The Impact of Cloud Versus Local Infrastructure on Automatic IoT-Driven Hydroponic Systems

Abstract

1. Introduction

1.1. Artificial Intelligence in Hydroponic Systems

1.2. IoT Sensors and Actuators in Hydroponic Systems

- RQ1: What are the configuration differences specific to each type of hydroponic infrastructure, both at the hardware and software levels, in a cloud versus local approach?

- RQ2: Which infrastructure is superior in a comparison based on performance indicators such as response time, operational reliability, implementation costs, operational costs, scalability, data accessibility, and security?

- RQ3: What implications do the performance differences have for the practical implementation of automatic hydroponic systems?

1.3. Paper Contributions and Structure

- Identification of a hardware infrastructure configuration that enables the automation of a hydroponic solution;

- Identification of possible software infrastructures compatible with the required hardware infrastructure;

- Analysis of the possibility of integrating an IoT infrastructure;

- Detailed comparative analysis between cloud infrastructure and local infrastructure for the two reference proposals of the research;

- The research analyzes the impact of using IoT equipment (M5Stack, hydroponic monitoring sensors) in both cloud and local environments;

- Detailed presentation of a method for implementing the two infrastructures;

- Assessment of the impact of response time (RT), operational reliability (OR), implementation costs (IC), operational costs (OC), configuration scalability (CS), data accessibility (DA), and data security (DS) through the two infrastructures;

- The research provides applicable recommendations for farmers who wish to adopt modern and intelligent solutions to improve decision-making processes and achieve agricultural digitalization.

2. Materials and Methods

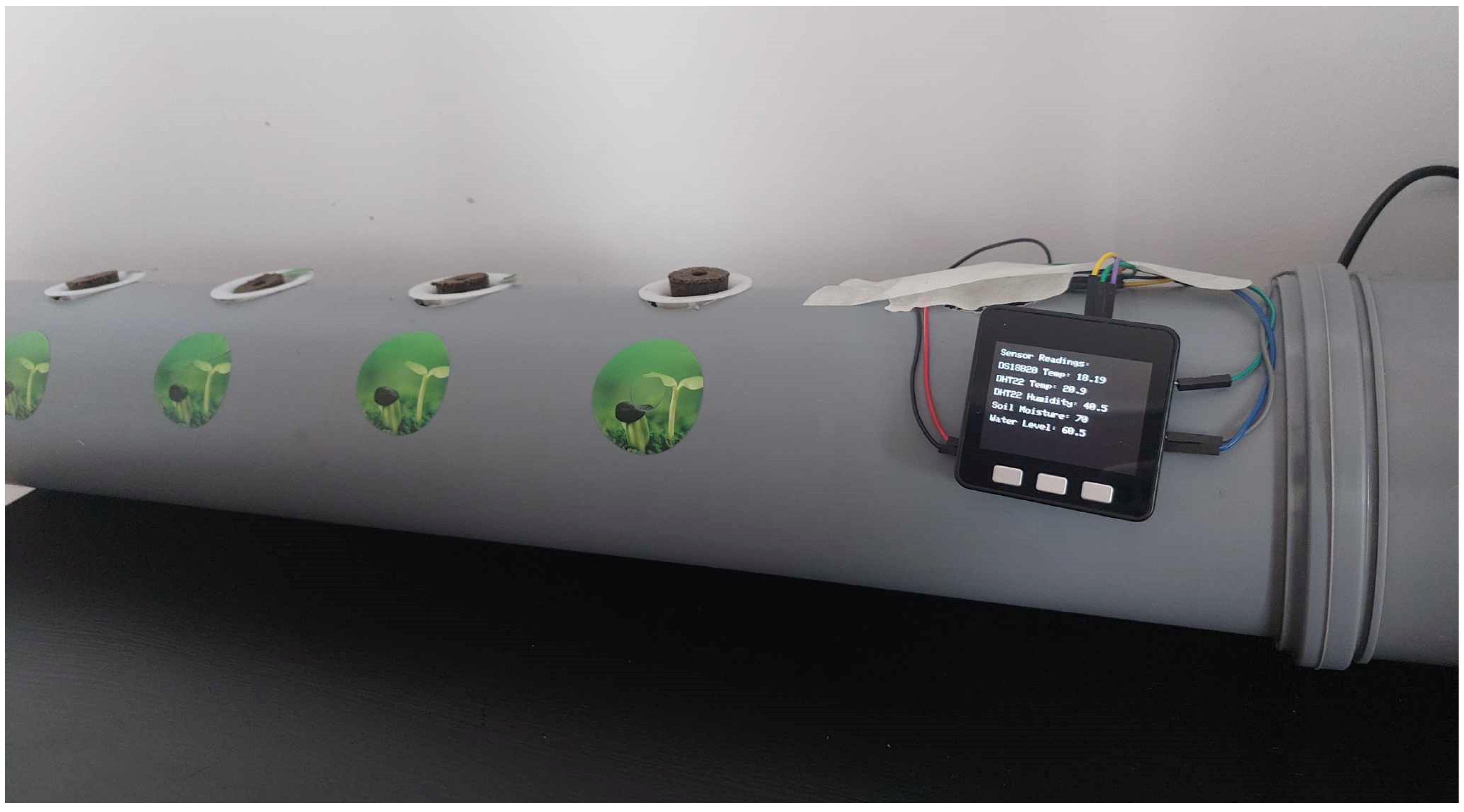

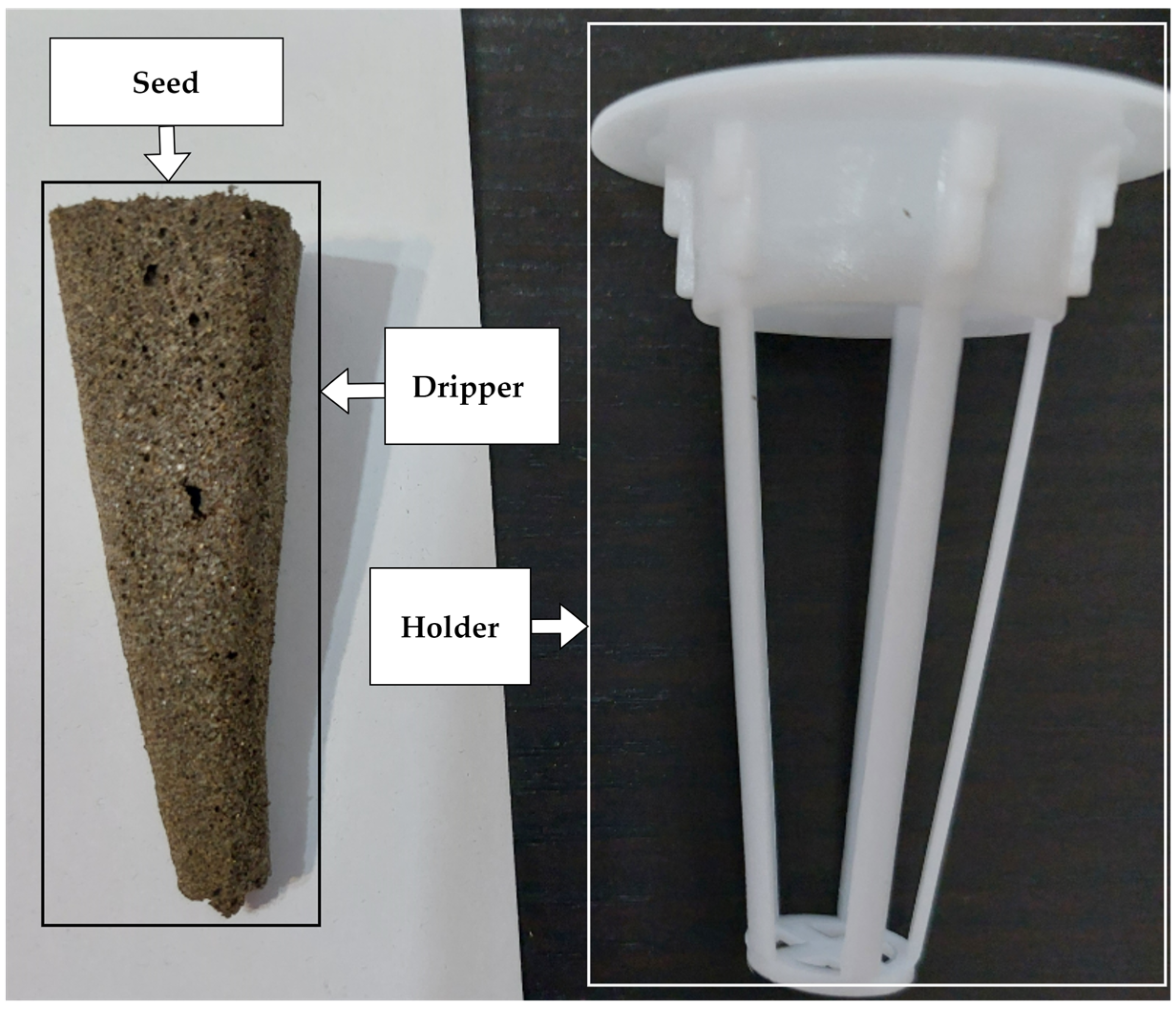

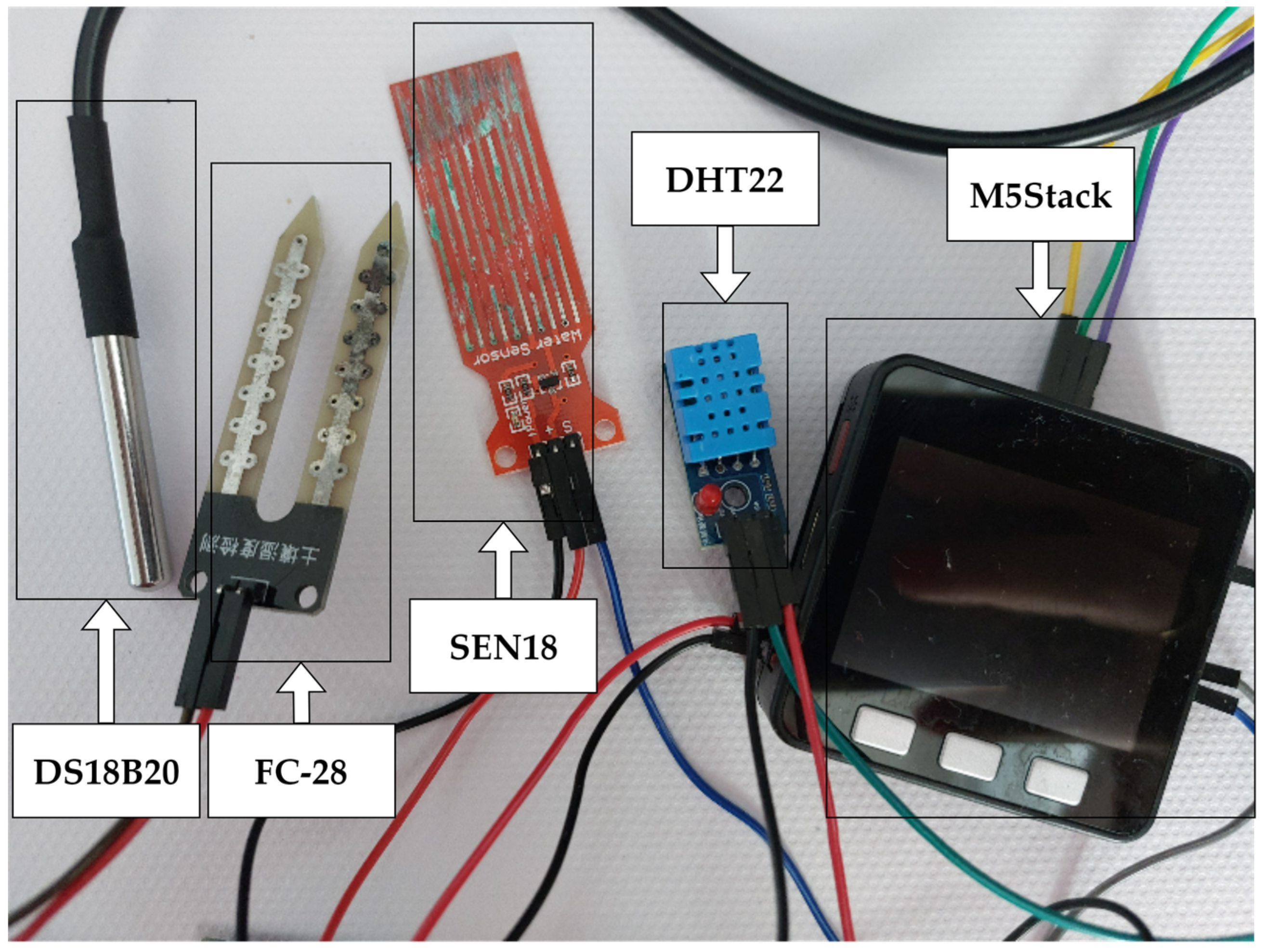

2.1. Prototype Infrastructure

- A liquid temperature sensor (DS18B20) for measuring the temperature of the nutrient solution;

- An electrical conductivity sensor (EC-5 Atlas Scientific) for determining the concentration of nutrients;

- A liquid level sensor (SEN18) for monitoring the amount of available nutrient solution;

- An environmental temperature and humidity monitoring sensor (DHT22).

- The growth of the population and the standard of living leads to an increase in food consumption, especially in urban agglomerated areas. In this context, traditional agriculture no longer represents a solution. For this reason, the integration of plant growing systems under non-traditional conditions becomes an acute necessity;

- Hydroponic systems require careful monitoring of nutrients, as they lack soil and are grown in environments that are generally not conducive to plant development;

- This type of plant cultivation requires reduced costs for plant maintenance, human resources, and the raw materials used, such as water, nutrients, and energy consumption. This is necessary because hydroponic agriculture must have lower production costs than traditional agriculture to be viable.

2.2. Proposed Software Infrastructure

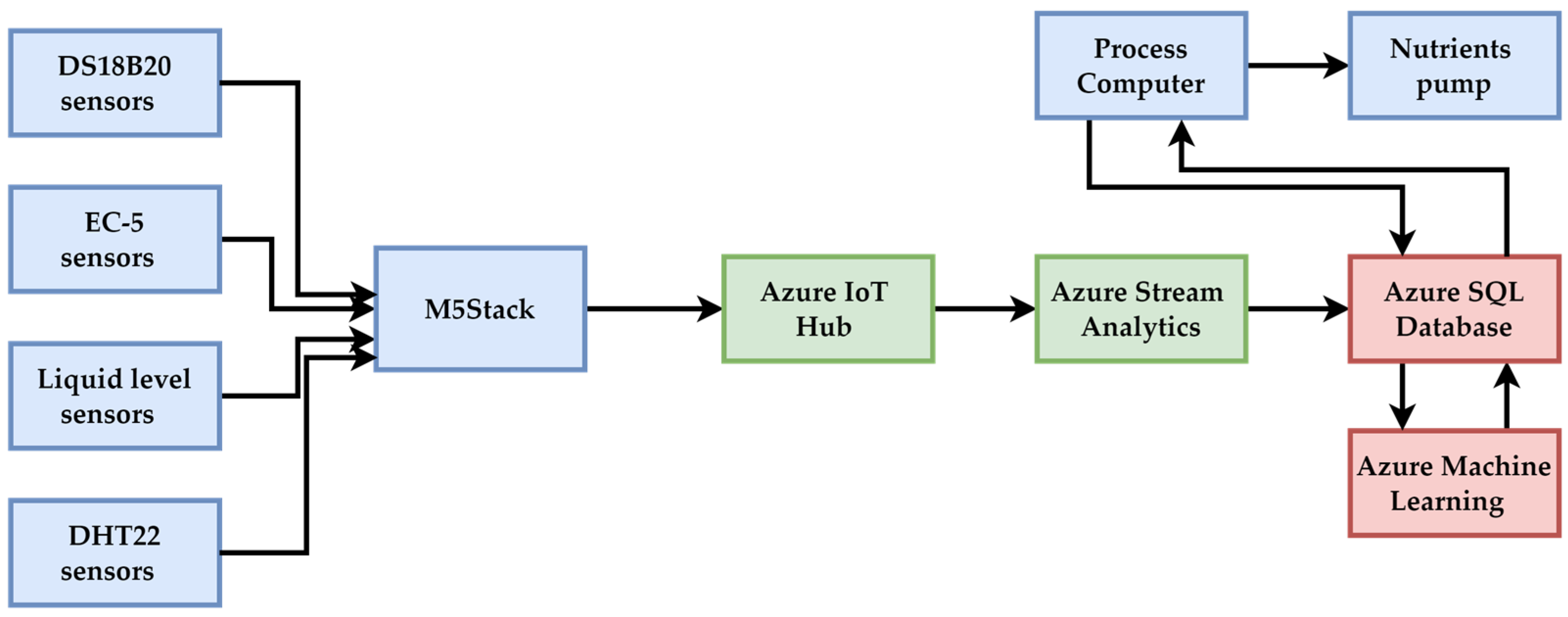

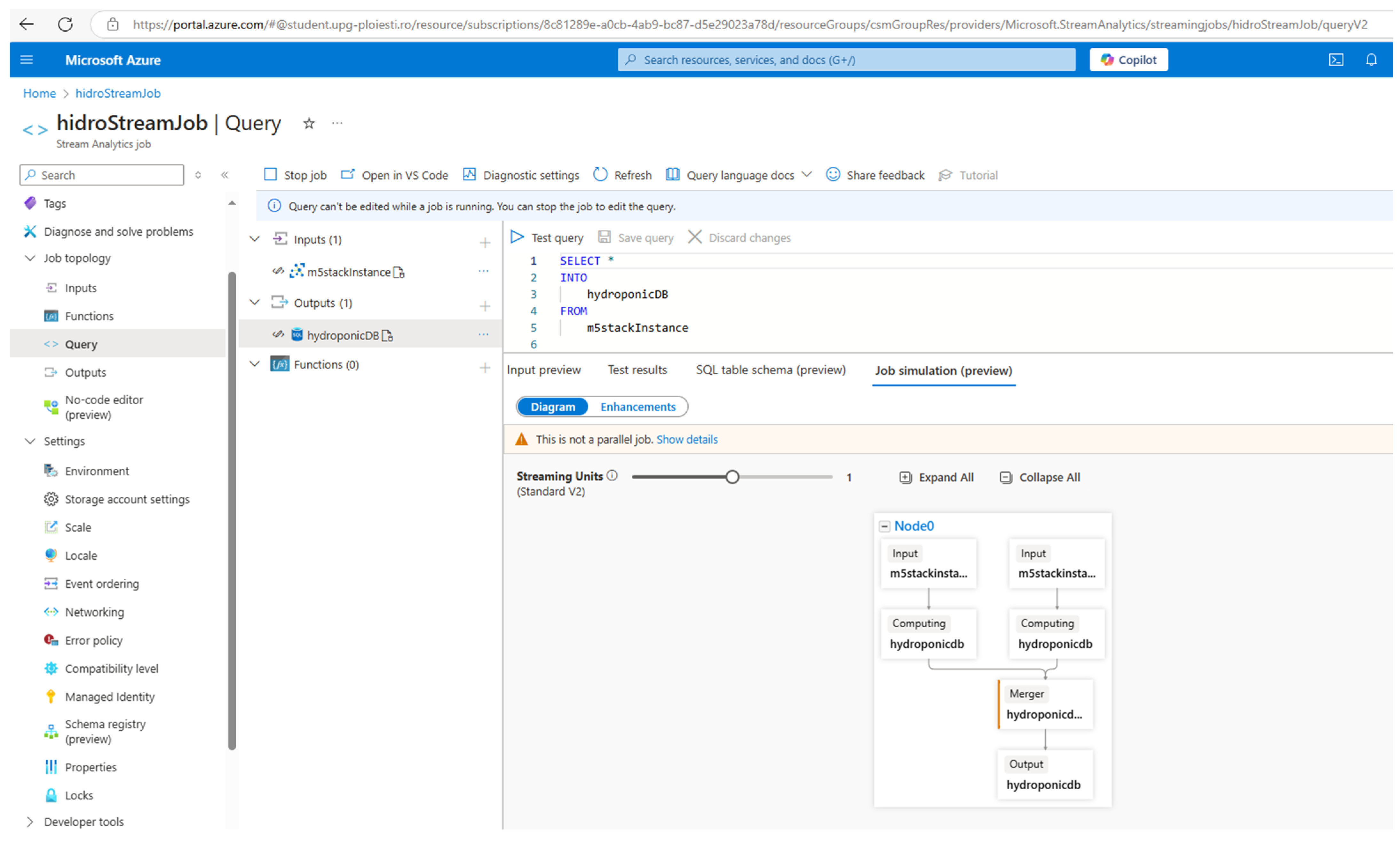

2.2.1. AFCI

- Azure IoT Hub for managing the M5Stack devices and collecting data from sensors;

- Azure Stream Analytics for processing events in real-time and triggering the activation of the pump based on decisions made using the ML model;

- Azure SQL Database stores data that allows the creation of a history. Analyzing the variability of the data enables the development of trends for ML models;

- Azure Machine Learning is used to develop predictive models that optimize the parameters of the nutrient solution.

2.2.2. LSI

- A local SQL Server database;

- A local Web project that can be accessed locally, allowing the M5Stack module to make requests to a local address and use it to add sensor values to the database;

- A script that retrieves data from the database via a cron job and uses a local ML component. Depending on the result returned by the ML model, it sets a flag in the database;

- Another script that runs via a cron job associated with the pump checks if the indicator is active, starts the pump, and deactivates the indicator in the database.

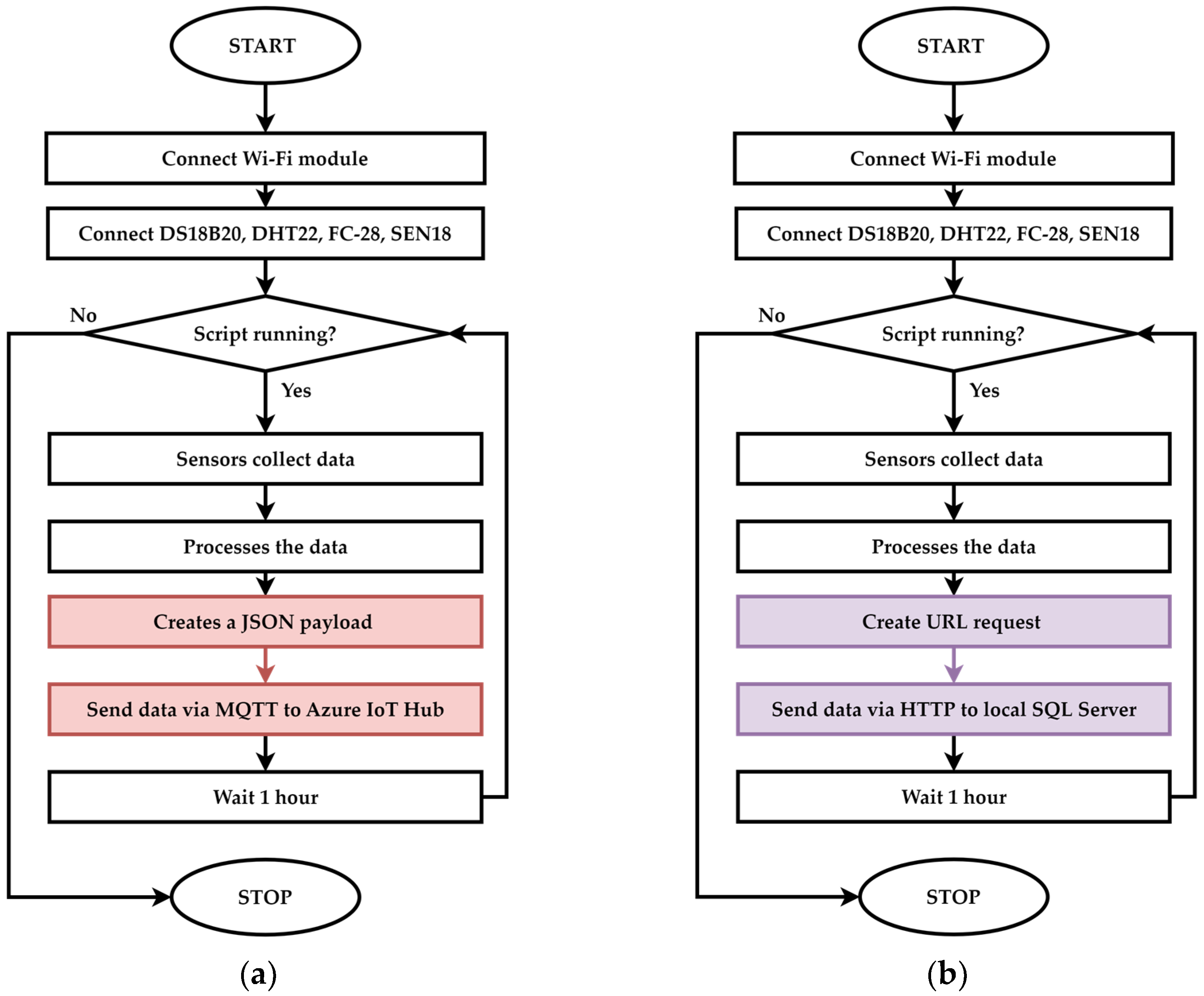

2.3. Automation Scheme for the Monitoring and Control Process of the Hydroponic System

2.4. Comparison Metrics Between AFCI and LSI

- RT-H1: The time for AFCI varies depending on the Internet connection. Sending data in the cloud may increase the RT, compared to LSI;

- RT-H2: The Internet connection does not affect the response time for LSI, as all processes run locally. However, the execution time per iteration within the process must be quantified for a relevant comparison with AFCI.

- OR-H1: AFCI may record downtime when Azure performs maintenance;

- OR-H2: LSI has no risk of downtime.

- IC-H1: AFCI has significantly higher IC than LSI because Azure programmers are experienced professionals trained explicitly in using these technologies, and the implementation time is much longer;

- IC-H2: LSI does not require senior-level programming skills. A mid-level programmer can implement such an infrastructure, lowering IC.

- OC-H1: The costs for Azure services (IoT Hub, server, SQL Database, cron) are higher than those of a local infrastructure;

- OC-H2: The costs for LSI can be zero.

- CS-H1: AFCI requires no fundamental modifications from the CS perspective;

- CS-H2: LSI requires a series of minimal modifications.

- DA-H1: Through AFCI, data can be accessed from anywhere in the world;

- DA-H2: LSI does not allow data visualization outside the intranet.

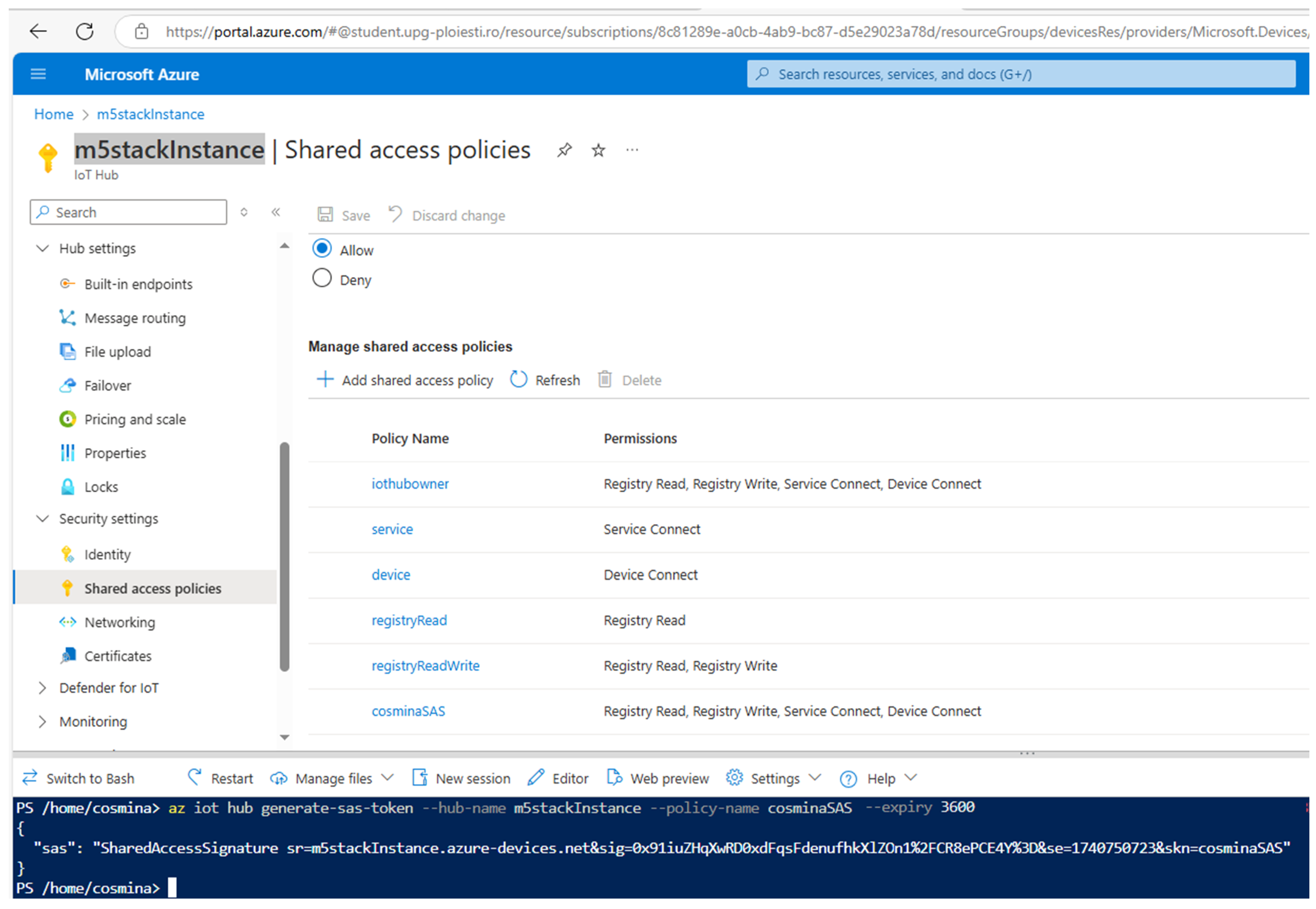

- DS-H1: AFCI benefits from all security layers through Azure’s pre-implemented mechanisms, even though the data is stored externally;

- DS-H2: LSI may have multiple security vulnerabilities if not explicitly addressed during the software infrastructure implementation.

3. Results

3.1. Hardware Comparison Infrastructure Between AFCI and LSI

3.2. Software Comparison Infrastructure Between AFCI and LSI

3.2.1. Software Infrastructure of the AFCI

- MessageId is null, meaning the message does not have a specific ID;

- ConnectionDeviceId is the unique identifier of the device, explicitly set in the Azure graphical interface for a specific device. The ID of the connected device is 1, uniquely identifying the device that sent the data;

- ConnectionDeviceGenerationId is the identifier for device generation;

- EnqueuedTime is the exact moment when the message was queued in IoT Hub.

3.2.2. Software Infrastructure of the LSI

- 1.

- Costs:

- Azure Stream Analytics is relatively expensive because it processes real-time data and uses paid cloud resources;

- Task Scheduler is free and runs locally on the PC, eliminating cloud infrastructure-related costs.

- 2.

- Complexity:

- Configuring a Stream Analytics job requires integration with IoT Hub, SQL Server, and other Azure services, which can be highly complex for users without experience;

- Task Scheduler runs the script locally for data processing and storage, making it much simpler to configure and not requiring an experienced programmer. This directly impacts the financial resource.

- 3.

- Performance:

- Azure offers pre-implemented, tested, and fully functional long-term services that relieve the owner of hardware infrastructure concerns, provide long-term support, and enable continuous processing, making it ideal for large volumes of data [58];

- Task Scheduler depends on the availability of the local PC, and if the device is turned off, the job will no longer run. This means the entire burden of continuous functionality falls on the owner.

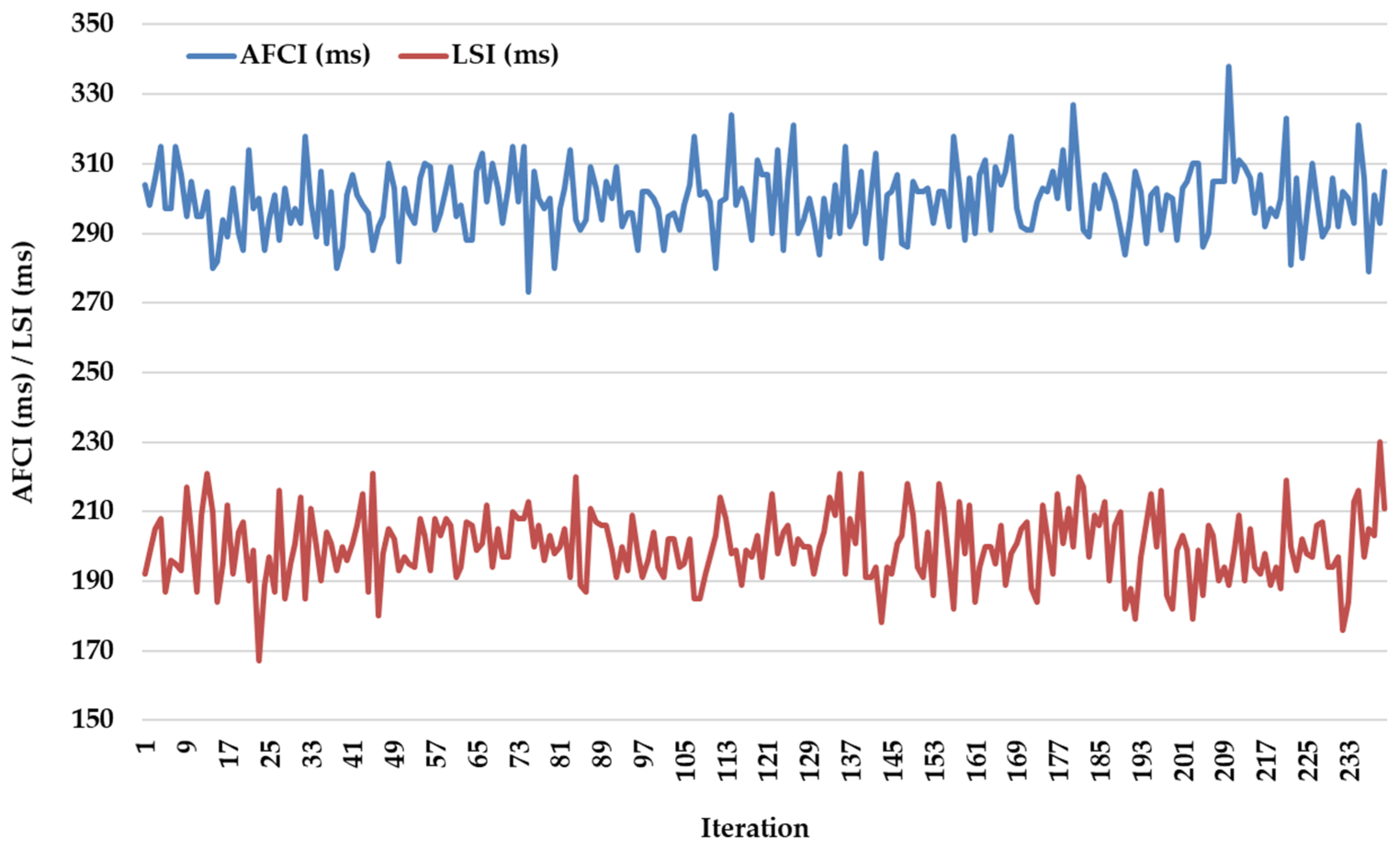

3.3. Metrics Results for Performance Comparison Between AFCI and LSI

- For AFCI, the average RT was approximately 300 ms;

- For LSI, the average response time was 200 ms.

- AFCI missed one measurement due to Azure unavailability, which could have been caused by maintenance or other service issues;

- LSI did not record any interruptions, confirming hypotheses OR-H1 and OR-H2.

- AFCI requires configuring a new device in the Azure platform and setting up the unique identification code in the firmware loaded on the device, with no other modifications needed;

- LSI requires similar changes, such as associating a unique device code that must be transmitted as an additional parameter through the URL. In this case, the changes are similar to those required for AFCI.

- The estimated minimum cost is approximately 75 USD/month for low resource usage;

- The estimated maximum cost is approximately 120 USD/month in the case of intensive use, including the increase in the volume of data stored and processed.

- Cost for 1 year (average scenario, 82.57 USD/month) results in approximately 990 USD/year;

- The cost over three years (without volume discounts) is approximately 2970 USD.

- Hardware maintenance is associated with the costs of replacing and maintaining local servers;

- Energy consumption of the local server that runs continuously. It can consume an average of 30–50 kWh per month, equivalent to approximately 3.65–6.07 USD/month. The authors note that these costs vary depending on the specific kWh price in each country and that the previous report is comparable to Romania.

- For AFCI, global data accessibility is advantageous. Figure 11 lists data from the database stored in the cloud. This database can be accessed from anywhere;

- For LSI, access is limited to the local network only.

4. Discussion

4.1. Interpretation of the Results

- RQ1: AFCI uses Microsoft Azure for all processes involving data from the IoT infrastructure. This underscores the need for a permanent internet connection. LSI manages data locally, using its own servers and dedicated scripts. Therefore, in the case of LSI, there is no dependency on the internet;

- RQ2: The performance indicators studied in the results show that LSI has a response time of 200 ms compared to 300 ms for AFCI. Additionally, LSI is superior to AFCI in terms of reliability and costs. AFCI offers scalability, global accessibility, and advanced security, but with recurring costs of USD 82.57/month;

- RQ3: LSI is ideal for small, autonomous farms where cost is a priority. AFCI is more suitable for large, distributed farms where accessibility and interoperability are central elements.

4.2. Limitations of the Study

4.3. Future Research Directions

- Analysis of multiple ML algorithms for modeling the hydroponic system from the perspective of pump activation. This research will examine both local ML.NET-specific algorithms and pre-implemented Azure ML algorithms. The study will also present the specific costs associated with the Azure ML Studio service;

- Optimization of chemical processes using pH predictions and anomaly detection in hydroponic measurements. This direction aims to improve the efficiency and reliability of hydroponic systems through advanced predictive techniques;

- Automatic water flow control systems in hydroponic systems with IoT infrastructure. Developing and testing systems capable of dynamically adjusting water flow based on real-time data;

- Study of environmental variability’s impact on plant growth in hydroponic systems. Investigating how fluctuations in environmental conditions affect crop development and yield;

- Prediction of water requirements for hydroponic systems dedicated to specific plant cultures for operational cost analysis using intelligent prediction tools. This research will focus on optimizing resource allocation and reducing costs through data-driven insights.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| AFCI | Azure Full Cloud Infrastructure |

| CS | Configuration scalability |

| DA | Data accessibility |

| DL | Deep learning |

| DS | Data security |

| DWC | Deep Water Culture |

| EC | Electrical conductivity |

| ECS | Electrical conductivity sensor |

| EH | Environmental humidity |

| ET | Environmental temperature |

| HTTP | Hypertext Transfer Protocol |

| IC | Implementation cost |

| IIS | Internet Information Services |

| IoT | Internet of Things |

| LL | Tank liquid level |

| LS | Level sensor |

| LSI | Local Software Infrastructure |

| LT | Liquid temperature |

| ML | Machine learning |

| MQTT | Message Queuing Telemetry Transport |

| NC | Nutrients concentration |

| NFT | Nutrient Film Technique |

| OC | Operational costs |

| OR | Operational reliability |

| PC | Personal computer |

| RT | Response time |

| SAS | Shared Access Signature |

| T-HS | Environmental temperature and humidity sensor |

| TS | Liquid temperature sensor |

| UTC | Coordinated Universal Time |

References

- Penjor, T.; Dorji, L.; Wangmo, D.; Yangzom, K.; Wangchuk, T. Automation of Hydroponics System using Open-source Hardware and Software with Remote Monitoring and Control. Bhutanese J. Agric. 2022, 5, 95–108. [Google Scholar] [CrossRef]

- Mohite, A.D.; Pathade, G.R. Hydroponics: A Review. Ecol. Environ. Conserv. 2024, 30, S314–S324. [Google Scholar] [CrossRef]

- Temanel, F.B.; Alipio-Ayban, L.M.B. Acclimatization of In Vitro Propagated Turmeric (Curcuma longa Linn.) in a Hydroponic System. Int. J. Sci. Res. Rev. 2024, 13, 11–23. [Google Scholar] [CrossRef]

- Ahmed, Z.F.R.; Alnuaimi, A.K.H.; Askri, A.; Tzortzakis, N. Evaluation of Lettuce (Lactuca sativa L.) Production under Hydroponic System: Nutrient Solution Derived from Fish Waste vs. Inorganic Nutrient Solution. Horticulturae 2021, 7, 292. [Google Scholar] [CrossRef]

- Kour, K.; Gupta, D.; Gupta, K.; Dhiman, G.; Juneja, S.; Viriyasitavat, W.; Mohafez, H.; Islam, M.A. Smart-Hydroponic-Based Framework for Saffron Cultivation: A Precision Smart Agriculture Perspective. Sustainability 2022, 14, 1120. [Google Scholar] [CrossRef]

- Musa, M.; Mabu, A.; Modu, F.; Adam, A.; Aliyu, F. Automated Hydroponic System using Wireless Sensor Networks. Adv. Sci. Technol. Eng. Syst. J. 2022, 7, 1–17. [Google Scholar] [CrossRef]

- Triyono, S.; Laksono, R.A.; Tusi, A. Performance of Dry Hydroponic System on Cultivation of Green Lettuce (Lactuca sativa L.). J. Ilm. Rekayasa Pertan. Dan Biosist. 2021, 9, 37–47. [Google Scholar] [CrossRef]

- Sanidhya, R.; Tejaswini, N.; Rashmi, S. Effect of Fluid Mechanics System in Growth of Vegetable Crops using Hydroponics Technique Compared to Conventional System. J. Adv. Res. Fluid Mech. Therm. Sci. 2023, 104, 12–20. [Google Scholar] [CrossRef]

- Roșca, C.-M.; Cărbureanu, M. A Comparative Analysis of Sorting Algorithms for Large-Scale Data: Performance Metrics and Language Efficiency. In Proceedings of the Emerging Trends and Technologies on Intelligent Systems. ETTIS 2024. Lecture Notes in Networks and Systems, Noida, India, 27–28 March 2024; pp. 99–113. [Google Scholar] [CrossRef]

- Popescu, C.; Gabor, M.R.; Stancu, A. Predictors for Green Energy vs. Fossil Fuels: The Case of Industrial Waste and Biogases in European Union Context. Agronomy 2024, 14, 1459. [Google Scholar] [CrossRef]

- Zhou, G.; Wei, Q.; Li, B.; Zeng, X.; Liu, G. Establishment and optimization of a hydroponic system for root morphological and nutritional analysis of citrus. Sci. Agric. 2020, 77. [Google Scholar] [CrossRef]

- Mei, C.; Zhou, D.; Chretien, R.L.; Turner, A.; Hou, G.; Evans, M.R.; Lowman, S. A Potential Application of Pseudomonas psychrotolerans IALR632 for Lettuce Growth Promotion in Hydroponics. Microorganisms 2023, 11, 376. [Google Scholar] [CrossRef] [PubMed]

- Wongkiew, S.; Hu, Z.; Lee, J.W.; Chandran, K.; Nhan, H.T.; Marcelino, K.R.; Khanal, S.K. Nitrogen Recovery via Aquaponics–Bioponics: Engineering Considerations and Perspectives. ACS EST Eng. 2021, 1, 326–339. [Google Scholar] [CrossRef]

- Baganz, G.F.M.; Junge, R.; Portella, M.C.; Goddek, S.; Keesman, K.J.; Baganz, D.; Staaks, G.; Shaw, C.; Lohrberg, F.; Kloas, W. The aquaponic principle—It is all about coupling. Rev. Aquac. 2022, 14, 252–264. [Google Scholar] [CrossRef]

- Haggag, W.M.; Fawzy, Z.F.; El Sawey, S. Organic Hydroponics Production. NASS J. Agric. Sci. 2020, 2, 1–7. [Google Scholar] [CrossRef]

- Omar, A.A.; Abdullahi, A.M.; Mohamed, A.L.; Ali, A.A.; Omar, A.F.; Habarwa, A.A.; Ali, A.M.; Osman, A.B.; Elmi, A.S. The Effect of Different Growing Media on the Growth of Lettuce. Daha Int. Univ. Acad. J. 2023, 2, 72–80. [Google Scholar] [CrossRef]

- Raimi, L.; Panait, M.; Sule, R. Leveraging Precision Agriculture for Sustainable Food Security in Sub-Saharan Africa: A Theoretical Discourse. In Shifting Patterns of Agricultural Trade; Erokhin, V., Tianming, G., Andrei, J.V., Eds.; Springer Nature: Singapore, 2021; pp. 491–509. [Google Scholar] [CrossRef]

- Verma, R.C.; Chaithanya, G.; Sachan, P.; Thilagam, P.; Bahadur, R.; Kumar, N.; Singh, B.V.; Mahesha, K.N. Exploring Hydroponics and the Associated Technologies for Use in Medium-and Small-scale Operations: A Review. Int. J. Environ. Clim. Chang. 2023, 13, 4474–4483. [Google Scholar] [CrossRef]

- Tuan, V.; Khattak, A.; Zhu, H.; Gao, W.; Wang, M. Combination of Multivariate Standard Addition Technique and Deep Kernel Learning Model for Determining Multi-Ion in Hydroponic Nutrient Solution. Sensors 2020, 20, 5314. [Google Scholar] [CrossRef] [PubMed]

- Rosca, C.M.; Stancu, A.; Ariciu, A.V. Algorithm for child adoption process using artificial intelligence and monitoring system for children. Internet Things 2024, 26, 101170. [Google Scholar] [CrossRef]

- Anzalone, A.; Pagliaro, A.; Tutone, A. An Introduction to Machine and Deep Learning Methods for Cloud Masking Applications. Appl. Sci. 2024, 14, 2887. [Google Scholar] [CrossRef]

- Mokhtar, A.; El-Ssawy, W.; He, H.; Al-Anasari, N.; Sammen, S.S.; Gyasi-Agyei, Y.; Abuarab, M. Using Machine Learning Models to Predict Hydroponically Grown Lettuce Yield. Front. Plant Sci. 2022, 13, 706042. [Google Scholar] [CrossRef]

- Rosca, C.-M.; Rădulescu, G.; Stancu, A. Artificial Intelligence of Things Infrastructure for Quality Control in Cast Manufacturing Environments Shedding Light on Industry Changes. Appl. Sci. 2025, 15, 2068. [Google Scholar] [CrossRef]

- El-Ssawy, W.; Abuarab, M.; El-Mogy, M.; Kassem, M.; Wasef, E.; Sultan, W.; Rady, M. The Impact of Advanced Static Magnetic Units on Water Properties and the Performance of Aeroponic and NFT Systems for Lettuce. Pol. J. Environ. Stud. 2020, 29, 2641–2652. [Google Scholar] [CrossRef]

- Naveena, A.; Saheb, S.N.; Mamidi, R.; Murthy, G.L.N. Automated hydroponic nutrient control system for smart agriculture. Indones. J. Electr. Eng. Comput. Sci. 2024, 33, 839. [Google Scholar] [CrossRef]

- Hiraguri, T.; Kimura, T.; Endo, K.; Ohya, T.; Takanashi, T.; Shimizu, H. Shape classification technology of pollinated tomato flowers for robotic implementation. Sci. Rep. 2023, 13, 2159. [Google Scholar] [CrossRef]

- Kabir, M.S.N.; Reza, M.N.; Chowdhury, M.; Ali, M.; Samsuzzaman; Ali, M.R.; Lee, K.Y.; Chung, S.-O. Technological Trends and Engineering Issues on Vertical Farms: A Review. Horticulturae 2023, 9, 1229. [Google Scholar] [CrossRef]

- Rajaseger, G.; Chan, K.L.; Tan, K.Y.; Ramasamy, S.; Khin, M.C.; Amaladoss, A.; Haribhai, P.K. Hydroponics: Current trends in sustainable crop production. Bioinformation 2023, 19, 925–938. [Google Scholar] [CrossRef] [PubMed]

- Amalia, A.F.; Rahayu, H.S.P.; Rahardjo, Y.P.; Hutahaean, L.; Rohaeni, E.S.; Indrawanto, C.; Saptati, R.A.; Siagian, V.; Waris, A. Artificial intelligence for small hydroponics farms employing fuzzy logic systems and economic analysis. Rev. Bras. De Eng. Agrícola E Ambient. 2023, 27, 690–697. [Google Scholar] [CrossRef]

- Pirtea, M.G.; Noja, G.G.; Cristea, M.; Panait, M. Interplay between environmental, social and governance coordinates and the financial performance of agricultural companies. Agric. Econ. 2021, 67, 479–490. [Google Scholar] [CrossRef]

- Rosca, C.M. Comparative Analysis of Object Classification Algorithms: Traditional Image Processing Versus Artificial Intelligence-Based Approach. Rom. J. Pet. Gas Technol. 2023, IV, 169–180. [Google Scholar] [CrossRef]

- Pagliaro, A.; Cusumano, G.; La Barbera, A.L.; La Parola, V.L.; Lombardi, S. Application of Machine Learning Ensemble Methods to ASTRI Mini-Array Cherenkov Event Reconstruction. Appl. Sci. 2023, 13, 8172. [Google Scholar] [CrossRef]

- Microsoft Azure. Pricing Calculator. Available online: https://azure.microsoft.com/en-us/pricing/calculator/ (accessed on 10 February 2025).

- Hendrawan, A.H.; Ramadhan, F.C.; Ritzkal, R.; Aprian, A.J.; Yanuarsyah, I.; Setiadi, D. TDS Sensor Based Automatic Nutrient Feeding System for Telegram-Assisted NFT Pakcoy Hydroponic System. Math. Model. Eng. Probl. 2024, 11, 3091–3106. [Google Scholar] [CrossRef]

- Vyavahare, G.D.; Lee, Y.; Seok, Y.J.; Kim, H.N.; Sung, J.; Park, J.H. Monitoring of Soil Nutrient Levels by an EC Sensor during Spring Onion (Allium fistulosum) Cultivation under Different Fertilizer Treatments. Agronomy 2023, 13, 2156. [Google Scholar] [CrossRef]

- Rivana, R.R.; Made, M.R.; Edilla; Jajang, J. Sistem Monitoring Nutrisi dan PH Air pada Tanaman Hidroponik Berbasis Internet of Things (IoT). J. Elektron. Dan Otomasi Ind. 2023, 10, 300–312. [Google Scholar] [CrossRef]

- Rosca, C.M.; Popescu, M.; Patrascioiu, C.; Stancu, A. Comparative Analysis of pH Level Between Pasteurized and UTH Milk Using Dedicated Developed Application. Rev. De Chim. 2019, 70, 3917–3920. [Google Scholar] [CrossRef]

- Miller, A.; Adhikari, R.; Nemali, K. Recycling Nutrient Solution Can Reduce Growth Due to Nutrient Deficiencies in Hydroponic Production. Front. Plant Sci. 2020, 11, 607643. [Google Scholar] [CrossRef]

- Rosca, C.M. Convergence Catalysts: Exploring the Fusion of Embedded Systems, IoT, and Artificial Intelligence. In Engineering Applications of AI and Swarm Intelligence; Yang, X.-S., Ed.; Springer Nature: Singapore, 2025; pp. 69–87. [Google Scholar] [CrossRef]

- Safira, M.; Yusuf, A.; Salim, T.I.; Alam, H.S. Design and Implementation of IOT-Based Monitoring System on Nanobubble-Based Hydroponics Farming. J. Tek. Pertan. Lampung 2023, 12, 470–483. [Google Scholar] [CrossRef]

- Tatas, K.; Al-Zoubi, A.; Christofides, N.; Zannettis, C.; Chrysostomou, M.; Panteli, S.; Antoniou, A. Reliable IoT-Based Monitoring and Control of Hydroponic Systems. Technologies 2022, 10, 26. [Google Scholar] [CrossRef]

- Li, J.; Yang, K.; Guo, X.; Huang, W.; Shi, C.; Guo, Y.; Wang, T.; Fu, H.; Pan, J. Mathematical model of hydraulic ram pump system. Proc. Inst. Mech. Eng. Part A J. Power Energy 2022, 236, 1097–1108. [Google Scholar] [CrossRef]

- Metra, D.P.J.; Credo, M.C. Design Analysis, Installation and Performance Evaluation of a Hydraulic Ram Pump System with a Modified Waste Valve. Vietnam. J. Sci. Technol. 2020, 58, 107. [Google Scholar] [CrossRef]

- Zhang, K.-C.; Shi, J.-Y. Pulsation Simulation and Energy Consumption Analysis of Series Pump Valve Cooperative Control Hydraulic System. Int. J. Fluid Power 2021, 22, 409–424. [Google Scholar] [CrossRef]

- Rosca, C.-M.; Stancu, A. Fusing Machine Learning and AI to Create a Framework for Employee Well-Being in the Era of Industry 5.0. Appl. Sci. 2024, 14, 10835. [Google Scholar] [CrossRef]

- Acharya, P.; Choi, N.Y.; Shrestha, S.; Jeong, S.; Lee, M.Y. Brain organoids: A revolutionary tool for modeling neurological disorders and development of therapeutics. Biotechnol. Bioeng. 2024, 121, 489–506. [Google Scholar] [CrossRef] [PubMed]

- Filippi, M.; Yasa, O.; Kamm, R.D.; Raman, R.; Katzschmann, R.K. Will microfluidics enable functionally integrated biohybrid robots? Proc. Natl. Acad. Sci. USA 2022, 119, e2200741119. [Google Scholar] [CrossRef] [PubMed]

- Dorsey, P.J.; Scalise, D.; Schulman, R. A model of spatio-temporal regulation within biomaterials using DNA reaction–diffusion waveguides. R. Soc. Open Sci. 2022, 9, 220200. [Google Scholar] [CrossRef]

- Schätzlein, E.; Blaeser, A. Recent trends in bioartificial muscle engineering and their applications in cultured meat, biorobotic systems and biohybrid implants. Commun. Biol. 2022, 5, 737. [Google Scholar] [CrossRef]

- Popescu, C.; Dissanayake, H.; Mansi, E.; Stancu, A. Eco Breakthroughs: Sustainable Materials Transforming the Future of Our Planet. Sustainability 2024, 16, 10790. [Google Scholar] [CrossRef]

- Rosca, C.M.; Gortoescu, I.A.; Tanase, M.R. Artificial Intelligence—Powered Video Content Generation Tools. Rom. J. Pet. Gas Technol. 2024, V, 131–144. [Google Scholar] [CrossRef]

- Nie, M.; Takeuchi, S. 3D Biofabrication Using Living Cells for Applications in Biohybrid Sensors and Actuators. ACS Appl. Bio Mater. 2020, 3, 8121–8126. [Google Scholar] [CrossRef]

- Sikdar, P.; Uddin, M.M.; Dip, T.M.; Islam, S.; Hoque, M.S.; Dhar, A.K.; Wu, S. Recent advances in the synthesis of smart hydrogels. Mater. Adv. 2021, 2, 4532–4573. [Google Scholar] [CrossRef]

- Cui, H.; Zhao, Q.; Zhang, L.; Du, X. Intelligent Polymer-Based Bioinspired Actuators: From Monofunction to Multifunction. Adv. Intell. Syst. 2020, 2, 2000138. [Google Scholar] [CrossRef]

- Yan, B. Actuators for Implantable Devices: A Broad View. Micromachines 2022, 13, 1756. [Google Scholar] [CrossRef] [PubMed]

- Sarkar, M.; Lee, T.-H.; Sahoo, P.K. Smart Healthcare: Exploring the Internet of Medical Things with Ambient Intelligence. Electronics 2024, 13, 2309. [Google Scholar] [CrossRef]

- Das, P.R.; Del Moro, D.S.; Givens, S.R.; Armstrong, S.P.; Walters, K.J. Propagation light intensity influences yield, morphology, and phytochemistry of purple-leaf butterhead lettuce (Lactuca sativa). J. Agric. Food Res. 2024, 16, 101210. [Google Scholar] [CrossRef]

- Rosca, C.M.; Ariciu, A.V. Unlocking Customer Sentiment Insights with Azure Sentiment Analysis: A Comprehensive Review and Analysis. Rom. J. Pet. Gas Technol. 2023, IV, 173–182. [Google Scholar] [CrossRef]

| Technology | Operating Principle | Advantages | Disadvantages |

|---|---|---|---|

| NFT | A thin layer of nutrient solution continuously flows over the roots | High water and nutrient efficiency Well-aerated roots | Susceptible to water flow interruptions Requires strict flow control |

| DWC | Roots are fully submerged in an oxygenated nutrient solution | Rapid plant growth; Simple system to implement | Requires constant oxygenation to prevent root suffocation |

| Ebb and Flow (Flood and Drain) | Alternates between flooding and draining the substrate | Provides good root oxygenation; Suitable for various plant types | High energy consumption Requires constant monitoring |

| Drip System | The nutrient solution is delivered directly to the roots via controlled dripping | Efficient for diverse crops; Low water consumption | Risk of clogged pipes; Requires regular maintenance |

| Metric Indicator | AFCI | LSI |

|---|---|---|

| RT | 0 | 1 |

| OR | 0 | 1 |

| IC | 0 | 1 |

| OC | 0 | 1 |

| CS | 1 | 1 |

| DA | 1 | 0 |

| DS | 1 | 0 |

| Total | 3 | 5 |

| Service Category | Service Type | Description | Estimated Monthly Cost (USD) |

|---|---|---|---|

| Internet of Things | Azure IoT Hub | Standard Tier, Free: 500 devices, 8000 msgs/day, 0.00 USD/mo, 0 IoT Hub Units; | 0 |

| Databases | Azure SQL Database | Single Database, vCore, General Purpose, Serverless, Standard-series (Gen 5), Locally Redundant, 1 Billed vCores, RA-GRS Backup Storage Redundancy, 0 GB Point-In-Time Restore, 0 × 5 GB Long Term Retention | 1.27 |

| Analytics | Azure Stream Analytics | Standard Type, 1 Streaming Unit(s) × 730 h; Stream Analytics on 1 Device(s) with IoT Edge | 81.30 |

| Total | - | - | 82.57 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rosca, C.-M.; Stancu, A.; Popescu, M. The Impact of Cloud Versus Local Infrastructure on Automatic IoT-Driven Hydroponic Systems. Appl. Sci. 2025, 15, 4016. https://doi.org/10.3390/app15074016

Rosca C-M, Stancu A, Popescu M. The Impact of Cloud Versus Local Infrastructure on Automatic IoT-Driven Hydroponic Systems. Applied Sciences. 2025; 15(7):4016. https://doi.org/10.3390/app15074016

Chicago/Turabian StyleRosca, Cosmina-Mihaela, Adrian Stancu, and Marian Popescu. 2025. "The Impact of Cloud Versus Local Infrastructure on Automatic IoT-Driven Hydroponic Systems" Applied Sciences 15, no. 7: 4016. https://doi.org/10.3390/app15074016

APA StyleRosca, C.-M., Stancu, A., & Popescu, M. (2025). The Impact of Cloud Versus Local Infrastructure on Automatic IoT-Driven Hydroponic Systems. Applied Sciences, 15(7), 4016. https://doi.org/10.3390/app15074016