The Full Lifecycle Evolution Model of Accidents: A Case Study of Underground Metal Mines in China

Abstract

:1. Introduction

2. Methodology

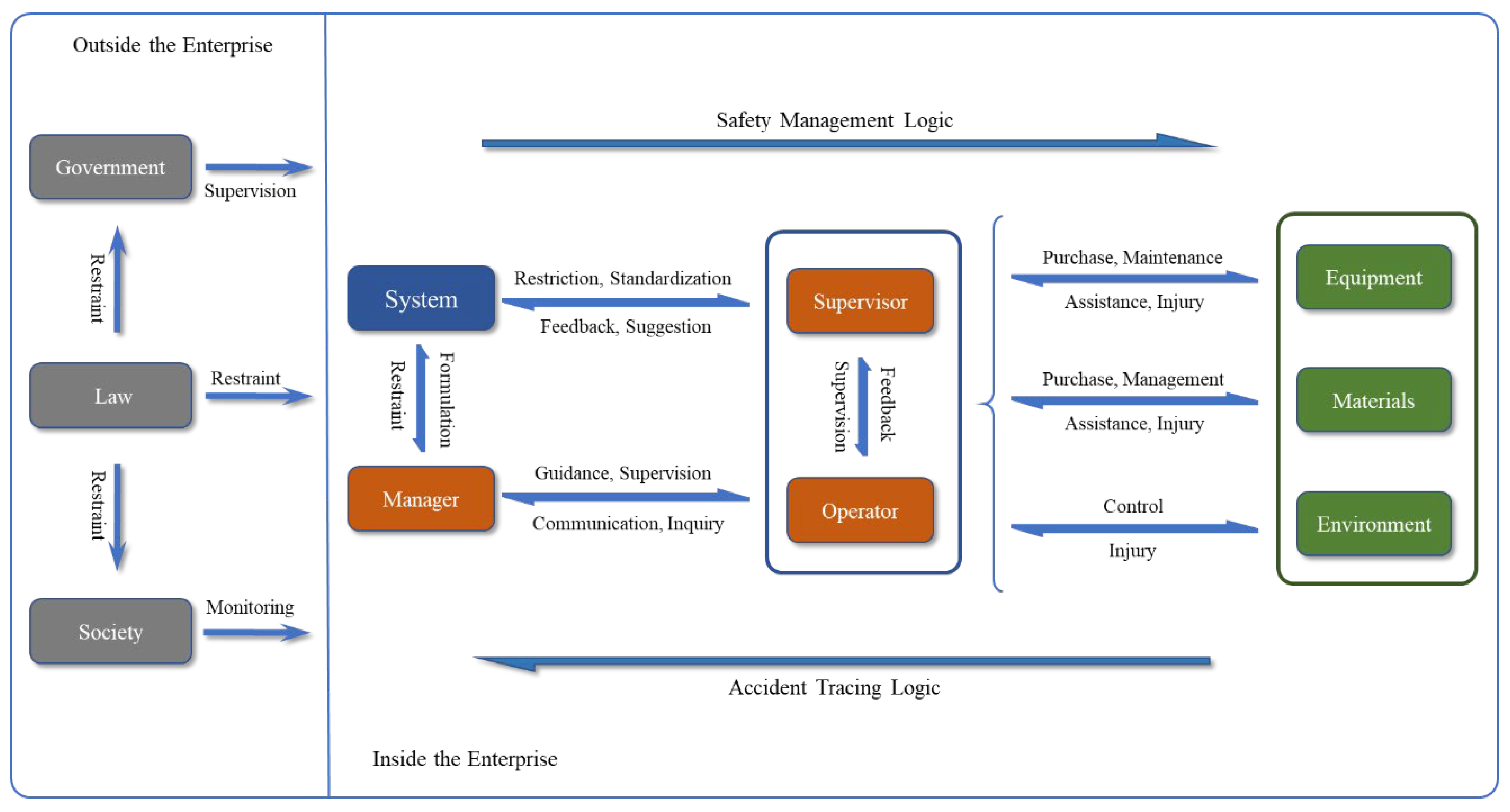

2.1. Safety Management Activity Analysis

2.1.1. Comparison of Major Accident Causation Theories

2.1.2. Analysis of Accident Causation Factors

- Human factors: Since the accident proneness theory, human error has been regarded as a critical factor in accidents. Heinrich’s accident causation chain theory posits that both unsafe behavior and unsafe conditions stem from human errors. In the SCM and HFACS, human factors occupy a central position in accident causation. Human factors are crucial because humans, as the only active agents in the production environment, influence all other factors, including the operation of machinery, any improvement to the working environment, and the establishment of management systems.

- Unsafe conditions: This factor includes all physical entities involved in production activities, aside from personnel. These can be further subdivided into equipment, materials, and the environment. Equipment refers to machinery and systems used to enhance production efficiency. Materials are man-made objects, aside from equipment, that lack power. The environment includes both natural and man-made settings. Changes in environmental factors can affect human behavior and tool performance, potentially triggering accidents.

- Management factors: In this study, management factors mainly refer to enterprise-level systems. Enterprises establish safety management systems in compliance with relevant laws, regulations, and standards to prevent safety management deficiencies and foster a positive safety culture [44].

- Legal factors: Laws and regulations related to safety management are enacted by each country based on its specific circumstances. These provide binding guidelines for government, society, and enterprises and serve as the primary foundation for enterprises’ safety management systems.

- Government factors: Government agencies oversee enterprise safety by implementing policies and supervising production safety. They also provide resources and support in the event of major accidents.

- Societal factors: society plays a supervisory role in ensuring production safety through public scrutiny and media oversight.

2.1.3. Accident Causation Logic

- (1)

- Role Classification in Safety Management

- Operators: Primarily interact with elements that may pose unsafe conditions, including equipment, materials, and the production environment. They are responsible for implementing specific safety measures.

- Supervisors: oversee the actions of operators to ensure compliance with safety regulations and operational procedures.

- Managers: ultimately responsible for production safety, managers establish and revise safety management systems in accordance with laws and policies.

- (2)

- Enterprise-Level Safety Management Logic

- (3)

- Accident Causation Logic

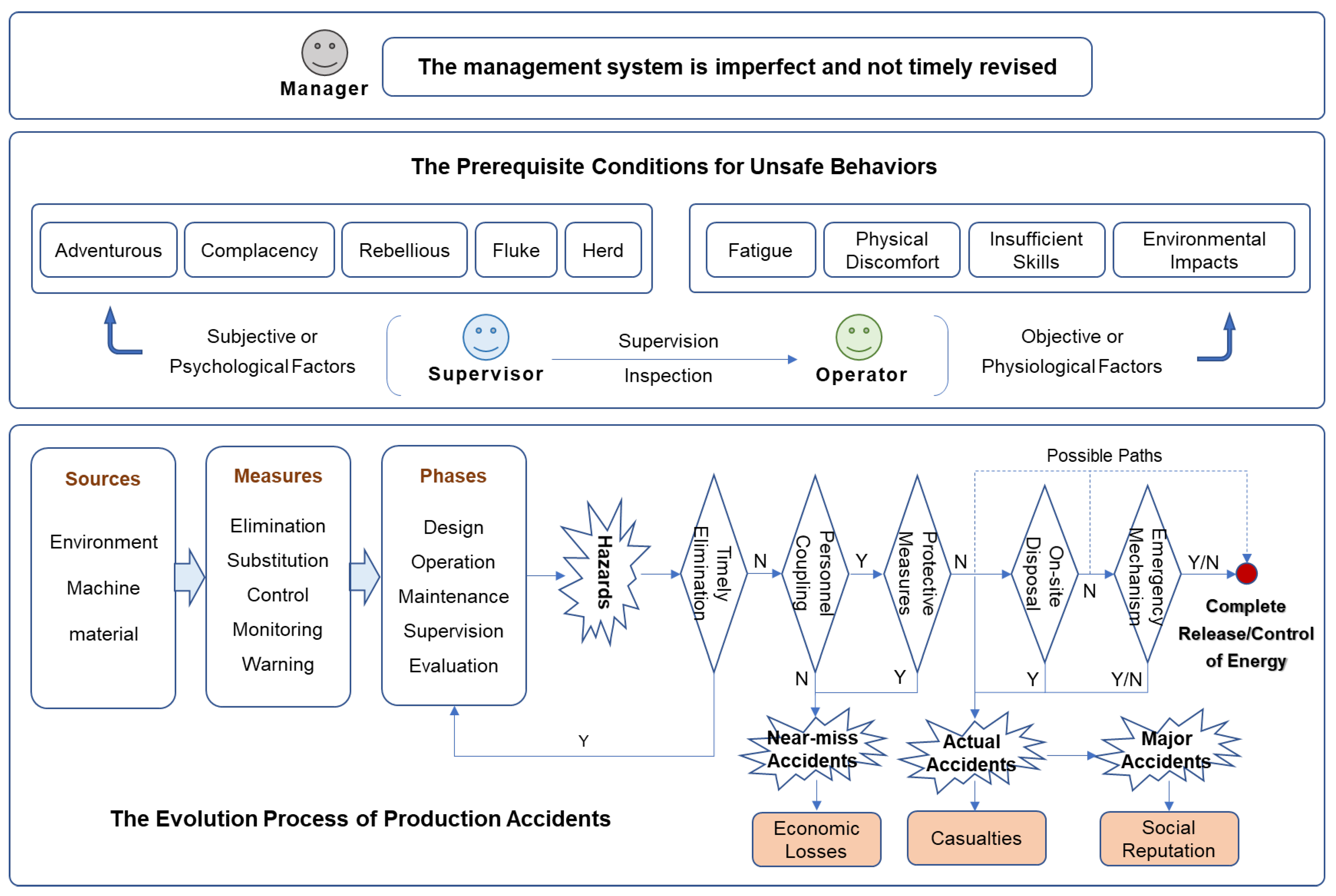

2.2. Full Lifecycle Evolution Model of Accidents

2.2.1. Accident Evolution Process

- (1)

- Hazard Identification and Control

- (2)

- Accident Development Stages

- (3)

- Accident Consequence Analysis

2.2.2. Prerequisite Conditions for Unsafe Behaviors

- (1)

- Psychological Factors:

- Fluke mentality: workers may hold the mistaken belief that occasional non-compliance with safety procedures will not necessarily lead to accidents, leading to unsafe behaviors.

- Complacency: overfamiliarity with the work environment and processes can cause a gradual decline in vigilance, making workers blind to potential safety risks.

- Herd mentality: when workers observe others engaging in unsafe behaviors without consequences, they may imitate these actions.

- Rebellious mentality: workers may develop resistance to safety management regulations or supervisors’ demands, deliberately engaging in unsafe behaviors as an act of defiance.

- Adventurous mentality: in pursuit of excitement or to complete tasks quickly, some workers may choose to take dangerous risks [46].

- (2)

- Physiological Factors:

- Fatigue: prolonged work hours or high-intensity labor can lead to physical fatigue, slower reaction times, and reduced attention, increasing the risk of unsafe behaviors.

- Physical discomfort: factors such as lack of sleep, hunger, or illness can impair a worker’s focus and job performance.

- Environmental impacts: high humidity, elevated temperatures, loud noise, and other environmental factors can negatively affect workers.

- Lack of safety skills or competence: insufficient safety training may leave workers without the skills to handle emergencies or operate equipment correctly, increasing the likelihood of errors during hazardous tasks.

2.2.3. Responsibility of Managers

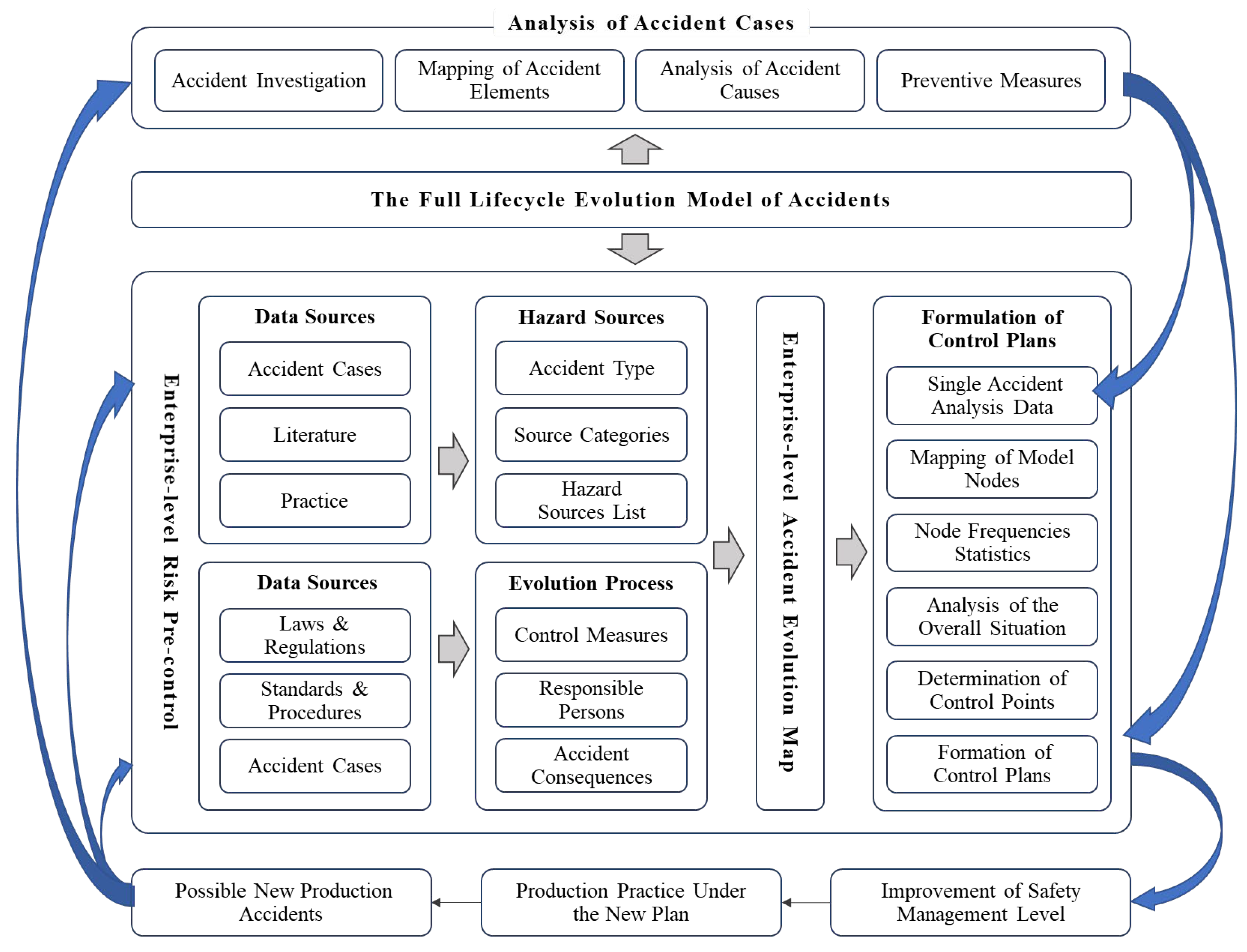

2.3. Application of the FLEM

- (1)

- Hazard source identification: identify potential accident types and the specific categories of hazard sources that could lead to such accidents within the enterprise, based on case studies, the relevant literature, or industry consensus.

- (2)

- Pathway mapping and construction: Based on legal regulations, industry standards, and operational procedures, determine the specific control measures for each hazard source and establish corresponding control systems at different stages of accident evolution. This forms the enterprise’s accident evolution pathway, where non-compliance with any part of the system represents a potential hazard.

- (3)

- Accident case statistical analysis: Map the causes identified in the individual accident analysis process to their corresponding points in the enterprise’s accident evolution pathway. Through statistical analysis of the frequency at each node, identify the critical weak points that require focused management and develop improvement measures or institutional adjustments to enhance the overall safety management level of the enterprise.

- (4)

- Model refinement and improvement: continuously improve the enterprise’s accident evolution pathway by repeating steps (1)–(3) as new production accidents occur during the implementation of new control measures.

3. Case Study

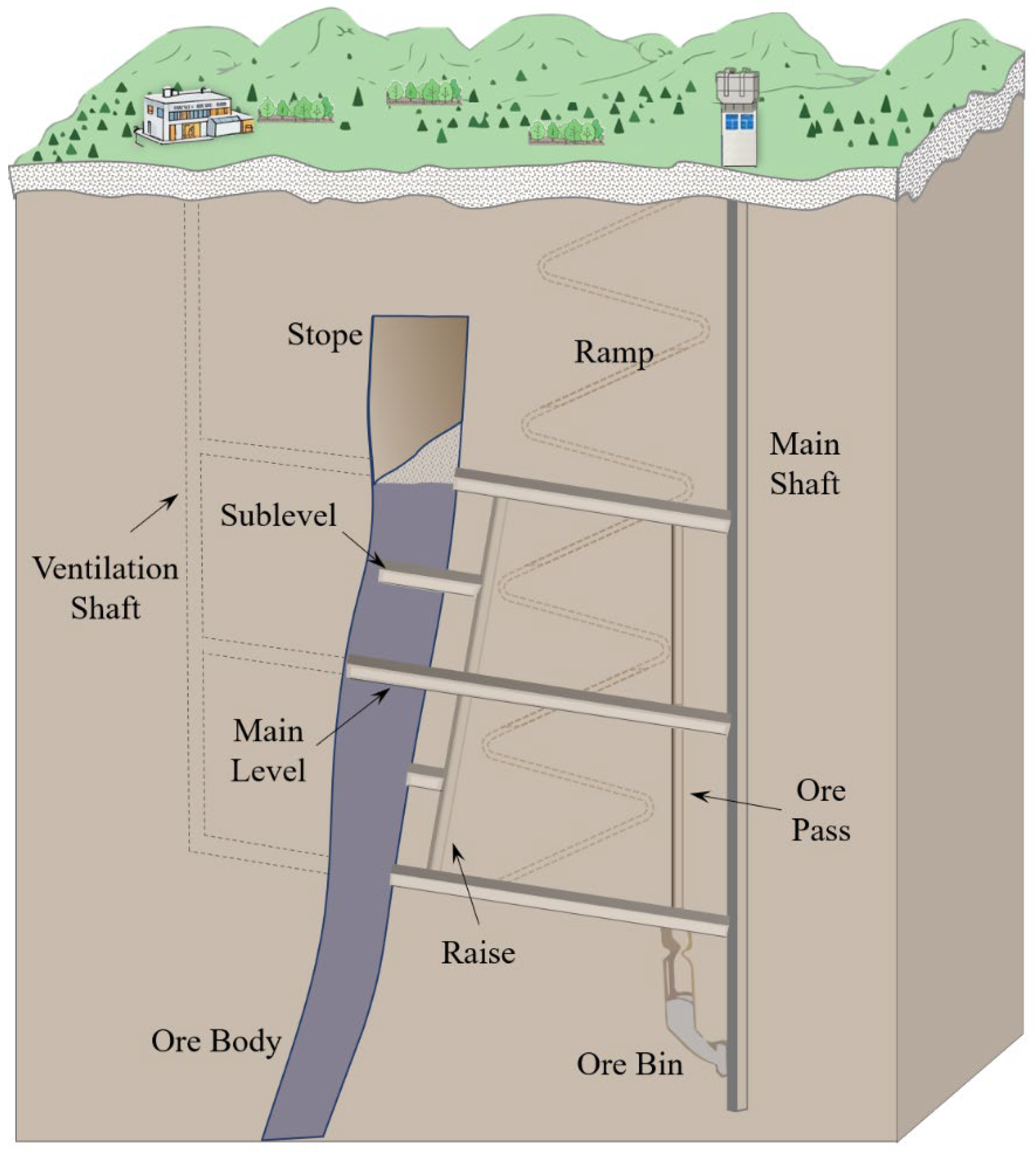

3.1. Overview of Underground Metal Mines

3.2. Accident Evolution Process in Underground Metal Mines

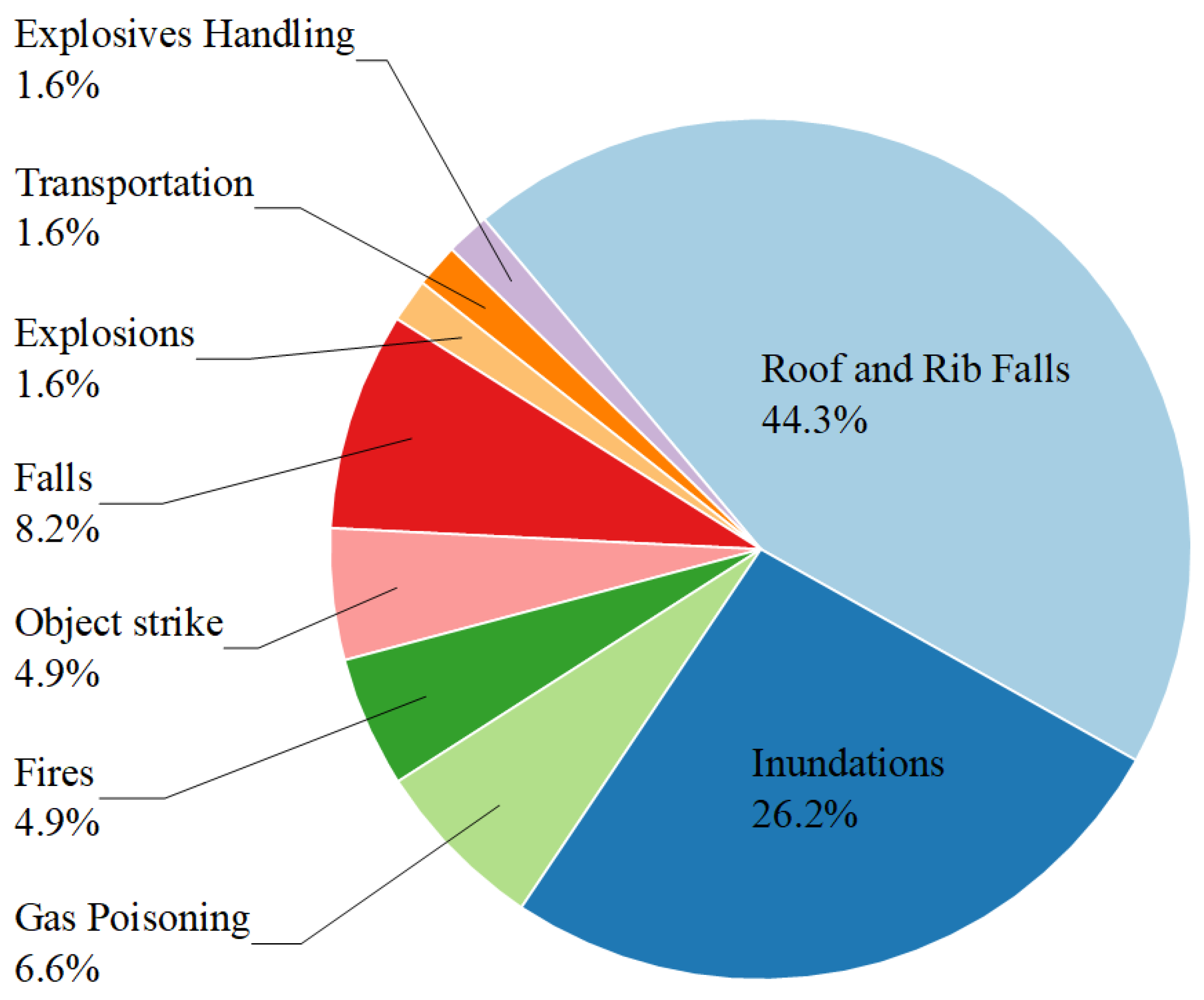

3.3. Accident Data Statistics and Quantification

4. Discussion

4.1. Analysis of Results

- Roof and rib falls: The majority (96.3%) of these accidents resulted from inadequate support and roof management. Furthermore, 14.8% of accidents were exacerbated by deficiencies in emergency response mechanisms. Unsafe behaviors, particularly insufficient safety awareness among workers, were identified as significant factors. These accidents often involved instantaneous energy release, making on-site response and protection measures less effective. The focus should be on improving roof support management and emergency preparedness, while enhancing workers’ safety awareness.

- Inundations: most accidents were due to inadequate hydrogeological investigations.

- Falls from heights: Some fall accidents were not linked to other hazards and could only be mitigated through personal protective measures. Increasing workers’ awareness of fall protection is crucial.

- Fires: These accidents were primarily caused by the failure of on-site response measures, highlighting the importance of emergency response training to mitigate the consequences of fire accidents.

- Gas poisoning: the serious consequences of these accidents were mostly due to improper rescue measures, leading to further escalation of the incident.

- Object strikes: Injuries from falling rocks were primarily due to the failure to wear protective equipment. Therefore, stricter enforcement of penalties for not wearing protective equipment during operations can significantly reduce the severity of such accidents.

- Most accident reports analyze the causes of accidents primarily based on direct and indirect factors, often lacking corresponding information on safety measures, on-site responses, emergency situations, and the preconditions for unsafe behaviors.

- Although all accident cases can be linked to corresponding causative nodes within the accident evolution pathways, the organization of these pathways primarily references relevant laws without constructing a more detailed accident evolution network based on safety regulations and operational standards, resulting in an overly broad analysis.

- The analysis of the preconditions for unsafe behaviors lacks a detailed classification of psychological factors, mainly because the publicly available accident cases are all related to fatalities, which prevents a thorough investigation of psychological aspects.

- The application of different accident data from various mines does not include a breakdown of responsible personnel.

4.2. Comparison with Existing Accident Causation Models

4.3. Limitations and Future Research Directions

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cao, Y.; Wang, X.; Yang, Z.; Wang, J.; Wang, H.; Liu, Z. Research in marine accidents: A bibliometric analysis, systematic review and future directions. Ocean Eng. 2023, 284, 115048. [Google Scholar] [CrossRef]

- Chen, P.; Fu, G.; Wang, Y.; Meng, H.; Lv, M. Accident causation models: A comparison of SCM and 24Model. Proc. Inst. Mech. Eng. Part O J. Risk Reliab. 2023, 237, 810–822. [Google Scholar] [CrossRef]

- Igene, O.O.; Johnson, C.W.; Long, J. An evaluation of the formalised AcciMap approach for accident analysis in healthcare. Cogn. Technol. Work 2022, 24, 161–181. [Google Scholar] [CrossRef]

- Oakman, J.; Kinsman, N.; Goode, N. A STAMP analysis of the staff safety management system in residential aged care. Saf. Sci. 2022, 146, 105563. [Google Scholar] [CrossRef]

- Ceylan, B.O.; Karatuğ, Ç.; Akyuz, E.; Arslanoğlu, Y.; Boustras, G. A system theory (STAMP) based quantitative accident analysis model for complex engineering systems. Saf. Sci. 2023, 166, 106232. [Google Scholar] [CrossRef]

- Wu, Y.; Fu, G.; Han, M.; Jia, Q.; Lyu, Q.; Wang, Y.; Wu, Z. Comparison of the theoretical elements and application characteristics of STAMP, FRAM, and 24Model: A major hazardous chemical explosion accident. J. Loss Prev. Process Ind. 2022, 80, 104880. [Google Scholar] [CrossRef]

- Read, G.J.; O’Brien, A.; Stanton, N.A.; Salmon, P.M. Learning lessons for automated vehicle design: Using systems thinking to analyse and compare automation-related accidents across transport domains. Saf. Sci. 2022, 153, 105822. [Google Scholar] [CrossRef]

- Klockner, K.; Toft, Y. Accident modelling of railway safety occurrences: The safety and failure event network (SAFE-Net) method. Procedia Manuf. 2015, 3, 1734–1741. [Google Scholar] [CrossRef]

- Huang, W.; Shuai, B.; Zuo, B.; Xu, Y.; Antwi, E. A systematic railway dangerous goods transportation system risk analysis approach: The 24Model. J. Loss Prev. Process Ind. 2019, 61, 94–103. [Google Scholar] [CrossRef]

- Salmon, P.M.; Hulme, A.; Walker, G.H.; Waterson, P.; Berber, E.; Stanton, N.A. The big picture on accident causation: A review, synthesis and meta-analysis of AcciMap studies. Saf. Sci. 2020, 126, 104650. [Google Scholar] [CrossRef]

- Rad, M.A.; Lefsrud, L.M.; Hendry, M.T. Application of systems thinking accident analysis methods: A review for railways. Saf. Sci. 2023, 160, 106066. [Google Scholar] [CrossRef]

- Lyu, Q.; Fu, G.; Wang, Y.; Li, J.; Han, M.; Peng, F.; Yang, C. How accident causation theory can facilitate smart safety management: An application of the 24Model. Process Saf. Environ. Prot. 2022, 162, 878–890. [Google Scholar] [CrossRef]

- Qiao, W.; Li, X.; Liu, Q. Systemic approaches to incident analysis in coal mines: Comparison of the STAMP, FRAM and “2–4” models. Resour. Policy 2019, 63, 101453. [Google Scholar] [CrossRef]

- Zeleskidis, A.; Dokas, I.M.; Papadopoulos, B.K. Knowing the safety level of a system in real-time: An extended mathematical model of the STAMP-based RealTSL methodology. Saf. Sci. 2022, 152, 105739. [Google Scholar] [CrossRef]

- Jia, Q.; Fu, G.; Xie, X.; Xue, Y.; Hu, S. Enhancing accident cause analysis through text classification and accident causation theory: A case study of coal mine gas explosion accidents. Process Saf. Environ. Prot. 2024, 185, 989–1002. [Google Scholar] [CrossRef]

- Cheng, L.; Jiang, B.; Guo, H. Modeling the causes of accidental gas explosions from the perspective of safety information loss. Process Saf. Prog. 2022, 41, 772–782. [Google Scholar] [CrossRef]

- Yılmaz, C.; Turan, A.H. The causes of occupational accidents in human resources: The human factors theory and the accident theory perspective. Int. J. Occup. Saf. Ergon. 2023, 29, 796–805. [Google Scholar] [CrossRef]

- Kaptan, M.; Sarıalïoğlu, S.; Uğurlu, Ö.; Wang, J. The evolution of the HFACS method used in analysis of marine accidents: A review. Int. J. Ind. Ergon. 2021, 86, 103225. [Google Scholar] [CrossRef]

- Farooqi, A.; Ryan, B.; Cobb, S. Using expert perspectives to explore factors affecting choice of methods in safety analysis. Saf. Sci. 2022, 146, 105571. [Google Scholar] [CrossRef]

- Tian, W.; Caponecchia, C. Using the functional resonance analysis method (FRAM) in aviation safety: A systematic review. J. Adv. Transp. 2020, 2020, 8898903. [Google Scholar] [CrossRef]

- Underwood, P.; Waterson, P. Systemic accident analysis: Examining the gap between research and practice. Accid. Anal. Prev. 2013, 55, 154–164. [Google Scholar] [CrossRef] [PubMed]

- Heinrich, H.W. Industrial Accident Prevention; A Scientific Approach; McGraw-Hill: New York, NY, USA, 1931. [Google Scholar]

- Haddon, W., Jr. On the escape of tigers: An ecologic note. Am. J. Public Health Nations Health 1970, 60, 2229–2234. [Google Scholar] [CrossRef] [PubMed]

- Bird, F.E.; Loftus, R.G. Loss Control Management; Institute Press: Loganville, PA, USA, 1976. [Google Scholar]

- Reason, J. Human Error; Cambridge University Press: Cambridge, UK, 1990. [Google Scholar] [CrossRef]

- Fu, G.; Xie, X.; Jia, Q.; Tong, W.; Ge, Y. Accidents analysis and prevention of coal and gas outburst: Understanding human errors in accidents. Process Saf. Environ. Prot. 2020, 134, 1–23. [Google Scholar] [CrossRef]

- Liu, Q.; Dou, F.; Meng, X. Building risk precontrol management systems for safety in China’s underground coal mines. Resour. Policy 2021, 74, 101631. [Google Scholar] [CrossRef]

- Grant, E.; Salmon, P.M.; Stevens, N.J.; Goode, N.; Read, G.J. Back to the future: What do accident causation models tell us about accident prediction? Saf. Sci. 2018, 104, 99–109. [Google Scholar] [CrossRef]

- Zhu, G.; Chen, G.; Zhu, J.; Meng, X.; Li, X. Modeling the evolution of major storm-disaster-induced accidents in the offshore oil and gas industry. Int. J. Environ. Res. Public Health 2022, 19, 7216. [Google Scholar] [CrossRef]

- Dai, C.; Xu, M.; Wang, W.; Ma, C.; Yang, L. Study on statistical indicators of economic loss of major chemical accidents. Process Saf. Prog. 2023, 42, 622–627. [Google Scholar] [CrossRef]

- Chen, S.; Cai, Q.; Yang, Y.; Xiao, C. Calculation method of indirect accident loss based on life value. In Proceedings of the Information Computing and Applications: First International Conference, ICICA 2010, Tangshan, China, 15–18 October 2010; Proceedings 1; Springer: Berlin/Heidelberg, Germany, 2010; pp. 486–492. [Google Scholar] [CrossRef]

- Chantith, C.; Permpoonwiwat, C.K.; Hamaide, B. Measure of productivity loss due to road traffic accidents in Thailand. IATSS Res. 2021, 45, 131–136. [Google Scholar] [CrossRef]

- Wang, Q.; Chen, S.; Chen, F.; Zhang, J.; Chen, L.; Li, J.; Dou, Z. A dynamic assessment method for risk evolution in chemical processes based on MFM-HAZOP-FDBN. Chem. Eng. Res. Des. 2024, 204, 471–486. [Google Scholar] [CrossRef]

- Recal, F.; Demirel, T. Comparison of machine learning methods in predicting binary and multi-class occupational accident severity. J. Intell. Fuzzy Syst. 2021, 40, 10981–10998. [Google Scholar] [CrossRef]

- Joe-Asare, T.; Stemn, E.; Amegbey, N. Causal and contributing factors of accidents in the Ghanaian mining industry. Saf. Sci. 2023, 159, 106036. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Wang, X.; Graham, T.; Wang, J. An analysis of factors affecting the severity of marine accidents. Reliab. Eng. Syst. Saf. 2021, 210, 107513. [Google Scholar] [CrossRef]

- Pinto, A.; Ribeiro, R.A.; Nunes, I.L. Fuzzy approach for reducing subjectivity in estimating occupational accident severity. Accid. Anal. Prev. 2012, 45, 281–290. [Google Scholar] [CrossRef] [PubMed]

- Zhang, G.; Yau, K.K.; Chen, G. Risk factors associated with traffic violations and accident severity in China. Accid. Anal. Prev. 2013, 59, 18–25. [Google Scholar] [CrossRef]

- Rasmussen, J. Risk management in a dynamic society: A modelling problem. Saf. Sci. 1997, 27, 183–213. [Google Scholar] [CrossRef]

- Shappell, S.A.; Wiegmann, D.A. The Human Factors Analysis and Classification System—HFACS; Office of Aviation Medicine, Federal Aviation Administration: Washington, DC, USA, 2000. [Google Scholar]

- Hollnagel, E.; Goteman, O. The functional resonance accident model. Proc. Cogn. Syst. Eng. Process Plant 2004, 2004, 155–161. [Google Scholar]

- Leveson, N. A new accident model for engineering safer systems. Saf. Sci. 2004, 42, 237–270. [Google Scholar] [CrossRef]

- Jia, Q.; Fu, G.; Xie, X.; Hu, S.; Wu, Y.; Li, J. LPG leakage and explosion accident analysis based on a new SAA method. J. Loss Prev. Process Ind. 2021, 71, 104467. [Google Scholar] [CrossRef]

- Daniellou, F.; Simard, M.; Boissière, I. Human and Organizational Factors of Safety: State of the Art; Foundation for an Industrial Safety Culture (FonCSI): Toulouse, France, 2011. [Google Scholar]

- Düzgün, H.S.; Leveson, N. Analysis of soma mine disaster using causal analysis based on systems theory (CAST). Saf. Sci. 2018, 110, 37–57. [Google Scholar]

- Hollnagel, E. The ETTO Principle: Efficiency-Thoroughness Trade-Off: Why Things That Go Right Sometimes Go Wrong; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- GB/T 6441-1986; Classification for Casualty Accidents of Enterprise Staff and Workers. State Bureau of Standards: Beijing, China, 1986.

- Wang, J.; Zhao, C.; Liu, Z. Can Historical Accident Data Improve Sustainable Urban Traffic Safety? A Predictive Modeling Study. Sustainability 2024, 16, 9642. [Google Scholar] [CrossRef]

| Model | Proposer | Core Concept | Contributions | Elements | Representation of Consequences |

|---|---|---|---|---|---|

| Domino Theory | Heinrich [22] | Accidents result from a chain reaction of multiple factors, including heredity, social environment, personal defects, unsafe behavior or conditions, and injury. | Introduced the safety pyramid and chain accident causation model. | Social environment, human errors, and unsafe conditions. | Injuries. |

| Energy Transfer Theory | Haddon [23] | Accidents involve unwanted or abnormal energy transfer, and preventing accidents requires preventing unintentional energy release. | Defined the physical nature of accidents from an energy perspective. | Energy sources and transmission paths. | Injuries. |

| Loss Causation Model (LCM) | Bird and Loftus [24] | Accidents result from management errors leading to unsafe behaviors or conditions, which ultimately cause accidents and losses. | Highlighted the importance of management control in accident prevention. | Management failures. | Losses. |

| Swiss Cheese Model (SCM) | Reason [25] | Accidents result from multiple layers of defense failure, occurring when several defenses fail simultaneously. | Visually demonstrated the multi-factor nature of accidents and the layered defense structure, emphasizing organizational defects. | Organizational influence, unsafe supervision, and unsafe behavior. | Not explicitly reflected. |

| AcciMap | Rasmussen [39] | Analyzes accident causes from a multi-level socio-technical system perspective, focusing on interactions across layers. | Provided a socio-technical perspective, emphasizing the multi-level interactions that influence accidents. | Government policies, regulatory agencies, company management, technical and operational management, employees, and equipment. | Not explicitly reflected. |

| Human Factors Analysis and Classification System (HFACS) | Shappell and Wiegmann [40] | Analyzes accident causes from a human factors perspective, including organizational influence, unsafe supervision, and unsafe behaviors. | A systematic, layered model for analyzing accidents from a human factors viewpoint. | Organizational influence, supervision. | Not explicitly reflected. |

| Functional Resonance Analysis Method (FRAM) | Hollnagel and Goteman [41] | Accident causes result from variability in the functions of complex systems, where accidents are the outcome of system dysfunction. | Emphasized the interdependence of system functions and is applicable to complex systems analysis. | Functional dependencies between system functions. | Not explicitly reflected. |

| Systems-Theoretic Accident Model and Processes (STAMP) | Leveson [42] | Accidents occur due to failures in control structures and feedback mechanisms within a system. | Highlighted the role of control and feedback mechanisms in ensuring safety: suited for complex systems. | Control structures, feedback mechanisms, and system boundaries. | Not explicitly reflected. |

| 24 Model | Fu et al. [43] | Divides accident causes into two types and four stages, covering human, material, managerial, and environmental aspects. | Integrated various theories, emphasizing the combined influence of human, material, and managerial factors on accidents. | Human factors, material factors, and management failures. | Not explicitly reflected. |

| Accident | Hazard Source | Code | Measure Type | Behavior Requirement | Basis |

|---|---|---|---|---|---|

| Roof and rib falls (T01) | Rock with high ground stress (S01) | M03-R01 | Control measure | The roadway support and stope roof management can ensure the safety of the workplace. | RIMSL-2.10.4 |

| M03-R02 | Control measure | The mine roadway layout leaves enough ore pillars or rock pillars to ensure production safety. | RIMSL-2.10.5 | ||

| M03-R03 | Control measure | It is prohibited to mine across layers and boundaries. | RIMSL-3.13 | ||

| M03-R04 | Control measure | The nature and scale of larger faults and fracture zones should be made clear. | RIMSL-2.5.1 | ||

| Object strike (T02) | Floating stone (S01) | M03-R01 | Control measure | Underground mining operations must manage the roof and ribs according to the regulations of the operation procedures. | RIMSL-3.17 |

| Inundation (T03) | Groundwater/Empty-area water (S01) | M03-R01 | Control measure | The nature of aquifers and aquitards, the hydraulic connections between aquifers, and between surface water and groundwater should be made clear. | RIMSL-2.5.2 |

| M03-R02 | Control measure | The distribution range, mining depth, and water accumulation situation of the original small kilns and old kilns within the mine design range should be made clear. | RIMSL-2.5.3 | ||

| M03-R03 | Control measure | The drainage equipment should meet the national safety standard or industry safety standard. | RIMSL-3.14.1 | ||

| M03-R04 | Control measure | The mine enterprise should mine within the scope approved by the mining license and is prohibited to mine across layers and boundaries. | RIMSL-3.13 | ||

| Rainwater (S02) | M03-R01 | Control measure | There should be ground and underground waterproof and drainage systems and measures to prevent surface water from flowing into the stope. | RIMSL-2.10.7 | |

| Gas poisoning (T04) | Toxic and harmful gases (S01) | M03-R01 | Control measure | Each mine has an independent ventilation system using mechanical ventilation to ensure sufficient air volume in the underground workplace. | RIMSL-2.10.2 |

| M03-R02 | Control measure | The concentration of toxic and harmful substances in the air of the mine workplace should not exceed the national standard or industry standard. | RIL3SM-3.16 | ||

| M04-R01 | Monitoring measure | Each mine is equipped with a sufficient number of ventilation detection instruments and toxic and harmful gas and underground environment detection instruments. | RIMSL-2.10.19 | ||

| Fire (T05) | Combustibles (S02) | M02-R01 | Substitution | The fireproof material should meet the national safety standard or industry safety standard. | RIMSL-3.14.3 |

| Ignition source (S02) | M01-R01 | Elimination | No one is allowed to carry tobacco and ignition tools down the mine. | RIMSL-3.18 | |

| M03-R01 | Control measure | There is a possibility of spontaneous combustion of minerals and dust explosion, and effective preventive measures for spontaneous combustion should be taken. | RIMSL-2.5.4 | ||

| M03-R03 | Control measure | There are fire prevention and extinguishing facilities and equipment. | RIMSL-2.10.10 | ||

| M03-R02 | Control measure | When conducting dangerous operations such as blasting, hoisting, hot work, and temporary electricity, specialized personnel should be arranged for on-site safety management. | WSL-2.43 | ||

| Explosive handling (T06) | Gunpowder, detonators in non-blasting operation sites (S01) | M03-R01 | Control measure | The place where the mine stores blasting materials meets the relevant national regulations. | RIMSL-2.10.16 |

| Explosions (T07) | Materials or equipment related to blasting (S01) | M03-R01 | Control measure | The blasting materials should meet the national safety standard or industry safety standard. | RIMSL-3.14.3 |

| M03-R02 | Control measure | The blasting operations and the manufacturing, storage, transport, test, and destruction of blasting materials in the mine must strictly implement the relevant national regulations. | RIMSL-3.24 | ||

| Electrocution (T08) | Electrical equipment with electricity (S01) | M03-R01 | Control measure | The ground and underground power distribution systems meet the relevant national regulations. | RIMSL-2.10.11 |

| M03-R02 | Control measure | Motors, transformers, distribution cabinets, electrical switches, and electrical control devices should meet the national safety standard or industry safety standard. | RIMSL-3.14.2 | ||

| M03-R03 | Control measure | Non-duty electrical personnel are not allowed to conduct electrical operations. | RIMSL-3.15 | ||

| Mechanical injury (T09) | Mechanical equipment other than vehicles (S01) | M01-R01 | Elimination | The state has a system of phasing out technologies and equipment that seriously endanger production safety. | WSL-2.38 |

| M03-R01 | Control measure | The mine enterprise should regularly inspect and repair its mechanical and electrical equipment and its protective devices and safety detection instruments and establish a technical archive to ensure safe use. | RIMSL-3.15 | ||

| M03-R02 | Control measure | Non-responsible equipment operation personnel are not allowed to operate the equipment. | RIMSL-3.15 | ||

| Transportation (T10) | Vehicle equipment (S01) | M01-R01 | Elimination | The state has a system of phasing out technologies and equipment that seriously endanger production safety. | WSL-2.38 |

| M03-R01 | Control measure | The selection of motor cars, overhead lines, and tracks can meet the safety requirements. | RIMSL-2.10.12.4 | ||

| M03-R02 | Control measure | The mechanical equipment for transporting people has reliable safety protection devices. | RIMSL-2.10.12.5 | ||

| Falls from heights (T11) | Lifting equipment (S01) | M03-R01 | Control measure | The mine lifting and transportation equipment, devices, and facilities meet the following requirements: The wire rope, connection device, lifting container, and safety chain have sufficient safety coefficients. | RIMSL-2.10.12.1 |

| M04-R01 | Monitoring measure | The lifting and transportation equipment has a sensitive and reliable signal device. | RIMSL-2.10.12.6 | ||

| Other places that make people far from the ground (S02) | M03-R01 | Control measure | The chute mine has safety measures to prevent and handle blockages. | RIMSL-2.10.8 | |

| M05-R01 | Warning measure | According to the requirements of different working places, set up mine safety signs. | RIMSL-4.40 |

| Code | Evolution Stage | Behavior Requirement | Basis |

|---|---|---|---|

| E01-R01 | Hidden Hazard Management | Take timely measures to deal with the accident hidden dangers in the mine. | RIMSL-4.29.7 |

| E02-R01 | Personnel Coupling | Production and operation units should set up obvious safety warning signs on production and operation places and relevant facilities and equipment with large risk factors. | WSL-2.21.35 |

| E02-R02 | When production and operation units conduct dangerous operations, such as blasting, hoisting, hot work, and temporary electricity, specialized personnel should be arranged for on-site safety management to ensure the compliance of operation procedures and the implementation of safety measures. | WSL-2.21.43 | |

| E03-R01 | Personnel Protection | Production and operation units must provide labor protection articles that meet the national standard or industry standard for employees and supervise and educate employees to wear and use them according to the use rules. | WSL-2.21.45 |

| E04-R01 | On-site Disposal | The mine enterprise should make each employee familiar with the mine disaster prevention and emergency plan and organize at least one mine disaster rescue drill every year. | RIMSL-4.40 |

| E05-R01 | Emergency Mechanism | The mine enterprise should compile a mine disaster prevention and emergency plan every year; at the end of each quarter, they should modify the plan according to the actual situation and formulate corresponding measures. | RIMSL-4.40 |

| E05-R02 | Production and operation units should formulate their own production safety accident emergency rescue plans. | WSL-5.81 | |

| E05-R03 | Establish an emergency rescue organization. | WSL-5.82 | |

| E05-R04 | Prepare necessary emergency rescue equipment, materials, and supplies and conduct regular maintenance and repair to ensure normal operation. | WSL-5.82 |

| Code | Category | Requirement | Basis |

|---|---|---|---|

| H01-S01-R01 | Fluke | Production and operation units should pay attention to the physical status, psychological status, and behavior habits of employees. They should strengthen the psychological counseling and spiritual comfort of employees and strictly implement the post-safety production responsibility to prevent accidents caused by abnormal behavior of employees. | WSL-2.21.44 |

| H01-S02-R01 | Complacency | ||

| H01-S03-R01 | Herd | ||

| H01-S04-R01 | Rebellious | ||

| H01-S05-R01 | Adventurous | ||

| H02-S01-R01 | Fatigue | The mine enterprise union lawfully safeguards the legitimate rights and interests of employees in production safety. | RIMSL-4.23 |

| H02-S02-R01 | Physical discomfort | When there is a situation that endangers the safety and health of employees, the mine enterprise should immediately correct or limit the time to solve it. | RIMSL-5.44 |

| H02-S03-R01 | Environmental impacts | In the intake air flow of the mining face, according to volume calculation, the oxygen content should not be less than 20%, the carbon dioxide content should not exceed 5%, and the air temperature at the underground working place should not exceed 28 °C. | RIMSL-3.22 |

| H02-S04-R01 | Insufficient skills | According to the regulations of this regulation, conduct safety education and training for employees. | RIMSL-4.29.5 |

| O-R01 | Manager | Seriously implement the provisions of the “Mine Safety Law” and this regulation as well as other laws and regulations related to mine production safety. | RIMSL-4.29.1 |

| O-R01 | Seriously implement the provisions of the “Mine Safety Law” and this regulation as well as other laws and regulations related to mine production safety. | RIMSL-4.29.1 | |

| O-R02 | Formulate the enterprise’s production safety management system. | RIMSL-4.28, RIMSL-4.29.2 | |

| O-R03 | Implement a double prevention mechanism of safety risk grading control and hidden danger investigation and treatment. | WSL-1.4 | |

| O-R04 | Ensure the effective implementation of the enterprise’s safety production investments. | WSL-2.21.4 |

| Accident Type | Hazard Source Code (N/P) | Violated Measure (N/P) | Personal Protection (N/P) | On-Site Disposal (N/P) | Emergency Situation (N/P) | Prerequisite Conditions Code (N/P) |

|---|---|---|---|---|---|---|

| T01 | S01 (27/100%) | M03-R01 (26/96.3%) | Not Involved (27/100%) | Not Involved (27/100%) | Not Involved (23/85.2%) Defective Emergency Process (4/14.8%) | H01 (20/74.1%) H02-S04 (7/25.9%) |

| M03-R02 (1/3.7%) | ||||||

| M03-R04 (3/11.1%) | ||||||

| T02 | S01 (3/100%) | M03-R01 (3/100%) | No Protection (3/100%) | Not Involved (3/100%) | Not Involved (3/100%) | H01 (3/100%) |

| T03 | S01 (14/87.5%) | M03-R01 (9/56.2%) | Not Involved (16/100%) | Not Involved (16/100%) | Not Involved (16/100%) | H01 (12/75.0%) |

| S02 (2/12.5%) | M03-R02 (7/43.8) | H02-S04 (4/25%) | ||||

| T04 | S01 (4/100%) | M03-R02 (2/50.0%) | Not Involved (3/75.0%) | Not Involved (3/75.0%) | Not Involved (2/50.0%) | H01 (4/100%) |

| M03-R03 (2/50.0%) | No Protection (1/25.0%) | On-site Measures Ineffective (1/25.0%) | Emergency Process Defective (2/50.0%) | |||

| T05 | S02 (3/100%) | M03-R02 (3/100%) | Not Involved (1/33.3%) | On-site Measures Ineffective (3/100%) | Not Involved (2/66.7) | H01 (3/100%) |

| No Protection (2/66.7) | Emergency Process Defective (1/33.3%) | |||||

| T06 | S01 (1/100%) | M03-R01 (1/100%) | No Protection (1/100%) | Not Involved (1/100%) | Not Involved (1/100%) | H01 (1/100%) |

| T07 | S01 (1/100%) | M03-R02 (1/100%) | Not Involved (1/100%) | Not Involved (1/100%) | Not Involved (1/100%) | H02-S04 (1/100%) |

| T10 | S01 (1/100%) | M01-R01 (1/100%) | Not Involved (1/100%) | Not Involved (1/100%) | Not Involved (1/100%) | H01 (1/100%) |

| T11 | S01 (3/60.0%) S02 (2/40.0%) | M03-R01 (3/60.0%) Not Applicable (2/40.0%) | Not Involved (2/40.0%) No Protection (3/60.0%) | Not Involved (5/100%) | Not Involved (4/80.0%) Emergency Process Defective (1/20.0%) | H01 (4/80.0%) |

| H02-S01 (1/20.0%) | ||||||

| H02-S04 (1/20.0%) |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiang, X.; Li, G.; Fan, C.; Zhao, W.; Wang, Q. The Full Lifecycle Evolution Model of Accidents: A Case Study of Underground Metal Mines in China. Appl. Sci. 2025, 15, 4004. https://doi.org/10.3390/app15074004

Qiang X, Li G, Fan C, Zhao W, Wang Q. The Full Lifecycle Evolution Model of Accidents: A Case Study of Underground Metal Mines in China. Applied Sciences. 2025; 15(7):4004. https://doi.org/10.3390/app15074004

Chicago/Turabian StyleQiang, Xingbang, Guoqing Li, Chunchao Fan, Wei Zhao, and Qiuling Wang. 2025. "The Full Lifecycle Evolution Model of Accidents: A Case Study of Underground Metal Mines in China" Applied Sciences 15, no. 7: 4004. https://doi.org/10.3390/app15074004

APA StyleQiang, X., Li, G., Fan, C., Zhao, W., & Wang, Q. (2025). The Full Lifecycle Evolution Model of Accidents: A Case Study of Underground Metal Mines in China. Applied Sciences, 15(7), 4004. https://doi.org/10.3390/app15074004