A UV-C LED Lamp Driver Circuit Applied to a Direct-Current-Input Voltage Source for Sterilization and Germicidal Applications

Abstract

1. Introduction

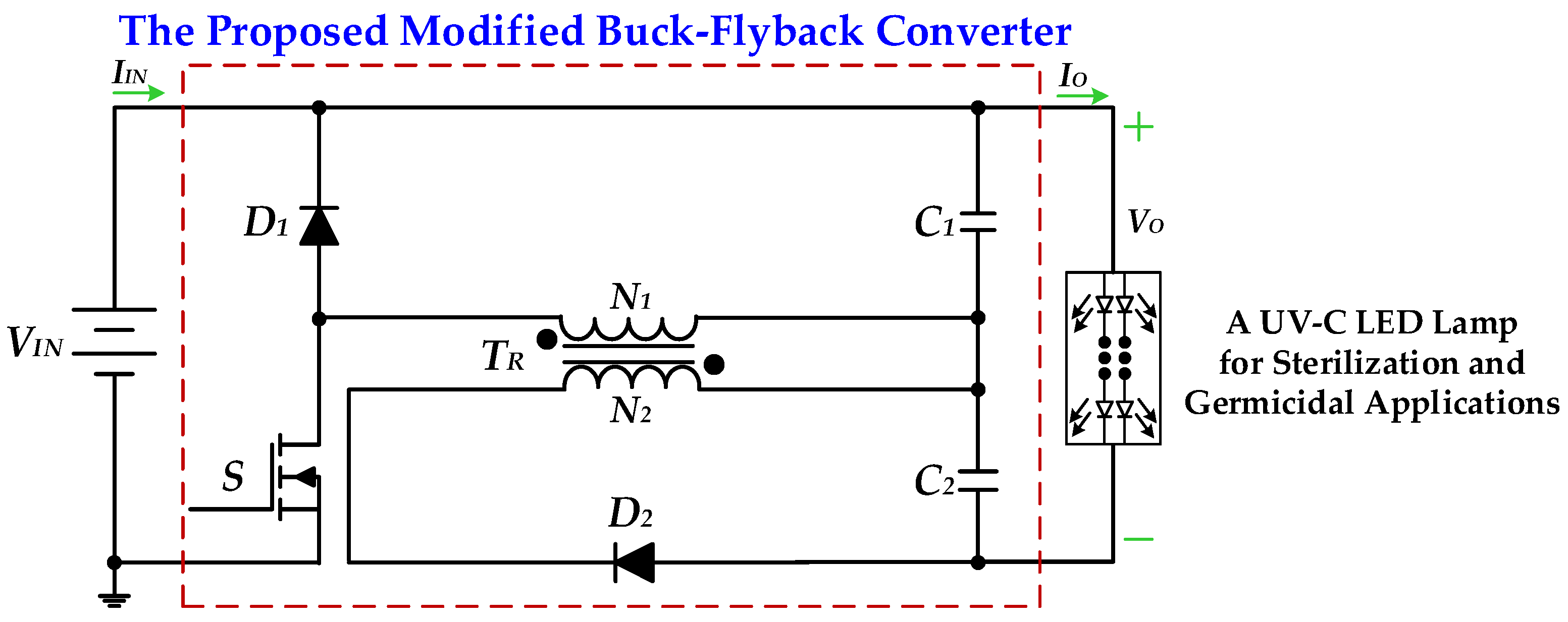

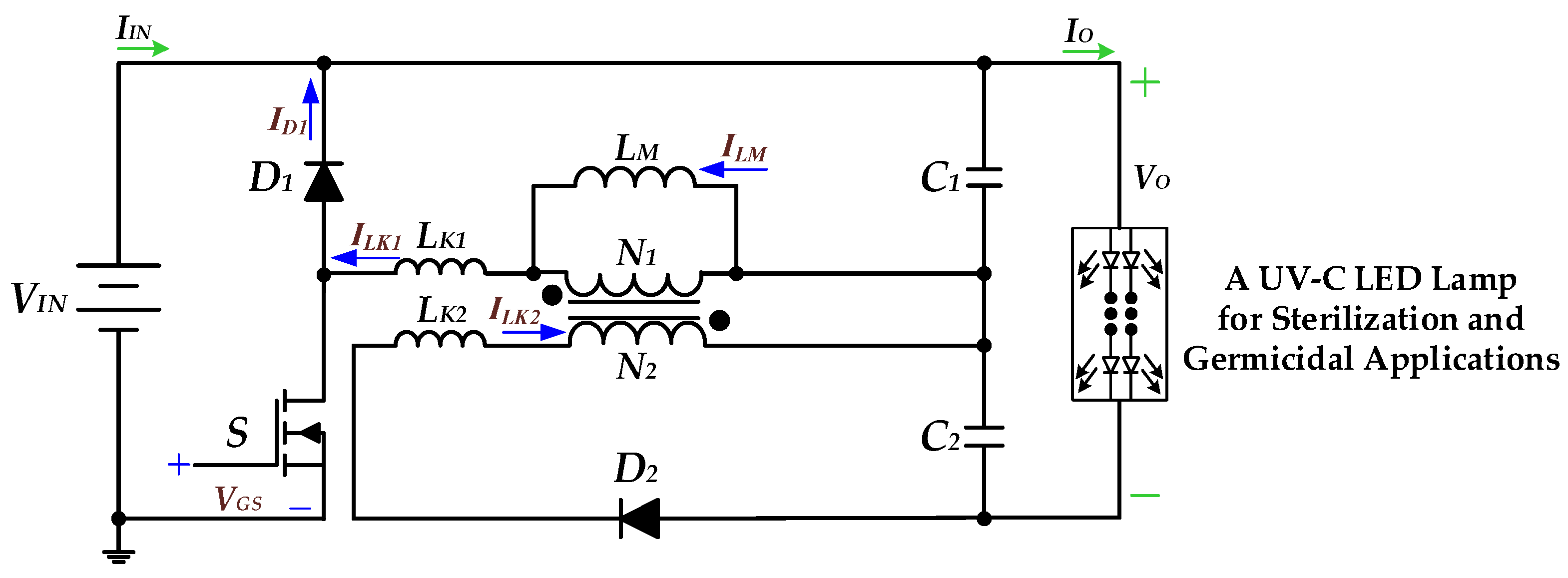

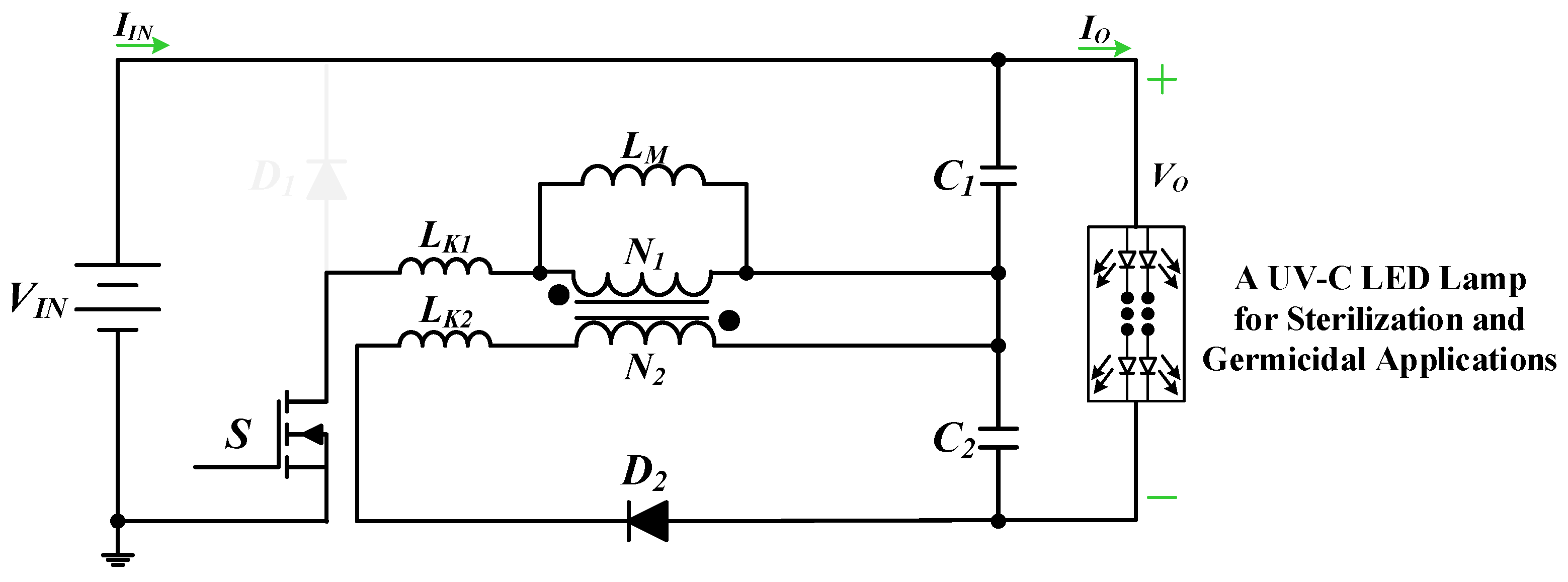

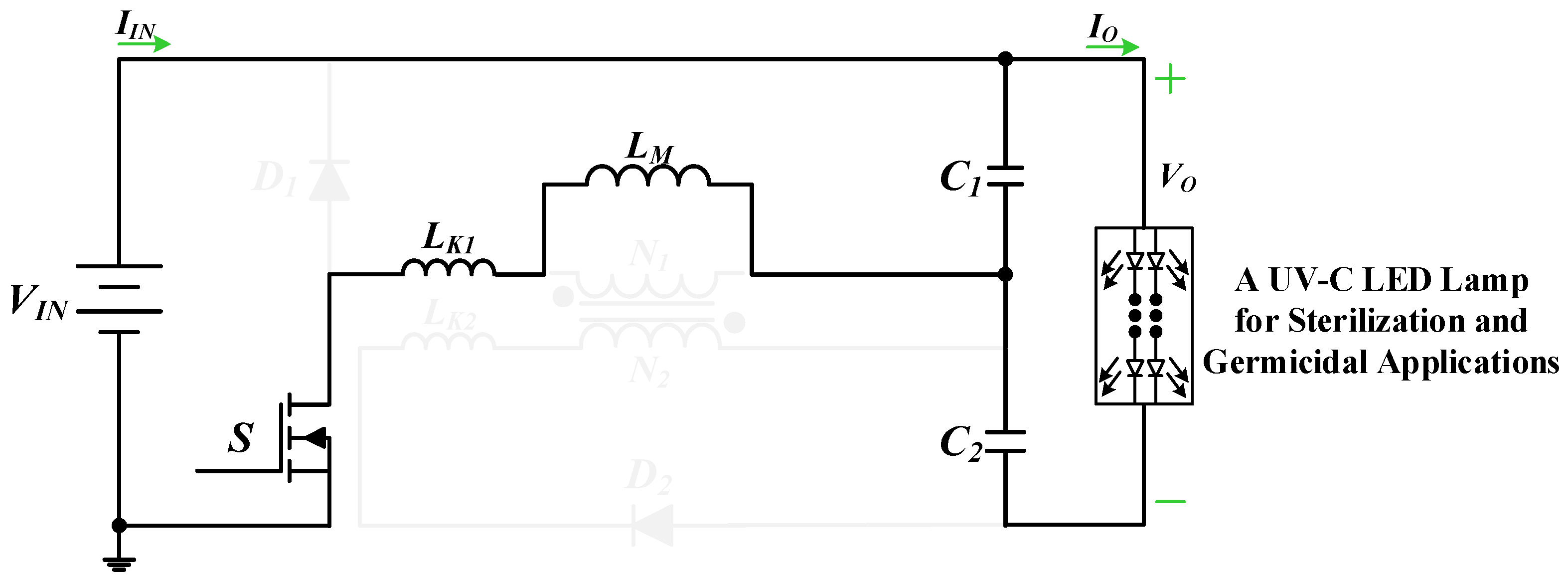

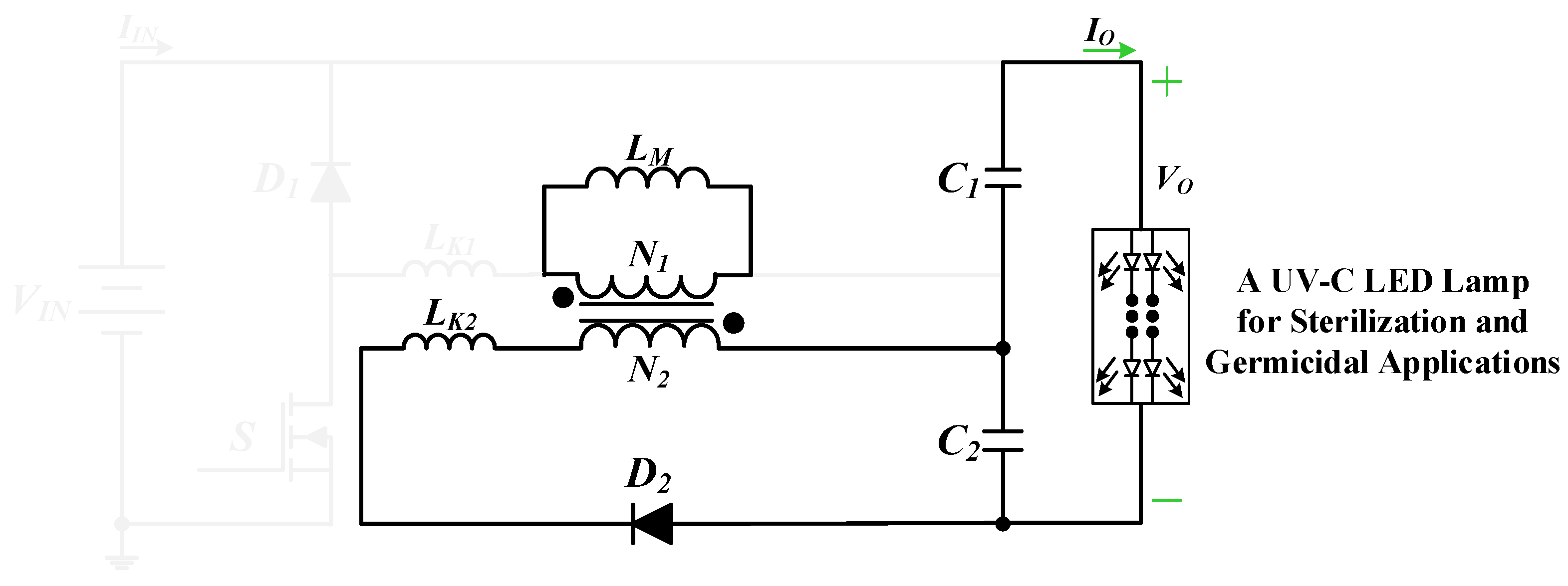

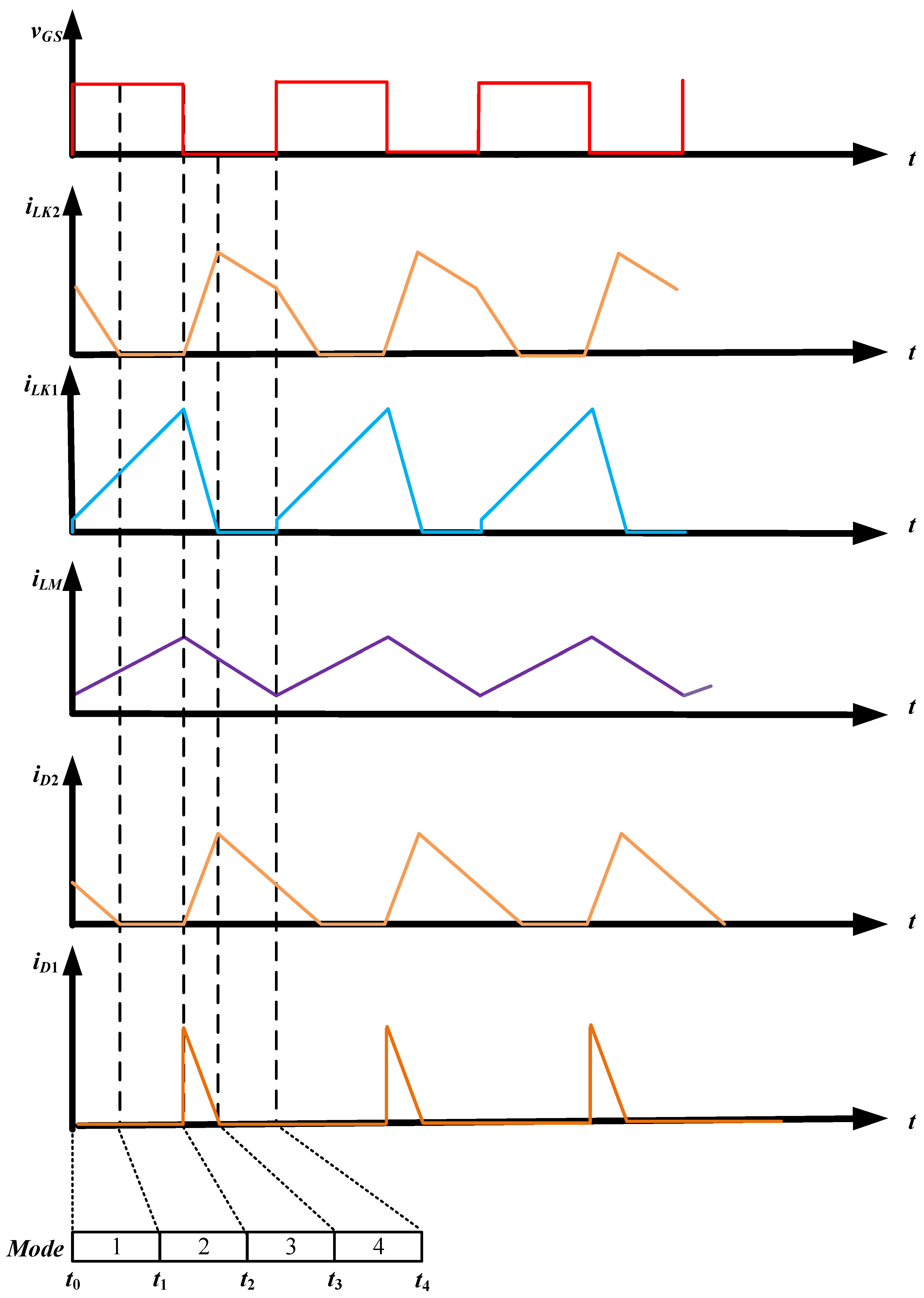

2. Descriptions and Operational Mode Analysis of the Proposed UV-C LED Lamp Driver Applied to a DC-Input Voltage for Sterilization and Germicidal Applications

- (a)

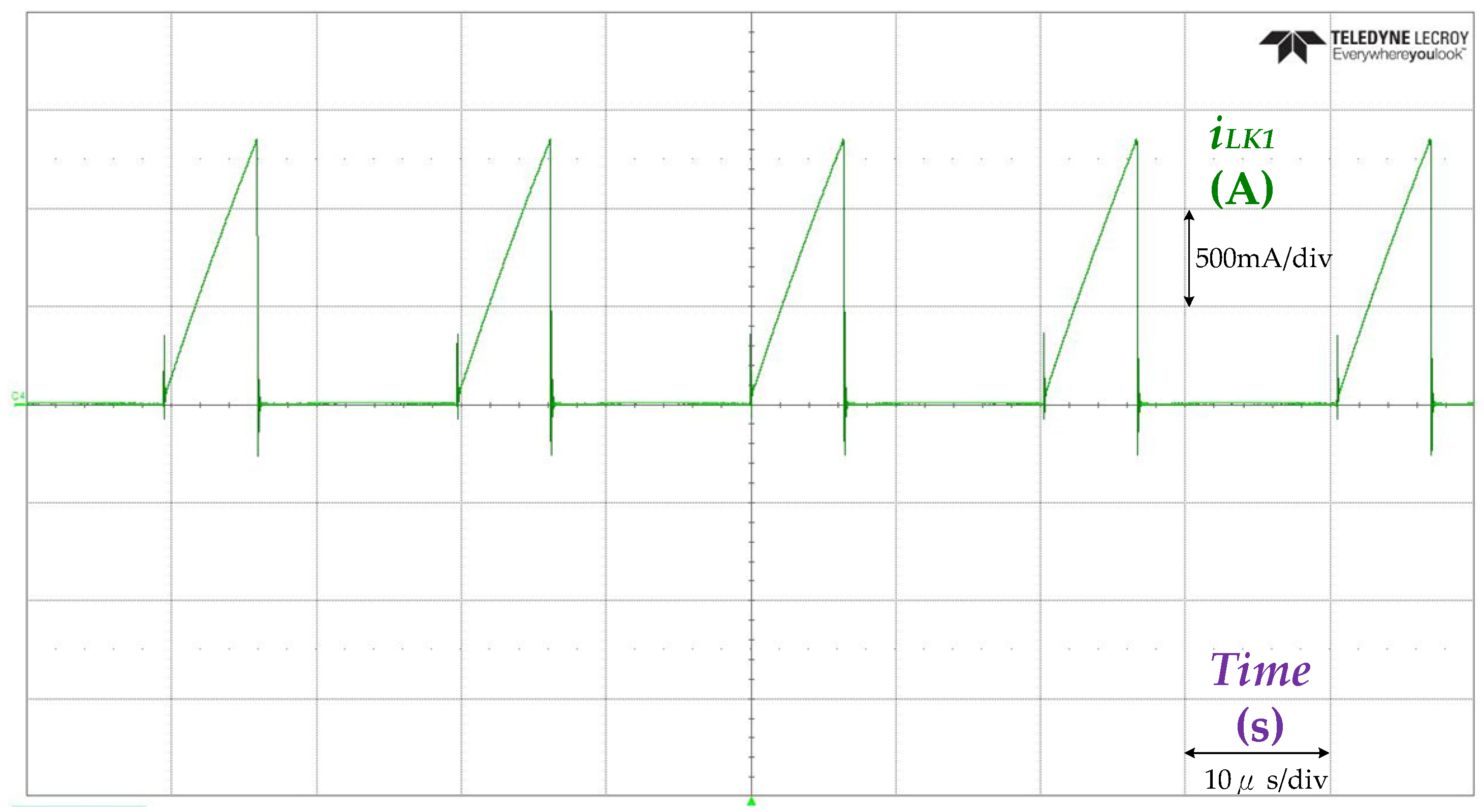

- The magnetizing inductor LM of the transformer TR is designed to operate in continuous conduction mode (CCM), which means that the minimum value of the current ILM of the magnetizing inductor is above zero. Here, LK1 and LK2 represent the primary and secondary leakage inductances of the transformer TR, respectively.

- (b)

- The energy storage capacitors C1 and C2 are assumed to have sufficient capacity, allowing the output voltage to be treated as a constant.

- (c)

- All remaining circuit components are considered ideal.

3. Design Considerations of Key Parameters in the Proposed UV-C LED Lamp Driver Circuit Applied to a DC-Input Voltage for Sterilization and Germicidal Applications

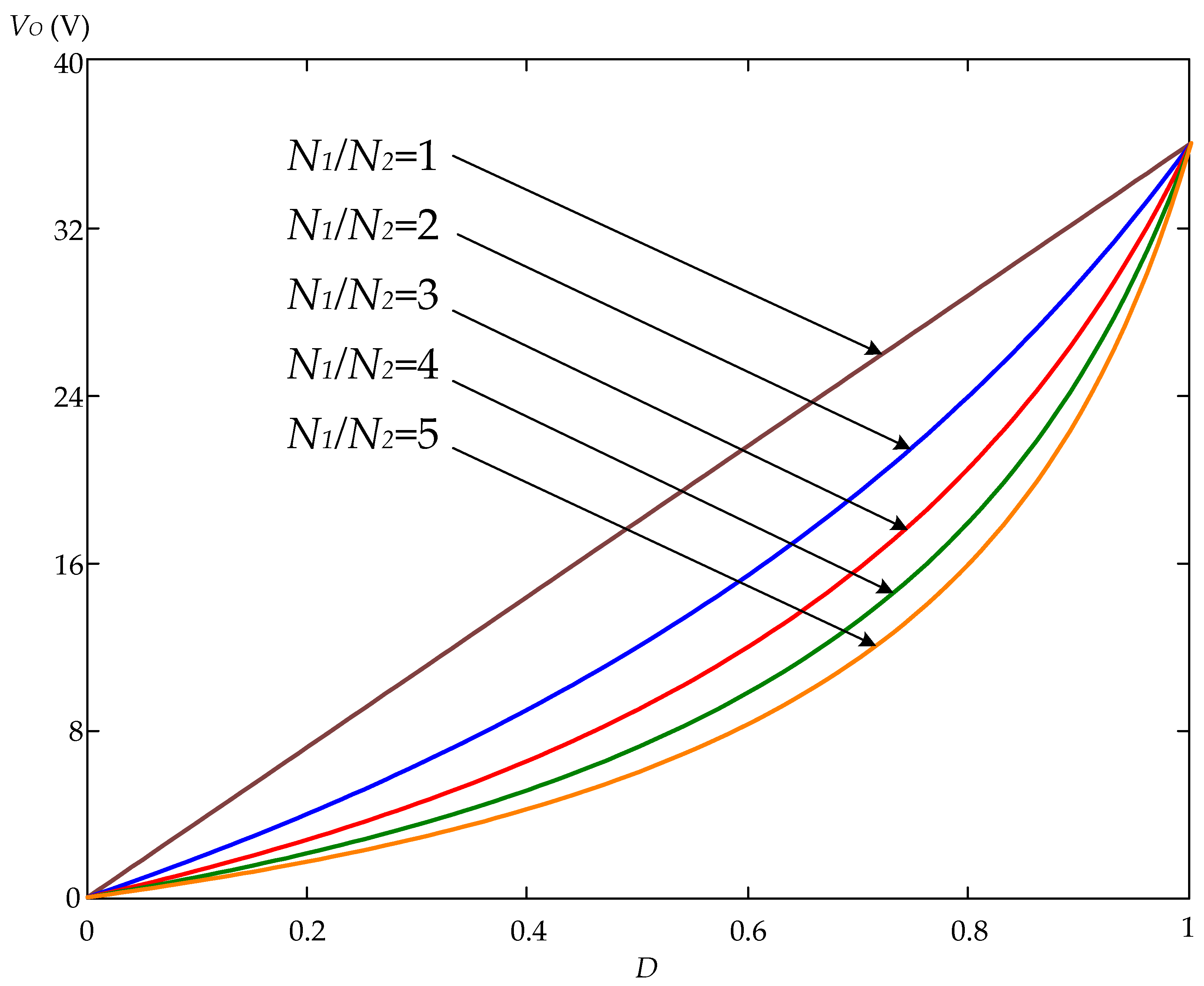

3.1. Design Consideration of the Duty Cycle D

3.2. Design Consideration of the Magnetizing Inductor LM

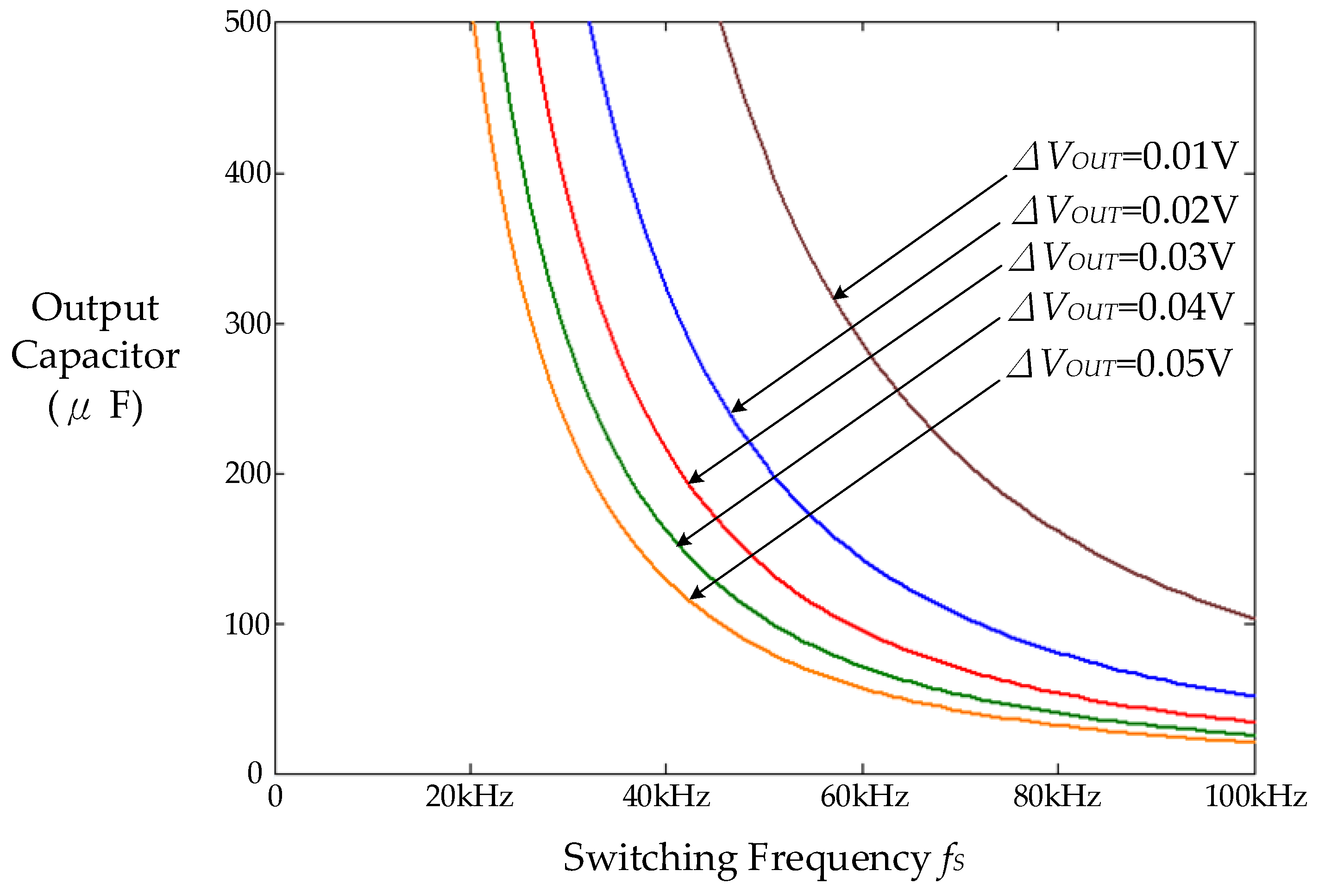

3.3. Design Consideration of the Output Capacitors CO1 and CO2

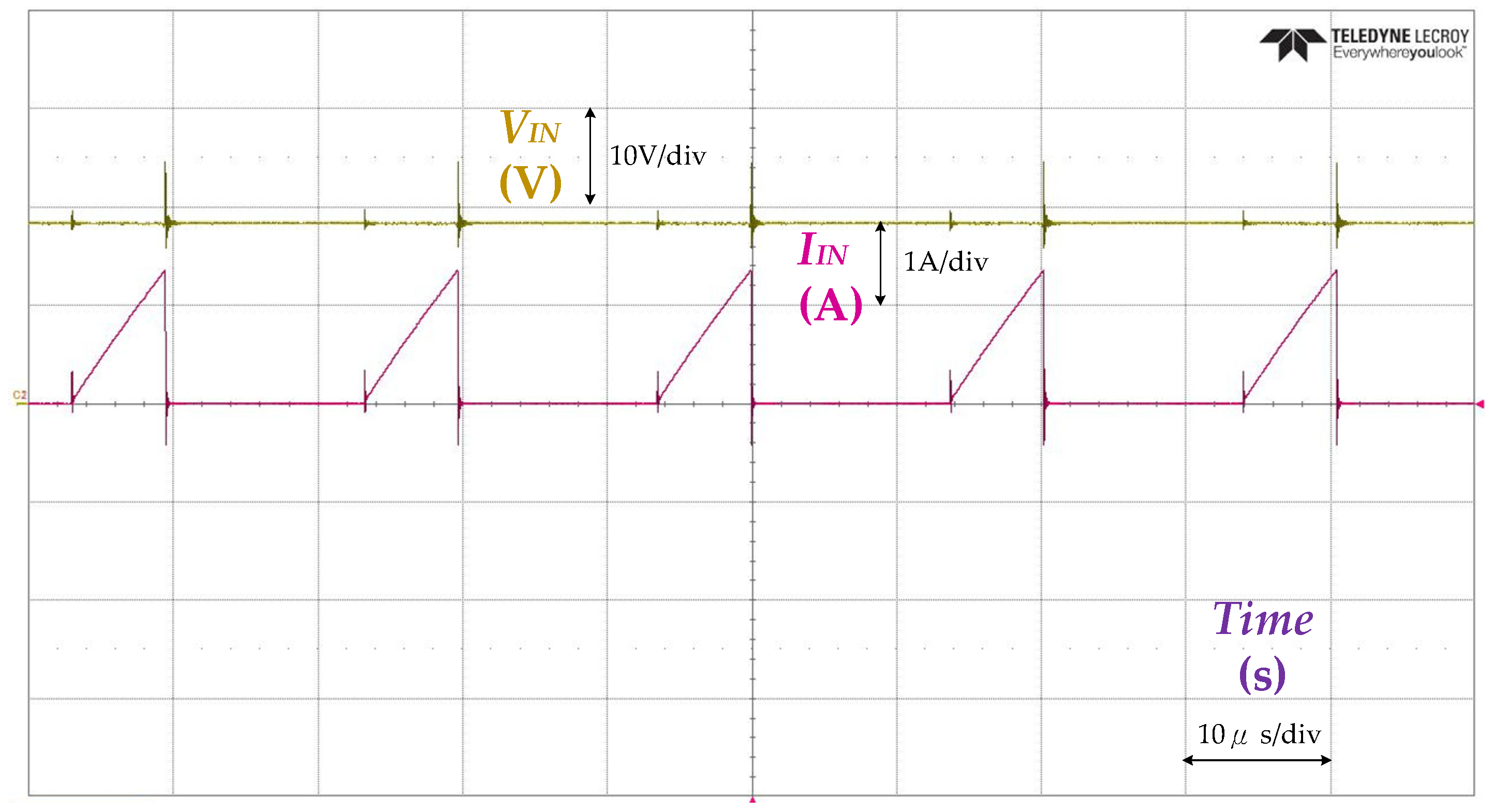

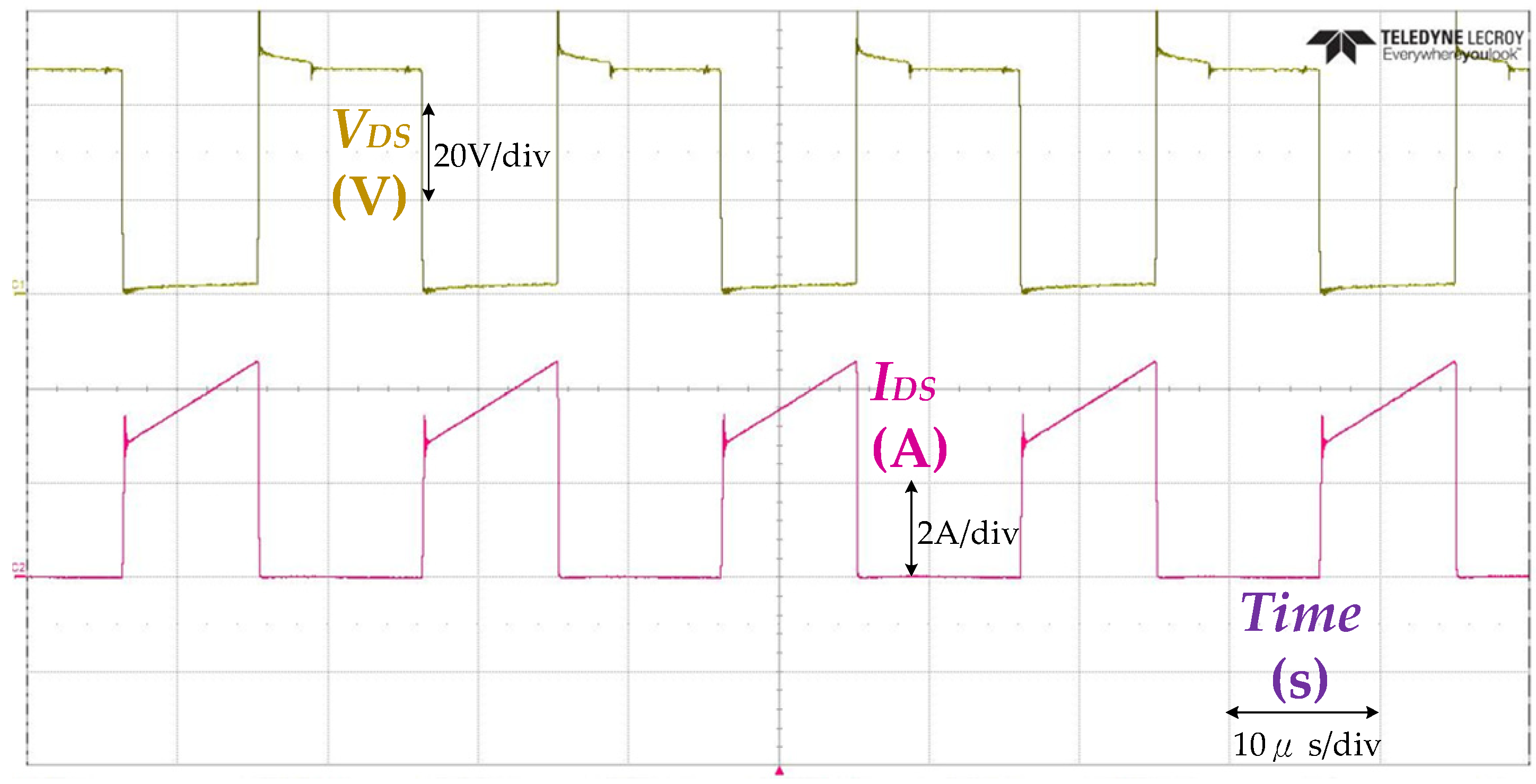

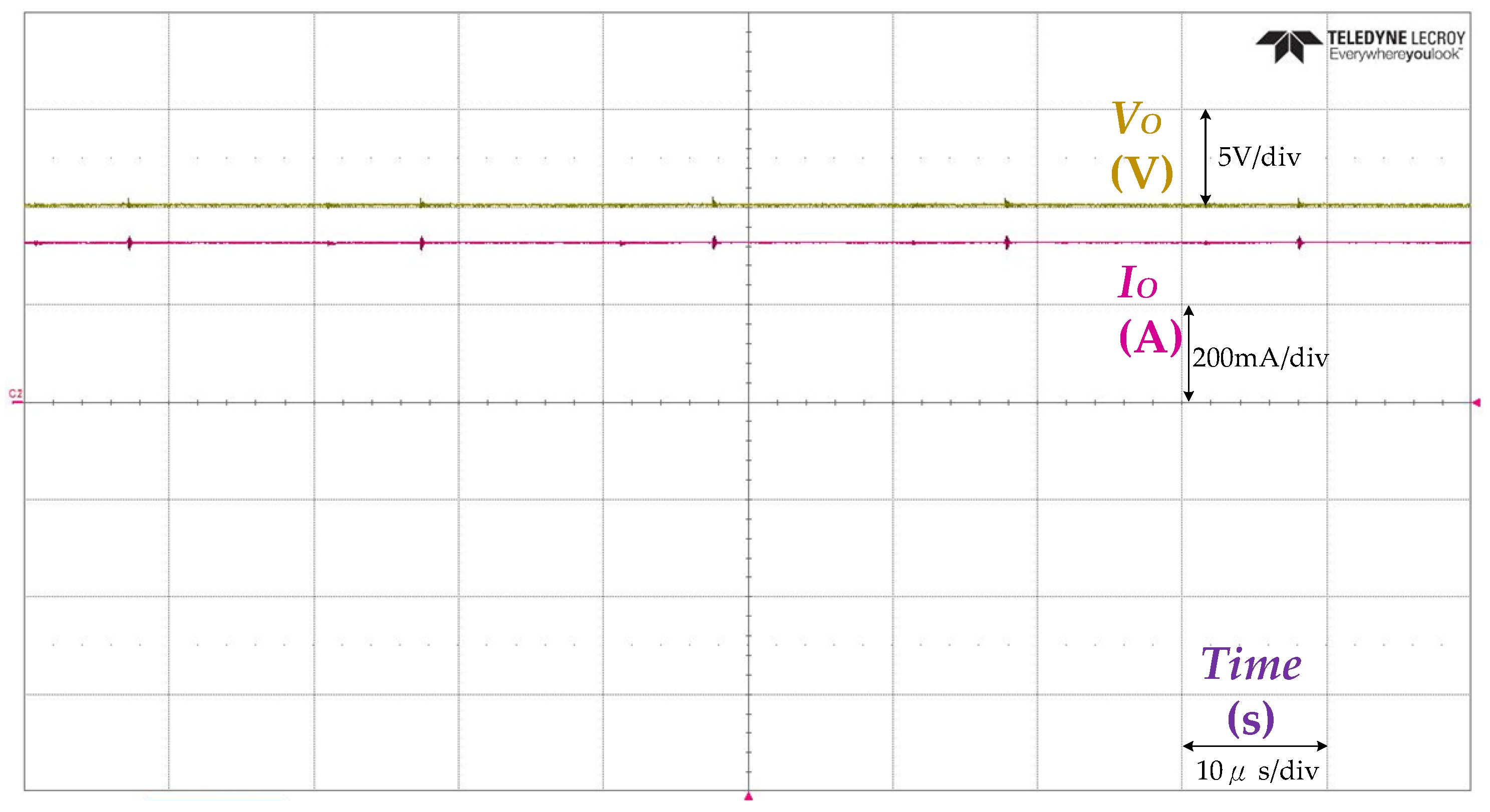

4. Experimental Results of Prototype UV-C LED Lamp Driver Circuit Applied to DC-Input Voltage Source for Sterilization and Germicidal Applications

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Kebbi, Y.; Muhammad, A.I.; Sant’Ana, A.S.; Prado-Silva, L.D.; Liu, D.; Ding, T. Recent advances on the application of UV-LED technology for microbial inactivation: Progress and mechanism. Compr. Rev. Food Sci. Food Saf. 2020, 19, 3501–3527. [Google Scholar] [CrossRef] [PubMed]

- Beck, S.E.; Ryu, H.; Boczek, L.A.; Cashdollar, J.L.; Jeanis, K.M.; Rosenblum, J.S.; Lawal, O.R.; Linden, K.G. Evaluating UV-C LED disinfection performance and investigating potential dual-wavelength synergy. Water Res. 2017, 109, 207–216. [Google Scholar] [CrossRef]

- Linden, K.G.; Hull, N.; Speight, V. Thinking outside the treatment plant: UV for water distribution system disinfection. Acc. Chem. Res. 2019, 52, 1226–1233. [Google Scholar] [CrossRef] [PubMed]

- Koutchm, T.; Popović, V.; Green, A. Chapter 1—Overview of Ultraviolet (UV) LEDs Technology for Applications in Food Production. In Ultraviolet LED Technology for Food Applications; Academic Press: New York, NY, USA, 2019; pp. 1–23. [Google Scholar]

- Song, K.; Mohseni, M.; Taghipour, F. Application of ultraviolet light-emitting diodes (UV-LEDs) for water disinfection: A review. Water Res. 2016, 94, 341–349. [Google Scholar] [CrossRef]

- Kim, D.; Kang, D. UVC LED Irradiation Effectively Inactivates Aerosolized Viruses, Bacteria, and Fungi in a Chamber-Type Air Disinfection System. Appl. Environ. Microbiol. 2018, 84, e00944-18. [Google Scholar] [CrossRef] [PubMed]

- Akgün, M.P.; Ünlütürk, S. Effects of ultraviolet light emitting diodes (LEDs) on microbial and enzyme inactivation of apple juice. Int. J. Food Microbiol. 2017, 260, 65–74. [Google Scholar] [CrossRef] [PubMed]

- Kaya, Z.; Yıldız, S.; Ünlütürk, S. Effect of UV-C irradiation and heat treatment on the shelf life stability of a lemon–melon juice blend: Multivariate statistical approach. Innov. Food Sci. Emerg. Technol. 2015, 29, 230–239. [Google Scholar] [CrossRef]

- Guan, Z.; Liu, P.; Zhou, T.; Zhou, L.; Zhang, D.; Xie, Q.; Yu, Q.; He, Y.; Wang, S.; Wang, X.; et al. Study on the Light Field Regulation of UVC-LED Disinfection for Cold Chain Transportation. Appl. Sci. 2022, 12, 1285. [Google Scholar] [CrossRef]

- Storm, N.; McKay, L.G.A.; Downs, S.N.; Johnson, R.I.; Birru, D.; de Samber, M.; Willaert, W.; Cennini, G.; Griffiths, A. Rapid and complete inactivation of SARS-CoV-2 by ultraviolet-C irradiation. Sci. Rep. 2020, 10, 22421. [Google Scholar] [CrossRef] [PubMed]

- McDevitt, J.J.; Rudnick, S.N.; Radonovich, L.J. Aerosol susceptibility of influenza virus to UV-C light. Appl. Environ. Microbiol. 2012, 78, 1666–1669. [Google Scholar] [CrossRef]

- Atari, N.; Mamane, H.; Silberbush, A.; Zuckerman, N.; Mandelboim, M.; Gerchman, Y. Disinfection of SARS-CoV-2 by UV-LED 267 nm: Comparing different variants. Sci. Rep. 2023, 13, 8229. [Google Scholar] [CrossRef] [PubMed]

- Ma, B.; Gundy, P.M.; Gerba, C.P.; Sobsey, M.D.; Linden, K.G. UV inactivation of SARS-CoV-2 across the UVC spectrum: KrCl excimer, mercury-vapor, and light-emitting-diode (LED) sources. Appl. Environ. Microbiol. 2021, 87, e01532-21. [Google Scholar] [CrossRef]

- Beck, S.E.; Rodriguez, R.A.; Hawkins, M.A.; Hargy, T.M.; Larason, T.C.; Linden, K.G. Comparison of UV-induced inactivation and RNA damage in MS2 phage across the germicidal UV spectrum. Appl. Environ. Microbiol. 2015, 82, 1468–1474. [Google Scholar] [CrossRef]

- Biasin, M.; Bianco, A.; Pareschi, G.; Cavalleri, A.; Cavatorta, C.; Fenizia, C.; Galli, P.; Lessio, L.; Lualdi, M.; Tombetti, E.; et al. Clerici. UV-C irradiation is highly effective in inactivating SARS-CoV-2 replication. Sci. Rep. 2021, 11, 6260–6267. [Google Scholar] [CrossRef] [PubMed]

- Matthew, U.O.; Nwanakwaugwu, A.C.; Kazaure, J.S.; Nwamouh, U.C.; Haruna, K.; Okafor, N.U.; Olawoyin, O.O. Ultra Violet (UV) Light Irradiation Device for Hospital Disinfection. Int. J. Inf. Commun. Technol. Hum. Dev. 2022, 14, 1–24. [Google Scholar] [CrossRef]

- Schmitz, C.; Poplata, T.; Feilen, A.; Strehmel, B. Radiation crosslinking of pigmented coating material by UV LEDs enabling depth curing and preventing oxygen inhibition. Prog. Org. Coat. 2020, 144, 105663. [Google Scholar] [CrossRef]

- Shatalov, M.; Jain, R.; Saxena, T.; Dobrinsky, A.; Shur, M. Chapter Two—Development of Deep UV LEDs and Current Problems in Material and Device Technology. Semicond. Semimet. 2017, 96, 45–83. [Google Scholar]

- Liang, J.J.; Liao, C.C.; Chang, C.S.; Lee, C.Y.; Chen, S.Y.; Huang, S.B.; Yeh, Y.F.; Singh, K.J.; Kuo, H.C.; Lin, Y.L.; et al. The Effectiveness of Far-Ultraviolet (UVC) Light Prototype Devices with Different Wavelengths on Disinfecting SARS-CoV-2. Appl. Sci. 2021, 11, 10661. [Google Scholar] [CrossRef]

- Moreno-Araujo, J.E.; Ruíz-Valdiviezo, V.M.; Camas-Anzueto, J.L.; Pérez-Patricio, M.; Hernández-Gutiérrez, C.A. Design strategies based on UV-C LED characterization to enhance Escherichia coli inactivation. J. Water Process Eng. 2024, 62, 105423. [Google Scholar] [CrossRef]

- Ueki, H.; Ito, M.; Furusawa, Y.; Yamayoshi, S.; Inoue, S.; Kawaoka, Y. A 265-Nanometer High-Power Deep-UV Light-Emitting Diode Rapidly Inactivates SARS-CoV-2 Aerosols. ASM J. 2022, 7, 1–7. [Google Scholar] [CrossRef]

- Kim, S.-J.; Kim, D.-K.; Kang, D.-H. Using UVC light-emitting diodes at wavelengths of 266 to 279 nanometers to inactivate foodborne pathogens and pasteurize sliced cheese. Appl. Environ. Microbiol. 2016, 82, 11–17. [Google Scholar] [CrossRef] [PubMed]

- Cheng, C.A.; Lan, L.F.; Hou, S.H.; Lin, C.K. A Single-Stage Electronic Lighting Driver for a Deep Ultraviolet LED Disinfection and Sterilization Lamp. In Proceedings of the The Workshop on Wide Bandgap Power Devices and Applications in Asia (WiPDA-Asia 2023), Hsinchu, Taiwan, 27–29 August 2023; pp. 1–3. [Google Scholar]

- Mathebula, T.; Leuschner, F.W.; Chowdhury, S.P. The Use of UVC-LEDs for the Disinfection of Mycobacterium Tuberculosis. In Proceedings of the 2018 IEEE PES/IAS PowerAfrica, Cape Town, South Africa, 28–29 June 2018; pp. 739–744. [Google Scholar]

- ICNIRP Statement Light-Emitting Diodes (LEDS): Implications for Safety. Available online: https://www.icnirp.org/cms/upload/publications/ICNIRPled2020.pdf (accessed on 10 November 2024).

- Juarez-Leon, F.A.; Soriano-Sánchez, A.G.; Rodríguez-Licea, M.A.; Perez-Pinal, F.J. Design and Implementation of a Germicidal UVC-LED Lamp. IEEE Access 2020, 8, 196951–196962. [Google Scholar] [CrossRef] [PubMed]

- Pouladi, F.; Farzanehfard, H.; Adib, E.; Le Sage, H. Single-Switch Soft-Switching LED Driver Suitable for Battery-Operated Systems. IEEE Trans. Ind. Electron. 2019, 66, 2726–2734. [Google Scholar] [CrossRef]

- Cheng, C.-A.; Chang, C.-H.; Chang, E.-C.; Cheng, H.-L.; Yan, W.-Y.; Lan, L.-F. A Novel Electronic Lighting Driver for a UV-C LED Disinfection and Sterilization Lamp Applied to a DC-Input Voltage Source. In Proceedings of the IEEE International Conference on Consumer Electronics (IEEE ICCE-TW 2024), Taichung, Taiwan, 9–11 July 2024. [Google Scholar]

- Cheng, C.-A.; Chang, C.-H.; Cheng, H.-L.; Chang, E.-C.; Lin, Y.-R.; Lan, L.-F. A Novel Light-Emitting Diode Streetlight Driver Circuit Applied to a Direct Current-Input Voltage Source. Sustainability 2023, 15, 10934. [Google Scholar] [CrossRef]

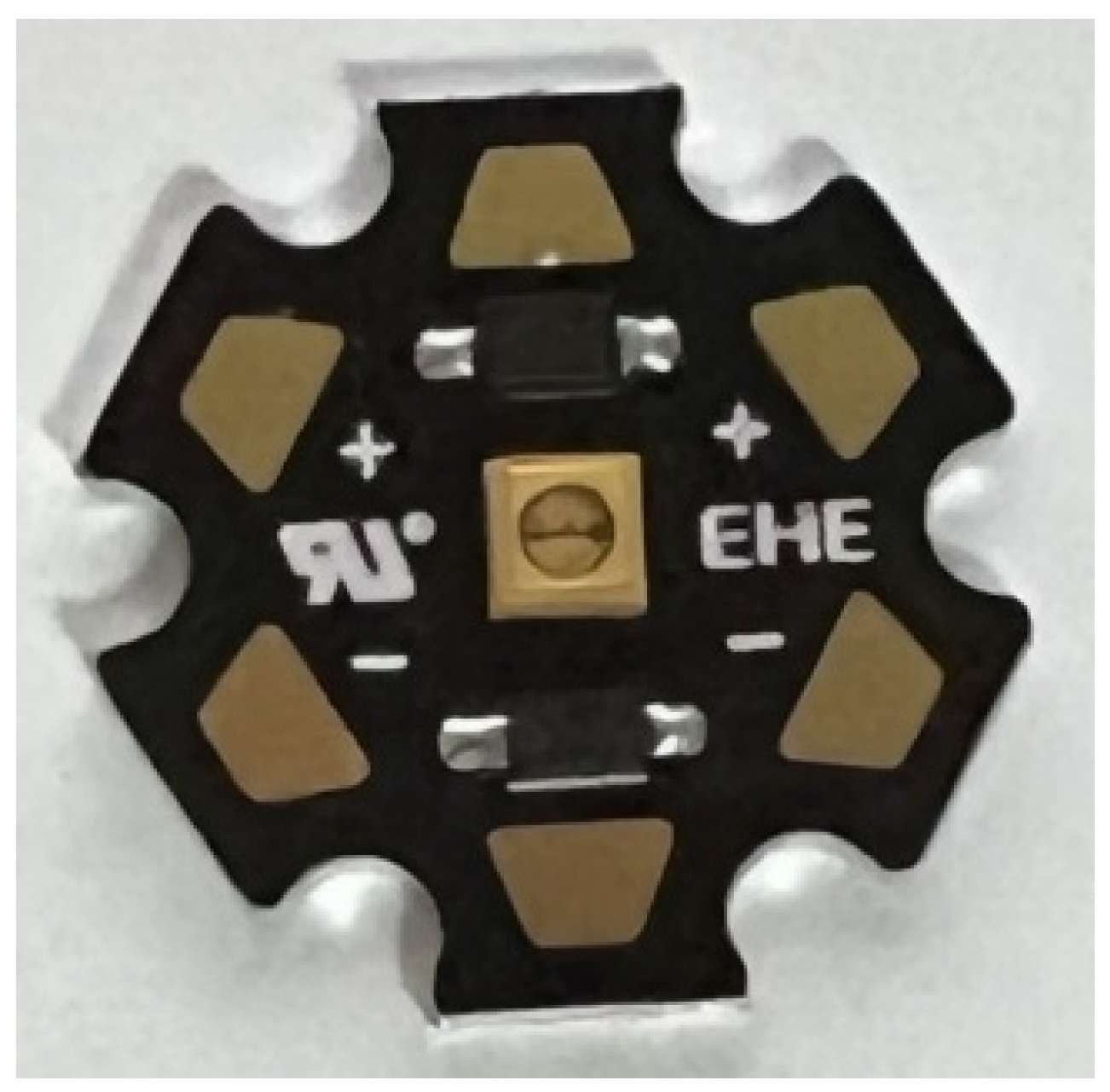

| Parameter | Value |

|---|---|

| Rated Power | 0.33 W |

| Rated Voltage | 10 V |

| Rated Current | 33 mA |

| Wavelength | 275 nm |

| Viewing Angle | 120 degrees |

| Parameter | Value |

|---|---|

| Output Power PO | 3.3 W |

| Output Voltage VO | 10 V |

| Output Current IO | 330 mA |

| Component | Value |

|---|---|

| Power Switch S | IRF840 |

| Magnetizing Inductor LM | 85 μH |

| Turns Ratio of Transformer | N1:N2 = 1:1 |

| Leakage Inductors LK1 and LK2 | 1 μH |

| Diodes D1 and D2 | MUR840 |

| Capacitors C1 and C2 | 220 μF |

| Item | The UV-C LED Sterilization and Germicidal Module in [26] | The UV-C LED Sterilization and Germicidal Module Utilized in This Paper |

|---|---|---|

| Typical Wavelength | 280 nm | 275 nm |

| Typical Optical Power | 40 mW | 4 mW |

| Viewing Angle | 130 degree | 120 degree |

| Operating Current | 350 mA | 330 mA |

| Item | Existing DC-DC LED Driver in Ref. [26] | Proposed DC-DC LED Driver |

|---|---|---|

| Circuit Structure | Ćuk converter | Modified buck–flyback converter |

| DC-Input Voltage | 48 V | 18 V |

| Output Power (Output Voltage/Current) | 7.5 W (75 V/0.1 A) | 3.3 W (10 V/0.33 A) |

| Number of Power Switches Needed | 1 | 1 |

| Number of Capacitors Needed | 3 | 2 |

| Number of Magnetic Elements Needed | 2 | 1 |

| Number of Diodes Needed | 1 | 2 |

| Measured Circuit Efficiency | 91.69% | 91.22% |

| Item | Existing DC-DC LED Driver in Ref. [27] | Proposed DC-DC LED Driver |

|---|---|---|

| Circuit Structure | Modified buck converter with a coupled inductors | Modified buck–flyback converter |

| DC-Input Voltage | 12 V | 18 V |

| Output Power (Output Voltage/Current) | 8 W (8 V/1 A) | 3.3 W (10 V/0.33 A) |

| Number of Power Switches Needed | 1 | 1 |

| Number of Capacitors Needed | 2 | 2 |

| Number of Magnetic Elements Needed | 1 | 1 |

| Number of Diodes Needed | 3 | 2 |

| Measured Circuit Efficiency | 91% | 91.22% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, C.-A.; Chang, C.-H.; Cheng, H.-L.; Chang, E.-C.; Yan, W.-Y.; Lan, L.-F. A UV-C LED Lamp Driver Circuit Applied to a Direct-Current-Input Voltage Source for Sterilization and Germicidal Applications. Appl. Sci. 2025, 15, 1498. https://doi.org/10.3390/app15031498

Cheng C-A, Chang C-H, Cheng H-L, Chang E-C, Yan W-Y, Lan L-F. A UV-C LED Lamp Driver Circuit Applied to a Direct-Current-Input Voltage Source for Sterilization and Germicidal Applications. Applied Sciences. 2025; 15(3):1498. https://doi.org/10.3390/app15031498

Chicago/Turabian StyleCheng, Chun-An, Chien-Hsuan Chang, Hung-Liang Cheng, En-Chih Chang, Wen-Yi Yan, and Long-Fu Lan. 2025. "A UV-C LED Lamp Driver Circuit Applied to a Direct-Current-Input Voltage Source for Sterilization and Germicidal Applications" Applied Sciences 15, no. 3: 1498. https://doi.org/10.3390/app15031498

APA StyleCheng, C.-A., Chang, C.-H., Cheng, H.-L., Chang, E.-C., Yan, W.-Y., & Lan, L.-F. (2025). A UV-C LED Lamp Driver Circuit Applied to a Direct-Current-Input Voltage Source for Sterilization and Germicidal Applications. Applied Sciences, 15(3), 1498. https://doi.org/10.3390/app15031498