A Comprehensive Review on Clay Soil Stabilization Using Rice Husk Ash and Lime Sludge

Abstract

1. Introduction

1.1. Stabilization History

1.2. Stabilization Methods

1.3. Conventional Stabilizers

- (1)

- (2)

- Implementing energy-efficient technologies and practices can reduce the overall energy consumption and emissions from cement production. This includes optimizing kiln operations, improving heat recovery systems, and employing more efficient grinding processes [52].

- (3)

- Carbon capture and storage (CCS) technologies aim to capture CO2 emissions from cement plants, store them underground, or utilize them in other industrial processes. CCS is still in the early stages of deployment in the cement industry but holds promise for significant emissions reduction [53].

- (4)

- Development efforts are underway to develop and promote low-carbon or carbon-neutral cement alternatives. These include cement made from supplementary cementitious materials like fly ash, blast furnace slag, or pozzolanic materials [54]. By implementing these measures, the cement industry can reduce its carbon footprint and contribute to global efforts to mitigate climate change.

1.4. Sustainable Stabilizers

2. Materials

2.1. Rice Husk Ash (RHA)

2.2. Lime Sludge (LS)

3. Laboratory Tests

3.1. Standard Proctor Compaction Test

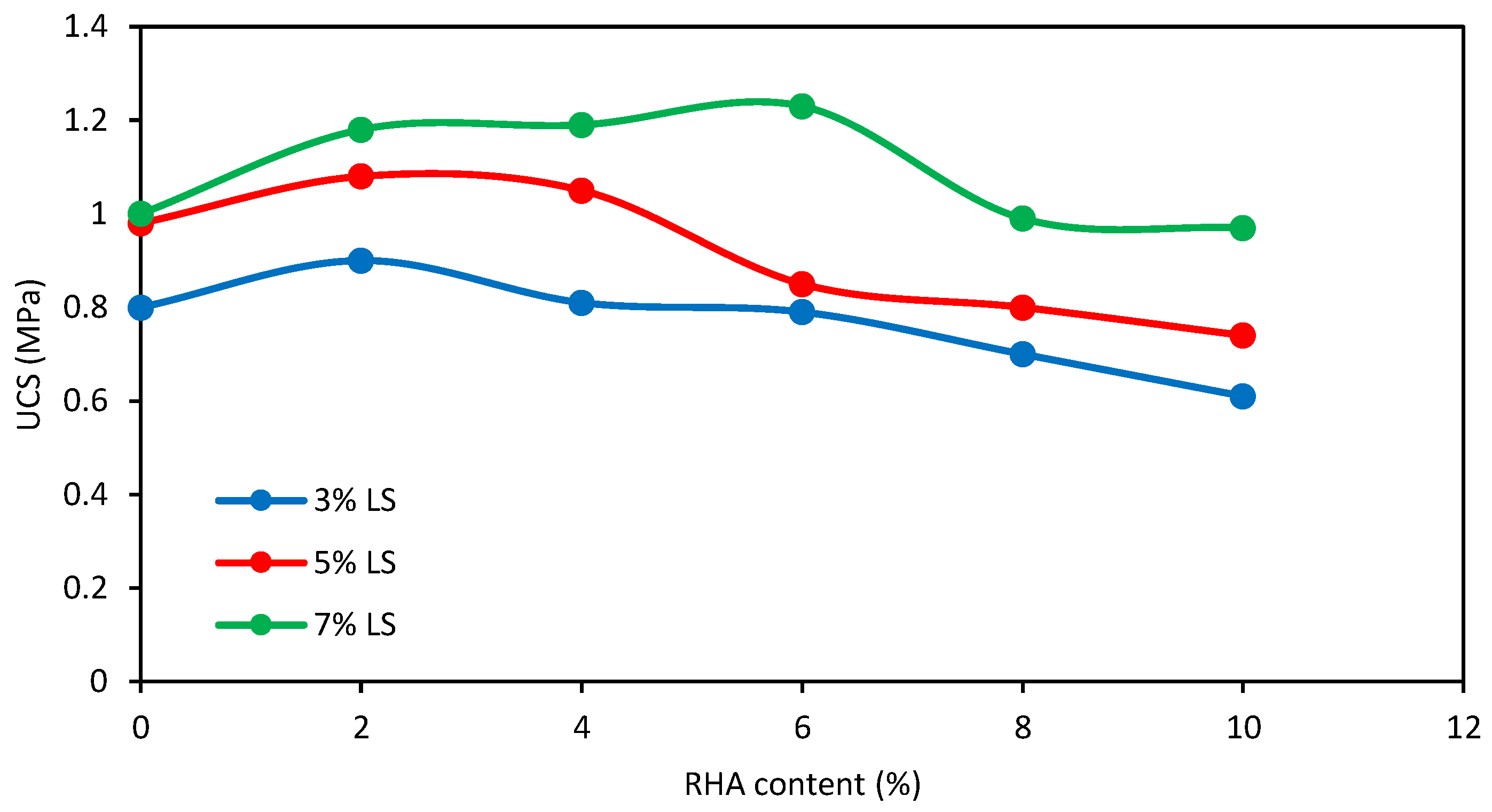

3.2. Unconfined Compressive Strength (UCS)

3.3. California Bearing Ratio (CBR)

4. Cost and Sustainability Evaluation

4.1. Cost Evaluation

4.2. Sustainability Evaluation

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Afrin, H. A Review on Different Types of Soil Stabilization Techniques. Int. J. Transp. Eng. Technol. 2017, 3, 19–24. [Google Scholar] [CrossRef]

- Amhadi, T.S.; Assaf, G.J. Overview of Soil Stabilization Methods in Road Construction. In Sustainable Solutions for Railways and Transportation Engineering: Proceedings of the 2nd GeoMEast International Congress and Exhibition on Sustainable Civil Infrastructures, Egypt 2018–The Official International Congress of the Soil-Structure Interaction Group in Egypt (SSIGE); Springer International Publishing: Cham, Switzerland, 2019; pp. 21–33. [Google Scholar]

- Manaviparast, H.R.; Araújo, N.; Cristelo, N.; Miranda, T. Study on Guardrail Post Behavior Located on Organic Soil Using Simplified Experimental and Numerical Methods. Soils Rocks 2022, 45, e2022077921. [Google Scholar] [CrossRef]

- Sujatha, E.R.; Saisree, S. Geotechnical Behaviour of Guar Gum-Treated Soil. Soils Found. 2019, 59, 2155–2166. [Google Scholar] [CrossRef]

- Huang, J.; Kogbara, R.B.; Hariharan, N.; Masad, E.A.; Little, D.N. A State-of-the-Art Review of Polymers Used in Soil Stabilization. Constr. Build. Mater. 2021, 305, 124685. [Google Scholar] [CrossRef]

- Onodagu, P.D.; Uzodinma, F.C.; Aginam, C.H. Effects of Untreated Oil-Palm Fruit Fibre Reinforcements on the Strength and Durability Properties of Non-Fired Pressed Mud Blocks. Niger. J. Technol. 2022, 41, 21–25. [Google Scholar] [CrossRef]

- Ullah, A.; Boumezerane, D.; Ahmad, F. Subgrade Improvement with Mixed Lime and Cement as Additives. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Yang, J.; Tan, F.H.; Tan, A. The Ancient Construction Materials and Methods: The Great Wall of China in Jinshanling as a Case Study. J. Constr. Eng. Proj. Manag. 2017, 7, 37–49. [Google Scholar] [CrossRef]

- Su, Z.; Yan, Z.; Nakashima, K.; Takano, C.; Kawasaki, S. Naturally Derived Cements Learned from the Wisdom of Ancestors: A Literature Review Based on the Experiences of Ancient China, India, and Rome. Materials 2023, 16, 603. [Google Scholar] [CrossRef] [PubMed]

- Vitti, P. Mortars and Masonry—Structural Lime and Gypsum Mortars in Antiquity and Middle Ages. Archaeol. Anthropol. Sci. 2021, 13, 164. [Google Scholar] [CrossRef]

- Mendonça, A.; Morais, P.V.; Pires, A.C.; Chung, A.P.; Oliveira, P.V. A Review on the Importance of Microbial Biopolymers Such as Xanthan Gum to Improve Soil Properties. Appl. Sci. 2020, 11, 170. [Google Scholar] [CrossRef]

- Jang, J. A Review of the Application of Biopolymers on Geotechnical Engineering and the Strengthening Mechanisms Between Typical Biopolymers and Soils. Adv. Mater. Sci. Eng. 2020, 1465709. [Google Scholar] [CrossRef]

- Ferreira, F.A.; Desir, J.M.; De Lima, G.E.S.; Pedroti, L.G.; De Carvalho, J.M.F.; Lotero, A.; Consoli, N.C. Evaluation of Mechanical and Microstructural Properties of Eggshell Lime/Rice Husk Ash Alkali-Activated Cement. Constr. Build. Mater. 2023, 364, 129931. [Google Scholar] [CrossRef]

- Ikeagwuani, C.C.; Nwonu, D.C. Emerging Trends in Expansive Soil Stabilisation: A Review. J. Rock Mech. Geotechnol. Eng. 2019, 11, 423–440. [Google Scholar] [CrossRef]

- Türköz, M.; Umu, S.U.; Öztürk, O. Effect of Silica Fume as a Waste Material for Sustainable Environment on the Stabilization and Dynamic Behavior of Dispersive Soil. Sustainability 2021, 13, 4321. [Google Scholar] [CrossRef]

- ALERTA, A.Z.A.; BAYRAKTAR, O.Y.; Soylemez, H. Investigation of the Effects of Modified Bitumen on Asphalt Concrete Performance by Industrial Waste. Kastamonu Univ. J. Eng. Sci. 2019, 5, 93–100. [Google Scholar]

- Kamal, I.; Bas, Y. Materials and Technologies in Road Pavements—An Overview. Mater. Today Proc. 2021, 42, 2660–2667. [Google Scholar] [CrossRef]

- Garipov, A.; Makarov, D.; Khozin, V.; Stepanov, S.; Ayupov, D. Cement Concrete Modified by Fine-Dispersed Anionactive Bitumen Emulsion for Road Construction. IOP Conf. Ser. Mater. Sci. Eng. 2020, 890, 012107. [Google Scholar] [CrossRef]

- Sinha, P.; Anusha Raj, K.; Kumar, S.; Singh, D. Mechanical Behavior of Geotextile and Geogrids on Soil Stabilization: A Review. In Recent Advances in Mechanical Engineering: Select Proceedings of CAMSE 2021; Springer: Berlin/Heidelberg, Germany, 2022; pp. 299–308. [Google Scholar]

- Kumar, S.; Singh, S.K. Subgrade Soil Stabilization Using Geosynthetics: A Critical Review. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Karami, H.; Pooni, J.; Robert, D.; Costa, S.; Li, J.; Setunge, S. Use of Secondary Additives in Fly Ash Based Soil Stabilization for Soft Subgrades. Transp. Geotechnol. 2021, 29, 100585. [Google Scholar] [CrossRef]

- Manaviparast, H.R.; Pinheiro, J.; Najafi, E.K.; Abreu, C.; Araújo, N.; Cristelo, N.; Miranda, T. Mechanical Behavior of a Mine Tailing Stabilized with a Sustainable Binder. Appl. Sci. 2023, 13, 4103. [Google Scholar] [CrossRef]

- Wu, J.; Deng, Y.; Zhang, G.; Zhou, A.; Tan, Y.; Xiao, H.; Zheng, Q. A Generic Framework of Unifying Industrial Byproducts for Soil Stabilization. J. Clean. Prod. 2021, 321, 128920. [Google Scholar] [CrossRef]

- Nawaz, M.; Heitor, A.; Sivakumar, M. Geopolymers in Construction—Recent Developments. Constr. Build. Mater. 2020, 260, 120472. [Google Scholar] [CrossRef]

- Onyelowe, K.; Van, D.B.; Igboayaka, C.; Orji, F.; Ugwuanyi, H. Rheology of Mechanical Properties of Soft Soil and Stabilization Protocols in the Developing Countries—Nigeria. Mater. Sci. Energy Technol. 2019, 2, 8–14. [Google Scholar] [CrossRef]

- Haris, A.; Dhanya, M. A Review on the Combined Effect of Lime, Fly Ash, and Geosynthetic Reinforcement on Soil. Appl. Sci. 2020. [Google Scholar]

- Andavan, S.; Pagadala, V.K. A Study on Soil Stabilization by Addition of Fly Ash and Lime. Mater. Today Proc. 2020, 22, 1125–1129. [Google Scholar] [CrossRef]

- Indiramma, P.; Sudharani, C.; Needhidasan, S. Utilization of Fly Ash and Lime to Stabilize the Expansive Soil and to Sustain Pollution-Free Environment—An Experimental Study. Mater. Today Proc. 2020, 22, 694–700. [Google Scholar] [CrossRef]

- Adabi, M.; Darvishan, E.; Eyvazi, G.; Jahanbaksh Motlagh, H. Geoenvironmental Application of Novel Persian Gum Biopolymer in Sandy Soil Stabilization. Arab. J. Sci. Eng. 2022, 47, 12915–12929. [Google Scholar] [CrossRef]

- Divya, M.J.; Bikku, M.P. Techniques of Ground Improvement and its Applications. Dogo Rangsang Res. J. 2022, 12, 7–21. [Google Scholar]

- Jawad, Z.H.; Shakir, R.R. Behavior of Foundation Rested on Geogrid-Reinforced Soil: A Review. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1094, 012110. [Google Scholar] [CrossRef]

- Zhang, T.; Liu, S.; Zhan, H.; Ma, C.; Cai, G. Durability of Silty Soil Stabilized with Recycled Lignin for Sustainable Engineering Materials. J. Clean. Prod. 2020, 248, 119293. [Google Scholar] [CrossRef]

- Tan, E.H.; Zahran, E.M.M.; Tan, S.J. A Review of Chemical Stabilisation in Road Construction. IOP Conf. Ser. Mater. Sci. Eng. 2020, 943, 012005. [Google Scholar] [CrossRef]

- Phang, I.R.K.; Wong, K.S.; Chan, Y.S.; Lau, S.Y. Effect of Surcharge Load on Microbial-Induced Calcite Precipitation (MICP) Treatment of Tropical Peat. IOP Conf. Ser. Mater. Sci. Eng. 2019, 495, 012068. [Google Scholar] [CrossRef]

- Schwerdt, S.; Mirschel, D.; Hildebrandt, T.; Wilke, M.; Schneider, P. Substitute Building Materials in Geogrid-Reinforced Soil Structures. Sustainability 2021, 13, 12519. [Google Scholar] [CrossRef]

- Puppala, A.J.; Congress, S.S.; Banerjee, A. Research Advancements in Expansive Soil Characterization, Stabilization, and Geoinfrastructure Monitoring. In Frontiers in Geotechnical Engineering; Springer: Singapore, 2019; pp. 15–29. [Google Scholar]

- Zhang, Y.; Wang, Y.; Shah, K.F.; Li, T. Moisture Stabilization of Embankment Subgrade with Capillary Barrier Cover Under Dry and Rainy Weathers. Transp. Geotechnol. 2023, 42, 101057. [Google Scholar] [CrossRef]

- Sharonova, O.M.; Kirilets, V.M.; Yumashev, V.V.; Solovyov, L.A.; Anshits, A.G. Phase Composition of High-Strength Binding Material Based on Fine Microspherical High-Calcium Fly Ash. Constr. Build. Mater. 2019, 216, 525–530. [Google Scholar] [CrossRef]

- Anburuvel, A. The Engineering Behind Soil Stabilization with Additives: A State-of-the-Art Review. Geotechnol. Geol. Eng. 2023, 42, 1–42. [Google Scholar] [CrossRef]

- Chen, K.; Wu, D.; Zhang, Z.; Pan, C.; Shen, X.; Xia, L.; Zang, J. Modeling and Optimization of Fly Ash–Slag-Based Geopolymer Using Response Surface Method and Its Application in Soft Soil Stabilization. Constr. Build. Mater. 2022, 315, 125723. [Google Scholar] [CrossRef]

- Wang, S.; Guo, S.; Gao, X.; Zhang, P.; Li, G. Effects of Cement Content and Soil Texture on Strength, Hydraulic, and Microstructural Characteristics of Cement-Stabilized Composite Soils. Bull. Eng. Geol. Environ. 2022, 81, 264. [Google Scholar] [CrossRef]

- Qiao, G.; Hou, D.; Li, W.; Yin, B.; Zhang, Y.; Wang, P. Molecular Insights into Migration of Heavy Metal Ion in Calcium Silicate Hydrate (CSH) Surface and Intra-CSH (Ca/Si = 1.3). Constr. Build. Mater. 2023, 365, 130097. [Google Scholar] [CrossRef]

- Baldovino, J.J.; Izzo, R.L.; Rose, J.L.; Domingos, M.D. Strength, Durability, and Microstructure of Geopolymers Based on Recycled-Glass Powder Waste and Dolomitic Lime for Soil Stabilization. Constr. Build. Mater. 2021, 271, 121874. [Google Scholar] [CrossRef]

- Chen, R.; Zhu, Y.; Lai, H.P.; Bao, W. Stabilization of Soft Soil Using Low-Carbon Alkali-Activated Binder. Environ. Earth Sci. 2020, 79, 1–13. [Google Scholar] [CrossRef]

- Muhammad, A.; Yusuf, A.; Umar, M. Assessment of Lateritic Soil Stabilized Using Metakaolin. J. Geotechnol. Stud. 2020, 5, 15–26. [Google Scholar]

- Naeini, A.A.; Siddiqua, S.; Cherian, C. A Novel Stabilized Rammed Earth Using Pulp Mill Fly Ash as Alternative Low Carbon Cementing Material. Constr. Build. Mater. 2021, 300, 124003. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, S.Y.; Chen, J.; Lee, C.H.; Cai, Z.; Ruan, H.D. Fabrication of Superhydrophobic Soil Stabilizers Derived from Solid Wastes Applied for Road Construction: A Review. Transp. Geotechnol. 2023, 40, 100974. [Google Scholar] [CrossRef]

- Chand, G.; Ram, S.; Kumar, S.; Gupta, U. Microstructural and Engineering Properties Investigation of Sustainable Hybrid Concrete Produced from Industrial Wastes. Cleaner Eng. Technol. 2021, 2, 100052. [Google Scholar] [CrossRef]

- Sim, S.; Her, S.; Suh, H.; Cho, S.; Im, S.; Li, P.; Bae, S. Influences of Alumina Type and Sulfate Content on Hydration and Physicochemical Changes in Portland–Limestone Cement. Constr. Build. Mater. 2024, 426, 135989. [Google Scholar] [CrossRef]

- Hossain, M.U.; Poon, C.S.; Wong, M.Y.K.; Khine, A. Techno-Environmental Feasibility of Wood Waste Derived Fuel for Cement Production. J. Clean. Prod. 2019, 230, 663–671. [Google Scholar] [CrossRef]

- Costa, F.N.; Ribeiro, D.V. Reduction in CO2 Emissions During Production of Cement, with Partial Replacement of Traditional Raw Materials by Civil Construction Waste (CCW). J. Clean. Prod. 2020, 276, 123302. [Google Scholar] [CrossRef]

- Patil, M.; Boraste, S.; Minde, P. A Comprehensive Review on Emerging Trends in Smart Green Building Technologies and Sustainable Materials. Mater. Today Proc. 2022, 65, 1813–1822. [Google Scholar] [CrossRef]

- Rosa, L.; Sanchez, D.L.; Realmonte, G.; Baldocchi, D.; D’Odorico, P. The Water Footprint of Carbon Capture and Storage Technologies. Renew. Sustain. Energy Rev. 2021, 138, 110511. [Google Scholar] [CrossRef]

- Najafi, E.K.; Tavares, P.; Miranda, T.; Manaviparast, H.R.; Cristelo, N. Ophthalmic Glass Lens Waste as an Alternative Soluble Silica Source for Alkali-Activation Reactions. Constr. Build. Mater. 2023, 392, 131854. [Google Scholar] [CrossRef]

- Amakye, S.Y.; Abbey, S.J.; Booth, C.A.; Mahamadu, A.M. Enhancing the Engineering Properties of Subgrade Materials Using Processed Waste: A Review. Geotechnics 2021, 1, 307–329. [Google Scholar] [CrossRef]

- Kamseu, E.; Alzari, V.; Rosa, R.; Nuvoli, D.; Sanna, D.; Mariani, A.; Leonelli, C. Marble Wastes Recycling: Design and Synthesis of Low-Temperature Calcium Silicate Hydrate Under Various CaO Ratio and Alkalinity. Materialia 2021, 20, 101224. [Google Scholar] [CrossRef]

- Sangmesh, B.; Patil, N.; Jaiswal, K.K.; Gowrishankar, T.P.; Selvakumar, K.K.; Jyothi, M.S.; Kumar, S. Development of Sustainable Alternative Materials for the Construction of Green Buildings Using Agricultural Residues: A Review. Constr. Build. Mater. 2023, 368, 130457. [Google Scholar]

- Boonphayak, P.; Khansumled, S.; Yatongchai, C. Synthesis of CaO-SiO2 Catalyst from Lime Mud and Kaolin Residue for Biodiesel Production. Mater. Lett. 2021, 283, 128759. [Google Scholar] [CrossRef]

- Sakr, M.A.; Azzam, W.R.; El-Sawwaf, M.A.; El-Disouky, E.A. Lime Columns Technique for the Improvement of Soft Clay—A Review. J. Multidiscip. Eng. Sci. Stud. 2021, 7, 3893–3897. [Google Scholar]

- Zada, U.; Jamal, A.; Iqbal, M.; Eldin, S.M.; Almoshaogeh, M.; Bekkouche, S.R.; Almuaythir, S. Recent Advances in Expansive Soil Stabilization Using Admixtures: Current Challenges and Opportunities. Case Stud. Constr. Mater. 2023, 18, e01985. [Google Scholar] [CrossRef]

- Rabbani, P.; Lajevardi, S.H. Laboratory Investigation of the Effect of Deep Soil Mixing Method on Engineering Properties of Soft Clay Stabilized by Slag and Lime. Methodology 2019, 7, 9. [Google Scholar]

- Vu, H.H.T.; Khan, M.D.; Chilakala, R.; Lai, T.Q.; Thenepalli, T.; Ahn, J.W.; Kim, J. Utilization of Lime Mud Waste from Paper Mills for Efficient Phosphorus Removal. Sustainability 2019, 11, 1524. [Google Scholar] [CrossRef]

- Eliaslankaran, Z.; Daud, N.N.N.; Yusoff, Z.M.; Rostami, V. Evaluation of the Effects of Cement and Lime with Rice Husk Ash as an Additive on Strength Behavior of Coastal Soil. Materials 2021, 14, 1140. [Google Scholar] [CrossRef] [PubMed]

- Ferronato, N.; Torretta, V. Waste Mismanagement in Developing Countries: A Review of Global Issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef] [PubMed]

- Abhijith, L.; Varghese, E.M. Removal of Zinc and Copper from Contaminated Soil by Using Adsorbents and Mulches. In AIP Conference Proceeding; AIP Publishing LLC: Melville, NY, USA, 2021; Volume 2396, p. 030005. [Google Scholar]

- Singh, S.; Ashesh, A.; Devi, N.L.; Yadav, I.C. A Comprehensive Review on Occurrence, Source, Effect, and Measurement Techniques of Polycyclic Aromatic Hydrocarbons in India. Microchem. J. 2022, 183, 108005. [Google Scholar] [CrossRef]

- Jasim, N.A.; Ibrahim, J.A.K. Stabilization of Al-Rustamiya Waste Water Treatment Plant Sludge Using Lime. J. Eng. 2020, 26, 165–172. [Google Scholar] [CrossRef]

- Elbehiry, F.; Alshaal, T.; Elhawat, N.; Elbasiouny, H. Environmental-Friendly and Cost-Effective Agricultural Wastes for Heavy Metals and Toxicants Removal from Wastewater. In Cost-Efficient Wastewater Treatment Technologies: Natural Systems; Springer International Publishing: Cham, Switzerland, 2021; pp. 107–127. [Google Scholar]

- Riza, M.; Ehsan, M.N.; Pervez, M.N.; Khyum, M.M.O.; Cai, Y.; Naddeo, V. Control of Eutrophication in Aquatic Ecosystems by Sustainable Dredging: Effectiveness, Environmental Impacts, and Implications. Case Stud. Chem. Environ. Eng. 2023, 7, 100297. [Google Scholar] [CrossRef]

- Raja, K.; Venkatachalam, S.; Vishnuvardhan, K.; Krishnan, R.S.R.; Selvan, V.T.; Vetriselvan, N. A Review on Soil Stabilization Using Rice Husk Ash and Lime Sludge. Mater. Today Proc. 2022, 65, 1205–1212. [Google Scholar] [CrossRef]

- Vijayan, D.S.; Parthiban, D. Effect of Solid Waste-Based Stabilizing Material for Strengthening of Expansive Soil—A Review. Environ. Technol. Innov. 2020, 20, 101108. [Google Scholar] [CrossRef]

- Pushpakumara, B.H.J.; Mendis, W.S.W. Suitability of Rice Husk Ash (RHA) with Lime as a Soil Stabilizer in Geotechnical Applications. Int. J. Geo-Eng. 2022, 13, 4. [Google Scholar] [CrossRef]

- Das, S.K.; Adediran, A.; Kaze, C.R.; Mustakim, S.M.; Leklou, N. Production, Characteristics, and Utilization of Rice Husk Ash in Alkali-Activated Materials: An Overview of Fresh and Hardened State Properties. Constr. Build. Mater. 2022, 345, 128341. [Google Scholar]

- Rahmat, A.; Nissa, R.C.; Nuraini, L.; Nurtanto, M.; Ramadhani, W.S. Analysis of Rice Husk Biochar Characteristics Under Different Pyrolysis Temperature. IOP Conf. Ser. Earth Environ. Sci. 2023, 1201, 012095. [Google Scholar]

- Naveen, C.C.; Kunnoth, B.; Pilli, S.; Rao, P.V.; Surampalli, R.Y.; Zhang, T.C.; Bhunia, P. Effects of Different Parameters and Co-Digestion Options on Anaerobic Digestion of Parboiled Rice Mill Wastewater: A Review. Bioenergy Res. 2022, 17, 1191–1207. [Google Scholar] [CrossRef]

- Liou, T.H.; Tseng, Y.K.; Zhang, T.Y.; Liu, Z.S.; Chen, J.Y. Rice Husk Char as a Sustainable Material for the Preparation of Graphene Oxide-Supported Biocarbons with Mesoporous Structure: A Characterization and Adsorption Study. Fuel 2023, 344, 128042. [Google Scholar] [CrossRef]

- Abbass, M.; Singh, D.; Singh, G. Properties of Hybrid Geopolymer Concrete Prepared Using Rice Husk Ash, Fly Ash, and GGBS with Coconut Fiber. Mater. Today Proc. 2021, 45, 4964–4970. [Google Scholar] [CrossRef]

- Ge, S.; Yek, P.N.Y.; Cheng, Y.W.; Xia, C.; Mahari, W.A.W.; Liew, R.K.; Lam, S.S. Progress in Microwave Pyrolysis Conversion of Agricultural Waste to Value-Added Biofuels: A Batch to Continuous Approach. Renew. Sustain. Energy Rev. 2021, 135, 110148. [Google Scholar] [CrossRef]

- Rithuparna, R.; Jittin, V.; Bahurudeen, A. Influence of Different Processing Methods on the Recycling Potential of Agro-Waste Ashes for Sustainable Cement Production: A Review. J. Clean. Prod. 2021, 316, 128242. [Google Scholar] [CrossRef]

- Bouzón, N.; Font, A.; Borrachero, M.V.; Soriano, L.; Monzó, J.; Tashima, M.M.; Payá, J. Evaluation of Thermo-Chemical Treatments for Rice Husk Ash Valorisation as a Source of Silica in Preparing Geopolymers. Materials 2023, 16, 4667. [Google Scholar] [CrossRef]

- Isberto, C.D.; Labra, K.L.; Landicho, J.M.B.; De Jesus, R. Optimized Preparation of Rice Husk Ash (RHA) as a Supplementary Cementitious Material. Geomate J. 2019, 16, 56–61. [Google Scholar] [CrossRef]

- Plando, F.R.P.; Gili, M.B.Z.; Maquiling, J.T. Microstructural Characterizations and Radiation Shielding Quantities of Rice Husk Ash-Based Self-Compacting Concrete and Its Precursors. Radiat. Phys. Chem. 2023, 208, 110916. [Google Scholar] [CrossRef]

- Lu, S.G.; Sun, F.F.; Zong, Y.T. Effect of Rice Husk Biochar and Coal Fly Ash on Some Physical Properties of Expansive Clayey Soil (Vertisol). Catena 2014, 114, 37–44. [Google Scholar] [CrossRef]

- Das, S.K.; Mishra, J.; Singh, S.K.; Mustakim, S.M.; Patel, A.; Das, S.K.; Behera, U. Characterization and Utilization of Rice Husk Ash (RHA) in Fly Ash–Blast Furnace Slag Based Geopolymer Concrete for Sustainable Future. Mater. Today Proc. 2020, 33, 5162–5167. [Google Scholar] [CrossRef]

- Nazarpour-Fard, H. Rice Husk Ash: Economical and High-Quality Natural-Based Reinforcing Filler for Linear Low-Density and High-Density Polyethylene. Polymers Renew. Resour. 2022, 13, 206–222. [Google Scholar] [CrossRef]

- Abdullah, M.N.I.; Mustapha, F.; Ahmad, K.A.; Mustapha, M.; Khan, T.; Singh, B.; Sebaey, T.A. Effect of Different Pre-Treatment on the Microstructure and Intumescent Properties of Rice Husk Ash-Based Geopolymer Hybrid Coating. Polymers 2022, 14, 2252. [Google Scholar] [CrossRef] [PubMed]

- Sivalingam, S.; Sen, S. Rice Husk Ash Derived Nanocrystalline ZSM-5 for Highly Efficient Removal of a Toxic Textile Dye. J. Mater. Res. Technol. 2020, 9, 14853–14864. [Google Scholar] [CrossRef]

- Nduka, D.O.; Olawuyi, B.J.; Fagbenle, O.I.; Fonteboa, B.G. Assessment of the Durability Dynamics of High-Performance Concrete Blended with a Fibrous Rice Husk Ash. Crystals 2022, 12, 75. [Google Scholar] [CrossRef]

- Althoey, F.; Zaid, O.; de-Prado-Gil, J.; Palencia, C.; Ali, E.; Hakeem, I.; Martínez-García, R. Impact of Sulfate Activation of Rice Husk Ash on the Performance of High Strength Steel Fiber Reinforced Recycled Aggregate Concrete. J. Build. Eng. 2022, 54, 104610. [Google Scholar] [CrossRef]

- Pham, T.M. Enhanced Properties of High-Silica Rice Husk Ash-Based Geopolymer Paste by Incorporating Basalt Fibers. Constr. Build. Mater. 2020, 245, 118422. [Google Scholar]

- Bijalwan, A.; Mishra, A.K.; Sonowal, B. Strength, Durability, and Toxicity Characteristics of Water Treatment Sludge Based Geopolymers for Subgrade Application. Constr. Build. Mater. 2024, 447, 138162. [Google Scholar] [CrossRef]

- Han, J.S.; Kang, D.S.; Seo, Y.B. Application of In Situ Calcium Carbonate Process for Producing Papermaking Fillers from Lime Mud. ACS Omega 2021, 6, 3884–3890. [Google Scholar] [CrossRef] [PubMed]

- Vashistha, P.; Kumar, V.; Singh, S.K.; Dutt, D.; Tomar, G.; Yadav, P. Valorization of Paper Mill Lime Sludge via Application in Building Construction Materials: A Review. Constr. Build. Mater. 2019, 211, 371–382. [Google Scholar] [CrossRef]

- Phanikumar, B.R.; Raju, E.R. Compaction and Strength Characteristics of an Expansive Clay Stabilized with Lime Sludge and Cement. Soils Found. 2020, 60, 129–138. [Google Scholar] [CrossRef]

- Peter, M.A. Effects of Stone Dust on Lime Stabilized Granular Soil. IOP Conf. Ser. Earth Environ. Sci. 2023, 1110, 012024. [Google Scholar] [CrossRef]

- Avinash, B.; Kumar, S.R. Influence of Industrial Wastes and Lime on Strength Characteristics of Clayey Soil. Magaz. Civ. Eng. 2023, 120, 12002. [Google Scholar]

- Majumder, M.; Venkatraman, S. Utilization of Lime as Subgrade Stabilizer in the Pavement Construction. Arab. J. Sci. Eng. 2022, 47, 4929–4942. [Google Scholar] [CrossRef]

- Guleria, A.; Thakur, S.; Gautam, C.P. Stabilization of Mohali Soil Using RHA and Lime Sludge; Jaypee University of Information Technology: Waknaghat, India, 2017. [Google Scholar]

- Liu, Y.; Su, Y.; Namdar, A.; Zhou, G.; She, Y.; Yang, Q. Utilization of Cementitious Material from Residual Rice Husk Ash and Lime in Stabilization of Expansive Soil. Adv. Civ. Eng. 2019. [Google Scholar] [CrossRef]

- Muntohar, A.S.; Widianti, A.; Hartono, E.; Diana, W. Engineering Properties of Silty Soil Stabilized with Lime and Rice Husk Ash and Reinforced with Waste Plastic Fiber. J. Mater. Civ. Eng. 2013, 25, 1260–1270. [Google Scholar] [CrossRef]

- Modarres, A.; Nosoudy, Y.M. Clay Stabilization Using Coal Waste and Lime—Technical and Environmental Impacts. Appl. Clay Sci. 2015, 116, 281–288. [Google Scholar] [CrossRef]

- Maheswaran, S.; Kalaiselvam, S.; Karthikeyan, S.S.; Kokila, C.; Palani, G.S. β-Belite Cements (β-Dicalcium Silicate) Obtained from Calcined Lime Sludge and Silica Fume. Cement Concr. Compos. 2016, 66, 57–65. [Google Scholar] [CrossRef]

- Kashyap, S.; Datta, D. Industrial Lime Sludge Waste–HDPE Composites: A Study of Their Mechanical, Thermal, and Morphological Properties. J. Thermoplast. Compos. Mater. 2018, 31, 1323–1340. [Google Scholar] [CrossRef]

- Vashistha, P.; Singh, S.K.; Dutt, D.; Kumar, V. Synthesis of Nanosilica from Fly Ash and Its Utilization with Lime Sludge in Concrete: An Environmentally Friendly and Sustainable Solution. Clean Technol. Environ. Policy 2019, 21, 1841–1853. [Google Scholar] [CrossRef]

- Prakash, J.; Kumari, K.; Kumar, V. Stabilization of Soil Using Rice Husk Ash. Int. J. Innov. Res. Sci. Eng. Technol. 2017, 6, 12997–13003. [Google Scholar]

- Bhattacharjee, A.; Borgohain, B. Improvement of California Bearing Ratio of Laterite Soil Using Rice Husk Ash. In Proceedings of the 50th Indian Geotechnical Conference, Pune, India, 17–19 December 2015. [Google Scholar]

- Rather, S.A.; Sharma, N.; Najar, I.A. Effects of Rice Husk Ash (RHA) and Alccofine-1101 on Stabilization of Clay Soil. Int. Res. J. Eng. Technol. 2019, 6, 474–478. [Google Scholar]

- Chandak, N.R.; Babu, A. Effect of Lime Sludge on Strength and Compaction of Soil. J. Civ. Eng. Res. 2015, 5, 18–20. [Google Scholar]

- Sabat, A.K. Engineering Properties of an Expansive Soil Stabilized with Rice Husk Ash and Lime Sludge. Int. J. Eng. Technol. 2013, 5, 4826–4833. [Google Scholar]

- Burra, S.G.; Kolay, P.K.; Puri, V.K.; Kumar, S. Strength and Compressibility of Kaolinite Clay Stabilized with Lime Sludge and Fly Ash. In Ground Improvement and Reinforced Soil Structures: Proceedings of Indian Geotechnical Conference 2020; Springer Singapore: Singapore, 2021; Volume 2, pp. 271–281. [Google Scholar]

- Harichane, K.; Ghrici, M.; Kenai, S.; Grine, K. Use of Natural Pozzolana and Lime for Stabilization of Cohesive Soils. Geotechnol. Geol. Eng. 2011, 29, 759–769. [Google Scholar] [CrossRef]

- Singh, S.; Chohan, J.S.; Kumar, R. Stabilization of Kaolin via Lime and Pond Ash. Mater. Today Proc. 2022, 51, 988–992. [Google Scholar] [CrossRef]

- Chenarboni, H.A.; Lajevardi, S.H.; Molaabasi, H.; Zeighami, E. The Effect of Zeolite and Cement Stabilization on the Mechanical Behavior of Expansive Soils. Constr. Build. Mater. 2021, 272, 121630. [Google Scholar] [CrossRef]

- Lin, D.F.; Lin, K.L.; Hung, M.J.; Luo, H.L. Sludge Ash/Hydrated Lime on the Geotechnical Properties of Soft Soil. J. Hazard. Mater. 2007, 145, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Sabat, A.K. Utilization of Bagasse Ash and Lime Sludge for Construction of Flexible Pavements in Expansive Soil Areas. Electron. J. Geotechnol. Eng. 2012, 17, 1037–1046. [Google Scholar]

- Hossain, K.M.A. Stabilized Soils Incorporating Combinations of Rice Husk Ash and Cement Kiln Dust. J. Mater. Civ. Eng. 2011, 23, 1320–1327. [Google Scholar] [CrossRef]

- Sabat, A.K.; Nanda, R.P. Effect of Marble Dust on Strength and Durability of Rice Husk Ash Stabilized Expansive Soil. Int. J. Civ. Struct. Eng. 2011, 1, 939–948. [Google Scholar]

- Jiang, X.; Huang, Z.; Ma, F.; Luo, X. Analysis of Strength Development and Soil–Water Characteristics of Rice Husk Ash–Lime Stabilized Soft Soil. Materials 2019, 12, 3873. [Google Scholar] [CrossRef] [PubMed]

- Niyomukiza, J.B.; Wardani, S.P.R.; Setiadji, B.H. The Effect of Curing Time on the Engineering Properties of Sawdust and Lime Stabilized Expansive Soils. In Proceedings of the 2nd International Symposium on Transportation Studies in Developing Countries (ISTSDC 2019); Atlantis Press: Amsterdam, The Netherlands, 2020; pp. 157–161. [Google Scholar]

- Gunjagi, M.D.; Wadar, R.; Patil, A.; Gurme, S.; Nalang, A.; Kamble, M. To Study the Effect of Lime and Rice Husk Ash on CBR Parameters of Black Cotton Soil. Int. Res. J. Eng. Technol. 2019, 6. [Google Scholar]

- Lakshmi, S.M.; Geetha, S.; Selvakumar, M.; Susanna, K.D. Strength Enhancement of Clayey Sand Subgrade Using Lime and Rice Husk Ash. Mater. Today Proc. 2021, 46, 7430–7435. [Google Scholar] [CrossRef]

- Lu, C.; Chen, J.; Gu, C.; Wang, J.; Cai, Y.; Zhang, T. Resilient and permanent deformation behaviors of construction and demolition wastes in unbound pavement base and subbase applications. Transp. Geotechnol. 2021, 28, 100541. [Google Scholar] [CrossRef]

- Anupam, A.K.; Kumar, P.; Ransingchung RN, G.D. Performance evaluation of structural properties for soil stabilised using rice husk ash. Road Mater. Pavement Des. 2014, 15, 539–553. [Google Scholar] [CrossRef]

- Domphoeun, R.; Otaghsaraei, A.E.; Nishimura, S. Geotechnical Properties of Rice Husk Ash and Coconut Fiber Stabilized Soil and Its Performance Evaluation as Subbase Material. Ph.D. Dissertation, Thammasat University, Bangkok, Thailand, 2023. [Google Scholar]

- Fall, M.; Sawangsuriya, A.; Benson, C.H.; Edil, T.B.; Bosscher, P.J. On the investigations of resilient modulus of residual tropical gravel lateritic soils from Senegal (West Africa). Geotechnol. Geol. Eng. 2008, 26, 13–35. [Google Scholar] [CrossRef]

- Karatai, T.R. Technical and Economic Evaluation of Soil Stabilization Using Rice Husk Ash (RHA) and Natural Lime (NL) as an Alternative to Cutting and Filling in Road Construction. Ph.D. Dissertation, JKUAT, Juja, Thika, 2018. [Google Scholar]

- Ganta, S. Soil Stabilization with Rice Husk Ash and Lime Sludge. Int. J. Res. 2017, 4, 1112–1119. [Google Scholar]

- Harikumar, M.; Firozemon, N.P.; Rithika, S.; Nipin, S.; Shayifa, T.S.; Jini, K.M. Experimental Investigation on Compressed Stabilized Earth Block. Int. J. Sci. Eng. Res. 2016, 7, 76–84. [Google Scholar]

- Chen, R.; Congress, S.S.C.; Cai, G.; Duan, W.; Liu, S. Sustainable Utilization of Biomass Waste-Rice Husk Ash as a New Solidified Material of Soil in Geotechnical Engineering: A Review. Constr. Build. Mater. 2021, 292, 123219. [Google Scholar] [CrossRef]

- Barwar, A.; Chandrappa, A.K.; Sahoo, U.C. Laboratory Investigations on Stabilization of Weak Clay Soil Using Rice Husk Ash and Cement. Innov. Infrastruct. Solut. 2022, 7, 327. [Google Scholar] [CrossRef]

- Asavapisit, S.; Macphee, D.E. Immobilization of Metal-Containing Waste in Alkali-Activated Lime–RHA Cementitious Matrices. Cem. Concr. Res. 2007, 37, 776–780. [Google Scholar] [CrossRef]

| Source | CaO | SiO2 | Na2O | MgO | Al2O3 | Fe2O3 | K2O | TiO2 | LOI |

|---|---|---|---|---|---|---|---|---|---|

| [84] | 0.578 | 96.235 | 0.054 | 0.269 | 0.281 | 1.366 | 0.454 | - | - |

| [85] | 0.82 | 80.82 | 0.96 | - | 0.25 | 0.38 | 1.25 | - | 12.70 |

| [86] | 0.37 | 87.49 | 0.01 | 0.01 | 0.05 | 0.04 | 0.8 | 0.01 | 11.21 |

| [87] | 0.62 | 89.69 | 1.02 | 0.57 | 1.01 | 0.23 | 0.81 | 4.06 | - |

| [88] | 0.82 | 80.02 | 0.01 | 0.74 | 1.81 | 0.79 | 1.01 | 0.43 | 10.62 |

| Mean | 0.6416 | 86.8508 | 0.4108 | 0.39725 | 0.6804 | 0.5612 | 0.8648 | 2.245 | 11.51 |

| SD | 0.1675 | 5.96 | 0.474 | 0.279 | 0.861 | 0.387 | 0.265 | 2.11 | 1.07 |

| Source | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | So3 | Na2O | LOI |

|---|---|---|---|---|---|---|---|---|

| [99] | 92.25 | 0.06 | 0.56 | 0.45 | 0.03 | - | 0.26 | 6.39 |

| [100] | 95.03 | 0 | 0.13 | 0.08 | 0.25 | 0.02 | 0.05 | 4.33 |

| [101] | 70.85 | 1.19 | 0.69 | 0.12 | 0.53 | - | 0.25 | 26.1 |

| [102] | 40.74 | 5.78 | 0.18 | 0.15 | 0.41 | 0.28 | 2.03 | - |

| Mean | 74.72 | 1.76 | 0.39 | 0.20 | 0.31 | 0.15 | 0.65 | 12.27 |

| SD | 25.10 | 2.74 | 0.28 | 0.17 | 0.22 | 0.18 | 0.93 | 12.02 |

| Parameters | Mr Values | Notes | Source |

|---|---|---|---|

| Unstabilized clay | 20–60 MPa | Baseline values before stabilization | [122] |

| Stabilized clay (RHA + Lime) | 100–200 MPa (7 days curing) | Significant improvement due to pozzolanic reactions; values depend on dosage and curing time | [123] |

| 150–300 MPa (28 days curing) | Long-term curing increases Mr due to continued reaction | [124] | |

| >300 MPa (optimized mix, extended curing) | Observed in some studies with well-optimized RHA-lime mixes | [125] |

| Materials | Cost Savings | Findings | Source |

|---|---|---|---|

| RHA + Natural Lime (NL) | 17% reduction in earthwork costs, 39% savings in subgrade construction costs | RHA with 2% NL effectively stabilized clay soils, offering lower costs than traditional techniques | [126] |

| RHA + Lime | Reduced cost compared to OPC or lime stabilization | RHA as an agricultural waste provided economic and sustainable stabilization, significantly lowering material expenses | [127] |

| RHA + Lime | Estimated 25% cost reduction compared to OPC | Higher performance with RHA–lime mixture, utilizing industrial waste at lower costs | [72] |

| RHA + Lime | Approximately 30% cheaper than using OPC | Optimal mix of 8% RHA and 5% lime reduced costs due to local availability of RHA and less lime requirement | [128] |

| RHA + LS | Significantly lower material costs compared to OPC or LS stabilization | RHA and LS provided sustainable alternatives with good performance characteristics at lower cost thresholds | [129] |

| LCA Aspect | RHA + LS Stabilization | Traditional Stabilizers (Lime/OPC) | Findings | Source |

|---|---|---|---|---|

| Carbon Emissions | ~30–50% reduction compared to OPC stabilization | High emissions from production (~800–1000 kg CO2/ton for OPC) | RHA and LS are byproducts with negligible emissions during production, compared to OPC and lime, which involve energy-intensive processes like calcination | [72] |

| Energy Consumption | ~60% lower than lime or OPC | High energy (~4–5 GJ/ton for OPC) | RHA and LS use energy only during minimal processing or transportation, compared to lime and OPC, which require extensive energy for raw material extraction and processing | [130] |

| Waste Utilization | 100% reuse of agricultural (RHA) and industrial (LS) byproducts | Zero waste reuse | RHA and LS reduce waste disposal needs and landfill usage, making the stabilization process sustainable | [126] |

| Transportation Emissions | Low (local availability in rice/agriculture regions) | Moderate to high (dependent on production site distance) | RHA and LS sourced locally minimize transportation emissions, while OPC and lime often require transport over long distances, adding to the carbon footprint | [129] |

| Landfill Reduction | Significant reduction in waste sent to landfills | No landfill impact | By utilizing RHA and LS, waste that would typically go to landfills is repurposed, reducing the environmental impact of disposal and the need for landfill space | [131] |

| Cost of Stabilization | ~25–50% lower than lime or OPC | High (cost of production and transport) | RHA and LS are low-cost or free byproducts, whereas lime and OPC involve substantial production costs that increase overall project expenses | [128] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Manaviparast, H.R.; Cristelo, N.; Pereira, E.; Miranda, T. A Comprehensive Review on Clay Soil Stabilization Using Rice Husk Ash and Lime Sludge. Appl. Sci. 2025, 15, 2376. https://doi.org/10.3390/app15052376

Manaviparast HR, Cristelo N, Pereira E, Miranda T. A Comprehensive Review on Clay Soil Stabilization Using Rice Husk Ash and Lime Sludge. Applied Sciences. 2025; 15(5):2376. https://doi.org/10.3390/app15052376

Chicago/Turabian StyleManaviparast, Hamid Reza, Nuno Cristelo, Eduardo Pereira, and Tiago Miranda. 2025. "A Comprehensive Review on Clay Soil Stabilization Using Rice Husk Ash and Lime Sludge" Applied Sciences 15, no. 5: 2376. https://doi.org/10.3390/app15052376

APA StyleManaviparast, H. R., Cristelo, N., Pereira, E., & Miranda, T. (2025). A Comprehensive Review on Clay Soil Stabilization Using Rice Husk Ash and Lime Sludge. Applied Sciences, 15(5), 2376. https://doi.org/10.3390/app15052376