Municipal Sewage Sludge Disposal in the Republic of Poland

Abstract

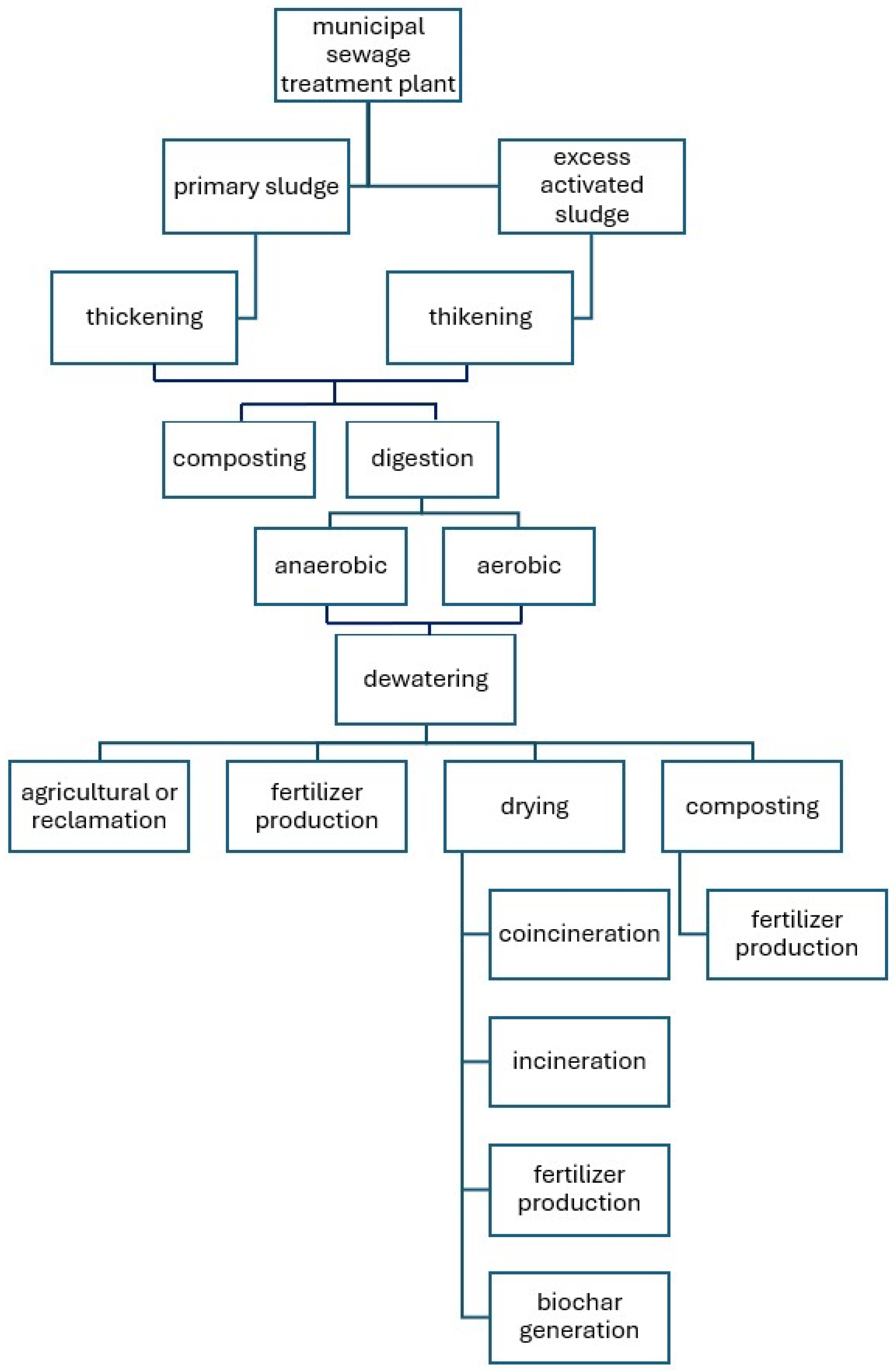

1. Introduction

- -

- To reduce the volume of sludge (removing water from it)—thickening, dewatering and drying;

- -

- To stabilize sludge (limiting its putrefaction, eliminating unpleasant odors, and reducing the content of organic substances);

- -

- Hygienization of sludge (covering processes that remove pathogenic organisms from the sludge and obtain a sanitary-safe product);

- -

- Preparation of sludge for its final form of management or disposal.

- -

- The amount of waste and the size of the municipal sewage treatment plant;

- -

- Sewage treatment technology;

- -

- Type of catchment area (city, commune, village);

- -

- The size of the catchment area;

- -

- The characteristics of the catchment area—presence of industrial plants and type of sewage system in the catchment area;

- -

- Quantitative and qualitative balance of treated sewage and generated sewage sludge;

- -

- Fuel properties of sewage sludge;

- -

- Flexibility of solutions, degree of automation;

- -

- Soil quality, and the height of groundwater level;

- -

- Availability of agricultural land and crop structure;

- -

- The presence of degraded areas;

- -

- The presence of protected areas;

- -

- The presence of flood areas;

- -

- Methods of disposal and utilization of municipal waste in the catchment area (composting plant, incinerator);

- -

- The presence of plants in the catchment area where the sewage sludge co-incineration process can take place (cement plant, CHP plant);

- -

- Investment costs;

- -

- Operating costs.

2. Methodology

3. Legal Aspects of Sludge Management in the Republic of Poland

- -

- Council Directive of 12 June 1986 on the protection of the environment, particularly the soil, when sewage sludge is used in agriculture—86/278/EEC [24].

- -

- Council Directive of 21 May 1991 concerning urban wastewater treatment—requiring monitoring and reporting of urban wastewater treatment and final disposal of urban sewage sludge for agglomerations. Article 14 of this Directive states that sewage sludge must be reused [25].

- -

- Directive (EU) 2024/3019 of the European Parliament and of the Council of 27 November 2024 concerning urban wastewater treatment [26]—Article 20 “Sludge and resource recovery” refers to encouraging the recovery of valuable resources and introducing the necessary measures that sludge management conforms to the waste hierarchy provided for in Article 4 of Directive 2008/98/EC [27]. Such sludge management shall maximize prevention, prepare for reuse, recycling, and other recovery of resources, in particular, phosphorus and nitrogen, and minimize the adverse effects on the environment and human health.

- -

- Council Directive 1999/31/EC of 26 April 1999 on the landfill of waste [28].

- -

- Directive 2008/98/EC of The European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives which regulate the recycling of waste, including sewage sludge. According to this Directive, sewage sludge, defined as waste, is subject to the procedure assigned to waste treatment [27].

- (1)

- in agriculture, which is understood as the cultivation of all agricultural products introduced into trade, including crops intended for the production of feed,

- (2)

- for the cultivation of plants intended for the production of compost,

- (3)

- for the cultivation of plants not intended for consumption and for the production of feed,

- (4)

- for the recultivation of areas, including land for agricultural purposes,

- (5)

- when adapting land to specific needs resulting from waste management plans, local spatial development plans, or decisions on development conditions and land development”.

- -

- Regulation of the Minister of the Environment of 11 May 2015 on the recovery of waste outside installations and facilities—Journal of Laws 2015, item 796 [29]. The regulation specifies the types of waste and the conditions for their recovery in the recovery processes R3—Recycling or reclamation of organic substances which are not used as solvents (including composting and other biological transformation processes)—in Annex No. 1 to the Act of 14 December 2012 on Waste, outside installations, or facilities.

- -

- Regulation of the Minister of the Environment of 20 January 2015 on the recovery process R10—Surface treatment with agricultural or environmental benefits—Journal of Laws 2015, item 132 [30]. The regulation specifies the conditions that must be met for the R10 process.

- -

- Regulation of the Minister of the Environment of 6 February 2015 on municipal sewage sludge—Journal of Laws 2015, item 257 [31]. The implementation of regulations related to the R10 process regulates in detail the conditions for the use of municipal sewage sludge. It specifies the conditions that must be met for the reclamation or agricultural use of municipal sewage sludge. The provisions limit the loads on sewage sludge and soils fertilized with sludge by specifying permissible concentrations of heavy metals. It also specifies the doses, scope, frequency, and reference methods of testing municipal sewage sludge and the land on which it is to be used.

- -

- Regulation of the Minister of Agriculture and Rural Development of 9 August 2024, on the implementation of certain provisions of the Act on Fertilizers and Fertilization—Journal of Laws 2024, item 1261 [32].

- -

- Act of 10 July 2007 on fertilizers and fertilization—Journal of Laws 2007, item 1033, as amended [33].

- -

- Regulation of the Minister of Development of 21 January 2016 on the requirements for conducting the process of thermal treatment of waste and methods of handling waste generated as a result of this process—Journal of Laws 2016, item 108 [34]. The regulation specifies the requirements for conducting the process of thermal treatment of waste and methods of handling waste generated as a result of the process.

- -

- Regulation of the Minister of Climate of 24 September 2020 on emission standards for certain types of installations, fuel incineration sources, and waste incineration or facilities—Journal of Laws of 2020, item 1860 [35].

- -

- Regulation of the Minister of the Environment of 6 June 2016 on the technical conditions for qualifying part of the energy recovered from the thermal treatment of waste—Journal of Laws 2016, item 847 [36].

- -

- Act of 20 February 2015 on renewable energy sources—Journal of Laws U. 2015, item 478, as amended [37].

- -

- Act of 27 April 2001—Environmental Protection Law [38].

- -

- Act of 20 July 2017 on Water Law—Journal of Laws, 2017, item 1566 [39].

4. Assumptions of the National Waste Management Plan

- (1)

- “Complete cessation of municipal sewage sludge storage;

- (2)

- Increasing the amount of municipal sewage sludge processed before being released into the environment;

- (3)

- Increasing the amount of municipal sewage sludge subjected to thermal processing;

- (4)

- Striving to maximize the degree of utilization of nutrients contained in sludge while meeting all requirements regarding sanitary, chemical, and environmental safety, with particular emphasis on the organic carbon contained in sludge and the ability of sludge to increase carbon dioxide sequestration in soils;

- (5)

- Reducing the amount of sewage sludge constituting waste generated in municipal sewage treatment plants, taking into account the waste management hierarchy;

- (6)

- Striving to limit the production of municipal sewage sludge constituting waste, which, owing to its quality, creates problems with its management via regulations”.

- (1)

- Prevent the formation of municipal sewage sludge;

- (2)

- Recycling municipal sewage sludge—organic recycling, including composting municipal sewage sludge with other waste to obtain material after the composting process is used for fertilizer purposes and mineral recycling with phosphorus recovery or in cement plants;

- (3)

- Use methods for the recovery of municipal sewage sludge (directly on the ground after meeting the conditions specified in the regulations; recovery, including recovery in composting plants, biogas plants, or cement plants), including energy recovery—for example, the use of sludge as biomass, which means incineration or recovery outside installations;

- (4)

- Disposal of municipal sewage sludge—in this process, sludge may be thermally transformed in waste incineration plants or co-incineration plants without energy recovery or stored after processing if it meets the requirements specified in legal regulations.

5. Methods of Disposal of Sewage Sludge

5.1. Agriculture

- (1)

- “The content of heavy metals in the sludge does not exceed the amounts specified in Annex No. 1;

- (2)

- In the case of using this sludge in agriculture and for land reclamation for agricultural purposes, no bacteria of the Salmonella genus were isolated from a representative sample of sludge weighing 100 g obtained in § 5;

- (3)

- The total number of live eggs of the intestinal parasites Ascaris sp., Trichuris sp., and Toxocara sp. in 1 kg of total solids, hereafter referred to as “TS.” of sludge intended for research use:

- In agriculture and for land reclamation for agricultural purposes is 0;

- For land reclamation is no more than 300;

- For adapting land to specific needs resulting from waste management plans; spatial development plans, or decisions on the conditions of development and land development is no more than 300;

- For growing plants intended for compost production is no more than 300;

- For growing plants not intended for consumption and the production of feed is no more than 300”.

5.2. Composting

5.3. Thermal Treatment

5.4. Phosphorus Recover

5.5. Biochar/Waste Adsorbent Generation/Preparation

- -

- Pre-dewatering;

- -

- Drying the material;

- -

- Carried out the carbonization process, usually in an inert gas atmosphere;

- -

- Chemical or physical activation process;

- -

- Washing the material after the activation processes;

- -

- Final drying.

5.6. Fertilizer Production

6. Conclusions

Funding

Conflicts of Interest

References

- Michałkiewicz, M.; Dymaczewski, Z.; Jaroszyński, T.; Jeż-Walkowiak, J.; Komorowska-Kaufman, M.; Niedzielski, W.; Sozański, M. Sewage Treatment Plant Operator’s Guide, 3rd ed.; PZITS: Poznań, Poland, 2011; ISBN 978-83-89696-38-X. (In Polish) [Google Scholar]

- Fukas-Płonka, L.; Zielewicz, E. Criteria for Selecting the Method of Processing Sewage Sludge. Directions of Processing and Management of Sewage Sludge; Heindrich, Z., Ed.; Wydawnictwo Seidel-Przywecki Sp. z o.o: Piaseczno, Poland, 2010. (In Polish) [Google Scholar]

- Teoh, S.K.; Li, L.Y. Feasibility of Alternative Sewage Sludge Treatment Methods from a Lifecycle Assessment (LCA) Perspective. J. Clean. Prod. 2020, 247, 119495. [Google Scholar] [CrossRef]

- Cieślik, B.M.; Namieśnik, J.; Konieczka, P. Review of Sewage Sludge Management: Standards, Regulations and Analytical Methods. J. Clean. Prod. 2015, 90, 1–15. [Google Scholar] [CrossRef]

- El Hammoudani, Y.; Dimane, F.; El Ouarghi, H. Characterization of Sewage Sludge Generated from Wastewater Treatment Plant in Relation to Agricultural Use. Environ. Water Sci. Public Health Territ. Intell. 2019, 3, 47–52. [Google Scholar]

- Bień, J.; Wystalska, K. Sewage Sludge. Theory and Practice, 3rd ed.; Wydawnictwo Politechniki Częstochowskiej: Częstochowa, Poland, 2011; ISBN 978-83-7193-517-6. (In Polish) [Google Scholar]

- Koc-Jurczyk, J.; Jurczyk, Ł. Sewage Sludge Management as a Tool for the Circular Economy. In Międzynarodowa Konferencja Strategie Wdrażania Zielonego Ładu: Woda i Surowce; Instytut Gospodarki Surowcami Mineralnymi i Energią PAN: Kraków, Poland, 2020; pp. 35–45. (In Polish) [Google Scholar]

- Aziz, S.Q.; Mustafa, J.S. Wastewater Sludge Characteristics, Treatment Techniques and Energy Production. Reciklaza I Odrziv. Razvoj 2022, 15, 9–26. [Google Scholar] [CrossRef]

- Vitenko, T.; Marynenko, N.; Kramar, I. Characteristics of Sewage Sludge Composition for Agricultural Use. Econ. Environ. 2023, 85, 296–307. [Google Scholar] [CrossRef]

- Romanos, D.; Nemer, N.; Khairallah, Y.; Abi Saab, M.T. Assessing the Quality of Sewage Sludge as an Agricultural Soil Amendment in Mediterranean Habitats. Int. J. Recycl. Org. Waste Agric. 2019, 8, 377–383. [Google Scholar] [CrossRef]

- Kominko, H.; Gorazda, K.; Wzorek, Z. Potentiality of Sewage Sludge-Based Organo-Mineral Fertilizer Production in Poland Considering Nutrient Value, Heavy Metal Content and Phytotoxicity for Rapeseed Crops. J. Environ. Manag. 2019, 248, 109283. [Google Scholar] [CrossRef]

- Pöykiö, R.; Watkins, G.; Dahl, O. Characterisation of Municipal Sewage Sludge as a Soil Improver and a Fertilizer Product. Ecol. Chem. Eng. 2019, 26, 547–557. [Google Scholar] [CrossRef]

- López, A.; Rodríguez-Chueca, J.; Mosteo, R.; Gómez, J.; Ormad, M.P. Microbiological Quality of Sewage Sludge after Digestion Treatment: A Pilot Scale Case of Study. J. Clean. Prod. 2020, 254, 120101. [Google Scholar] [CrossRef]

- Koyuncuoğlu, P.; Erden, G. Sampling, Pre-Treatment, and Identification Methods of Microplastics in Sewage Sludge and Their Effects in Agricultural Soils: A Review. Environ. Monit. Assess. 2021, 193, 175. [Google Scholar] [CrossRef]

- Corradini, F.; Meza, P.; Eguiluz, R.; Casado, F.; Huerta-Lwanga, E.; Geissen, V. Evidence of Microplastic Accumulation in Agricultural Soils from Sewage Sludge Disposal. Sci. Total Environ. 2019, 671, 411–420. [Google Scholar] [CrossRef] [PubMed]

- Silva, C.; Almeida, C.M.M.; Rodrigues, J.A.; Silva, S.; do Rosário Coelho, M.; Martins, A.; Lourinho, R.; Cardoso, E.; Cardoso, V.V.; Benoliel, M.J.; et al. Improving the Control of Pharmaceutical Compounds in Activated Sludge Wastewater Treatment Plants: Key Operating Conditions and Monitoring Parameters. J. Water Process Eng. 2023, 54, 103985. [Google Scholar] [CrossRef]

- Šauer, P.; Švecová, H.; Grabicová, K.; Gönül Aydın, F.; Mackuľak, T.; Kodeš, V.; Blytt, L.D.; Henninge, L.B.; Grabic, R.; Kocour Kroupová, H. Bisphenols Emerging in Norwegian and Czech Aquatic Environments Show Transthyretin Binding Potency and Other Less-Studied Endocrine-Disrupting Activities. Sci. Total Environ. 2021, 751, 141801. [Google Scholar] [CrossRef] [PubMed]

- Kim Lazcano, R.; de Perre, C.; Mashtare, M.L.; Lee, L.S. Per- and Polyfluoroalkyl Substances in Commercially Available Biosolid-Based Products: The Effect of Treatment Processes. Water Environ. Res. A Res. Publ. Water Environ. Fed. 2019, 91, 1669–1677. [Google Scholar] [CrossRef]

- Sun, S.-J.; Zhao, Z.-B.; Li, B.; Ma, L.-X.; Fu, D.-L.; Sun, X.-Z.; Thapa, S.; Shen, J.-M.; Qi, H.; Wu, Y.-N. Occurrence, Composition Profiles and Risk Assessment of Polycyclic Aromatic Hydrocarbons in Municipal Sewage Sludge in China. Environ. Pollut. 2019, 245, 764–770. [Google Scholar] [CrossRef]

- Tomczyk, B.; Siatecka, A.; Jędruchniewicz, K.; Sochacka, A.; Bogusz, A.; Oleszczuk, P. Polycyclic Aromatic Hydrocarbons (PAHs) Persistence, Bioavailability and Toxicity in Sewage Sludge- or Sewage Sludge-Derived Biochar-Amended Soil. Sci. Total Environ. 2020, 747, 141123. [Google Scholar] [CrossRef]

- Kacprzak, M.; Neczaj, E.; Fijałkowski, K.; Grobelak, A.; Grosser, A.; Worwag, M.; Rorat, A.; Brattebo, H.; Almås, Å.; Singh, B.R. Sewage Sludge Disposal Strategies for Sustainable Development. Environ. Res. 2017, 156, 39–46. [Google Scholar] [CrossRef]

- Wojciechowska, M. Statistical Analyses; Statistics Poland, Agriculture and Environment Department: Warsaw, Poland, 2023. (In Polish) [Google Scholar]

- Act of 14 December 2012 on Waste (Journal of Laws, 2013, Item 21, Poland). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20130000021/U/D20130021Lj.pdf (accessed on 14 March 2025).

- Council Directive of 12 June 1986 on the Protection of the Environment, and in Particular of the Soil, When Sewage Sludge Is Used in Agriculture—86/278/EEC; European Union: Brussels, Belgium, 1986.

- Council Directive of 21 May 1991 Concerning Urban Waste Water Treatment (91/271/EEC); European Union: Brussels, Belgium, 1991.

- Directive (EU) 2024/3019 of the European Parliament and of the Council of 27 November 2024 Concerning Urban Wastewater Treatment; European Union: Brussels, Belgium, 2024; Volume 3019, pp. 1–59.

- Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain; European Union: Brussels, Belgium, 2008. [CrossRef]

- Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste; European Union: Brussels, Belgium, 1999.

- Regulation of the Minister of the Environment of 11 May 2015 on the Recovery of Waste Out-Side Installations and Facilities (Journal of Laws 2015, Item 796). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20150000796/O/D20150796.pdf (accessed on 14 March 2025).

- Regulation of the Minister of the Environment of 20 January 2015 on the Recovery Process R10 (Journal of Laws 2015, Item 132). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20150000132/O/D20150132.pdf (accessed on 14 March 2025).

- Regulation of the Minister of the Environment of 6 February 2015 on Municipal Sewage Sludge (Journal of Laws 2015, Item 257). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20150000257/O/D20150257.pdf (accessed on 14 March 2025).

- Regulation of the Minister of Agriculture and Rural Development of August 9, 2024, on the Implementation of Certain Provisions of the Act on Fertilizers and Fertilization (Journal of Laws 2024, Item 1261). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20240001261/O/D20241261.pdf (accessed on 14 March 2025).

- Act of 10 July 2007 on Fertilizers and Fertilization (Journal of Laws 2007,No 147, Item 1033, as Amended, Poland). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20071471033/U/D20071033Lj.pdf (accessed on 14 March 2025).

- Regulation of the Minister of Development of 21 January 2016 on the Requirements for Conducting the Process of Thermal Treatment of Waste and Methods of Handling Waste Gen-Erated as a Result of This Process (Journal of Laws 2016, Item 108). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20160000108/O/D20160108.pdf (accessed on 14 March 2025).

- Regulation of the Minister of Climate of 24 September 2020 on Emission Standards for Cer-Tain Types of Installations, Fuel Incineration Sources, and Waste Incineration or Facilities (Journal of Laws of 2020, Item 1860). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20200001860/O/D20201860.pdf (accessed on 14 March 2025).

- Regulation of the Minister of the Environment of 6 June 2016 on the Technical Conditions for Qualifying Part of the Energy Recovered from the Thermal Treatment of Waste (Journal of Laws 2016, Item 847). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20160000847/O/D20160847.pdf (accessed on 14 March 2025).

- Act of 20 February 2015 on Renewable Energy Sources (Journal of Laws. 2015, Item 478, as Amended, Poland). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20150000478/U/D20150478Lj.pdf (accessed on 14 March 2025).

- Act of 27 April 2001 on Environmental Protection Law (Journal of Laws, 2001, No 62, Item 627, Poland). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20010620627/U/D20010627Lj.pdf (accessed on 14 March 2025).

- Act of 20 July 2017 on Water Law (Journal of Laws, 2017, Item 1566, Poland). Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WDU20170001566/U/D20171566Lj.pdf (accessed on 14 March 2025).

- Resolution No. 96 of the Council of Ministers of 12 June 2023 on the National Waste Management Plan 2028, Poland. Available online: https://isap.sejm.gov.pl/isap.nsf/download.xsp/WMP20230000702/O/M20230702.pdf (accessed on 14 March 2025).

- Roig, N.; Sierra, J.; Martí, E.; Nadal, M.; Schuhmacher, M.; Domingo, J.L. Long-Term Amendment of Spanish Soils with Sewage Sludge: Effects on Soil Functioning. Agric. Ecosyst. Environ. 2012, 158, 41–48. [Google Scholar] [CrossRef]

- Houillon, G.; Jolliet, O. Life Cycle Assessment of Processes for the Treatment of Wastewater Urban Sludge: Energy and Global Warming Analysis. J. Clean. Prod. 2005, 13, 287–299. [Google Scholar] [CrossRef]

- Hušek, M.; Homma, R.; Moško, J.; Pohořelý, M.; Oshita, K. P-Recovery versus Current Sewage Sludge Treatment Policy in the Czech Republic and Japan. Clean Technol. Environ. Policy 2024, 26, 1883–1899. [Google Scholar] [CrossRef]

- Milieu Ltd; WRc; RPA for the European Commission. Environmental, Economic and Social Impacts of the Use of Sewage Sludge on Land Final Report Part I: Overview Report; European Commission: Brussels, Belgium, 2010. [Google Scholar]

- Oleszkiewicz, J.A.; Kalinowska, E. Sewage Sludge Management: A Decision-Maker’s Guide; LEM: Kraków, Poland, 1998; ISBN 8390896001. (In Polish) [Google Scholar]

- Ozores-Hampton, M.; Biala, J.; Evanylo, G.; Faucette, B.; Cooperband, L.; Roe, N.; Creque, J.A.; Sullivan, D. Chapter 16—Compost Use. In The Composting Handbook; Rynk, R., Ed.; Academic Press: Cambridge, MA, USA, 2022; pp. 777–846. ISBN 978-0-323-85602-7. [Google Scholar]

- Xu, C.; Mou, B. Short-Term Effects of Composted Cattle Manure or Cotton Burr on Growth, Physiology, and Phytochemical of Spinach. HortScience 2016, 51, 1517–1523. [Google Scholar] [CrossRef]

- Goldan, E.; Nedeff, V.; Barsan, N.; Culea, M.; Panainte-Lehadus, M.; Mosnegutu, E.; Tomozei, C.; Chitimus, D.; Irimia, O. Assessment of Manure Compost Used as Soil Amendment—A Review. Processes 2023, 11, 1167. [Google Scholar] [CrossRef]

- Pergola, M.; Piccolo, A.; Palese, A.M.; Ingrao, C.; Di Meo, V.; Celano, G. A Combined Assessment of the Energy, Economic and Environmental Issues Associated with on-Farm Manure Composting Processes: Two Case Studies in South of Italy. J. Clean. Prod. 2018, 172, 3969–3981. [Google Scholar] [CrossRef]

- Sewage Treatment Plant Słupsk, Poland—Sludge Composting. Available online: https://kompostownia.wodociagi.slupsk.pl/informacje-podstawowe/2/ (accessed on 30 January 2025).

- Sewage Treatment Plant Ełk, Poland—Sludge Composting. Available online: https://pwikelk.pl/technologia/oczyszczalnia-sciekow/ (accessed on 4 February 2025).

- Sewage Treatment Plant Piła, Poland—Sludge Composting. Available online: https://gwda.pl/o_spolce/informacje/kompostownia/ (accessed on 4 February 2025).

- Ignatowicz, K.; Garlicka, K.; Breńko, T. Impact of Sewage Sludge Composition on the Content of Selected Metals and Their Fractions. Inżynieria Ekol. 2011, 25, 231–241. (In Polish) [Google Scholar]

- Mills, N.; Pearce, P.; Farrow, J.; Thorpe, R.B.; Kirkby, N.F. Environmental & Economic Life Cycle Assessment of Current & Future Sewage Sludge to Energy Technologies. Waste Manag. 2014, 34, 185–195. [Google Scholar] [CrossRef]

- Werle, S. Sewage Sludge-To-Energy Management in Eastern Europe: A Polish Perspective. Ecol. Chem. Eng. S 2015, 22, 459–469. [Google Scholar] [CrossRef]

- Bień, J. Management of Municipal Sewage Sludge Using Thermal Methods. Inżynieria I Ochr. Sr. 2012, 15, 439–450. (In Polish) [Google Scholar]

- Bień, J.; Neczaj, E.; Worwąg, M.; Grosser, A.; Nowak, D.; Milczarek, M.; Janik, M. Directions of Sludge Management in Poland after 2013. Inżynieria I Ochr. Sr. 2011, 14, 375–384. (In Polish) [Google Scholar]

- Samolada, M.C.; Zabaniotou, A.A. Comparative Assessment of Municipal Sewage Sludge Incineration, Gasification and Pyrolysis for a Sustainable Sludge-to-Energy Management in Greece. Waste Manag. 2014, 34, 411–420. [Google Scholar] [CrossRef]

- Donatello, S.; Cheeseman, C.R. Recycling and Recovery Routes for Incinerated Sewage Sludge Ash (ISSA): A Review. Waste Manag. 2013, 33, 2328–2340. [Google Scholar] [CrossRef]

- Spinosa, L.; Ayol, A.; Baudez, J.C.; Canziani, R.; Jenicek, P.; Leonard, A.; Rulkens, W.; Xu, G.; van Dijk, L. Sustainable and Innovative Solutions for Sewage Sludge Management. Water 2011, 3, 702–717. [Google Scholar] [CrossRef]

- Kasprzyk, M.; Gajewska, M.; Molendowska, S. Phosphorus recovery possibilities from leachates, sewage sludge and ashes after thermal treatment of sewage sludge. Inżynieria Ekol. 2017, 18, 65–78. [Google Scholar] [CrossRef] [PubMed]

- Egle, L.; Rechberger, H.; Zessner, M. Overview and Description of Technologies for Recovering Phosphorus from Municipal Wastewater. Resour. Conserv. Recycl. 2015, 105, 325–346. [Google Scholar] [CrossRef]

- Petzet, S.; Peplinski, B.; Cornel, P. On Wet Chemical Phosphorus Recovery from Sewage Sludge Ash by Acidic or Alkaline Leaching and an Optimized Combination of Both. Water Res. 2012, 46, 3769–3780. [Google Scholar] [CrossRef]

- Poluszuńska, J.; Ślęzak, E. Possibilities of Recovering Phosphorus from Sewage Sludge. Pr. Inst. Ceram. I Mater. Bud. 2015, 21, 7–21. (In Polish) [Google Scholar]

- Blöcher, C.; Niewersch, C.; Melin, T. Phosphorus Recovery from Sewage Sludge with a Hybrid Process of Low Pressure Wet Oxidation and Nanofiltration. Water Res. 2012, 46, 2009–2019. [Google Scholar] [CrossRef]

- Wzorek, Z.; Gorazda, K. Phosphorus Recovery from Waste Methods Review. Pol. J. Chem. Technol. 2007, 9, 57–60. [Google Scholar] [CrossRef]

- Boutoussov, M. Thermal Process for Separating Heavy Metals from Ash in Agglomerated Form; 2009. European Patent Office EP 2016203B1, 25 December 2013. [Google Scholar]

- Desmidt, E.; Ghyselbrecht, K.; Zhang, Y.; Pinoy, L.; Van Der Bruggen, B.; Verstraete, W.; Rabaey, K.; Meesschaert, B. Global Phosphorus Scarcity and Full-Scale P-Recovery Techniques: A Review. Crit. Rev. Environ. Sci. Technol. 2015, 45, 336–384. [Google Scholar] [CrossRef]

- Weigand, H.; Bertau, M.; Hübner, W.; Bohndick, F.; Bruckert, A. RecoPhos: Full-Scale Fertilizer Production from Sewage Sludge Ash. Waste Manag. 2013, 33, 540–544. [Google Scholar] [CrossRef]

- PoFerAsh. Available online: https://ptt.arp.pl/bazy/polferash-polskie-nawozy-stałe-i-zawiesinowe-z-alternatywnych-surowców-fosforowych/ (accessed on 4 February 2025).

- Gorazda, K.; Tarko, B.; Wzorek, Z.; Kominko, H.; Nowak, A.K.; Kulczycka, J.; Henclik, A.; Smol, M. Fertilisers Production from Ashes after Sewage Sludge Combustion—A Strategy towards Sustainable Development. Environ. Res. 2017, 154, 171–180. [Google Scholar] [CrossRef]

- Bhattacharya, T.; Khan, A.; Ghosh, T.; Kim, J.T.; Rhim, J.W. Advances and Prospects for Biochar Utilization in Food Processing and Packaging Applications. Sustain. Mater. Technol. 2024, 39, e00831. [Google Scholar] [CrossRef]

- Rangabhashiyam, S.; Lins, P.V.d.S.; Oliveira, L.M.d.M.; Sepulveda, P.; Ighalo, J.O.; Rajapaksha, A.U.; Meili, L. Sewage Sludge-Derived Biochar for the Adsorptive Removal of Wastewater Pollutants: A Critical Review. Environ. Pollut. 2022, 293, 118581. [Google Scholar] [CrossRef]

- Mushtaq, S.; Jamil, F.; Hussain, M.; Inayat, A.; Majeed, K.; Akhter, P.; Khurram, M.S.; Shanableh, A.; Kim, Y.M.; Park, Y.K. Utilizing Sludge-Based Activated Carbon for Targeted Leachate Mitigation in Wastewater Treatment. Environ. Res. 2024, 249, 118326. [Google Scholar] [CrossRef] [PubMed]

- Pieczykolan, B.; Płonka, I. Application of Excess Activated Sludge as Waste Sorbent for Dyes Removal from Their Aqueous Solutions. Ecol. Chem. Eng. S 2019, 26, 773–784. [Google Scholar] [CrossRef]

- Pieczykolan, B.; Płonka, I.; Zając, R. Chemically Modified Excessive Sludge As an Adsorbent of Dyes. Proc. ECOpole 2020, 14, 29–37. [Google Scholar] [CrossRef]

- Hu, J.; Zhao, L.; Luo, J.; Gong, H.; Zhu, N. A Sustainable Reuse Strategy of Converting Waste Activated Sludge into Biochar for Contaminants Removal from Water: Modifications, Applications and Perspectives. J. Hazard. Mater. 2022, 438, 129437. [Google Scholar] [CrossRef]

- Rio, S.; Le Coq, L.; Faur, C.; Lecomte, D.; Le Cloirec, P. Preparation of Adsorbents from Sewage Sludge by Steam Activation for Industrial Emission Treatment. Process Saf. Environ. Prot. 2006, 84, 258–264. [Google Scholar] [CrossRef]

- Wang, X.; Zhu, N.; Yin, B. Preparation of Sludge-Based Activated Carbon and Its Application in Dye Wastewater Treatment. J. Hazard. Mater. 2008, 153, 22–27. [Google Scholar] [CrossRef]

- Björklund, K.; Li, L.Y. Adsorption of Organic Stormwater Pollutants onto Activated Carbon from Sewage Sludge. J. Environ. Manag. 2017, 197, 490–497. [Google Scholar] [CrossRef]

- Montoya-Bautista, C.V.; Mohamed, B.A.; Li, L.Y. Sludge-Based Activated Carbon from Two Municipal Sewage Sludge Precursors for Improved Secondary Wastewater-Treatment Discharge-Effluent. J. Environ. Chem. Eng. 2022, 10, 108704. [Google Scholar] [CrossRef]

- Fan, L.; Wan, W.; Wang, X.; Cai, J.; Chen, F.; Chen, W.; Ji, L.; Luo, H.; Cheng, L. Adsorption Removal of Cr(VI) with Activated Carbon Prepared by Co-Pyrolysis of Rice Straw and Sewage Sludge with ZnCl2 Activation. Water. Air. Soil Pollut. 2019, 230, 233. [Google Scholar] [CrossRef]

- Guo, T.; Yao, S.; Chen, H.; Yu, X.; Wang, M.; Chen, Y. Characteristics and Adsorption Study of the Activated Carbon Derived from Municipal Sewage Sludge. Water Sci. Technol. 2017, 76, 1697–1705. [Google Scholar] [CrossRef] [PubMed]

- Rozada, F.; Calvo, L.F.; García, A.I.; Martín-Villacorta, J.; Otero, M. Dye Adsorption by Sewage Sludge-Based Activated Carbons in Batch and Fixed-Bed Systems. Bioresour. Technol. 2003, 87, 221–230. [Google Scholar] [CrossRef] [PubMed]

- Stefanelli, E.; Vitolo, S.; Di Fidio, N.; Puccini, M. Tailoring the Porosity of Chemically Activated Carbons Derived from the HTC Treatment of Sewage Sludge for the Removal of Pollutants from Gaseous and Aqueous Phases. J. Environ. Manag. 2023, 345, 118887. [Google Scholar] [CrossRef]

- Singh, S.; Kumar, V.; Dhanjal, D.S.; Datta, S.; Bhatia, D.; Dhiman, J.; Samuel, J.; Prasad, R.; Singh, J. A Sustainable Paradigm of Sewage Sludge Biochar: Valorization, Opportunities, Challenges and Future Prospects. J. Clean. Prod. 2020, 269, 122259. [Google Scholar] [CrossRef]

- Zhao, L.; Sun, Z.F.; Pan, X.W.; Tan, J.Y.; Yang, S.S.; Wu, J.T.; Chen, C.; Yuan, Y.; Ren, N.Q. Sewage Sludge Derived Biochar for Environmental Improvement: Advances, Challenges, and Solutions. Water Res. X 2023, 18, 100167. [Google Scholar] [CrossRef]

- Li, J.; Cao, L.; Li, B.; Huang, H.; Yu, W.; Sun, C.; Long, K.; Young, B. Utilization of Activated Sludge and Shell Wastes for the Preparation of Ca-Loaded Biochar for Phosphate Removal and Recovery. J. Clean. Prod. 2023, 382, 135395. [Google Scholar] [CrossRef]

- Minaei, S.; Zoroufchi Benis, K.; McPhedran, K.N.; Soltan, J. Adsorption of Sulfamethoxazole and Lincomycin from Single and Binary Aqueous Systems Using Acid-Modified Biochar from Activated Sludge Biomass. J. Environ. Manag. 2024, 358, 120742. [Google Scholar] [CrossRef]

- Liu, Z.; Singer, S.; Tong, Y.; Kimbell, L.; Anderson, E.; Hughes, M.; Zitomer, D.; McNamara, P. Characteristics and Applications of Biochars Derived from Wastewater Solids. Renew. Sustain. Energy Rev. 2018, 90, 650–664. [Google Scholar] [CrossRef]

- Technology for Producing Granular Fertilizer Products from Stabilized Sewage Sludge. Available online: https://nawozysciekowe.gig.eu/ (accessed on 30 January 2025).

- Styszko, K.; Durak, J.; Kończak, B.; Głodniok, M.; Borgulat, A. The Impact of Sewage Sludge Processing on the Safety of Its Use. Sci. Rep. 2022, 12, 12227. [Google Scholar] [CrossRef]

- Kominko, H.; Gorazda, K.; Wzorek, Z.; Wojtas, K. Sustainable Management of Sewage Sludge for the Production of Organo-Mineral Fertilizers. Waste Biomass Valorization 2018, 9, 1817–1826. [Google Scholar] [CrossRef]

- Zawartka, P.; Kończak, B. Organic-Mineral Fertilizer and Method for Producing It. Polish Patent PL 234676B1, 3 December 2019. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/be34f12eb701e3b079c8977553eb728b#search=%22Spos%C3%B3b%20otrzymywania%20nawozu%20organiczno-mineralnego%20z%20ustabilizowanych%20komunalnych%20osad%C3%B3w%20%C5%9Bciekowych%20oraz%20naw%C3%B3z%20organiczno-mineralny%22 (accessed on 14 March 2025).

- Zawartka, P.; Kończak, B. Method for Obtaining Granular Fertilizer with Prolonged Release of Components. Polish Patent PL 233663B1, 10 September 2019. Available online: https://api-ewyszukiwarka.pue.uprp.gov.pl/api/collection/531efa418e9cf486d15eedc2e826647e#search=%22Spos%C3%B3b%20otrzymywania%20nawozu%20organiczno-mineralnego%20z%20ustabilizowanych%20komunalnych%20osad%C3%B3w%20%C5%9Bciekowych%20oraz%20naw%C3%B3z%20organiczno-mineralny%22 (accessed on 14 March 2025).

- Masłoń, A.; Czarnota, J. Method of Producing an Organic-Mineral Fertilizer and an Organic-Mieral Fertilizer. Polish Patent PL 242576B1, 21 December 2022. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.435403 (accessed on 14 March 2025).

- Kominko, H.; Gorazda, K.; Wzorek, Z. Multi-Component Organic-Mineral Fertilizer, Especially for Rapeseed. Polish Patent PL 243440B1, 14 June 2023. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.438489 (accessed on 14 March 2025).

- Kominko, H.; Gorazda, K.; Wzorek, Z. Multi-Component Organic-Mineral Fertilizer, Especially for Maize. Polish Patent PL 243439B1, 14 June 2023. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.438488 (accessed on 14 March 2025).

- Kominko, H.; Gorazda, K.; Wzorek, Z. Multi-Ingredient Organic-Mineral Fertilizer for Sunflower Cultivation. Polish Patent PL 243441B1, 14 June 2023. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.438492 (accessed on 14 March 2025).

- Kominko, H.; Gorazda, K.; Wzorek, Z. Method of Obtaining Granular Multi-Component Organic-Mineral Fertilizer. Polish Patent PL 243442B1, 14 June 2023. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.438497 (accessed on 14 March 2025).

- Michalak, P.; Antonkiewicz, J.; Targosz, B. Method for Producing Fertilizer from Sewage Sludges. Polish Patent PL 228796B1, 5 December 2017. Available online: https://ewyszukiwarka.pue.uprp.gov.pl/search/pwp-details/P.411157 (accessed on 14 March 2025).

- Iżewska, A.; Kiper, J.; Bering, S.; Mazur, J.; Zalewska, P.; Tarnowski, K. Method for Producing Organic-Mineral Fertilizer-Application. Polish Patent PL 421521A1, 19 November 2018. [Google Scholar]

| Parameter | Total Solids TS | Volatile Solids VS | Fat | Phosphorus | Protein | Cellulose | Nitrogen | Potassium | pH | Reference |

|---|---|---|---|---|---|---|---|---|---|---|

| Unit | % | % TS | % TS | % TS | % TS | % TS | % TS | % TS | - | |

| Primary sludge | 2–8 | 60–80 | 5–8 | 0.8–2.8 | 20–30 | 8–15 | 1.5–4.0 | nd | 5.0–8.0 | [1] |

| Excess activated sludge | 0.4–1.2 | 60–85 | 5–12 | 1.5–3.0 | 32–41 | nd | 2.4–7.0 | nd | 6.5–8.0 | [1] |

| Primary sludge | 4–9 | 65–80 | nd | 0.6–2.9 | 18–30 | 8–16 | 1.4–4.2 | nd | 5.5–8.0 | [8] |

| Excess activated sludge | 0.6–1.2 | 60–85 | nd | 3–10 | 30–40 | nd | 2.5–5.0 | nd | 6.6–8.0 | [8] |

| Mixed sludge | 14.6–67.7 | nd | nd | 2.1–2.6 | nd | nd | 1.1–1.66 | 0.29–0.58 | 6.7–7.6 | [9] |

| Heavy Metals | Iron | Nickel | Chrome | Zinc | Lead | Copper | Cadmium | Mercury | References |

|---|---|---|---|---|---|---|---|---|---|

| Mixed fermented sludge [g/kg TS] typical value | 20 | 0.07 | 1.6 | 1.7 | 0.6 | nd | nd | nd | [1] |

| Mixed fermented sludge [g/kg TS] maximum value | 153 | 3.5 | 99 | 28 | 26 | 99 | nd | nd | [1] |

| Mixed stabilized sludge [g/kg TS] minimum value | nd | 0.02 | 0.03 | 0,91 | 0.01 | 0.04 | 0.002 | 0.002 | [11] |

| Mixed stabilized sludge [g/kg TS] maximum value | nd | 0.14 | 0.3 | 4.5 | 0.17 | 0.5 | 0.016 | 0.007 | [11] |

| Mixed stabilized sludge [g/kg TS] minimum value | 0.0002 | 0.11 | 0.32 | 0.37 | 0.004 | 0.06 | 0.00 | 0.0003 | [10] |

| Mixed stabilized sludge [g/kg TS] maximum value | 0.003 | 0.12 | 0.25 | 0.77 | 0.15 | 0.15 | 0.005 | 0.004 | [10] |

| Mixed stabilized sludge [g/kg TS] minimum value | 12.7 | 0.03 | 0.02 | 0.89 | 0.12 | 0.1 | 0.03 | nd | [9] |

| Mixed stabilized sludge [g/kg TS] maximum value | 14.5 | 0.56 | 0.33 | 1.57 | 0.52 | 0.45 | 0.06 | nd | [9] |

| Mixed fermented sludge [g/kg TS] typical value | 69 | 0.014 | 0.03 | 0.35 | 0.01 | 0.27 | 0.0005 | 0.0014 | [12] |

| No | Location | Nominal Capacity in Thousand Mg TS/Year |

|---|---|---|

| 1 | Warsaw—Sewage Treatment Plant “Czajka” | 62.2 |

| 2 | Krakow—Sewage Treatment Plant “Płaszów” | 23.0 |

| 3 | Łódź—Group Sewage Treatment Plant | 21.0 |

| 4 | Gdańsk—Sewage Treatment Plant “East” | 15.24 |

| 5 | Gdynia—Sewage treatment plant “Dębogórze” | 9.5 |

| 6 | Bydgoszcz—Sewage treatment plant “Fordon” | 7.8 |

| 7 | Zielona Góra—Sewage treatment plant “Łącza” | 6.4 |

| 8 | Kielce—Sewage treatment plant “Sitkówka” | 6.2 |

| 9 | Szczecin—Sewage treatment plant “Pomorzany” | 6.0 |

| 10 | Olsztyn—Sewage Treatment Plant “Łyna” | 3.2 |

| 11 | Łomża—Łomża Sewage Treatment Plant | 1.5 |

| TOTAL | 162.04 |

| Parameter | Unit | Value |

|---|---|---|

| Nitrogen | % by weight TS | 1–1.3 |

| Phosphorus | % by weight TS | 1–1.92 |

| Potassium | % by weight TS | 0.2–0.5 |

| Calcium | % by weight TS | 15–19 |

| Magnesium | % by weight TS | 6–9 |

| Organic substances | % by weight TS | 35 |

| pH | - | 6.0–9.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Płonka, I.; Kudlek, E.; Pieczykolan, B. Municipal Sewage Sludge Disposal in the Republic of Poland. Appl. Sci. 2025, 15, 3375. https://doi.org/10.3390/app15063375

Płonka I, Kudlek E, Pieczykolan B. Municipal Sewage Sludge Disposal in the Republic of Poland. Applied Sciences. 2025; 15(6):3375. https://doi.org/10.3390/app15063375

Chicago/Turabian StylePłonka, Izabela, Edyta Kudlek, and Barbara Pieczykolan. 2025. "Municipal Sewage Sludge Disposal in the Republic of Poland" Applied Sciences 15, no. 6: 3375. https://doi.org/10.3390/app15063375

APA StylePłonka, I., Kudlek, E., & Pieczykolan, B. (2025). Municipal Sewage Sludge Disposal in the Republic of Poland. Applied Sciences, 15(6), 3375. https://doi.org/10.3390/app15063375