Experimental Investigation of Shear Behavior and Pore Structure Evolution in Heat-Treated Granite Subjected to Liquid Nitrogen and Water Cooling

Abstract

:1. Introduction

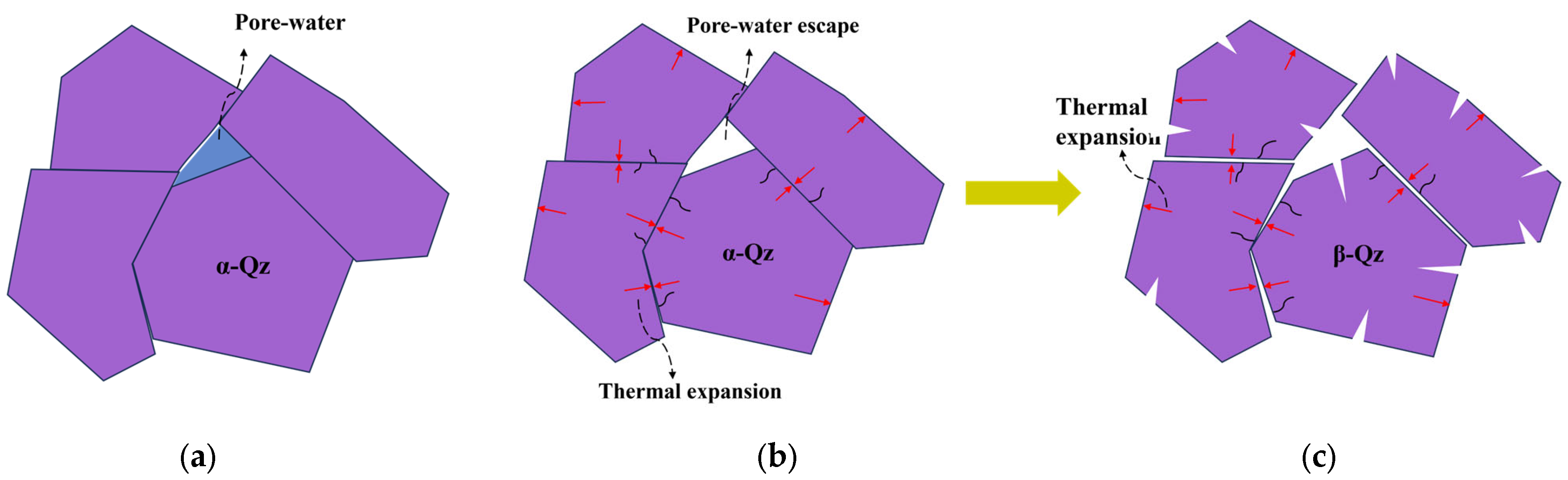

2. Materials and Methods

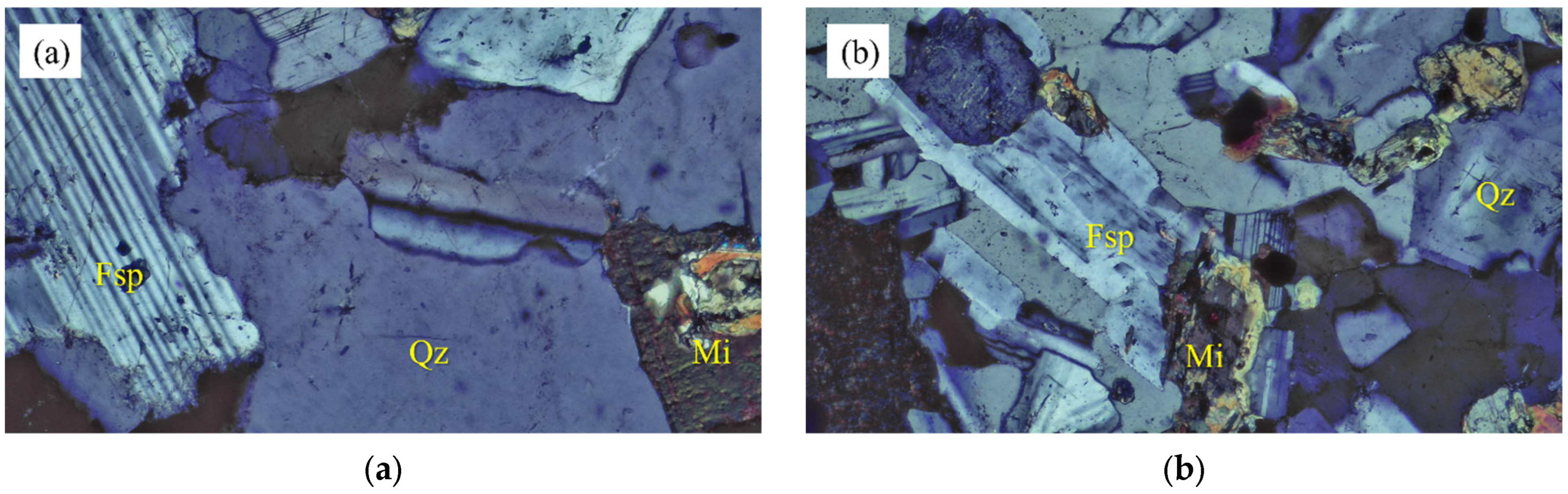

2.1. Sample Preparation

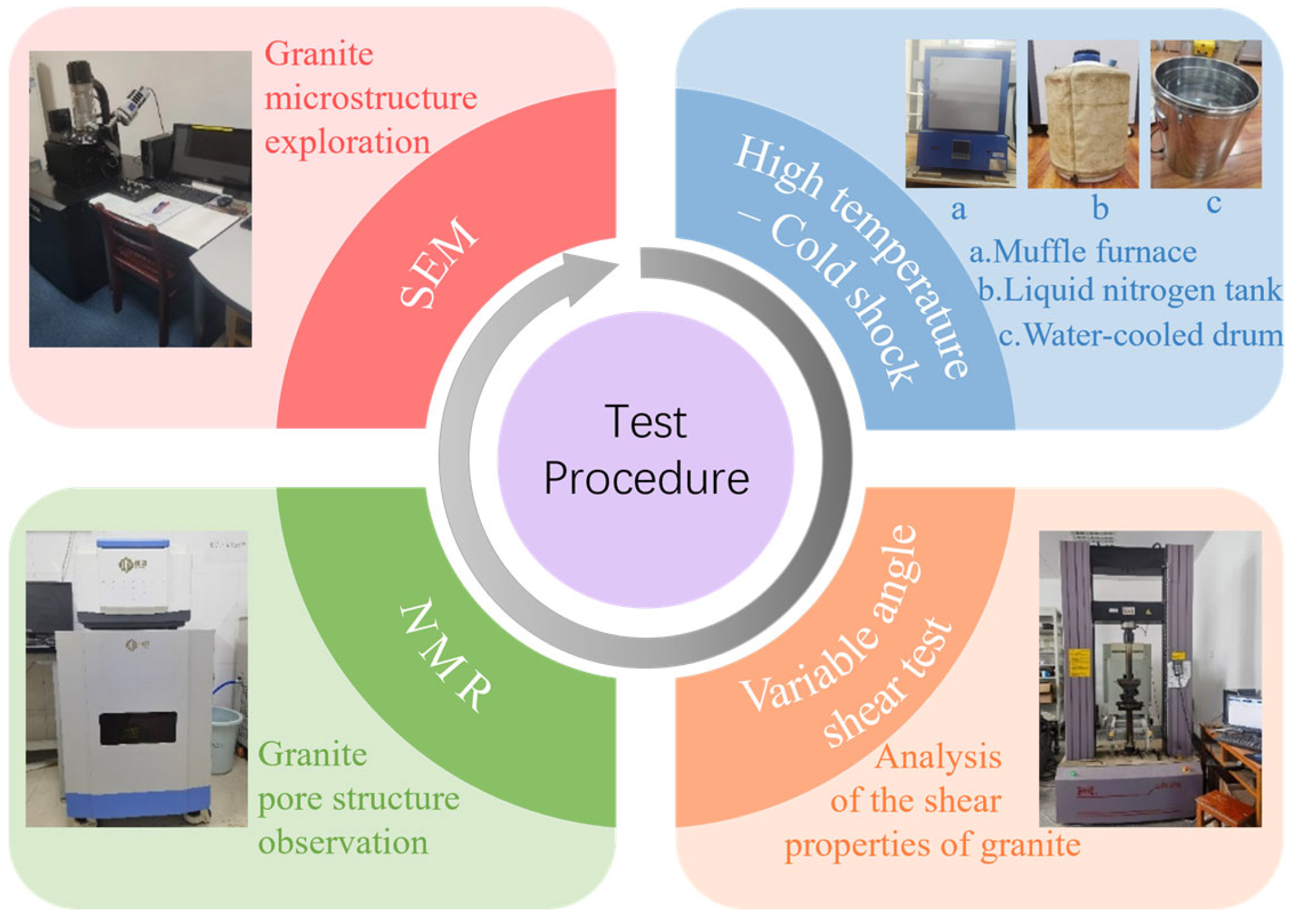

2.2. Experimental Equipment

2.3. Experimental Procedure

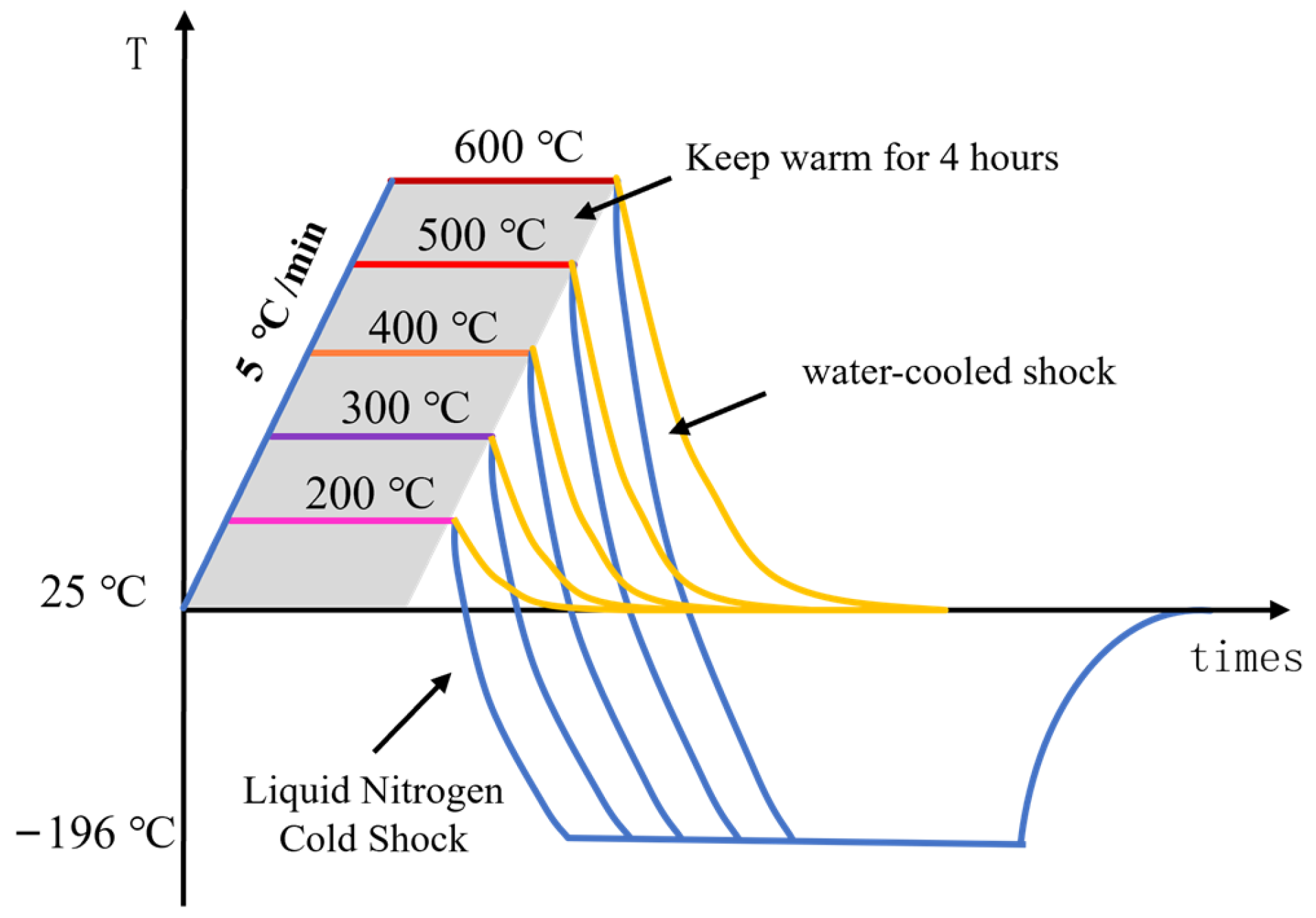

2.3.1. High-Temperature Cold-Shock Test

2.3.2. Shear Test

3. Results and Discussion

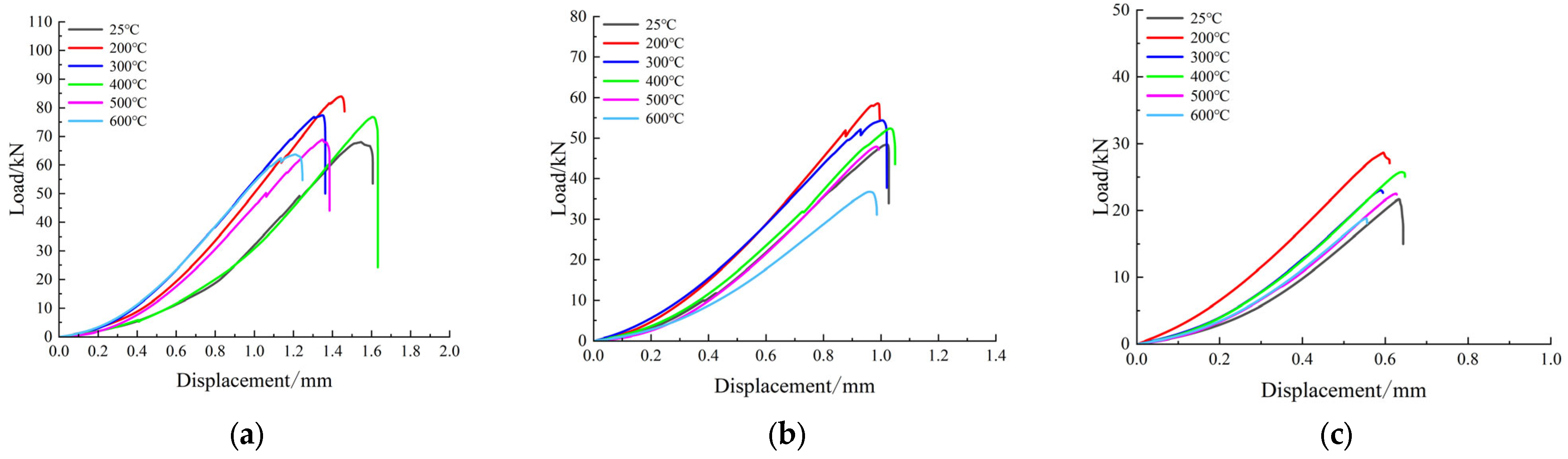

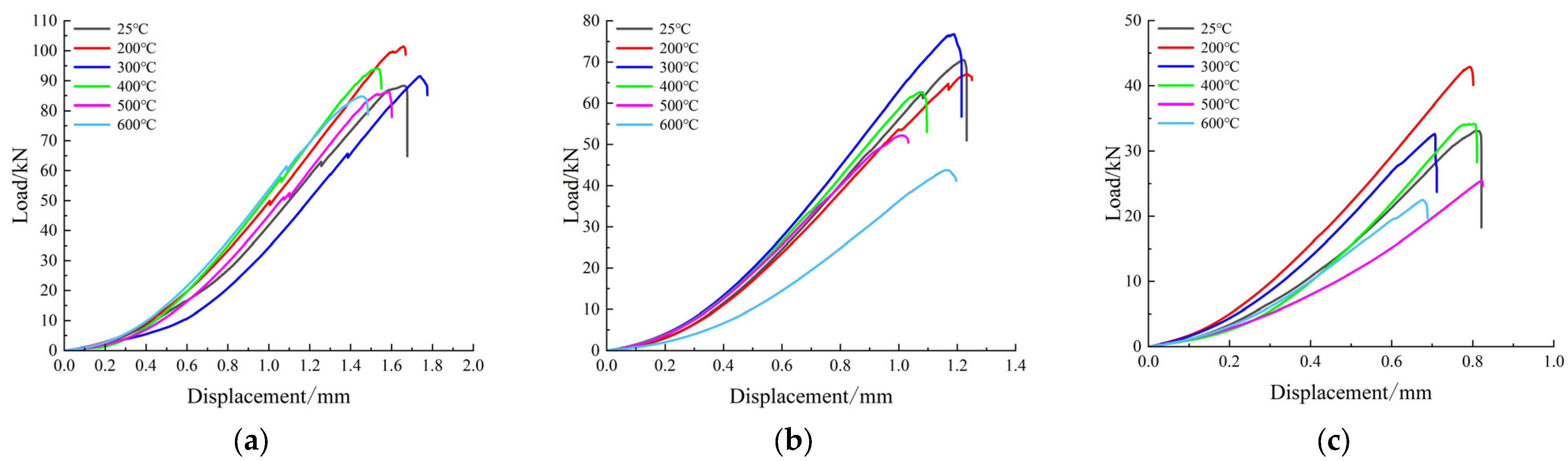

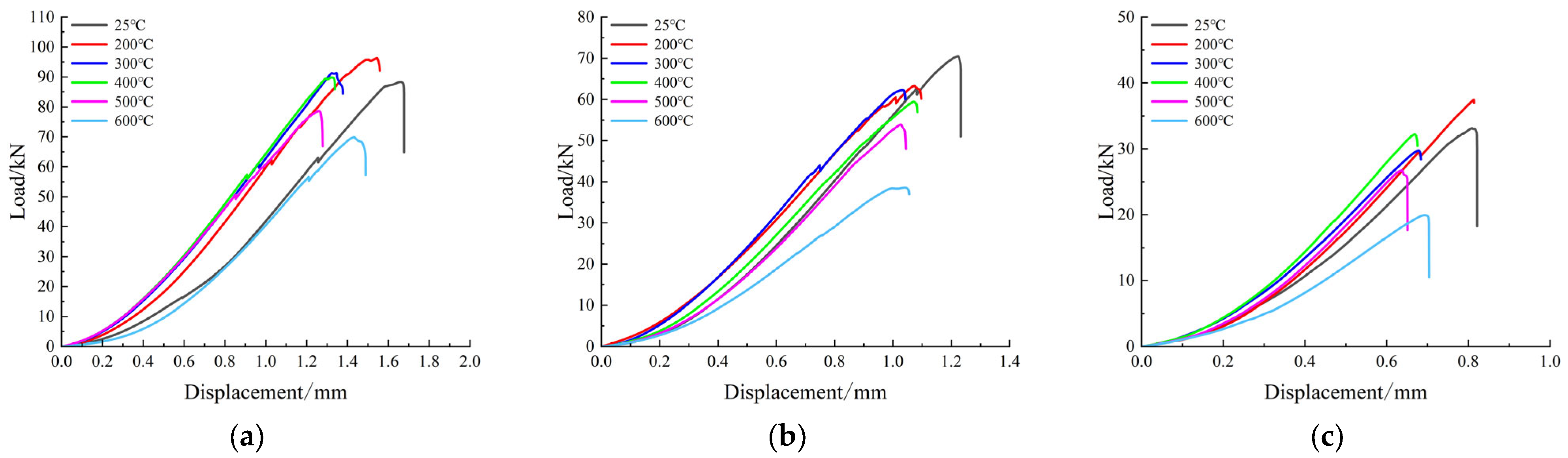

3.1. Shear Load–Displacement Curves

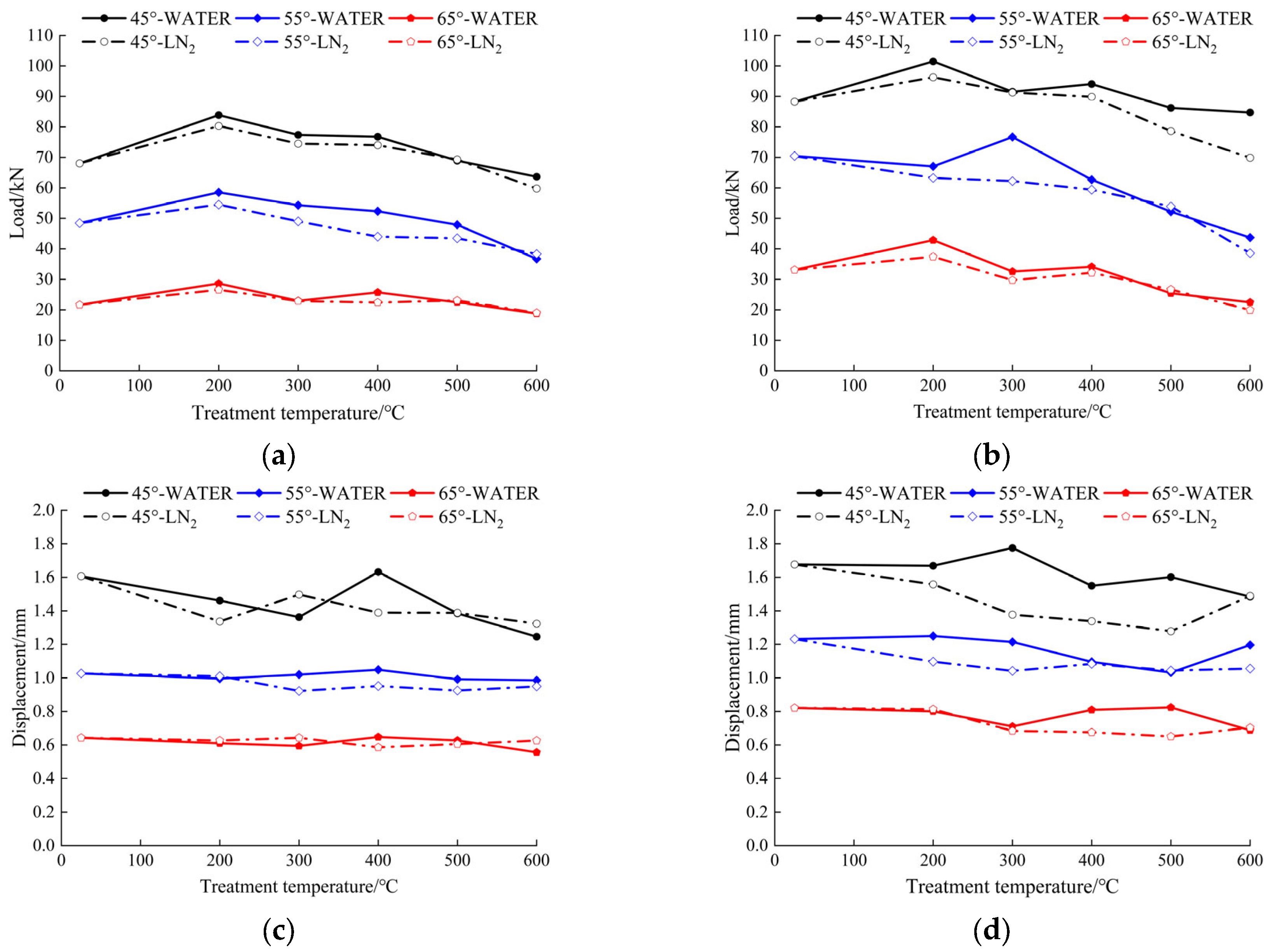

3.2. Shear Mechanical Properties

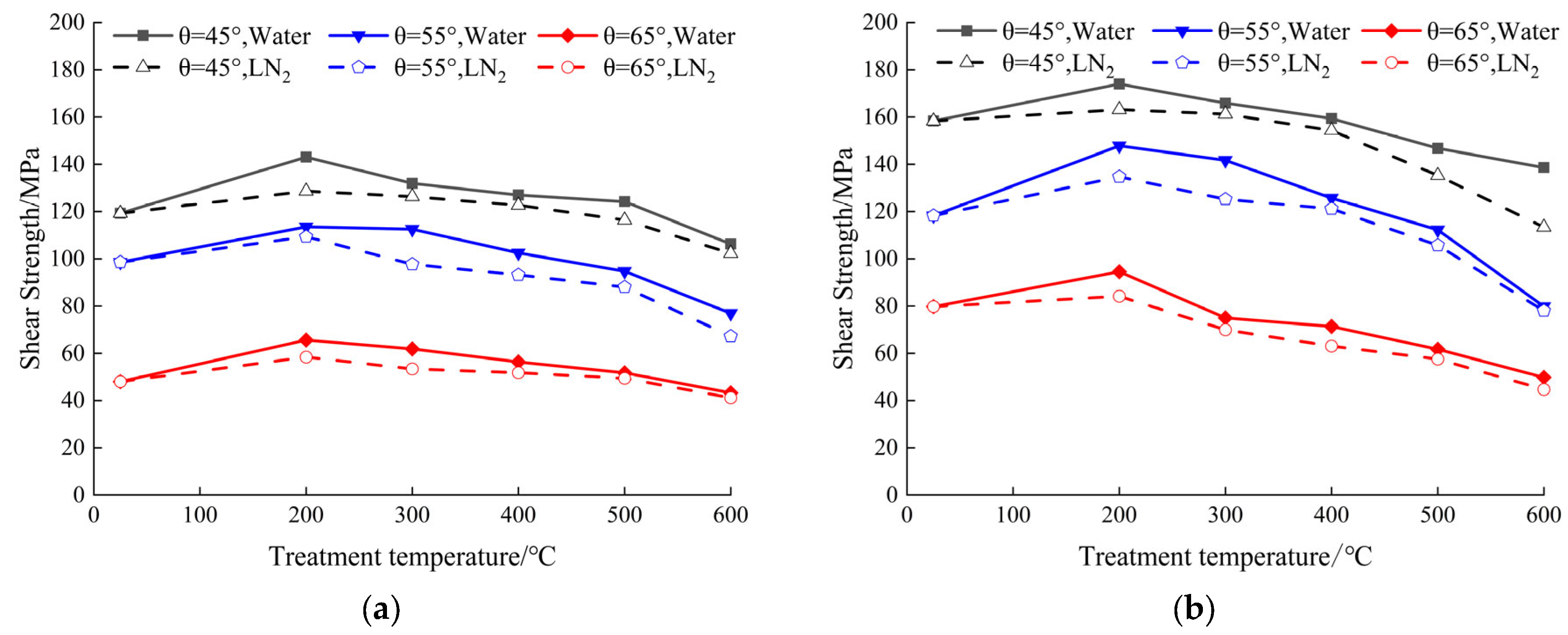

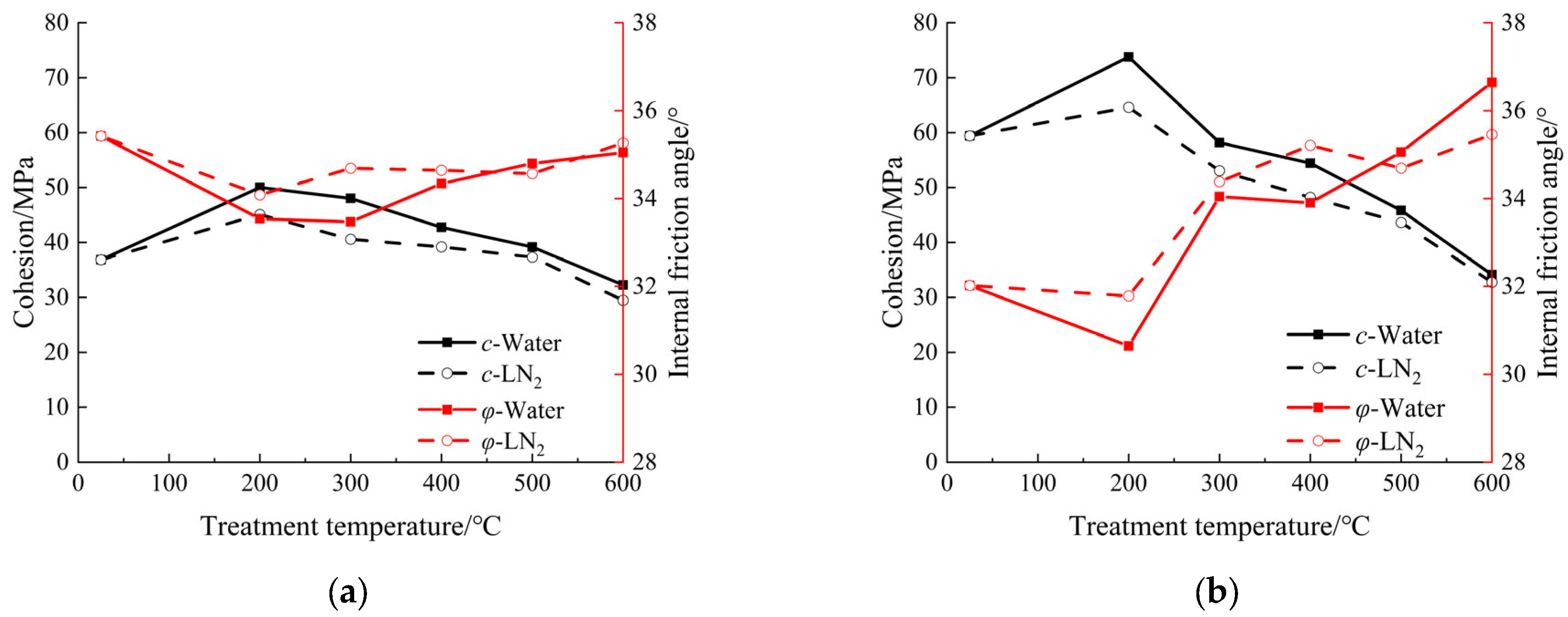

3.2.1. Effect of Heat Treatment Temperature on Shear Mechanical Properties

3.2.2. Effect of Cooling Method on Shear Mechanical Properties

3.2.3. Effect of Particle Size on Shear Mechanical Properties

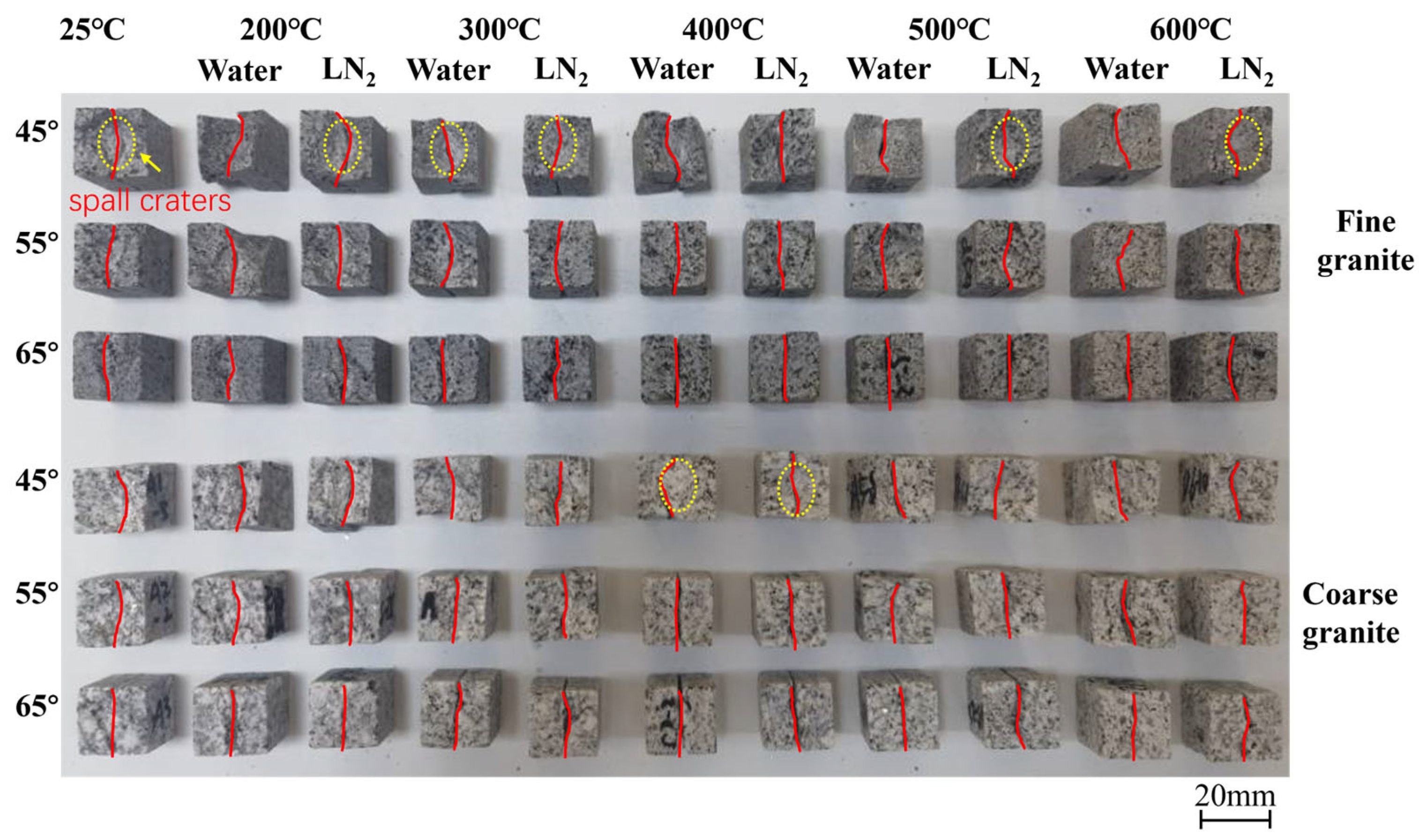

3.3. Macroscopic Failure

3.4. Pore Evolution

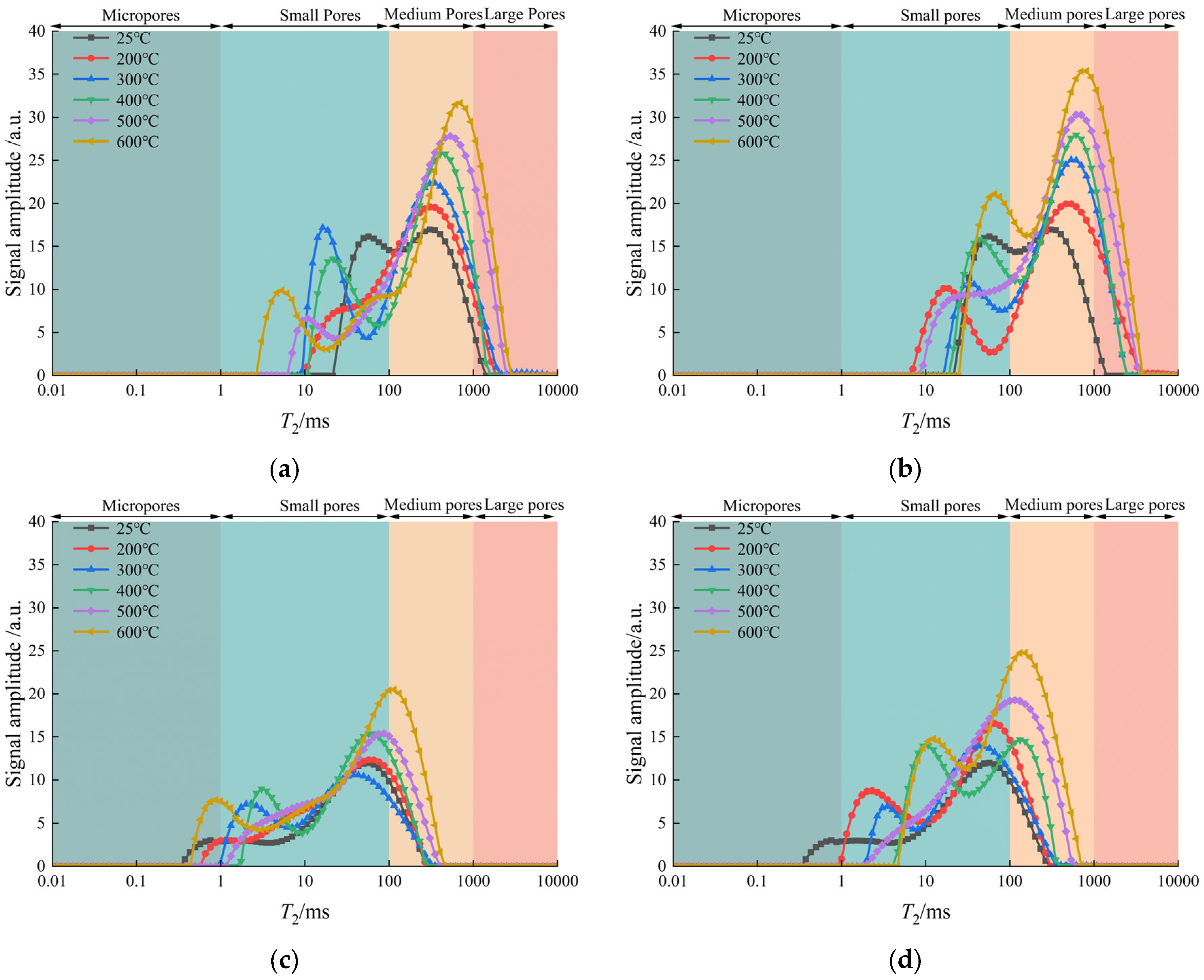

3.4.1. Spectrum Curve Analysis

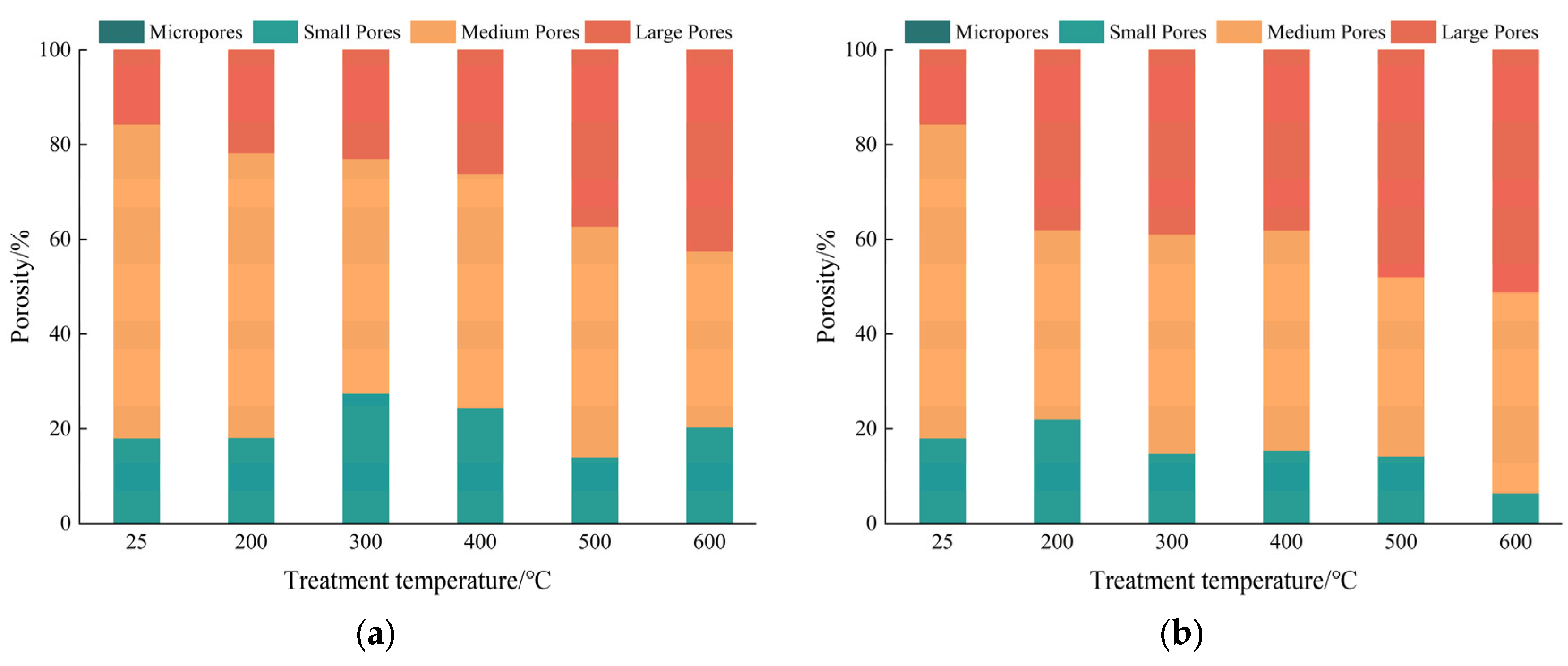

3.4.2. Pore Size Distribution Changes

3.5. Microscopic Failure Mechanism Analysis

3.6. Damage Variable

4. Conclusions

- As the shear angle is increased, a continuous decrease in peak load and peak displacement is exhibited by both coarse- and fine-grained granite samples. Furthermore, liquid nitrogen cold shock exhibited a more pronounced effect on the peak displacement of fine-grained granite when the heat treatment temperature and shear angle were constant, with the overall effect being less than that of water-cooling shock.

- Granite shear strength and cohesion generally exhibit a trend of initial increase followed by a decrease with rising thermal treatment temperatures, whereas the internal friction angle shows an inverse trend. Notably, the thermal hardening effect is most pronounced at 200 °C. Furthermore, at the same thermal treatment temperature, granite subjected to liquid nitrogen thermal shock has lower shear strength and cohesion compared to granite treated with water thermal shock.

- This study established that the application of liquid nitrogen cold shock resulted in a pronounced alteration in the internal pore distribution within granite, thereby enhancing the connectivity between pores. In comparison to the impact of water-cooling shock, liquid nitrogen cold shock exhibited a significant augmentation in the proportion of medium pores and large pores within the granite.

- At ambient temperature, intragranular cracking is the predominant form of internal cracking in granite; however, as the heat treatment temperature is increased, the cracks gradually transition to transgranular cracks and the integrity of the fracture surface is reduced, with the surface changing from smooth to rough. Furthermore, the application of liquid nitrogen cold shock has been demonstrated to result in the emergence of numerous micro- and small-sized pores on the fracture surface of granite. This effect underscores its superior efficacy in fostering the development of intricate fracture networks within dry hot rock reservoirs.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Chen, J.L.; Jiang, F.M. Designing multi-well layout for enhanced geothermal system to better exploit hot dry rock geothermal energy. Renew. Energy 2015, 74, 37–48. [Google Scholar] [CrossRef]

- Breede, K.; Dzebisashvili, K.; Liu, X.; Falcone, G. A systematic review of enhanced (or engineered) geothermal systems: Past, present and future. Geotherm. Energy 2013, 1, 4. [Google Scholar] [CrossRef]

- Blackwell, D.D.; Negraru, P.T.; Richards, M.C. Assessment of the enhanced geothermal system resource base of the United States. Nat. Resour. Res. 2006, 15, 283–308. [Google Scholar] [CrossRef]

- Yin, T.B.; Li, Q.; Li, X.B. Experimental investigation on mode I fracture characteristics of granite after cyclic heating and cooling treatments. Eng. Fract. Mech. 2019, 222, 106740. [Google Scholar] [CrossRef]

- Anderson, A.; Rezaie, B. Geothermal technology: Trends and potential role in a sustainable future. Appl. Energy 2019, 248, 18–34. [Google Scholar] [CrossRef]

- Enayatpour, S.; van Oort, E.; Patzek, T. Thermal cooling to improve hydraulic fracturing efficiency and hydrocarbon production in shales. J. Nat. Gas Sci. Eng. 2019, 62, 184–201. [Google Scholar] [CrossRef]

- Hong, C.Y.; Yang, R.Y.; Huang, Z.W.; Zhuang, X.Y.; Wen, H.-T.; Hu, X.-L. Enhance liquid nitrogen fracturing performance on hot dry rock by cyclic injection. Pet. Sci. 2023, 20, 951–972. [Google Scholar] [CrossRef]

- Ma, X.; Wang, G.L.; Hu, D.W.; Liu, Y.G.; Zhou, H.; Liu, F. Mechanical properties of granite under real-time high temperature and three-dimensional stress. Int. J. Rock Mech. Min. Sci. 2020, 136, 104521. [Google Scholar] [CrossRef]

- Paul, S.; Chattopadhyaya, S.; Raina, A.; Sharma, S.; Li, C.; Zhang, Y.; Kumar, A.; Tag-Eldin, E. A review on the impact of high-temperature treatment on the physico-mechanical, dynamic, and thermal properties of granite. Sustainability 2022, 14, 14839. [Google Scholar] [CrossRef]

- Kumari, W.; Beaumont, D.; Ranjith, P.; Perera, M.; Avanthi Isaka, B.; Khandelwal, M. An experimental study on tensile characteristics of granite rocks exposed to different high-temperature treatments. Geomech. Geophys. Geo-Energy Geo-Resour. 2019, 5, 47–64. [Google Scholar] [CrossRef]

- Gautam, P.; Verma, A.; Jha, M.; Sharma, P.; Singh, T. Effect of high temperature on physical and mechanical properties of Jalore granite. J. Appl. Geophys. 2018, 159, 460–474. [Google Scholar] [CrossRef]

- Chicco, J.M.; Vacha, D.; Mandrone, G. Thermo-physical and geo-mechanical characterization of faulted carbonate rock masses (Valdieri, Italy). Remote Sens. 2019, 11, 179. [Google Scholar] [CrossRef]

- Chicco, J.M.; Comina, C.; Mandrone, G.; Vacha, D.; Vagnon, F. Field surveys in heterogeneous rock masses aimed at hydraulic conductivity assessment. SN Appl. Sci. 2023, 5, 374. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Zhang, F.; Yang, K.; Cai, Z.Y. Effects of real-time high temperature and loading rate on deformation and strength behavior of granite. Geofluids 2022, 2022, 9426378. [Google Scholar] [CrossRef]

- Srinivasan, V.; Hasainar, H.; Singh, T. Experimental study on failure and fracturing attributes of granite after thermal treatments with different cooling conditions. Eng. Geol. 2022, 310, 106867. [Google Scholar] [CrossRef]

- Dwivedi, R.; Goel, R.; Prasad, V.; Sinha, A. Thermo-mechanical properties of Indian and other granites. Int. J. Rock Mech. Min. Sci. 2008, 45, 303–315. [Google Scholar] [CrossRef]

- Qin, Y.; Tian, H.; Xu, N.X.; Chen, Y. Physical and mechanical properties of granite after high-temperature treatment. Rock Mech. Rock Eng. 2020, 53, 305–322. [Google Scholar] [CrossRef]

- Zhang, F.; Zhao, J.J.; Hu, D.W.; Skoczylas, F.; Shao, J.F. Laboratory investigation on physical and mechanical properties of granite after heating and water-cooling treatment. Rock Mech. Rock Eng. 2018, 51, 677–694. [Google Scholar] [CrossRef]

- Elwegaa, K.; Emadi, H. The effect of thermal shocking with nitrogen gas on the porosities, permeabilities, and rock mechanical properties of unconventional reservoirs. Energies 2018, 11, 2131. [Google Scholar] [CrossRef]

- Wu, X.G.; Huang, Z.W.; Zhang, S.K.; Cheng, Z.; Li, R.; Song, H.Y.; Wen, H.T.; Huang, P.P. Damage analysis of high-temperature rocks subjected to LN 2 thermal shock. Rock Mech. Rock Eng. 2019, 52, 2585–2603. [Google Scholar] [CrossRef]

- Zhang, S.K.; Huang, Z.W.; Zhang, H.Y.; Guo, Z.Q.; Wu, X.G.; Wang, T.Y.; Zhang, C.C.; Xiong, C. Experimental study of thermal-crack characteristics on hot dry rock impacted by liquid nitrogen jet. Geothermics 2018, 76, 253–260. [Google Scholar] [CrossRef]

- Wu, X.G.; Huang, Z.W.; Song, H.Y.; Zhang, S.K.; Cheng, Z.; Li, R.; Wen, H.T.; Huang, P.P.; Dai, X.W. Variations of physical and mechanical properties of heated granite after rapid cooling with liquid nitrogen. Rock Mech. Rock Eng. 2019, 52, 2123–2139. [Google Scholar] [CrossRef]

- Cai, C.Z.; Ren, K.D.; Tao, Z.X.; Xing, Y.; Gao, F.; Zou, Z.x.; Feng, Y.r. Experimental investigation of the damage characteristics of high-temperature granite subjected to liquid nitrogen treatment. Nat. Resour. Res. 2022, 31, 2603–2627. [Google Scholar] [CrossRef]

- Longinos, S.N.; Serik, A.; Zhang, D.; Wang, L.; Hazlett, R. Experimental evaluation of liquid nitrogen fracturing on the coal rocks in Karaganda Basin, Kazakhstan. Arab. J. Sci. Eng. 2023, 48, 16623–16638. [Google Scholar] [CrossRef]

- Liu, K.W.; Huang, X.H.; Zhang, S.; Guo, T.F.; Ma, S.Z.; Zhou, Z.X. Effects of thermal treatment on the shear behavior and characteristics of intact sandstone: Laboratory experiment of variable-angle shear. Bull. Eng. Geol. Environ. 2022, 81, 471. [Google Scholar] [CrossRef]

- He, M.; Yu, L.Y.; Liu, R.C.; Jiang, Y.J.; Li, Z.C.; Wang, X.L. Experimental investigation on mechanical behaviors of granites after high-temperature exposure. J. Cent. South Univ. 2022, 29, 1332–1344. [Google Scholar] [CrossRef]

- Zhang, C.X.; Li, D.Y.; Luo, P.K.; Su, X.L.; Zhou, A.H. Compression-shear failure of thermally treated granite: Insights from digital image correlation analysis. Geothermics 2025, 125, 103157. [Google Scholar] [CrossRef]

- Du, K.; Li, X.F.; Wang, S.Y.; Tao, M.; Li, G.; Wang, S.F. Compression-shear failure properties and acoustic emission (AE) characteristics of rocks in variable angle shear and direct shear tests. Measurement 2021, 183, 109814. [Google Scholar] [CrossRef]

- Abdellah, W.R.; Bader, S.A.; Kim, J.-G.; Ali, M.A. Numerical simulation of mechanical behavior of rock samples under uniaxial and triaxial compression tests. Min. Miner. Depos. 2023, 17, 1–11. [Google Scholar] [CrossRef]

- Li, Q.; Yin, T.B.; Li, X.B.; Zhang, S.S. Effects of rapid cooling treatment on heated sandstone: A comparison between water and liquid nitrogen cooling. Bull. Eng. Geol. Environ. 2020, 79, 313–327. [Google Scholar] [CrossRef]

- Ma, T.S.; Zhu, G.S.; Peng, N.; Qiu, Y.; Liu, Y.; Zou, J.Y. Physical-mechanical properties and thermal-induced damage of granite after high-temperature pretreatment. Arab. J. Geosci. 2021, 14, 1–12. [Google Scholar] [CrossRef]

- Gong, F.Q.; Luo, S.; Lin, G.; Li, X. Evaluation of shear strength parameters of rocks by preset angle shear, direct shear and triaxial compression tests. Rock Mech. Rock Eng. 2020, 53, 2505–2519. [Google Scholar] [CrossRef]

- Muralha, J.; Grasselli, G.; Tatone, B.; Blümel, M.; Chryssanthakis, P.; Yujing, J. ISRM suggested method for laboratory determination of the shear strength of rock joints: Revised version. Rock Mech. Rock Eng. 2014, 47, 291–302. [Google Scholar] [CrossRef]

- Li, Y.Y.; Dang, J.M.; Zhang, S.C.; Shen, B.T.; Zheng, D.; Zhang, H.Z.; Hou, J.Q. Shear mechanical properties and surface damage characteristics of granite fractures treated by real-time high temperature. J. Cent. South Univ. 2023, 30, 2004–2017. [Google Scholar] [CrossRef]

- Huang, Y.G.; Yang, W.X.; Zhao, A.N.; Guo, W.B. Shear strength and re-failure characteristics of intact red sandstone and grouting-reinforced body of fractured red sandstone under different shear angles. Minerals 2022, 12, 1580. [Google Scholar] [CrossRef]

- Griffiths, L.; Heap, M.J.; Baud, P.; Schmittbuhl, J. Quantification of microcrack characteristics and implications for stiffness and strength of granite. Int. J. Rock Mech. Min. Sci. 2017, 100, 138–150. [Google Scholar] [CrossRef]

- Coulomb, C. Essai sur une application des regles de maximis et minimis a quelques problemes de statique relatifs a 1’architecture. Mem. Div. Sav. Acad. 1773, 7, 343–382. [Google Scholar]

- Luo, S.; Gong, F.Q.; Peng, K. Theoretical shear damage characterization of intact rock under compressive-shear stress considering energy dissipation. Int. J. Damage Mech. 2023, 32, 962–983. [Google Scholar] [CrossRef]

- Yang, S.Q.; Ranjith, P.; Jing, H.W.; Tian, W.L.; Ju, Y. An experimental investigation on thermal damage and failure mechanical behavior of granite after exposure to different high temperature treatments. Geothermics 2017, 65, 180–197. [Google Scholar] [CrossRef]

- Yin, W.; Feng, Z.; Zhao, Y.J.R.M.; Engineering, R. Effect of grain size on the mechanical behaviour of granite under high temperature and triaxial stresses. Rock Mech. Rock Eng. 2021, 54, 745–758. [Google Scholar] [CrossRef]

- Zhou, H.Y.; Liu, Z.B.; Shen, W.Q.; Feng, T.; Zhang, G. Mechanical property and thermal degradation mechanism of granite in thermal-mechanical coupled triaxial compression. Int. J. Rock Mech. Min. Sci. 2022, 160, 105270. [Google Scholar] [CrossRef]

- Li, Q.; Li, X.B.; Yin, T.B. Factors affecting pore structure of granite under cyclic heating and cooling: A nuclear magnetic resonance investigation. Geothermics 2021, 96, 102198. [Google Scholar] [CrossRef]

- Chen, S.W.; Yang, C.H.; Wang, G.B. Evolution of thermal damage and permeability of Beishan granite. Appl. Therm. Eng. 2017, 110, 1533–1542. [Google Scholar] [CrossRef]

- Xi, Y.; Xing, J.H.; Jiang, H.L.; Fan, L.F.; Li, J. Pore characteristic evolution and damage deterioration of granite subjected to the thermal and cooling treatments combined with the NMR method. Bull. Eng. Geol. Environ. 2023, 82, 182. [Google Scholar] [CrossRef]

- Wu, Y.; Hu, L.H.; Yu, J.; Li, X.Z.; Yang, L.N.; Xue, S.; Zhang, K. The sensitivity of mechanical properties and pore structures of Beishan granite to large variation of temperature in nuclear waste storage sites. Environ. Sci. Pollut. Res. 2023, 30, 75195–75212. [Google Scholar] [CrossRef]

- Lei, R.D.; Wang, Y.; Zhang, L.; Liu, B.L.; Long, K.; Luo, P.; Wang, Y.K. The evolution of sandstone microstructure and mechanical properties with thermal damage. Energy Sci. Eng. 2019, 7, 3058–3075. [Google Scholar] [CrossRef]

- Shang, X.J.; Zhang, Z.Z.; Xu, X.L.; Liu, T.T.; Xing, Y. Mineral composition, pore structure, and mechanical characteristics of pyroxene granite exposed to heat treatments. Minerals 2019, 9, 553. [Google Scholar] [CrossRef]

- Akasheva, Z.K.; Bolysbek, D.; Assilbekov, B.; Yergesh, A.; Zhanseit, A.Y. Pore-network modeling and determination of rock and two-phase fluid flow properties. Eng. J. Satbayev Univ. 2021, 143, 106–114. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, L.; Xiao, X.D.; Liang, X.; Wang, H.H.; Zhang, H.D.; Liu, B. Experimental study on fracture properties of heat-treated granite in I-II mixed mode suffered from water and liquid nitrogen cooling methods. Eng. Fract. Mech. 2024, 311, 110570. [Google Scholar] [CrossRef]

- Gu, Q.X.; Huang, Z.; Zhao, K.; Zhong, W.; Liu, L.; Li, S.J.; Ma, D.; Liu, Q. Experimental investigation on the influence of temperature on the fracture surface variations of granite after Brazilian splitting tests. Int. J. Therm. Sci. 2024, 203, 109159. [Google Scholar] [CrossRef]

- Shen, Y.J.; Zhang, Y.L.; Gao, F.; Yang, G.S.; Lai, X.P. Influence of temperature on the microstructure deterioration of sandstone. Energies 2018, 11, 1753. [Google Scholar] [CrossRef]

- Johnson, S.E.; Song, W.J.; Cook, A.C.; Vel, S.S.; Gerbi, C.C. The quartz α↔ β phase transition: Does it drive damage and reaction in continental crust? Earth Planet. Sci. Lett. 2021, 553, 116622. [Google Scholar] [CrossRef]

- Hovis, G.L.; Tribaudino, M.; Leaman, A.; Almer, C.; Altomare, C.; Morris, M.; Maksymiw, N.; Morris, D.; Jackson, K.; Scott, B. Thermal expansion of minerals in the pyroxene system and examination of various thermal expansion models. Am. Mineral. 2021, 106, 883–899. [Google Scholar] [CrossRef]

| Granite | Mineralogical Composition (%) | Natural Density (g/cm3) | Porosity (%) | |||

|---|---|---|---|---|---|---|

| Quartz | Micas | Feldspar-Sodium | Potassium Feldspar | |||

| Coarse | 23.16 | 18.45 | 30.37 | 28.02 | 2.63 | 0.81 |

| Fine | 14.5 | 27.02 | 58.47 | 2.80 | 0.44 | |

| Temperature (°C) | Shear Strength (%) | Cohesion (%) | Internal Friction Angle (%) | |||

|---|---|---|---|---|---|---|

| 45° | 55° | 65° | ||||

| High-Temperature Water-Cooled Impact | 200 | 20.0 | 15.2 | 38.0 | 36.7 | −5.2 |

| 300 | 10.6 | 14.2 | 30.2 | 31.3 | −5.4 | |

| 400 | 6.6 | 4.0 | 18.5 | 16.9 | −2.9 | |

| 500 | 4. | −3.9 | 8.8 | 7.1 | −1.6 | |

| 600 | −10. | −21.9 | −9.0 | −11.8 | −0.9 | |

| High-Temperature Liquid-Nitrogen-Cooled Impact | 200 | 7.9 | 10.9 | 22.9 | 23.2 | −3.6 |

| 300 | 6.0 | −0.9 | 12.4 | 10.9 | −1.9 | |

| 400 | 2.9 | −5.4 | 9.0 | 7.1 | −2.0 | |

| 500 | −2.3 | −10.7 | 4.0 | 2.0 | −2.3 | |

| 600 | −14.2 | −31.8 | −13.3 | −19.4 | −0.3 | |

| Temperature (°C) | Shear Strength (%) | Cohesion (%) | Internal Friction Angle (%) | |||

|---|---|---|---|---|---|---|

| 45° | 55° | 65° | ||||

| High-TemperatureWater-CooledImpact | 200 | 10.2 | 25.0 | 19.1 | 24.5 | −4.3 |

| 300 | 5.1 | 19.9 | −5.6 | −1.8 | 6.3 | |

| 400 | 0.9 | 6.4 | −10.1 | −8.1 | 5.9 | |

| 500 | −7.0 | −5.0 | −22.3 | −22.6 | 9.5 | |

| 600 | −12.2 | −32.5 | −37.3 | −42.4 | 14.5 | |

| High-TemperatureLiquid-Nitrogen-CooledImpact | 200 | 3.3 | 14.0 | 6.0 | 9.1 | −0.7 |

| 300 | 2.1 | 5.9 | −11.9 | −10.4 | 7.4 | |

| 400 | −2.3 | 2.5 | −20.6 | −18.6 | 10.0 | |

| 500 | −14.3 | −10.6 | −27.5 | −26.3 | 8.4 | |

| 600 | −28.2 | −34.0 | −43.7 | −44.8 | 10.7 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, F.; Liu, S.; Zhang, S.; Zhang, Y.; Quan, S.; Li, M. Experimental Investigation of Shear Behavior and Pore Structure Evolution in Heat-Treated Granite Subjected to Liquid Nitrogen and Water Cooling. Appl. Sci. 2025, 15, 4581. https://doi.org/10.3390/app15084581

Zhang F, Liu S, Zhang S, Zhang Y, Quan S, Li M. Experimental Investigation of Shear Behavior and Pore Structure Evolution in Heat-Treated Granite Subjected to Liquid Nitrogen and Water Cooling. Applied Sciences. 2025; 15(8):4581. https://doi.org/10.3390/app15084581

Chicago/Turabian StyleZhang, Fan, Shengyuan Liu, Subiao Zhang, Yiming Zhang, Shaohui Quan, and Man Li. 2025. "Experimental Investigation of Shear Behavior and Pore Structure Evolution in Heat-Treated Granite Subjected to Liquid Nitrogen and Water Cooling" Applied Sciences 15, no. 8: 4581. https://doi.org/10.3390/app15084581

APA StyleZhang, F., Liu, S., Zhang, S., Zhang, Y., Quan, S., & Li, M. (2025). Experimental Investigation of Shear Behavior and Pore Structure Evolution in Heat-Treated Granite Subjected to Liquid Nitrogen and Water Cooling. Applied Sciences, 15(8), 4581. https://doi.org/10.3390/app15084581