The Strain Heterogeneity and Microstructural Shear Bands in AZ31B Magnesium Alloy

Abstract

:Featured Application

Abstract

1. Introduction

2. Materials and Methods

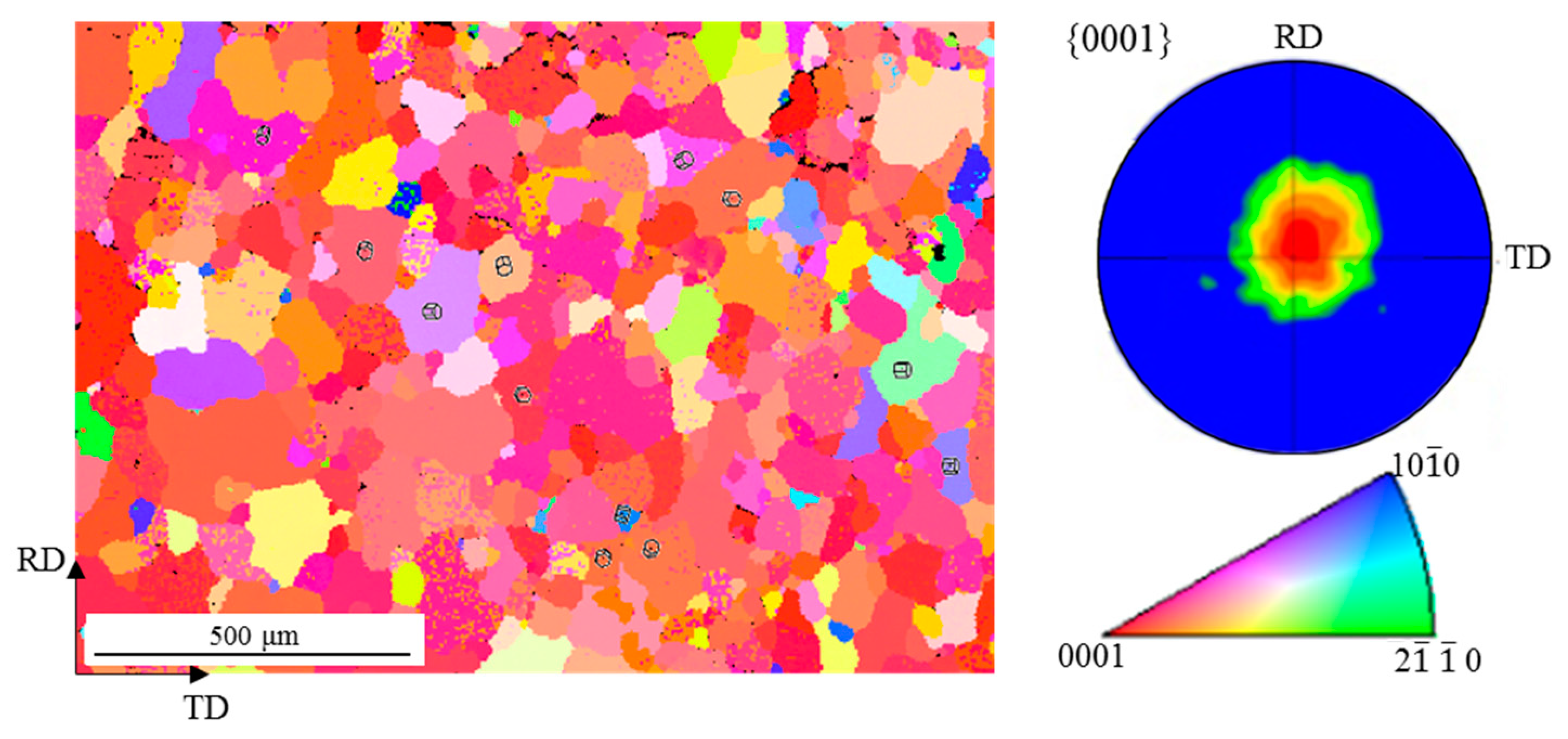

2.1. Sample Preparation

2.2. Microstructure Observation

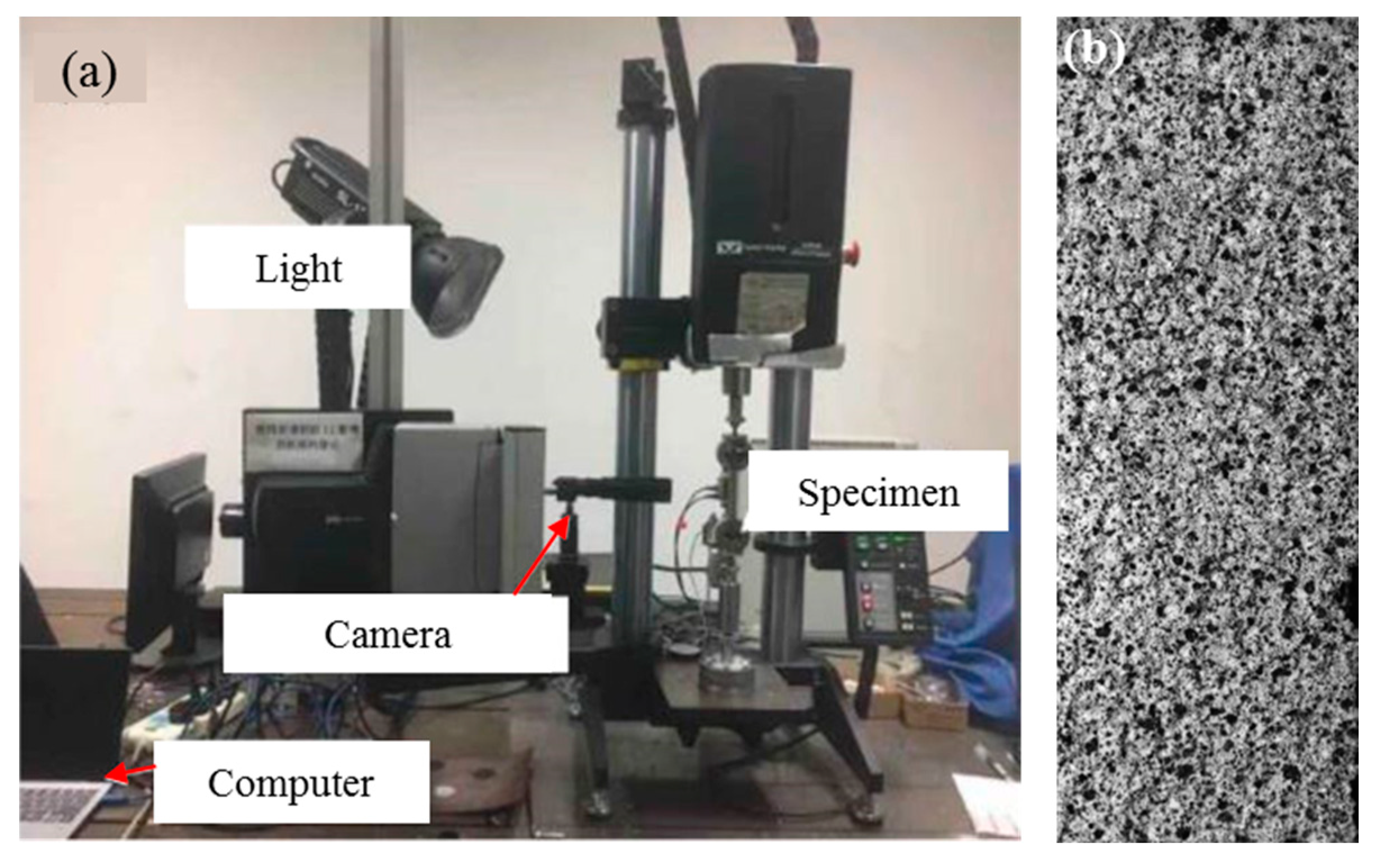

2.3. DIC Setup and Test Procedure

2.4. In Situ Testing Procedure

3. Results

3.1. Macroscopic Mechanical Properties

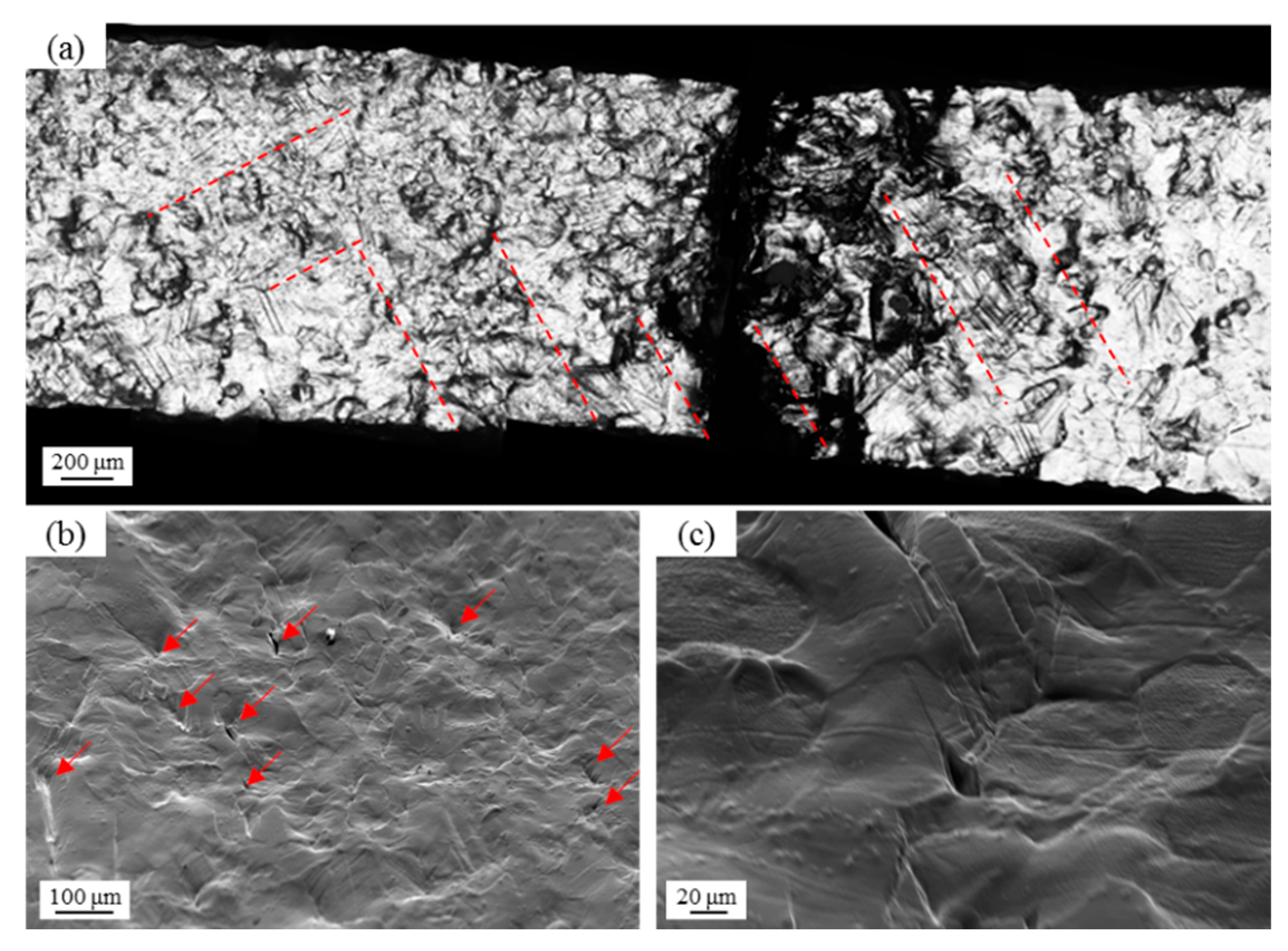

3.2. Failure Morphology

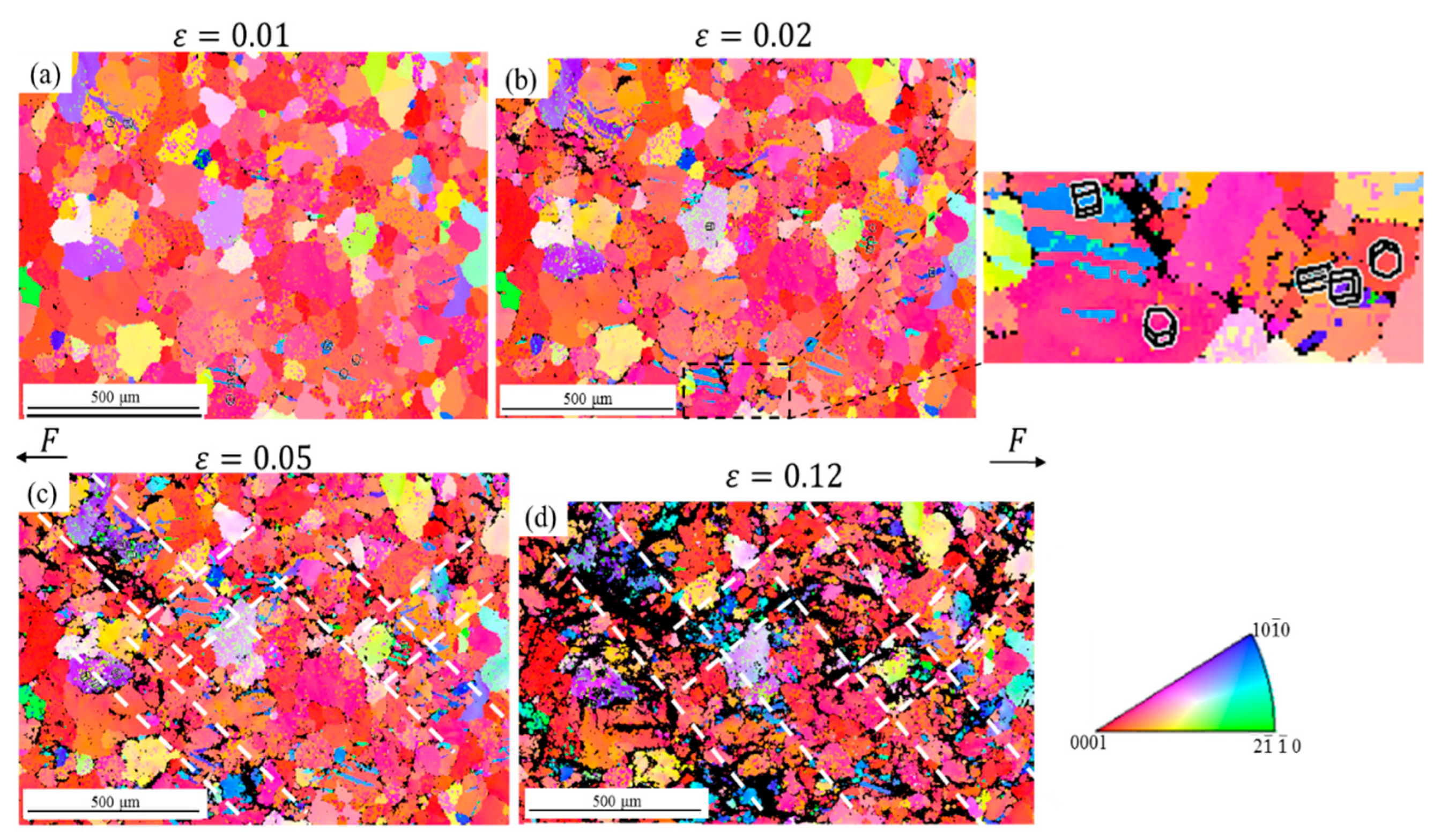

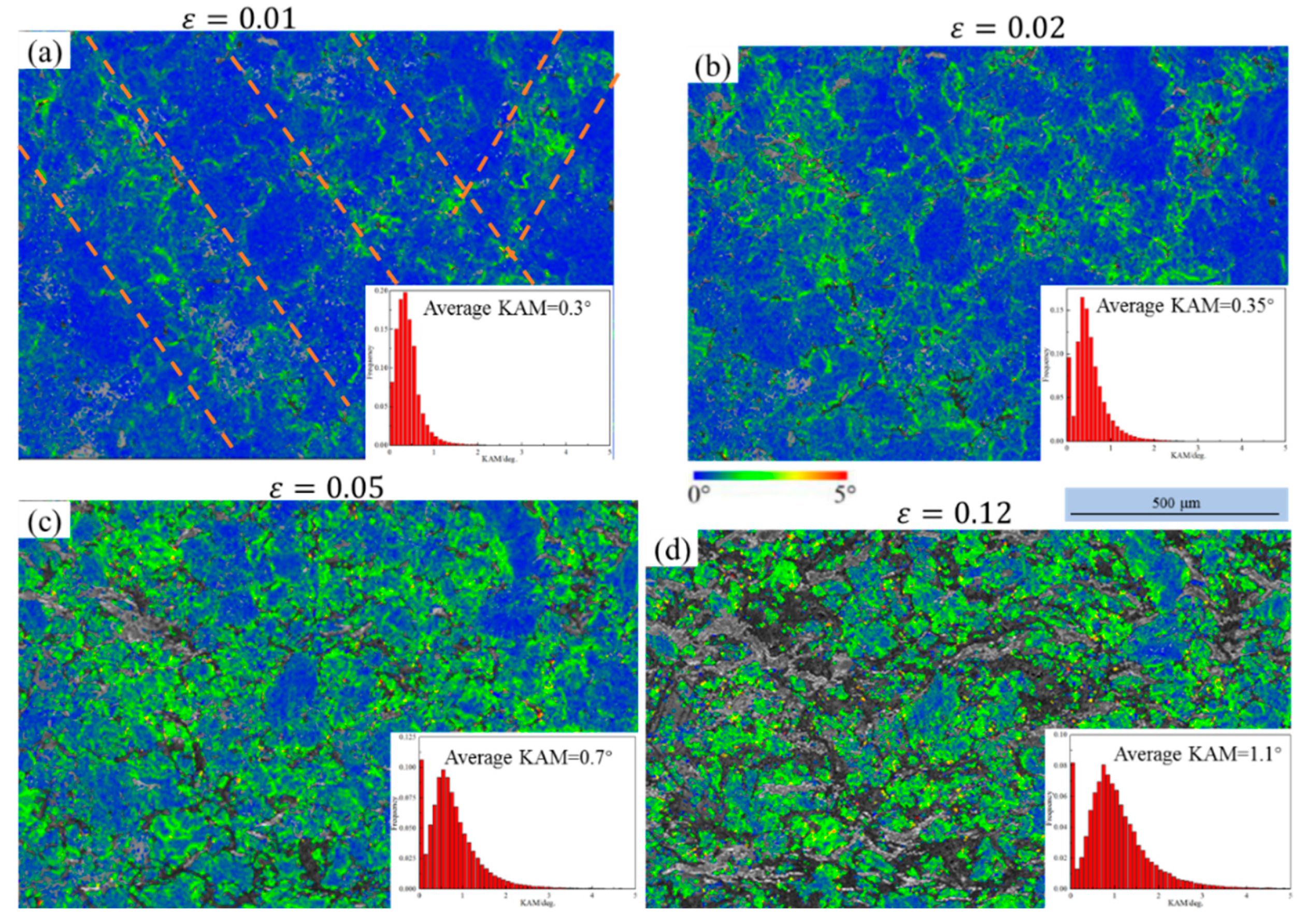

3.3. Microstructure Evolution

4. Discussion

5. Conclusions

- (1)

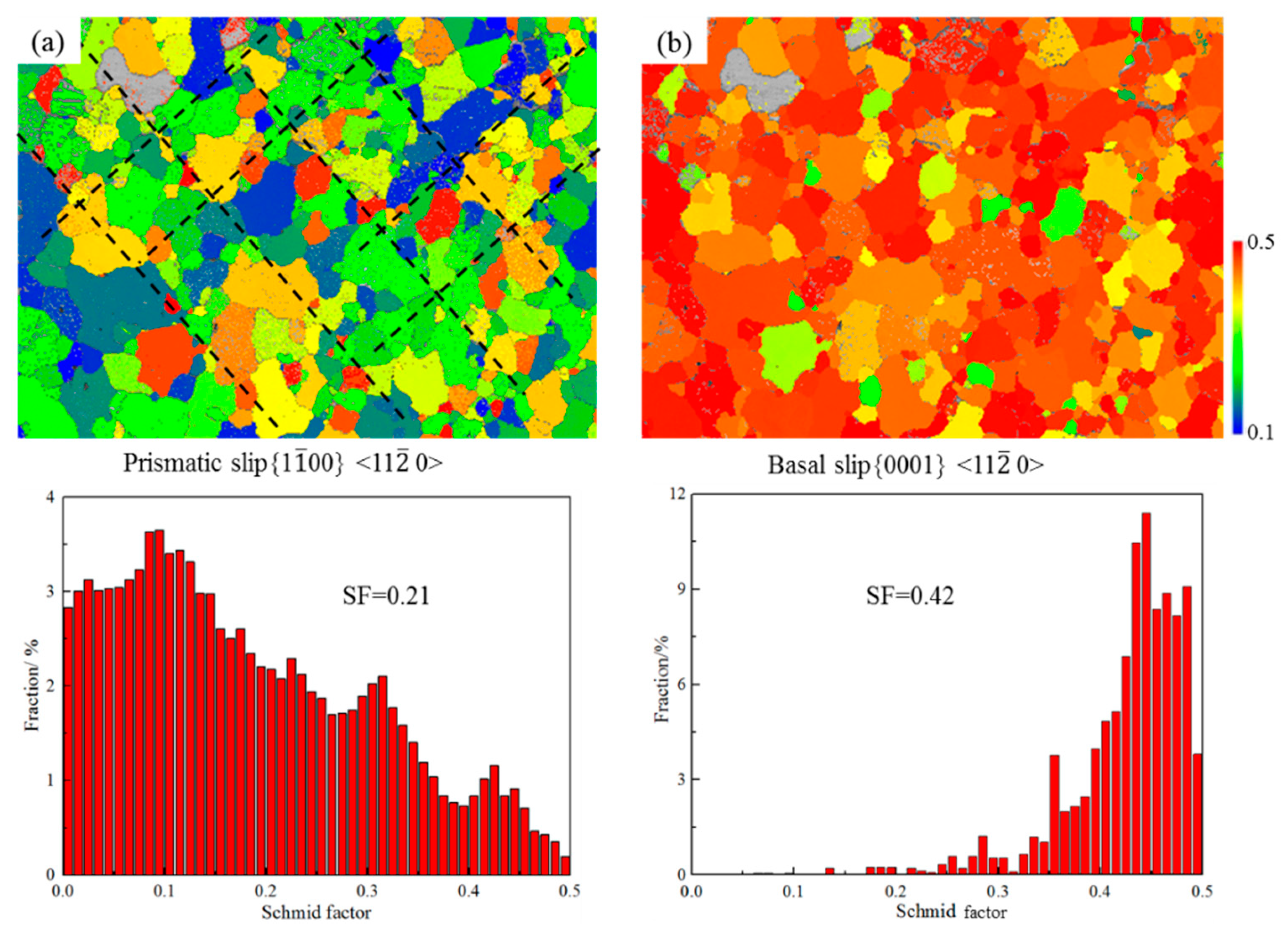

- During the uniaxial tensile loading process, the AZ31B magnesium alloy surface exhibited a densely packed network of discrete shear bands, which effectively mitigated the strain concentration, facilitating stable plastic deformation. However, as the strength of these shear bands intensified, reaching the ultimate strength threshold of the sample, the material underwent catastrophic failure upon the intersection and surface manifestation of shear bands oriented in diverse directions.

- (2)

- In situ tensile testing and microscopic examination revealed that the deformation zone originated from twins within localized grains, emphasizing the pivotal role of com-pressive twinning. The high density of the twins within the deformation bands enhanced the dislocation slip pathways, leading to intense deformation. As the twins grew towards the grain boundaries, they encountered difficulties in coordinating de-formation, triggering the initiation of microcracks at the grain interfaces. Subsequently, with the progression of plastic deformation, these microcracks proliferated and coalesced, ultimately causing material failure.

- (3)

- An analysis of the Schmidt factors in the initial sample illuminated the directional nature of the prismatic slip within grains. Notably, localized enhancements in prismatic slip intensified the formation of intersecting shear bands, thereby coordinating material deformation in a harmonious manner.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhong, C.; Liu, F.; Wu, Y.; Le, J.; Liu, L.; He, M.; Zhu, J.; Hu, W. Protective diffusion coatings on magnesium alloys: A review of recent developments. J. Alloys Compd. 2012, 520, 11–21. [Google Scholar] [CrossRef]

- Mordike, B.; Ebart, T. Magnesium: Properties-applications-potential. Mater. Sci. Eng. A 2001, 302, 37–45. [Google Scholar] [CrossRef]

- Liu, Q. Research progress on plastic deformation mechanism of Mg alloys. Acta Metall. Sin. 2010, 48, 1458–1472. [Google Scholar] [CrossRef]

- Styczynski, A.; Hartig, C.; Bohlen, J.; Letzig, D. Cold rolling textures in AZ31 wrought magnesium alloy. Scr. Mater. 2004, 50, 943–947. [Google Scholar] [CrossRef]

- Malik, A.; Wang, Y.; Nazeer, F.; Khan, M.A. Effect of pre-compression on changes in texture and yielding behavior of ZK61 Mg alloy. Vacuum 2020, 172, 109039. [Google Scholar] [CrossRef]

- Cottam, R.; Robson, J.; Lorimer, G.; Davis, B. Dynamic recrystallization of Mg and Mg-Y alloys: Crystallographic texture development. Mater. Sci. Eng. A 2008, 485, 375–382. [Google Scholar] [CrossRef]

- Agnew, S.R.; Brown, D.W.; Tomé, C.N. Validating a polycrystal model for the elastoplastic response of magnesium alloy AZ31 using in situ neutron diffraction. Acta Mater. 2006, 54, 4841–4852. [Google Scholar] [CrossRef]

- Beyerlein, I.J.; McCabe, R.J.; Tomé, C.N. Effect of microstructure on the nucleation of deformation twins in polycrystalline high-purity magnesium: A multi-scale modeling study. J. Mech. Phys. Solids 2011, 59, 988–1003. [Google Scholar] [CrossRef]

- Khan, A.; Pandey, A.; Gnäupel-Herold, T.; Mishra, R.K. Mechanical response and texture evolution of AZ31 alloy at large strains for different strain rates and temperatures. Int. J. Plast. 2011, 27, 688–706. [Google Scholar] [CrossRef]

- Knezevic, M.; Levinson, A.; Harris, R.; Mishra, R.K.; Doherty, R.D.; Kalidindi, S.R. Deformation twinning in AZ31: Influence on strain hardening and texture evolution. Acta Mater. 2010, 58, 6230–6242. [Google Scholar] [CrossRef]

- Jiang, J.; Godfrey, A.; Liu, W.; Liu, Q. Microtexture evolution via deformation twinning and slip during compression of magnesium alloy AZ31. Mater. Sci. Eng. A 2008, 483–484, 576–579. [Google Scholar] [CrossRef]

- Jiang, L.; Jonas, J.; Luo, A.; Sachdev, A.K.; Godet, S. Influence of {10–12} extension twinning on the flow behavior of AZ31 Mg alloy. Mater. Sci. Eng. A 2007, 445–446, 302–309. [Google Scholar] [CrossRef]

- Zhang, W.; Ye, Y.; He, L.; Li, P.; Zhang, H. Dynamic mechanical response and microstructural evolution of extruded Mg AZ31B plate over a wide range of strain rates. J. Alloys Compd. 2017, 696, 1067–1079. [Google Scholar] [CrossRef]

- Martin, É.; Capolungo, L.; Jiang, L.; Jonas, J.J. Variant selection during secondary twinning in Mg-3% Al. Acta Mater. 2010, 58, 3970–3983. [Google Scholar] [CrossRef]

- Mu, S.; Jonas, J.J.; Gottstein, G. Variant selection of primary, secondary and tertiary twins in a deformed Mg alloy. Acta Mater. 2012, 60, 2043–2053. [Google Scholar] [CrossRef]

- Wang, F.; Sandlöbes, S.; Diehl, M.; Sharma, L.; Roters, F.; Raabe, D. In situ observation of collective grain-scale mechanics in Mg and Mg–rare earth alloys. Acta Mater. 2014, 80, 77–93. [Google Scholar] [CrossRef]

- Kapan, E.; Shafaghi, N.; Uc̣ar, S.; Aydıner, C.C. Texture-dependent character of strain heterogeneity in Magnesium AZ31 under reversed loading. Mater. Sci. Eng. A 2017, 684, 706–711. [Google Scholar] [CrossRef]

- Hazeli, K.; Cuadra, J.; Vanniamparambil, P.A.; Kontsos, A. In situ identification of twin-related bands near yielding in a magnesium alloy. Scr. Mater. 2013, 68, 83–86. [Google Scholar] [CrossRef]

- Sandlöbes, S.; Zaefferer, S.; Schestakow, I.; Yi, S.; Gonzalez-Martinez, R. On the role of non-basal deformation mechanisms for the ductility of Mg and Mg-Y alloys. Acta Mater. 2011, 59, 429–439. [Google Scholar] [CrossRef]

- Agnew, S.; Tomé, C.; Brown, D.; Holden, T.; Vogel, S. Study of slip mechanisms in a magnesium alloy by neutron diffraction and modeling. Scr. Mater. 2003, 48, 1003–1008. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, Y.; Li, W.; Yan, Z.; Hu, P.; Liu, X. Microstructure Characterization and Mechanical Properties of an AM60B Magnesium Alloy Sheet Prepared by the Double-Pass High Strain Rate Rolling with Gradient Cooling. Adv. Eng. Mater. 2021, 23, 2000625. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, C.; Li, Y.; Guo, F.; He, Q.; Wang, M.; Wu, X.; Scattergood, R.O.; Zhu, Y. Dense dispersed shear bands in gradient-structured Ni. Int. J. Plast. 2020, 124, 186–198. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhao, Z. Fractography; Higher Education Press: Beijing, China, 2006; pp. 122–153. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Q.; Zhang, X.; Yang, X.; Huang, M. The Strain Heterogeneity and Microstructural Shear Bands in AZ31B Magnesium Alloy. Appl. Sci. 2025, 15, 1571. https://doi.org/10.3390/app15031571

Zhang Q, Zhang X, Yang X, Huang M. The Strain Heterogeneity and Microstructural Shear Bands in AZ31B Magnesium Alloy. Applied Sciences. 2025; 15(3):1571. https://doi.org/10.3390/app15031571

Chicago/Turabian StyleZhang, Qinghui, Xuhui Zhang, Xiaojuan Yang, and Min Huang. 2025. "The Strain Heterogeneity and Microstructural Shear Bands in AZ31B Magnesium Alloy" Applied Sciences 15, no. 3: 1571. https://doi.org/10.3390/app15031571

APA StyleZhang, Q., Zhang, X., Yang, X., & Huang, M. (2025). The Strain Heterogeneity and Microstructural Shear Bands in AZ31B Magnesium Alloy. Applied Sciences, 15(3), 1571. https://doi.org/10.3390/app15031571