Experimental Study on Grouting Diffusion Law of Tunnel Secondary Lining Cracks Based on Different Slurry Viscosities

Abstract

:Featured Application

Abstract

1. Introduction

2. Grouting Diffusion Test for Tunnel Second Lining Cracks

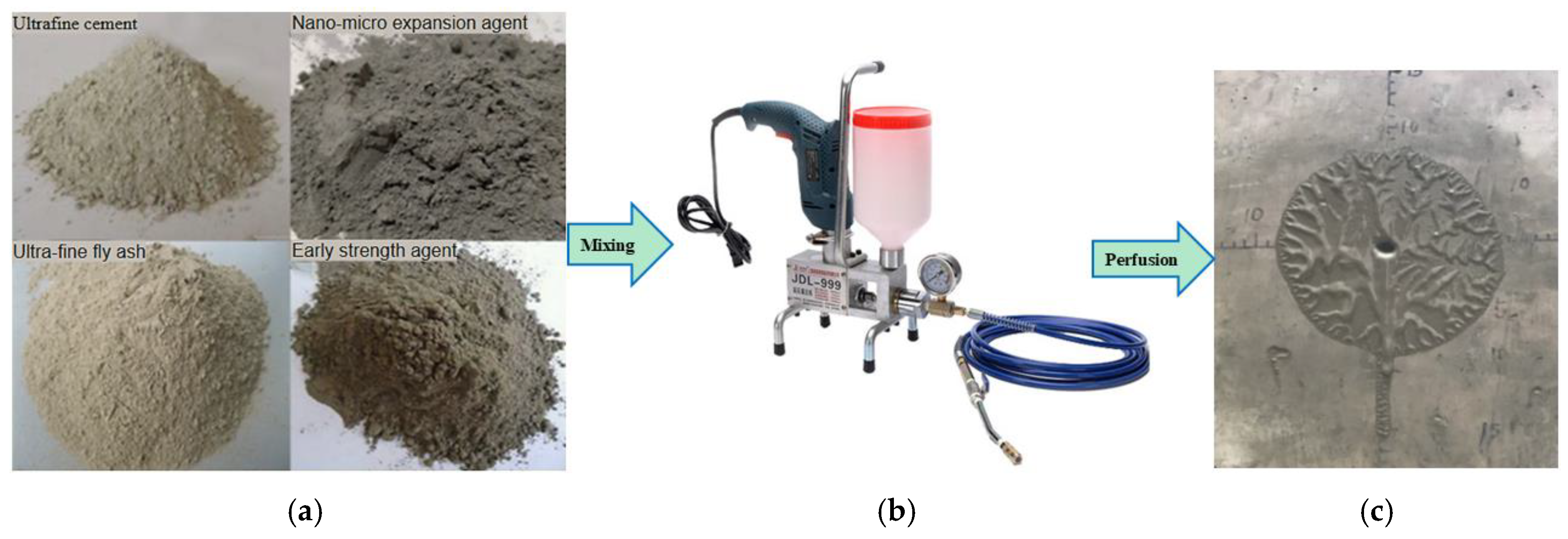

2.1. Material Parameters

2.2. Slurry Initial Viscosity Test

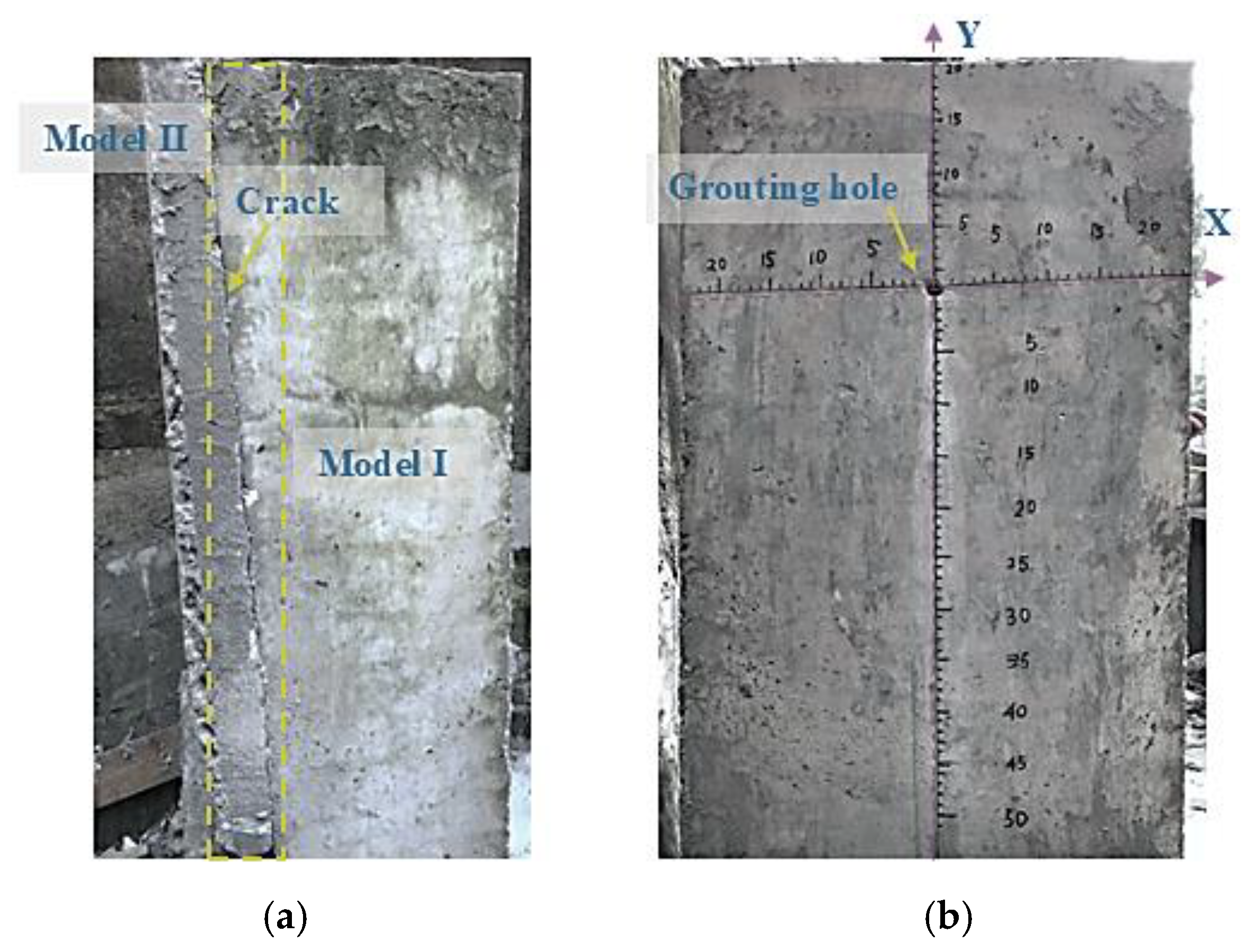

2.3. Tunnel Second Lining Crack Modeling

2.4. Experimental Method and Process

- (1)

- Carry out mechanical drilling at 20 cm from the top of Model Ⅰ, with the direction of drilling being the direction normal to the cross-section of the fissure and install the grouting needles tightly after the drilling is completed and carry out the sealing treatment to ensure that there is no leakage of slurry in the process of grouting.

- (2)

- To precisely capture the morphology of slurry transport during diffusion, a right-angle coordinate system was meticulously inscribed on the test model with the grouting hole as the origin O. In this system, the X coordinates extend horizontally, while the Y coordinates extend vertically downward, as illustrated in Figure 3b.

- (3)

- The crack width was set to be 0.4 mm, which was controlled by placing a washer between Model Ⅰ and Model Ⅱ.

- (4)

- Experiment adopted a high-pressure cement slurry grouting machine, and this machine output the maximum pressure was 12,000 Psi; the slurry was injected into the face where the crack was located by means of a grouting needle, and the rate of slurry injection was recorded.

- (5)

- During the grouting process, Model Ⅱ was turned on and the spreading pattern and transport distance of the slurry were photographed every 2.5 s. After clearing the slurry between the crack and the grouting machine, then we continue to be closed Model Ⅱ repeat the above steps.

3. Analysis of Test Results

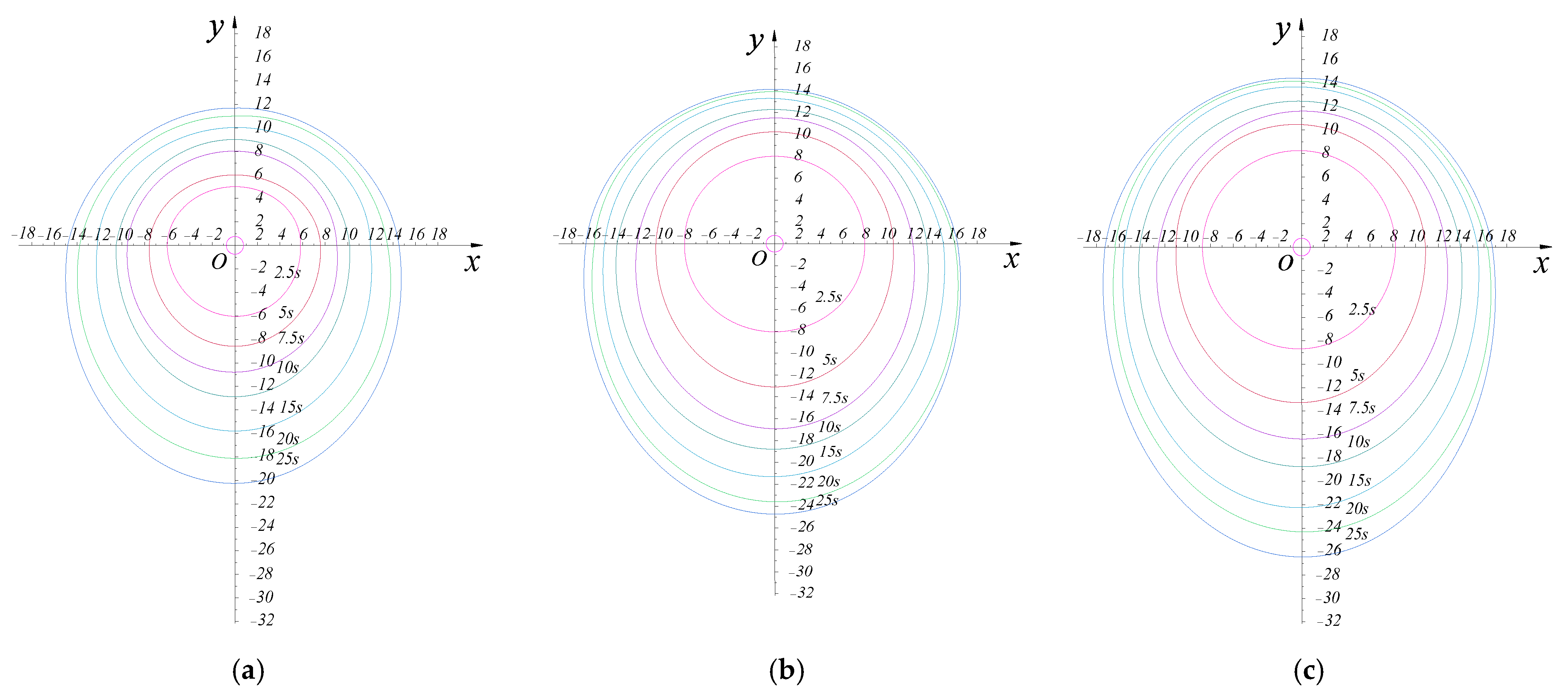

3.1. Diffusion Pattern of Grouting with Different Water–Cement Ratios

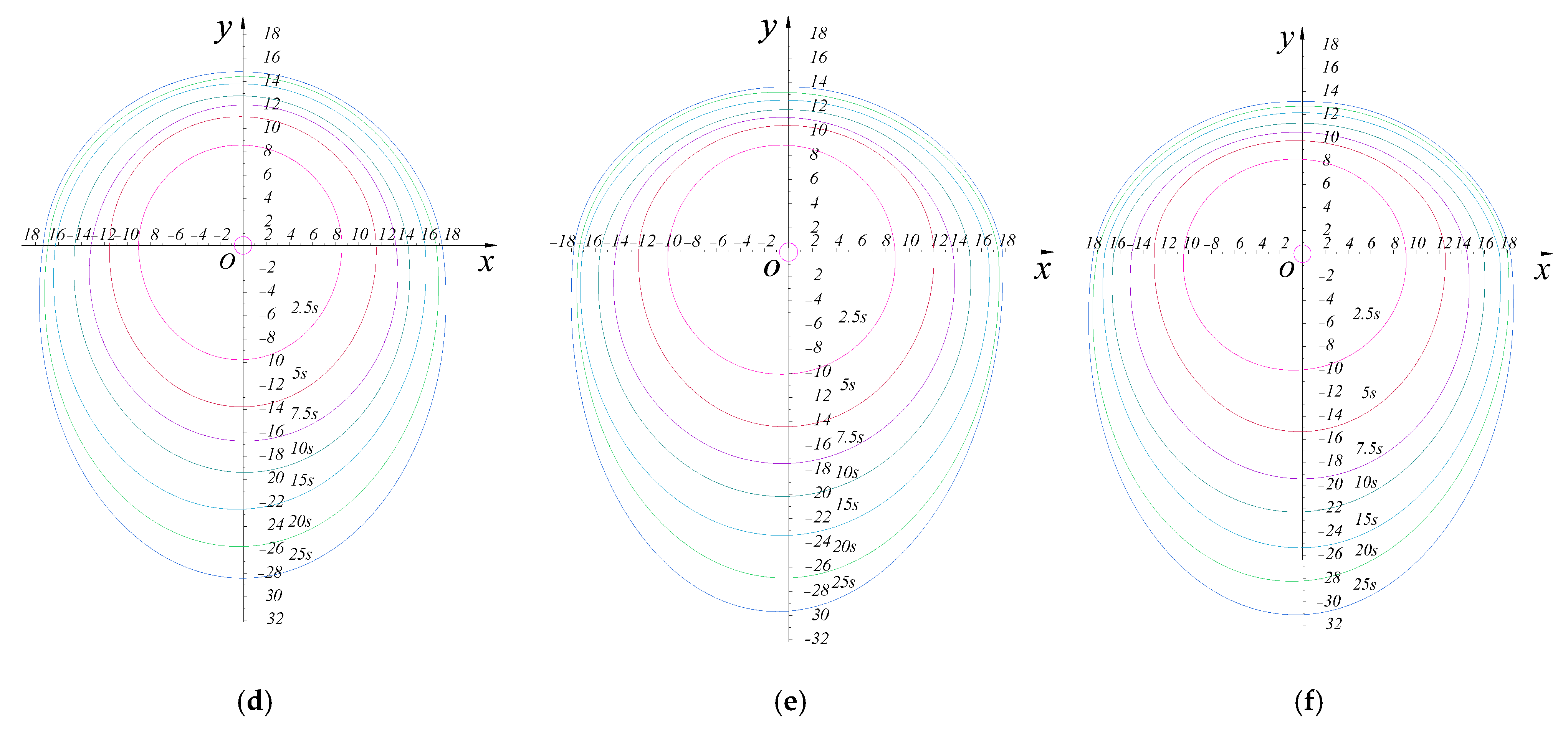

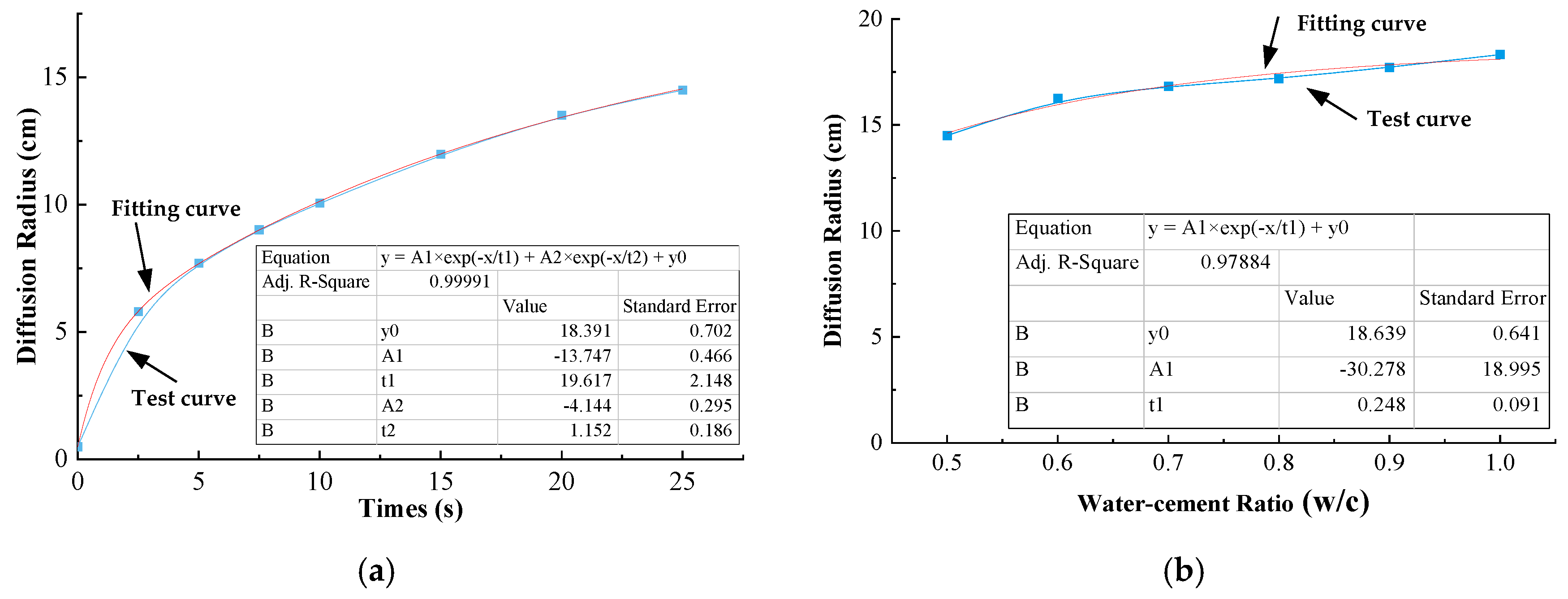

3.2. Slurry Diffusion Radius Time Profile Analysis

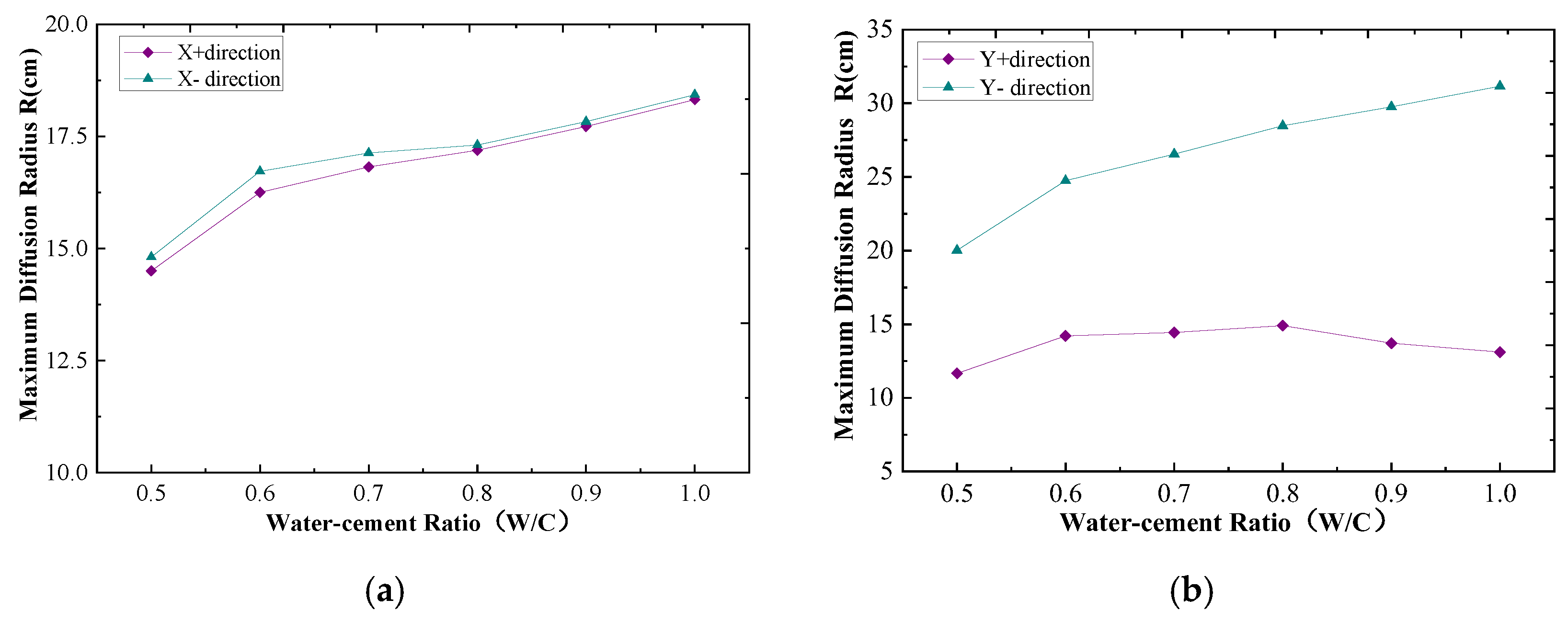

3.3. Analysis of the Maximum Spreading Radius of the Slurry

4. Diffusion Law of Grouting with Different Water–Cement Ratios

4.1. Relationship Between Changes in Diffusion Radius

4.2. Establishment of the Diffusion Equation

5. Conclusions and Discussion

- (1)

- As the water–cement ratio increases from 0.5 to 1.0, the initial viscosity of the ultrafine cement slurry decreases from 33.6 mPa·s to 1.80 mPa·s. By changing the water–cement ratio of the cement grouting material, the initial viscosity parameters of the slurry have changed. Through the grouting test, it can be found that the diffusion of ultrafine cement slurry in cracks is mainly divided into three diffusion forms: circular diffusion zone, excessive diffusion zone, and elliptical diffusion zone. It is a circular diffusion zone within 0 to 2.5 s; 2.5 s to 5 s is the excessive diffusion zone; 5 s to 25 s is the elliptic diffusion zone. At the initial stage of grouting at 0 to 2.5 s, the slurry is not affected by self-weight, and the diffusion form is circular. After that, with the increase in time under the action of self-weight, the asymmetric elliptic characteristics of the diffusion form become more and more obvious, and the larger the water–cement ratio, the more obvious the overall diffusion asymmetry.

- (2)

- The analysis of the maximum diffusion radius can be seen in the y + direction of the maximum diffusion radius, but with the increase in the water–cement ratio, there is a tendency to increase and then decrease, which is subject to viscous stress, slurry pressure, and the common effect of self-weight, and there is a maximum diffusion radius of the water–cement ratio of the critical value of the diffusion radius through the analysis of the experimental data to obtain the diffusion radius of the extreme value of the critical water–cement ratio for ξ = 0.8.

- (3)

- The value of the maximum radius of diffusion increases with the water–cement ratio (W/C) (or is inversely proportional to the viscosity). As the water–cement ratio increases from 0.5 to 0.6, the maximum diffusion radius, , exhibits a significant increase. Within the water–cement ratio range of 0.6 to 1.0, the growth of becomes relatively stable. However, within the range of 0.8 to 1.0, the diffusion radius in the y+ direction is notably influenced by viscosity and gravitational effects, lead ing to a decreasing trend in .

- (4)

- Through the collection and analysis of test data, the diffusion radius R and time t change function equation is obtained as ; the maximum diffusion radius value of and the change in the water–cement ratio function equation is . The next step is to study the diffusion law of oblique crack grouting. It is helpful to perfect the study of the grouting diffusion law of tunnel secondary lining cracks.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hong, K.; Feng, H. Development Trends and Views of Highway Tunnels in China over the Past Decade. China J. Highw. Transp. 2020, 33, 62–76. (In Chinese) [Google Scholar]

- Ge, S.; Gao, W.; Wang, Y.; Xie, Y.; Chen, X.; Wang, S. Review on evaluation and treatment of traffic shield tunnel defects in China. Chin. Civil Eng. J. 2023, 56, 119–128. (In Chinese) [Google Scholar]

- Gong, X.; Guo, P. Prevention and Mitigation Methods for Water Leakage in Tunnels and Underground Structures. China J. Highw. Transp. 2021, 34, 1–30. (In Chinese) [Google Scholar]

- Du, X.; Li, Z.; Fang, H.; Li, B.; Zhao, X.; Zhai, K.; Xue, B.; Wang, S. A State-of-the-Art Review on the Study of the Diffusion Mechanism of Fissure Grouting. Appl. Sci. 2024, 14, 2540. [Google Scholar] [CrossRef]

- Luo, Y.; Chen, J. Research Status and Progress of Tunnel Frost Damage. J. Traffic Transp. Eng. 2019, 6, 297–309. [Google Scholar] [CrossRef]

- Zhou, H.; Zhang, Y.; Zhu, W.; Zhong, Q.; Huang, X. Optimisation of Synchronous Grouting Mix Ratio for Shield Tunnels. Appl. Sci. 2024, 14, 4098. [Google Scholar] [CrossRef]

- Ding, Y.; Zhang, X.; Zhang, B. Preliminary Study on Double Lining Support Design for Water Plugging of Highway Tunnel under High Water Pressure in Mountain Area Based on Limited Drainage. Appl. Sci. 2022, 12, 7905. [Google Scholar] [CrossRef]

- Wang, M.; Zhao, C.; Yang, S.; Xu, J. Optimizing Grouting Parameters to Control Ground Deformation in the Shield Tunneling. Buildings 2024, 14, 2799. [Google Scholar] [CrossRef]

- Zhang, D.; Ye, Z.; Chu, W.; Zhang, J.; Shao, H. Experimental study on the rehabilitation of a shield tunnel lining with excessive transverse deformation by lateral grouting. Tunn. Undergr. Space Technol. 2024, 148, 105748. [Google Scholar] [CrossRef]

- Han, X.; Ye, F.; Wang, Y.; Xia, Y. Predictive Maintenance Decision-making of Tunnel Lining Structure Based on Deterioration Reliability. China J. Highw. Transp. 2021, 34, 104–115. (In Chinese) [Google Scholar]

- Huang, H.; Zhang, D. Recent Progress on Refined Sensing and Control of Safety and Risk of Long-and Large-scale Tunnel Lining Structures. China J. Highw. Transp. 2020, 33, 46–61. (In Chinese) [Google Scholar]

- Jiang, P.; Zhang, Z.; Zheng, H.; Huang, J. Coupling analysis method of grouting construction with deformation response of adjacent existing tunnel. Tunn. Undergr. Space Technol. 2024, 15, 312–330. [Google Scholar] [CrossRef]

- Wang, H.; Huang, H.; Feng, Y.; Zhang, D. Characterization of Crack and Leakage Defects of Concrete Linings of Road Tunnels in China. ASCE-ASME J. Risk Uncertain. Eng. Syst. Part A Civ. Eng. 2018, 4, 04018041. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, Y.; Zong, Z.; Zhou, X.; Lin, W. Reliability Analysis Methods in Tunnel Construction and Operation. J. Chongqing Jiaotong Univ. (Nat. Sci.) 2020, 39, 1–13. (In Chinese) [Google Scholar]

- Hu, Z.; Ding, H.; Lai, J.; Wang, H.; Wang, X.; He, S. The durability of shotcrete in cold region tunnel: A review. Constr. Build. Mater. 2018, 185, 670–683. [Google Scholar] [CrossRef]

- Zhang, B.; Zhou, Y.; Zhang, X.; Wang, Z.; Yang, W.; Ban, Y. Experimental Study on Grouting Diffusion Law of the Different Crack Widths in Tunnel Lining. KSCE J. Civ. Eng. 2023, 27, 1789–1799. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, X.; Wang, E. Quantitative evaluation of the onset and evolution for the non-Darcy behavior of the partially filled rough fracture. Water Resour. Res. 2024, 60, e2023WR036494. [Google Scholar] [CrossRef]

- Jian, L.; Zhao, X.; Wu, J.; Yan, H.; Wan, Y.; Wang, S.; Zhang, C.; Long, R. Preparation, properties and grouting process simulation of cement-based grout for loose deposits. Constr. Build. Mater. 2022, 360, 129596. [Google Scholar] [CrossRef]

- Li, S.; Liu, R.; Zhang, Q.; Sun, Z.; Zhang, X.; Zhu, M. Research on C-S Slurry Diffusion Mechanism with Time-Dependent Behavior of Viscosity. Chin. J. Mech. Eng. 2013, 32, 2415–2421. (In Chinese) [Google Scholar]

- Liu, R.; Zhang, L.; Zhang, Q.; Yang, L.; Li, Z.; Sun, Z.; Zhang, S.; Zhu, G. Numerical Simulation of Crack Grouting Process of Quick Setting Slurry with Running Water and Its Experimental Verification. Rock Soil Mech. 2017, 36, 3297–3306. (In Chinese) [Google Scholar]

- Zhou, J.; Zha, L.; Meng, S.; Zhang, Y. Optimization on overall performance of Modified Ultrafine Cementitious Grout Materials (MUCG) and hydration mechanism analysis. PLoS ONE 2024, 19, e0309312. [Google Scholar] [CrossRef] [PubMed]

- Zhou, Z.; Du, X.; Wang, S.; Cai, X.; Chen, L. Micro mechanism of the diffusion of cement-based grouts in porous media under two hydraulic operating conditions: Constant flow rate and constant pressure. Acta Geotech. 2019, 14, 825–841. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Q.; Liu, R.; Li, S. Grouting Mechanism in Fractured Rock Considering Slurry-rock Stress Coupling Effects. Chin. J. Geotech. Eng. 2018, 40, 2003–2011. (In Chinese) [Google Scholar]

- Fu, N.H.J.; Thorn, J. Radial Penetration of Cementitious Grout Laboratory Verification of Grout Spread in a Fracture Model. Tunn. Undergr. Space Technol. 2018, 72, 228–232. [Google Scholar] [CrossRef]

- Wang, X.; Li, L.; Mu, W.; Yang, T.; An, J.; Du, Y. Diffusion mechanism of cement-based slurry in frozen and thawed fractured rock mass in alpine region. Constr. Build. Mater. 2024, 411, 134584. [Google Scholar] [CrossRef]

- Luo, P.; Li, Z.; Fan, B.; Zhang, Y. Theoretical Study on Flow Model for Tilted Single Fracture Bingham Grouts. J. Shandong Univ. Sci. Technol. (Nat. Sci.) 2010, 29, 49–53. (In Chinese) [Google Scholar]

- Xu, X.; Wu, Z.; Weng, L.; Chu, Z.; Liu, Q.; Wang, Z. Investigating the impacts of reinforcement range and grouting timing on grouting reinforcement effectiveness for tunnels in fault rupture zones using a numerical manifold method. Eng. Geol. 2024, 330, 107423. [Google Scholar] [CrossRef]

- Zhou, M.; Li, S.; Zheng, Z.; Liu, R.; Chen, M.; Ma, C. Theoretical and experimental study on the rheological properties of WIS grout and the dispersion and sealing mechanism. Int. J. Min. Sci. Technol. 2022, 32, 669–684. [Google Scholar] [CrossRef]

- Li, X.; Wang, L.; Hao, M.; Zhong, Y.; Zhang, B. An Analytical Solution for the Radial Flow of Variable Density Grout in Rock Fractures. Constr. Build. Mater. 2019, 206, 630–640. [Google Scholar] [CrossRef]

- Wu, Y.; Deng, Y.; Zhang, X.; Liu, L.; Zhao, C.; Zhang, J. Grout Diffusion Mechanism along the Pile Shaft during the Process of Pile Tip Post-Grouting in Sand. Appl. Sci. 2024, 14, 5389. [Google Scholar] [CrossRef]

- Hao, Y.; Guo, C.; Shi, M.; Wang, F.; Xia, Y.; Wang, C. Application of polymer split grouting technology in earthen dam: Diffusion law and applicability. Constr. Build. Mater. 2023, 369, 130612. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, H.; Yin, J.; Xue, Y. Infiltration Grouting Mechanism of Bingham Fluids in Porous Media with Different Particle Size Distributions. Appl. Sci. 2023, 13, 11986. [Google Scholar] [CrossRef]

- Jiang, D.; Cheng, X.; Luan, H.; Wang, T.; Zhang, M.; Hao, R. Experimental Investigation on the Law of Grout Diffusion in Fractured Porous Rock Mass and Its Application. Processes 2018, 6, 191–201. [Google Scholar] [CrossRef]

- Hu, H.-X.; Cao, W.; Deng, C.; Lu, Y.-F. Experimental Study on the Relationship between Time-Varying Uplift Displacement and Grout Diffusion in Sand. Appl. Sci. 2024, 14, 3922. [Google Scholar] [CrossRef]

- Zhang, B.; Gao, F.; Zhang, X.; Zhou, Y.; Hu, B.; Song, H. Study on Modified Cement-Sodium Silicate Material and Grouting Technology for Repairing Underground Concrete Structure Cracks. Arab. J. Geosci. 2019, 12, 680. [Google Scholar] [CrossRef]

| Material | Ultrafine Cement | Ultrafine Fly Ash | Expansive Agent | Early Strength Agent |

|---|---|---|---|---|

| Particle Size/Grade/Type | ≤8 μm, D50 ≤18 μm, D90 | Ⅰ | HSDZ-60 | MNF-9 |

| Mass Ratio | 75% | 20% | 3% | 2% |

| Crack Width δ | Water–Cement Ratio W/C | Initial Grouting Pressure P0 | Fracture Plane Dip Angle θ | Grouting Port Speed |

|---|---|---|---|---|

| 0.4 mm | 0.5~1.0 | 0.05 MPa | 90° | 5 mL/s |

| W/C | 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 |

| Initial Viscosity (mPa·s) | 33.62 | 20.20 | 6.26 | 3.24 | 2.53 | 1.80 |

| Diffusion Radius R (cm) | Time | ||||||

|---|---|---|---|---|---|---|---|

| 0.5 | 0.6 | 0.7 | 0.8 | 0.9 | 1.0 | ||

| Direction x+ | 0 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| 2.5 | 5.81 | 8.02 | 8.22 | 8.71 | 8.92 | 9.12 | |

| 5.0 | 7.71 | 10.48 | 10.95 | 11.57 | 12.01 | 12.51 | |

| 7.5 | 9.02 | 12.21 | 12.62 | 13.22 | 13.73 | 14.59 | |

| 10.0 | 10.07 | 13.55 | 13.96 | 14.34 | 14.98 | 15.98 | |

| 15.0 | 11.98 | 15.01 | 15.41 | 15.76 | 16.55 | 17.35 | |

| 20.0 | 13.52 | 16.01 | 16.37 | 16.85 | 17.43 | 18.03 | |

| 25.0 | 14.50 | 16.25 | 16.82 | 17.19 | 17.72 | 18.32 | |

| Direction x− | 0 | −0.50 | −0.50 | −0.50 | −0.50 | −0.50 | −0.50 |

| 2.5 | −6.02 | −8.03 | −8.70 | −9.15 | −9.95 | −10.45 | |

| 5.0 | −7.77 | −10.52 | −11.02 | −11.52 | −12.43 | −13.13 | |

| 7.5 | −9.53 | −12.23 | −12.53 | −13.21 | −14.35 | −14.95 | |

| 10.0 | −10.55 | −13.98 | −14.18 | −14.58 | −15.63 | −16.12 | |

| 15.0 | −12.22 | −15.12 | −15.62 | −16.21 | −17.06 | −17.46 | |

| 20.0 | −13.79 | −16.03 | −16.49 | −16.97 | −17.45 | −17.95 | |

| 25.0 | −14.81 | −16.72 | −17.13 | −17.31 | −17.83 | −18.43 | |

| Direction y+ | 0 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 | 0.50 |

| 2.5 | 5.03 | 8.01 | 8.21 | 8.88 | 8.81 | 8.21 | |

| 5.0 | 6.85 | 10.22 | 10.52 | 10.97 | 10.22 | 9.85 | |

| 7.5 | 8.08 | 11.52 | 11.62 | 11.94 | 11.16 | 10.56 | |

| 10.0 | 8.95 | 12.23 | 12.53 | 12.80 | 11.74 | 11.33 | |

| 15.0 | 10.06 | 13.35 | 13.65 | 13.84 | 12.73 | 12.24 | |

| 20.0 | 11.02 | 13.89 | 14.10 | 14.56 | 13.34 | 12.79 | |

| 25.0 | 11.66 | 14.21 | 14.44 | 14.91 | 13.71 | 13.11 | |

| Direction y− | 0 | −0.50 | −0.50 | −0.50 | −0.50 | −0.50 | −0.50 |

| 2.5 | −6.05 | −8.12 | −8.71 | −9.86 | −10.05 | −10.05 | |

| 5.0 | −8.55 | −13.01 | −13.31 | −13.84 | −14.38 | −15.38 | |

| 7.5 | −10.75 | −15.86 | −16.36 | −16.76 | −17.43 | −19.43 | |

| 10.0 | −12.89 | −18.75 | −18.58 | −19.44 | −20.18 | −22.18 | |

| 15.0 | −15.88 | −21.30 | −22.33 | −22.59 | −23.41 | −25.41 | |

| 20.0 | −18.12 | −23.62 | −24.42 | −25.74 | −26.68 | −28.18 | |

| 25.0 | −20.02 | −24.75 | −26.55 | −28.48 | −29.76 | −31.16 | |

| Equation | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Direction | Correlation Coefficient | Correlation Coefficient | ||||||||

| x+ | 18.39 | −13.75 | 19.62 | −4.14 | 1.15 | 1 | 18.64 | −30.28 | 0.25 | 0.98 |

| x− | −17.59 | 4.00 | 1.04 | 13.09 | 16.27 | 1 | −18.34 | 51.55 | 0.18 | 0.96 |

| y+ | 12.78 | −3.81 | 1.59 | −8.48 | 12.73 | 1 | 0.083 | 14.76 | 0.70 | 0.91 |

| y− | −30.12 | 24.98 | 27.31 | 5.03 | 2.23 | 1 | −32.82 | 80.38 | 0.27 | 0.99 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, B.; Liu, P.; Wu, Y.; Wu, L.; Li, C.; Liu, S.; Zhou, Y. Experimental Study on Grouting Diffusion Law of Tunnel Secondary Lining Cracks Based on Different Slurry Viscosities. Appl. Sci. 2025, 15, 1955. https://doi.org/10.3390/app15041955

Zhang B, Liu P, Wu Y, Wu L, Li C, Liu S, Zhou Y. Experimental Study on Grouting Diffusion Law of Tunnel Secondary Lining Cracks Based on Different Slurry Viscosities. Applied Sciences. 2025; 15(4):1955. https://doi.org/10.3390/app15041955

Chicago/Turabian StyleZhang, Bin, Peng Liu, Yi Wu, Liming Wu, Chen Li, Shiyang Liu, and Yuanfu Zhou. 2025. "Experimental Study on Grouting Diffusion Law of Tunnel Secondary Lining Cracks Based on Different Slurry Viscosities" Applied Sciences 15, no. 4: 1955. https://doi.org/10.3390/app15041955

APA StyleZhang, B., Liu, P., Wu, Y., Wu, L., Li, C., Liu, S., & Zhou, Y. (2025). Experimental Study on Grouting Diffusion Law of Tunnel Secondary Lining Cracks Based on Different Slurry Viscosities. Applied Sciences, 15(4), 1955. https://doi.org/10.3390/app15041955