AI-Driven Predictive Maintenance in Mining: A Systematic Literature Review on Fault Detection, Digital Twins, and Intelligent Asset Management

Abstract

1. Introduction

- (1)

- Which AI- and physics-based methodologies are most effective for early fault detection in mining environments, and how do they compare in terms of performance and reliability?

- (2)

- How do digital twins and advanced monitoring strategies (e.g., IoT and Big Data) enhance the efficiency and robustness of predictive maintenance?

- (3)

- How are predictive maintenance methods being applied to improve energy efficiency and sustainability in industrial mining processes?

- (4)

- What barriers, challenges, and opportunities influence the adoption of predictive monitoring systems—particularly regarding data quality, scalability, and industrial deployment?

- (5)

- Which research gaps persist in the use of hybrid (physics- and data-driven) models and explainable AI within Mining 4.0, and how can these gaps be addressed to foster broader innovation and adoption?

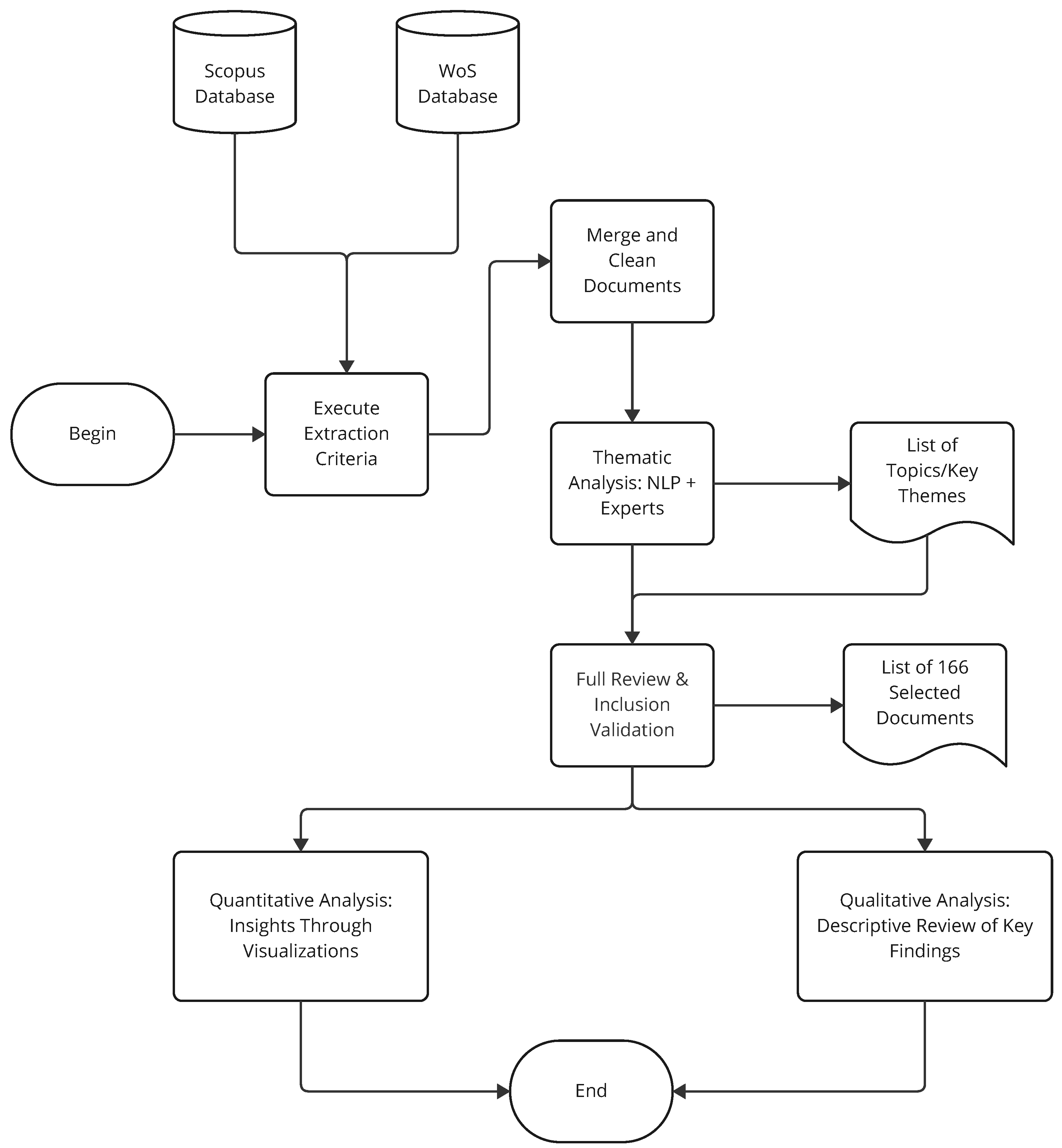

2. Systematic Analysis Methodology

- Search Terms: The query used was:

- Document Types: The search included various types of indexed publications, such as research articles, reviews, and conference proceedings.

- Scopus: Selected for its extensive coverage of high-quality scientific literature across diverse disciplines.

- Web of Science (WoS): Chosen due to its credibility and focus on engineering and technical research.

- Inclusion Criteria:

- –

- Articles published between 2015 and 2025.

- –

- Studies written in English.

- –

- Publications in journals classified as Q1 or Q2 in the Scopus or WoS indices, as well as in peer-reviewed conference proceedings indexed in Scopus or WoS.

- –

- At least five verified citations.

- –

- Direct applications in industrial equipment focused on mining or related industries.

- Exclusion Criteria:

- –

- Articles with restricted access without verification possibility.

- –

- Publications in languages other than English.

- –

- Duplicate documents across the consulted databases.

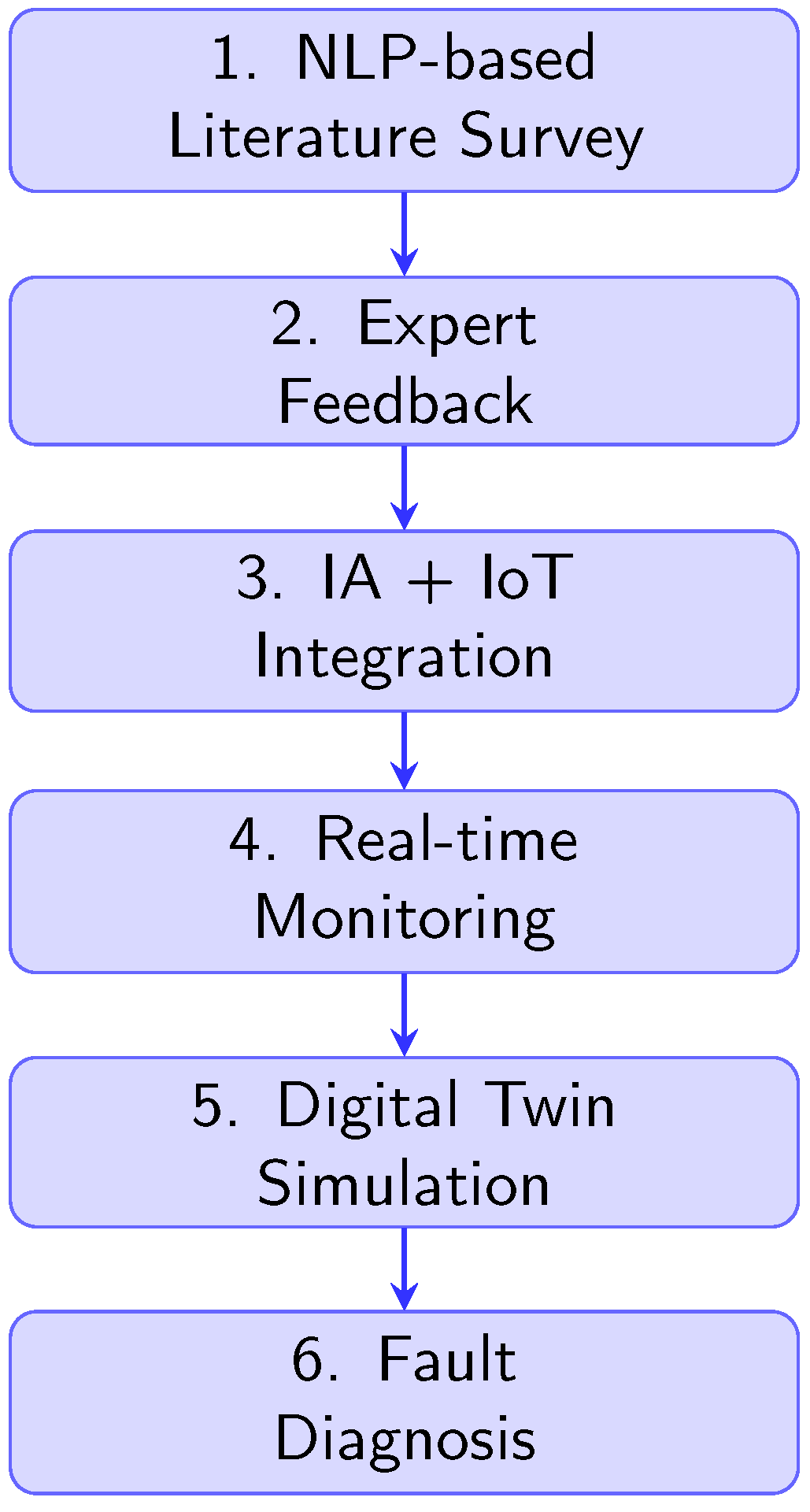

- Document Corpus: The process begins with a consolidated set of documents, selected after applying inclusion and exclusion criteria. This ensures that only relevant and high-quality studies are included for analysis.

- NLP Pre-processing: A systematic text-cleaning process is applied, including tokenization, stop-word removal, and lexical normalization. These steps prepare the textual data for subsequent analytical processes.

- NLP Topic Modeling and Term Extraction: Statistical and machine learning-based approaches are used to detect recurring themes and key terms within the document set.

- Expert Validation and Feedback: Domain experts review the preliminary themes, providing insights to refine and correct any inconsistencies.

- Integration of Experts’ Insights (Hybrid Review): Expert feedback is integrated into the thematic classification, ensuring a balance between automated processing and domain relevance.

- Refined Themes and Categorization: Based on expert contributions, topics are relabeled and organized into a structured framework.

- Final Thematic Structure: The process concludes with a validated set of thematic categories that serve as the foundation for subsequent quantitative and qualitative analysis.

PRISMA-Compliant Systematic Review with LLM-Enhanced Methodology

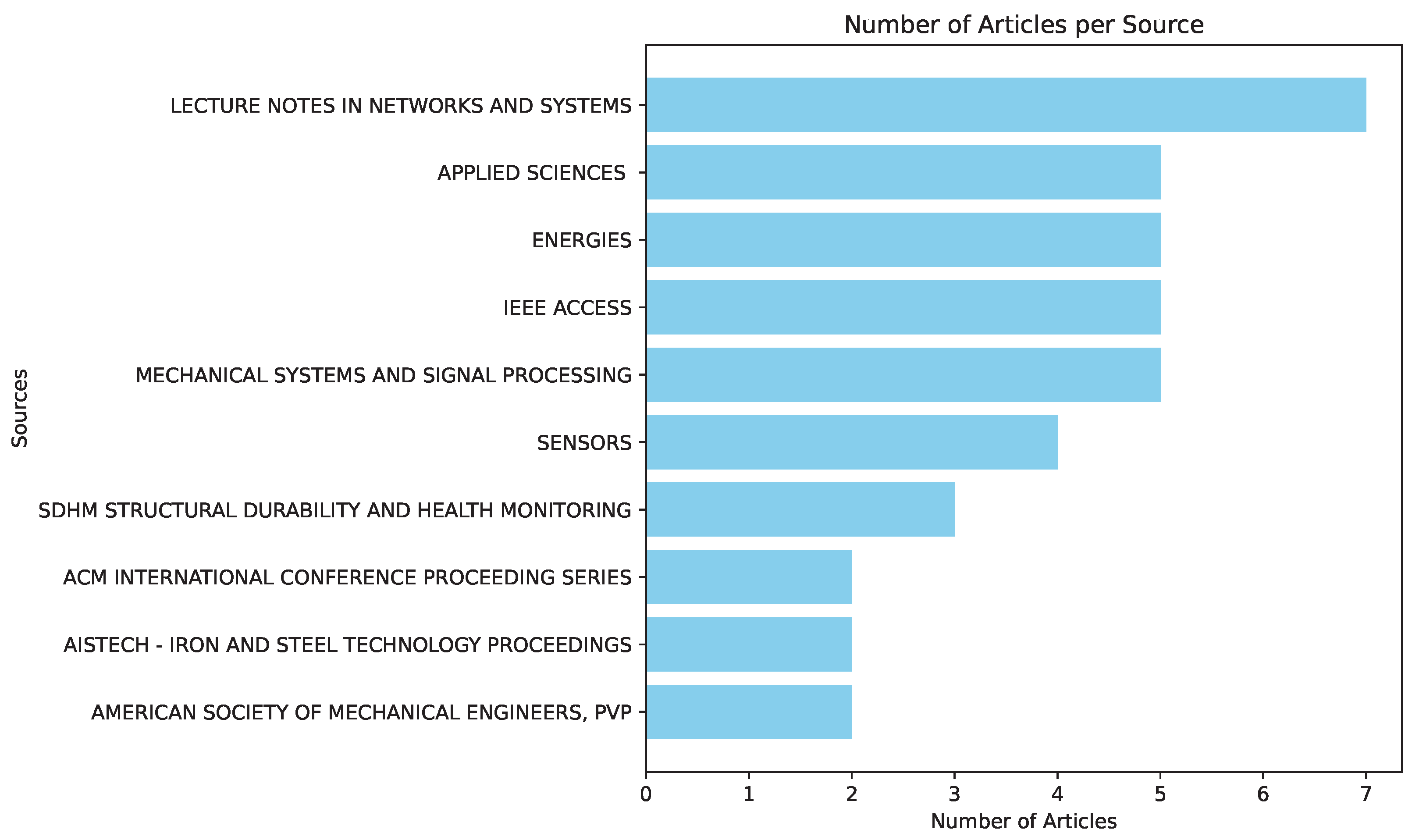

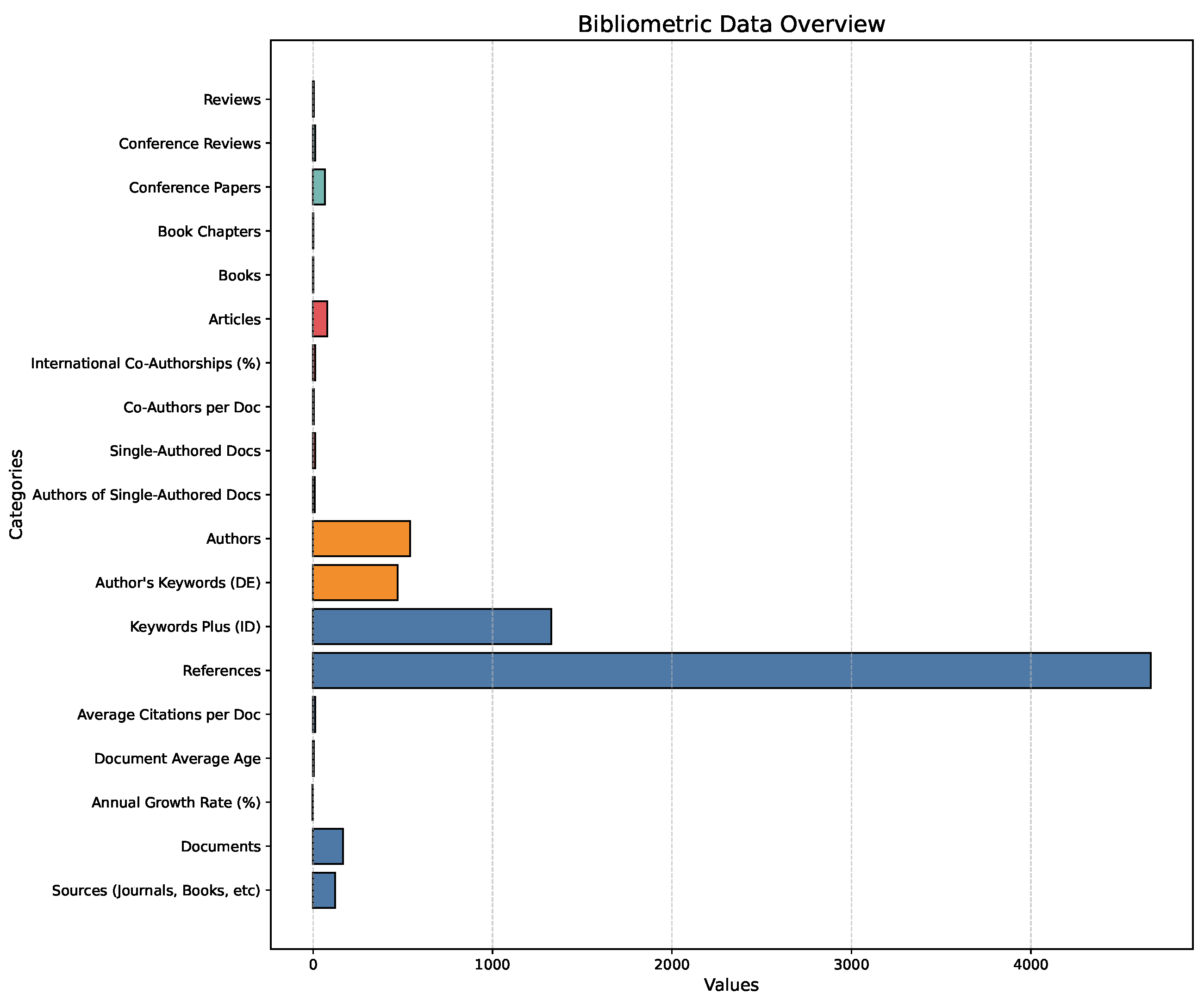

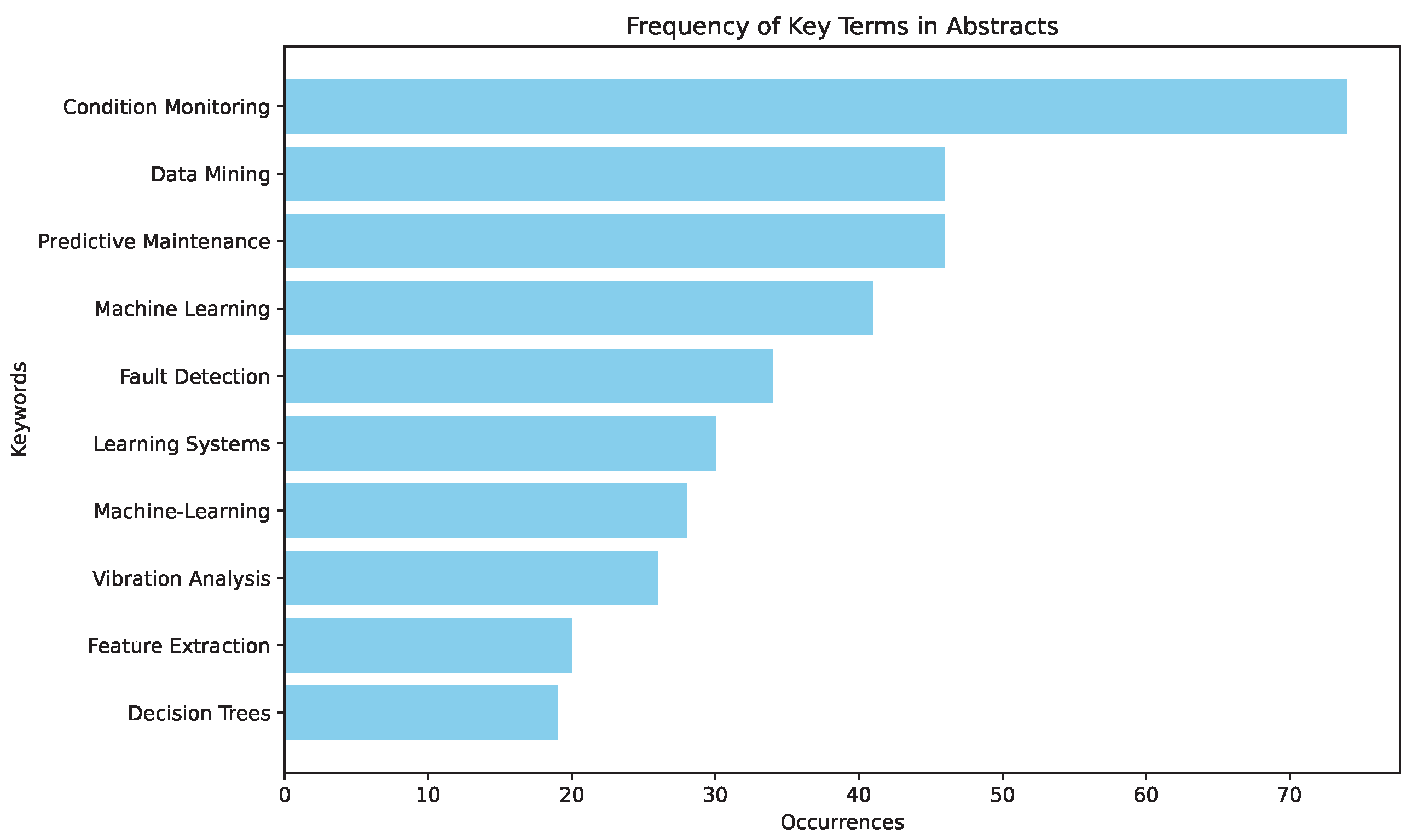

3. Quantitative Analysis: Overview of Selected Studies

4. Hybrid Thematic Analysis: Key Findings from NLP and Expert Review

- Sectoral Applications and Monitoring of Critical Failures: Studies targeting early detection and forecasting of failures in high-impact industrial systems, such as mining, energy, and manufacturing, featuring advances in vibration analysis, real-time diagnostics, and IoT integration [4,6,54,55,56,57].

- Foundational Technologies and Advanced Methodologies: Developments in AI algorithms (deep learning, optimization, LLMs), Big Data applications in industry, and the integration of chaotic systems. The role of sensors and data acquisition platforms is also highlighted, enabling more accurate and efficient predictive maintenance [10,11,12,13,15,32,33,34,62].

4.1. Energy Efficiency in Industrial Processes

4.2. Sectoral Applications and Monitoring of Critical Failures

4.2.1. Predictive Monitoring of Failures in Critical Systems

4.2.2. Advancements in Vibration Analysis for Predictive Maintenance

4.2.3. Integration of IoT and Machine Learning in Asset Monitoring

4.3. Digital Twins: Transforming Predictive Maintenance and Asset Management

4.3.1. Digital Twins and Predictive Models in Asset Management

4.3.2. Digital Twins and Their Application in Predictive Maintenance

4.4. Foundational Technologies and Advanced Methodologies

4.4.1. Advanced Algorithms in Predictive Maintenance

4.4.2. Optimization of Algorithms for Predictive Monitoring

4.4.3. IoT Integration in Predictive Monitoring Systems

4.4.4. Sensors and Their Role in Data Acquisition for Predictive Maintenance

5. Discussion

5.1. Summarized Tables on AI Techniques and Performance

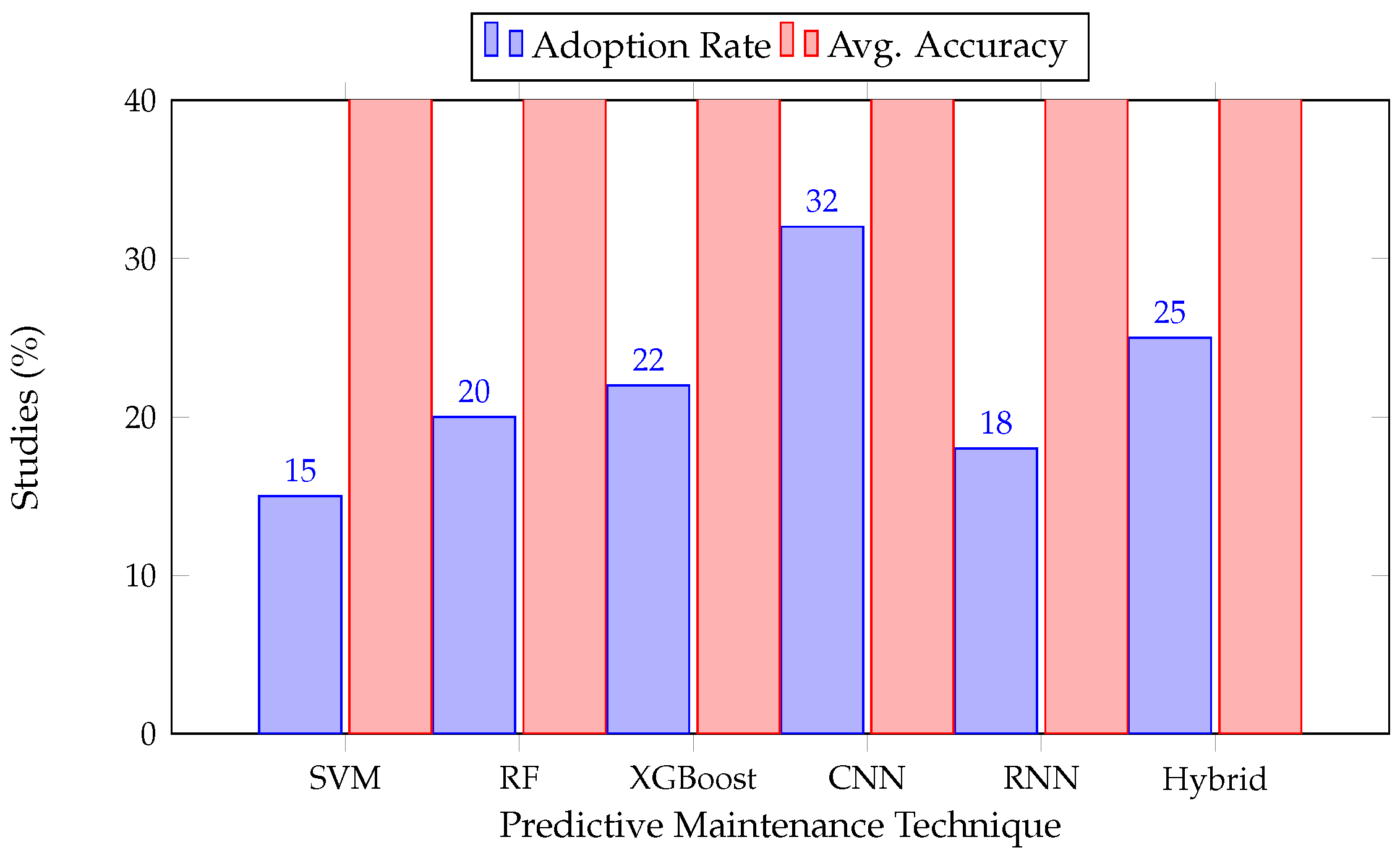

- ML techniques with ensemble strategies (e.g., XGBoost, RF) frequently exhibit strong performance across a variety of data modalities.

Cited Literature on Techniques and Results

5.2. Graphical Comparisons of Predictive Maintenance Approaches

5.3. Infographic Solutions for Procedural Overviews

References and Use Cases

5.4. Anomaly Methods and Comparative

- Data dependence and sensor requirements;

- Computational overhead and real-time feasibility;

- Model interpretability and trust;

- Cost of field deployment and skill level needed;

- Adaptability to different environmental constraints.

6. Conclusions and Future Perspectives

Future Research Directions

- Holistic Digital Twin Solutions: Enriching digital twins with advanced physics-based and AI-driven co-simulations, targeting not just localized equipment but entire production chains (e.g., drill-and-blast, haulage, and processing) [40,41,80,85]. Refining these models with in situ sensor feedback can significantly enhance predictive accuracy for complex, large-scale mining processes.

- Robust Explainable AI Methods: Developing interpretable models to enhance human trust and operational decision-making, particularly for high-risk equipment failures that could compromise safety [32,34,38]. Implementing transparent algorithms can improve user acceptance and reduce errors in critical interventions.

- Adaptive Hybrid Approaches: Exploring how fractional-order controllers [86] and chaotic system dynamics [75,89,90] can enhance the predictive accuracy of machine learning under nonlinear and highly uncertain mining conditions [36,37,49]. Adaptive architectures, capable of incremental learning, are also vital for continuously evolving operational environments.

Funding

Acknowledgments

Conflicts of Interest

References

- Rahal, J.R.; Schwarz, A.; Sahelices, B.; Weis, R.; Antón, S.D. The asset administration shell as enabler for predictive maintenance: A review. J. Intell. Manuf. 2025, 36, 19–33. [Google Scholar] [CrossRef]

- Gunckel, P.; Lobos, G.; Rodríguez, F.; Bustos, R.; Godoy, D. Methodology proposal for the development of failure prediction models applied to conveyor belts of mining material using machine learning. Reliab. Eng. Syst. Saf. 2025, 256, 110709. [Google Scholar] [CrossRef]

- Sahoo, A.; Tripathy, D. Applications of AI and machine learning in mining: Digitization and future directions. Saf. Extrem. Environ. 2025, 7, 4. [Google Scholar] [CrossRef]

- Singh, S. Machine learning: Approaches to predicting reliability and developing maintenance strategies. Mater. Res. Proc. 2023, 27, 308. [Google Scholar] [CrossRef]

- Bauler, V.; Cordioli, J.; Silva, D.; Braga, D. Bearing Fault Detection in Conveyor Belt Drums Using Machine Learning. In Proceedings of the Annual Conference of the Prognostics and Health Management Society, PHM, Nashville, TN, USA, 9–10 November 2024. [Google Scholar] [CrossRef]

- Rafezi, H.; Hassani, F. Drill bit wear monitoring and failure prediction for mining automation. Int. J. Min. Sci. Technol. 2023, 33, 289–296. [Google Scholar] [CrossRef]

- Sandhu, H.K.; Bodda, S.S.; Yan, E.; Sabharwall, P.; Gupta, A. A comparative study on deep learning models for condition monitoring of advanced reactor piping systems. Mech. Syst. Signal Process. 2024, 209, 111091. [Google Scholar] [CrossRef]

- Ullah, S.; Li, S.; Khan, K.; Khan, S.; Khan, I.; Eldin, S.M. An Investigation of Exhaust Gas Temperature of Aircraft Engine Using LSTM. IEEE Access 2023, 11, 5168–5177. [Google Scholar] [CrossRef]

- Mallioris, P.; Kokkas, G.; Styliadis-Heinz, A.; Margaritis, I.; Stergiopoulos, F.; Bechtsis, D. Conceptual Framework of Predictive Maintenance in a Canning Industry. In Proceedings of the HAICTA, Athens, Greece, 22–25 September 2022; pp. 253–259. [Google Scholar]

- Babu, E.; Francis, J.; Thomas, E.; Cherian, R.; Sunandhan, S.S. Review on Various Signal Processing Techniques for Predictive Maintenance. In Proceedings of the 2022 2nd International Conference on Power Electronics and IoT Applications in Renewable Energy and Its Control, PARC 2022, Mathura, India, 21–22 January 2022. [Google Scholar] [CrossRef]

- Dey, S.; Salim, O.; Masoumi, H.; Karmakar, N.C. A Novel UHF RFID Sensor Based Crack Detection Technique for Coal Mining Conveyor Belt. IEEE J. Radio Freq. Identif. 2022, 6, 19–30. [Google Scholar] [CrossRef]

- Stephen, C.; Guguloth, V.; Sivasailam, K.; Gu, Y.; Parmar, R.; Banerjee, C. Prediction of cavitation using machine learning techniques on centrifugal pump. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2024. [Google Scholar] [CrossRef]

- Kurundkar, S.; Andhale, A.; Chaudhari, R.; Datir, S.; Harak, N.; Hiwrale, K. Smart Helmet and Health Monitoring Kit for Mining Workers. In Proceedings of the 2023 2nd International Conference on Futuristic Technologies, INCOFT 2023, Karnataka, India, 24–26 November 2023. [Google Scholar] [CrossRef]

- Atmaja, B.T.; Ihsannur, H.; Arifianto, D. Lab-Scale Vibration Analysis Dataset and Baseline Methods for Machinery Fault Diagnosis with Machine Learning. J. Vib. Eng. Technol. 2024, 12, 1991–2001. [Google Scholar] [CrossRef]

- Leon-Medina, J.X.; Parés, N.; Anaya, M.; Tibaduiza, D.A.; Pozo, F. Ensemble of feature extraction methods to improve the structural damage classification in a wind turbine foundation. In Bulletin of the Polish Academy of Sciences: Technical Sciences; Polish Academy of Sciences: Olstyn, Poland, 2023. [Google Scholar] [CrossRef]

- Hiwase, S.D.; Jagtap, P. Predictive Maintenance of Automotive Component Using Digital Twin Model; Technical Report; SAE Technical Paper: Warrendale, PA, USA, 2022. [Google Scholar] [CrossRef]

- Kapuria, A.; Cole, D.G. Integrating Survival Analysis with Bayesian Statistics to Forecast the Remaining Useful Life of a Centrifugal Pump Conditional to Multiple Fault Types. Energies 2023, 16, 3707. [Google Scholar] [CrossRef]

- Praveen Kumar, B.V.; Sivalakshmi, P.; Muthumarilakshmi, S.; Suresh, G.; Vijayalakshmi, K.; Srinivasan, C. Real-Time Monitoring of Electrical Faults in Industrial Machinery Using IoT and Random Forest Regression. In Proceedings of the 2nd International Conference on Intelligent Cyber Physical Systems and Internet of Things, ICoICI 2024-Proceedings, Coimbatore, India, 28–30 August 2024. [Google Scholar] [CrossRef]

- Jayaswal, B.; Agrawal, S.S.; Jain, S.; Singh, R.; Kashyap, K.; Chauhan, P. Predictive maintenance system for rotating machinery onboard ships for detecting performance degradation. Scalable Comput. 2023, 24, 1231–1240. [Google Scholar] [CrossRef]

- Araquistain, I.; Garcia, D.; Zamora, D.; Armijo, A.; Fernández-Navamuel, A.; Jimenez, J.C.; Beristain, U. Predictive-Cognitive Maintenance for Advanced Integrated railway Management. In Proceedings of the 11th European Workshop on Structural Health Monitoring, EWSHM 2024, Potsdam, Germany, 10–13 June 2024. [Google Scholar] [CrossRef]

- Ahmed, M.S.; Al Bloushi, M.A.; Ali, A. Case Study: Application of Wireless Condition Based Monitoring by Applying Machine Learning Models. In Proceedings of the Society of Petroleum Engineers-ADIPEC 2022, Abu Dhabi, United Arab Emirates, 31 October–3 November 2022. [Google Scholar] [CrossRef]

- Chuang, S.M.; Chen, C.S.; Wu, E.H. Implementation of Non-intrusive Intelligent Sensor System and 5G Edge Computing Gateway for Smart Factory. In Proceedings of the 4th IEEE Eurasia Conference on IoT, Communication and Engineering 2022, ECICE 2022, Yunlin, Taiwan, 28–30 October 2022. [Google Scholar] [CrossRef]

- Salem, K.; AbdelGwad, E.; Kouta, H. Predicting Forced Blower Failures Using Machine Learning Algorithms and Vibration Data for Effective Maintenance Strategies. J. Fail. Anal. Prev. 2023, 23, 2191–2203. [Google Scholar] [CrossRef]

- Harsh, T.; Kumar, T.; Mohanty, A.; Pandey, A. Predictive Maintenance of Industrial Machines using ML and IoT. In Proceedings of the 2024 3rd International Conference on Artificial Intelligence for Internet of Things, AIIoT 2024, Vellore, India, 3–4 May 2024. [Google Scholar] [CrossRef]

- Farooq, U.; Ademola, M.; Shaalan, A. Comparative Analysis of Machine Learning Models for Predictive Maintenance of Ball Bearing Systems. Electronics 2024, 13, 438. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, C.; Zhao, W.; Xie, Y.; Guo, D.; Zhang, D. Blade Crack Diagnosis Based on Blade Tip Timing and Convolution Neural Networks. Appl. Sci. 2023, 13, 1102. [Google Scholar] [CrossRef]

- de las Morenas, J.; Moya-Fernández, F.; López-Gómez, J.A. The Edge Application of Machine Learning Techniques for Fault Diagnosis in Electrical Machines. Sensors 2023, 23, 2649. [Google Scholar] [CrossRef]

- Tahkola, M.; Szucs, A.; Halme, J.; Zeb, A.; Keranen, J. A Novel Machine Learning-Based Approach for Induction Machine Fault Classifier Development—A Broken Rotor Bar Case Study. Energies 2022, 15, 3317. [Google Scholar] [CrossRef]

- Qin, B.; Wang, Y.; Liu, K.; Jiang, S.; Luo, Q. A novel online tool condition monitoring method for milling titanium alloy with consideration of tool wear law. Mech. Syst. Signal Process. 2023, 199, 110467. [Google Scholar] [CrossRef]

- Mahesh, T.R.; Chandrasekaran, S.; Ram, V.A.; Kumar, V.V.; Vivek, V.; Guluwadi, S. Data-Driven Intelligent Condition Adaptation of Feature Extraction for Bearing Fault Detection Using Deep Responsible Active Learning. IEEE Access 2024, 12, 45381–45397. [Google Scholar] [CrossRef]

- Ramu, K.; Narayanan, K. Predictive maintenance using RNN and LSTM models. J. Theor. Appl. Inf. Technol. 2023, 101. [Google Scholar]

- Wang, Y.; Wang, P. Explainable machine learning for motor fault diagnosis. In Proceedings of the 2023 IEEE International Instrumentation and Measurement Technology Conference (I2MTC), Kuala Lumpur, Malaysia, 22–25 May 2023. [Google Scholar] [CrossRef]

- Suawa, P.; Meisel, T.; Jongmanns, M.; Huebner, M.; Reichenbach, M. Modeling and Fault Detection of Brushless Direct Current Motor by Deep Learning Sensor Data Fusion. Sensors 2022, 22, 3516. [Google Scholar] [CrossRef]

- Ahmad, A.; Song, C.; Tan, R.; Gartler, M.; Klopper, B. Active Learning Application for Recognizing Steps in Chemical Batch Production. In Proceedings of the IEEE International Conference on Emerging Technologies and Factory Automation, ETFA, Stuttgart, Germany, 6–9 September 2022. [Google Scholar] [CrossRef]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 statement: An updated guideline for reporting systematic reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef] [PubMed]

- El Hami, A. Uncertainty and Artificial Intelligence: Additive Manufacturing, Vibratory Control, Agro-Composite, Mechatronics: Volume 1; John Wiley & Sons: Hoboken, NJ, USA, 2023. [Google Scholar] [CrossRef]

- de Paula Monteiro, R.; Lucatto Marra, A.; Vidoni, R.; Garcia, C.; Concli, F. A Hybrid Finite Element Method–Analytical Model for Classifying the Effects of Cracks on Gear Train Systems Using Artificial Neural Networks. Appl. Sci. 2022, 12, 7814. [Google Scholar] [CrossRef]

- Juodelyte, D.; Cheplygina, V.; Graversen, T.; Bonnet, P. Predicting Bearings Degradation Stages for Predictive Maintenance in the Pharmaceutical Industry. In Proceedings of the ACM SIGKDD International Conference on Knowledge Discovery and Data Mining, Washington DC, USA, 14–18 August 2022. [Google Scholar] [CrossRef]

- Aliyu, R.; Mokhtar, A.A.; Hussin, H. Classification of Pump Failure Using a Decision Tree Technique. In Lecture Notes in Mechanical Engineering; Springer Nature: Singapore, 2024. [Google Scholar] [CrossRef]

- Rosati, R.; Romeo, L.; Cecchini, G.; Tonetto, F.; Viti, P.; Mancini, A.; Frontoni, E. From knowledge-based to big data analytic model: A novel IoT and machine learning based decision support system for predictive maintenance in Industry 4.0. J. Intell. Manuf. 2023, 34, 107–121. [Google Scholar] [CrossRef]

- Banyay, G.A.; Palamara, M.J.; Smith, S.D. Coupling of neutron noise and dynamic finite element analyses to perform remote condition monitoring for reactor vessel internals. In Pressure Vessels and Piping Conference; American Society of Mechanical Engineers: New York, NY, USA, 2021. [Google Scholar] [CrossRef]

- Xu, Y.; Laima, S.; Li, H.; Li, N.; Jin, Y.; Han, F. Risk intelligence of infrastructures: A predictive maintenance approach. In Proceedings of the IABSE Conference Seoul 2020, Seoul, Republic of Korea, 9–10 November 2020; pp. 33–41. [Google Scholar] [CrossRef]

- Maurya, S.; Singh, V.; Verma, N.K.; Mechefske, C.K. Condition-Based Monitoring in Variable Machine Running Conditions Using Low-Level Knowledge Transfer with DNN. IEEE Trans. Autom. Sci. Eng. 2021, 18, 1983–1997. [Google Scholar] [CrossRef]

- Verma, J.G.; Patel, S.; Kankar, P. Fault diagnosis of gearbox based on ITD-tunable Q-factor wavelet transform. Indian J. Pure Appl. Phys. 2021, 59, 223–228. [Google Scholar]

- Davis, J.; Lauden, A.; Li, B.; Stohl, K. How to eliminate missed problems and false alarms using machine learning for vibration monitoring and analysis. In Proceedings of the AISTech-Iron and Steel Technology Conference Proceedings, Nashville, TN, USA, 29 June–1 July 2021. [Google Scholar] [CrossRef]

- Trizoglou, P.; Liu, X.; Lin, Z. Fault detection by an ensemble framework of Extreme Gradient Boosting (XGBoost) in the operation of offshore wind turbines. Renew. Energy 2021, 179, 945–962. [Google Scholar] [CrossRef]

- Khorsheed, R.M.; Beyca, O.F. An integrated machine learning: Utility theory framework for real-time predictive maintenance in pumping systems. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2021, 235, 887–901. [Google Scholar] [CrossRef]

- Rabia, H. Predictive Asset Analytics: The Future of Maintenance. In Proceedings of the Society of Petroleum Engineers-Abu Dhabi International Petroleum Exhibition and Conference, ADIP 2021, Abu Dhabi, United Arab Emirates, 15–18 November 2021. [Google Scholar] [CrossRef]

- Aqueveque, P.; Radrigan, L.; Pastene, F.; Morales, A.S.; Guerra, E. Data-Driven Condition Monitoring of Mining Mobile Machinery in Non-Stationary Operations Using Wireless Accelerometer Sensor Modules. IEEE Access 2021, 9, 17365–17381. [Google Scholar] [CrossRef]

- Sandhu, H.K.; Bodda, S.S.; Gupta, A. Deep learning framework for post-hazard condition monitoring of nuclear safety systems. Struct. Health Monit. 2021. [Google Scholar] [CrossRef]

- Binanzer, L.; Merkle, L.; Dazer, M.; Nicola, A. Pitting Detection for Prognostics and Health Management in Gearbox Applications. In Proceedings of the International Conference on Gears 2023 VDI Berichte, Munich Germany, 13–15 September 2023. [Google Scholar] [CrossRef]

- Alfeo, A.; Cimino, M.; Gagliardi, G. Automatic Feature Extraction for Bearings’ Degradation Assessment using Minimally Pre-processed Time series and Multi-modal Feature Learning. In Proceedings of the International Conference on Innovative Intelligent Industrial Production and Logistics, Valletta, Malta, 24–26 October 2022. [Google Scholar] [CrossRef]

- Velasquez, V.; Flores, W. Machine Learning Approach for Predictive Maintenance in Hydroelectric Power Plants. In Proceedings of the 2022 IEEE Biennial Congress of Argentina, ARGENCON 2022, San Juan, Argentina, 7–9 September 2022. [Google Scholar] [CrossRef]

- Shi, M.; Ding, C.; Que, H.; Wu, C.; Shi, J.; Shen, C.; Huang, W.; Zhu, Z. Multilayer-graph-embedded extreme learning machine for performance degradation prognosis of bearing. Meas. J. Int. Meas. Confed. 2023, 207, 112299. [Google Scholar] [CrossRef]

- Lang, X.; Nilsson, H.; Mao, W. A machine learning based analysis of bearing vibrations for predictive maintenance in a hydropower plant. In IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2024. [Google Scholar] [CrossRef]

- Jang, J.G.; Noh, C.M.; Kim, S.S.; Shin, S.C.; Lee, S.S.; Lee, J.C. Vibration data feature extraction and deep learning-based preprocessing method for highly accurate motor fault diagnosis. J. Comput. Des. Eng. 2023, 10, 204–220. [Google Scholar] [CrossRef]

- Nikfar, M.; Bitencourt, J.; Mykoniatis, K. A Two-Phase Machine Learning Approach for Predictive Maintenance of Low Voltage Industrial Motors. Procedia Comput. Sci. 2022, 200, 111–120. [Google Scholar] [CrossRef]

- Fu, X.; Han, J.; Castle, M.; Cao, K. Digital twin-driven vibration amplitude simulation for condition monitoring of axial blowers in blast furnace ironmaking. Syst. Sci. Control Eng. 2023, 11, 2152400. [Google Scholar] [CrossRef]

- Fahmi, A.T.W.K.; Reza Kashyzadeh, K.; Ghorbani, S. Advancements in Gas Turbine Fault Detection: A Machine Learning Approach Based on the Temporal Convolutional Network–Autoencoder Model. Appl. Sci. 2024, 14, 4551. [Google Scholar] [CrossRef]

- Lang, X.; Nilsson, H.; Mao, W. Analysis of hydropower plant guide bearing vibrations by machine learning based identification of steady operations. Renew. Energy 2024, 236, 121463. [Google Scholar] [CrossRef]

- Laña, I.; Bascoy, P.G.; Aranguren, A.; Gil, S.; Landa-Torres, I. Industrial Pump Condition Monitoring with Audio Samples: A Low-Rank Linear Autoencoder Feature Extraction Approach. In Proceedings of the 2024 IEEE International Conference on Omni-Layer Intelligent Systems, COINS 2024, London, UK, 29–31 July 2024. [Google Scholar] [CrossRef]

- Ou, T.; Chen, W. On accurate prediction of transfer chute wear using a digital wear sensor and discrete element modelling. Powder Technol. 2022, 407, 117680. [Google Scholar] [CrossRef]

- Vélez Sánchez, H.; Hurtado Cortés, L.L. Data Collection: Use and Transformation in Predictive Maintenance Models. In Lecture Notes in Networks and Systems; Springer: Cham, Switzerland, 2022. [Google Scholar] [CrossRef]

- Hajar, I.; Kassim, M.; Minhat, M.S.; Azmi, I.N. Optimal efficiency on nuclear reactor secondary cooling process using machine learning model. Int. J. Electr. Comput. Eng. 2024, 14, 6287–6299. [Google Scholar] [CrossRef]

- Colla, V.; Vannucci, M.; Mocci, C.; Giacomini, A.; Cestari, L.; Paluzzano, E. Machine learning applied to prediction of shape defects in round cross-section rolled bars. Metall. Ital. 2023, 114, 9–16. [Google Scholar]

- Das, A.; Agrawal, A.; Kundoliya, N.; Dutta, A.; Pal, S.K.; Kumar, R. Condition monitoring of industrial exhaust motor-fan assembly using statistical feature optimization with nature-inspired optimizers. In Proceedings of the 2024 IEEE 3rd International Conference on Control, Instrumentation, Energy and Communication, CIEC 2024-Proceedings, Kolkata, India, 25–27 January 2024; pp. 97–102. [Google Scholar] [CrossRef]

- Qureshi, U.; Rashid, A.; Altini, N.; Bevilacqua, V.; La Scala, M. Radiometric Infrared Thermography of Solar Photovoltaic Systems: An Explainable Predictive Maintenance Approach for Remote Aerial Diagnostic Monitoring. Smart Cities 2024, 7, 1261–1288. [Google Scholar] [CrossRef]

- Fera, F.; Spandonidis, C. A Fault Diagnosis Approach Utilizing Artificial Intelligence for Maritime Power Systems within an Integrated Digital Twin Framework. Appl. Sci. 2024, 14, 8107. [Google Scholar] [CrossRef]

- Kirankumar, M.V.; Kumari, P.; Raghavendra, B.K.; Vyankatesh, K.S. Fault Diagnosis in Belts Using Signal Processing Techniques and Machine Learning. Commun. Comput. Inf. Sci. 2025, 2231 CCIS, 128–144. [Google Scholar] [CrossRef]

- Huang, S.; Najibullah, M. Unbalance Monitoring of an Overhung Rotor Using a Physics-Based and Machine Learning Approach. In Proceedings of the 29th International Congress on Sound and Vibration, Prague, Czech Republic, 9 July 2023; pp. 9–13. [Google Scholar]

- Roy, S.; Tufail, S.; Tariq, M.; Sarwat, A. Photovoltaic Inverter Failure Mechanism Estimation Using Unsupervised Machine Learning and Reliability Assessment. IEEE Trans. Reliab. 2024, 73, 1418–1432. [Google Scholar] [CrossRef]

- Ravikumar, K.N.; Aralikatti, S.S.; Kumar, H.; Kumar, G.N.; Gangadharan, K.V. Fault diagnosis of antifriction bearing in internal combustion engine gearbox using data mining techniques. Int. J. Syst. Assur. Eng. Manag. 2022, 13, 1121–1134. [Google Scholar] [CrossRef]

- Wang, X.; Liu, Y.; Liang, X.; Zhang, C.; Yang, C.; Gui, W. Learning an Enhanced TCN-LSTM Network for Temperature Process Modeling in Rotary Kilns. IEEE Trans. Autom. Sci. Eng. 2024, 22, 3056–3067. [Google Scholar] [CrossRef]

- García Peyrano, O.; Vignolo, J.; Mayer, R.; Marticorena, M. Online Unbalance Detection and Diagnosis on Large Flexible Rotors by SVR and ANN trained by Dynamic Multibody Simulations. J. Dyn. Monit. Diagn. 2022, 1, 139–147. [Google Scholar] [CrossRef]

- Matouk, A.; Botros, M. Hidden chaotic attractors and self-excited chaotic attractors in a novel circuit system via Grünwald–Letnikov, Caputo-Fabrizio and Atangana-Baleanu fractional operators. Alex. Eng. J. 2025, 116, 525–534. [Google Scholar] [CrossRef]

- Cancemi, S.A.; Frano, R.L. Unsupervised neural network approach for identifying anomalous events in nuclear power plants. In Proceedings of the International Conference on Nuclear Engineering, Proceedings, ICONE, Kyoto, Japan, 21–26 May 2023. [Google Scholar]

- Yap, J.; Lim, M.; Salman, L.M. Improved versatility and robustness of bearing fault detection and diagnostic method for nuclear power plant. Nucl. Eng. Des. 2024, 428, 113474. [Google Scholar] [CrossRef]

- Cancemi, S.A.; Lo Frano, R. Anomalies Detection in Structures, System and Components for Supporting Nuclear Long Term Operation Program. In International Conference on Nuclear Engineering, Proceedings, ICONE; American Society of Mechanical Engineers: New York, NY, USA, 2022. [Google Scholar] [CrossRef]

- Wahid, A.; Breslin, J.G.; Intizar, M.A. Prediction of Machine Failure in Industry 4.0: A Hybrid CNN-LSTM Framework. Appl. Sci. 2022, 12, 4221. [Google Scholar] [CrossRef]

- Marti-Puig, P.; Touhami, I.A.; Perarnau, R.C.; Serra-Serra, M. Industrial AI in condition-based maintenance: A case study in wooden piece manufacturing. Comput. Ind. Eng. 2024, 188, 109907. [Google Scholar] [CrossRef]

- Lv, T.; Cen, Z.; Huang, X.; Cai, C.; Zeng, K.; Zhang, Y.; Chen, Z.; Tang, X. Review of Data-Driven Condition Monitoring and Fault Diagnosis Technologies for Submarine Cable. In Lecture Notes in Electrical Engineering; Springer: Singapore, 2025; Volume 1288 LNEE, pp. 597–610. [Google Scholar] [CrossRef]

- Dahal, S.P.; Dahal, M.; Silwal, B. Historical Data Based Monitoring of Hydro Generator Using Machine Learning. In Proceedings of the International Conference on Software, Knowledge Information, Industrial Management and Applications, SKIMA, Phnom Penh, Cambodia, 2–4 December 2022. [Google Scholar] [CrossRef]

- Li, X.; Dang, Y.; Zheng, W.; Shen, J. Research on Power Grid Information System Based on Artificial Intelligence-driven Automatic Fault Handling Decision Support. In Proceedings of the 2024 IEEE 4th International Conference on Electronic Technology, Communication and Information, ICETCI 2024, Changchun, China, 24–26 May 2024. [Google Scholar] [CrossRef]

- Don, M.; Wanasinghe, T.; Gosine, R.; Warrian, P. Digital Twins and Enabling Technology Applications in Mining: Research Trends, Opportunities, and Challenges. IEEE Access 2025, 13, 6945–6963. [Google Scholar]

- Srinivasan, B.; Srinivasan, V. A comparative study on AI/ML-based transient temperature predictions and real-time operational transient temperature data of coke drum. In Pressure Vessels and Piping Division (Publication) PVP; American Society of Mechanical Engineers: New York, NY, USA, 2023; Volume 7, p. v007t09a012. [Google Scholar] [CrossRef]

- Pazmiño, R.; Pavon, W.; Armstrong, M.; Simani, S. Performance Evaluation of Fractional Proportional–Integral–Derivative Controllers Tuned by Heuristic Algorithms for Nonlinear Interconnected Tanks. Algorithms 2024, 17, 306. [Google Scholar] [CrossRef]

- Senarathna, S.I.; Prasanshi, L.A.U.; Senanayake, S.D.W.; Wimalarathne, D.; Kumarawadu, S.; Logeeshan, V.; Wanigasekara, C. A Data-Driven Approach Based on Artificial Neural Networks for the Detection and Classification of Bearing Anomalies in Power Generation Plants. In Proceedings of the 2023 IEEE World AI IoT Congress, AIIoT 2023, Seattle, WA, USA, 7–10 June 2023; pp. 415–420. [Google Scholar] [CrossRef]

- Aqueveque, P.; Radrigan, L.; Morales, A.S.; Willenbrinck, E. Development of a Cyber-Physical System to Monitor Early Failures Detection in Vibrating Screens. IEEE Access 2021, 9, 145866–145885. [Google Scholar] [CrossRef]

- Demirkol, A.S.; Sahin, M.E.; Karakaya, B.; Ulutas, H.; Ascoli, A.; Tetzlaff, R. Real time hybrid medical image encryption algorithm combining memristor-based chaos with DNA coding. Chaos Solitons Fractals 2024, 183, 114923. [Google Scholar] [CrossRef]

- Lu, R.; Alexander, P.; Natiq, H.; Karthikeyan, A.; Jafari, S.; Petrzela, J. The Intricacies of Sprott-B System with Fractional-Order Derivatives: Dynamical Analysis, Synchronization, and Circuit Implementation. Entropy 2023, 25, 1352. [Google Scholar] [CrossRef]

| Item | Methodological Stage | Relevant PRISMA 2020 Items | Location in Manuscript |

|---|---|---|---|

| 1. | Define Research Scope: Establish research questions, objectives, and domain focus (fault detection, machine learning, predictive maintenance). | 3 (Rationale), 4 (Objectives) | Section 1 (Introduction) |

| 2. | Design Search Strategy: Use predefined search terms (“fault detection” AND “machine learning” AND “predictive maintenance”) and logical operators in Scopus and WoS. | 6 (Information sources), 7 (Search strategy) | Section 2 (Methodology) |

| 3. | Specify Data Sources: Select high-impact, multidisciplinary databases (Scopus, WoS). | 6 (Databases, Registers) | Sources of Information |

| 4. | Apply Inclusion Criteria: Years: 2015–2025; Language: English; Q1–Q2 journals or indexed conference proceedings; ≥5 citations; Direct mining/industrial applications. | 5 (Eligibility Criteria) | Inclusion Criteria |

| 5. | Apply Exclusion Criteria: Restricted-access articles; Non-English publications; Duplicate documents. | 5 (Eligibility Criteria) | Exclusion Criteria |

| 6. | Merge and Clean Documents: Consolidate, remove duplicates, and verify accessibility and relevance. | 8 (Selection process), 16a (Study selection) | Merge and Clean Documents |

| 7. | NLP-Assisted Thematic Analysis: Apply advanced NLP and bibliometric techniques to identify recurring terms, latent patterns, and emerging themes. | 9 (Data collection), 10b (Other variables), 13c (Presentation of results) | Thematic Analysis: NLP + Experts |

| 8. | Expert Validation: Combine automated clustering with domain-expert insights to refine and reclassify themes, ensuring contextual accuracy. | 9 (Data collection), 10b (Other variables) | Thematic Analysis: NLP + Experts |

| 9. | Hybrid Review and Final Inclusion: Adopt NLP-based ranking and manual expert screening for quality control and dataset alignment. | 8 (Selection process), 16a (Study selection) | Full Review and Inclusion Validation |

| 10. | Quantitative Synthesis: Use bibliometric methods (e.g., histograms, co-occurrence networks) to identify topic trends, collaborations, and research gaps. | 13 (Synthesis methods), 19 (Results of individual studies), 20 (Results of syntheses) | Quantitative Analysis: Insights Through Visualizations |

| 11. | Qualitative Synthesis: Perform a descriptive review of the most relevant documents, grouped by key themes (e.g., sustainability, IoT, digital twins). | 13 (Synthesis methods), 19 (Results of individual studies), 20 (Results of syntheses) | Qualitative Analysis: Descriptive Review of Key Findings |

| 12. | Flow Diagram: Illustrate the workflow (search → validation → synthesis) in a dedicated figure. | 16a (Study selection), 16b (Excluded studies) | Figure 1 and Figure 2 |

| 13. | Meta-Synthesis and Recommendations: Converge findings into practical recommendations, discussing future research directions and industrial relevance. | 23 (Discussion), 24 (Registration and protocol) | End of Qualitative Analysis + Section 5 (Discussion) |

| Thematic Category | Key Findings (NLP + Expert Review) | Relevance and Potential Impact |

|---|---|---|

| Energy Efficiency and Sustainability |

| |

| Sectoral Applications and Monitoring of Critical Failures |

| |

| Digital Twins and Asset Management |

| |

| Foundational Technologies and Advanced Methodologies |

|

| Dimension | Main Observations | Key Gaps and Potential Solutions |

|---|---|---|

| Energy Efficiency and Sustainability |

| |

| Sectorial Applications and Critical Failures |

| |

| Digital Twins and Asset Management | ||

| Fundamental Technologies and Advanced Methods |

| Process Stage | Key Sensors | Machine Learning Techniques |

|---|---|---|

| Crushing | Vibration sensors, hydraulic pressure sensors, motor temperature sensors, acoustic sensors, energy consumption meters [49,53,62]. | Predictive maintenance using Random Forest [53,62], fault detection via CNNs, anomaly detection with Autoencoders [11], regression models for energy consumption forecasting [49]. |

| Material Transport (Conveyors) | Belt misalignment sensors, load sensors (strain gauges), speed sensors, temperature sensors for rollers, optical particle size sensors [5,18,21,59]. | Support Vector Machines for belt wear classification [21], Reinforcement Learning for dynamic speed control [59], Bayesian Networks for failure prediction, and image-based particle size estimation with Deep Learning [18]. |

| Agglomeration | Moisture sensors, flow meters for reagents, viscosity sensors, temperature sensors [36,66]. | Decision Trees for reagent optimization, RNNs for moisture-level prediction [36], and Fuzzy Logic for viscosity control. |

| Leaching | pH sensors, ORP sensors, flow meters for leaching solutions, pressure sensors in drip irrigation, conductivity sensors, and online spectrophotometers for metal concentration [6,83]. | Gaussian Processes for real-time pH forecasting, Deep Reinforcement Learning for acid dosing optimization [6], PCA for metal concentration monitoring, and LSTM networks for solution flow control [83]. |

| Solvent Extraction (SX) | pH sensors, ORP sensors, conductivity meters, flow meters for organic/aqueous phases, level sensors in separation tanks [23,32,58]. | Gradient Boosting for phase separation efficiency prediction [58], Self-Organizing Maps for anomaly detection in organic extraction, and Reinforcement Learning for dynamic solvent flow optimization [32]. |

| Electrowinning (EW) | Voltage and current sensors, electrolyte temperature sensors, pH/ORP probes, level sensors in electrolytic cells, metal concentration sensors [38,41,44,51]. | Neural Networks for predicting optimal current density [51], Reinforcement Learning for voltage control [38], time-series forecasting with LSTMs for electrolyte monitoring [41], and Decision Trees for cathode quality classification [44]. |

| Algorithm | Representative Studies | Acc. (%) | F1 (%) | Inf. T. | Complexity | Common Mining Applications |

|---|---|---|---|---|---|---|

| Random Forest (RF) | Farooq et al. [25] Harsh et al. [24] | 90–96 | 88–95 | Medium | Moderate | Bearing fault detection, chute blockages |

| Support Vector Machine (SVM) | Rahal et al. [1] Singh et al. [4] | 88–93 | 85–92 | Low | Moderate | Conveyor belt wear classification, motor diagnostics |

| Extreme Gradient Boosting (XGBoost) | Bauler et al. [5] Salem et al. [23] | 92–97 | 90–96 | Medium | Moderate-High | Vibration-based anomaly detection, sub-level caving |

| Convolutional Neural Networks (CNN) | Mahesh et al. [30] Atmaja et al. [14] | 93–98 | 92–97 | Higher | High | Automated crack, gear fault identification |

| Recurrent Neural Networks (RNN/LSTM) | Ramu & Narayanan [31] Ullah et al. [8] | 90–95 | 88–94 | Higher | Moderate-High | Time-series data for ventilation, mill loads |

| Autoencoders (AE/TCN-AE) | Qureshi et al. [67] Fahmi et al. [59] | 91–96 | 88–95 | Medium | Moderate | Early fault detection, acoustic sensor data |

| Hybrid Physics-based + ML | Lang et al. [55] Huang & Najibullah [70] | 85–93 | 80–90 | Varies | Moderate-High | Fluid–structure interactions, rotor unbalance |

| Model/Approach | Data Needs | Computational Load | Interpretability/Cost |

|---|---|---|---|

| Method A (Shallow ML) | Low to Medium | Moderate (edge-friendly) | Medium interpretability/Low cost |

| Method B (Deep Neural) | High | High GPU/Cloud | Lower interpretability/Higher cost |

| Method C (Hybrid Domain + ML) | Medium | Varies | Potentially high interpretability/Medium cost |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rojas, L.; Peña, Á.; Garcia, J. AI-Driven Predictive Maintenance in Mining: A Systematic Literature Review on Fault Detection, Digital Twins, and Intelligent Asset Management. Appl. Sci. 2025, 15, 3337. https://doi.org/10.3390/app15063337

Rojas L, Peña Á, Garcia J. AI-Driven Predictive Maintenance in Mining: A Systematic Literature Review on Fault Detection, Digital Twins, and Intelligent Asset Management. Applied Sciences. 2025; 15(6):3337. https://doi.org/10.3390/app15063337

Chicago/Turabian StyleRojas, Luis, Álvaro Peña, and José Garcia. 2025. "AI-Driven Predictive Maintenance in Mining: A Systematic Literature Review on Fault Detection, Digital Twins, and Intelligent Asset Management" Applied Sciences 15, no. 6: 3337. https://doi.org/10.3390/app15063337

APA StyleRojas, L., Peña, Á., & Garcia, J. (2025). AI-Driven Predictive Maintenance in Mining: A Systematic Literature Review on Fault Detection, Digital Twins, and Intelligent Asset Management. Applied Sciences, 15(6), 3337. https://doi.org/10.3390/app15063337