Analysis of Different Guide Elements’ Designs in Hydraulic Cylinders

Abstract

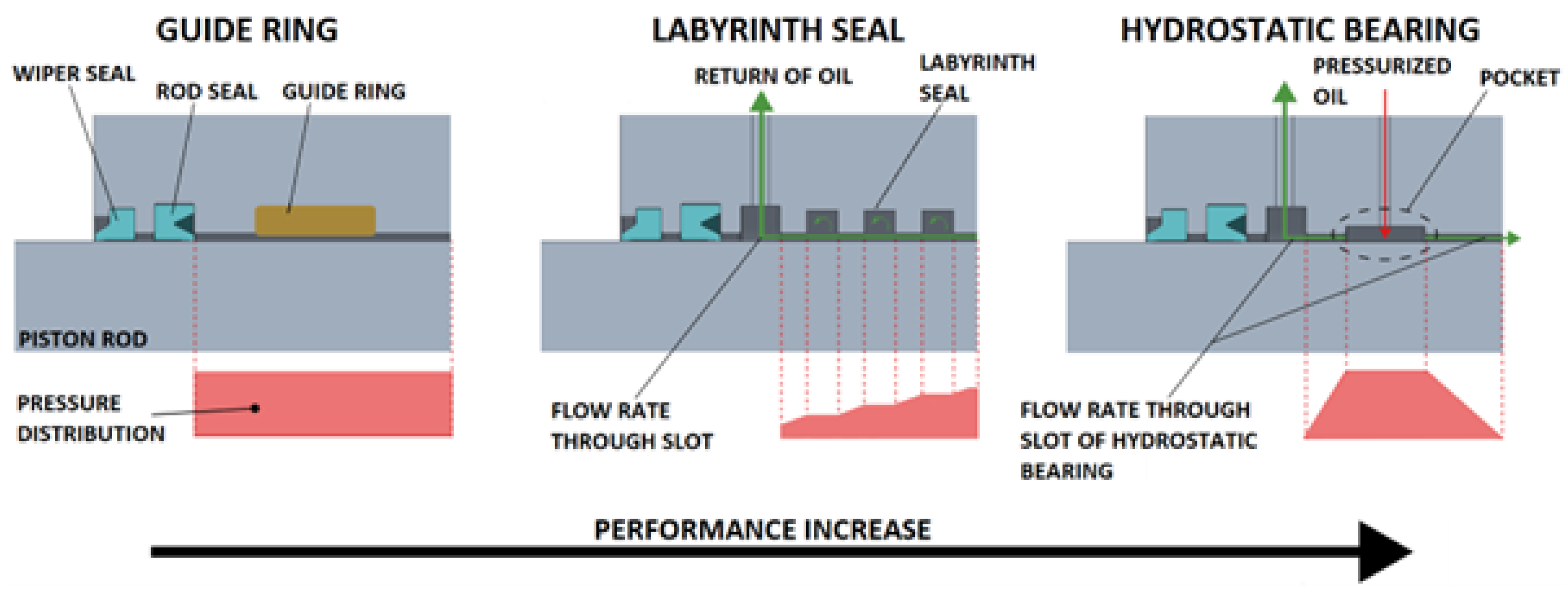

1. Introduction

2. Design and Methods

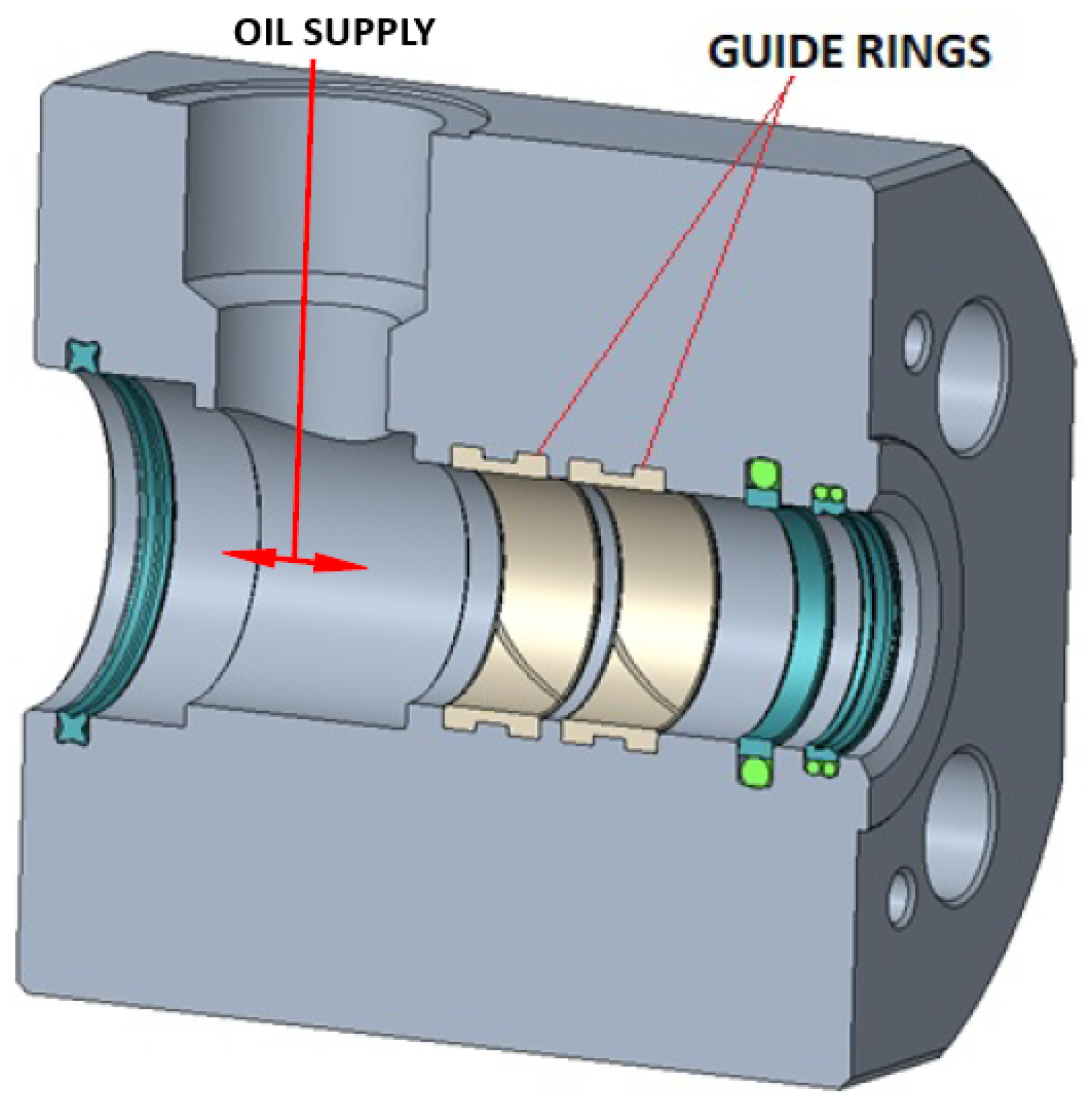

2.1. Design of the Guide with Guide Rings

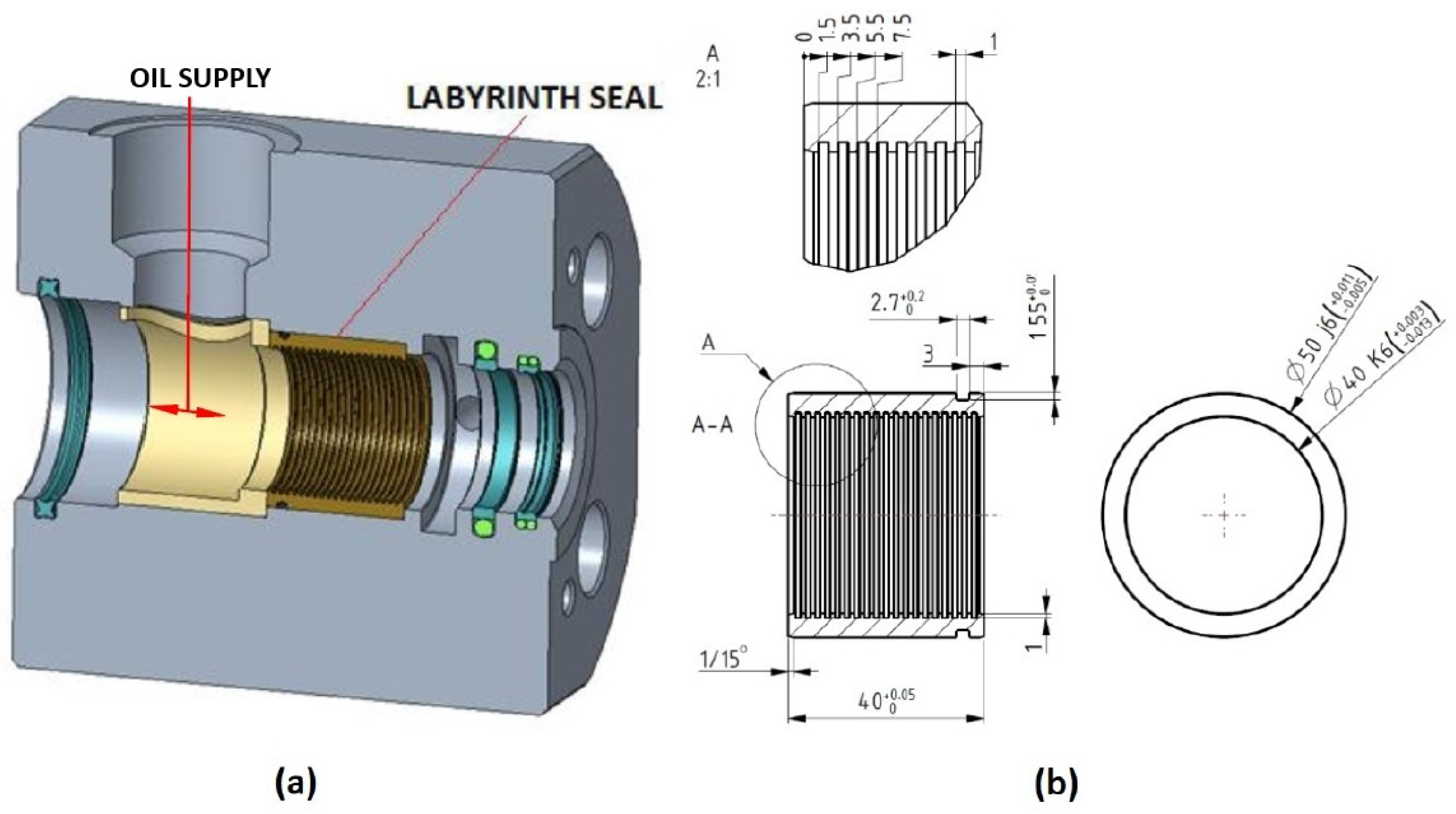

2.2. Design of the Guide with Labyrinth Seal

2.3. Design of the Guide with Hydrostatic Bearing

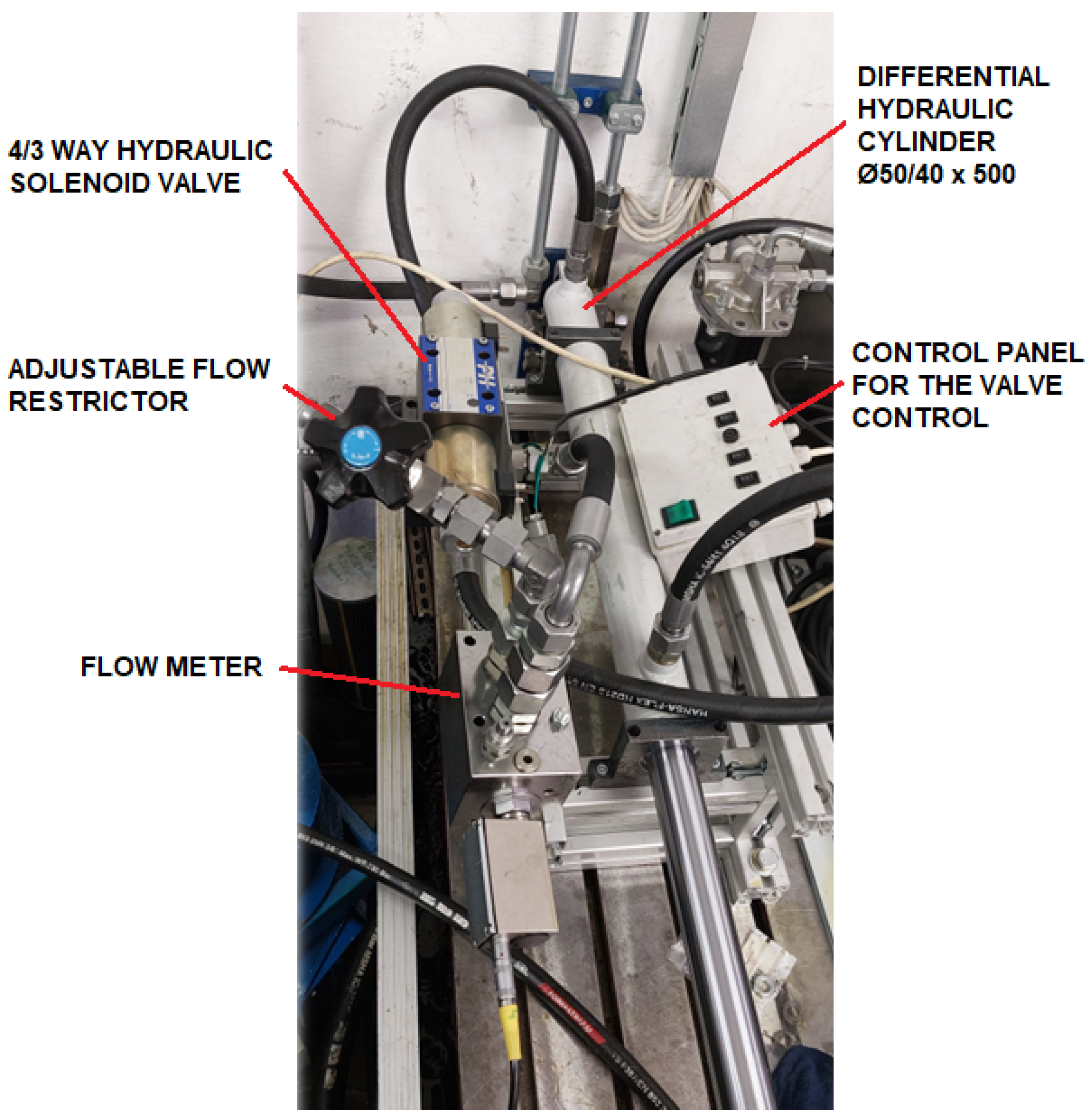

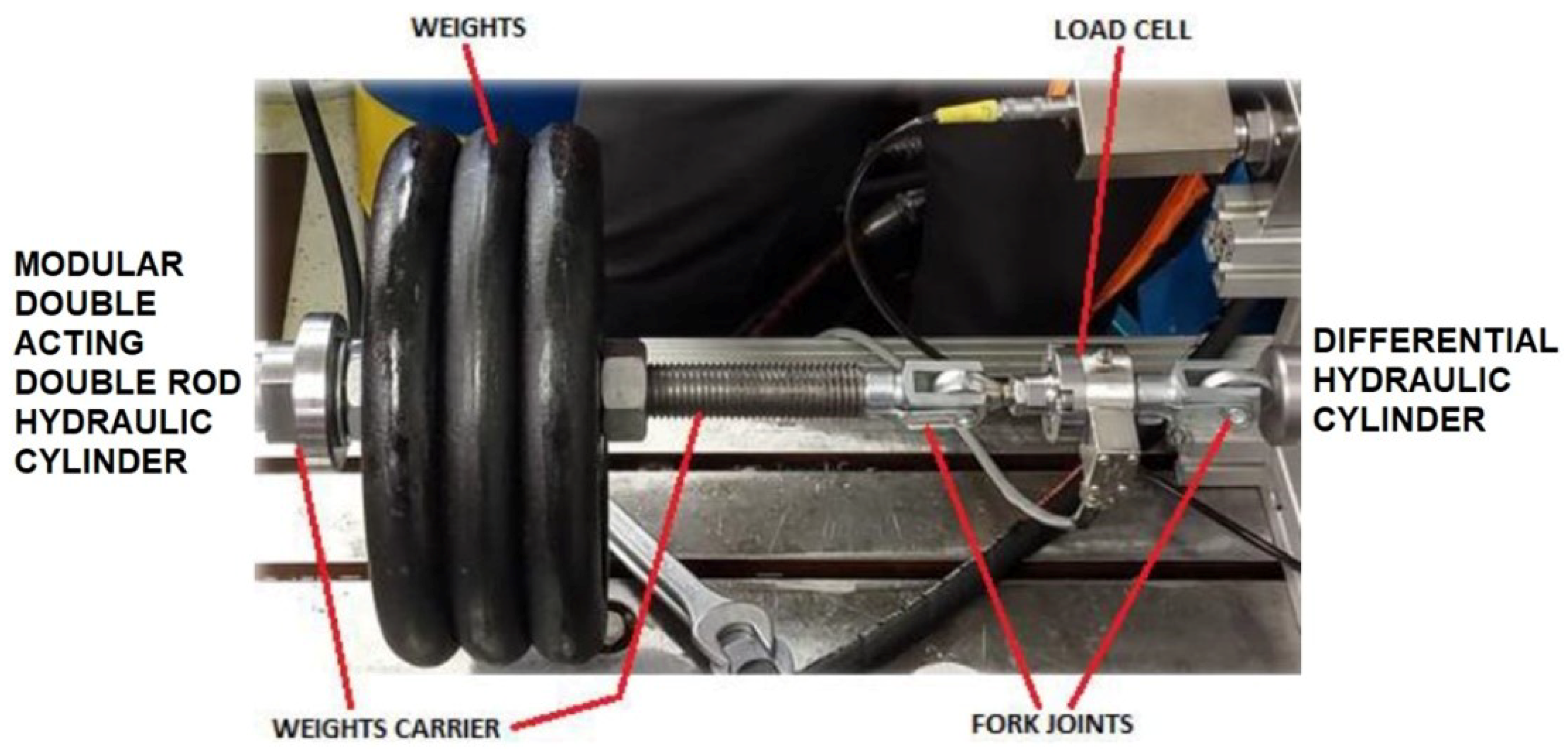

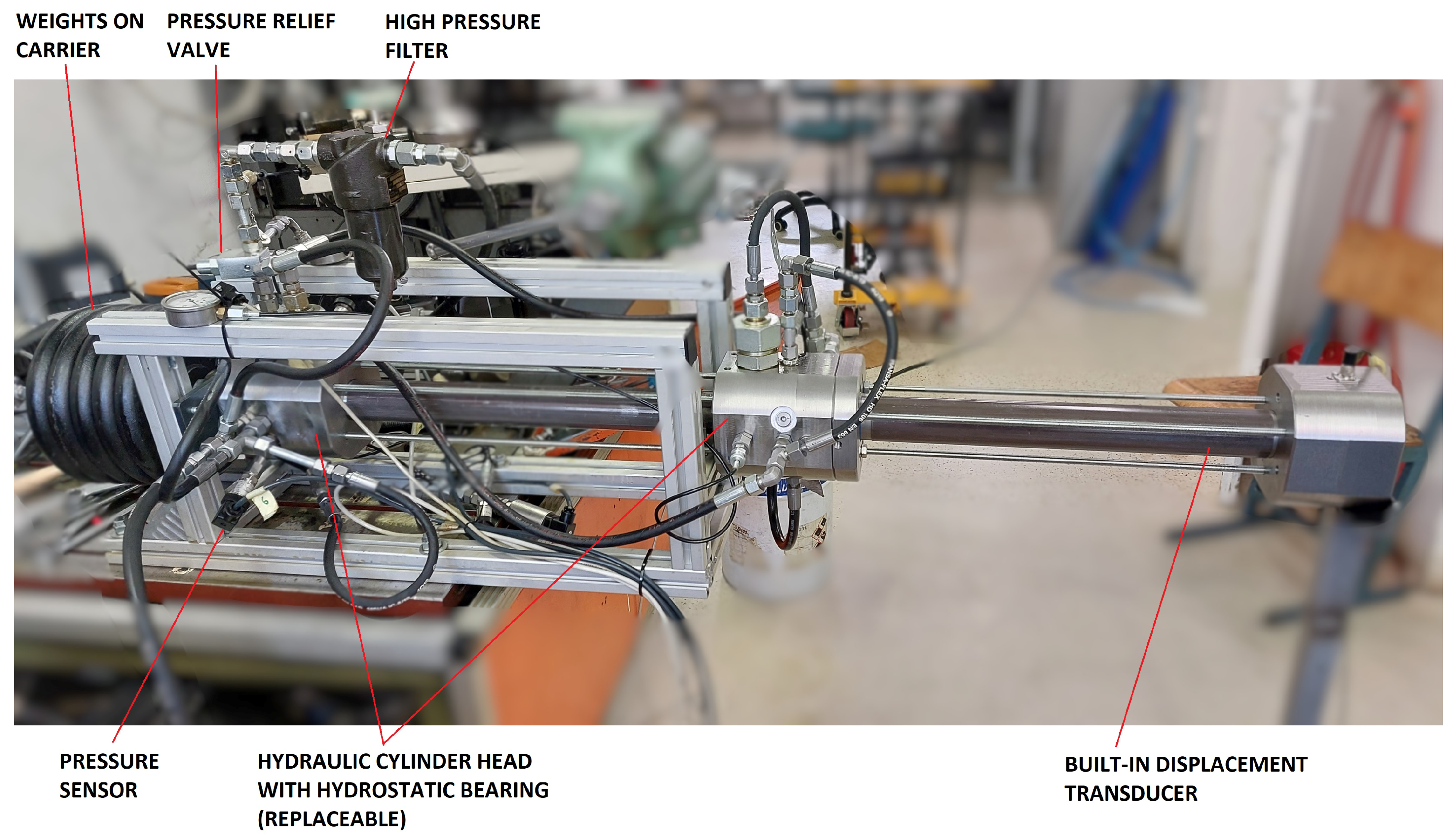

3. Experimental Setup

3.1. The Measurement Procedure

3.2. Hydraulic Schemes

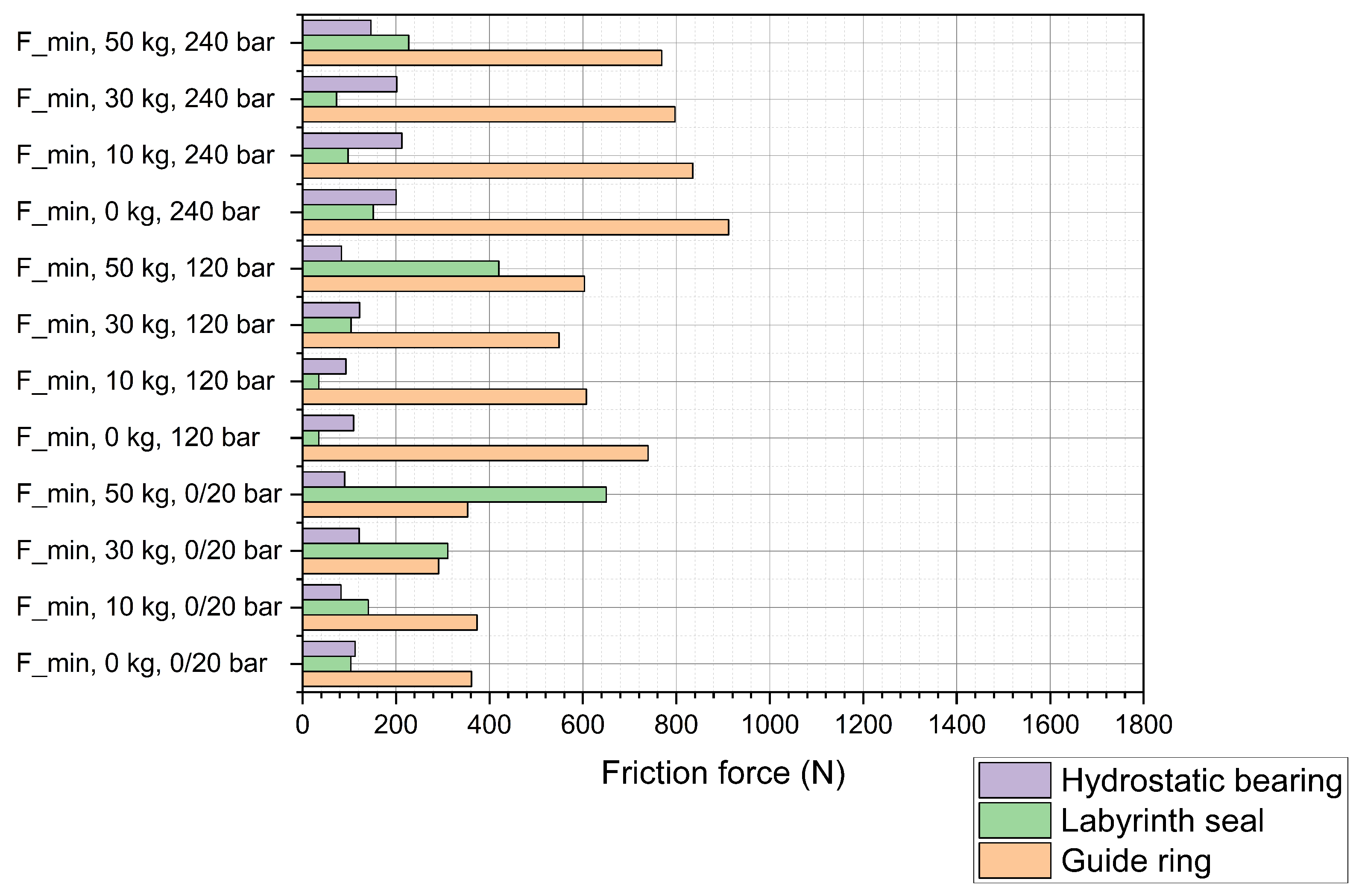

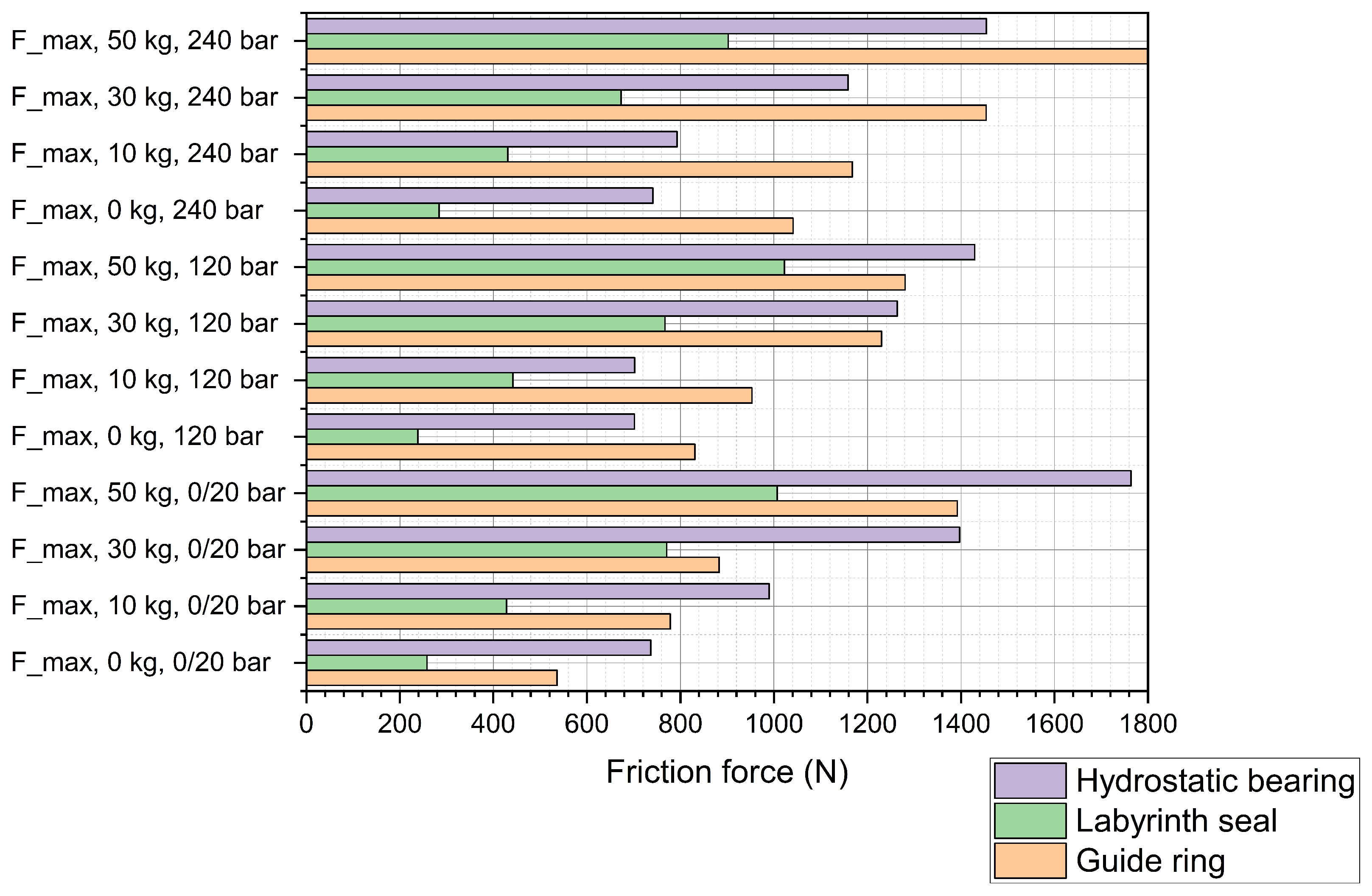

4. Results

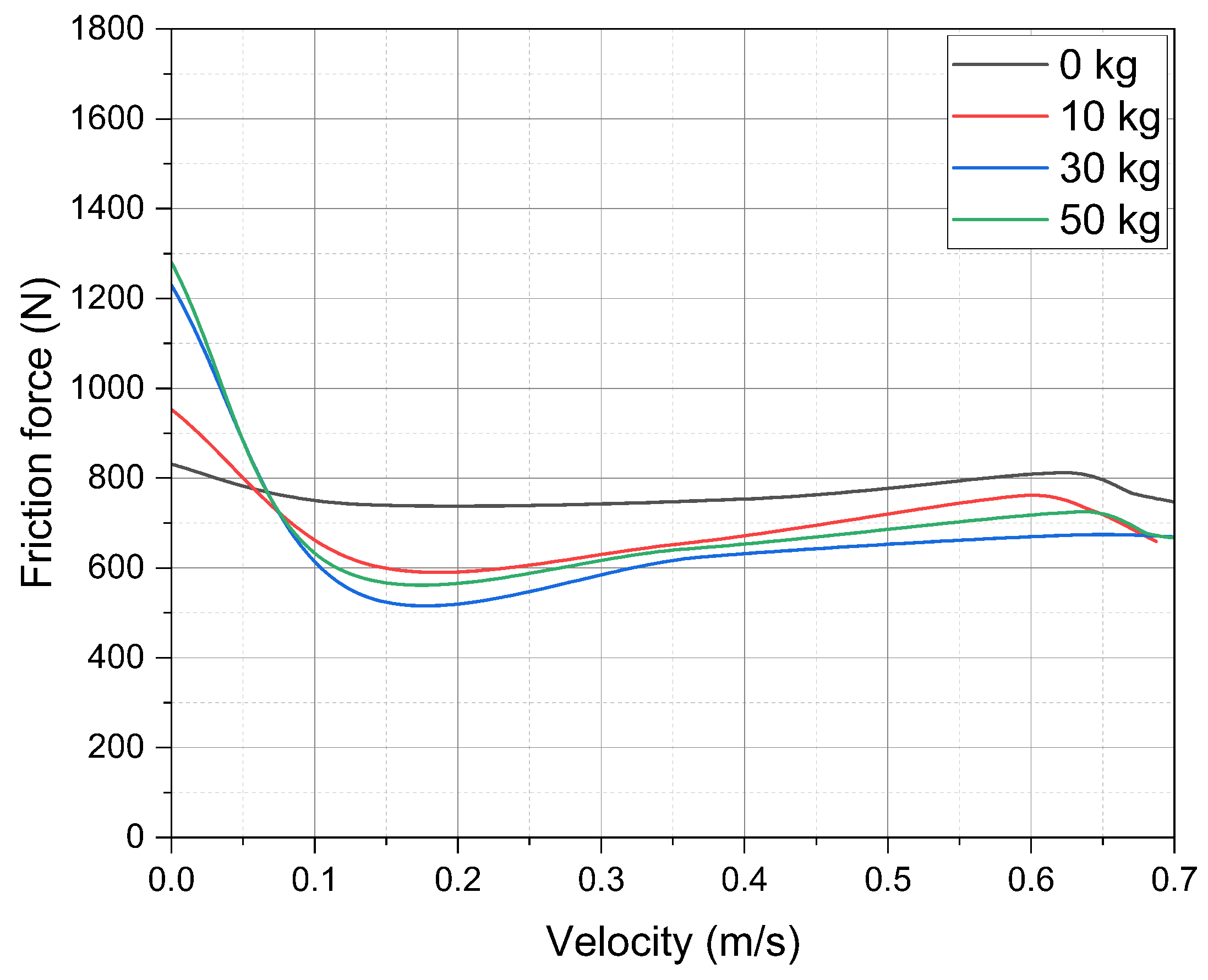

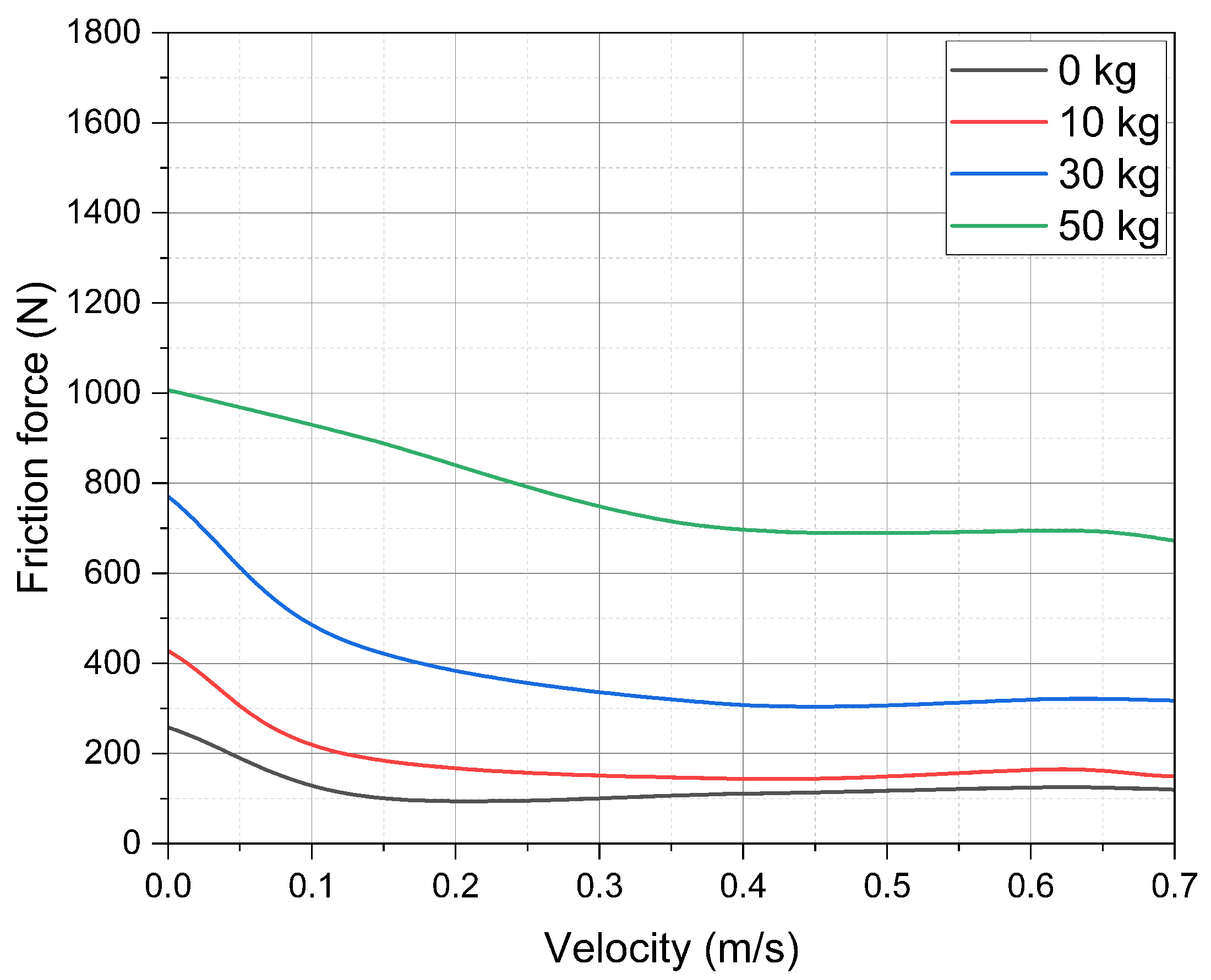

4.1. Guidance with Guide Rings

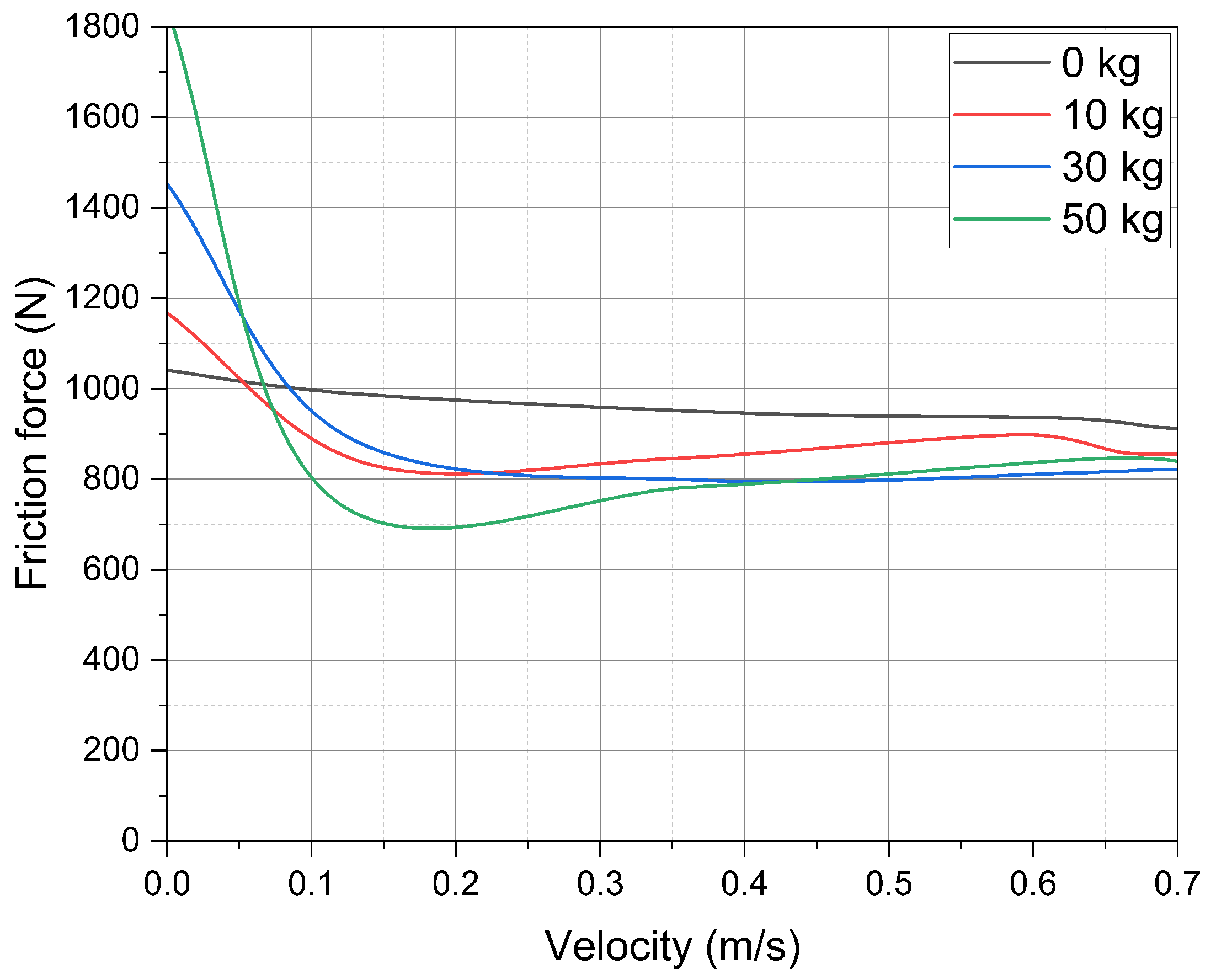

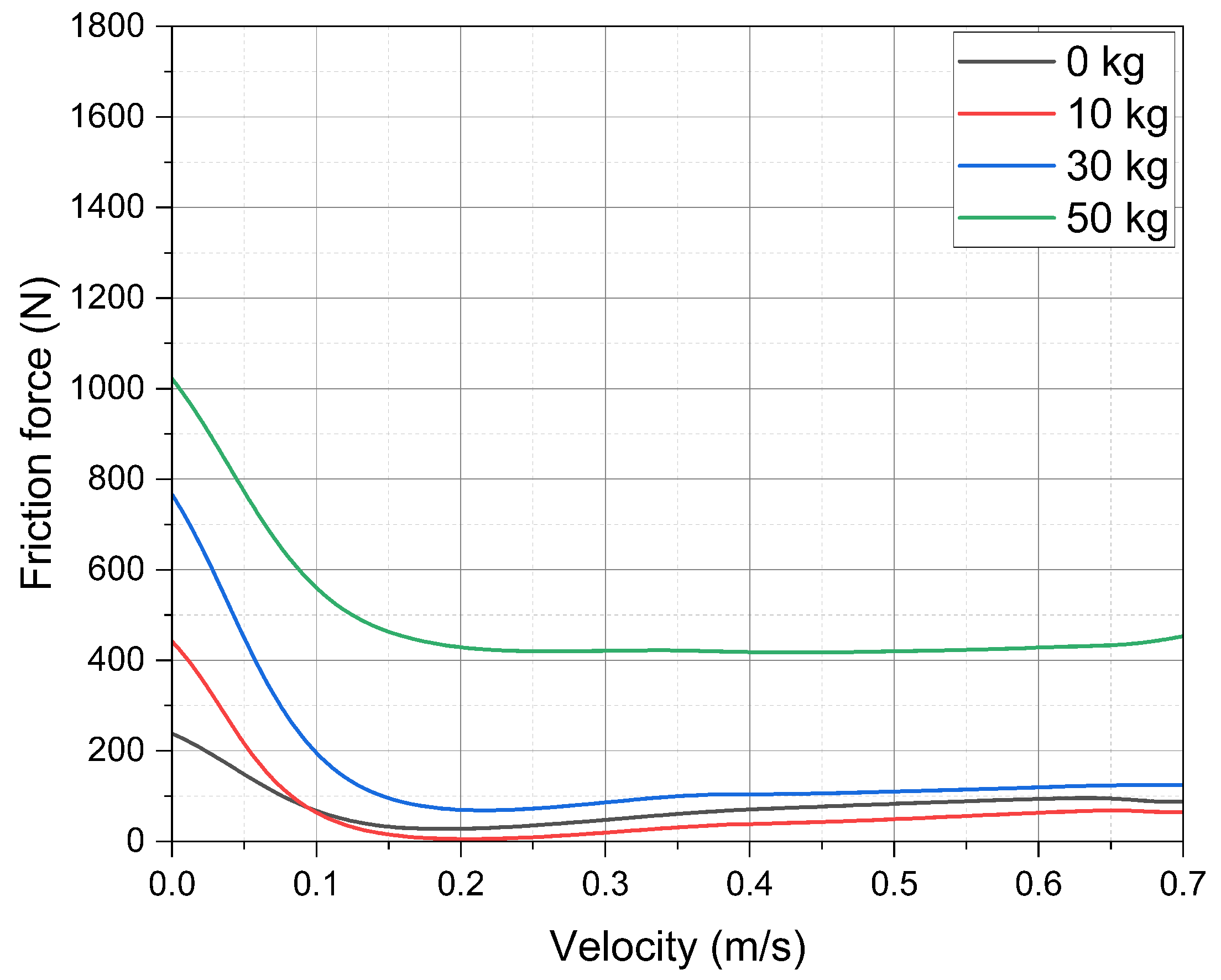

4.2. Guidance with Labyrinth Seal

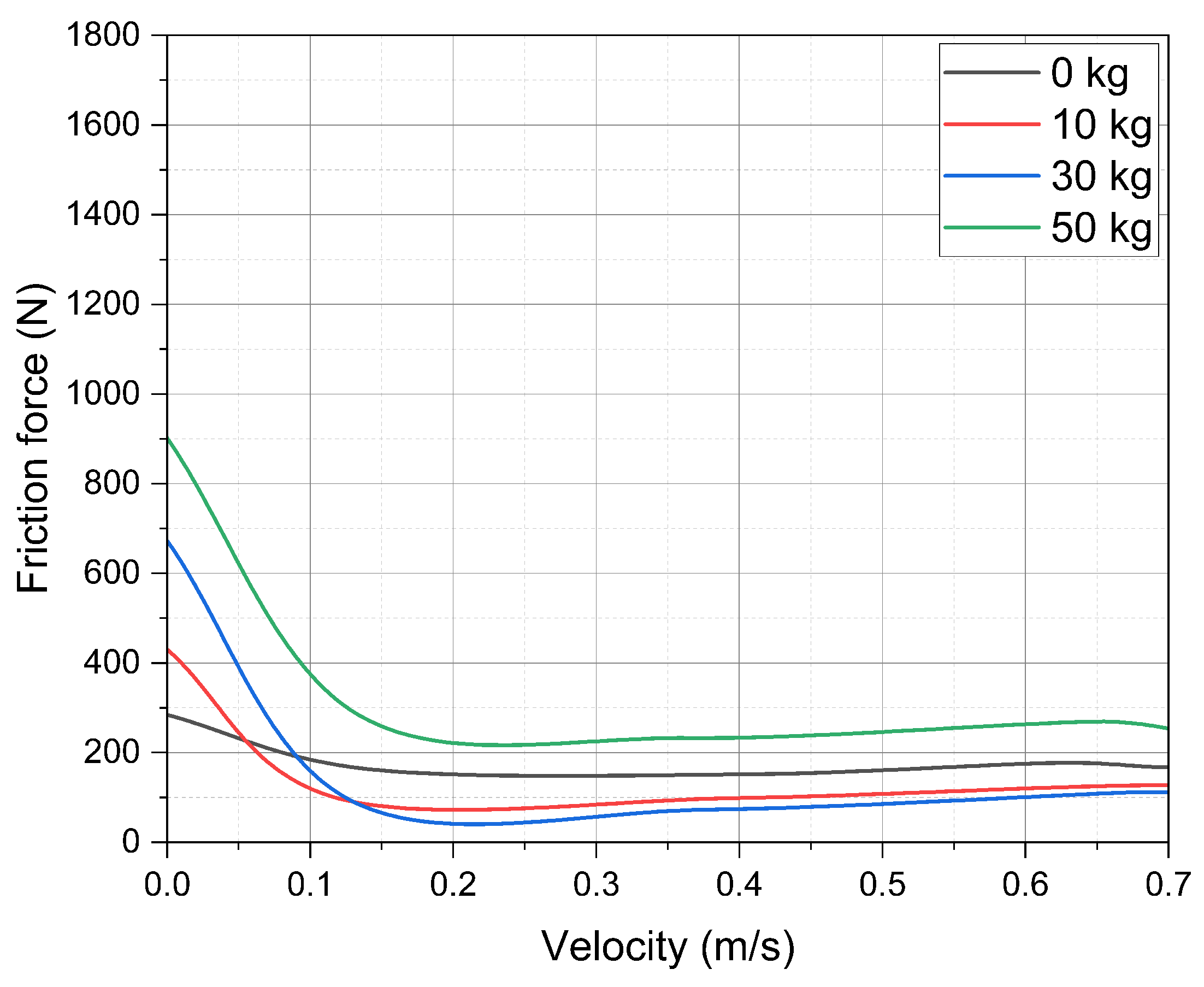

4.3. Guidance with Hydrostatic Seal

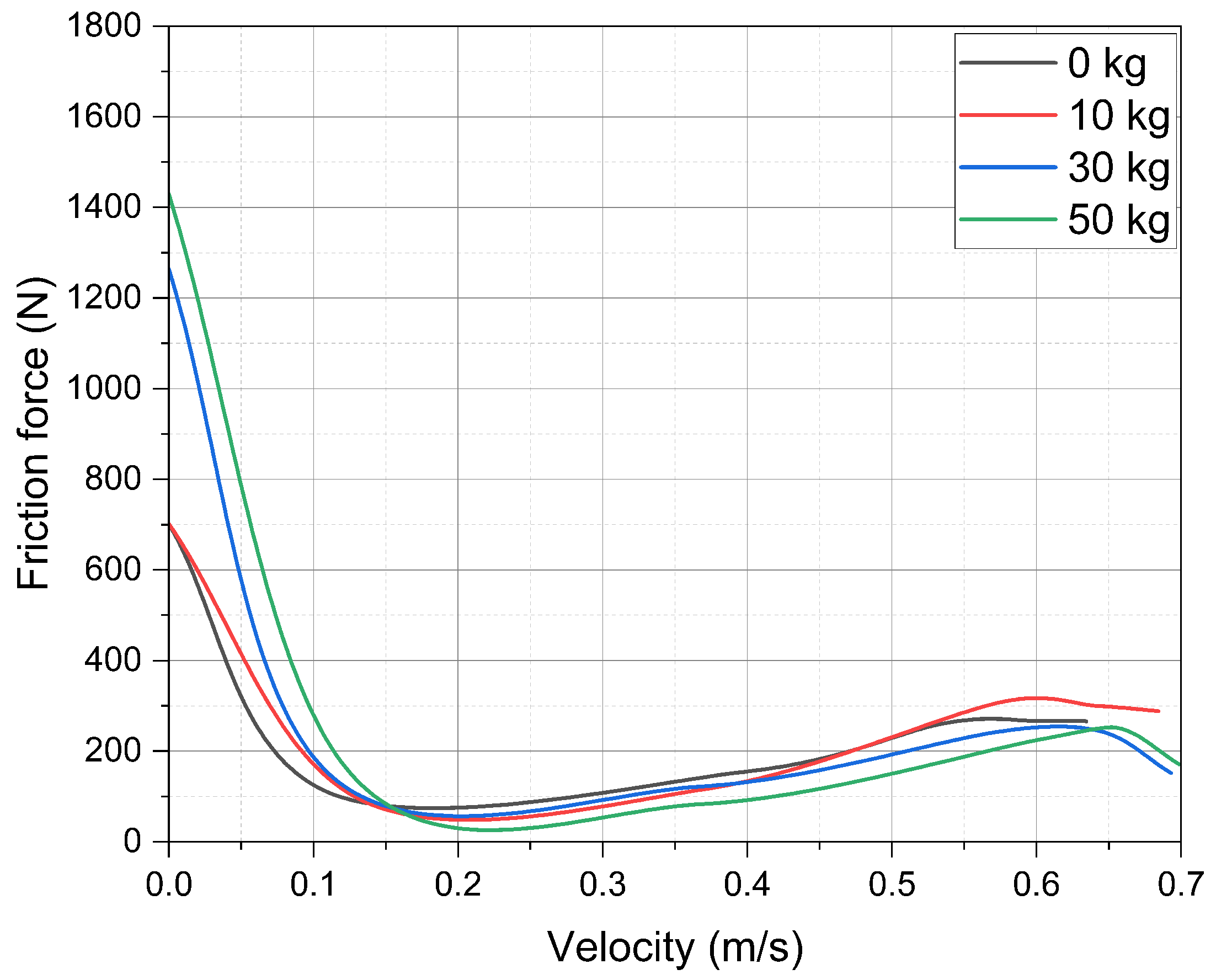

5. Discussion

5.1. Guidance with Guide Rings

5.2. Guidance with Labyrinth Seal

5.3. Guidance with Hydrostatic Bearing

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pabsetti, P.; Murty, R.S.V.N.; Bhoje, J.; Mathew, S.; Harivenkatesh; Rahul, K.; Feroskhan, M. Performance of hydraulic oils and its additives in fluid power system: A review. IOP Conf. Ser. Earth Environ. Sci. 2023, 1161, 012009. [Google Scholar] [CrossRef]

- Majdič, F.; Pezdirnik, J.; Kalin, M. Voda Kot Kapljevina vs. Pogonsko-Krmilni Hidravliki: Doktorsko Delo. Ph.D. Thesis, Univerza v Ljubljani, Ljubljana, Slovenia, 2010. [Google Scholar]

- Kambic, M.; Kalb, R.; Tic, V.; Lovrec, D. Compatibility of ionic liquids with hydraulic system components. Adv. Prod. Eng. Manag. 2018, 13, 492–503. [Google Scholar] [CrossRef]

- Lovrec, D.; Kalb, R.; Tič, V. Application Areas of Ionic Hydraulic Fluids. Chem. Eng. Technol. 2023, 46, 14–20. [Google Scholar] [CrossRef]

- Manring, N.D.; Fales, R.C. Hydraulic Control Systems; Wiley: Hoboken, NJ, USA, 2019. [Google Scholar] [CrossRef]

- Chen, P.; Chua, P.; Lim, G. A study of hydraulic seal integrity. Mech. Syst. Signal Process. 2007, 21, 1115–1126. [Google Scholar] [CrossRef]

- Sotoodeh, K. Actuator selection and sizing for valves. SN Appl. Sci. 2019, 1, 1207. [Google Scholar] [CrossRef]

- Abuowda, K.; Okhotnikov, I.; Noroozi, S.; Godfrey, P.; Dupac, M. A review of electrohydraulic independent metering technology. ISA Trans. 2020, 98, 364–381. [Google Scholar] [CrossRef]

- Mattila, J.; Koivumaki, J.; Caldwell, D.G.; Semini, C. A Survey on Control of Hydraulic Robotic Manipulators with Projection to Future Trends. IEEE/ASME Trans. Mechatron. 2017, 22, 669–680. [Google Scholar] [CrossRef]

- Tanaka, Y.; Sakama, S.; Nakano, K.; Kosodo, H. Comparative Study on Dynamic Characteristics of Hydraulic, Pneumatic and Electric Motors. In Proceedings of the ASME/BATH 2013 Symposium on Fluid Power and Motion Control, American Society of Mechanical Engineers, Sarasota, FL, USA, 6–9 October 2013. [Google Scholar] [CrossRef]

- Wiens, T.; Deibert, B. A Low-Cost Miniature Electrohydrostatic Actuator System. Actuators 2020, 9, 130. [Google Scholar] [CrossRef]

- Sakama, S.; Tanaka, Y.; Kamimura, A. Characteristics of Hydraulic and Electric Servo Motors. Actuators 2022, 11, 11. [Google Scholar] [CrossRef]

- Fassbender, D.; Zakharov, V.; Minav, T. Utilization of electric prime movers in hydraulic heavy-duty-mobile-machine implement systems. Autom. Constr. 2021, 132, 103964. [Google Scholar] [CrossRef]

- Pan, Q.; Zeng, Y.; Li, Y.; Jiang, X.; Huang, M. Experimental investigation of friction behaviors for double-acting hydraulic actuators with different reciprocating seals. Tribol. Int. 2021, 153, 106506. [Google Scholar] [CrossRef]

- Kastrevc, M.; Gubeljak, N.; Detiček, E. Design and tuning of the Lyapunov based nonlinear position control of electrohydraulic servo systems. Facta Univ. Ser. Mech. Eng. 2022, 62, 163–170. [Google Scholar]

- Shi, H.; Gong, G.; Yang, H.; Mei, X. Compliance of hydraulic system and its applications in thrust system design of shield tunneling machine. Sci. China Technol. Sci. 2013, 56, 2124–2131. [Google Scholar] [CrossRef]

- Davis, S. Pneumatic Actuators. Actuators 2018, 7, 62. [Google Scholar] [CrossRef]

- Meng, F.; Huang, Q.; Yu, Z.; Chen, X.; Fan, X.; Zhang, W.; Ming, A. Explosive electric actuator and control for legged robots. Engineering 2022, 12, 39–47. [Google Scholar] [CrossRef]

- Valilou, S. Nonlinear Model and Control of Electro-Hydraulic Servo Systems. Ph.D. Thesis, University of Bergamo, Bergamo, Italy, 2017. [Google Scholar]

- Maltezos, E.; Papoutsidakis, M.; De Negri, V. A study of hydraulic actuator control methods in simulation. Int. J. Eng. Appl. Sci. Technol. 2019, 4, 455–462. [Google Scholar] [CrossRef]

- Papoutsidakis, M.; Chatzopoulos, A.; Papachristos, D.; Drosos, C. Hydraulics and Pneumatics: Operational Characteristics and Control for Modern Industry Applications. Int. J. Comput. Appl. 2019, 178, 31–40. [Google Scholar] [CrossRef]

- Mendoza, G.; Igartua, A.; Fernandez-Diaz, B.; Urquiola, F.; Vivanco, S.; Arguizoniz, R. Vegetable oils as hydraulic fluids for agricultural applications. Grasas Y Aceites 2011, 62, 29–38. [Google Scholar] [CrossRef]

- Tkáč, Z.; Čorňák, Š.; Cviklovič, V.; Kosiba, J.; Glos, J.; Jablonický, J.; Bernát, R. Research of Biodegradable Fluid Impacts on Operation of Tractor Hydraulic System. Acta Technol. Agric. 2017, 20, 42–45. [Google Scholar] [CrossRef]

- Jabal, M.; Abdulmunem, A.; Abd, H. As a potential hydraulic fluid: Corn oil behavior characteristics examination. J. Therm. Eng. 2021, 7, 215–221. [Google Scholar] [CrossRef]

- Kučera, M.; Aleš, Z.; Ivandić, Z.; Hujo, Ľ. Possibility of hydraulic fluids with a low environmental impact application in agriculture and transport machinery. J. Cent. Eur. Agric. 2013, 14, 1575–1584. [Google Scholar] [CrossRef]

- Tič, V.; Tašner, T.; Lovrec, D. Enhanced lubricant management to reduce costs and minimise environmental impact. Energy 2014, 77, 108–116. [Google Scholar] [CrossRef]

- Chiavola, O.; Frattini, E.; Palmieri, F.; Fioravanti, A.; Marani, P. On the Efficiency of Mobile Hydraulic Power Packs Operating with New and Aged Eco-Friendly Fluids. Energies 2023, 16, 5681. [Google Scholar] [CrossRef]

- Mozetič, M.; Majdič, F. Trenje Batnih Tesnil vs. Hidravličnem Valju in Trajnostni Preizkus; Univerza v Ljubljani: Ljubljana, Slovenia, 2022. [Google Scholar]

- Oblak, R.; Kramar, P. Senzorji za Zaznavanje Pozicije Batnice vs. Hidravličnem Valju; Univerza v Ljubljani: Ljubljana, Slovenia, 2016. [Google Scholar]

- Chen, X.; Zheng, F.; Gan, W.; Xing, S. Exploration and Research on Key Technologies for Improving the Response Speed of Servo-Hydraulic Cylinders. Appl. Sci. 2022, 12, 4162. [Google Scholar] [CrossRef]

- Beacham, T.E.; Towler, F.H. Hydraulic Seals. Proc. Inst. Mech. Eng. 1949, 160, 532–569. [Google Scholar] [CrossRef]

- Wang, Q.J.; Chung, Y.W. (Eds.) Encyclopedia of Tribology; Springer: Boston, MA, USA, 2013. [Google Scholar] [CrossRef]

- Nikas, G.K.; Hasegawa, T. Research on the tribology of hydraulic reciprocating seals. In Tribology Research Trends; Nova Science Publishers, Inc.: Hauppauge, NY, USA, 2008; pp. 11–56. [Google Scholar]

- Heipl, O.; Murrenhoff, H. Friction of hydraulic rod seals at high velocities. Tribol. Int. 2015, 85, 66–73. [Google Scholar] [CrossRef]

- Huang, Y.; Salant, R.F. Simulation of a hydraulic rod seal with a textured rod and starvation. Tribol. Int. 2016, 95, 306–315. [Google Scholar] [CrossRef]

- Zhang, Z.; Gao, D.; Guan, T.; Liang, Y.; Zhao, J.; Wang, L.; Tang, J. Experimental Study on Friction and Wear Characteristics of Hydraulic Reciprocating Rotary Seals. Lubricants 2023, 11, 385. [Google Scholar] [CrossRef]

- Belforte, G.; Bertetto, A.M.; Mazza, L. Test rig for friction force measurements in pneumatic components and seals. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2013, 227, 43–59. [Google Scholar] [CrossRef]

- Belforte, G.; Conte, M.; Manuello Bertetto, A.; Mazza, L.; Raparelli, T.; Visconte, C. Indirect contact pressure evaluation on pneumatic rod seals. Tribol. Int. 2018, 118, 240–245. [Google Scholar] [CrossRef]

- Reichert, M. Development of High-Response Piezo-Servovalves for Improved Performance of Electrohydraulic Cylinder Drives. Ph.D. Thesis, Fakultät für Maschinenwesen, Aachen, Germany, 2010. [Google Scholar]

- Azzi, A.; Maoui, A.; Fatu, A.; Fily, S.; Souchet, D. Experimental study of friction in pneumatic seals. Tribol. Int. 2019, 135, 432–443. [Google Scholar] [CrossRef]

- Mazza, L.; Belforte, G. Analytical/Experimental Study of the Contribution of Individual Seals to Friction Force in Pneumatic Actuators. J. Tribol. 2017, 139. [Google Scholar] [CrossRef]

- Ambu, R.; Bertetto, A.M.; Mazza, L. Re-design of a guide bearing for pneumatic actuators and life tests comparison. Tribol. Int. 2016, 96, 317–325. [Google Scholar] [CrossRef]

- Manuello Bertetto, A.; Mazza, L.; Orrù, P. Contact Pressure Distribution in Guide Bearings for Pneumatic Actuators. Exp. Tech. 2015, 39, 46–54. [Google Scholar] [CrossRef]

- SKF Group. Machined Seals Product Range; SKF Group: 2019. Available online: https://cdn.skfmediahub.skf.com/api/public/0901d196809ce435/pdf_preview_medium/0901d196809ce435_pdf_preview_medium.pdf (accessed on 8 April 2025).

- Lee, Y.B.; Park, J.W.; Lee, G.C. A Study on Failure Analysis and High Performance of Hydraulic Servo Actuator. Appl. Sci. 2020, 10, 7451. [Google Scholar] [CrossRef]

- Brian, W.B. Hydrostatic, Aerostatic and Hybrid Bearing Design; Elsevier: Amsterdam, The Netherlands, 2012. [Google Scholar] [CrossRef]

- San Andrés, L.; Wu, T.; Barajas-Rivera, J.; Zhang, J.; Kawashita, R. Leakage and Cavity Pressures in an Interlocking Labyrinth Gas Seal: Measurements vs. Predictions. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar] [CrossRef]

- Li, D.; Li, Y.; Li, Z.; Wang, Y. Theory analyses and applications of magnetic fluids in sealing. Friction 2023, 11, 1771–1793. [Google Scholar] [CrossRef]

- Zardin, B.; Natali, E.; Cillo, G.; Borghi, M. Modelling of hydrostatic bearings for servo-cylinders. In AIP Conference Proceedings; AIP Publishing: Melville, NY, USA, 2019; p. 020156. [Google Scholar] [CrossRef]

- Patil, S.; Khairnar, A.; Phalle, V.M.; Limaye, P.K. Design of Self-Compensating Hydrostatic Bearing for Actuators. SSRN Electron. J. 2018, 1–6. [Google Scholar] [CrossRef]

- Metlikovič, P.; Emri, I. Naprava za merjenje lezenja torzijsko obremenjenih polimernih preizkušancev. Stroj. Vestn.-J. Mech. Eng. 1990, 26, 101–104. [Google Scholar]

- Liu, Z.; Wang, Y.; Cai, L.; Zhao, Y.; Cheng, Q.; Dong, X. A review of hydrostatic bearing system: Researches and applications. Adv. Mech. Eng. 2017, 9, 168781401773053. [Google Scholar] [CrossRef]

- Cheng, M. Leakage Flow of Labyrinth Seals in Hydraulic Components. In Proceedings of the ASME 2004 Heat Transfer/Fluids Engineering Summer Conference, Charlotte, NC, USA, 11–15 July 2004; pp. 1–8. [Google Scholar] [CrossRef]

- Trček, Č.; Majdič, F. Vpliv Radalnih Utorov na Pretoke Skozi Kolobarjaste Reže v Hidravliki; Univerza v Ljubljani: Ljubljana, Slovenia, 2014. [Google Scholar]

- Nabae, H.; Hemmi, M.; Hirota, Y.; Ide, T.; Suzumori, K.; Endo, G. Super-low friction and lightweight hydraulic cylinder using multi-directional forging magnesium alloy and its application to robotic leg. Adv. Robot. 2018, 32, 524–534. [Google Scholar] [CrossRef]

- Li, W.; Wang, X.; Zhang, X.; Zhang, X.; Zhu, Y.; Chen, H. Experimental and Numerical Investigations of Closed Radial Inflow Turbine with Labyrinth Seals. J. Eng. Gas Turbines Power 2018, 140, 102502. [Google Scholar] [CrossRef]

- GmbH, K.K. Non-Contact Labyrinth Seals Protect Rotating Equipment. Adhes. ADHESIVES+ SEALANTS 2021, 18, 24–25. [Google Scholar]

- Sheng, N.; Ruggiero, E.J.; Devi, R.; Guo, J.; Cirri, M. Experimental and Analytical Leakage Characterization of Annular Gas Seals: Honeycomb, Labyrinth and Pocket Damper Seals. In Proceedings of the VASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 6–10 June 2011; pp. 723–729. [Google Scholar] [CrossRef]

- Robinson, J.W.; Zhou, Y.; Bhattacharya, P.; Erck, R.; Qu, J.; Bays, J.T.; Cosimbescu, L. Probing the molecular design of hyper-branched aryl polyesters towards lubricant applications. Sci. Rep. 2016, 6, 18624. [Google Scholar] [CrossRef] [PubMed]

| Type | A26-F |

|---|---|

| Dimensions (d × D × L) [mm] | 40 × 48.8 × 6.3 |

| Sealing material/Energizer | X-ECOPUR/NBR70 |

| Temperature [°C] | −30 to +100 |

| Velocity max [m/s] | 5 |

| Type | S09-D |

|---|---|

| Dimensions (d × D × L) [mm] | 40 × 55.1 × 6.3 |

| Sealing material/Energizer | X-ECOPUR/NBR70 |

| Temperature [°C] | −30 to +100 |

| Velocity max [m/s] | 5 |

| Type | F08 |

|---|---|

| Dimensions (D × d/d1 × L/L1) | 40 × 48/44 × 18/6 mm |

| Guide ring material | PTFE with 40% bronze |

| Temperature | −200 °C to +200 °C |

| Velocity max | 5 m/s |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pustavrh, J.; Trajkovski, A.; Tič, V.; Polajnar, M.; Bohinc, U.; Majdič, F. Analysis of Different Guide Elements’ Designs in Hydraulic Cylinders. Appl. Sci. 2025, 15, 4738. https://doi.org/10.3390/app15094738

Pustavrh J, Trajkovski A, Tič V, Polajnar M, Bohinc U, Majdič F. Analysis of Different Guide Elements’ Designs in Hydraulic Cylinders. Applied Sciences. 2025; 15(9):4738. https://doi.org/10.3390/app15094738

Chicago/Turabian StylePustavrh, Jan, Ana Trajkovski, Vito Tič, Marko Polajnar, Uroš Bohinc, and Franc Majdič. 2025. "Analysis of Different Guide Elements’ Designs in Hydraulic Cylinders" Applied Sciences 15, no. 9: 4738. https://doi.org/10.3390/app15094738

APA StylePustavrh, J., Trajkovski, A., Tič, V., Polajnar, M., Bohinc, U., & Majdič, F. (2025). Analysis of Different Guide Elements’ Designs in Hydraulic Cylinders. Applied Sciences, 15(9), 4738. https://doi.org/10.3390/app15094738