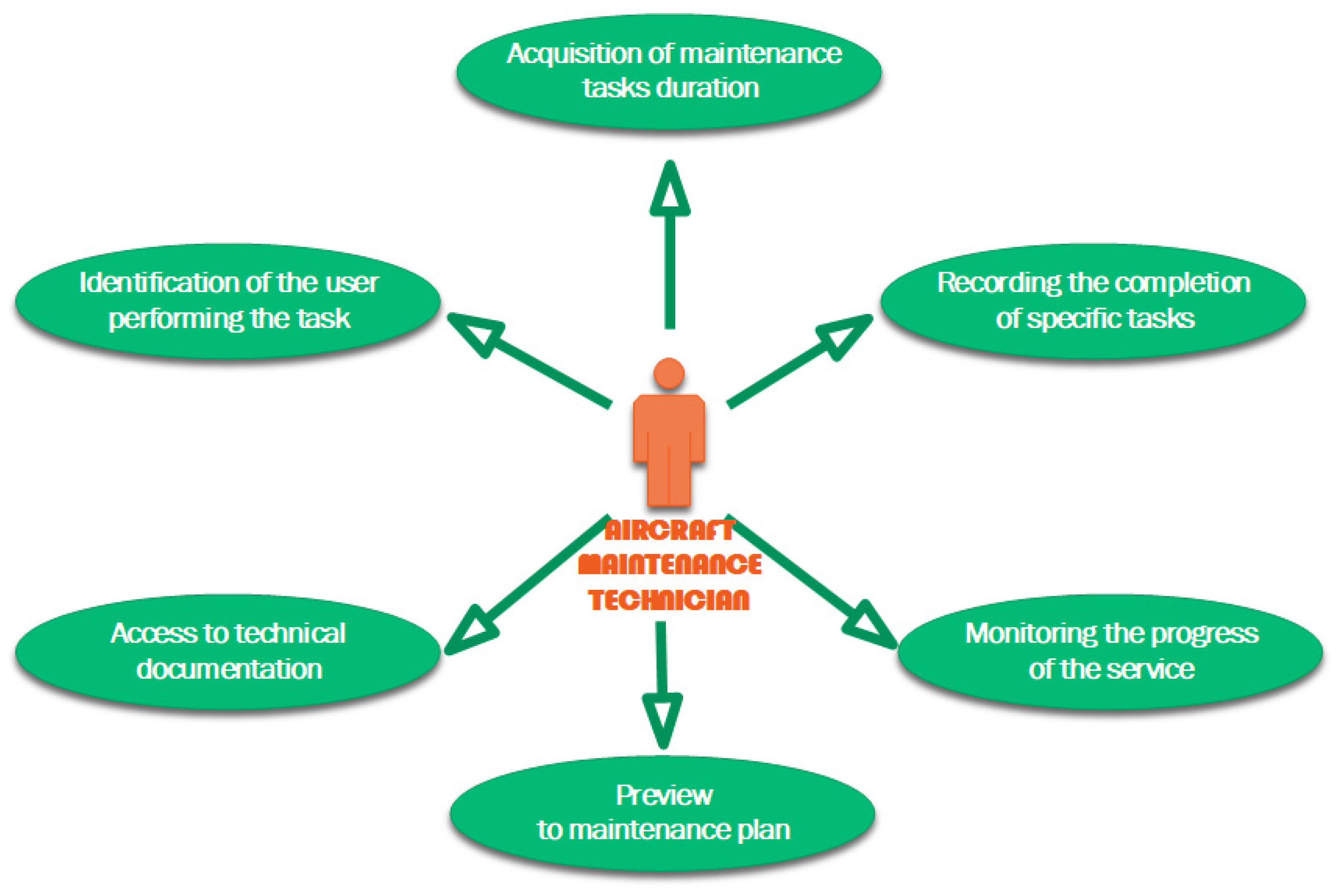

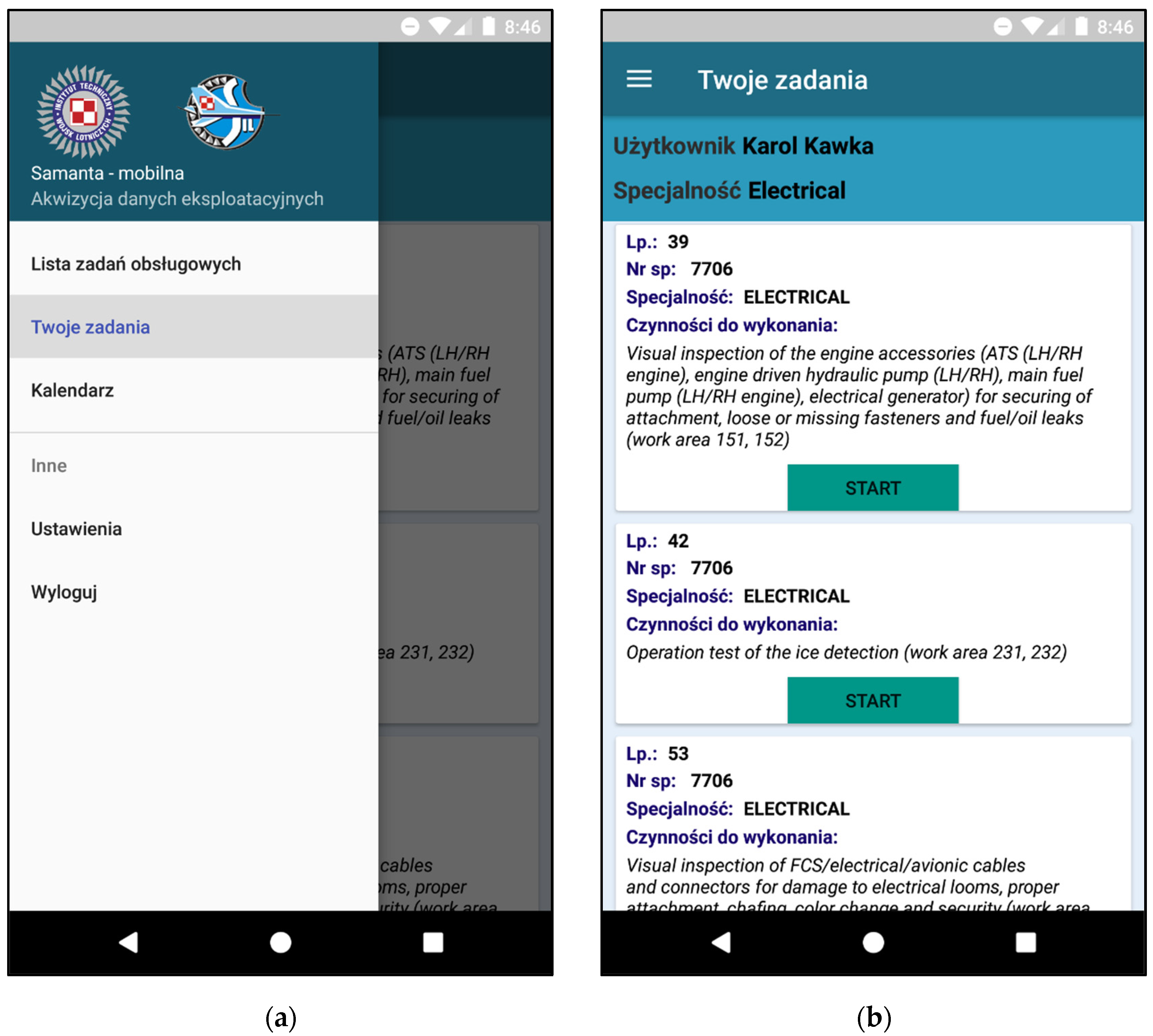

4.3. Functional Characteristics of the Mobile Application

5. Assessment of the Usefulness of the Collected Data

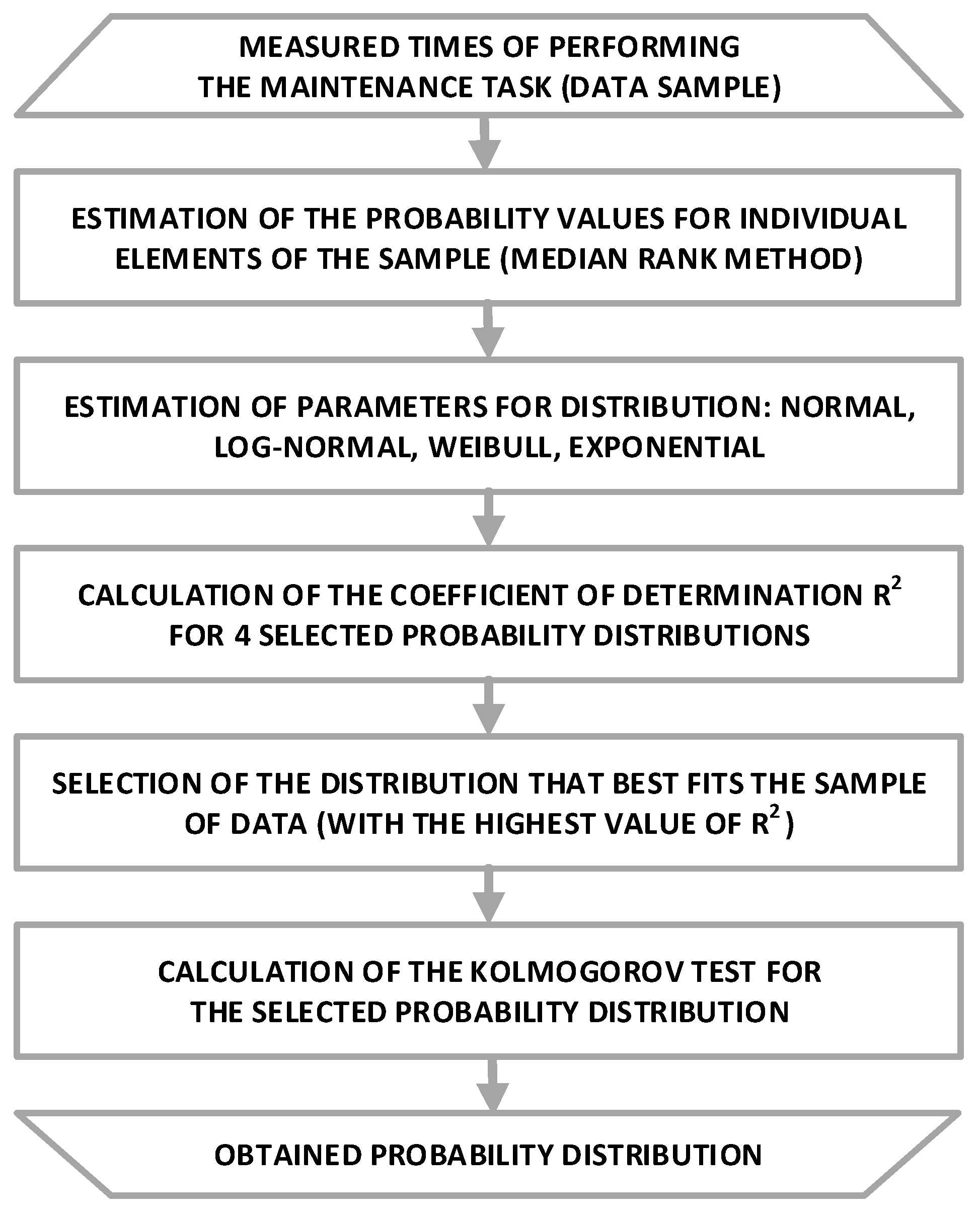

5.1. Examination of Probability Distributions of Maintenance Tasks

- —probability value estimated using the Median Rank method;

- —are the parameters of the scale, shape, and position of the probability distribution, respectively;

- —the distribution function of the standard normal distribution, N(0, 1);

- —the inverse distribution function of the standard normal distribution, N(0, 1).

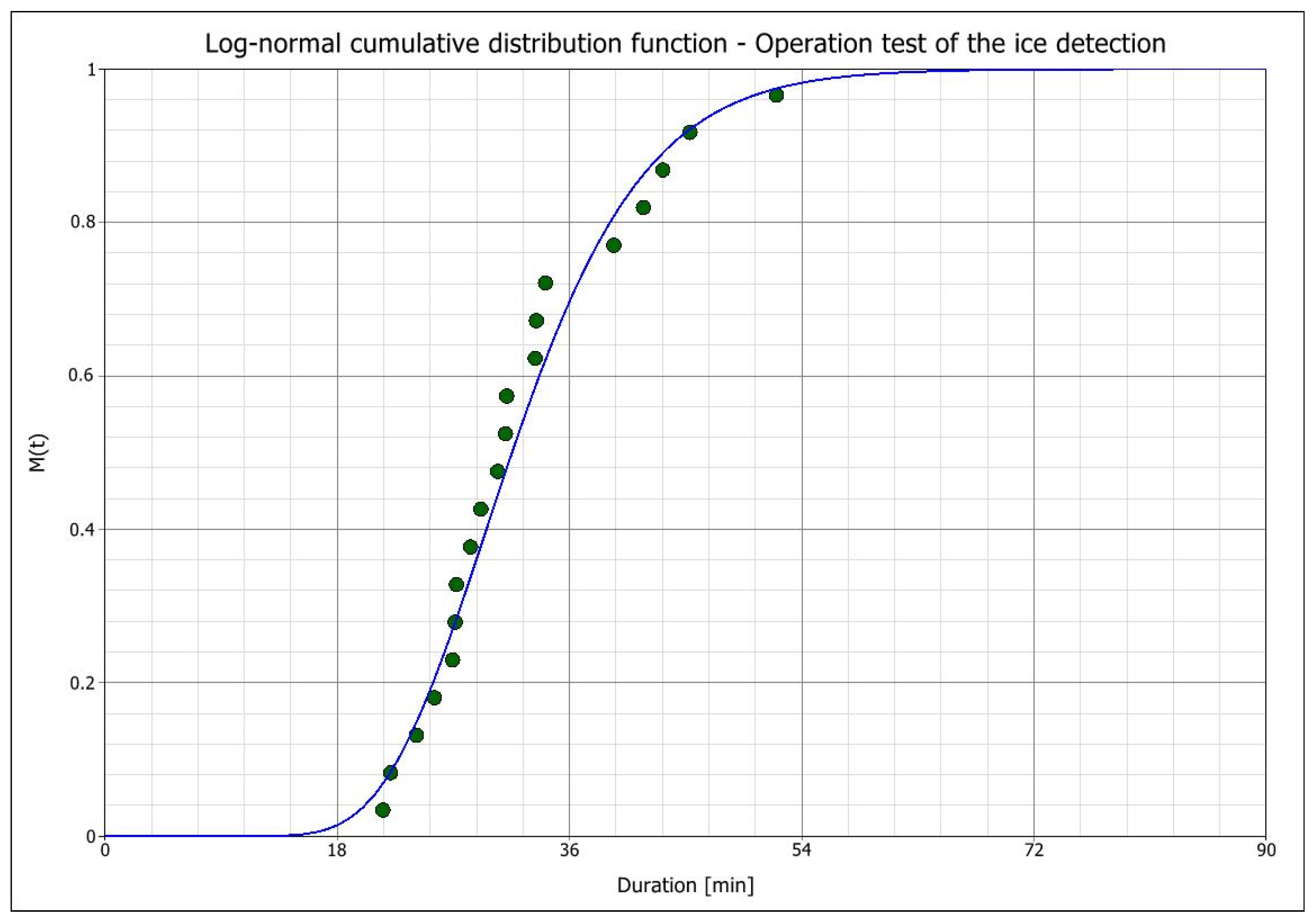

5.2. Identification of the Probability Distribution of an Exemplary Technical Task

- Scale parameter μ = 3.45;

- Shape parameter σ = 0.256.

6. Discussion

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Tsakalerou, M.; Nurmaganbetov, D.; Beltenov, N. Aircraft Maintenance 4.0 in an era of disruptions. Procedia Comput. Sci. 2022, 200, 121–131. [Google Scholar] [CrossRef]

- Brzozowski, B.; Kawka, K.; Kaźmierczak, K.; Rochala, Z.; Wojtowicz, K. Supporting the Process of Aircraft Maintenance with Mobile Devices. Trans. Aerosp. Res. 2017, 2017, 7–18. [Google Scholar] [CrossRef]

- Zieja, M.; Kawka, K.; Wojtowicz, K.; Wetoszka, A.; Pietrzak, T. Portable biometric module software for military aviation support system. Aviat. Secur. Issues 2023, 4, 235–252. [Google Scholar] [CrossRef]

- Glinka, S.; Bajer, J.; Wierzbicki, D.; Karwowska, K.; Kedzierski, M. The Use of Deep Learning Methods for Object Height Estimation in High Resolution Satellite Images. Sensors 2023, 23, 8162. [Google Scholar] [CrossRef]

- Dangut, M.D.; Jennions, I.K.; King, S.; Skaf, Z. Application of deep reinforcement learning for extremely rare failure prediction in aircraft maintenance. Mech. Syst. Signal Process. 2022, 171, 108873. [Google Scholar] [CrossRef]

- Pigłas, M.; Radoń, T.; Szymański, M.; Krutkow, A.; Przystawska, A. Information system support for military aircraft operations SI SAMANTA as a tool to support logistic resource management. J. KONBiN 2020, 50, 269–286. [Google Scholar] [CrossRef]

- Smith, D.J. Reliability, Maintainability and Risk, 9th ed.; Butterworth-Heinemann: Oxford, UK, 2017. [Google Scholar]

- Korba, P.; Šváb, P.; Vereš, M.; Lukáč, J. Optimizing Aviation Maintenance through Algorithmic Approach of Real-Life Data. Appl. Sci. 2023, 13, 3824. [Google Scholar] [CrossRef]

- Izdebski, M.; Jacyna-Gołda, I.; Gołębiowski, P.; Gołda, P.; Pyza, D.; Żak, J. Decision problems in designing database architecture for the assessment of logistics services, Scientific Journal of Silesian University of Technology. Ser. Transp. 2020, 108, 53–71. [Google Scholar] [CrossRef]

- Juncen, V.G. Effectiveness of Aircraft Ground Operation Course in Enriching the Aircraft Maintenance Program. IRE J. 2023, 7, 563–579. [Google Scholar]

- Yang, L.; Zhou, S.; Ma, X.; Chen, Y.; Jia, H.; Dai, W. Group machinery intelligent maintenance: Adaptive health prediction and global dynamic maintenance decision-making. Reliab. Eng. Syst. Saf. 2024, 252, 110426. [Google Scholar] [CrossRef]

- Zhang, Q.; Liu, Y.; Xiahou, T.; Huang, H. A heuristic maintenance scheduling framework for a military aircraft fleet under limited maintenance capacities. Reliab. Eng. Syst. Saf. 2023, 235, 109239. [Google Scholar] [CrossRef]

- Pastrana, C.; Ricardo, R. Improving Efficiency in Military Aircraft Maintenance Operations in Terms of Jobs Completion Time. PRCR J. 2022. Available online: https://prcrepository.org/xmlui/handle/20.500.12475/2177 (accessed on 12 October 2024).

- Melo, S.P.; Barke, A.; Cerdas, F.; Thies, C.; Mennenga, M.; Spengler, T.S.; Herrmann, C. Sustainability Assessment and Engineering of Emerging Aircraft Technologies—Challenges, Methods and Tools. Sustainability 2020, 12, 5663. [Google Scholar] [CrossRef]

- Bisanti, G.M.; Mainetti, L.; Montanaro, T.; Patrono, L.; Sergi, I. Digital twins for aircraft maintenance and operation: A systematic literature review and an IoT-enabled modular architecture. Internet Things 2023, 24, 100991. [Google Scholar] [CrossRef]

- Wu, W.; Vu, V. Application of Virtual Reality Method in Aircraft Maintenance Service—Taking Dornier 228 as an Example. Appl. Sci. 2022, 12, 7283. [Google Scholar] [CrossRef]

- Chen, Y.; Ma, X.; Wei, F.; Yang, L.; Qiu, Q. Dynamic Scheduling of Intelligent Group Maintenance Planning under Usage Availability Constraint. Mathematics 2022, 10, 2730. [Google Scholar] [CrossRef]

- Perehuda, O.; Rodionov, A.; Fedorchuk, D.; Zhuravskyi, S.; Konvisar, M.; Volynets, T.; Datsyk, V.; Zakalad, M.; Tsybulia, S.; Trysnyuk, T. Devising a method for integrated dataset formation and selecting a model for recognizing the technical condition of unmanned aerial vehicle. East.-Eur. J. Enterp. Technol. 2024, 5, 42–51. [Google Scholar] [CrossRef]

- Okoro, O.C.; Zaliskyi, M.; Dmytriiev, S.; Solomentsev, O.; Sribna, O. Optimization of Maintenance Task Interval of Aircraft Systems. Int. J. Comput. Netw. Inf. Secur. 2022, 14, 77–89. [Google Scholar] [CrossRef]

- Yazdi, M. Maintenance Strategies and Optimization Techniques. In Advances in Computational Mathematics for Industrial System Reliability and Maintainability; Springer Series in Reliability Engineering; Springer: Berlin/Heidelberg, Germany, 2024; pp. 43–58. [Google Scholar] [CrossRef]

- Andrade, P.; Silva, C.; Ribeiro, B.; Santos, B.F. Aircraft Maintenance Check Scheduling Using Reinforcement Learning. Aerospace 2021, 8, 113. [Google Scholar] [CrossRef]

- De Pater, I.; Reijins, A.; Mitici, M. Alarm-based predictive maintenance scheduling for aircraft engines with imperfect Remaining Useful Life prognostics. Reliab. Eng. Syst. Saf. 2022, 221, 108341. [Google Scholar] [CrossRef]

- Blond, K.; Himschoot, A.; Klein, E.; Conley, S.; Clark, A. Adapting Commercial Best Practices to U.S. Air Force Maintenance Scheduling. Aerospace 2023, 10, 61. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; Zhao, X.; Xiang, J. Predictive Maintenance Scheduling for Aircraft Engines Based on Remaining Useful Life Prediction. IEEE Internet Things J. 2024, 11, 23020–23031. [Google Scholar] [CrossRef]

- Fu, S.; Avdelidis, N.P. Prognostic and Health Management of Critical Aircraft Systems and Components: An Overview. Sensors 2023, 23, 8124. [Google Scholar] [CrossRef]

- Pop, G.I.; Titu, A.M.; Pop, A.B. Enhancing Aerospace Industry Efficiency and Sustainability: Process Integration and Quality Management in the Context of Industry 4.0. Sustainability 2023, 15, 16206. [Google Scholar] [CrossRef]

- Zuluaga, A.E.M.; De Mantenimiento, E.E.G.; Marcos, C.S. Development of a Mobile Application for Maintenance Management. In Proceedings of the 2023 VI Congreso Internacional en Inteligencia Ambiental, Ingeniería de Software y Salud Electrónica y Móvil (AmITIC), Cali, Colombia, 25–27 October 2023; pp. 1–8. [Google Scholar] [CrossRef]

- OTAC Reliability Monitoring Programs. OTAC 39-14. 2021. Available online: https://www.airsafety.aero/getmedia/6d844aa3-8a14-4199-824c-15aa4cbfda61/20210126_ALPR08_OTAC_39-14_Reliability_Monitoring_Programmes_Issue1.pdf?ext=.pdf (accessed on 12 October 2024).

- Alomar, I.; Yatskiv (Jackiva), I. Digitalization in aircraft maintenance processes. Vilnius Tech J. 2023, 27, 86–94. [Google Scholar] [CrossRef]

- Kechagias, E.P.; Gayialis, S.P.; Konstantakopoulos, G.D.; Papadopoulos, G.A. An Application of a Multi-Criteria Approach for the Development of a Process Reference Model for Supply Chain Operations. Sustainability 2020, 12, 5791. [Google Scholar] [CrossRef]

- IEC 60050-192; International Electrotechnical Vocabulary. Chapter 192: Dependability and Quality of Service. International Electrotechnical Commission: Geneva, Switzerland, 2015.

- STANREC 4174, ADMP-02 Guidance for Dependability Management; Guidance for Dependability In-Service; Edition A Version 1; NATO: Brussels, Belgium, 2014.

- Eddarhri, M.; Adib, J.; Hain, M.; Marzak, A. Towards predictive maintenance: The case of the aeronautical industry. Procedia Comput. Sci. 2022, 203, 769–774. [Google Scholar] [CrossRef]

- Patton, J.D. Preventive Maintenance, 3rd ed.; International Society of Automation: Pittsburgh, PA, USA, 2016. [Google Scholar]

- Zhang, Y.; Li, C.; Su, X.; Cui, R.; Wan, B. A baseline-reactive scheduling method for carrier-based aircraft maintenance tasks. Complex Intell. Syst. 2023, 9, 367–397. [Google Scholar] [CrossRef]

- Okeagu, F.N.; Mgbemena, C.E. A systematic review of digital twin systems for improved predictive maintenance of equipment in smart factories. Int. J. Ind. Prod. Eng. 2022, 1, 1–20. [Google Scholar]

- Zieja, M.; Ważny, M.; Stępień, S. Distribution determination of time of exceeding permissible condition as used to determine lifetimes of selected aeronautical devices/systems. Eksploat. Niezawodn. 2016, 18, 57–64. [Google Scholar] [CrossRef]

- Miśkiewicz, R.; Wolniak, R. Practical Application of the Industry 4.0 Concept in a Steel Company. Sustainability 2020, 12, 5776. [Google Scholar] [CrossRef]

- Kawka, K.; Wojtowicz, K.; Zieja, M. Examination and evaluation of training jet aircraft maintainability. In Proceedings of the 2020 IEEE International Workshop on Metrology for Aerospace, Pisa, Italy, 22–24 June 2020; IEEE: Piscataway, NJ, USA. [Google Scholar] [CrossRef]

- Wibowo, U.; Kurniawan, I.E.; Prayitno, H. Implementation of Safety Risk Management in Aircraft Airffame Maintenance. Sinergi Int. J. Logist. 2023, 1, 85–95. [Google Scholar] [CrossRef]

- Jodejko-Pietruczuk, A.; Werbińska-Wojciechowska, S. Availability model of technical objects-block inspection policy implementation. In Proceedings of the Safety and Reliability: Methodology and Applications Conference, Wrocław, Poland, 14–18 September 2014. [Google Scholar] [CrossRef]

- Marugán, A.P.; García Márquez, F.P.; Pinar Pérez, J.M. Optimal maintenance management of offshore wind farms. Energies 2016, 9, 46. [Google Scholar] [CrossRef]

- Stanton, I.; Munir, K.; Ikram, A.; El-Bakry, M. Predictive maintenance analytics and implementation for aircraft: Challenges and opportunities. INCOSE Syst. Eng. 2022, 26, 216–237. [Google Scholar] [CrossRef]

- Inspections Requirements Handbook, PI 1T-M346(PLAF)-6; Leonardo Spa Aircraft Division: Venegono Superiore, Italy, 2017.

- Jacyna, M.; Izdebski, M.; Szczepański, E.; Gołda, P. The task assignment of vehicles for a production company. Symmetry 2018, 10, 551. [Google Scholar] [CrossRef]

- Rabanal, A.; Ulazia, A.; Ibarra-Berastegi, G.; Sáenz, J.; Elosegui, U. A benchmarking multi-criteria method for the identification of defective anemometers in wind farms. Energies 2019, 12, 28. [Google Scholar] [CrossRef]

- Paiva, R.G.N.; Cavalcante, C.A.V.; Do, P. Applying association rules in the maintenance and reliability of physical systems: A review. Comput. Ind. Eng. 2024, 194, 110332. [Google Scholar] [CrossRef]

- Zhang, Y.; Yang, X.; Shardt, Y.A.W.; Cui, J.; Tong, C. A KPI-based probabilistic soft sensor development approach that maximizes the coefficient of determination. Sensors 2018, 18, 3058. [Google Scholar] [CrossRef]

- Oszczypała, M.; Konwerski, J.; Ziółkowski, J.; Małachowski, J. Reliability analysis and redundancy optimization of k-out-of-n systems with random variable k using continuous time Markov chain and Monte Carlo simulation. Reliab. Eng. Syst. Saf. 2024, 242, 109780. [Google Scholar] [CrossRef]

- Ziółkowski, J.; Oszczypała, M.; Lęgas, A.; Konwerski, J.; Małachowski, J. A method for calculating the technical readiness of aviation refuelling vehicles. Eksploat. Niezawodn. 2024, 26, 187888. [Google Scholar] [CrossRef]

| 2018 | 2019 | 2020 | |

|---|---|---|---|

| I quarter | 98.76% | 87.96% | 75.58% |

| II quarter | 94.69% | 68.67% | 72.57% |

| III quarter | 100.00% | 80.18% | 76.11% |

| IV quarter | 94.69% | 53.27% | 76.11% |

| Annual | 96.81% | 64.78% | 75.75% |

| Duration [Days]: | |

|---|---|

| Expected value | 10.7 |

| Median | 9.5 |

| Variance | 13.1 |

| Standard deviation | 3.5 |

| Minimum value | 5.0 |

| Maximum value | 19.0 |

| Gap | 14 |

| Distribution Type | Normal | Log-Normal | Weibull | Exponential |

|---|---|---|---|---|

| Distributor | ||||

| Distribution coordinates | ||||

| Distribution parameters |

| No. | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Duration [min:sec] | 24:12 | 34:00 | 27:25 | 25:36 | 33:30 | 52:06 | 28:24 | 22:12 | 43:18 | 27:00 |

| No. | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 |

| Duration [min:sec] | 29:13 | 45:24 | 39:30 | 31:11 | 31:05 | 30:30 | 41:49 | 27:18 | 21:36 | 33:24 |

| Distribution Coordinates | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Normal: | Log-Normal: | Weibull: | Exponential: | |||||||

| 1 | 21.6 | 0.03 | 21.60 | −1.82 | 3.07 | −1.82 | 3.07 | −3.35 | 21.60 | −0.03 |

| 2 | 22.2 | 0.08 | 22.20 | −1.38 | 3.10 | −1.38 | 3.10 | −2.44 | 22.20 | −0.09 |

| 3 | 24.2 | 0.13 | 24.20 | −1.12 | 3.19 | −1.12 | 3.19 | −1.95 | 24.20 | −0.14 |

| 4 | 25.6 | 0.18 | 25.60 | −0.91 | 3.24 | −0.91 | 3.24 | −1.61 | 25.60 | −0.20 |

| 5 | 27.0 | 0.23 | 27.00 | −0.74 | 3.30 | −0.74 | 3.30 | −1.34 | 27.00 | −0.26 |

| 6 | 27.2 | 0.28 | 27.20 | −0.58 | 3.30 | −0.58 | 3.30 | −1.12 | 27.20 | −0.33 |

| 7 | 27.3 | 0.33 | 27.30 | −0.44 | 3.31 | −0.44 | 3.31 | −0.92 | 27.30 | −0.40 |

| 8 | 28.4 | 0.38 | 28.40 | −0.31 | 3.35 | −0.31 | 3.35 | −0.75 | 28.40 | −0.47 |

| 9 | 29.2 | 0.43 | 29.20 | −0.19 | 3.37 | −0.19 | 3.37 | −0.59 | 29.20 | −0.56 |

| 10 | 30.5 | 0.48 | 30.50 | −0.06 | 3.42 | −0.06 | 3.42 | −0.44 | 30.50 | −0.65 |

| 11 | 31.1 | 0.52 | 31.10 | 0.06 | 3.44 | 0.06 | 3.44 | −0.30 | 31.10 | −0.74 |

| 12 | 31.2 | 0.57 | 31.20 | 0.19 | 3.44 | 0.19 | 3.44 | −0.16 | 31.20 | −0.85 |

| 13 | 33.4 | 0.62 | 33.40 | 0.31 | 3.51 | 0.31 | 3.51 | −0.03 | 33.40 | −0.97 |

| 14 | 33.5 | 0.67 | 33.50 | 0.44 | 3.51 | 0.44 | 3.51 | 0.11 | 33.50 | −1.11 |

| 15 | 34.2 | 0.72 | 34.20 | 0.58 | 3.53 | 0.58 | 3.53 | 0.24 | 34.20 | −1.28 |

| 16 | 39.5 | 0.77 | 39.50 | 0.74 | 3.68 | 0.74 | 3.68 | 0.38 | 39.50 | −1.47 |

| 17 | 41.8 | 0.82 | 41.80 | 0.91 | 3.73 | 0.91 | 3.73 | 0.53 | 41.80 | −1.71 |

| 18 | 43.3 | 0.87 | 43.30 | 1.12 | 3.77 | 1.12 | 3.77 | 0.70 | 43.30 | −2.02 |

| 19 | 45.4 | 0.92 | 45.40 | 1.38 | 3.82 | 1.38 | 3.82 | 0.91 | 45.40 | −2.48 |

| 20 | 52.1 | 0.97 | 52.10 | 1.82 | 3.95 | 1.82 | 3.95 | 1.22 | 52.10 | −3.37 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żyluk, A.; Zieja, M.; Kawka, K.; Główczyk, B. Monitoring and Improving Aircraft Maintenance Processes Using IT Systems. Appl. Sci. 2025, 15, 1374. https://doi.org/10.3390/app15031374

Żyluk A, Zieja M, Kawka K, Główczyk B. Monitoring and Improving Aircraft Maintenance Processes Using IT Systems. Applied Sciences. 2025; 15(3):1374. https://doi.org/10.3390/app15031374

Chicago/Turabian StyleŻyluk, Andrzej, Mariusz Zieja, Karol Kawka, and Bartłomiej Główczyk. 2025. "Monitoring and Improving Aircraft Maintenance Processes Using IT Systems" Applied Sciences 15, no. 3: 1374. https://doi.org/10.3390/app15031374

APA StyleŻyluk, A., Zieja, M., Kawka, K., & Główczyk, B. (2025). Monitoring and Improving Aircraft Maintenance Processes Using IT Systems. Applied Sciences, 15(3), 1374. https://doi.org/10.3390/app15031374