A Review on Achieving Sustainability in the Petroleum Industry Through the Integration of Lean and Green

Abstract

1. Introduction

2. Lean and Green Overview

2.1. Industries Application of Lean and Green

2.1.1. Automotive Industry

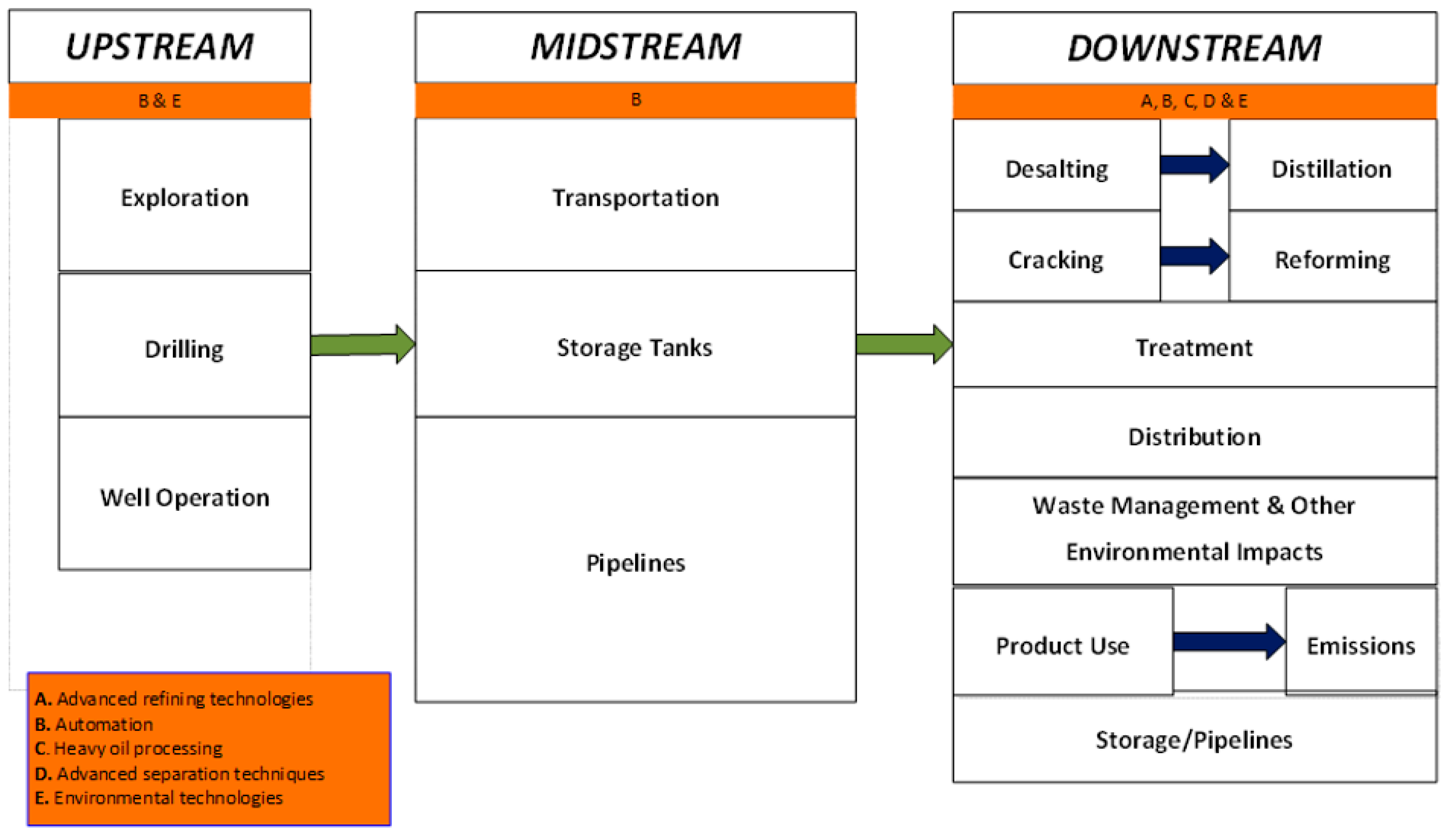

2.1.2. The Petroleum Industry

2.2. Benefits of Integrating Lean and Green

2.3. Sustainability Challenges in the SSA Petroleum Industry and Practical Strategic Solutions

- Project delays in the SSA petroleum industry are often because of infrastructure and technological barriers, as the countries still depend on foreign technologies and expertise [78]. Addressing these issues includes the following:

- Establishing Petroleum technology institutes for the development of Indigenous oil and gas innovations, like Saudi Arabia’s King Abdullah Petroleum Studies & Research Center (KAPSARC) [79].

- The use of blockchain in tracking transaction oil transparency is used in the Abu Dhabi National Oil Company (ADNOC) to reduce fraud [80].

- Adopting Al, digital twin technologies, like the British petroleum “Field of the Future” project that utilizes digital twin simulations for optimizing oilfields [81].

- Implementation of advanced technologies. Chevron implemented 3D seismic imaging technology, and ExxonMobil implemented data analytic technology, which has led to improved efficiency and significant cost savings [48].

- Political instability is characterized by corruption, militancy, inconsistency in policy, and civil unrest, which has affected the social and economic growth of the region [82]. Addressing these challenges includes the following:

- Collaboration between countries. Mozambique’s government and Rwandan forces collaborated to combat insurgents targeting LNG projects in Cabo Delgado, highlighting the importance of increased security collaborations [83].

- Establishing sovereign wealth funds (SWFs) to manage oil revenues and invest in long-term infrastructure projects, such as Norway’s SWF, which has brought economic stability for future generations and prevented corruption [84].

- Using digital technology to strengthen security. Saudi Aramco’s pipeline security system employs AI-powered monitoring to prevent sabotage [84].

- The monetization of flare gases to reduce flaring. The Nigerian Government is tackling the issue of flare gas through the Nigeria gas flare commercialization program launched (NGFCP) in 2016, ensuring the monetization of flare gas by selling it to investors [85].

- Regulatory approvals from different government agencies can delay project delivery. This challenge can be overcome by creating a one-stop regulatory agency. For example, Angola has created a one-stop shop for local content compliance for the petroleum industry. Equatorial Guinea has created a one-stop shop that allows investors to set up business within one week [86,87].

2.4. Lean–Green Models for the SSA Petroleum Industry

2.5. Sustainable Value Stream Mapping (Sus-VSM)

3. Research Methodology

- RQ1:

- What are the lean and green tools/techniques suitable to incorporate sustainability?

- RQ2:

- What are the practical strategic solutions to the sustainability challenges In the SSA Petroleum Industry?

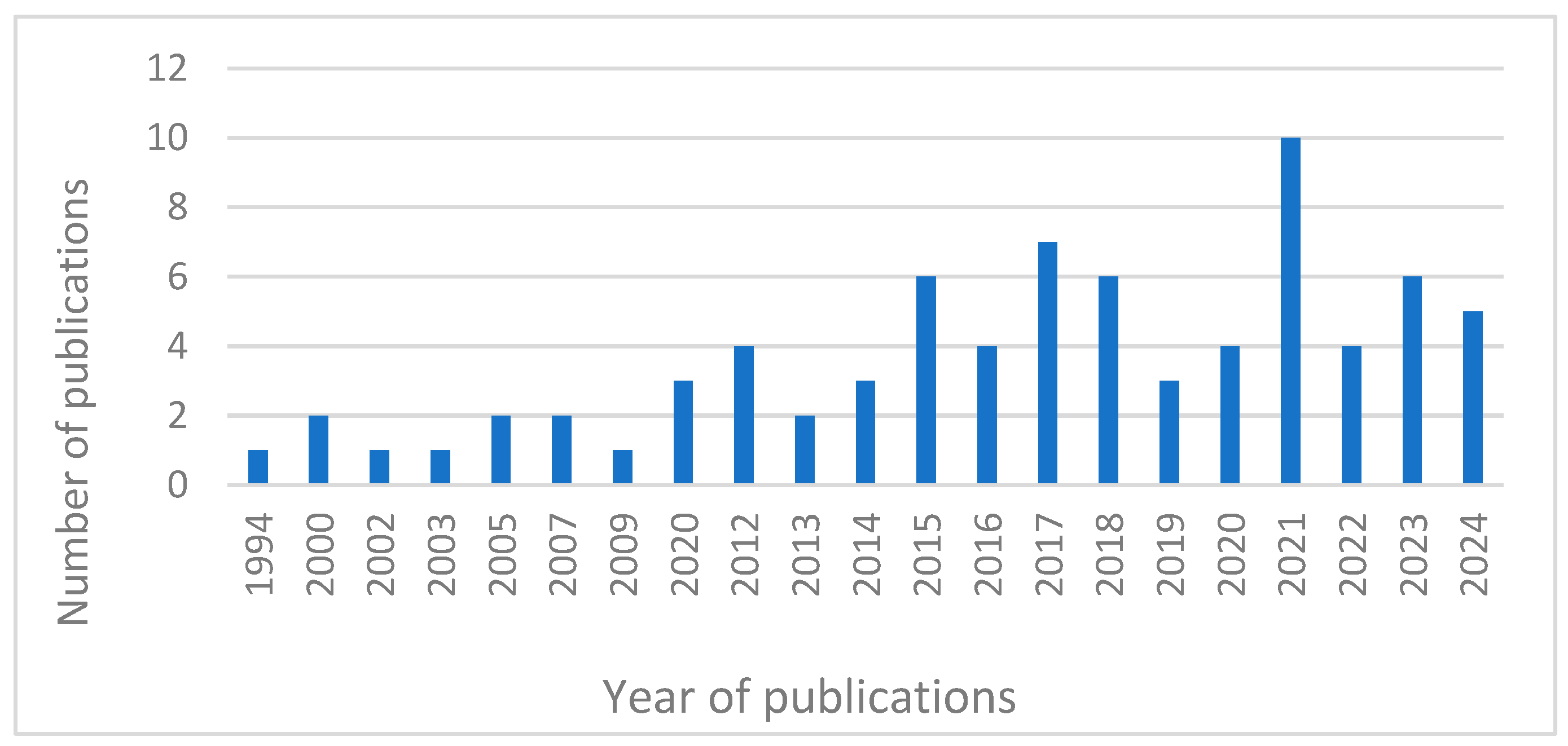

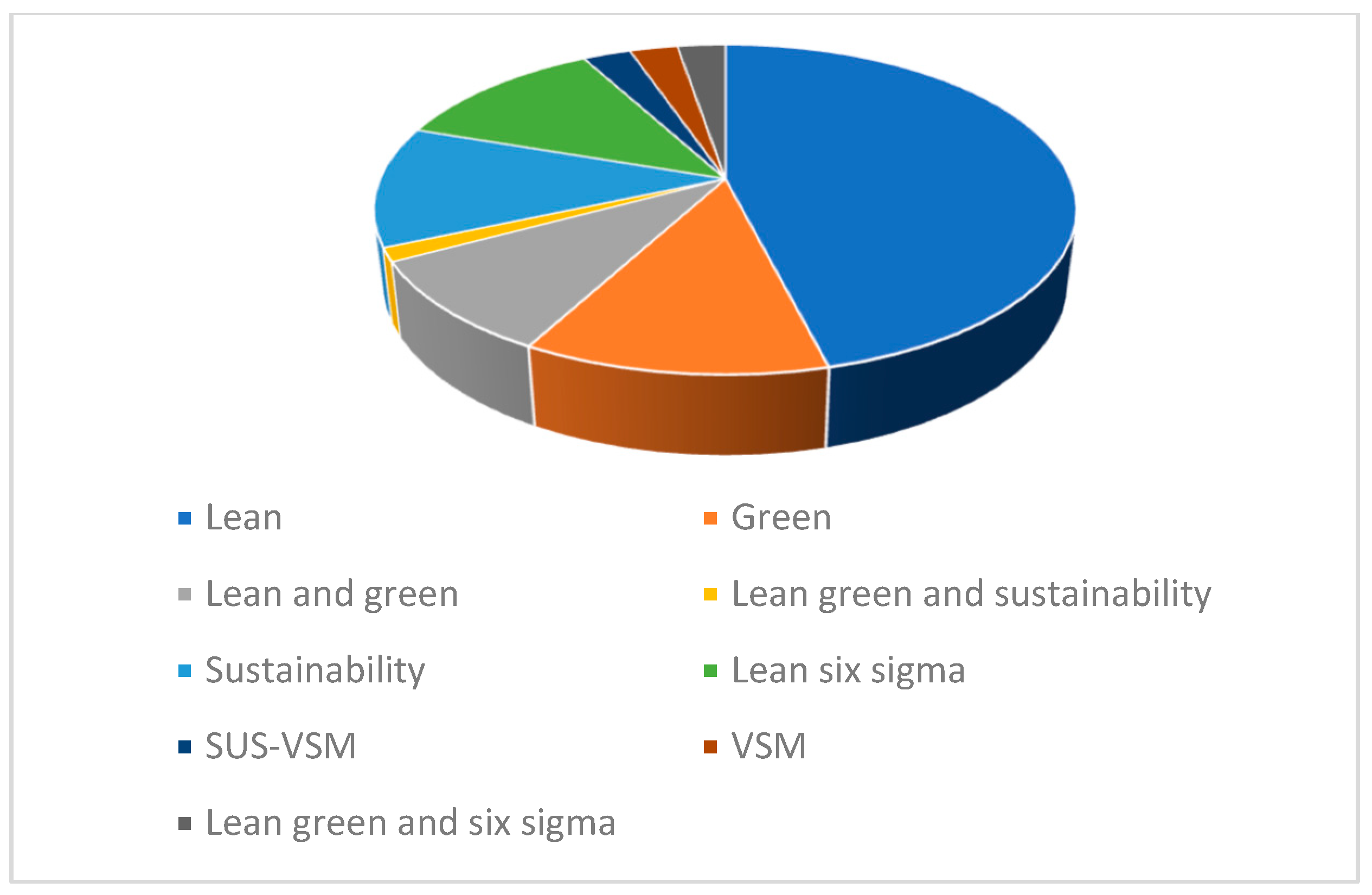

4. Descriptive Analysis

5. Key Findings and Critical Discussion

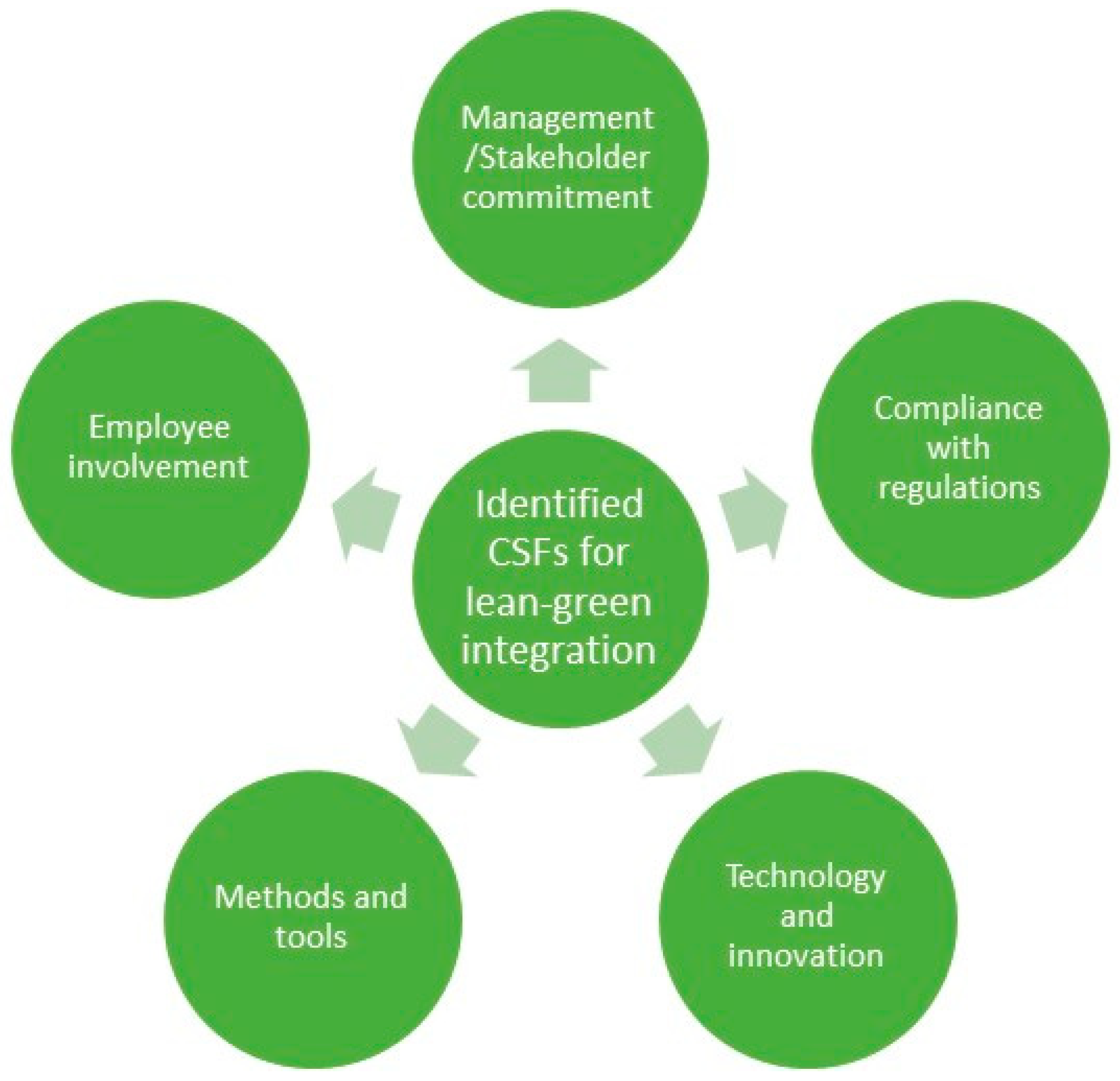

5.1. Identified Critical Success Factors for the Lean–Green Integration

5.1.1. Management/Stakeholders Commitment

5.1.2. Employee Involvement

5.1.3. Compliance with Regulations

5.1.4. Methods and Tools

5.1.5. Technology and Innovation

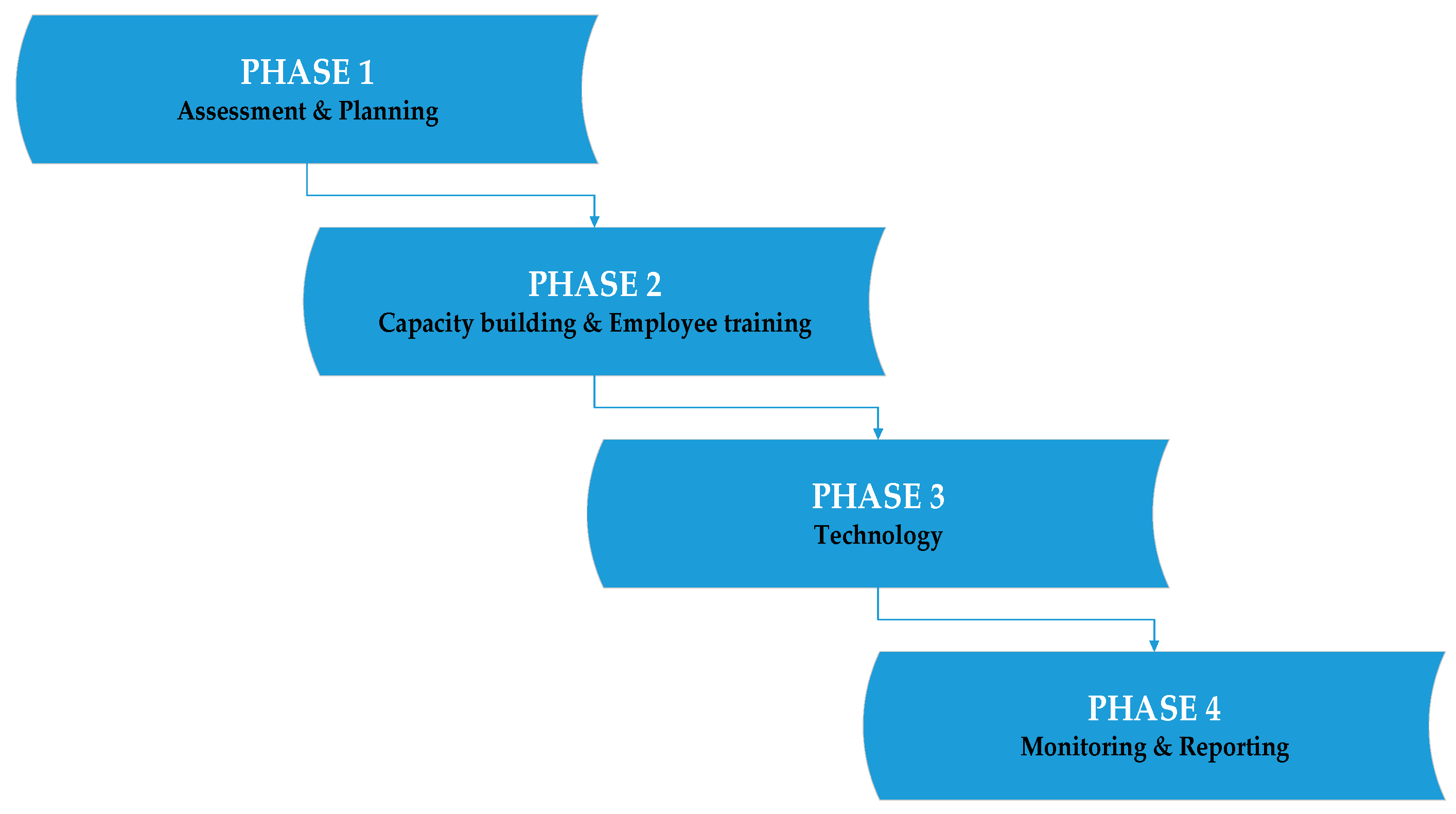

5.2. Roadmap for the Implementation of Lean and Green

- KPIs that align with the goals of lean–green, such as waste reduction, energy efficiency, and employee satisfaction, should be developed.

- Using technologies for the continuous monitoring of gas emissions and waste generation. For example, Chevron uses technologies to find and fix methane emissions.

- Produce reports using established reporting standards like the Global Reporting Initiative.

6. Conclusions, Limitations, and Future Prospects

6.1. Conclusions

6.2. Limitations

6.3. Future Prospects

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Aregbe, A.G. Natural gas flaring—Alternative solutions. World J. Eng. Technol. 2016, 5, 139–153. [Google Scholar] [CrossRef]

- Elvidge, C.D.; Bazilian, M.D.; Zhizhin, M.; Ghosh, T.; Baugh, K.; Hsu, F.-C. The potential role of natural gas flaring in meeting greenhouse gas mitigation targets. Energy Strat. Rev. 2018, 20, 156–162. [Google Scholar] [CrossRef]

- World Bank. 2022 Global Gas Flaring Tracker Report; World Bank: Washington, DC, USA, 2022; Available online: https://www.worldbank.org/en/programs/gasflaringreduction/publication/2022-global-gas-flaring-tracker-report (accessed on 18 February 2025).

- WorldMetrics. Oil Industry Statistics: Market Data Report 2024. Available online: https://worldmetrics.org/oil-and-gas-industry-statistics/ (accessed on 18 February 2025).

- Garza-Reyes, J.A. Lean and green–a systematic review of the state of the art literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef]

- Garza-Reyes, J.A.; Villarreal, B.; Kumar, V.; Ruiz, P.M. Lean and green in the transport and logistics sector–a case study of simultaneous deployment. Prod. Plan. Control. 2016, 27, 1221–1232. [Google Scholar] [CrossRef]

- Shokri, A.; Antony, J.; Garaza-Reyes, J.A. Modelling Interaction and Prioritisation of Barriers to Green Lean Six Sigma Implementation in the Manufacturing Through ISM-MICMAC and Fuzzy AHP. 2021. Available online: https://researchportal.northumbria.ac.uk/files/108448385/EurOMA_2023_full_paper_A._Shokri.pdf (accessed on 18 February 2025).

- Silva, G.M.; Gomes, P.J. Lean production, green supply chain management and environmental performance: A configurational perspective based on the Portuguese context. Int. J. Lean Six Sigma 2023, 16, 518–541. [Google Scholar] [CrossRef]

- Teixeira, P.; Sá, J.C.; Silva, F.J.G.; Ferreira, L.P.; Santos, G.; Fontoura, P. Connecting lean and green with sustainability towards a conceptual model. J. Clean. Prod. 2021, 322, 129047. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Nand, A.; Castka, P. Lean-green integration and its impact on sustainability performance: A critical review. J. Clean. Prod. 2019, 236, 117697. [Google Scholar] [CrossRef]

- Patel, A.S.; Patel, K.M. Status of Lean Six Sigma implementation in Indian industries: A cross-sectional national survey. Int. J. Lean Six Sigma 2022, 14, 791–814. [Google Scholar] [CrossRef]

- Nascimento, D.L.D.M.; Goncalvez Quelhas, O.L.; Gusmão Caiado, R.G.; Tortorella, G.L.; Garza-Reyes, J.A.; Rocha-Lona, L. A lean six sigma framework for continuous and incremental improvement in the Petroleum sector. Int. J. Lean Six Sigma 2020, 11, 577–595. [Google Scholar] [CrossRef]

- Ratnayake, R.C.; Chaudry, O. Maintaining sustainable performance in operating petroleum assets via a lean-six-sigma approach: A case study from engineering support services. Int. J. Lean Six Sigma 2017, 8, 33–52. [Google Scholar] [CrossRef]

- Tsarouhas, P. Reliability, availability and maintainability analysis of a bag production industry based on the six sigma DMAIC approach. Int. J. Lean Six Sigma 2021, 12, 237–263. [Google Scholar] [CrossRef]

- Alzoubi, H.M.; In’airat, M.; Ahmed, G. Investigating the impact of total quality management practices and Six Sigma processes to enhance the quality and reduce the cost of quality: The case of Dubai. Int. J. Bus. Excell. 2022, 27, 94–109. [Google Scholar] [CrossRef]

- Verrier, B.; Rose, B.; Caillaud, E. Lean and green strategy: The lean and greenhouse and maturity deployment model. J. Clean. Prod. 2016, 116, 150–156. [Google Scholar] [CrossRef]

- Adegoke, A.; Ayenor, G.; Nnoaham, I.; Okwuosah, S.; Osadebe, O. Bonga North Story: Beyond 1 Billion Barrels–Driving Growth with Subsea Tiebacks in Deepwater Nigeria. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2024; OTC: Houston, TX, USA, 2024; p. D041S045R006. [Google Scholar]

- Mohammed, M.; Brewer, R.; Amuda, D.; Anyankpele, P.; Oreagba, T.; Marshal, T.; Ilesanmi, O.; Osolu, O. Powering Bonga to One Billion Barrels Through Innovative Project Delivery and Technology Deployment. In Proceedings of the Offshore Technology Conference, Houston, TX, USA, 6–9 May 2024; OTC: Houston, TX, USA, 2024; p. D041S045R005. [Google Scholar]

- Matiluko, O.E. Evaluation of Lean Manufacturing Concept Implementation in The Upstream Petroleum Industry Through Critical Success Factors. Int. J. Pet. Gas Explor. Manag. 2023, 6, 11–32. [Google Scholar]

- Rachman, A.; Ratnayake, R.C. Adoption and implementation potential of the lean concept in the petroleum industry: State-of-the-art. Int. J. Lean Six Sigma 2019, 10, 311–338. [Google Scholar] [CrossRef]

- Uzochukwu, O.C.; Ossai, I.F. Lean production: A frontier for improving performance of Petroleum companies in Nigeria. Pyrex J. Bus. Financ. Manag. Res. 2016, 2, 35–41. [Google Scholar]

- Shah, R.; Ward, P.T. Defining and developing measures of lean production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Chiarini, A. The Seven Wastes of Lean Organization. Lean Organization: From the Tools of the Toyota Production System to Lean Office; Springer: Berlin/Heidelberg, Germany, 2013; pp. 15–30. [Google Scholar]

- Hildebrandt, M.G.; Kidholm, K.; Pedersen, J.E.; Naghavi-Behzad, M.; Knudsen, T.; Krag, A.; Ryg, J.; Gerke, O.; Lassen, A.T.; Ellingsen, T. How to increase value and reduce waste in research: Initial experiences of applying Lean thinking and visual management in research leadership. BMJ Open 2022, 12, e058179. [Google Scholar] [CrossRef]

- Chiarini, A.; Cherrafi, A. Improving patient satisfaction using lean manufacturing tools. Case studies from Italy. In Proceedings of the 20th Excellence in Services International Conference, Verona, Italy, 7–8 September 2017; pp. 177–182. [Google Scholar]

- Eldeep, A.M.; Farag, M.A.; Abd El-hafez, L.M. Using BIM as a lean management tool in construction processes A case study. Ain Shams Eng. J. 2022, 13, 101556. [Google Scholar] [CrossRef]

- Nallusamy, S.; Adil Ahamed, M.A. Implementation of lean tools in an automotive industry for productivity enhancement-A case study. Int. J. Eng. Res. Afr. 2017, 29, 175–185. [Google Scholar] [CrossRef]

- Ribeiro, P.; Sá, J.C.; Ferreira, L.P.; Silva, F.J.G.; Pereira, M.T.; Santos, G. The Impact of the Application of Lean Tools for Improvement of Process in a Plastic Company: A case study. Procedia Manuf. 2019, 38, 765–775. [Google Scholar] [CrossRef]

- Rodrigues, J.; Sá, J.C.; Silva, F.J.; Ferreira, L.P.; Jimenez, G.; Santos, G. A rapid improvement process through “quick-win” lean tools: A case study. Systems 2020, 8, 55. [Google Scholar] [CrossRef]

- Li, J.; Song, G.; Cai, M.; Bian, J.; Mohammed, B.S. Green environment and circular economy: A state-of-the-art analysis. Sustain. Energy Technol. Assess. 2022, 52, 102106. [Google Scholar] [CrossRef]

- Lim, M.K.; Lai, M.; Wang, C.; Lee, Y. Circular economy to ensure production operational sustainability: A green-lean approach. Sustain. Prod. Consum. 2022, 30, 130–144. [Google Scholar] [CrossRef]

- Peña, C.; Civit, B.; Gallego-Schmid, A.; Druckman, A.; Pires, A.C.; Weidema, B.; Mieras, E.; Wang, F.; Fava, J.; Cordella, M. Using life cycle assessment to achieve a circular economy. Int. J. Life Cycle Assess. 2021, 26, 215–220. [Google Scholar] [CrossRef]

- Dües, C.M.; Tan, K.H.; Lim, M. Green as the new Lean: How to use Lean practices as a catalyst to greening your supply chain. J. Clean. Prod. 2013, 40, 93–100. [Google Scholar] [CrossRef]

- Faulkner, W.; Badurdeen, F. Sustainable Value Stream Mapping (Sus-VSM): Methodology to visualize and assess manufacturing sustainability performance. J. Clean. Prod. 2014, 85, 8–18. [Google Scholar] [CrossRef]

- Kaswan, M.S.; Rathi, R. Green Lean Six Sigma for sustainable development: Integration and framework. Environ. Impact Assess. Rev. 2020, 83, 106396. [Google Scholar] [CrossRef]

- Da Silva, F.J.G.; Gouveia, R.M. Cleaner Production; Springer International Publishing: Berlin/Heidelberg, Germany, 2020. [Google Scholar]

- Abreu, M.F.; Alves, A.C.; Moreira, F. Lean-Green models for eco-efficient and sustainable production. Energy 2017, 137, 846–853. [Google Scholar] [CrossRef]

- Reis, L.V.; Kipper, L.M.; Velásquez, F.D.G.; Hofmann, N.; Frozza, R.; Ocampo, S.A.; Hernandez, C.A.T. A model for Lean and Green integration and monitoring for the coffee sector. Comput. Electron. Agric. 2018, 150, 62–73. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz Machado, V. Green and lean implementation: An assessment in the automotive industry. Int. J. Lean Six Sigma 2017, 8, 65–88. [Google Scholar] [CrossRef]

- Hammou, I.A.; Oulfarsi, S.; Hebaz, A.; Eddine, A.S. Assessing the lean-green practices in the automotive industry: Perspectives from academia and industry. Environ. Soc. Psychol. 2023, 8, 1–15. [Google Scholar] [CrossRef]

- Queiroz, G.A.; Filho, A.G.A.; Núñez, J.F.; Santa-Eulalia, L.A.; Delai, I.; Torkomian, A.L.V. Lean and Green Manufacturing in operations strategy: Cases from the automotive industry. Oper. Manag. Res. 2024, 17, 916–940. [Google Scholar] [CrossRef]

- Elemure, I.; Dhakal, H.N.; Leseure, M.; Radulovic, J. Integration of lean green and sustainability in manufacturing: A review on current state and future perspectives. Sustainability 2023, 15, 10261. [Google Scholar] [CrossRef]

- Sarkar, A.N. Promoting eco-innovations to leverage sustainable development of eco-industry and green growth. Eur. J. Sustain. Dev. 2013, 2, 171–224. [Google Scholar]

- Gordon, J. The Automotive Industry: The Potential for Sustainable Regional Cooperation. Master’s Thesis, Faculty of Commerce, University of Cape Town, Cape Town, South Africa, 2021. [Google Scholar]

- Agbo, C.O.A. Nigeria’s automotive policy and the quest for a viable automotive industry: A lesson for the developing economies. J. Sci. Technol. Policy Manag. 2020, 11, 585–603. [Google Scholar] [CrossRef]

- Cherrafi, A.; Garza-Reyes, J.A.; Belhadi, A.; Kamble, S.S.; Elbaz, J. A readiness self-assessment model for implementing green lean initiatives. J. Clean. Prod. 2021, 309, 127401. [Google Scholar] [CrossRef]

- Singh, H.; Li, C.; Cheng, P.; Wang, X.; Hao, G.; Liu, Q. Real-Time Optimization and Decarbonization of Petroleum Production Value Chain Enabled by Industry 4.0 Technologies: A Critical Review. SPE Prod. Oper. 2023, 38, 433–451. [Google Scholar]

- Alagoz, E.; Alghawi, Y.; Ergul, M.S. Innovation in Exploration and Production: How Technology Is Changing the Petroleum Landscape. J. Energy Nat. Resour. 2023, 12, 25–29. [Google Scholar]

- Santos, M.C. Development of a Fixing and Adjusting Device for Chevron Osteotomy. Ph.D. Thesis, Instituto Superior de Engenharia de Coimbra, Coimbra, Portugal, 2023. [Google Scholar]

- Rahat, A.B. Importance of Social Investment Projects by Chevron for the Economic Development of Bangladesh; BRAC University: Dhaka, Bangladesh, 2023. [Google Scholar]

- Johnson, N. Strategic Mastery: Uncleashing the Power of LNG Program Development through Advanced Techniques; Lambert Academic Publishing: London, UK, 2023. [Google Scholar]

- Serena, B. Carbon Capture and Storage: The Solution to Climate Change or to the Fossil Fuels’ Survival? Critically Framing EU’s Discourses Around CCS. Master’s thesis, University of Stavanger, Stavanger, Norway, 2023. [Google Scholar]

- Hassan, Q.; Viktor, P.; Al-Musawi, T.J.; Ali, B.M.; Algburi, S.; Alzoubi, H.M.; Al-Jiboory, A.K.; Sameen, A.Z.; Salman, H.M.; Jaszczur, M. The renewable energy role in the global energy transition. Renew. Energy Focus 2024, 48, 100545. [Google Scholar] [CrossRef]

- Oseme, K. Claims-to-Action Consistency of Major Petroleum Firms: A Comparison of Saudi Aramco, ExxonMobil and Shell. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2023. [Google Scholar]

- Shehri, T.A.; Braun, J.F.; Howarth, N.; Lanza, A.; Luomi, M. Saudi Arabia’s climate change policy and the circular carbon economy approach. Clim. Policy 2023, 23, 151–167. [Google Scholar] [CrossRef]

- Krane, J. Net Zero Saudi Arabia: How Green Can the Oil Kingdom Get? University of Cambridge: Cambridge, UK, 2023. [Google Scholar]

- Sahraoui, M.A.; Rahmoune, C.; Zair, M.; Gougam, F.; Damou, A. Enhancing fault diagnosis of undesirable events in oil & gas systems: A machine learning approach with new criteria for stability analysis and classification accuracy. Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng. 2023. [Google Scholar] [CrossRef]

- Borges Filho, M.N.; Mello, T.; Scheid, C.M.; Calçada, L.A.; Waldmann, A.T.; Martins, A.L.; Pinto, J.C. The Monitoring of Abnormal Fluid Properties Based on PCA Technique as an Alternative Strategy to Support Autonomous Drilling Operations. SPE J. 2023, 29, 742–763. [Google Scholar] [CrossRef]

- Jing, L.; El-Houjeiri, H.M.; Monfort, J.C.; Brandt, A.R.; Masnadi, M.S.; Gordon, D.; Bergerson, J.A. Carbon intensity of global crude oil refining and mitigation potential. Nat. Clim. Change 2020, 10, 526–532. [Google Scholar] [CrossRef]

- Yatimi, Y.; Mendil, J.; Marafi, M.; Alalou, A.; Al-Dahhan, M.H. Advancement in Heavy Oil Upgrading and Sustainable Exploration Emerging Technologies. Arab. J. Chem. 2024, 17, 105610. [Google Scholar] [CrossRef]

- Khor, C.S. Model-Based Optimization for Petroleum Refinery Configuration Design; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar]

- Qing, W. Global Practice of AI and Big Data in Oil and Gas Industry. In Machine Learning and Data Science in the Oil and Gas Industry; Gulf Professional Publishing: Houston, TX, USA, 2021; pp. 181–210. [Google Scholar]

- Gao, Y.; Murshed, M.; Ozturk, I.; Saqib, N.; Siddik, A.B.; Alam, M.M. Can financing technological development programs mitigate mineral resource consumption-related environmental problems faced by Sub-Saharan African nations? Resour. Policy 2023, 87, 104343. [Google Scholar] [CrossRef]

- Lively, R.P. The refinery of today, tomorrow, and the future: A separations perspective. AIChE J. 2021, 67, 1. [Google Scholar] [CrossRef]

- Fu, T.; Xiao, C.; Sun, J. Core: Automatic molecule optimization using copy & refine strategy. In Proceedings of the 34th AAAI Conference on Artificial Intelligence, New York, NY, USA, 7–12 February 2020; AAAI Press: Palo Alto, CA, USA, 2020; Volume 34, pp. 638–645. [Google Scholar]

- Speight, J.G. The Refinery of the Future; Gulf Professional Publishing: Houston, TX, USA, 2020. [Google Scholar]

- King, A.A.; Lenox, M.J. Lean and green? An empirical examination of the relationship between lean production and environmental performance. Prod. Oper. Manag. 2001, 10, 244–256. [Google Scholar] [CrossRef]

- ISO 14001:2015; Environmental Management Systems—Requirements with Guidance for Use. ISO: Geneva, Switzerland, 2015.

- Elmansy, R. IKEA Sustainable Design Strategy. Available online: https://www.designorate.com/ikea-sustainable-design-strategy/#:~:text=IKEA%20has%20established%20a%20sustainability,renewable%20materials%2C%20and%20reduce%20waste (accessed on 18 February 2025).

- Unilever. 2010–2020: A Decade of Sustainable Growth. Available online: https://www.unilever.com/our-company/our-history-and-archives/2010-2020/#:~:text=In%20the%20face%20of%20climate,represent%20half%20of%20our%20growth (accessed on 18 February 2025).

- Choudhary, S.; Nayak, R.; Dora, M.; Mishra, N.; Ghadge, A. An integrated lean and green approach for improving sustainability performance: A case study of a packaging manufacturing SME in the UK. Prod. Plan. Control. 2019, 30, 353–368. [Google Scholar] [CrossRef]

- Inman, R.A.; Green, K.W. Lean and green combine to impact environmental and operational performance. Int. J. Prod. Res. 2018, 56, 4802–4818. [Google Scholar] [CrossRef]

- Dey, P.K.; Malesios, C.; De, D.; Chowdhury, S.; Abdelaziz, F.B. Could lean practices and process innovation enhance supply chain sustainability of small and medium-sized enterprises? Bus. Strategy Environ. 2019, 28, 582–598. [Google Scholar] [CrossRef]

- Belhadi, A.; Touriki, F.E.; El Fezazi, S. Benefits of adopting lean production on green performance of SMEs: A case study. Prod. Plan. Control. 2018, 29, 873–894. [Google Scholar] [CrossRef]

- Afum, E.; Zhang, R.; Agyabeng-Mensah, Y.; Sun, Z. Sustainability excellence: The interactions of lean production, internal green practices and green product innovation. Int. J. Lean Six Sigma 2021, 12, 1089–1114. [Google Scholar] [CrossRef]

- Cherrafi, A.; Elfezazi, S.; Hurley, B.; Garza-Reyes, J.A.; Kumar, V.; Anosike, A.; Batista, L. Green and lean: A Gemba–Kaizen model for sustainability enhancement. Prod. Plan. Control. 2019, 30, 385–399. [Google Scholar] [CrossRef]

- Appiah, M.; Onifade, S.T.; Gyamfi, B.A. Pathways to Sustainability in Sub-Sahara Africa: Are Institutional Quality Levels Subservient in Achieving Green GDP Growth? J. Knowl. Econ. 2024, 1–25. [Google Scholar] [CrossRef]

- Kojima, M.; Matthews, W.; Sexsmith, F. Petroleum Markets in Sub-Saharan Africa; World Bank: Washington, DC, USA, 2010. [Google Scholar]

- Saudipedia. King Abdullah Petroleum Studies and Research Center. Available online: https://saudipedia.com/en/article/548/government-and-politics/centers/king-abdullah-petroleum-studies-and-researchcenter#:~:text=KAPSARC%20conducts%20international%20cooperative%20research,tools%2C%20and%20data%20for%20research (accessed on 2 February 2025).

- TechCentral. Real-World Uses of Blockchain: From Supply Chain to Equity. Available online: https://www.techcentral.ie/real-world-uses-of-blockchain-from-supply-chain-to-equity/#:~:text=The%20Abu%20Dhabi%20National%20Oil%20Company%20ADNOC,oil%20and%20gas%20production%20accounting%20anywhere%20in (accessed on 2 February 2025).

- Lu, H.; Guo, L.; Azimi, M.; Huang, K. Oil and Gas 4.0 era: A systematic review and outlook. Comput. Ind. 2019, 111, 68–90. [Google Scholar] [CrossRef]

- Babajide, A. Conflict and Economic Growth in Sub-Saharan Africa. Ph.D. Thesis, Loughborough University, Loughborough, UK, 2018. [Google Scholar]

- Center for Strategic and International Studies (CSIS). Winning in Cabo Delgado. CSIS 2018. Available online: https://www.csis.org/analysis/winning-cabo-delgado (accessed on 2 February 2025).

- Léo, H. The Norwegian Sovereign Wealth Fund: A Unique Model for Managing Oil Rents. Blog Bio Ressour. 2024. Available online: https://blog.bio-ressources.com/2024/12/04/the-norwegian-sovereign-wealth-fund-a-unique-model-for-managing-oil-rents/ (accessed on 18 February 2025).

- International Energy Agency. Nigerian Gas Flare Commercialisation Programme. IEA 2020. Available online: https://www.iea.org/policies/8680-nigerian-gas-flare-commercialisation-programme (accessed on 18 February 2025).

- Energy Capital & Power. Angola Oil and Gas (AOG) 2024: Technical Track to Target Low-Carbon Technologies & Accelerated Project Deployment. Available online: https://energycapitalandpower.africa-newsroom.com/press/angola-oil-and-gas-aog-2024-technical-track-to-target-lowcarbon-technologies-accelerated-project-deployment?lang=en#:~:text=and%20well%20recovery.-,The%20country%20is%20implementing%20an%20%E2%80%9CIncremental%20Production%E2%80%9D%20initiative%20this%20year,workshop%20on%20Low%20Carbon%20Solutions (accessed on 18 February 2025).

- Emeka-Okoli, S.; Nwankwo, T.C.; Otonnah, C.A.; Nwankwo, E.E. Effective Stakeholder Relationship Management in The Oil & Gas Sector: A Conceptual And Review Perspective. Financ. Account. Res. J. 2024, 6, 372–383. [Google Scholar]

- Awan, U.; Sroufe, R. Sustainability in the circular economy: Insights and dynamics of designing circular business models. Appl. Sci. 2022, 12, 1521. [Google Scholar] [CrossRef]

- Segun-Falade, O.D.; Osundare, O.S.; Kedi, W.E.; Okeleke, P.A.; Ijomah, T.I.; Abdul-Azeez, O.Y. Developing innovative software solutions for effective energy management systems in industry. Eng. Sci. Technol. J. 2024, 5, 2649–2669. [Google Scholar] [CrossRef]

- Hegedić, M.; Gudlin, M.; Golec, M.; Tošanović, N. Lean and Green Decision Model for Lean Tools Selection. Sustainability 2024, 16, 1173. [Google Scholar] [CrossRef]

- Brown, A.; Amundson, J.; Badurdeen, F. Sustainable value stream mapping (Sus-VSM) in different manufacturing system configurations: Application case studies. J. Clean. Prod. 2014, 85, 164–179. [Google Scholar] [CrossRef]

- Batwara, A.; Sharma, V.; Makkar, M.; Giallanza, A. Impact of smart sustainable value stream mapping–Fuzzy PSI decision-making framework. Sustain. Futures 2024, 7, 100201. [Google Scholar] [CrossRef]

- Ng, R.; Low, J.S.C.; Song, B. Integrating and implementing Lean and Green practices based on proposition of Carbon-Value Efficiency metric. J. Clean. Prod. 2015, 95, 242–255. [Google Scholar] [CrossRef]

- iPoint-systems. Sustainability in the Automotive Industry: Driving the Transition to a Circular Economy in the Automotive Industry. Available online: https://go.ipoint-systems.com/blog/sustainability-automotive-industry#:~:text=From%20using%20recycled%20materials%20in,economy%20in%20the%20automotive%20industry (accessed on 18 February 2025).

- Hartini, S.; Ciptomulyono, U.; Anityasari, M.; Pudjotomo, D. Sustainable-value stream mapping to evaluate sustainability performance: Case study in an Indonesian furniture company. In MATEC Web of Conferences; EDP Sciences: Les Ulis, France, 2018; Volume 154, p. 01055. [Google Scholar]

- Simons, D.; Mason, R. Lean and green: ‘Doing more with less’. Int. Commer. Rev. Ecr. J. 2003, 3, 84. [Google Scholar]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine that Changed the World: The Story of Lean Production-Toyota’s Secret Weapon in the Global Car Wars That is Now Revolutionizing World Industry; Simon and Schuster: New York, NY, USA, 2007. [Google Scholar]

- Caldera, H.T.S.; Desha, C.; Dawes, L. Evaluating the enablers and barriers for successful implementation of sustainable business practice in ‘lean’SMEs. J. Clean. Prod. 2019, 218, 575–590. [Google Scholar] [CrossRef]

- Wong, W.P.; Wong, K.Y. Synergizing an ecosphere of lean for sustainable operations. J. Clean. Prod. 2014, 85, 51–66. [Google Scholar] [CrossRef]

- Sony, M.; Naik, S. Industry 4.0 integration with socio-technical systems theory: A systematic review and proposed theoretical model. Technol. Soc. 2020, 61, 101248. [Google Scholar] [CrossRef]

- Bimha, H.; Hoque, M.; Munapo, E. The impact of supply chain management practices on industry competitiveness: A mixed-methods study on the Zimbabwean petroleum industry. Afr. J. Sci. Technol. Innov. Dev. 2020, 12, 97–109. [Google Scholar] [CrossRef]

- Das, M.; Rangarajan, K. Impact of policy initiatives and collaborative synergy on sustainability and business growth of Indian SMEs. Indian Growth Dev. Rev. 2020, 13, 607–627. [Google Scholar] [CrossRef]

- Jung, J.; von der Assen, N.; Bardow, A. Sensitivity coefficient-based uncertainty analysis for multi-functionality in LCA. Int. J. Life Cycle Assess. 2014, 19, 661–676. [Google Scholar] [CrossRef]

- Andreazza de Freitas, G.; Hernandes de Paula e Silva, M.; Aparecido Lopes Silva, D. Overall lean and green effectiveness based on the environmentally sustainable value stream mapping adapted to agribusiness. Int. J. Lean Six Sigma 2025, 16, 25–53. [Google Scholar] [CrossRef]

- Albliwi, S.; Antony, J.; Lim, S.A.H.; van der Wiele, T. Critical failure factors of Lean Six Sigma: A systematic literature review. Int. J. Qual. Reliab. Manag. 2014, 31, 1012–1030. [Google Scholar] [CrossRef]

- Zyl-Cillié, V.; Maria, M.; van Dun, D.H.; Meijer, H. Toward a roadmap for sustainable lean adoption in hospitals: A Delphi study. BMC Health Serv. Res. 2024, 24, 1088. [Google Scholar]

- Grove, A.L.; Meredith, J.O.; Macintyre, M.; Angelis, J.; Neailey, K. UK health visiting: Challenges faced during lean implementation. Leadersh. Health Serv. 2010, 23, 204–218. [Google Scholar] [CrossRef]

- Siegel, R.; Antony, J.; Govindan, K.; Garza-Reyes, J.A.; Lameijer, B.; Samadhiya, A. A framework for the systematic implementation of Green-Lean and sustainability in SMEs. Prod. Plan. Control. 2024, 35, 71–89. [Google Scholar] [CrossRef]

- Abu, R.; Patchigolla, K.; Simms, N. A review on qualitative assessment of natural gas utilisation options for eliminating routine Nigerian gas flaring. Gases 2023, 3, 1–24. [Google Scholar] [CrossRef]

- U.S. Department of Commerce. Ghana: Energy and Renewables. Available online: https://www.trade.gov/country-commercial-guides/ghana-energy-and-renewables (accessed on 18 February 2025).

- Skordoulis, M.; Kyriakopoulos, G.; Ntanos, S.; Galatsidas, S.; Arabatzis, G.; Chalikias, M.; Kalantonis, P. The mediating role of firm strategy in the relationship between green entrepreneurship, green innovation, and competitive advantage: The case of medium and large-sized firms in Greece. Sustainability 2022, 14, 3286. [Google Scholar] [CrossRef]

| Company Name | Practice | Results |

|---|---|---|

| Shell (UK) | Implemented a closed-loop water recycling system in their fracking operation and invested in carbon capture and storage [47]. | Minimized water usage and wastewater disposal and reduced greenhouse gas. |

| Chevron (USA) | Implemented advanced analytics and automation methods to monitor operations [48,49,50]. | Reduced the operational waste and environmental impact of drilling operations. |

| Total (France) | Installed energy-efficient equipment and renewable energy sources [48]. | Reduction in carbon footprint, energy consumption, and emissions. |

| Statoil (Norway) | Invested in innovative technologies like gas compression for capturing and utilization [51,52]. | Reduced greenhouse gas and maximized resource utilization. |

| BP (UK) | Invested in renewable energy sources such as wind and solar power and infrastructure for electric charging vehicles [48,53]. | Reduced emission and improved energy performance. |

| Aramco (Saudi Arabia) | Invested in carbon capture and storage technologies [54,55,56]. | Reduction in greenhouse gas emissions. |

| Petrobras (Brazil) | Improved drilling efficiency using real-time monitoring and data analytics [57,58]. | Reduction in environmental waste. |

| Initiatives | Possible Impact | Application for SSA |

|---|---|---|

| A. Advanced refining technologies such as molecular refining, catalysis, and digitalization [64,65,66]. | Allows refineries to create bespoke processing techniques to optimize yields of desired products, cleaner production, and minimize waste. | If implemented, it will enable predictive maintenance, which minimizes costs and downtime. It will also enhance efficiency and product quality through improved process control. |

| B. Automation [61,62,66]. | Streamlines real-time process optimization and the predictive maintenance of facilities and equipment, utilizing data analytics, sensor data, and digitalization to reduce energy consumption, improve efficiency, and enhance product quality. | It would improve energy efficiency and impact the entire petroleum value chain if implemented. |

| C. Heavy Oil processing (visbreaking and hydrocracking) [59,60,61,64]. | The visbreaking process breaks down heavy oil molecules, resulting in lighter components like diesel and gasoline, while hydrocracking technology merges cracking with hydrogenation, resulting in lighter products. | Ensure consistent regulatory compliance and stakeholders’ engagement regarding agreed-upon refining outputs. Cleaner energy would be produced from these lighter products. |

| D. Advanced separation techniques (adsorption, membrane separation, and extractive distillation) [59,60,61,64]. | Adsorption, extractive distillation, and membrane separation are methods used to selectively capture and separate components from crude oil, enhancing product yields and reducing energy consumption. | Reduce energy consumption and improve product quality and energy efficiency throughout the petroleum value chain. |

| E. Environmental technologies [59,60,64,67]. | Clean technologies, such as hydrotreating, and environmental technologies, such as flare gas recovery units and tail gas treating units, produce cleaner-burning fuels with reduced emissions. | Ensure consistent regulatory compliance and stakeholders’ engagement regarding agreed refining outputs and flare limits. Cleaner energy from these lighter products and reduced GHG emissions. |

| Industry | Benefits | Reference/Country |

|---|---|---|

| Manufacturing SME | Increase the overall operational efficiency by decreasing the lead time by 63%, and enhance the environmental performance by decreasing the average carbon footprint by 77%. | [71]/UK |

| Manufacturing Plant | Improve operational performance through the elimination of waste, thereby reducing costs and enhancing sustainability. | [72]/USA |

| Manufacturing SME | Enhanced supply chain sustainability. | [73]/UK |

| Manufacturing | The company has seen significant improvements in operational metrics, including increased value-added time, decreased quality defect rates, decreased inventory, and increased availability. These improvements have reduced water, energy, and raw materials consumption, resulting in greener performance. | [74]/Africa |

| Manufacturing | This study found that while lean production and green practices significantly impact sustainability performance, green product innovation only significantly impacts financial performance. | [75]/Africa |

| Agriculture | Develop a model for the evaluation of the integration of lean and green systems for sustainability in the agriculture sector. | [38]/Columbia |

| Aerospace Automotive | Help reduce the consumption of resources and improve their environmental performance. | [76]/USA and Africa |

| Model | Benefits |

|---|---|

| Gemba–Kaizen model [76] | Reduce resource consumption and improve environmental performance. |

| Circular economy model [88] | Minimizes waste by reducing, reusing, and recycling. |

| Sustainable energy management system [89] | Helps industries identify inefficiencies and implement corrective measures promptly. |

| Lean–green decision model [90] | Effective economic and environmental indicators. |

| Self-assessment model [46] | Assessment of green–lean implementation readiness. |

| Section 1 | Section 2 | Section 3 | Section 4 | Section 5 and Section 6 | |

|---|---|---|---|---|---|

| Phases | Introduction | Literature review | Methodology | Descriptive analysis | Key findings and conclusion |

| Objectives | Overview of the research, aims, and questions | Methods used and literature review | Analysis and categorization of articles | Findings, prospects, and limitations | |

| Method |

|

| |||

| Tools |

|

| |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Dibia, F.; Dibia, C.; Dhakal, H.N.; Okpako, O.; Radulovic, J.; Isike, A. A Review on Achieving Sustainability in the Petroleum Industry Through the Integration of Lean and Green. Appl. Sci. 2025, 15, 2333. https://doi.org/10.3390/app15052333

Dibia F, Dibia C, Dhakal HN, Okpako O, Radulovic J, Isike A. A Review on Achieving Sustainability in the Petroleum Industry Through the Integration of Lean and Green. Applied Sciences. 2025; 15(5):2333. https://doi.org/10.3390/app15052333

Chicago/Turabian StyleDibia, Felister, Chinedu Dibia, Hom Nath Dhakal, Oghenovo Okpako, Jovana Radulovic, and Augustine Isike. 2025. "A Review on Achieving Sustainability in the Petroleum Industry Through the Integration of Lean and Green" Applied Sciences 15, no. 5: 2333. https://doi.org/10.3390/app15052333

APA StyleDibia, F., Dibia, C., Dhakal, H. N., Okpako, O., Radulovic, J., & Isike, A. (2025). A Review on Achieving Sustainability in the Petroleum Industry Through the Integration of Lean and Green. Applied Sciences, 15(5), 2333. https://doi.org/10.3390/app15052333