An Effective Energetic Application of Orange Waste in Multi-Component Co-Digestion with Municipal Sewage Sludge

Abstract

:1. Introduction

2. Materials and Methods

2.1. Substrate Characteristics

2.2. Experimental Procedure and Labotatory Installation

- S1—control series, mono-digestion of MSS;

- S2—two-component co-digestion of MSS and 1.5 g of OW;

- S3—two-component co-digestion of MSS and 1.0 g of IPW;

- S4—three-component co-digestion of MSS, 1.0 g of IPW, and 1.5 g of OW.

2.3. Analitical Methods

2.4. Kinetic Evaluation

2.5. Energy Balance Evaluation

3. Results and Discussion

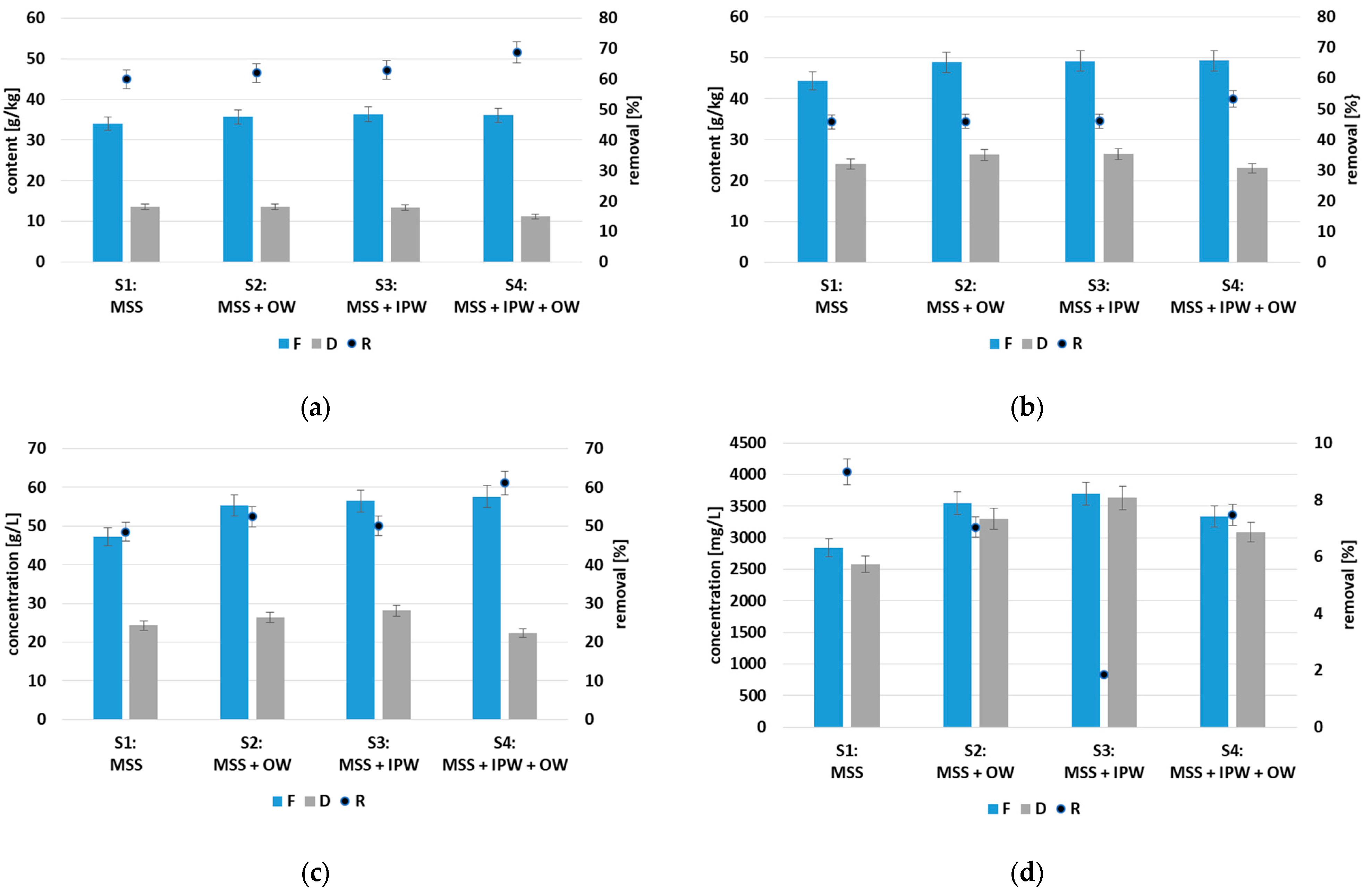

3.1. Process Performance

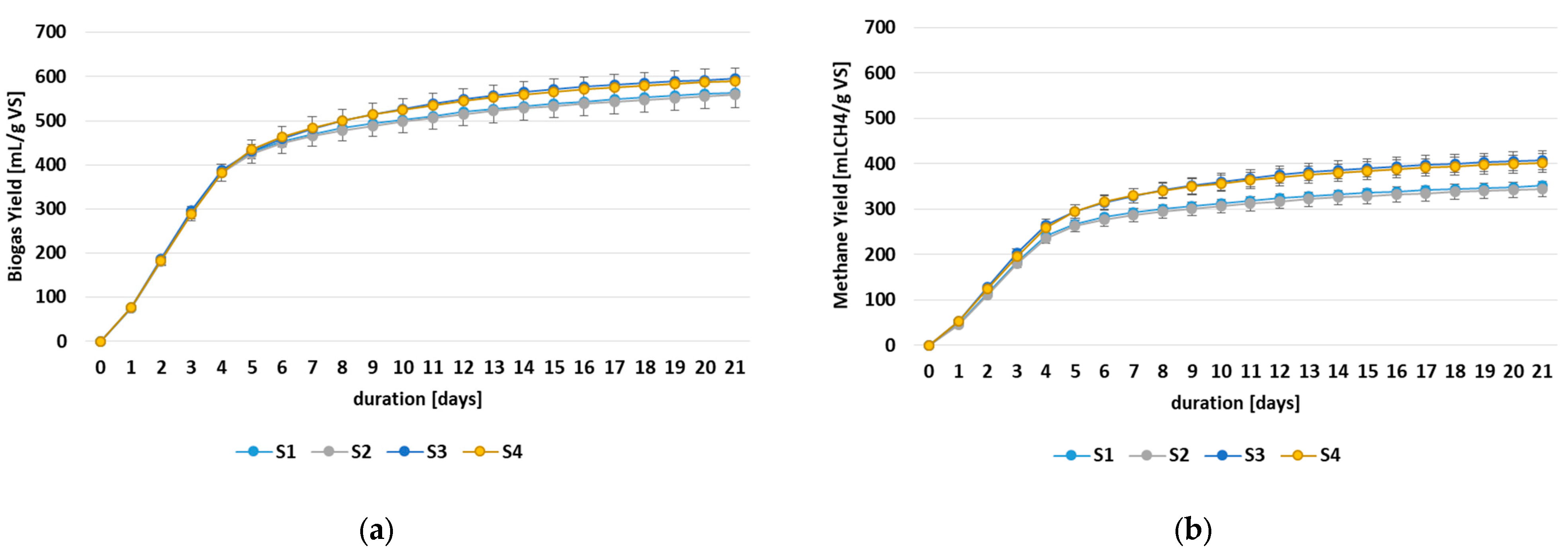

3.2. Methane Production and Its Kinetics

3.3. Energy Balance Evaluation

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ngabala, F.J.; Emmanuel, J.K. Potential substrates for biogas production through anaerobic digestion-an alternative energy source. Heliyon 2024, 10, e40632. [Google Scholar] [CrossRef] [PubMed]

- Corigliano, O.; Algieri, A. A comprehensive investigation on energy consumptions, impacts, and challenges of the food industry. Energy Convers. Manag. X 2024, 23, 10661. [Google Scholar] [CrossRef]

- Bernet, N.; Escudié, R.; Steyer, J.P. Anaerobic Digestion: Application to the Energy Recovery of Agricultural Co-products and Food Industry Waste. In Green Chemistry and Agro-Food Industry: Towards a Sustainable Bioeconomy; Baumberger, S., Ed.; Springer: Cham, Switzerland, 2024; pp. 85–103. [Google Scholar] [CrossRef]

- Duan, Y.; Wang, Z.; Ganeshan, P.; Sar, T.; Xu, S.; Rajendran, K.; Sindhu, R.; Binod, P.; Pandey, A.; Zhang, Z.; et al. Anaerobic digestion in global bio-energy production for sustainable bioeconomy: Potential and research challenges. Renew. Sust. Energ. Rev. 2025, 208, 114985. [Google Scholar] [CrossRef]

- Manakas, P.; Balafoutis, A.T.; Kottaridi, C.; Vlysidis, A. Sustainability assessment of orange peel waste valorization pathways from juice industries. Biomass Conv. Bioref. 2024, 1–20. [Google Scholar] [CrossRef]

- Bocker, R.; Silva, E.K. Pulsed electric field technology as a promising pre-treatment for enhancing orange agro-industrial waste biorefinery. RSC Adv. 2024, 14, 2116–2133. [Google Scholar] [CrossRef]

- Kalengyo, R.B.; Ibrahim, M.G.; Fujii, M.; Nasr, M. Utilizing orange peel waste biomass in textile wastewater treatment and its recyclability for dual biogas and biochar production: A techno-economic sustainable approach. Biomass Conv. Bioref. 2024, 14, 19875–19888. [Google Scholar] [CrossRef]

- Ahmad, T.; Danish, M.; Dadi, M.; Siraj, K.; Sundaram, T.; Raj, D.S.; Majeed, S.; Ramasamy, S. Potentials of orange wastes in wastewater treatment technology: A comprehensive review. J. Water Process. Eng. 2024, 67, 106113. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Fazzino, F.; Folino, A.; Paone, E.; Komilis, D. Semi-Continuous Anaerobic Digestion of Orange Peel Waste: Effect of Activated Carbon Addition and Alkaline Pretreatment on the Process. Sustainability 2019, 11, 3386. [Google Scholar] [CrossRef]

- Martín, M.A.; Siles, J.A.; Chica, A.F.; Martín, A. Biomethanization of orange peel waste. Bioresour. Technol. 2010, 101, 8993–8999. [Google Scholar] [CrossRef]

- Calabrò, P.S.; Fazzino, F.; Sidari, R.; Zema, D.A. Optimization of orange peel waste ensiling for sustainable anaerobic digestion. Renew. Energy 2020, 154, 849–862. [Google Scholar] [CrossRef]

- Wikandari, R.; Nguyen, H.; Millati, R.; Niklasson, C.; Taherzadeh, M.J. Improvement of biogas production from orange peel waste by leaching of limonene. Biomed. Res. Int. 2015, 2015, 494182. [Google Scholar] [CrossRef] [PubMed]

- Fagbohungbe, M.O.; Herbert, B.M.J.; Hurst, L.; Ibeto, C.N.; Li, H.; Usmani, S.Q.; Semple, K.T. The challenges of anaerobic digestion and the role of biochar in optimizing anaerobic digestion. Waste Manag. 2017, 61, 236–249. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Zhao, W.; Zhang, H.; Wang, Z.; Fan, C.; Zang, L. Recent achievements in enhancing anaerobic digestion with carbon- based functional materials. Bioresour. Technol. 2018, 266, 555–567. [Google Scholar] [CrossRef] [PubMed]

- Nayeri, D.; Mohammadi, P.; Bashardoust, P.; Eshtiaghi, N. A comprehensive review on the recent development of anaerobic sludge digestions: Performance, mechanism, operational factors, and future challenges. Results Eng. 2024, 22, 102292. [Google Scholar] [CrossRef]

- Sakaveli, F.; Petala, M.; Tsiridis, V.; Darakas, E. Enhancing Methane Yield in Anaerobic Co-Digestion of Primary Sewage Sludge: A Comprehensive Review on Potential Additives and Strategies. Waste 2024, 2, 29–57. [Google Scholar] [CrossRef]

- Ahmad, A.; Yadav, A.K.; Singh, A.; Singh, D.K. A comprehensive machine learning-coupled response surface methodology approach for predictive modeling and optimization of biogas potential in anaerobic Co-digestion of organic waste. Biomass Bioenergy 2024, 180, 106995. [Google Scholar] [CrossRef]

- Li, P.; Zhao, H.; Cheng, C.; Hou, T.; Shen, D.; Jiao, Y. A review on anaerobic co-digestion of sewage sludge with other organic wastes for methane production: Mechanism, process, improvement and industrial application. Biomass Bioenergy 2024, 185, 107241. [Google Scholar] [CrossRef]

- Guedes, M.T.J.C.; Soroka, V.D.; Marder, M.; Stacke, C.N.G.; Konrad, O.; Silva, M.C.D.A. Biogas generation through anaerobic digestion of orange peel waste and crude glycerol in single-stage and two-stage batch system. Environ. Qual. Manag. 2024, 34, e22234. [Google Scholar] [CrossRef]

- Bouaita, R.; Derbal, K.; Panico, A.; Iasimone, F.; Pontoni, L.; Fabbricino, M.; Pirozzi, F. Methane production from anaerobic co-digestion of orange peel waste and organic fraction of municipal solid waste in batch and semi-continuous reactors. Biomass Bioenergy 2022, 160, 106421. [Google Scholar] [CrossRef]

- Lane, G.A. Laboratory scale anaerobic digestion of fruit and vegetable solid waste. Biomass 1984, 5, 245–259. [Google Scholar] [CrossRef]

- Bouallagui, H.; Lahdhed, H.; Romdan, B.E.; Rachdi, B.; Hamdi, M. Improvement of fruit and vegetable waste anaerobic digestion performance and stability with co-substrates addition. J. Environ. Manag. 2009, 90, 1844–1849. [Google Scholar] [CrossRef] [PubMed]

- Negro, V.; Alvarado-Morales, M.; Tsapekos, P.; Fino, D.; Ruggeri, B.; Angelidaki, I. Co-digestion of orange peels and marine seaweed with cattle manure to suppress inhibition from toxicants. Biomass Conv. Bioref. 2022, 12, 3209–3218. [Google Scholar] [CrossRef]

- Serrano, A.; Siles López, J.A.; Chica, A.F.; Martín, M.A.; Karouach, F.; Mesfioui, A.; El Bari, H. Mesophilic anaerobic co-digestion of sewage sludge and orange peel waste. Environ. Technol. 2014, 35, 898–906. [Google Scholar] [CrossRef]

- Carvalho, A.; Fragoso, R.; Gominho, J.; Duarte, E. Effect of Minimizing D-Limonene Compound on Anaerobic Co-digestion Feeding Mixtures to Improve Methane Yield. Waste Biomass Valor. 2019, 10, 75–83. [Google Scholar] [CrossRef]

- Masłoń, A.; Czarnota, J.; Szczyrba, P.; Szaja, A.; Szulżyk-Cieplak, J.; Łagód, G. Assessment of Energy Self-Sufficiency of Wastewater Treatment Plants—A Case Study from Poland. Energies 2024, 17, 1164. [Google Scholar] [CrossRef]

- LCK Cuvette Test System. Available online: https://uk.hach.com/lck (accessed on 27 January 2025).

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater, 22nd ed.; APHA: Washington, DC, USA, 2012. [Google Scholar]

- Koch, K.; Lippert, T.; Drewes, J.E. The role of inoculum’s origin on the methane yield of different substrates in biochemical methane potential (BMP) tests. Bioresour. Technol. 2017, 243, 457–463. [Google Scholar] [CrossRef]

- Ware, A.; Power, N. Modelling methane production kinetics of complex poultry slaughterhouse wastes using sigmoidal growth functions. Renew. Energy 2017, 104, 50–59. [Google Scholar] [CrossRef]

- Kabouris, J.C.; Tezel, U.; Spyros, G.; Pavlostathis, S.G.; Engelmann, M.; Todd, A.C.; Gillette, R. The anaerobic biodegradability of municipal sludge and fat, oil and grease at mesophilic conditions. Water Environ. Res. 2008, 80, 212. [Google Scholar] [CrossRef]

- Kabouris, J.C.; Tezel, U.; Spyros, G.; Pavlostathis, S.G.; Engelmann, M.; Dulaney, J.A.; Todd, A.C.; Gillette, R. Mesophilic and thermophilic anaerobic digestion of municipal sludge and fat, oil and grease. Water Environ. Res. 2009, 81, 476–485. [Google Scholar] [CrossRef]

- Tandukar, M.; Pavlostathis, S.G. Anaerobic co-digestion of municipal sludge with fat-oil-grease (FOG) enhances the destruction of sludge solids. Chemosphere 2022, 292, 133530. [Google Scholar] [CrossRef]

- Rahimieh, A.; Nosrati, M.; Zamir, S.M. Anaerobic Digestion of a Curious VFA Complex Feed for Biomethane Production; A Study on ANN Modeling Optimized with Genetic Algorithm. Desalination Water Treat. 2024, 317, 100257. [Google Scholar] [CrossRef]

- Zhao, W.; Jeanne Huang, J.; Hua, B.; Huang, Z.; Droste, R.L.; Chen, L.; Wang, B.; Yang, C.; Yang, S. A new strategy to recover from volatile fatty acid inhibition in anaerobic digestion by photosynthetic bacteria. Bioresour. Technol. 2020, 311, 123501. [Google Scholar] [CrossRef] [PubMed]

- Gerardi, M.H. (Ed.) Alkalinity and pH. In The Microbiology of Anaerobic Digesters; Wiley: Hoboken, NJ, USA, 2003. [Google Scholar] [CrossRef]

- Wu, D.; Li, L.; Peng, Y.; Yang, P.; Peng, X.; Sun, Y.; Wang, X. State indicators of anaerobic digestion: A critical review on process monitoring and diagnosis. Renew. Sust. Energy Rev. 2021, 148, 111260. [Google Scholar] [CrossRef]

- Syaichurrozi, I.; Budiyono; Sumardiono, S. Predicting kinetic model of biogas production and biodegradability organic materials: Biogas production from vinasse at variation of COD/N ratio. Bioresour. Technol. 2013, 149, 390–397. [Google Scholar] [CrossRef]

- Trujillo-Reyes, Á.; Pérez, A.G.; Cuéllar, S.G.; Serrano, A.; Cubero-Cardoso, J.; Jeison, D.; Fermoso, F.G. Evaluation of toxic effect of monoterpene compounds on anaerobic digestion. J. Environ. Chem. Eng. 2024, 12, 112035. [Google Scholar] [CrossRef]

- Chubur, V.; Hasan, G.; Kára, J.; Hanzlíková, I.; Chernysh, Y.; Sedláček, J.; Wang, J.; Roubík, H. Utilization of citrus, date, and jujube substrates for anaerobic digestion processes. Biofuels Bioprod. Bioref. 2024, 18, 1917–1929. [Google Scholar] [CrossRef]

- Ruiz, B.; Flotats, X. Effect of limonene on batch anaerobic digestion of citrus peel waste. Biochem. Eng. J. 2016, 109, 9–18. [Google Scholar] [CrossRef]

- Gutiérrez, M.C.; Serrano, A.; Alonso-Fariñas, B.; Siles, J.A.; Martín, M.A. Impact of D-Limonene in the technical and economic feasibility of the anaerobic digestion applied in biorefineries. Biomass Conv. Bioref. 2024, 14, 14877–14888. [Google Scholar] [CrossRef]

- Liu, Y.; Xi, Y.; Li, Q.; Dzakpasu, M.; Chen, R.; Li, Y.Y. Biokinetic and microbial insights into regulatory mechanisms of long-chain fatty acid degradation during food waste-lipid co-digestion within anaerobic membrane bioreactor. Bioresour. Technol. 2024, 408, 131223. [Google Scholar] [CrossRef]

- Demirel, B.; Örok, M.; Hot, E.; Erkişi, S.; Albükrek, M.; Onay, T. Recovery of biogas as a source of renewable energy from ice-cream production residues and wastewater. Environ. Technol. 2013, 34, 2099–2104. [Google Scholar] [CrossRef]

- Worwąg, M.; Neczaj, E.; Grosser, A.; Krzemińska, D. Methane production from fat-rich materials. Civ. Environ. Eng. Rep. 2011, 6, 147–162. [Google Scholar]

- Grosser, A.; Neczaj, E.; Singh, B.R.; Almås, Å.R.; Brattebø, H.; Kacprzak, M. Anaerobic digestion of sewage sludge with grease trap sludge and municipal solid waste as co-substrates. Environ. Res. 2017, 155, 249–260. [Google Scholar] [CrossRef] [PubMed]

- Szaja, A.; Montusiewicz, A.; Pasieczna-Patkowska, S.; Lebiocka, M. Technological and Energetic Aspects of Multi-Component Co-Digestion of the Beverage Industry Wastes and Municipal Sewage Sludge. Energies 2022, 15, 5395. [Google Scholar] [CrossRef]

- Khadka, A.; Parajuli, A.; Dangol, S.; Thapa, B.; Sapkota, L.; Carmona-Martínez, A.A.; Ghimire, A. Effect of the Substrate to Inoculum Ratios on the Kinetics of Biogas Production during the Mesophilic Anaerobic Digestion of Food Waste. Energies 2022, 15, 834. [Google Scholar] [CrossRef]

- Ibro, M.K.; Ancha, V.R.; Lemma, D.B. Biogas Production Optimization in the Anaerobic Codigestion Process: A Critical Review on Process Parameters Modeling and Simulation Tools. J. Chem. 2024, 1, 1–25. [Google Scholar] [CrossRef]

- Karki, R.; Chuenchart, W.; Surendra, K.C.; Sung, S.; Raskin, L.; Khanal, S.K. Anaerobic co-digestion of various organic wastes: Kinetic modeling and synergistic impact evaluation. Bioresour. Technol. 2022, 343, 126063. [Google Scholar] [CrossRef]

- Parameswaran, P.; Rittmann, B.E. Feasibility of anaerobic co-digestion of pig waste and paper sludge. Bioresour. Technol. 2012, 124, 163–168. [Google Scholar] [CrossRef]

- Shen, J.; Yan, H.; Zhang, R.H.; Liu, G.Q.; Chen, C. Characterization and methane production of different nut residue wastes in anaerobic digestion. Renew. Energy 2018, 116, 835–841. [Google Scholar] [CrossRef]

- Shen, J.; Zhao, C.; Liu, Y.; Zhang, R.; Liu, G.; Chen, C. Biogas production from anaerobic co-digestion of durian shell with chicken, dairy, and pig manures. Energy Convers. Manag. 2019, 198, 110535. [Google Scholar] [CrossRef]

- Smetana, G.; Grosser, A. Kinetic study of high-solids anaerobic co-digestion of pre-treated organic waste in terms of methane production. Desalination Water Treat. 2023, 305, 60–80. [Google Scholar] [CrossRef]

| Parameter | Unit | IPW | MSS | OW | Inoculum |

|---|---|---|---|---|---|

| COD | g/L | 464 ± 7.8 | 47.4 ± 6.2 | 10.9 ± 1.2 | |

| sCOD | g/L | 449.8 ± 12.3 | 2.48 ± 0.04 | ||

| TS | g/kg | 989.5 ± 33.1 | 43.4 ± 3.7 | 940.3 ± 23.4 | 24.45 ± 5.8 |

| VS | g/kg | 979.6 ± 25.1 | 34.0 ± 4.1 | 874.5 ± 60.1 | 14.37 ± 3.7 |

| VFA | mg/L | 121 ± 8.9 | 715 ± 21.4 | 470 ± 14.2 | |

| TA | mg/L | 4375 ± 56.3 | 735 ± 47.3 | 30.1 ± 8.9 | |

| pH | 3.52 ± 0.5 | 5.62 ± 0.7 | 4.94 ± 0.9 | 7.36 ± 2.1 | |

| TP | mg/L | 19.6 ± 5.4 | 474 ± 44 | 16.3 ± 2.3 | |

| TN | mg/L | 1542 ± 30.1 | 1701 ± 36 | 90.1 ± 9.8 | |

| N-NH4+ | mg/L | 2850 ± 17.2 | 102 ± 10.1 | 36.1 ± 5.8 | |

| P-PO43− | mg/L | 11.2 ± 1.4 | 265 ± 8.9 | 12.3 ± 3.2 | |

| Phenols | mg/L | 1.3 ± 0.4 | 7.4 ± 1.1 | 64.1 ± 4.5 | |

| D-limonene | ppb | nd | nd | 312.7 ± 11.3 |

| Parameter | Unit | S1 | S2 | S3 | S4 | ||||

|---|---|---|---|---|---|---|---|---|---|

| F | D | F | D | F | D | F | D | ||

| TA | mg/L | 635 ± 19.1 | 4896 ± 120 | 680 ± 18.9 | 4590 ± 135 | 694 ± 15.7 | 4916.5 ± 135 | 732 ± 12.3 | 4915.5 ± 140 |

| VFA | mg/L | 715 ± 35.2 | 224.5 ± 9.8 | 725 ± 29 | 314 ± 7.9 | 694 ± 21 | 275 ± 17 | 742 ± 15.1 | 237 ± 14.1 |

| pH | - | 5.62 ± 0.1 | 7.35 ± 0.2 | 5.5 ± 0.1 | 7.25 ± 0.3 | 5.75 ± 0.2 | 7.38 ± 0.4 | 5.75 ± 0.1 | 7.4 ± 0.07 |

| TP | mg/L | 474 ± 9.5 | 648.5 ± 12.3 | 550 ± 10.2 | 690 ± 14.5 | 650 ± 18.1 | 760 ± 16.2 | 655 ± 21.4 | 628 ± 11.3 |

| TN | mg/L | 1701 ± 85.1 | 2065 ± 80 | 1954 ± 54.1 | 2300 ± 47 | 2033 ± 39.5 | 2290 ± 37.1 | 2087 ± 39.1 | 2064 ± 38.2 |

| N-NH4+ | mg/L | 80.2 ± 3.2 | 248.25 ± 10.2 | 100 ± 9.7 | 312 ± 9.9 | 109 ± 7.8 | 173.3 ± 7.9 | 89.7 ± 5.9 | 242.9 ± 4.7 |

| P-PO43− | mg/L | 176 ± 13.3 | 111.7 ± 8.9 | 258 ± 5.7 | 114 ± 4.4 | 264 ± 5.5 | 116 ± 5.7 | 266 ± 4.8 | 116 ± 7.8 |

| Description | Parameter | Unit | S1 | S2 | S3 | S4 |

|---|---|---|---|---|---|---|

| Experimental data | Biogas yield | mL/g VS | 563.8 | 558.2 | 595.5 | 590.5 |

| Methane yield | mL/g VS | 351.3 | 344.3 | 407.6 | 401.6 | |

| CH4 | % | 62.3 | 61.68 | 68.45 | 68.01 | |

| LGM | Mp | mL/g VS | 329.9 | 323.3 | 384.8 | 379.1 |

| Rm | mL/g VS d | 62.6 | 61.4 | 62.2 | 64.3 | |

| λ | d | 0.33 | 0.33 | 0.11 | 0.23 | |

| R2 | - | 0.9889 | 0.98733 | 0.98576 | 0.9879 | |

| HM | Mp | mL/g VS | 337.2 | 330.6 | 400.2 | 394.1 |

| k | 1/d | 0.273 | 0.274 | 0.243 | 0.246 | |

| R2 | - | 0.98729 | 0.98729 | 0.99086 | 0.98936 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szaja, A.; Czarnota, J.; Masłoń, A.; Lebiocka, M. An Effective Energetic Application of Orange Waste in Multi-Component Co-Digestion with Municipal Sewage Sludge. Appl. Sci. 2025, 15, 1537. https://doi.org/10.3390/app15031537

Szaja A, Czarnota J, Masłoń A, Lebiocka M. An Effective Energetic Application of Orange Waste in Multi-Component Co-Digestion with Municipal Sewage Sludge. Applied Sciences. 2025; 15(3):1537. https://doi.org/10.3390/app15031537

Chicago/Turabian StyleSzaja, Aleksandra, Joanna Czarnota, Adam Masłoń, and Magdalena Lebiocka. 2025. "An Effective Energetic Application of Orange Waste in Multi-Component Co-Digestion with Municipal Sewage Sludge" Applied Sciences 15, no. 3: 1537. https://doi.org/10.3390/app15031537

APA StyleSzaja, A., Czarnota, J., Masłoń, A., & Lebiocka, M. (2025). An Effective Energetic Application of Orange Waste in Multi-Component Co-Digestion with Municipal Sewage Sludge. Applied Sciences, 15(3), 1537. https://doi.org/10.3390/app15031537