Transcritical R744 Supermarket Refrigeration System Integrated with a Heat-Driven Ejector Chiller

Abstract

1. Introduction

- Inclusion of subcooling is expected to degrade the performance of the CO2 ejector. As subcooling lowers the temperature of the motive stream, it leads to a reduction in the pressure lift, entrainment ratio, and the efficiency of the ejector. This would lead to ineffective utilization of the CO2 ejectors.

- Inclusion of the CO2 ejector and the associated control systems would further increase the total investment cost.

2. Materials and Methods

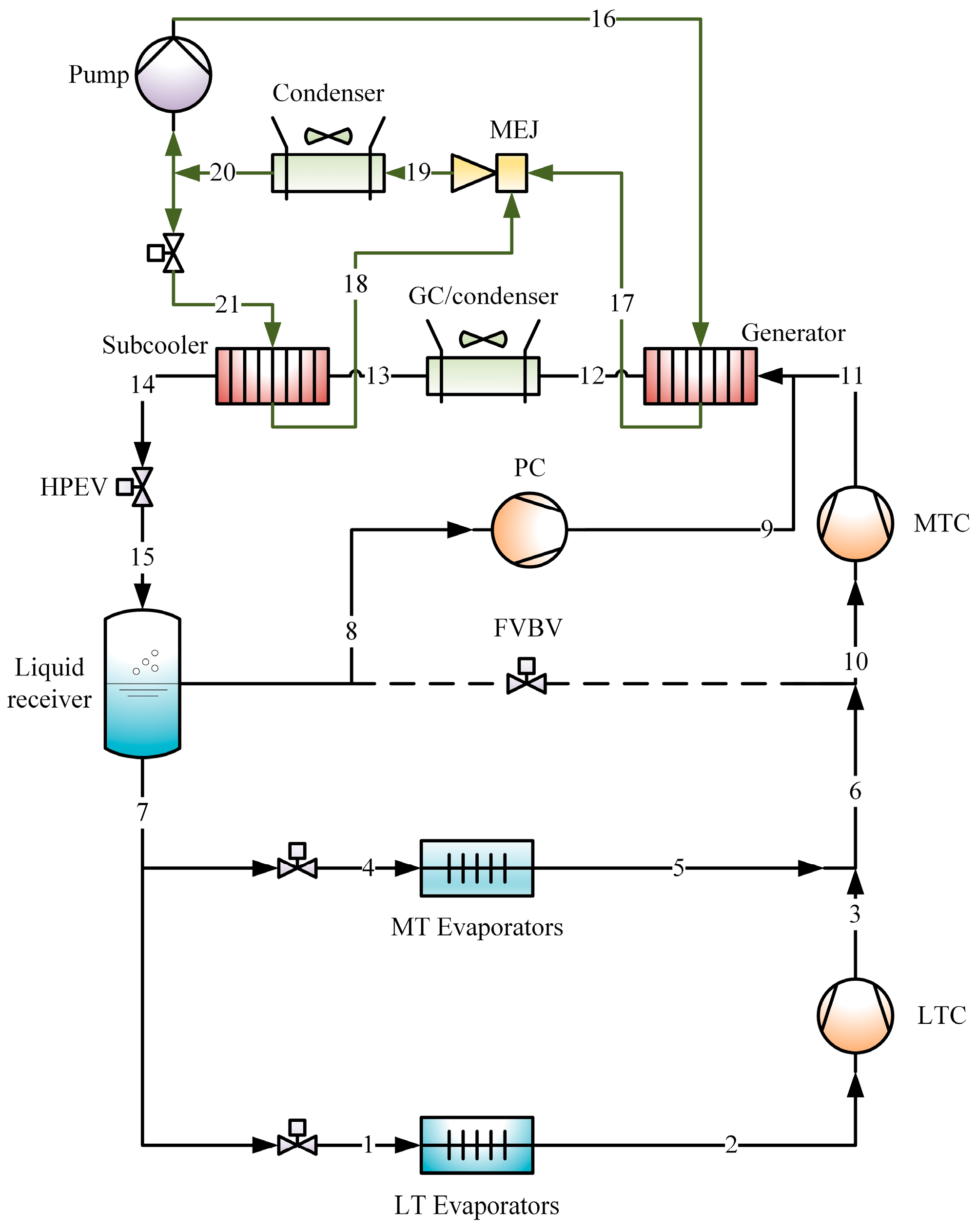

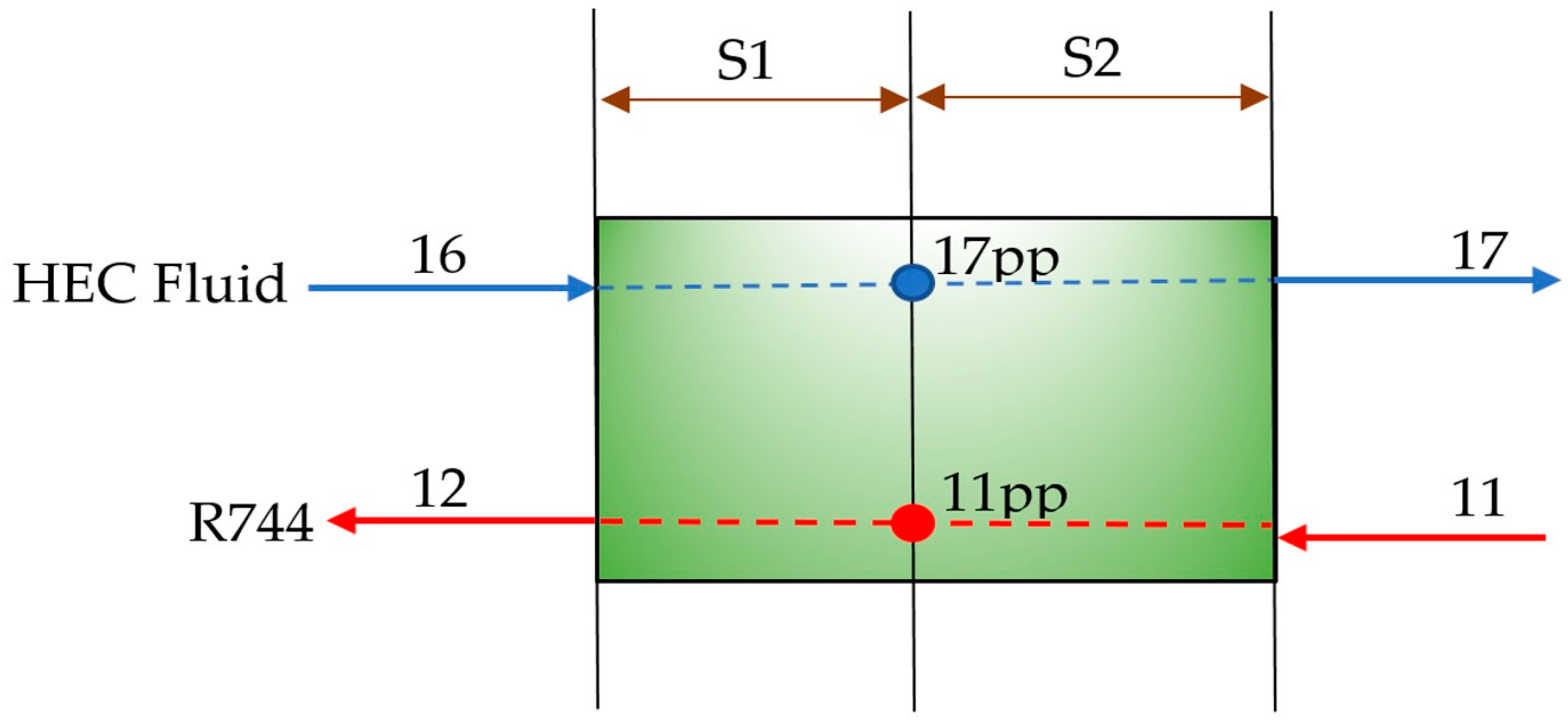

2.1. System Description

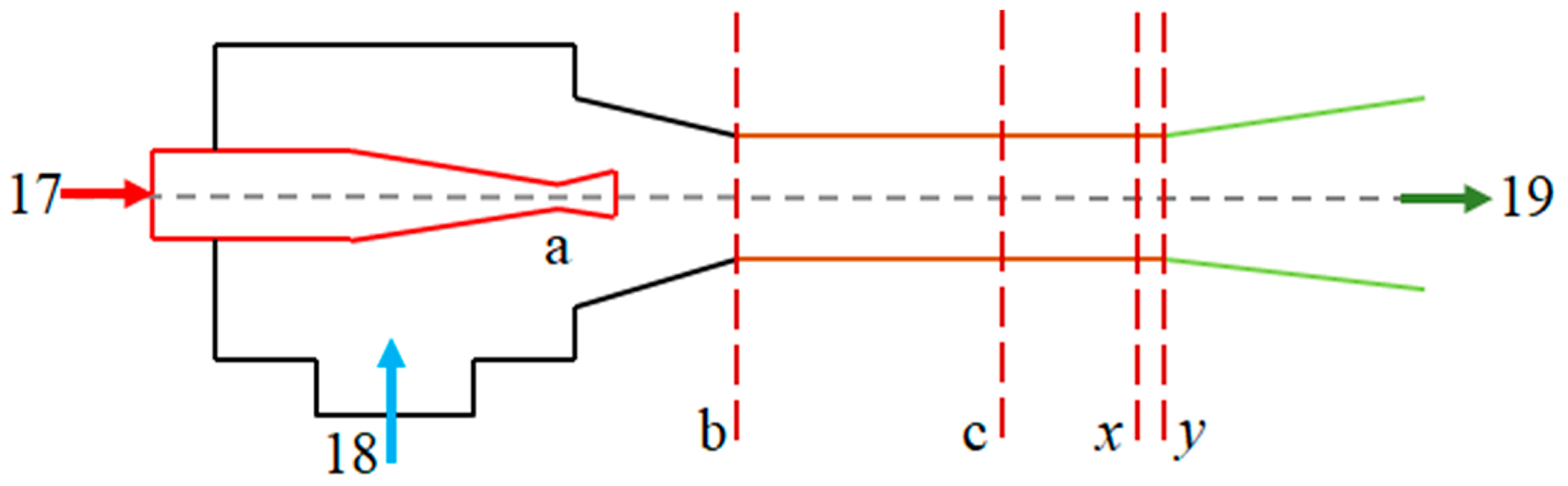

2.2. Mathematical Modeling and Simulation

- Steady state operations;

- Drop in pressure in the heat exchangers and the pipelines were neglected;

- Constant pressure in the mixing chamber of the ejector;

- Heat losses/gains from the components were neglected;

- Kinetic energy of the fluid stream at the inlet of the nozzle and outlet of the diffuser of the ejector were neglected.

3. Results and Discussion

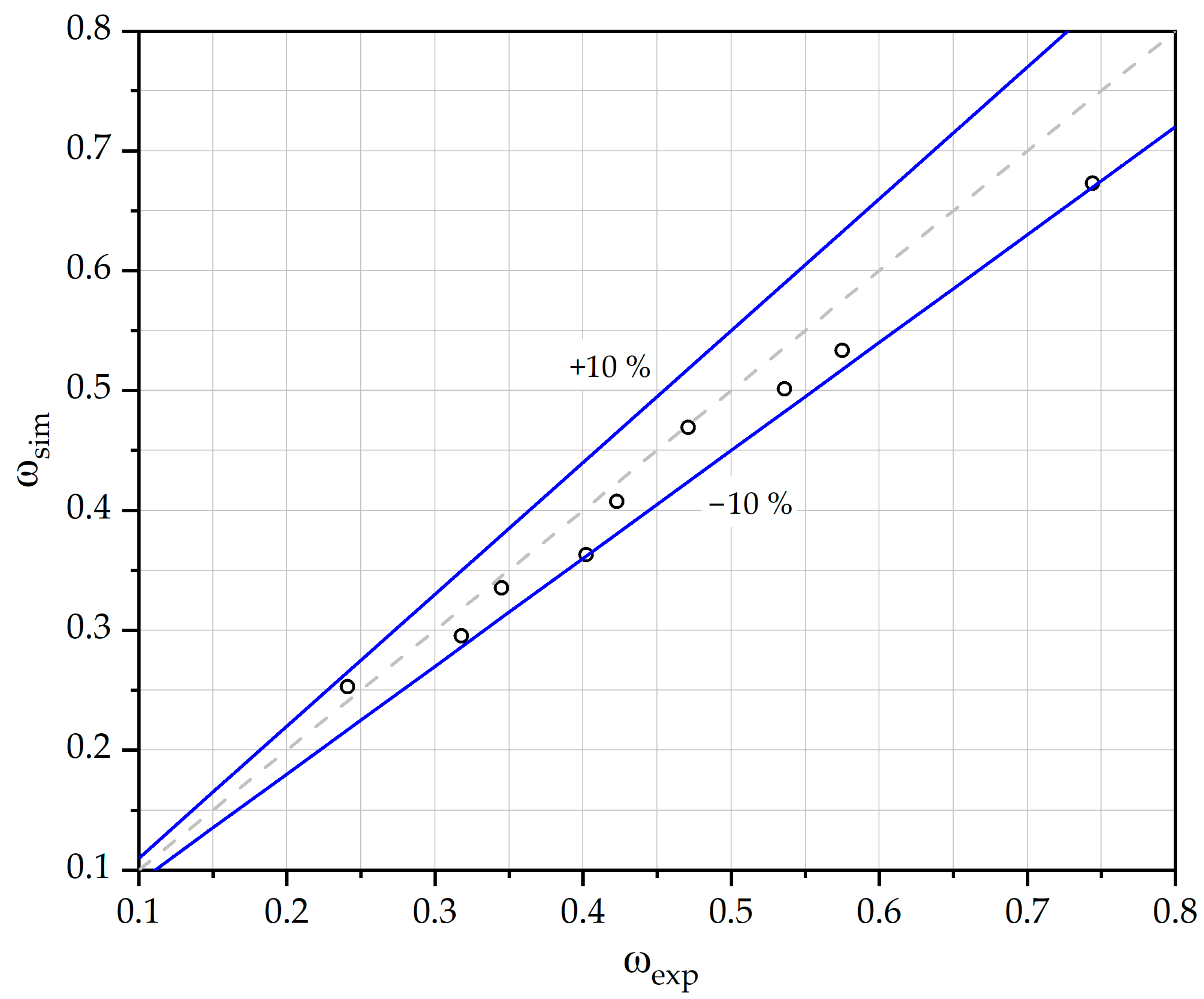

3.1. Experimental Validation of the Ejector Model

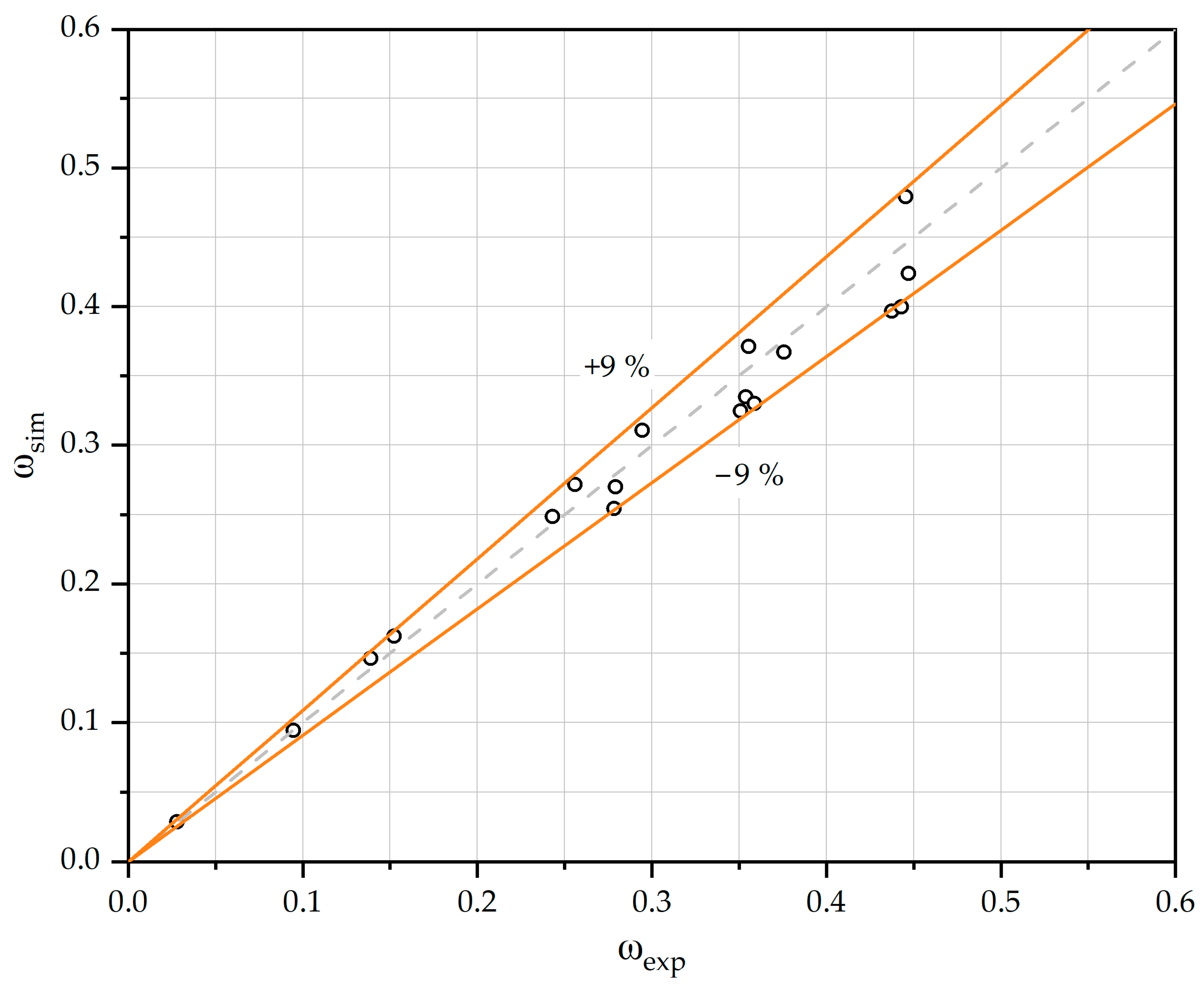

3.2. Experimental Validation of the HEC and the R744 Refrigeration System

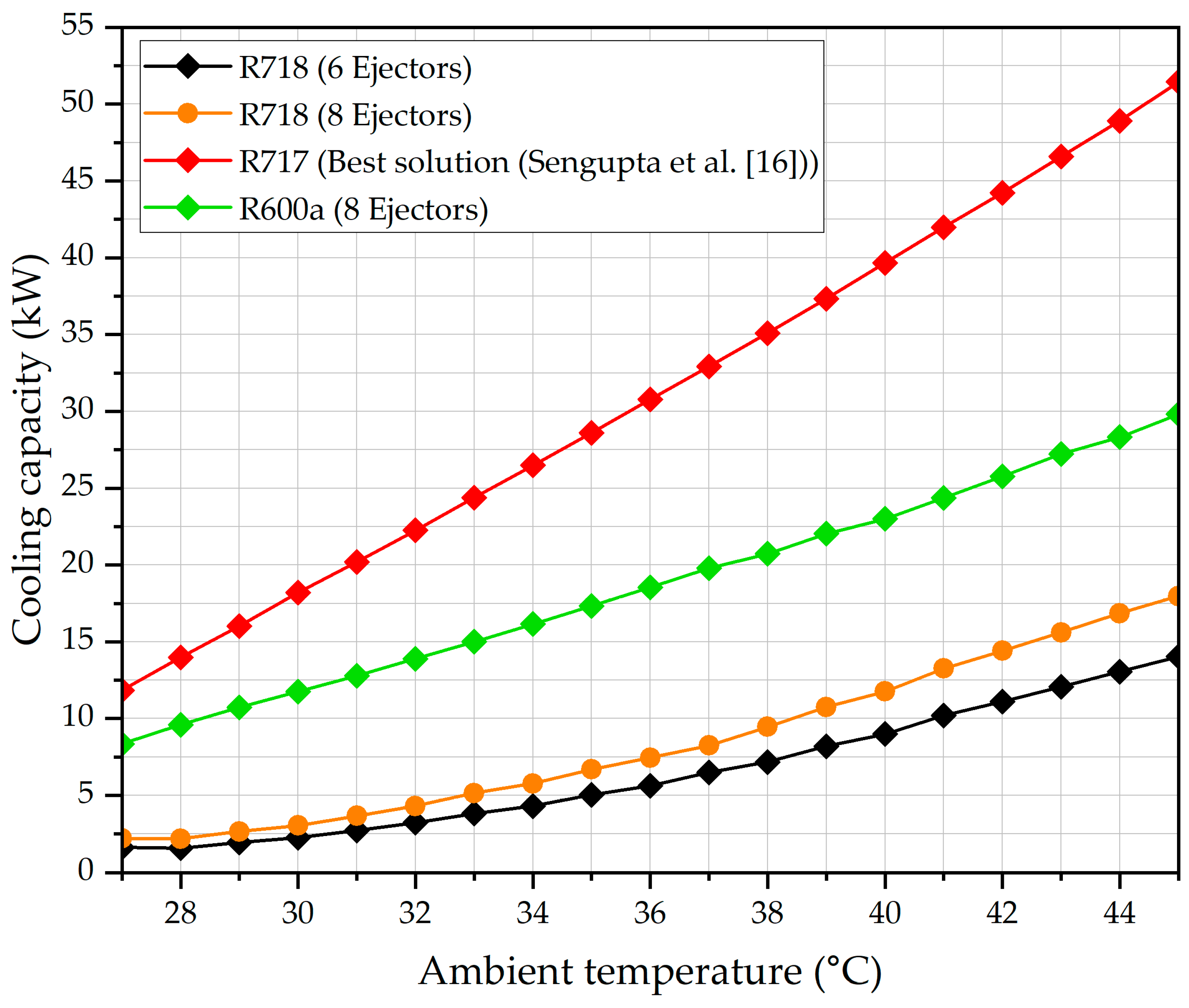

3.3. Performance Comparison of the Proposed System with R717, R718, and R600a as the Refrigerant for the HEC Cycle

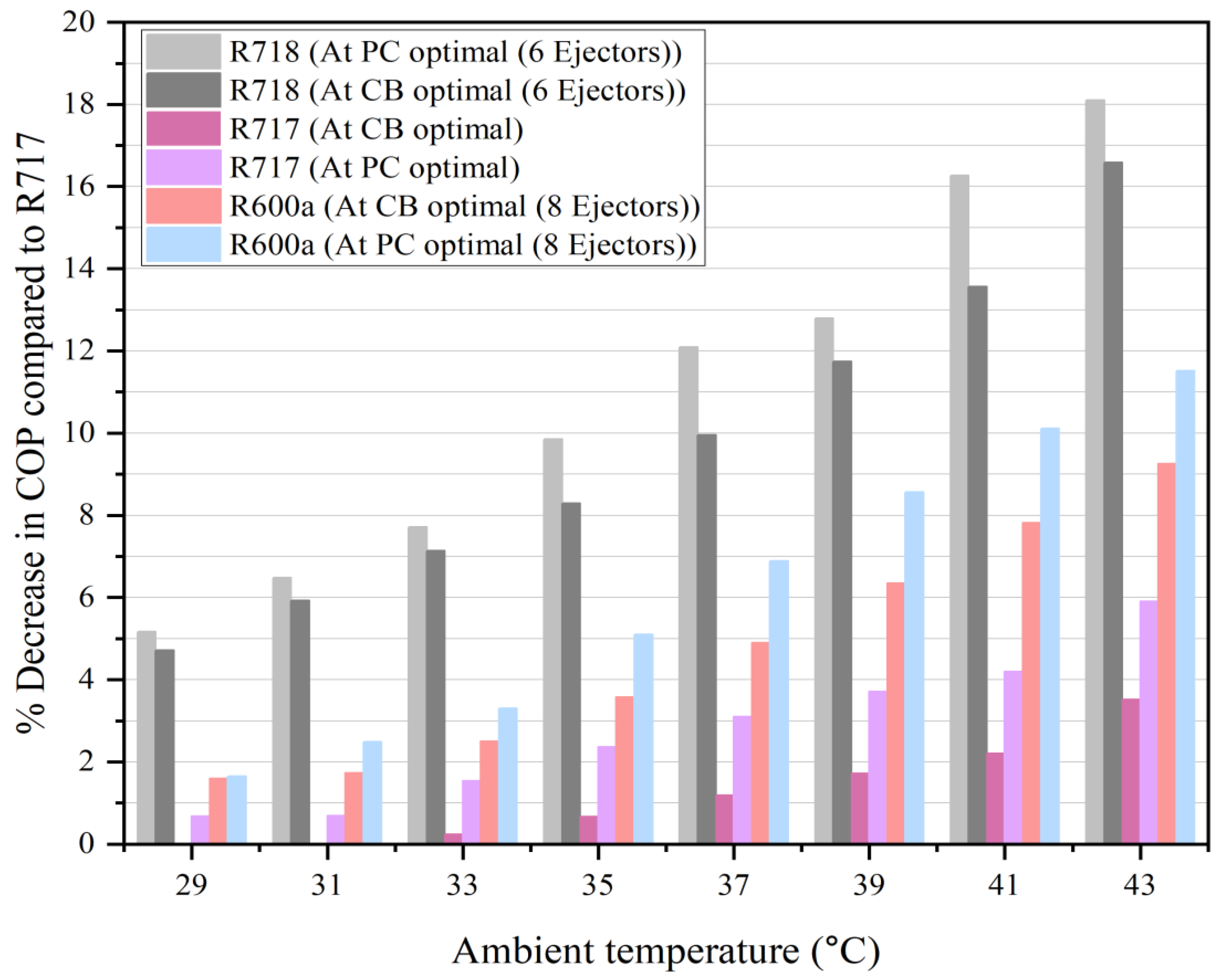

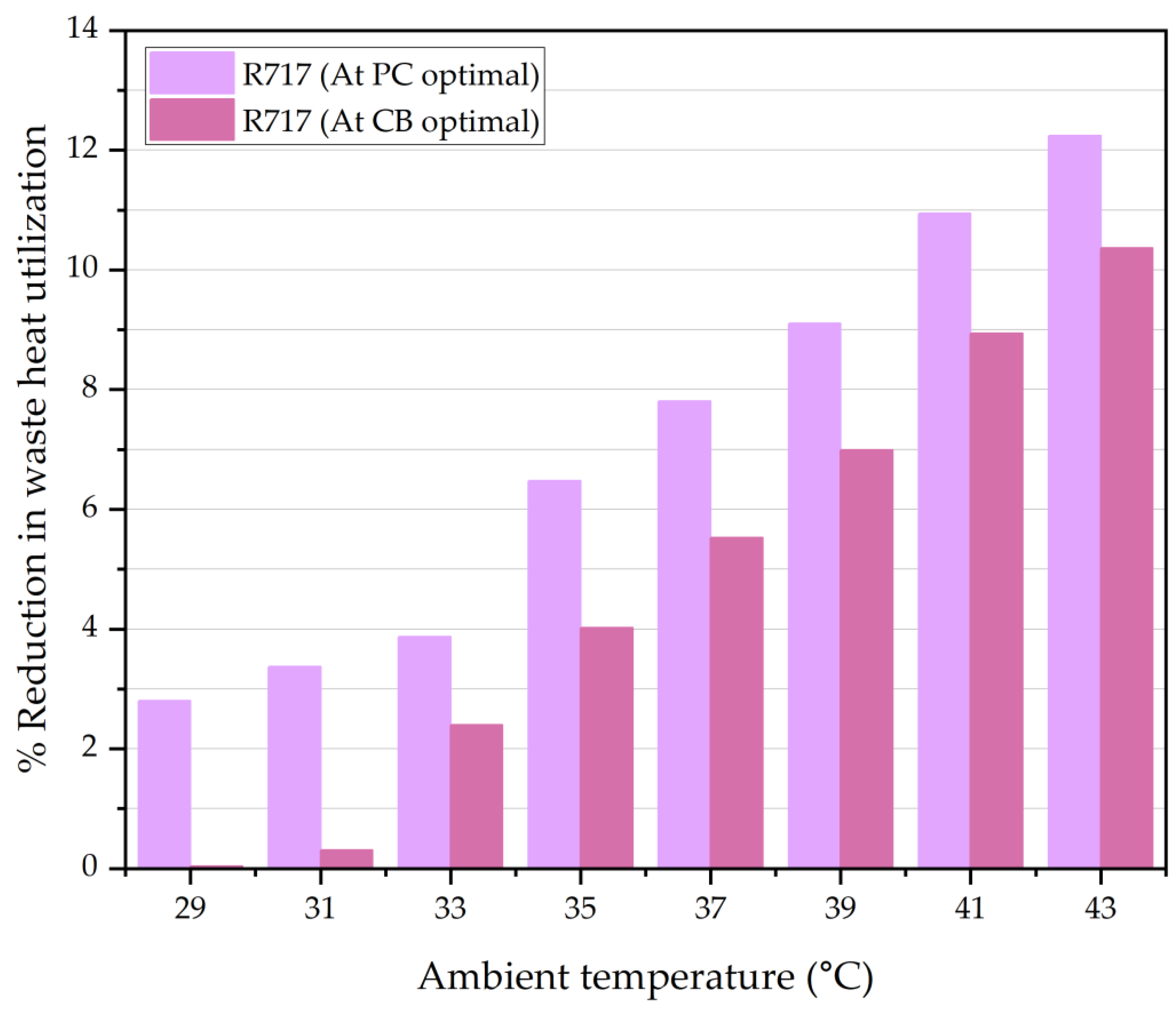

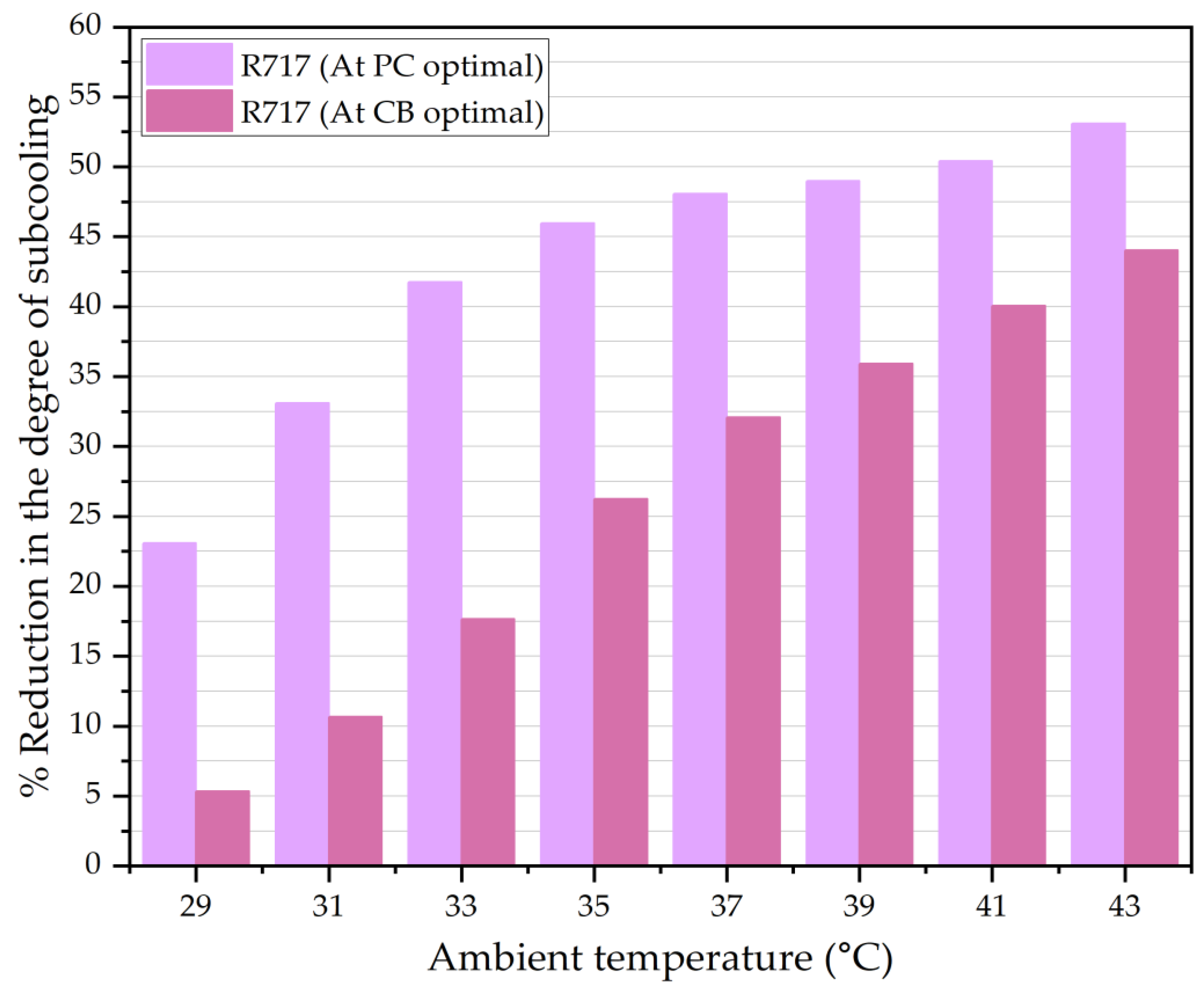

3.4. Impact of Operating the Proposed System at the Optimal Conditions of the Conventional R744 Systems

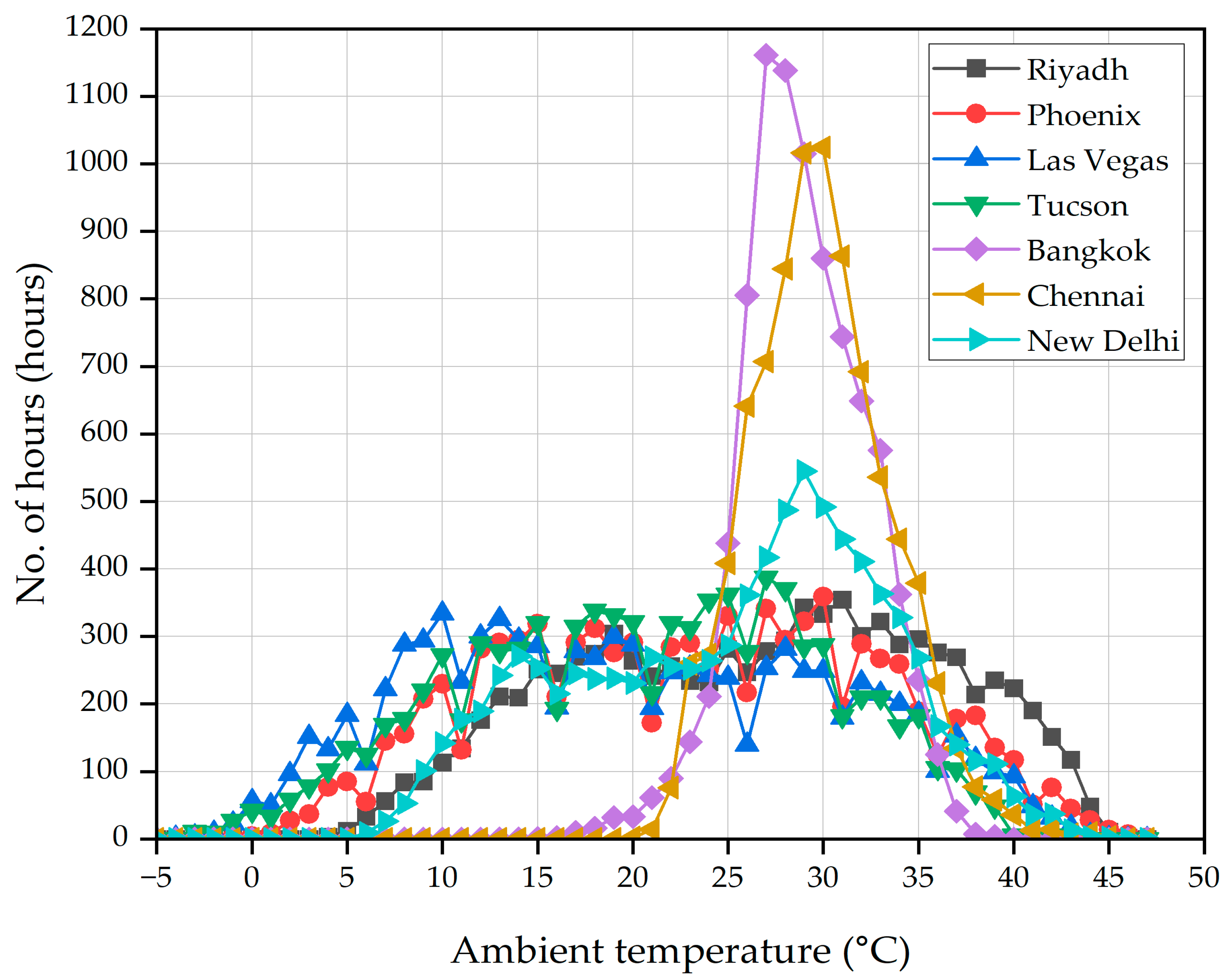

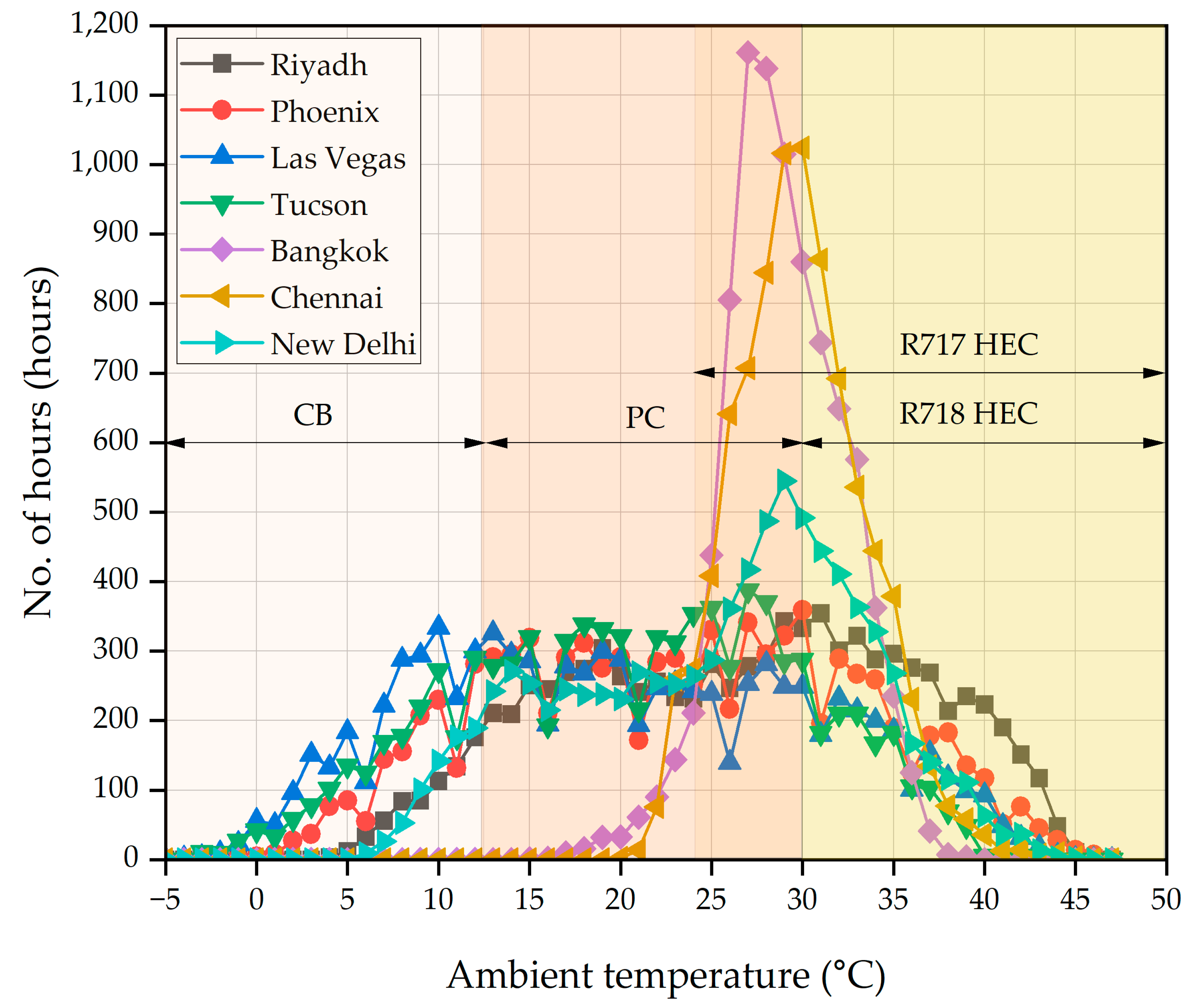

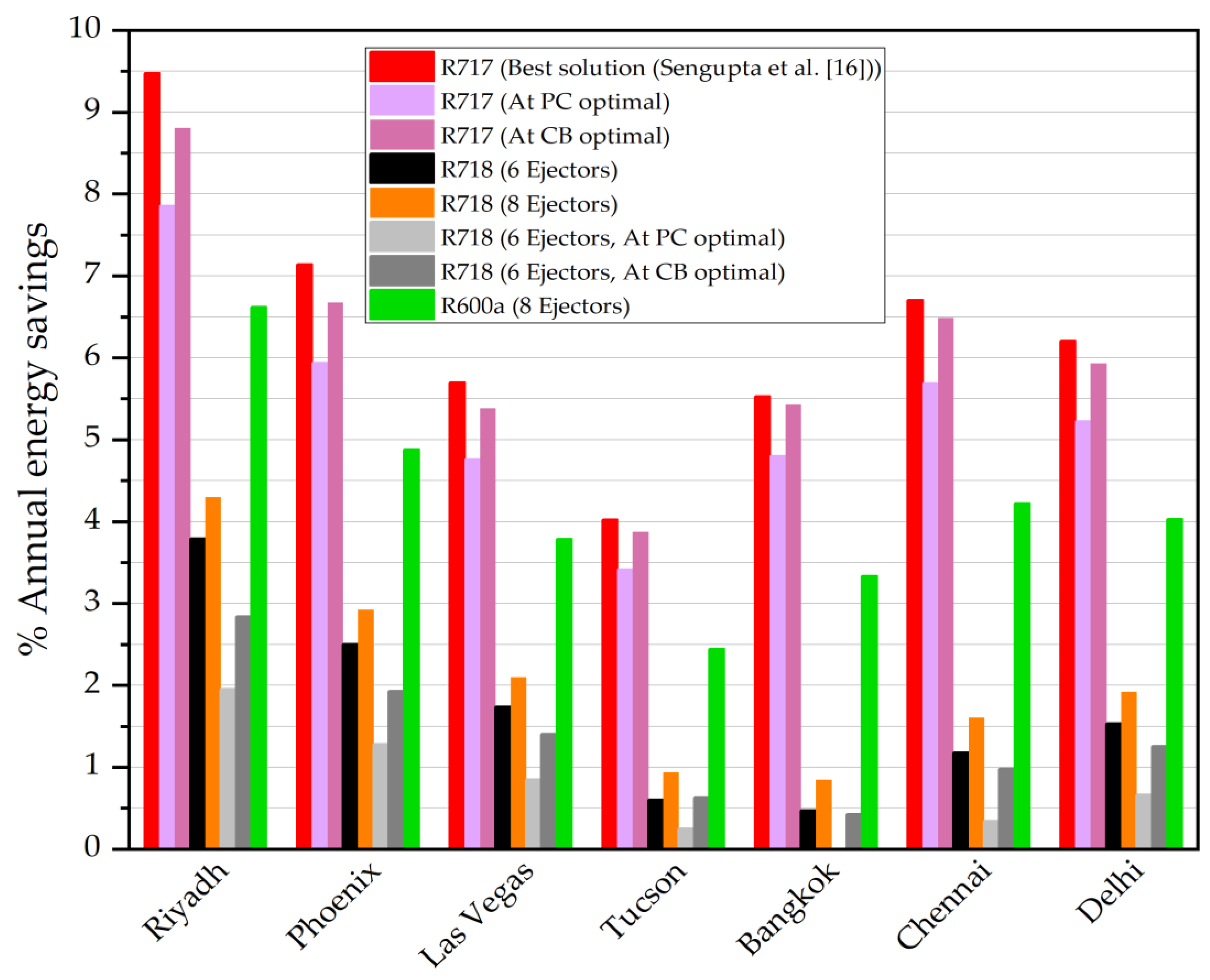

3.5. Energy Savings Comparison Among the Investigated Systems

3.6. Economic Analysis of the Investigated Systems

3.7. Selection of the Most Suitable Refrigerant for the HEC Unit and Associated Challenges

4. Conclusions

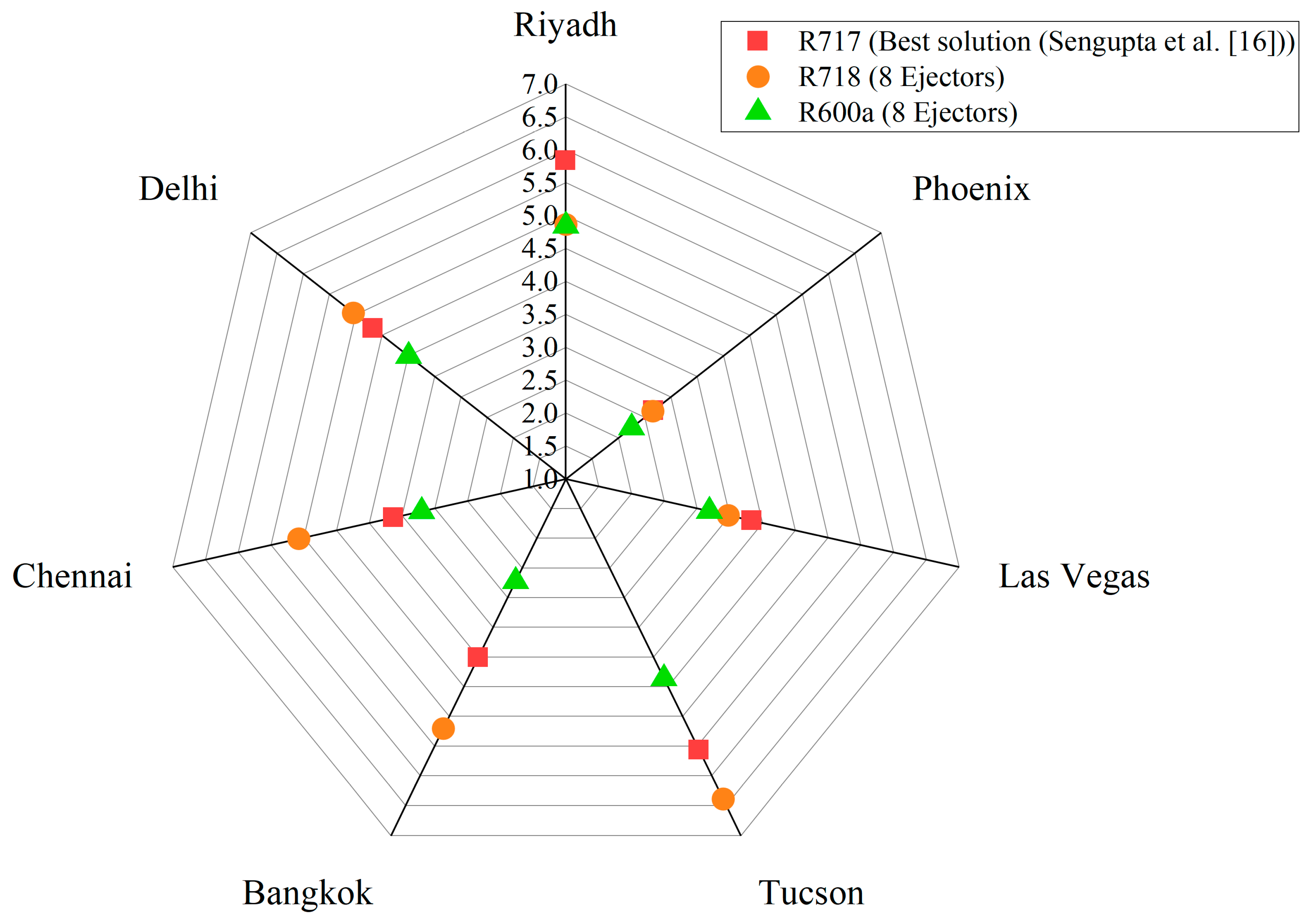

- The integration of an R717-based HEC was found to improve the COP of the R744 refrigeration system by 3.7% at 27 °C to 12.1% at 45 °C compared to the R718-based HEC, and 1.6% at 27 °C to 7.6% at 45 °C compared to the R600a-based HEC unit;

- The R718-based HEC was found to be effective at outdoor air temperatures above 30 °C, while the R717 system could be operated beyond 24 °C. This tended to reduce the operational range of the R718 system;

- Even with eight ejectors, the cooling capacities of the R718- and R600a-based HECs were found to be lower by 67% and 42%, respectively, compared to the five-ejector integrated R717 system;

- The use of CB high pressure controllers with the proposed system was found to impose relatively less penalty in the system performance compared to the high pressure controllers of the PC system;

- The energy-saving potential of the R744 refrigeration system integrated with the R717-based HEC (6.2% to 9.4%) was found to be relatively higher compared to the R718 (0.7% to 2.8%) and R600a-based HECs (2.5% to 6.6%);

- Although the additional investment incurred due to the installation of the R718-based HEC was significantly lower compared to the R717 and R600a systems, the AIRT associated with the R600a-based HEC (2.3–4.8 years) was found to be relatively lower than the R717 (2.7–5.8 years) and R718 systems (2.7–6.4 years) in all the selected locations.

- Even though the initial investment was high, R717 was found to be the best refrigerant for the HEC unit in terms of energy savings; however, necessary safety measures are required to be taken for use in sectors like supermarkets. R718 can definitely be an alternative to R717 in the future, once the technology associated with it becomes matured.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| app | Approach temperature (K) |

| AEC | Annual energy consumption (kWh) |

| AIRT | Additional investment recovery time (years) |

| CB | Conventional booster system |

| COP | Coefficient of performance |

| DOS | Degree of subcooling (K) |

| f | Frequency of ambient temperature (hours) |

| FVBV | Flash vapor by-pass valve |

| GC | Gas cooler |

| GWP | Global warming potential |

| h | Specific enthalpy (kJ/kg) |

| HEC | Heat driven ejector chiller |

| HFO | Hydro-fluoro-olefin |

| HPEV | High pressure expansion valve |

| LT | Low temperature |

| LTC | Low temperature compressor |

| Mass flow rate (kg/s) | |

| MEJ | Multi-ejector rack |

| MT | Medium temperature |

| MTC | Medium temperature compressor |

| P | Pressure (kPa) |

| pp | Pinch point temperature (K) |

| PBT | Persistent, bio-accumulative, and toxic |

| PC | Parallel compressor |

| Refrigeration load (kW) | |

| s | Specific entropy (kJ/kg-K) |

| T | Temperature (°C) |

| u | Velocity (m/s) |

| Power consumption (kW) | |

| x | Quality of refrigerant |

| Subscripts | |

| amb | Ambient |

| diff | Diffuser |

| dis | Discharge |

| exp | Experimental |

| mix | Mixing chamber |

| noz | Nozzle |

| sat | Saturation |

| sim | Simulation |

| sub | Sub-critical |

| suc | Suction |

| vap | Vapor |

| Greek | |

| η | Efficiency |

| ω | Entrainment ratio |

| Density (kg/m3) | |

References

- Tassou, S.A.; Ge, Y.; Hadawey, A.; Marriott, D. Energy consumption and conservation in food retailing. Appl. Therm. Eng. 2011, 31, 147–156. [Google Scholar] [CrossRef]

- Lundqvist, P. Recent Refrigeration Equipment Trends in Supermarkets: Energy Efficiency as Leading Edge; Academia Press: Cambridge, MA, USA, 2000. [Google Scholar]

- Schönenberger, J.; Hafner, A.; Banasiak, K.; Girotto, S. Experience with ejectors implemented in a R744 booster system operating in a supermarket. In Proceedings of the 11th IIR Gustav Lorentzen Conference on Natural Refrigerants, Hangzhou, China, 31 August–2 September 2014. [Google Scholar]

- Schulz, M.; Kourkoulas, D. Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16 April 2014 on fluorinated greenhouse gases and repealing Regulation (EC) No. 842/2006. Off. J. Eur. Union 2014, 2014, L150/195-230. [Google Scholar]

- What Are HFOs? Available online: https://advancedmaterials.honeywell.com/be/en/hfo-facts/what-are-hfos (accessed on 2 April 2024).

- Chesi, A.; Esposito, F.; Ferrara, G.; Ferrari, L. Experimental analysis of R744 parallel compression cycle. Appl. Energy 2014, 135, 274–285. [Google Scholar] [CrossRef]

- Lata, M.; Gupta, D.K. Simulation and performance evaluation of trans-critical CO2 refrigeration system with modified evaporative cooled finned tube gas cooler in Indian context. Appl. Therm. Eng. 2021, 186, 116500. [Google Scholar] [CrossRef]

- Liu, X.; Yu, K.; Wan, X.; Li, X. Performance evaluation of CO2 supermarket refrigeration system with multi-ejector and dedicated mechanical subcooling. Energy Rep. 2021, 7, 5214–5227. [Google Scholar] [CrossRef]

- Casi, Á.; Aranguren, P.; Araiz, M.; Sanchez, D.; Cabello, R.; Astrain, D. Performance assessment of an experimental CO2 transcritical refrigeration plant working with a thermoelectric subcooler in combination with an internal heat exchanger. Energy Convers. Manag. 2022, 268, 115963. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Incorporation of an organic Rankine cycle in a transcritical booster CO2 refrigeration system. Int. J. Energy Res. 2020, 44, 7974–7988. [Google Scholar] [CrossRef]

- Pardiñas, Á.; Hafner, A.; Banasiak, K. Integrated R744 ejector supported parallel compression racks for supermarkets. Experimental results. In Proceedings of the 13th IIR Gustav Lorentzen Conference on Natural Refrigerants, Valencia, Spain, 18–20 June 2018. [Google Scholar]

- Singh, S.; Hafner, A.; Maiya, M.P.; Banasiak, K.; Neksa, P. Multiejector CO2 cooling system with evaporative gascooler for a supermarket application in tropical regions. Appl. Therm. Eng. 2021, 190, 116766. [Google Scholar] [CrossRef]

- Toffoletti, G.; Barta, R.B.; Grajales, S.M.; Liu, H.; Ziviani, D.; Groll, E. Experimental comparison of cycle modifications and ejector control methods using variable geometry and CO2 pump in a multi-evaporator transcritical CO2 refrigeration system. Int. J. Refrig. 2025, 169, 226–240. [Google Scholar] [CrossRef]

- Saeed, M.Z.; Hafner, A.; Thatte, A.; Gabrielii, C.H. Simultaneous implementation of rotary pressure exchanger and ejectors for CO2 refrigeration system. In Proceedings of the 15th IIR Gustav Lorentzen Conference on Natural Refrigerants, Trondheim, Norway, 13–15 June 2022. [Google Scholar]

- Guruchethan, A.M.; Reddy, Y.S.K.; Maiya, M.P.; Hafner, A. Performance evaluation of absorption cooling assisted transcritical CO2 refrigeration systems. Int. J. Refrig. 2023, 155, 362–374. [Google Scholar] [CrossRef]

- Sengupta, A.; Gullo, P.; Khorshidi, V.; Dasgupta, M.S. Waste heat utilization: Energy and economic benefits from multi-ejector chiller sub-cooling R744 supermarket refrigeration systems. Energy 2024, 312, 133657. [Google Scholar] [CrossRef]

- Mastrullo, R.; Mauro, A.W.; Napoli, G.; Viscito, L. Thermo-economic optimization and environmental analysis of a waste heat driven multi-ejector chiller for maritime applications. Case Stud. Therm. Eng. 2024, 54, 104081. [Google Scholar] [CrossRef]

- Arora, A.; Singh, N.K.; Monga, S.; Kumar, O. Energy and exergy analysis of a combined transcritical CO2 compression refrigeration and single effect H2O-LiBr vapour absorption system. Int. J. Exergy 2011, 9, 453–471. [Google Scholar] [CrossRef]

- Bellos, E.; Tzivanidis, C. Enhancing the performance of a CO2 refrigeration system with the use of an absorption chiller. Int. J. Refrig. 2019, 108, 37–52. [Google Scholar] [CrossRef]

- Kumar, K.; Gupta, H.K.; Kumar, P. Analysis of a hybrid transcritical CO2 vapor compression and vapor ejector refrigeration system. Appl. Therm. Eng. 2020, 181, 115945. [Google Scholar] [CrossRef]

- Yadav, V.K.; Sarkar, J. Thermodynamic, economic, and environmental analyses of various novel ejector refrigeration subcooled transcritical CO2 systems. Int. J. Energy Res. 2021, 45, 16115–16133. [Google Scholar] [CrossRef]

- Ierin, V.; Chen, G.; Volovyk, O.; Shestopalov, K. Hybrid two–stage CO2 transcritical mechanical compression–ejector cooling cycle: Thermodynamic analysis and optimization. Int. J. Refrig. 2021, 132, 45–55. [Google Scholar] [CrossRef]

- Karampour, M.; Sawalha, S. State-of-the-art integrated CO2 refrigeration system for supermarkets: A comparative analysis. Int. J. Refrig. 2018, 86, 239–257. [Google Scholar] [CrossRef]

- Gullo, P.; Elmegaard, B.; Cortella, G. Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates. Int. J. Refrig. 2016, 64, 61–79. [Google Scholar] [CrossRef]

- Lillo, G.; Mastrullo, R.; Mauro, A.W.; Trinchieri, R.; Viscito, L. Thermo-economic analysis of a hybrid ejector refrigerating system based on a low grade heat source. Energies 2020, 13, 562. [Google Scholar] [CrossRef]

- Chen, J.; Havtun, H.; Palm, B. Investigation of ejectors in refrigeration system: Optimum performance evaluation and ejector area ratios perspectives. Appl. Therm. Eng. 2014, 64, 182–191. [Google Scholar] [CrossRef]

- Viscito, L.; Lillo, G.; Napoli, G.; Mauro, A.W. Waste heat driven multi-ejector cooling systems: Optimization of design at partial load; seasonal performance and cost evaluation. Energies 2021, 14, 5663. [Google Scholar] [CrossRef]

- EnergyPlus. Available online: https://energyplus.net/weather (accessed on 2 April 2024).

- Electricity Prices Around the World. Available online: https://www.globalpetrolprices.com/electricity_prices/ (accessed on 2 April 2024).

- Lemmon, E.W.; Bell, I.H.; Huber, M.L.; McLinden, M.O. NIST Standard Reference Database 23: Reference Fluid Thermodynamic and Transport Properties-REFPROP, Version 10.0; National Institute of Standards and Technology, Standard Reference Data Program: Gaithersburg, MD, USA, 2018.

- The MathWorks, Inc. MATLAB, Version: 9.13.0 (R2022b). Available online: https://www.mathworks.com (accessed on 2 April 2024).

- Shestopalov, K.O.; Huang, B.J.; Petrenko, V.O.; Volovyk, O.S. Investigation of an experimental ejector refrigeration machine operating with refrigerant R245fa at design and off-design working conditions. Part 2. Theoretical and experimental results. Int. J. Refrig. 2015, 55, 212–223. [Google Scholar] [CrossRef]

- Li, F.; Li, R.; Li, X.; Tian, Q. Experimental investigation on a R134a ejector refrigeration system under overall modes. Appl. Therm. Eng. 2018, 137, 784–791. [Google Scholar] [CrossRef]

- Śmierciew, K.; Gagan, J.; Butrymowicz, D.; Karwacki, J. Experimental investigations of solar driven ejector air-conditioning system. Energy Build. 2014, 80, 260–267. [Google Scholar] [CrossRef]

| Compressor | Operating Mode | Global Efficiency [24] |

|---|---|---|

| LTC | Subcritical | |

| MTC | Subcritical | |

| MTC | Transcritical | |

| PC | Subcritical | |

| PC | Transcritical |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sengupta, A.; Gullo, P.; Khorshidi, V.; Dasgupta, M.S. Transcritical R744 Supermarket Refrigeration System Integrated with a Heat-Driven Ejector Chiller. Appl. Sci. 2025, 15, 2955. https://doi.org/10.3390/app15062955

Sengupta A, Gullo P, Khorshidi V, Dasgupta MS. Transcritical R744 Supermarket Refrigeration System Integrated with a Heat-Driven Ejector Chiller. Applied Sciences. 2025; 15(6):2955. https://doi.org/10.3390/app15062955

Chicago/Turabian StyleSengupta, Ayan, Paride Gullo, Vahid Khorshidi, and Mani Sankar Dasgupta. 2025. "Transcritical R744 Supermarket Refrigeration System Integrated with a Heat-Driven Ejector Chiller" Applied Sciences 15, no. 6: 2955. https://doi.org/10.3390/app15062955

APA StyleSengupta, A., Gullo, P., Khorshidi, V., & Dasgupta, M. S. (2025). Transcritical R744 Supermarket Refrigeration System Integrated with a Heat-Driven Ejector Chiller. Applied Sciences, 15(6), 2955. https://doi.org/10.3390/app15062955