Mechanical Behaviour of Rock Samples with Burst Liability Under Different Pre-Cycling Thresholds

Abstract

:1. Introduction

2. Materials and Methods

2.1. Preparation of Sandstones with Burst Liability

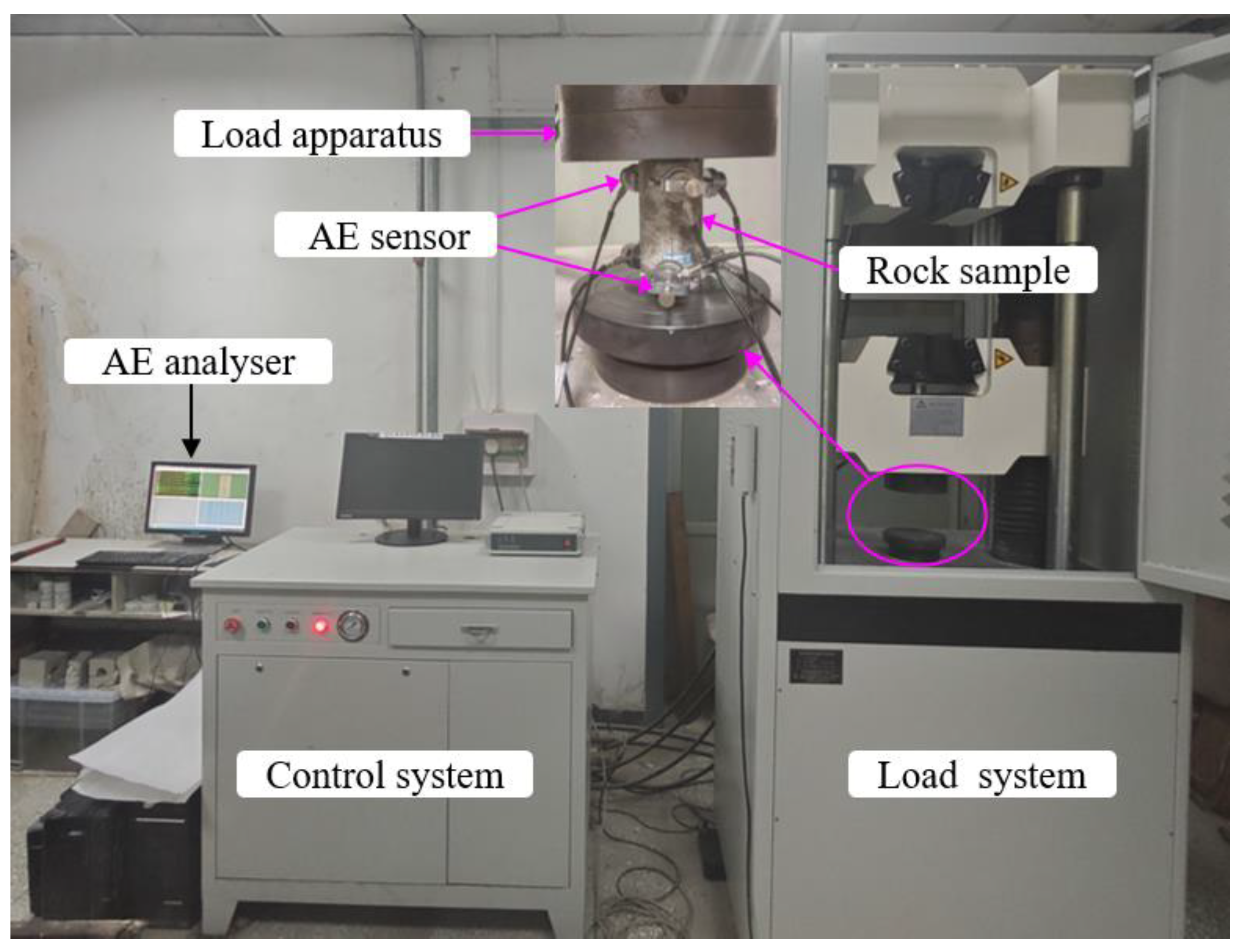

2.2. Experimental Apparatus

2.3. Experimental Methods

3. Results

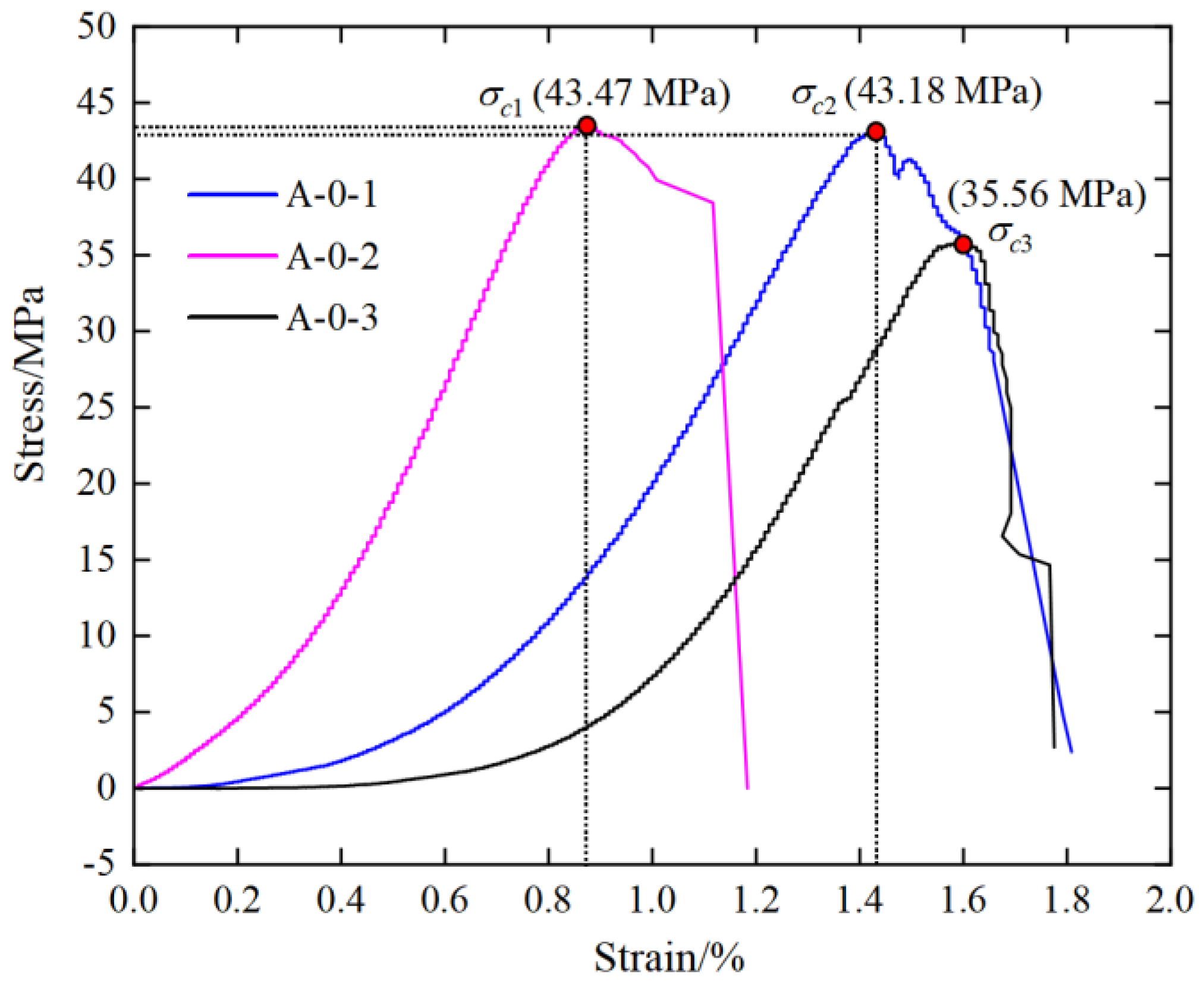

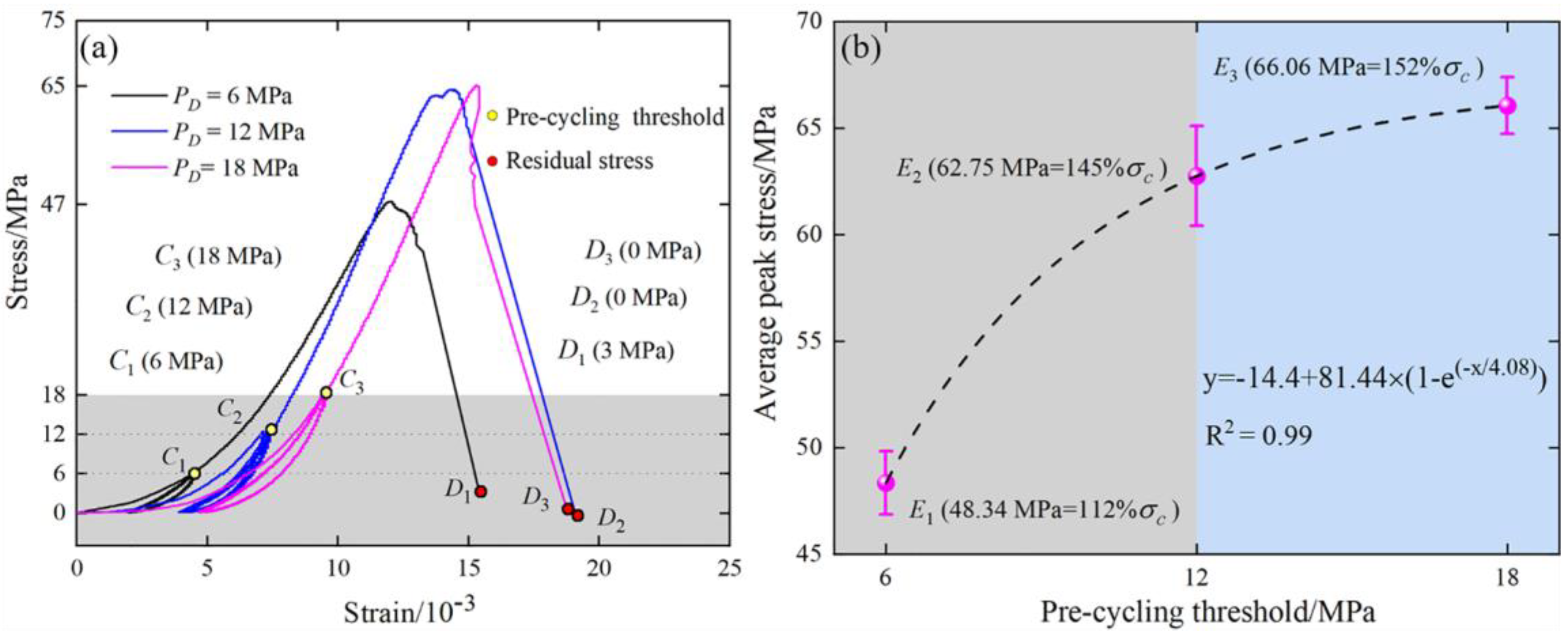

3.1. Strength Characteristics of Rock Samples with Burst Liability

- There was rock debris in rock samples in the disturbance stage during pre-cycling loading and unloading. After the rock debris filled primary pores in rock samples under pre-cycling load, the inter-pore density was enhanced. The compressive performance of rock samples was improved.

- For rock samples, within the limiting closure stress of the original pore, pre-cycling thresholds could increase the bearing capacity of rock samples.

- The maximum pre-cycling threshold was smaller than the damage threshold. Therefore, the accumulated fatigue was not enough to cause damage to rocks. Then, under the pre-cycling threshold, the uniaxial compressive strength (UCS) gradually increased with the pre-cycling threshold. As for the reason, it was explained that the compaction strengthening effect of the internal structure was prominent under the pre-cycling threshold. Moreover, the compaction degree was greater than the fatigue degree.

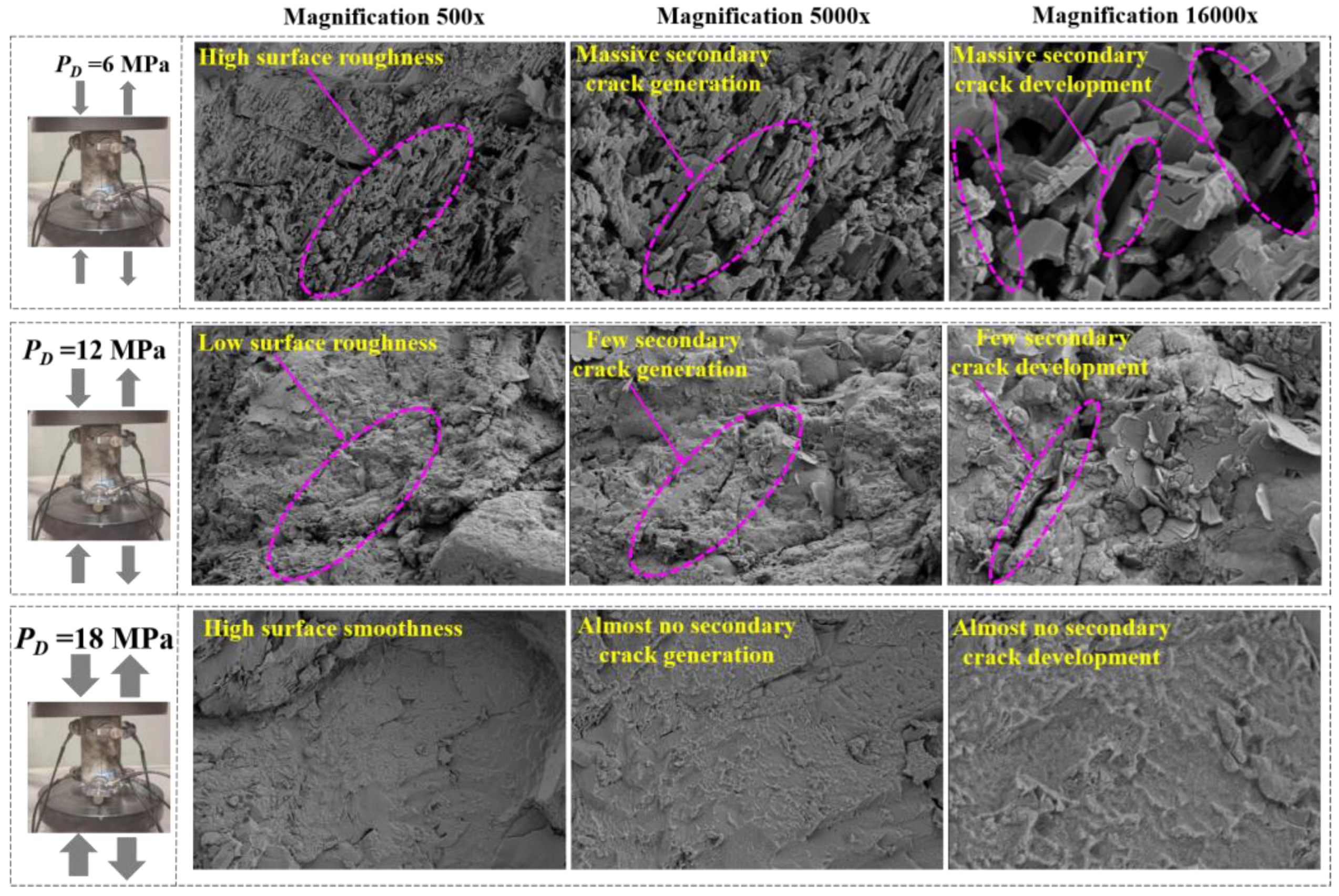

3.2. Microstructure Characteristics of Rock Samples with Burst Liability

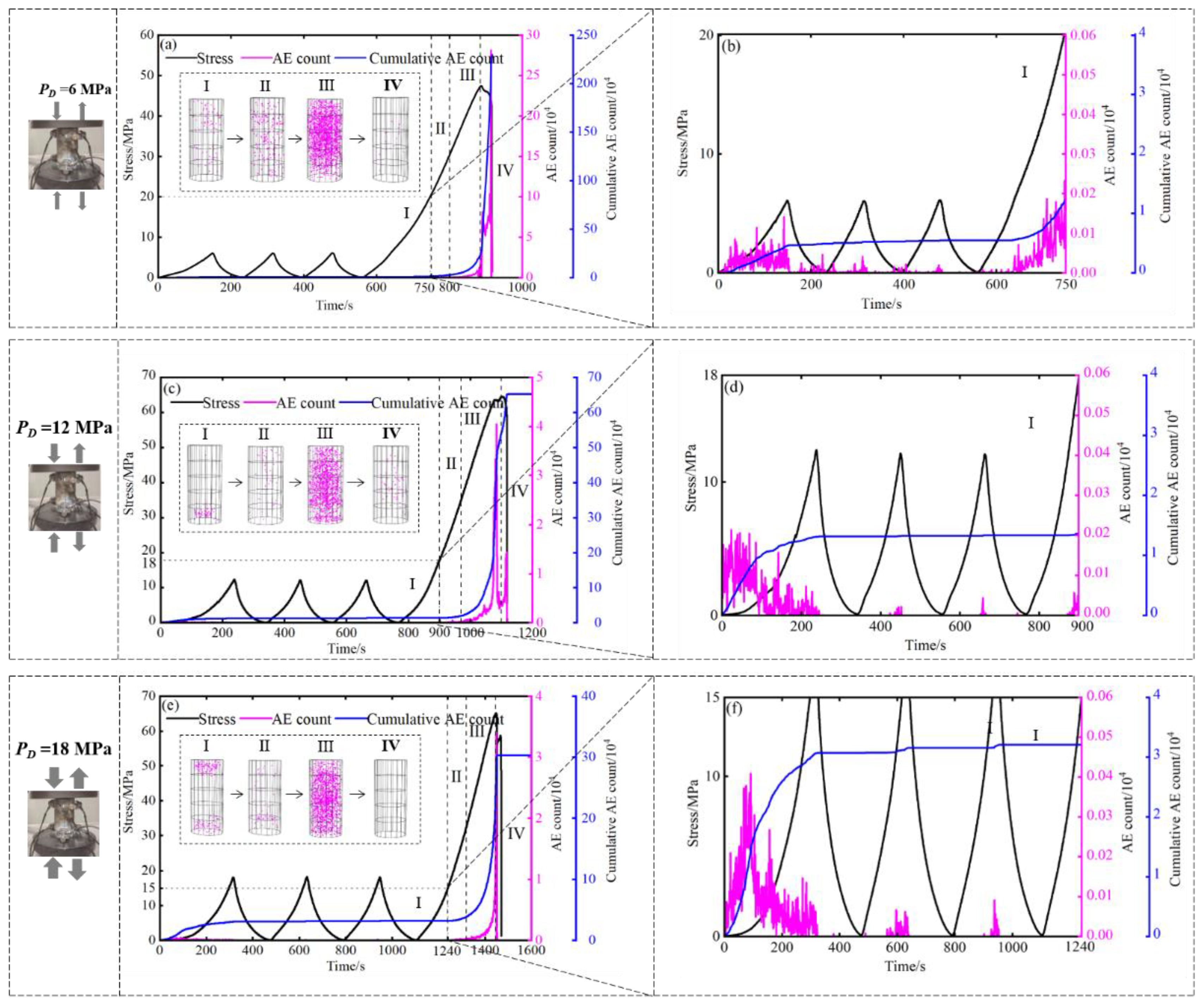

3.3. AE Signal Characteristics of Rock Samples with Burst Liability

- (1)

- Compaction stage (I)

- (2)

- Elastic stage (II)

- (3)

- Crack development stage (III)

- (4)

- Failure stage (IV)

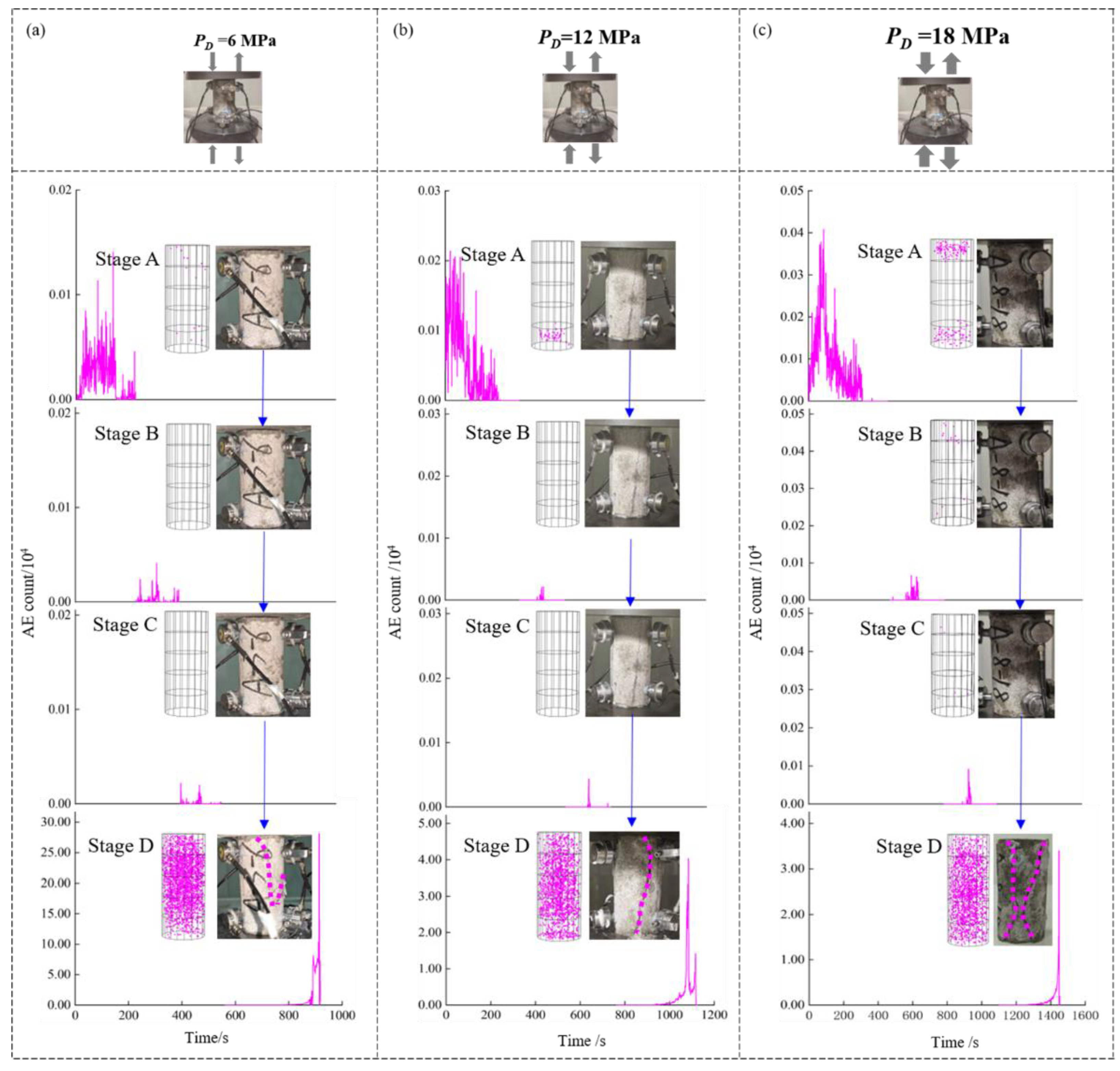

3.4. The Kaiser Effect Characteristics of Rock Samples with Burst Liability

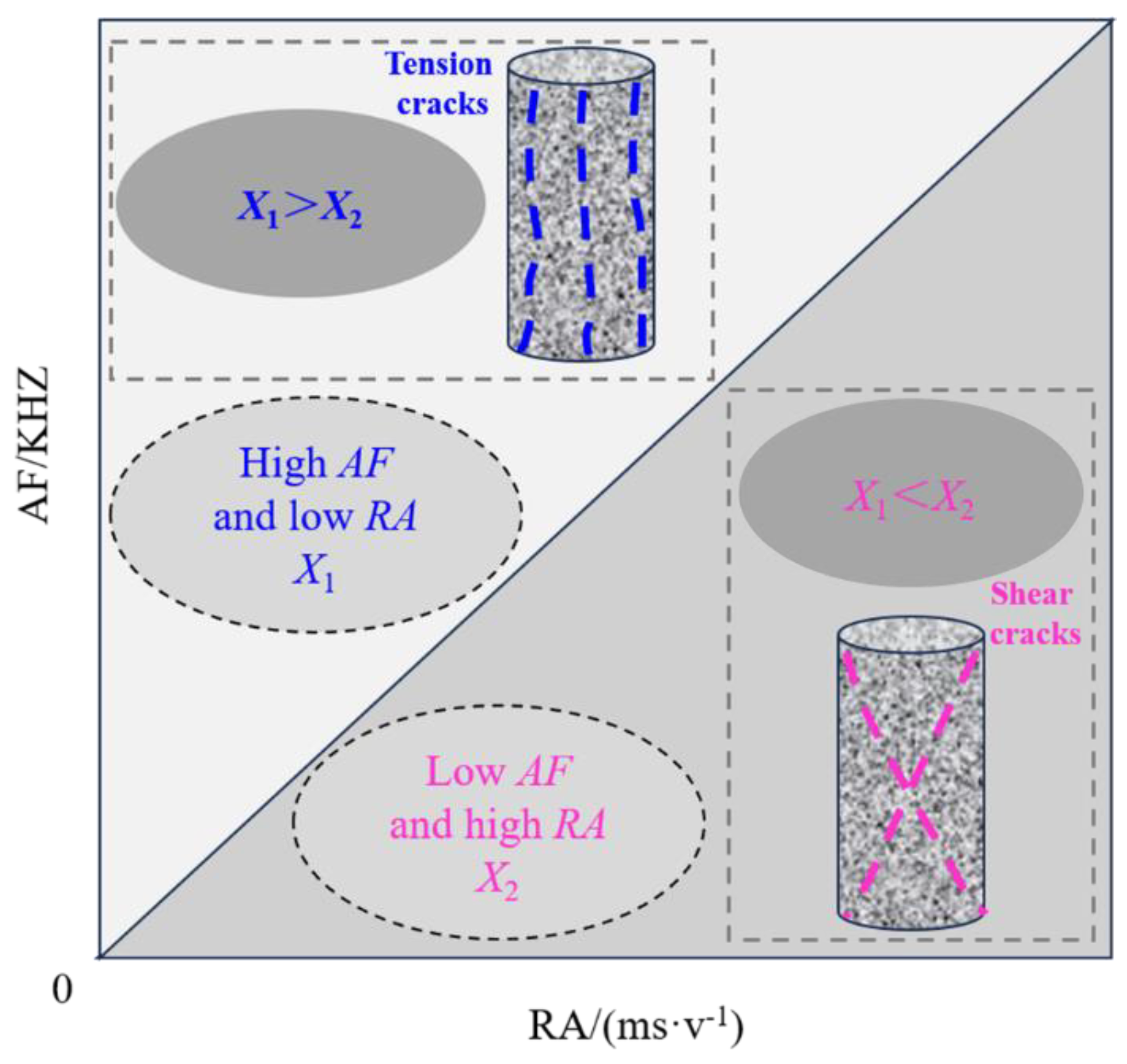

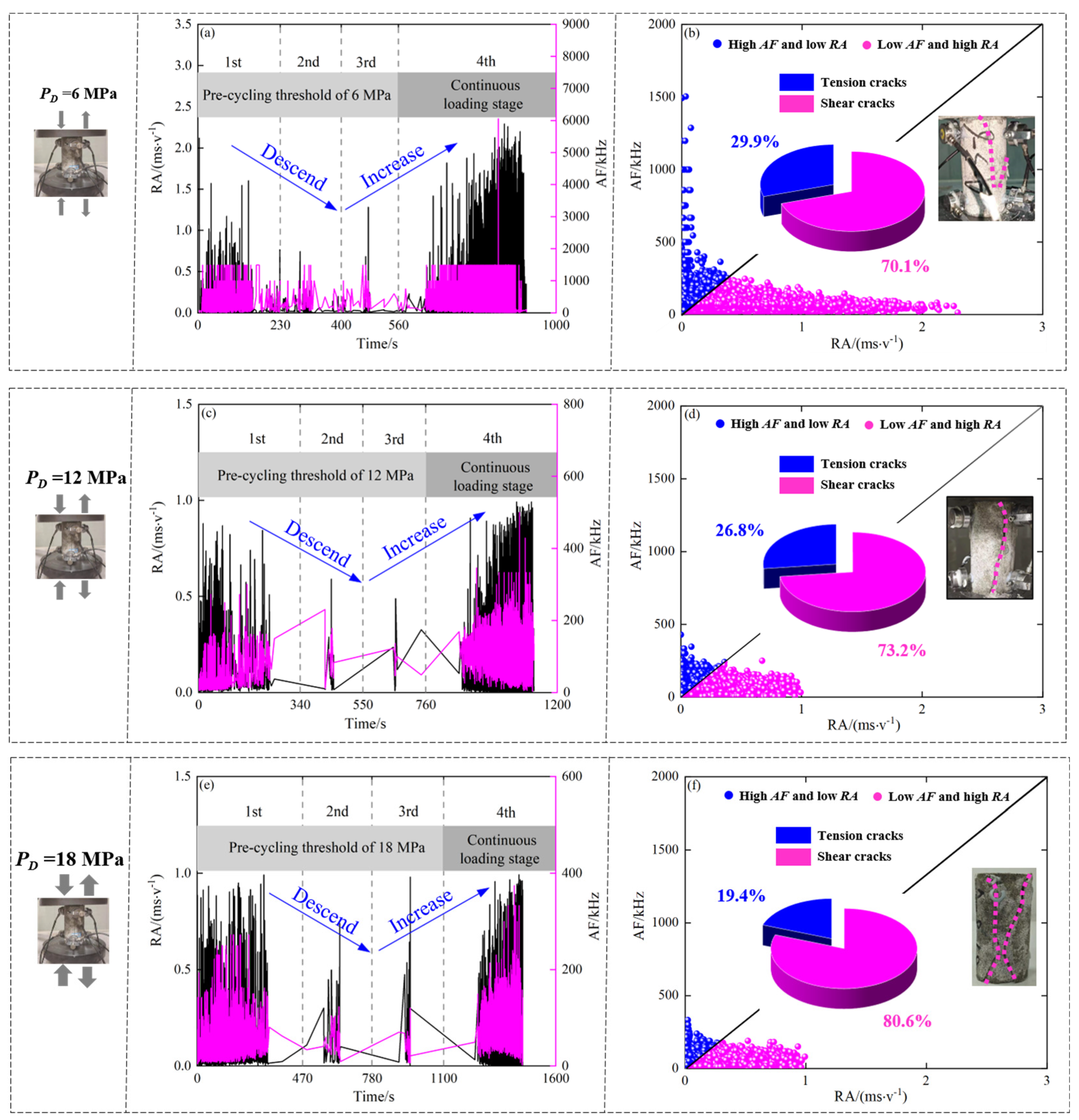

3.5. AF-RA Characteristics of Rock Samples with Burst Liability

4. Discussion

5. Conclusions

- (1)

- The average peak stress increased linearly with the increasing pre-cycling thresholds. However, the increasing trend became gentle. The stress-strengthening effect was gradually weakened with the increasing pre-cycling threshold.

- (2)

- With the increasing pre-cycling threshold, the surface roughness of rock samples gradually decreased. The number of secondary cracks gradually decreased. Additionally, the crack development phenomenon of rock samples gradually disappeared with the increasing pre-cycling threshold.

- (3)

- Under each pre-cycling threshold, AE signals show an initial rapid growth trend, a rapid decline trend and a final sharp rise trend with the increasing time. There was almost no AE signal in stage B. Under each pre-cycling threshold, no macroscopic secondary crack was generated in rock samples during pre-cycling loading and unloading.

- (4)

- AF-RA decreased first and then increased with the increasing time. The AF-RA distribution was different in different time periods. It was mainly distributed in stage A and stage D. The distribution form was “dense-sparse-dense”.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cui, F.; Zhang, S.; Lai, X.; Fang, X.; Dong, S. Mechanical characteristics and energy regulation evolution mechanisms of cavity filling of rock samples from roof with strong bursting liability. Chin. J. Rock Mech. Eng. 2020, 39, 2439–2450. [Google Scholar]

- Zuo, J.; Song, H. Energy evolution law and differential energy instability model of coal-rock combined body. J. China Coal Soc. 2022, 47, 3037–3051. [Google Scholar]

- Chen, G.; Li, T.; Zhang, G.; Li, J.; Liu, G.; He, Y.; Li, Y. Determination of bursting liability of coal-rock combined body based on residual energy release rate index. Chin. J. Rock Mech. Eng. 2023, 42, 1366–1383. [Google Scholar]

- Skrzypkowski, K. Case studies of rock bolt support loads and rock mass monitoring for the room and pillar method in the Legnica-Gogow copper district in Poland. Energies 2020, 13, 2998. [Google Scholar] [CrossRef]

- Ding, X.; Xiao, X.; Pan, Y.; Di, W. Study on damage evolution and fracture energy of coal with different bursting liability under uniaxial compressive test. J. Min. Saf. Eng. 2022, 39, 517–526. [Google Scholar]

- Liu, X.; Pan, Y.; Li, M.; Kang, Z.; Zhou, H.; Qiao, S. Permeability of hydrated shale rocks under cyclic loading and unloading conditions. J. China Coal Soc. 2022, 47, 103–114. [Google Scholar]

- Jiang, D.; Yang, Z.; Fan, J.; Li, Z.; Suo, J.; Chen, J. Experimental study of load rate effect of salt rock during loading and unloading. Rock Soil Mech. 2023, 44, 403–414. [Google Scholar]

- Zheng, D.; Ozbayoglu, E.; Miska, S.; Baldino, S. An experimental study on the influence of cyclic loading and eccentric casing geometry on cement sheath integrity. In Proceedings of the ARMA US Rock Mechanics/Geomechanics Symposium, Golden, CO, USA, 23–26 June 2024; p. D041S048R001. [Google Scholar]

- Ren, Y.; Wu, Y. Study on mechanical properties of sandstone under different cyclic loading and unloading rates. Nonferrous Met. Eng. 2022, 12, 111–119. [Google Scholar]

- Long, Y.; Sun, L.; Cai, Z.; Jiang, Z.; Wang, Z.; He, Q.; Bai, Z. Cyclic loading and unloading of weakly consolidated sandstone with various water contents. Sustainability 2023, 15, 13866. [Google Scholar] [CrossRef]

- Zhao, G.; Liu, Z.; Meng, X.; Zhang, R.; Gu, Q.; Qi, M. Energy evolution of sandstone under true triaxial cyclic principal stress. Rock Soil Mech. 2020, 44, 1875–1890. [Google Scholar]

- Xu, W.; Zhao, G.; Meng, X.; Liu, Z.; Liu, C.; Qi, M. Anisotropy and energy evolution mechanism of rock mass under true triaxial loading-unloading. J. China Coal Soc. 2023, 48, 1502–1515. [Google Scholar]

- Zhang, J.; Song, Z. Mechanical response and failure characteristics of deep sandstone under triaxial loading and unloading. J. Min. Saf. Eng. 2020, 37, 409–418+428. [Google Scholar]

- Li, J.; Hong, L.; Zhou, K.; Xia, C.; Zhu, L. Limestone acoustic emission evolution characteristics under different experimental loading and unloading conditions. Front. Phys. 2020, 8, 590710. [Google Scholar] [CrossRef]

- Xu, H.; Ma, L.; Cao, K.; Khan, N.M.; Hussain, S.; Niu, D.; Alarifi, S.S.; Bacha, S. Precursors of cyclic loading and unloading sandstone failure based on “acoustic-thermal” loading-unloading response ratio. Sustainability 2023, 15, 10158. [Google Scholar] [CrossRef]

- Wang, T.; Wang, C.; Xue, F.; Wang, L.; Teshome, B.H.; Xue, M. Acoustic emission characteristics and energy evolution of red sandstone samples under cyclic loading and unloading. Shock Vib. 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Meng, Q.; Chen, Y.; Zhang, M.; Han, L.; Pu, H.; Liu, J. On the kaiser effect of rock under cyclic loading and unloading conditions: Insights from acoustic emission monitoring. Energies 2019, 12, 3255. [Google Scholar] [CrossRef]

- Wang, Z.; Zhou, H.; An, L.; Wang, C. Failure process characteristics and energy evolution of granite under cyclic loading and unloading condition. J. China Univ. Min. Technol. 2020, 49, 874–881. [Google Scholar]

- Liu, H.; Qin, T. Study on damage characteristics and acoustic emission Kaiser effect of sandstone under cyclic loading and unloading conditions. Coal Sci. Technol. 2019, 47, 73–80. [Google Scholar]

- Zhang, D.; Bai, X.; Qi, X.; Zhang, X.; Yi, L. Acoustic emission characteristics and in-situ stresses of bedding rock based on Kaiser effect. Chin. J. Rock Mech. Eng. 2016, 35, 87–97. [Google Scholar]

- Gan, Y.; Wu, S.; Ren, Y.; Zhang, G. Evaluation indexes of granite splitting failure based on RA and AF of AE parameters. Rock Soil Mech. 2020, 41, 2324–2332. [Google Scholar]

- Ge, Z.; Sun, Q.; Wang, M.; Zhao, C. Fracture feature recognition of sandstone after high temperature based on RA/AF. Coal Geol. Explor. 2021, 49, 176–183. [Google Scholar]

- Jiang, C.; Wei, C.; Zhuang, W.; Duan, M.; Chen, Y.; Yu, T. Research on deformation characteristics and energy evolution mechanisms of shale under constant amplitude cyclic loading. Chin. J. Rock Mech. Eng. 2020, 39, 2416–2428. [Google Scholar]

- Liu, Z.; Dong, X.; Zhang, X. Experimental study on mechanical properties of bedding coal and rock under graded cyclic loading. Chin. J. Rock Mech. Eng. 2021, 40, 2593–2602. [Google Scholar]

- Wu, Z.; Song, Z.; Tan, J.; Zhang, Y.; Qi, Z. The evolution law of rock energy under different graded cyclic loading and unloading modes. J. Min. Saf. Eng. 2020, 37, 836–844+851. [Google Scholar]

- Xiao, F.; Jiang, D.; Wu, F.; Zou, Q.; Chen, J.; Chen, B.; Sun, Z. Effects of prior cyclic loading damage on failure characteristics of sandstone under true-triaxial unloading conditions. Int. J. Rock Mech. Min. Sci. 2020, 132, 104379. [Google Scholar] [CrossRef]

- Wang, Z.; Yang, Y.; Xu, Y.; Xin, C.; Liang, P.; Guo, N. Analysis of energy evolution and acoustic emission characteristics of rocks under cyclic loading and unloading. Appl. Sci. 2023, 13, 10453. [Google Scholar] [CrossRef]

- Zeng, P. Correlation on Frequency Characteristics of Acoustic Emission with Stress State of Bump-Prone Rocks. Ph.D. thesis, University of Science and Technology Beijing, Beijing, China, 2017. [Google Scholar]

- Zhao, Y.; Jiang, Y.; Han, Z. Experimental study on acoustic and thermal infrared characteristics of bump-prone coal. Chin. J. Rock Mech. Eng. 2007, 27, 2416–2428. [Google Scholar]

- Chen, J.; Zeng, B.; Hu, S.; Xu, W.; Wang, S.; Liu, Z. Mechanical behaviour and instability mechanism of sandstones with impact tendency under different loading paths. Int. J. Min. Reclam. Environ. 2024; 38, 1–20. [Google Scholar] [CrossRef]

- Yang, L.; Wang, X.; Li, J. Energy evolution and damage characteristics of coal with different bursting liability under uniaxial compression. Coal Sci. Technol. 2021, 49, 111–118. [Google Scholar]

- Pan, Y.; Yang, Y.; Luo, H.; Li, Z.; Zhu, X. Impulse propensity coal force—Electric induction Rule test study. J. Saf. Environ. 2018, 18, 119–123. [Google Scholar]

- GB/T 50266-2013; Standard for Test Methods of Engineering Rock Mass. China Planning Press: Beijing, China, 2013; pp. 1–64.

- GB/T 25217.1-2010; Methods for Test, Monitoring and Prevention of Rock Burst—Part 1: Classification and Laboratory Test Method on Bursting Liability of Roof Strata. Standards Press of China: Beijing, China, 2010; pp. 1–8.

- Chen, J.; Zeng, B.; Xu, W.; Wang, K.; Wang, S.; Hu, S.; Song, Z.; Wu, S. Progressive failure characteristics and damage constitutive model of rock samples under immersion conditions. J. China Coal Soc. 2024, 135, 1–19. [Google Scholar] [CrossRef]

- Wang, R.; Wei, C.; Liu, J.; Li, Z.; Tan, Y. Macro and micro characteristics of jointed sandstone under cyclic loading and unloading. Chin. J. Rock Mech. Eng. 2023, 42, 810–820. [Google Scholar]

- Li, X.; Yao, Z.; Huang, X.; Liu, Z.; Zhao, X.; Mu, K. Investigation of deformation and failure characteristics and energy evolution of sandstone under cyclic loading and unloading. Rock Soil Mech. 2021, 42, 1693–1704. [Google Scholar]

- Jia, P.; Qian, Y.; Wang, Y.; Wang, Q. Fracture mechanism and precursors of thermally damaged granite uniaxial compression based on acoustic emission information. Chin. J. Eng. 2023, 45, 2129–2139. [Google Scholar]

- Wu, B.; Wang, W.; Guo, D. Strength damage and AE characteristics of fractured sandstone under the influence of water intrusion times. J. Min. Saf. Eng. 2020, 37, 1054–1060. [Google Scholar]

- Wang, J.; Yuan, G. Acoustic emission and fracture characteristics of deep sandstone under different loading rates. J. Min. Saf. Eng. 2023, 5, 65–76. [Google Scholar]

- Liu, Y.; Qiu, L.; Lou, Q.; Wei, M.; Yin, S.; Li, P.; Cheng, X. Research on time-frequency characteristics of acoustic-electric signals in process of rock failure under load. J. Mine Autom. 2020, 46, 87–91. [Google Scholar]

- Zhu, X.; Tang, Y.; Fan, J.; Hu, J.; Liu, J.; He, C. Experimental study on failure precursors of fine sandstone based on critical slowing down theory. Chin. J. Rock Mech. Eng. 2022, 41, 53–61. [Google Scholar]

- Zhang, Y.; Cao, L.; Li, Z.; Chen, T. Experimental study on Kaiser effect characteristics of granite under different cyclic loading stresses. J. Exp. Mech. 2021, 36, 123–132. [Google Scholar]

- Shi, K.; Mei, F.; Chen, M.; Yang, Z.; Luo, W. Experimental study on the effect of high stress cyclic loading on Kaiser effect in marble. Chin. J. Rock Mech. Eng. 2017, 36, 2906–2916. [Google Scholar]

- Zhao, K.; Yan, D.; Zhong, C.; Zhi, X.; Wang, X.; Xiong, X. Comprehensive analysis method and experimental verification for in-situ stress measurement by acoustic emission tests. Chin. J. Geotech. Eng. 2012, 34, 1403–1411. [Google Scholar]

- Chen, J.; Zeng, B.; Xu, W.; Hu, S.; Wang, S.; Wang, K.; Zhang, W.; Wu, S.; Song, Z. Mechanical behaviour and damage constitutive model of semi-circular arch tunnels with straight walls under soaking conditions. Eng. Fail. Anal. 2025, 169, 1–23. [Google Scholar] [CrossRef]

- Du, K.; Li, X.; Tao, M.; Wang, S. Experimental study on acoustic emission (AE) characteristics and crack classification during rock fracture in several basic lab tests. Int. J. Rock Mech. Min. Sci. 2020, 133, 104411. [Google Scholar] [CrossRef]

- Song, Z.; Zhang, J.; Dong, X.; Wang, Y. Characterization and evaluation of brittleness of deep bedded sandstone from the perspective of the whole life-cycle evolution process. Int. J. Min. Sci. Technol. 2023, 33, 481–502. [Google Scholar] [CrossRef]

- Vasyliev, L.; Malich, M.; Vasyliev, D.; Katan, V.; Rizo, Z. Improving a technique to calculate strength of cylindrical rock samples in terms of uniaxial compression. Min. Miner. Depos. 2023, 17, 43–50. [Google Scholar] [CrossRef]

- Winkler, M.B.; Fruehwirt, T.; Marcher, T. Elastic behavior of transversely isotropic cylindrical rock samples under uniaxial compression considering ideal and frictional boundary conditions. Appl. Sci. 2024, 14, 17. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Gomez, R.; Zagorski, K.; Zagorska, A.; Gomez-Espina, R. Review of underground mining methods in world-class base metal deposits: Experiences from Poland and Chile. Energies 2023, 16, 148. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Y.; Wang, Y.; Bai, Q. Discrete element method simulation of granular materials considering particle breakage in geotechnical and mining engineering: A short review. Green Smart Min. Eng. 2024, 1, 190–207. [Google Scholar] [CrossRef]

| Burst Liability Category | Burst Liability Amplitude | Bending Energy Index UWQ/kJ |

|---|---|---|

| I | No | UWQ < 15 |

| II | Weak | 15 ≤ UWQ ≤ 120 |

| III | Strong | UWQ > 120 |

| Sample | Height (mm) | Diameter (mm) | Density (kg/m3) | Peak Stress (MPa) |

|---|---|---|---|---|

| A-0-1 | 100.04 | 49.98 | 2436 | 43.47 |

| A-0-2 | 99.98 | 49.96 | 2451 | 43.18 |

| Mean | 100.01 | 49.97 | 2444 | 43.33 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, J.; Zeng, B.; Xu, W.; Wang, K.; Skrzypkowski, K.; Zagórski, K.; Zagórska, A.; Rak, Z. Mechanical Behaviour of Rock Samples with Burst Liability Under Different Pre-Cycling Thresholds. Appl. Sci. 2025, 15, 2760. https://doi.org/10.3390/app15052760

Chen J, Zeng B, Xu W, Wang K, Skrzypkowski K, Zagórski K, Zagórska A, Rak Z. Mechanical Behaviour of Rock Samples with Burst Liability Under Different Pre-Cycling Thresholds. Applied Sciences. 2025; 15(5):2760. https://doi.org/10.3390/app15052760

Chicago/Turabian StyleChen, Jianhang, Banquan Zeng, Wuyan Xu, Kun Wang, Krzysztof Skrzypkowski, Krzysztof Zagórski, Anna Zagórska, and Zbigniew Rak. 2025. "Mechanical Behaviour of Rock Samples with Burst Liability Under Different Pre-Cycling Thresholds" Applied Sciences 15, no. 5: 2760. https://doi.org/10.3390/app15052760

APA StyleChen, J., Zeng, B., Xu, W., Wang, K., Skrzypkowski, K., Zagórski, K., Zagórska, A., & Rak, Z. (2025). Mechanical Behaviour of Rock Samples with Burst Liability Under Different Pre-Cycling Thresholds. Applied Sciences, 15(5), 2760. https://doi.org/10.3390/app15052760