Calculation Schemes for Determining Contact Stresses in Railway Rails

Abstract

1. Introduction

2. Materials and Methods

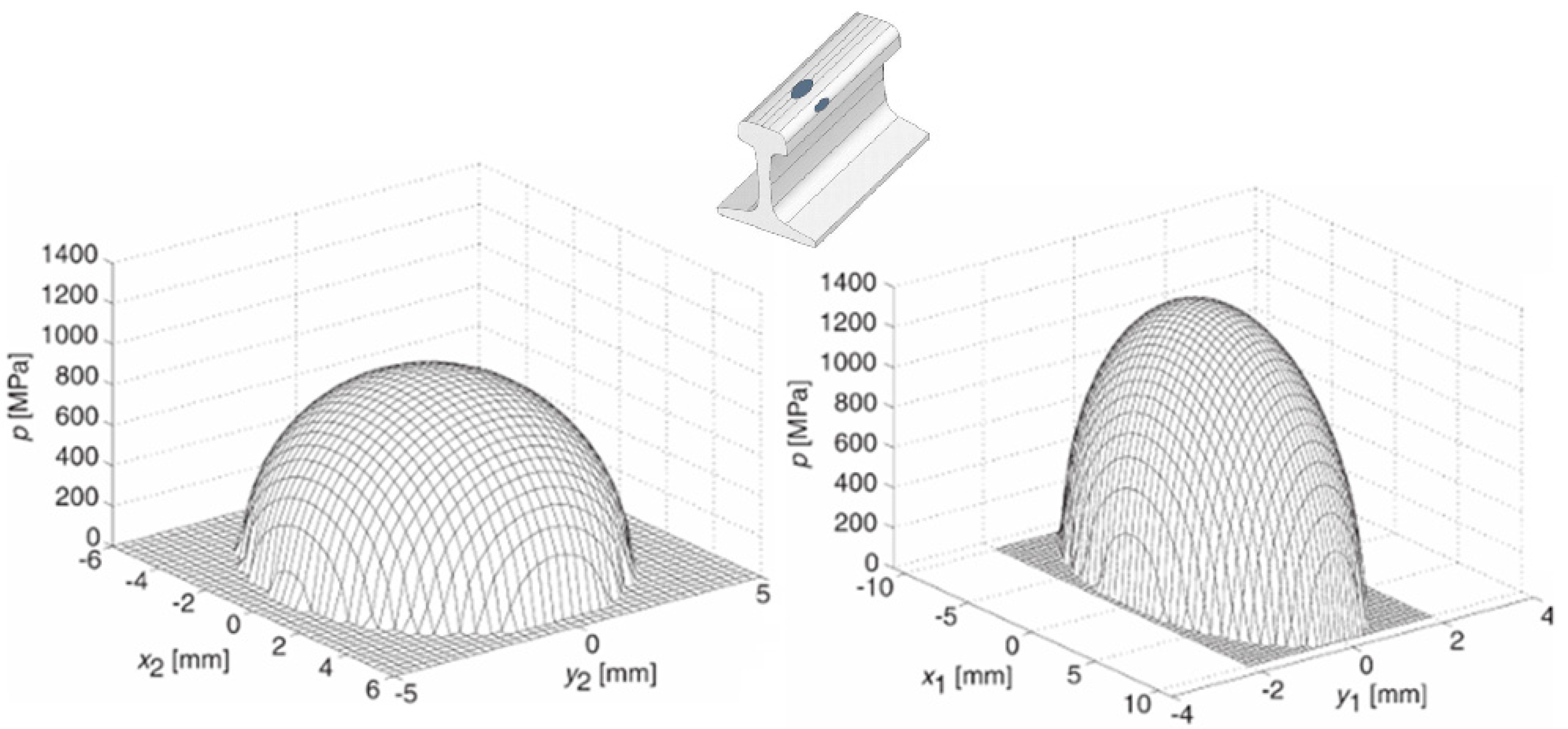

2.1. Analytical Solution of the Contact Problem

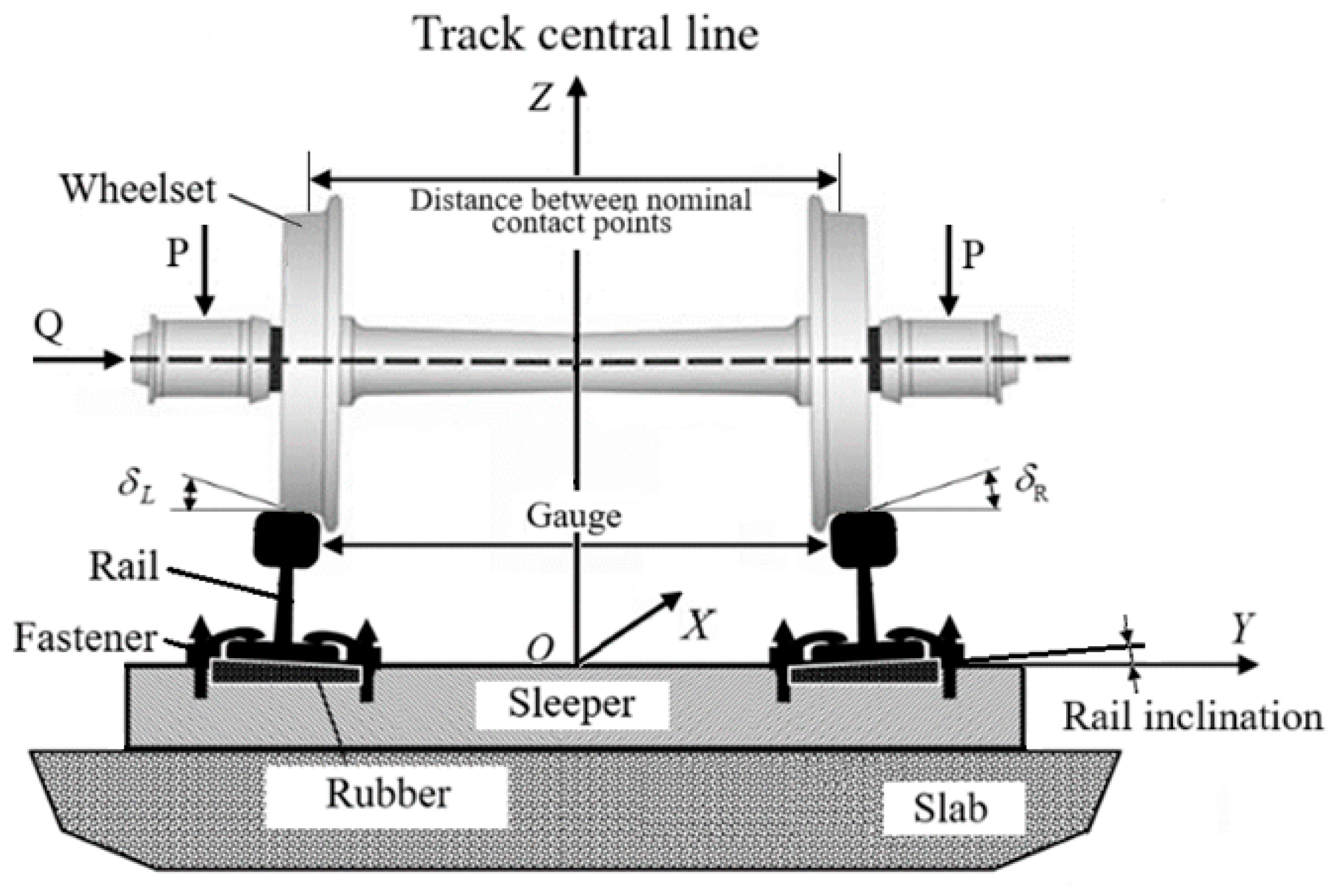

2.2. Computational Schemes for Rails—Wheels Contact Problems

- The stiffness of the sub-rail foundation, which affects deflections and angles of the rail twisting under wheel loads;

- The inclination of the rail base relative to the sub-rail foundation;

- The degree of outer rail elevation in curved track sections;

- Track gauge width;

- The profiles of the contact surfaces.

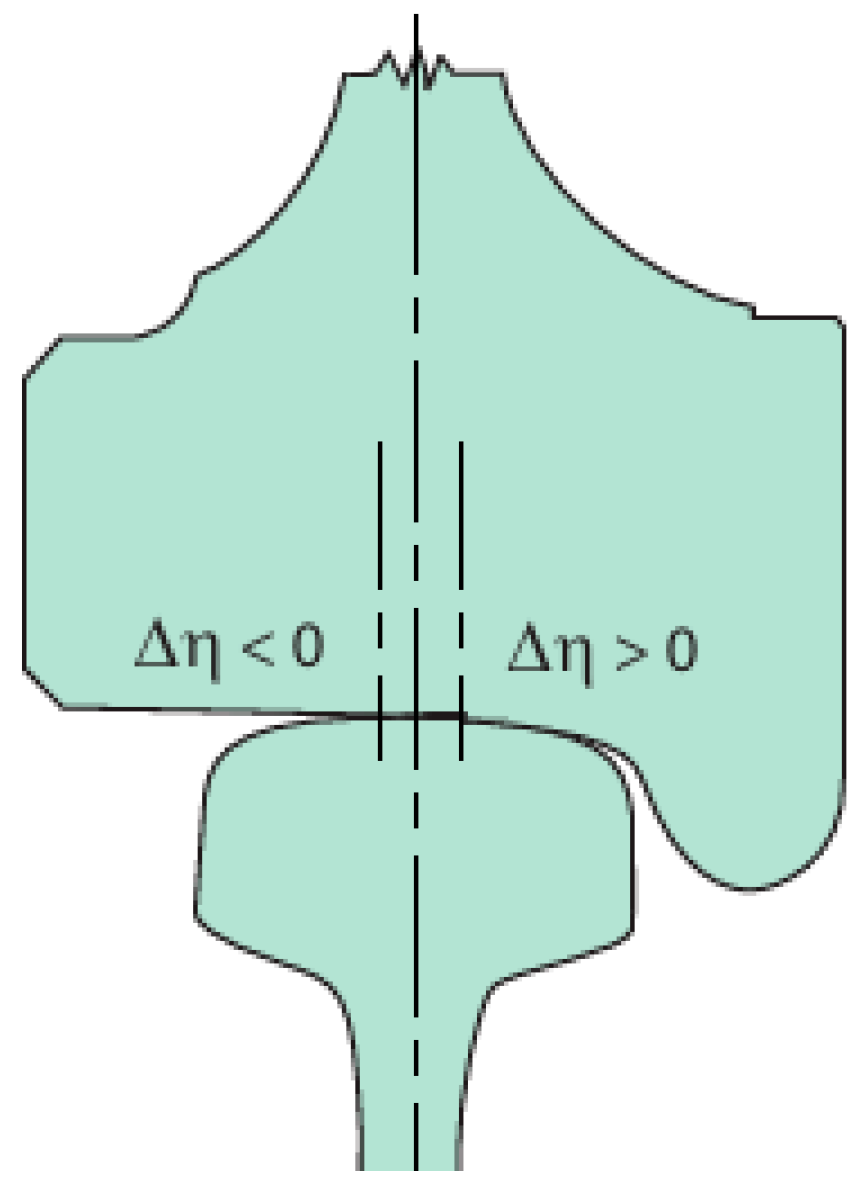

- Contact should be single-point and conformal;

- The rolling surfaces should have equivalent conicity that maximizes the wavelength of the bogie’s lateral oscillations and meets the requirements of the international standard UIC Code 519 [50].

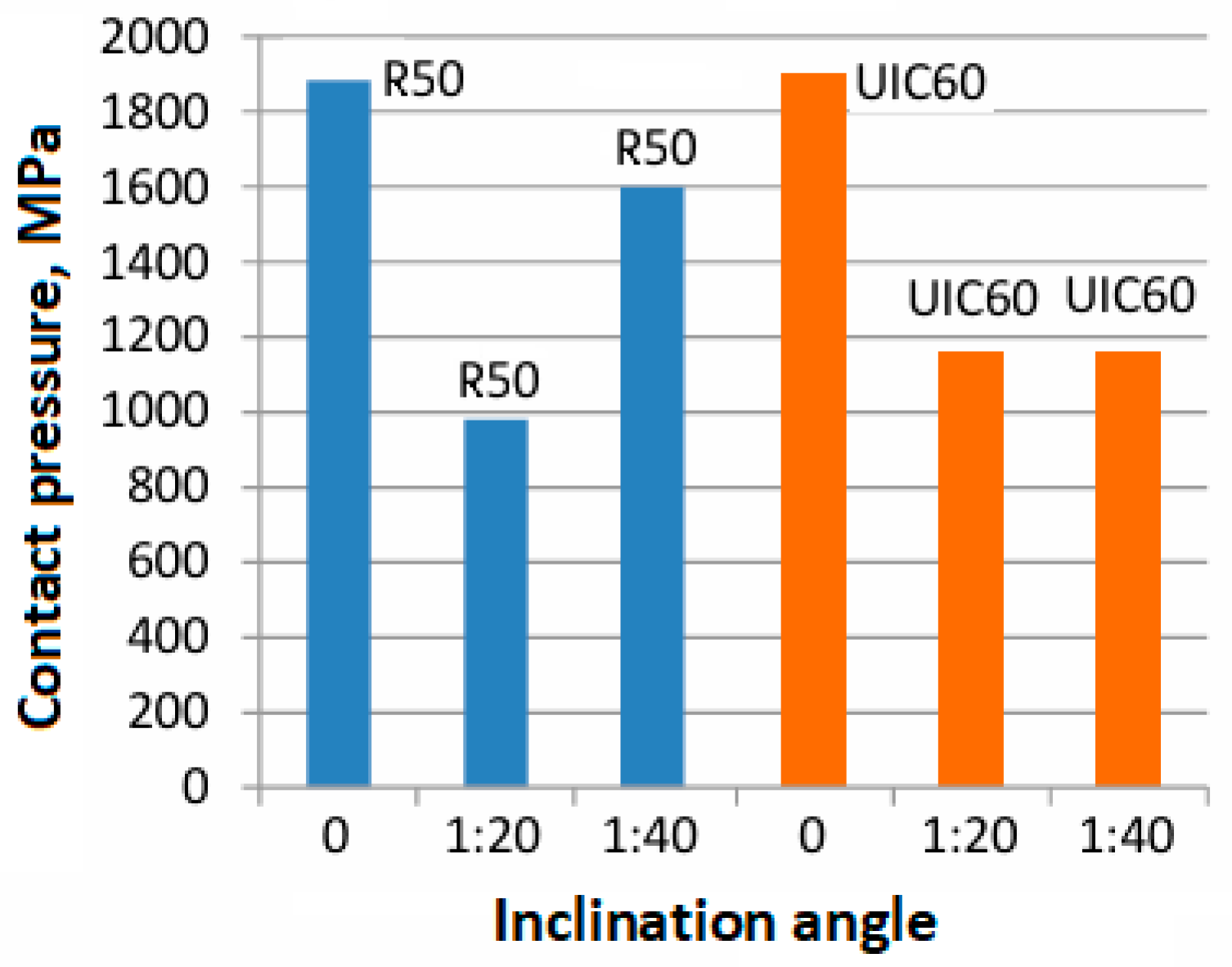

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Elkhoury, N.; Hitihamillage, L.; Moridpour, S.; Robert, D. Degradation Prediction of Rail Tracks: A Review of the Existing Literature. Open Transp. J. 2018, 12, 88–104. [Google Scholar] [CrossRef]

- Semaan, N.; Zayed, Т. An assessment model for structural performance of subway systems. Int. J. Sci. Environ. Technol. 2014, 3, 1943–1968. [Google Scholar]

- Shur, E.A. Quality, Service Failure Rate, and Prospects of Rail Perfection. In Proceedings of the Internationales Symposium “Schienenfehler” Tagungsbericht, Brandenburg an der Havel, Germany, 16–17 November 2000; pp. 6-1–6-10. [Google Scholar]

- INNOTRACK Project No. TIP5-CT-2006-031415O. D4.1.4-Rail Degradation Algorithms. December 2009; 40p. Chalmers Railway Mechanics. Available online: https://www.charmec.chalmers.se/innotrack/deliverables/sp4/d414-f3-rail_degradation_algorithms.pdf (accessed on 2 March 2025).

- Edel, K.-O.; Budnitzki, G.; Schnitzer, T. Schienenfehler. Beanspruchung und Schädigung von Eisenbahnschienen; Springer Vieweg: Wiesbaden, Germany, 2021; 606p. [Google Scholar]

- Magel, E.E. Rolling Contact Fatigue: A Comprehensive Review; Technical Report 11/24; U.S. Department of Transportation, Federal Railroad Administration, Office of Railroad Policy and Development: Washington, DC, USA, 2011; 132p.

- Track Inspector Rail Defect Reference Manual; U.S. Department of Transportation, Federal Railroad Administration, Office of Railroad Safety: Washington, DC, USA, 2015; Revision 2; 82p.

- Olver, A.V. The mechanism of rolling contact fatigue: An update. Proc. Inst. Mech. Engng. Part J J. Eng. Tribol. 2005, 219, 313–330. [Google Scholar] [CrossRef]

- Edel, K.-O. Systematisierung der Schienenfehler. In Proceedings of the Internationales Symposium “Schienenfehler” Tagungsbericht, Brandenburg an der Havel, Germany, 16–17 November 2000; pp. 1-1–1-15. [Google Scholar]

- UIC Code 712. In Rail Defects, 4th ed.; International Union of Railways: Paris, France, 2002; 107p, ISBN 2-7461-0341-9.

- Ringsberg, J.W. Life prediction of rolling contact fatigue crack initiation. Int. J. Fatigue 2001, 23, 575–586. [Google Scholar] [CrossRef]

- Zwierczyk, P.T.; Váradi, K. Frictional contact FE analysis in a railway wheel-rail contact. Period. Polytech. Mech. Eng. 2014, 58, 93–99. [Google Scholar] [CrossRef]

- Sladkowski, A.; Sitarz, M. Analysis of wheel-rail interaction using FE software. Wear 2005, 258, 1217–1223. [Google Scholar] [CrossRef]

- Kosarchuk, V.V.; Danilenko, É.I.; Agarkov, A.V. Effect of railcar wheel tire profiles on the contact stress level in subway rails. Strength Mater. 2020, 52, 398–406. [Google Scholar] [CrossRef]

- Trummer, G.; Marte, C.; Scheriau, S.; Dietmaier, P.; Sommitsch, C.; Six, K. Modelling wear and rolling contact fatigue: Parametric study and experimental results. Wear 2016, 366–367, 71–77. [Google Scholar] [CrossRef]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; 452p, ISBN 978-0-521-25576-9. [Google Scholar]

- Aleshin, V.V. On Applications of Semi-Analytical Methods of Contact Mechanics. Front. Mech. Eng. 2020, 6, 30. [Google Scholar] [CrossRef]

- Telliskivi, T.; Olofsson, U. Contact mechanics analysis of measured wheel-rail profiles using the finite element method. J. Rail Rapid Transit. 2000, 215, 65–72. [Google Scholar] [CrossRef]

- Pohrt, R.; Li, Q. Complete Boundary Element Formulation for Normal and Tangential Contact Problems. Phys. Mesomech. 2014, 17, 334–340. [Google Scholar] [CrossRef]

- Wang, Q.; Sun, L.; Zhang, X.; Liu, S.; Zhu, D. FFT-Based Methods for Computational Contact Mechanics. Front. Mech. Eng. 2020, 6, 61. [Google Scholar] [CrossRef]

- Kalliorinne, K.; Larsson, R.; Pérez-Ràfols, F.; Liwicki, M.; Almqvist, A. Artificial Neural Network Architecture for Prediction of Contact Mechanical Response. Front. Mech. Eng. 2021, 6, 579825. [Google Scholar] [CrossRef]

- DSTU GOST 4835:2008; Cars Wheelsets of Mainline Railway Cars with a Gauge of 1520 mm. Derzhspozhyvstandart: Kyiv, Ukraine, 2008; 14p.

- DSTU 4344:2004; Ordinary Rails for Broad Gauge Railways. Derzhspozhyvstandart: Kyiv, Ukraine, 2005; 28p.

- Kozlovsky, A.; Taran, Y.; Staroseletsky, M.; Esaulov, V.; Gubenko, S.; Sładkowski, A.; Shramko, A. Improvement of Profiles of the Working Surface for Carload and Locomotive Wheels. In Proceedings of the Vth International Science Conference for Middle and Eastern European Countries, Katowice, Poland, 3–5 July 2002. 7p. [Google Scholar]

- Cooper, D.H. Tables of Hertzian Contact-Stress Coefficients; Report R-3R7; University of Illinois, Coordinated Science Laboratory: Urbana, IL, USA, 1968; 34p. [Google Scholar]

- Lundberg, G.; Sjövall, H. Stress and Deformation in Elastic Solids; Publ. No. 4; Institute of Theory of Elasticity, Chalmers University of Technology: Göteborg, Sweden, 1958. [Google Scholar]

- Ringsberg, J.W.; Josefson, B.L. Finite element analyses of rolling contact fatigue crack initiation in railheads. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit. 2001, 215, 243–259. [Google Scholar] [CrossRef]

- Urassa, P.; Habte, H.S.; Mohammedseid, A. Crack influence and fatigue life assessment in rail profiles: A numerical study. Front. Built Environ. 2023, 9, 1304557. [Google Scholar] [CrossRef]

- Wang, Y.; Xiao, H.; Zhang, Z.; Cui, X.; Chi, Y.; Nadakatti, M. The formation, development and classification of rail corrugation: A survey on Chinese metro. Railw. Eng. Sci. 2025, 33, 43–61. [Google Scholar] [CrossRef]

- Krishna, V.V.; Hossein-Nia, S.; Casanueva, C.; Stichel, S.; Trummer, G.; Six, K. Rail RCF damage quantification and comparison for different damage models. Rail. Eng. Sci. 2022, 30, 23–40. [Google Scholar] [CrossRef]

- Zhang, S.; Liu, Q.; Spiryagin, M.; Wu, Q.; Ding, H.; Wen, Z.; Wang, W. Gaps, challenges and possible solution for prediction of wheel–rail rolling contact fatigue crack initiation. Railw. Eng. Sci. 2023, 31, 207–232. [Google Scholar] [CrossRef]

- Jaifu, A.; Raeon, S.; Pimsarn, M. Study of fatigue crack initiation location of wheel and rail under rolling contact using finite element method. MATEC Web Conf. 2018, 192, 02012. [Google Scholar] [CrossRef][Green Version]

- Suh, N.P. The delamination theory of wear. Wear 1973, 25, 111–124. [Google Scholar] [CrossRef]

- Suh, N.P.; Sin, H.-C. Surface Traction and Crack Propagation in Delamination Wear; Report LMP/TRB-81-03; Laboratory for Manufacturing and Productivity, School of Engineering, Massachusetts Institute of Technology: Cambridge, MA, USA, 1981; 188p. [Google Scholar]

- Esaulov, V.P.; Sladkovskii, A.V. Determination of the digitizing errors generated in the finite-element computation of railway wheels. Strength Mater. 1990, 22, 740–743. [Google Scholar] [CrossRef]

- INNOTRACK Report D 4.3.5 “Simulation of Materials Deformation and RCF”. 2009; 43p. Chalmers Railway Mechanics. Available online: https://www.charmec.chalmers.se/innotrack/deliverables/sp4/d435-f3-simulation_material_deformation_rcf.pdf (accessed on 2 March 2025).

- Liu, B.; Stefano, B. Analysis of Wheel-Roller Contact and Comparison with the Wheel-Rail Case. Urban Rail Transit. 2015, 1, 215–226. [Google Scholar] [CrossRef]

- Kosarchuk, V.; Aharkov, О.; Tverdomed, V. Life assessment of rails by criterion of occurrence of fatigue cracks. Transp. Syst. Technol. 2021, 38, 194–200. [Google Scholar] [CrossRef]

- van Belkom, A. A simplified method for calculating load distribution and rail deflections in track, incorporating the influence of sleeper stiffness. Adv. Struct. Eng. 2020, 23, 2358–2372. [Google Scholar] [CrossRef]

- Sun, L.P.; Zhang, J.; Zhang, J. Analyses on Wheel-Rail Contact Using Finite Element Method during Passing through Curved Track. In Proceedings of the International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, China, 11–12 April 2009; pp. 728–731. [Google Scholar] [CrossRef]

- Kleiner, O.; Schindler, C. Untersuchungen zur Beanspruchung von Rad und Schiene. EI-Der Eisenbahningenieur 2009, 60, 12–18. [Google Scholar]

- Kleiner, O.; Schindler, C. Geometrie und Druckspannungen im Rad/Schiene-Kontakt. EI-Der Eisenbahningenieur 2011, 62, 9–12. [Google Scholar]

- Bogojević, N.; Lučanin, V.; Tatić, B. Influence of wheel profiles on rolling contact fatigue and wear rate of railway wheels. Mech. Transp. Commun. 2013, 11, VI-34–VI-40. [Google Scholar]

- Gerlici, J.; Lack, T. Contact geometry influence on the rail/wheel surface stress distribution. Рrocedia Eng. 2010, 2, 2249–2257. [Google Scholar] [CrossRef]

- Choi, H.Y.; Lee, D.H.; Song, C.Y.; Lee, J. Optimization of rail profile to reduce wear on curved track. Int. J. Precis. Eng. Manuf. 2013, 14, 619–625. [Google Scholar] [CrossRef]

- Jahed, H.; Farshi, B.; Eshraghi, M.A.; Nasr, A. A numerical optimization technique for design of wheel profiles. Wear 2008, 264, 1–10. [Google Scholar] [CrossRef]

- Wang, J.; Ren, Z.; Chen, J.; Chen, L. Study on Rail Profile Optimization Based on the Nonlinear Relationship between Profile and Wear Rate. Math. Probl. Eng. 2017, 2017, 6956514. [Google Scholar] [CrossRef]

- Magel, E.E.; Kalousek, J. The application of contact mechanics to rail profile design and rail grinding. Wear 2002, 253, 308–316. [Google Scholar] [CrossRef]

- Ye, Y.; Sun, Y.; Dongfang, S.; Shi, D.; Hecht, M. Optimizing wheel profiles and suspensions for railway vehicles operating on specific lines to reduce wheel wear: A case study. Multibody Syst. Dyn. 2021, 51, 91–122. [Google Scholar] [CrossRef]

- UIC Code 519: Method for Determining the Equivalent Conicity; Ed. No 1; International Union of Railways: Paris, France, 2004; 99p.

- Blokhina, G.S. Criterion of Economic Efficiency of Introduction of Railway Wheels with New Profiles of Rolling Surface. Probl. Increasing Effic. Infrastruct. 2001, 5, 16–20. [Google Scholar]

- Korotenko, M.L.; Zabolotny, O.M.; Neduzha, L.O.; Nesterenko, N.M.; Yagoda, D.O. Experimental study of wear of tires of VL11M electric locomotives with different profiles. Bull. Dnipropetr. Natl. Univ. Railw. Transp. Named After Acad. V. Lazaryan 2005, 8, 53–57. [Google Scholar] [CrossRef]

- Garg, V.K.; Dukkipati, R.V. Dynamics of Railway Vehicle Systems; Academic Press: Orland, CA, USA, 1984; 407p. [Google Scholar] [CrossRef]

- Kalker, J.J. Three-Dimensional Elastic Bodies in Rolling Contact; Kluwer Academic Publishers: Dordrecht, The Netherlands, 1990; 314p. [Google Scholar] [CrossRef]

- Iwnicki, S. (Ed.) Handbook of Railway Vehicle Dynamics; Taylor & Francis Group, LLC: Boca Raton, FL, USA; London, UK; New York, NY, USA, 2006. [Google Scholar] [CrossRef]

- Sharma, R.C. Recent Advances in Railway Vehicle Dynamics. Int. J. Veh. Struct. Syst. 2012, 4, 52–63. [Google Scholar] [CrossRef]

- Knothe, K. History of wheel/rail contact mechanics from Redtenbacher to Kalker. Veh. Syst. Dyn. 2008, 46, 49–66. [Google Scholar] [CrossRef]

- Eickhoff, B.M.; Evans, J.R.; Minnis, A.J. A review of modelling methods for railway vehicle suspension components. Veh. Syst. Dyn. 1995, 24, 469–496. [Google Scholar] [CrossRef]

- Wen, Z.; Xiao, G.; Xiao, X.; Jin, X.; Zhu, M. Dynamic vehicle–track interaction and plastic deformation of rail at rail welds. Eng. Fail. Anal. 2009, 16, 1221–1237. [Google Scholar] [CrossRef]

- Darenskiy, A.; Vitolberg, V.; Fast, D.; Klymenko, A.; Leibuk, Y. A mathematical model of the rail track presented as a bar on elastic and dissipative supports under the influence of moving loads. MATEC Web Conf. 2017, 116, 03002. [Google Scholar] [CrossRef]

- Sun, Y.Q.; Cole, C.; Spiryagin, M. Monitoring vertical wheel–rail contact forces based on freight wagon inverse modelling. Adv. Mech. Eng. 2015, 7. [Google Scholar] [CrossRef]

- Xia, F.; Cole, C.; Wolfs, P. Wheel rail contact forces prediction and validation with field tests. In Proceedings of the Conference on Railway Engineering, Perth, Australia, 7–10 September 2008; pp. 73–82. [Google Scholar]

- Palin, E.J.; Stipanovic Oslakovic, I.; Gavin, K.; Quinn, A. Implications of climate change for railway infrastructure. WIREs Clim. Chang. 2021, 12, e728. [Google Scholar] [CrossRef]

- Senić, A.; Dobrodolac, M.; Stojadinović, Z. Development of Risk Quantification Models in Road Infrastructure Projects. Sustainability 2024, 16, 7694. [Google Scholar] [CrossRef]

- Sharma, S.K.; Kumar, A. Ride performance of a high-speed rail vehicle using controlled semi active suspension system. Smart Mater. Struct. 2017, 26, 055026. [Google Scholar] [CrossRef]

- Gallyamov, D.I.; Ovchinnikov, D.V. Effects of rail canting on the contact stress and pressure in the wheel–rail system. Russ. Railw. Sci. J. 2023, 82, 9–17. [Google Scholar] [CrossRef]

- Goodbrake, С.; Motiwale, S.; Sacks, M.S. A neural network finite element method for contact mechanics. Comput. Methods Appl. Mech. Eng. 2024, 419, 116671. [Google Scholar] [CrossRef]

- Tanzim, N.; Nbhan, S.; Liew, T.H.; Chin, C.W.; Yousif, B.F. ANN for Tribological Applications. In Proceedings of the ASME International Mechanical Engineering Congress and Exposition, Lake Buena Vista, FL, USA, 13–19 November 2009; Paper No 10161. pp. 13–16. [Google Scholar] [CrossRef]

| 0 | 0.2 | 0.4 | 0.6 | 0.8 | 1.0 | |

| 0.785 | 0.745 | 0.665 | 0.590 | 0.530 | 0.480 | |

| 0.300 | 0.322 | 0.325 | 0.323 | 0.317 | 0.310 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kosarchuk, V.; Tverdomed, V.; Bambura, O. Calculation Schemes for Determining Contact Stresses in Railway Rails. Appl. Sci. 2025, 15, 2970. https://doi.org/10.3390/app15062970

Kosarchuk V, Tverdomed V, Bambura O. Calculation Schemes for Determining Contact Stresses in Railway Rails. Applied Sciences. 2025; 15(6):2970. https://doi.org/10.3390/app15062970

Chicago/Turabian StyleKosarchuk, Valerii, Volodymyr Tverdomed, and Olha Bambura. 2025. "Calculation Schemes for Determining Contact Stresses in Railway Rails" Applied Sciences 15, no. 6: 2970. https://doi.org/10.3390/app15062970

APA StyleKosarchuk, V., Tverdomed, V., & Bambura, O. (2025). Calculation Schemes for Determining Contact Stresses in Railway Rails. Applied Sciences, 15(6), 2970. https://doi.org/10.3390/app15062970