Factors Influencing the Acceptance of Industry 4.0 Technologies in Various Sectors: A Systematic Review and Meta-Analysis

Abstract

1. Introduction

2. A Literature Review

2.1. Industry 4.0 Technologies

2.2. Adoption of TAM and Its Extensions

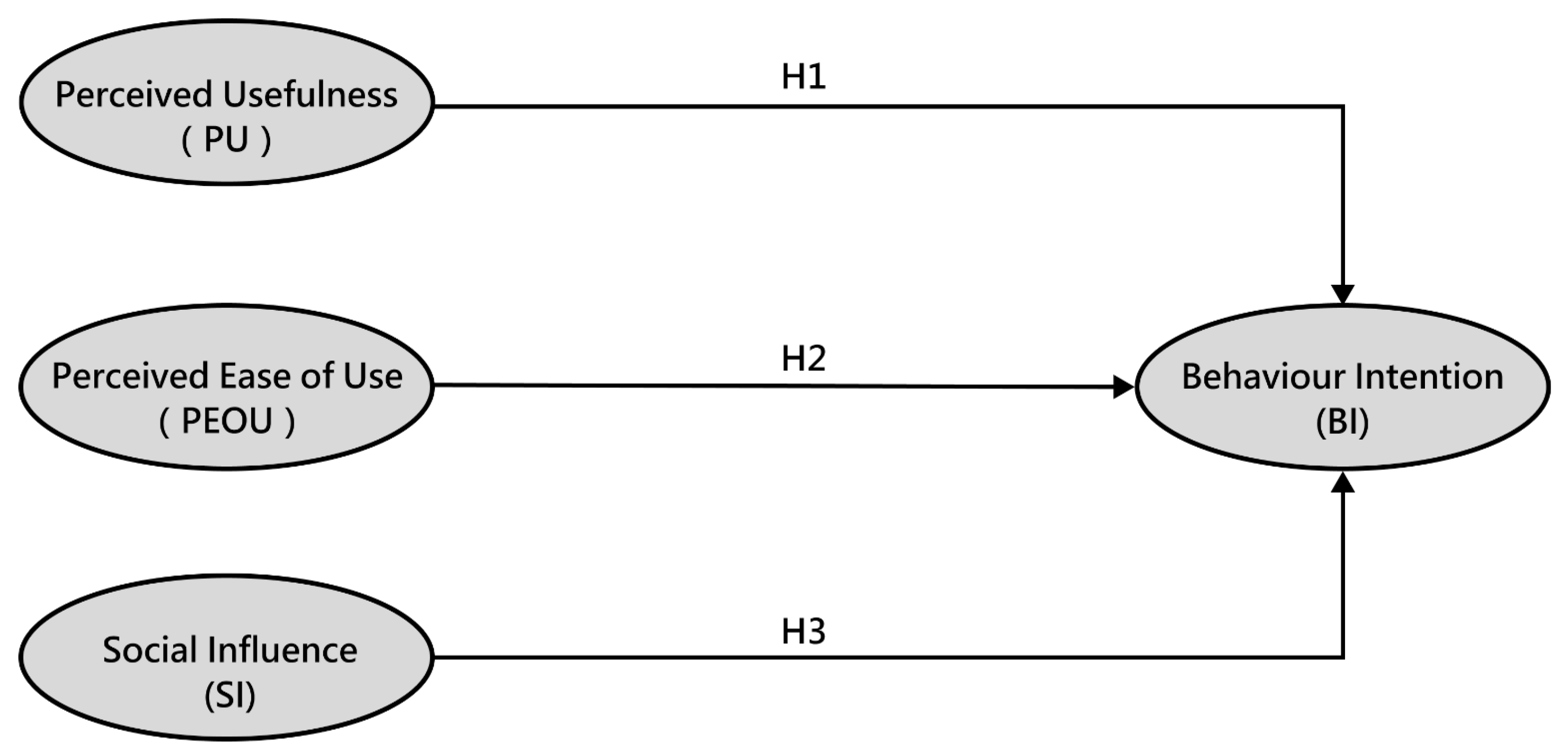

3. Research Framework and Hypothesis

4. Research Design

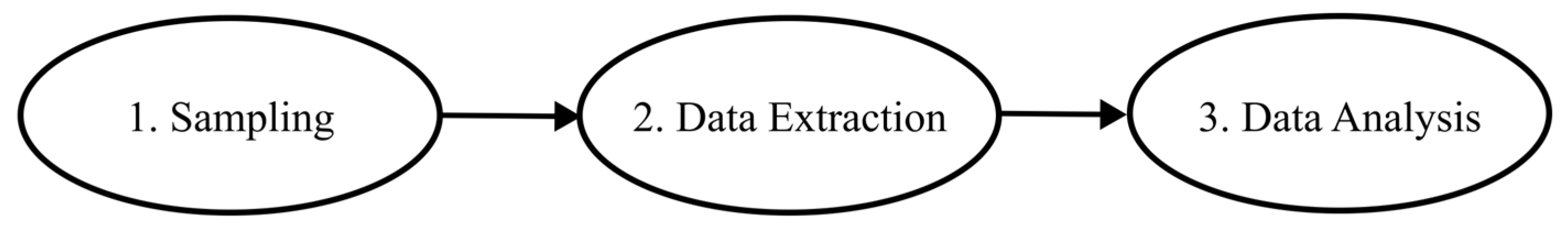

4.1. Methodology

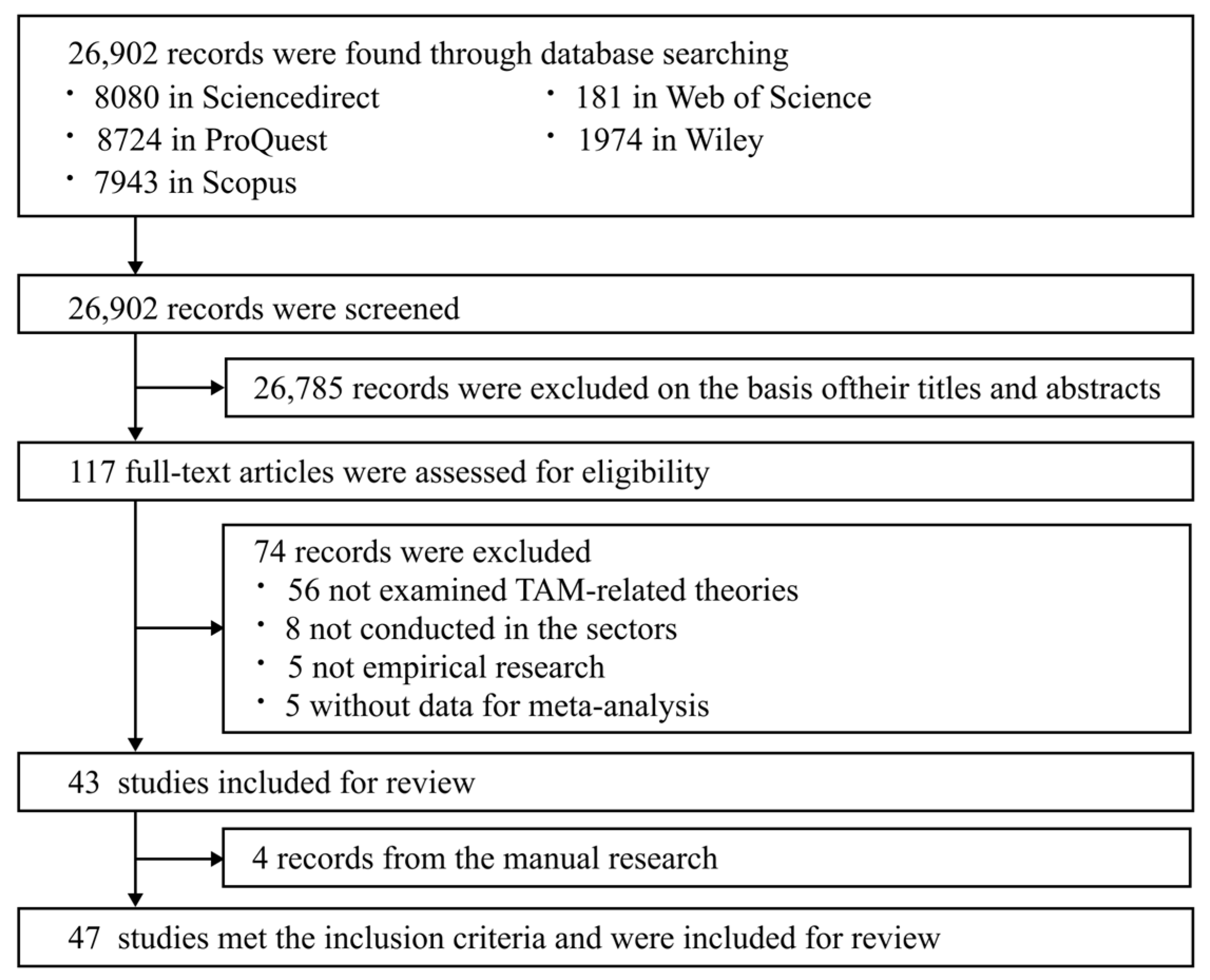

4.2. Sampling

4.3. Data Extraction

4.4. Data Analysis

5. Results

5.1. Study Characteristics

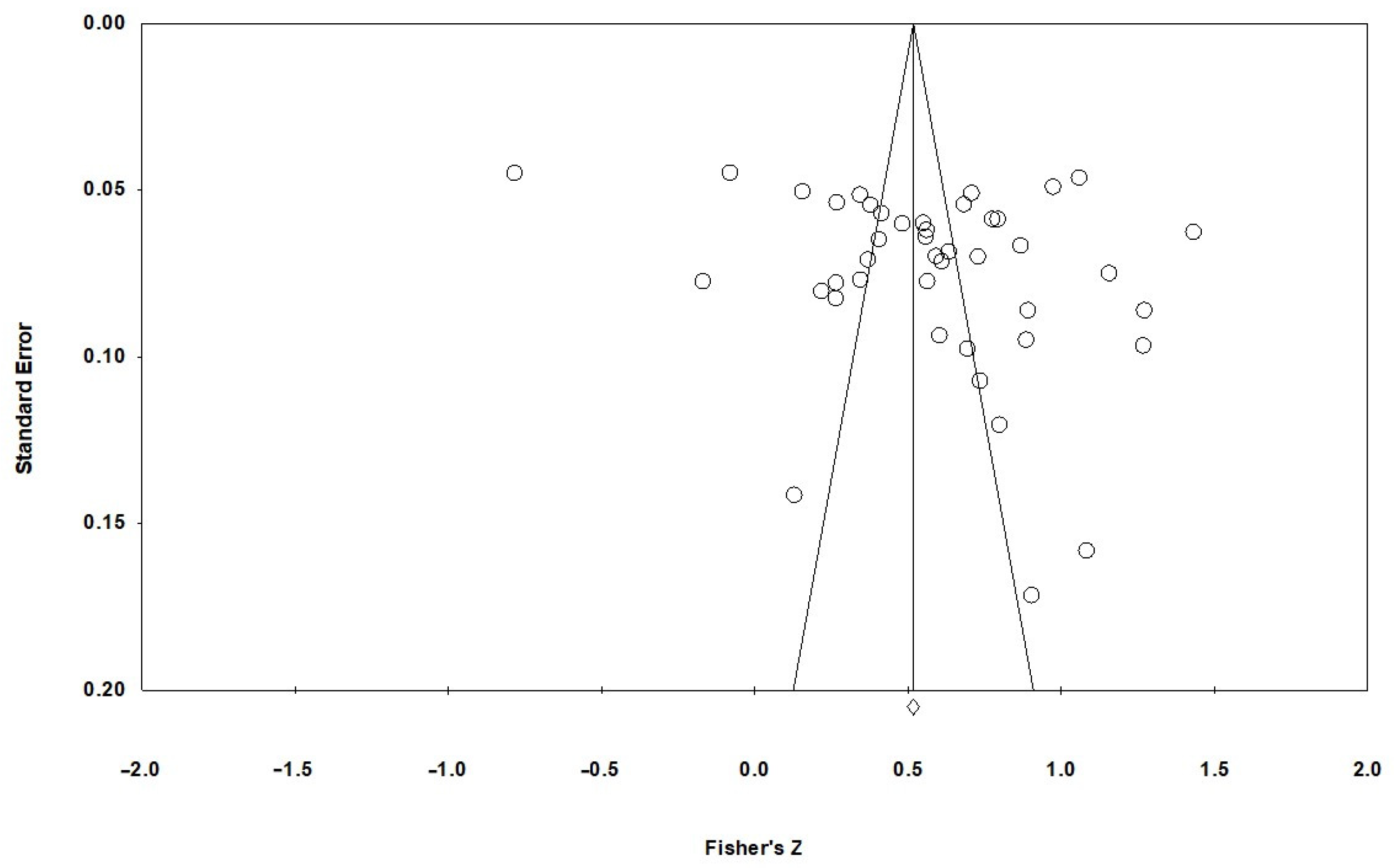

5.2. Overall Effect Sizes

5.3. Moderator Analysis

5.3.1. Subgroup Analysis

5.3.2. Meta-Regressions

6. Discussion

6.1. Direct Associations

6.2. Moderator Effects

6.3. Theoretical Implications

6.4. Practical Implications

6.5. Limitations and Future Directions

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Raja Santhi, A.; Muthuswamy, P. Industry 5.0 or industry 4.0 S? Introduction to industry 4.0 and a peek into the prospective industry 5.0 technologies. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 17, 947–979. [Google Scholar] [CrossRef]

- Zhang, C.; Chen, Y.; Chen, H.; Chong, D. Industry 4.0 and its implementation: A review. Inf. Syst. Front. 2024, 26, 1773–1783. [Google Scholar] [CrossRef]

- Singh, A.; Madaan, G.; Hr, S.; Kumar, A. Smart manufacturing systems: A futuristics roadmap towards application of industry 4.0 technologies. Int. J. Comput. Integr. Manuf. 2023, 36, 411–428. [Google Scholar] [CrossRef]

- Kotzias, K.; Bukhsh, F.A.; Arachchige, J.J.; Daneva, M.; Abhishta, A. Industry 4.0 and healthcare: Context, applications, benefits and challenges. IET Softw. 2023, 17, 195–248. [Google Scholar] [CrossRef]

- Sharma, M.; Luthra, S.; Joshi, S.; Kumar, A.; Jain, A. Green logistics driven circular practices adoption in industry 4.0 Era: A moderating effect of institution pressure and supply chain flexibility. J. Clean. Prod. 2023, 383, 135284. [Google Scholar] [CrossRef]

- Almeida, R.P.; Ayala, N.F.; Benitez, G.B.; Kliemann Neto, F.J.; Frank, A.G. How to assess investments in industry 4.0 technologies? A multiple-criteria framework for economic, financial, and sociotechnical factors. Prod. Plan. Control 2023, 34, 1583–1602. [Google Scholar] [CrossRef]

- Tortorella, G.L.; Prashar, A.; Carim Junior, G.; Mostafa, S.; Barros, A.; Lima, R.M.; Hines, P. Organizational culture and Industry 4.0 design principles: An empirical study on their relationship. Prod. Plan. Control 2024, 35, 1263–1277. [Google Scholar] [CrossRef]

- Khan, T.; Emon, M.M.H.; Rahman, M.A. A systematic review on exploring the influence of Industry 4.0 technologies to enhance supply chain visibility and operational efficiency. Rev. Bus. Econ. Stud. 2024, 12, 6–27. [Google Scholar] [CrossRef]

- Kadir, B.A.; Broberg, O.; da Conceição, C.S. Current research and future perspectives on human factors and ergonomics in Industry 4.0. Comput. Ind. Eng. 2019, 137, 106004. [Google Scholar] [CrossRef]

- Broday, E.E. Participatory Ergonomics in the context of Industry 4.0: A literature review. Theor. Issues Ergon. Sci. 2020, 22, 237–250. [Google Scholar] [CrossRef]

- Reiman, A.; Kaivo-Oja, J.; Parviainen, E.; Takala, E.-P.; Lauraeus, T. Human factors and ergonomics in manufacturing in the industry 4.0 context—A scoping review. Technol. Soc. 2021, 65, 101572. [Google Scholar] [CrossRef]

- Anes, H.; Pinto, T.; Lima, C.; Nogueira, P.; Reis, A. Wearable devices in Industry 4.0: A systematic literature review. In Proceedings of the International Symposium on Distributed Computing and Artificial Intelligence, Lille, France, 25–27 June 2023; pp. 332–341. [Google Scholar]

- Arcidiacono, F.; Ancarani, A.; Di Mauro, C.; Schupp, F. Where the rubber meets the road. Industry 4.0 among SMEs in the automotive sector. IEEE Eng. Manag. Rev. 2019, 47, 86–93. [Google Scholar] [CrossRef]

- Glass, G.V. Primary, secondary, and meta-analysis of research. Educ. Res. 1976, 5, 3–8. [Google Scholar] [CrossRef]

- Zhao, Y.; Ni, Q.; Zhou, R. What factors influence the mobile health service adoption? A meta-analysis and the moderating role of age. Int. J. Inf. Manag. 2018, 43, 342–350. [Google Scholar] [CrossRef]

- Chung, J.-E.; Oh, S.-G.; Moon, H.-C. What drives SMEs to adopt smart technologies in Korea? Focusing on technological factors. Technol. Soc. 2022, 71, 102109. [Google Scholar] [CrossRef]

- Kar, S.; Kar, A.K.; Gupta, M.P. Industrial internet of things and emerging digital technologies–modeling professionals’ learning behavior. IEEE Access 2021, 9, 30017–30034. [Google Scholar] [CrossRef]

- Mokhtar, S.S.S.; Mahomed, A.S.B.; Aziz, Y.A.; Rahman, S.A. Industry 4.0: The importance of innovation in adopting cloud computing among SMEs in Malaysia. Pol. J. Manag. Stud. 2020, 22, 310–322. [Google Scholar] [CrossRef]

- Ahmad Tarmizi, H.; Kamarulzaman, N.; Abd Rahman, A.; Atan, R. Adoption of internet of things among Malaysian halal agro-food SMEs and its challenges. Food Res. 2020, 4, 256–265. [Google Scholar] [CrossRef]

- Jaafreh, A.B. The effect factors in the adoption of Internet of Things (IoT) technology in the SME in KSA: An empirical study. Int. Rev. Manag. Bus. Res. 2018, 7, 135–148. [Google Scholar]

- Jones, N.B.; Graham, C.M. Can the IoT help small businesses? Bull. Sci. Technol. Soc. 2018, 38, 3–12. [Google Scholar] [CrossRef]

- Hajoary, P.K. Industry 4.0 maturity and readiness models: A systematic literature review and future framework. Int. J. Innov. Technol. Manag. 2020, 17, 2030005. [Google Scholar] [CrossRef]

- Paul, G.; Abele, N.D.; Kluth, K. A review and qualitative meta-analysis of digital human modeling and cyber-physical-systems in Ergonomics 4.0. IISE Trans. Occup. Ergon. Hum. Factors 2021, 9, 111–123. [Google Scholar] [CrossRef] [PubMed]

- Ramanujan, D.; Bernstein, W.Z.; Diaz-Elsayed, N.; Haapala, K.R. The role of Industry 4.0 technologies in manufacturing sustainability assessment. J. Manuf. Sci. Eng. 2023, 145, 010801. [Google Scholar] [CrossRef]

- Raj, A.; Jeyaraj, A. Antecedents and consequents of industry 4.0 adoption using technology, organization and environment (TOE) framework: A meta-analysis. Ann. Oper. Res. 2023, 322, 101–124. [Google Scholar] [CrossRef]

- Ferri, L.; Spanò, R.; Maffei, M.; Fiondella, C. How risk perception influences CEOs’ technological decisions: Extending the technology acceptance model to small and medium-sized enterprises’ technology decision makers. Eur. J. Innov. Manag. 2021, 24, 777–798. [Google Scholar] [CrossRef]

- Sigov, A.; Ratkin, L.; Ivanov, L.A.; Xu, L.D. Emerging enabling technologies for industry 4.0 and beyond. Inf. Syst. Front. 2024, 26, 1585–1595. [Google Scholar] [CrossRef]

- Shrivastava, A.; Krishna, K.M.; Rinawa, M.L.; Soni, M.; Ramkumar, G.; Jaiswal, S. Inclusion of IoT, ML, and blockchain technologies in next generation industry 4.0 environment. Mater. Today Proc. 2023, 80, 3471–3475. [Google Scholar] [CrossRef]

- Converso, G.; Gallo, M.; Murino, T.; Vespoli, S. Predicting failure probability in Industry 4.0 production systems: A workload-based prognostic model for maintenance planning. Appl. Sci. 2023, 13, 1938. [Google Scholar] [CrossRef]

- Strazzullo, S. Fostering digital trust in manufacturing companies: Exploring the impact of industry 4.0 technologies. J. Innov. Knowl. 2024, 9, 100621. [Google Scholar] [CrossRef]

- Klingenberg, C.O.; Borges, M.A.V.; Antunes Jr, J.A.V. Industry 4.0 as a data-driven paradigm: A systematic literature review on technologies. J. Manuf. Technol. Manag. 2021, 32, 570–592. [Google Scholar] [CrossRef]

- Barcellini, F.; Béarée, R.; Benchekroun, T.-H.; Bounouar, M.; Buchmann, W.; Dubey, G.; Lafeuillade, A.-C.; Moricot, C.; Rosselin-Bareille, C.; Saraceno, M. Promises of industry 4.0 under the magnifying glass of interdisciplinarity: Revealing operators and managers work and challenging collaborative robot design. Cogn. Technol. Work 2023, 25, 251–271. [Google Scholar] [CrossRef]

- Arana-Landín, G.; Uriarte-Gallastegi, N.; Landeta-Manzano, B.; Laskurain-Iturbe, I. The contribution of lean management—Industry 4.0 technologies to improving energy efficiency. Energies 2023, 16, 2124. [Google Scholar] [CrossRef]

- Stefanini, R.; Vignali, G. The influence of Industry 4.0 enabling technologies on social, economic and environmental sustainability of the food sector. Int. J. Prod. Res. 2024, 62, 3800–3817. [Google Scholar] [CrossRef]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 framework: A systematic literature review identifying the current trends and future perspectives. Process Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Ben-Daya, M.; Hassini, E.; Bahroun, Z. Internet of things and supply chain management: A literature review. Int. J. Prod. Res. 2019, 57, 4719–4742. [Google Scholar] [CrossRef]

- Liao, Y.; Deschamps, F.; Loures, E.d.F.R.; Ramos, L.F.P. Past, present and future of Industry 4.0—A systematic literature review and research agenda proposal. Int. J. Prod. Res. 2017, 55, 3609–3629. [Google Scholar] [CrossRef]

- Martins, G.D.; Gonçalves, R.F.; Petroni, B.C. Blockchain in manufacturing revolution based on machine to machine transaction: A systematic review. Braz. J. Oper. Prod. Manag. 2019, 16, 294–302. [Google Scholar] [CrossRef]

- Cui, Y.; Kara, S.; Chan, K.C. Manufacturing big data ecosystem: A systematic literature review. Robot. Comput.-Integr. Manuf. 2020, 62, 101861. [Google Scholar] [CrossRef]

- Duan, L.; Da Xu, L. Data analytics in industry 4.0: A survey. Inf. Syst. Front. 2024, 26, 2287–2303. [Google Scholar] [CrossRef]

- Xu, Z.; Zhang, K.; Min, H.; Wang, Z.; Zhao, X.; Liu, P. What drives people to accept automated vehicles? Findings from a field experiment. Transp. Res. Part C Emerg. Technol. 2018, 95, 320–334. [Google Scholar] [CrossRef]

- Raj, A.; Dwivedi, G.; Sharma, A.; de Sousa Jabbour, A.B.L.; Rajak, S. Barriers to the adoption of industry 4.0 technologies in the manufacturing sector: An inter-country comparative perspective. Int. J. Prod. Econ. 2020, 224, 107546. [Google Scholar] [CrossRef]

- Horváth, D.; Szabó, R.Z. Driving forces and barriers of Industry 4.0: Do multinational and small and medium-sized companies have equal opportunities? Technol. Forecast. Soc. Change 2019, 146, 119–132. [Google Scholar] [CrossRef]

- Castelo-Branco, I.; Cruz-Jesus, F.; Oliveira, T. Assessing Industry 4.0 readiness in manufacturing: Evidence for the European Union. Comput. Ind. 2019, 107, 22–32. [Google Scholar] [CrossRef]

- Saniuk, S.; Saniuk, A.; Cagáňová, D. Cyber Industry Networks as an environment of the Industry 4.0 implementation. Wirel. Netw. 2021, 27, 1649–1655. [Google Scholar] [CrossRef]

- Cohen, Y.; Naseraldin, H.; Chaudhuri, A.; Pilati, F. Assembly systems in Industry 4.0 era: A road map to understand Assembly 4.0. Int. J. Adv. Manuf. Technol. 2019, 105, 4037–4054. [Google Scholar] [CrossRef]

- Hoyer, C.; Gunawan, I.; Reaiche, C.H. The implementation of industry 4.0—A systematic literature review of the key factors. Syst. Res. Behav. Sci. 2020, 37, 557–578. [Google Scholar] [CrossRef]

- Sung, T.K. Industry 4.0: A Korea perspective. Technol. Forecast. Soc. Change 2018, 132, 40–45. [Google Scholar] [CrossRef]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Change 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Sommer, L. Industrial revolution-industry 4.0: Are German manufacturing SMEs the first victims of this revolution? J. Ind. Eng. Manag. 2015, 8, 1512–1532. [Google Scholar] [CrossRef]

- Vaidya, S.; Ambad, P.; Bhosle, S. Industry 4.0—A glimpse. Procedia Manuf. 2018, 20, 233–238. [Google Scholar] [CrossRef]

- Schneider, P. Managerial challenges of Industry 4.0: An empirically backed research agenda for a nascent field. Rev. Manag. Sci. 2018, 12, 803–848. [Google Scholar] [CrossRef]

- Lin, D.; Lee, C.K.; Lau, H.; Yang, Y. Strategic response to Industry 4.0: An empirical investigation on the Chinese automotive industry. Ind. Manag. Data Syst. 2018, 118, 589–605. [Google Scholar] [CrossRef]

- Davies, R.; Coole, T.; Smith, A. Review of socio-technical considerations to ensure successful implementation of Industry 4.0. Procedia Manuf. 2017, 11, 1288–1295. [Google Scholar] [CrossRef]

- Müller, J.M.; Kiel, D.; Voigt, K.-I. What drives the implementation of Industry 4.0? The role of opportunities and challenges in the context of sustainability. Sustainability 2018, 10, 247. [Google Scholar] [CrossRef]

- Ahuett-Garza, H.; Kurfess, T. A brief discussion on the trends of habilitating technologies for Industry 4.0 and Smart manufacturing. Manuf. Lett. 2018, 15, 60–63. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption challenges and benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Müller, J.M.; Buliga, O.; Voigt, K.-I. Fortune favors the prepared: How SMEs approach business model innovations in Industry 4.0. Technol. Forecast. Soc. Change 2018, 132, 2–17. [Google Scholar] [CrossRef]

- Badri, A.; Boudreau-Trudel, B.; Souissi, A.S. Occupational health and safety in the industry 4.0 era: A cause for major concern? Saf. Sci. 2018, 109, 403–411. [Google Scholar] [CrossRef]

- Wisniewski, M.; Gladysz, B.; Ejsmont, K.; Wodecki, A.; Van Erp, T. Industry 4.0 solutions impacts on critical infrastructure safety and protection—A systematic literature review. IEEE Access 2022, 10, 82716–82735. [Google Scholar] [CrossRef]

- Buer, S.-V.; Strandhagen, J.O.; Chan, F.T. The link between Industry 4.0 and lean manufacturing: Mapping current research and establishing a research agenda. Int. J. Prod. Res. 2018, 56, 2924–2940. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Teuteberg, F. Understanding the implications of digitisation and automation in the context of Industry 4.0: A triangulation approach and elements of a research agenda for the construction industry. Comput. Ind. 2016, 83, 121–139. [Google Scholar] [CrossRef]

- Garg, K.; Goswami, C.; Chhatrawat, R.; Dhakar, S.K.; Kumar, G. Internet of things in manufacturing: A review. Mater. Today Proc. 2022, 51, 286–288. [Google Scholar] [CrossRef]

- Singh, G.; Gaur, L.; Ramakrishnan, R. Internet of Things-Technology adoption model in India. Pertanika J. Sci. Technol. 2017, 25, 835–846. [Google Scholar]

- Hossain, M.S.; Muhammad, G. Cloud-assisted industrial internet of things (iiot)–enabled framework for health monitoring. Comput. Netw. 2016, 101, 192–202. [Google Scholar] [CrossRef]

- Peukert, B.; Benecke, S.; Clavell, J.; Neugebauer, S.; Nissen, N.F.; Uhlmann, E.; Lang, K.-D.; Finkbeiner, M. Addressing sustainability and flexibility in manufacturing via smart modular machine tool frames to support sustainable value creation. Procedia CIRP 2015, 29, 514–519. [Google Scholar] [CrossRef]

- Hofmann, E.; Rüsch, M. Industry 4.0 and the current status as well as future prospects on logistics. Comput. Ind. 2017, 89, 23–34. [Google Scholar] [CrossRef]

- Oettmeier, K.; Hofmann, E. Additive manufacturing technology adoption: An empirical analysis of general and supply chain-related determinants. J. Bus. Econ. 2017, 87, 97–124. [Google Scholar] [CrossRef]

- Leonhardt, F.; Wiedemann, A. Realigning Risk Management in the Light of Industry 4.0. 2015. Available online: https://ssrn.com/abstract=2678947 (accessed on 4 March 2025).

- Orlikowski, W.J. The duality of technology: Rethinking the concept of technology in organizations. Organ. Sci. 1992, 3, 398–427. [Google Scholar] [CrossRef]

- Davis, F.D.; Bagozzi, R.P.; Warshaw, P.R. User acceptance of computer technology: A comparison of two theoretical models. Manag. Sci. 1989, 35, 982–1003. [Google Scholar] [CrossRef]

- Chong, A.Y.L.; Blut, M.; Zheng, S. Factors influencing the acceptance of healthcare information technologies: A meta-analysis. Inf. Manag. 2022, 59, 103604. [Google Scholar] [CrossRef]

- Venkatesh, V.; Davis, F.D. A theoretical extension of the technology acceptance model: Four longitudinal field studies. Manag. Sci. 2000, 46, 186–204. [Google Scholar] [CrossRef]

- Venkatesh, V.; Bala, H. Technology acceptance model 3 and a research agenda on interventions. Decis. Sci. 2008, 39, 273–315. [Google Scholar] [CrossRef]

- Venkatesh, V.; Morris, M.G.; Davis, G.B.; Davis, F.D. User acceptance of information technology: Toward a unified view. MIS Q. 2003, 27, 425–478. [Google Scholar] [CrossRef]

- Peng, L.; Man, S.S.; Chan, A.H.; Ng, J.Y. Personal, social and regulatory factors associated with telecare acceptance by Hong Kong older adults: An indication of governmental role in facilitating telecare adoption. Int. J. Hum.-Comput. Interact. 2023, 39, 1059–1071. [Google Scholar] [CrossRef]

- Scherer, R.; Siddiq, F.; Tondeur, J. The technology acceptance model (TAM): A meta-analytic structural equation modeling approach to explaining teachers’ adoption of digital technology in education. Comput. Educ. 2019, 128, 13–35. [Google Scholar] [CrossRef]

- Man, S.S.; Guo, Y.; Chan, A.H.S.; Zhuang, H. Acceptance of online mapping technology among older adults: Technology acceptance model with facilitating condition, compatibility, and self-satisfaction. ISPRS Int. J. Geo-Inf. 2022, 11, 558. [Google Scholar] [CrossRef]

- Rafique, H.; Almagrabi, A.O.; Shamim, A.; Anwar, F.; Bashir, A.K. Investigating the acceptance of mobile library applications with an extended technology acceptance model (TAM). Comput. Educ. 2020, 145, 103732. [Google Scholar] [CrossRef]

- Man, S.S.; Xiong, W.; Chang, F.; Chan, A.H.S. Critical factors influencing acceptance of automated vehicles by Hong Kong drivers. IEEE Access 2020, 8, 109845–109856. [Google Scholar] [CrossRef]

- Man, S.S.; Ding, M.; Li, X.; Chan, A.H.S.; Zhang, T. Acceptance of highly automated vehicles: The role of facilitating condition, technology anxiety, social influence and trust. Int. J. Hum.-Comput. Interact. 2024, 41, 3684–3695. [Google Scholar] [CrossRef]

- Man, S.S.; Wang, J.; Chan, A.H.S.; Liu, L. Ageing in the digital age: What drives virtual reality technology adoption among older adults? Ergonomics 2025, 1–15. [Google Scholar] [CrossRef]

- Man, S.S.; Fang, Y.; Chan, A.H.S.; Han, J. VR technology acceptance for English learning amongst secondary school students: Role of classroom climate and language learning anxiety. Educ. Inf. Technol. 2024, 30, 4131–4155. [Google Scholar] [CrossRef]

- Venkatesh, V.; Thong, J.Y.; Xu, X. Consumer acceptance and use of information technology: Extending the unified theory of acceptance and use of technology. MIS Q. 2012, 36, 157–178. [Google Scholar] [CrossRef]

- Wong, T.K.M.; Man, S.S.; Chan, A.H.S. Exploring the acceptance of PPE by construction workers: An extension of the technology acceptance model with safety management practices and safety consciousness. Saf. Sci. 2021, 139, 105239. [Google Scholar] [CrossRef]

- Chauhan, S.; Jaiswal, M. A meta-analysis of e-health applications acceptance: Moderating impact of user types and e-health application types. J. Enterp. Inf. Manag. 2017, 30, 295–319. [Google Scholar] [CrossRef]

- Tao, D.; Wang, T.; Wang, T.; Zhang, T.; Zhang, X.; Qu, X. A systematic review and meta-analysis of user acceptance of consumer-oriented health information technologies. Comput. Hum. Behav. 2020, 104, 106147. [Google Scholar] [CrossRef]

- Šumak, B.; Heričko, M.; Budimac, Z.; Pušnik, M. Investigation of moderator factors in e-business adoption: A quantitative meta-analysis of moderating effects on the drivers of intention and behavior. Comput. Sci. Inf. Syst. 2017, 14, 75–102. [Google Scholar] [CrossRef]

- Rodríguez-Espíndola, O.; Chowdhury, S.; Dey, P.K.; Albores, P.; Emrouznejad, A. Analysis of the adoption of emergent technologies for risk management in the era of digital manufacturing. Technol. Forecast. Soc. Change 2022, 178, 121562. [Google Scholar] [CrossRef]

- Narwane, V.S.; Raut, R.D.; Gardas, B.B.; Kavre, M.S.; Narkhede, B.E. Factors affecting the adoption of cloud of things: The case study of Indian small and medium enterprises. J. Syst. Inf. Technol. 2019, 21, 397–418. [Google Scholar] [CrossRef]

- Chen, J.-H.; Ha, N.T.T.; Tai, H.-W.; Chang, C.-A. The willingness to adopt the Internet of Things (IoT) conception in Taiwan’s construction industry. J. Civ. Eng. Manag. 2020, 26, 534–550. [Google Scholar] [CrossRef]

- Zainab, A.; Kiran, K.; Karim, N.; Sukmawati, M. UTAUT’S performance consistency: Empirical evidence from a library management system. Malays. J. Libr. Inf. Sci. 2018, 23, 17–32. [Google Scholar] [CrossRef]

- Verma, S.; Bhattacharyya, S.S.; Kumar, S. An extension of the technology acceptance model in the big data analytics system implementation environment. Inf. Process. Manag. 2018, 54, 791–806. [Google Scholar] [CrossRef]

- Wuni, I.Y.; Shen, G.Q. Barriers to the adoption of modular integrated construction: Systematic review and meta-analysis, integrated conceptual framework, and strategies. J. Clean. Prod. 2020, 249, 119347. [Google Scholar] [CrossRef]

- Man, S.S.; Huang, C.; Ye, Q.; Chang, F.; Chan, A.H.S. Pedestrians’ Interaction with eHMI-equipped Autonomous Vehicles: A Bibliometric Analysis and Systematic Review. Accid. Anal. Prev. 2025, 209, 107826. [Google Scholar] [CrossRef] [PubMed]

- Shorten, A.; Bratches, R.; Shorten, B. What is a meta-analysis? Evid.-Based Nurs. 2025, 28, 74–76. [Google Scholar] [CrossRef]

- Quintana, D.S. A guide for calculating study-level statistical power for meta-analyses. Adv. Methods Pract. Psychol. Sci. 2023, 6, 25152459221147260. [Google Scholar] [CrossRef]

- Papakostidis, C.; Giannoudis, P.V. Meta-analysis. What have we learned? Injury 2023, 54, S30–S34. [Google Scholar] [CrossRef]

- Nakagawa, S.; Yang, Y.; Macartney, E.L.; Spake, R.; Lagisz, M. Quantitative evidence synthesis: A practical guide on meta-analysis, meta-regression, and publication bias tests for environmental sciences. Environ. Evid. 2023, 12, 8. [Google Scholar] [CrossRef]

- Rosenthal, R.; DiMatteo, M.R. Meta-analysis: Recent developments in quantitative methods for literature reviews. Annu. Rev. Psychol. 2001, 52, 59–82. [Google Scholar] [CrossRef]

- Man, S.S.; Li, X.; Lin, X.J.; Lee, Y.-C.; Chan, A.H.S. Assessing the Effectiveness of Virtual Reality Interventions on Anxiety, Stress, and Negative Emotions in College Students: A Meta-Analysis of Randomized Controlled Trials. Int. J. Hum.-Comput. Interact. 2024; 1–17. [Google Scholar] [CrossRef]

- Paul, J.; Barari, M. Meta-analysis and traditional systematic literature reviews—What, why, when, where, and how? Psychol. Mark. 2022, 39, 1099–1115. [Google Scholar] [CrossRef]

- Man, S.S.; Wen, H.; So, B.C.L. Are virtual reality applications effective for construction safety training and education? A systematic review and meta-analysis. J. Saf. Res. 2024, 88, 230–243. [Google Scholar] [CrossRef]

- Oesterreich, T.D.; Anton, E.; Teuteberg, F.; Dwivedi, Y.K. The role of the social and technical factors in creating business value from big data analytics: A meta-analysis. J. Bus. Res. 2022, 153, 128–149. [Google Scholar] [CrossRef]

- Peterson, R.A.; Brown, S.P. On the use of beta coefficients in meta-analysis. J. Appl. Psychol. 2005, 90, 175. [Google Scholar] [CrossRef]

- Borenstein, M. Comprehensive Meta-Analysis Software; John Wiley & Sons Ltd.: Hoboken, NJ, USA, 2022. [Google Scholar]

- Cumming, G. Understanding the New Statistics: Effect Sizes, Confidence Intervals, and Meta-Analysis; Routledge: London, UK, 2013. [Google Scholar]

- Field, A.P. The problems in using fixed-effects models of meta-analysis on real-world data. Underst. Stat. Stat. Issues Psychol. Educ. Soc. Sci. 2003, 2, 105–124. [Google Scholar] [CrossRef]

- Egger, M.; Smith, G.D.; Schneider, M.; Minder, C. Bias in meta-analysis detected by a simple, graphical test. BMJ 1997, 315, 629–634. [Google Scholar] [CrossRef]

- Jahrami, H.A.; Alsibai, J.; Clark, C.C.; Faris, M.e.A.-I.E. A systematic review, meta-analysis, and meta-regression of the impact of diurnal intermittent fasting during Ramadan on body weight in healthy subjects aged 16 years and above. Eur. J. Nutr. 2020, 59, 2291–2316. [Google Scholar] [CrossRef] [PubMed]

- Tiffany, T.; Rosman, D. Understanding National Culture in Smart Technology Acceptance—A Case of Indonesia and Australia. In Proceedings of the 2024 9th International Conference on Business and Industrial Research (ICBIR), Bangkok, Thailand, 23–24 May 2024; pp. 662–667. [Google Scholar]

- Norzelan, N.A.; Mohamed, I.S.; Mohamad, M. Technology acceptance of artificial intelligence (AI) among heads of finance and accounting units in the shared service industry. Technol. Forecast. Soc. Change 2024, 198, 123022. [Google Scholar] [CrossRef]

- Abdullah, A.A.H.; Almaqtari, F.A. The impact of artificial intelligence and Industry 4.0 on transforming accounting and auditing practices. J. Open Innov. Technol. Mark. Complex. 2024, 10, 100218. [Google Scholar] [CrossRef]

- Wu, R.; Yu, Z. Investigating users’ acceptance of the metaverse with an extended technology acceptance model. International J. Hum.–Comput. Interact. 2024, 40, 5810–5826. [Google Scholar] [CrossRef]

- Vitezić, V.; Perić, M. The role of digital skills in the acceptance of artificial intelligence. J. Bus. Ind. Mark. 2024, 39, 1546–1566. [Google Scholar] [CrossRef]

- Cordero, D.; Altamirano, K.L.; Parra, J.O.; Espinoza, W.S. Intention to adopt industry 4.0 by organizations in Colombia, Ecuador, Mexico, Panama, and Peru. IEEE Access 2023, 11, 8362–8386. [Google Scholar] [CrossRef]

- Zhang, X.Y.; Lee, S.Y. A research on users’ behavioral intention to adopt Internet of Things (IoT) technology in the logistics industry: The case of Cainiao Logistics Network. J. Int. Logist. Trade 2023, 21, 41–60. [Google Scholar] [CrossRef]

- Selim, S.; Dogan, R.S.; Sen, M. A New Technology Acceptance Model on Industry 4.0: A Firm Based Regional Analysis. Electron. J. Appl. Stat. Anal. 2023, 16, 272–293. [Google Scholar] [CrossRef]

- de Andrés-Sánchez, J.; Gené-Albesa, J. Explaining policyholders’ chatbot acceptance with an unified technology acceptance and use of technology-based model. J. Theor. Appl. Electron. Commer. Res. 2023, 18, 1217–1237. [Google Scholar] [CrossRef]

- Okoro, C.S.; Nnaji, C.; Adediran, A. Determinants of immersive technology acceptance in the construction industry: Management perspective. Eng. Constr. Archit. Manag. 2023, 30, 2645–2668. [Google Scholar] [CrossRef]

- Alam, S.S.; Masukujjaman, M.; Ahmad, M.; Jaffor, R. Acceptance of online distance learning (ODL) among students: Mediating role of utilitarian and hedonic value. Educ. Inf. Technol. 2023, 28, 8503–8536. [Google Scholar] [CrossRef]

- Sciarelli, M.; Prisco, A.; Gheith, M.H.; Muto, V. Factors affecting the adoption of blockchain technology in innovative Italian companies: An extended TAM approach. J. Strategy Manag. 2022, 15, 495–507. [Google Scholar] [CrossRef]

- Amron, M.T.; Noh, N.H.M.; Mohamad, M.A. Predicting the Acceptance of Cloud Computing in Higher Education Institutions by Extending the Technology Readiness Theory. Asian J. Univ. Educ. 2022, 18, 767–779. [Google Scholar]

- Na, S.; Heo, S.; Han, S.; Shin, Y.; Roh, Y. Acceptance model of artificial intelligence (AI)-based technologies in construction firms: Applying the Technology Acceptance Model (TAM) in combination with the Technology–Organisation–Environment (TOE) framework. Buildings 2022, 12, 90. [Google Scholar] [CrossRef]

- Perdana, A.; Lee, H.H.; Arisandi, D.; Koh, S. Accelerating data analytics adoption in small and mid-size enterprises: A Singapore context. Technol. Soc. 2022, 69, 101966. [Google Scholar] [CrossRef]

- Igwe, U.S.; Mohamed, S.F.; Azwarie, M.B.M.D.; Ugulu, R.A.; Ajayi, O. Acceptance of contemporary technologies for cost management of construction projects. J. Inf. Technol. Constr. 2022, 27, 864–883. [Google Scholar] [CrossRef]

- Jain, R.; Garg, N.; Khera, S.N. Adoption of AI-enabled tools in social development organizations in India: An extension of UTAUT model. Front. Psychol. 2022, 13, 893691. [Google Scholar] [CrossRef]

- Henao-Ramírez, A.M.; Lopez-Zapata, E. Analysis of the factors influencing adoption of 3D design digital technologies in Colombian firms. J. Enterp. Inf. Manag. 2022, 35, 429–454. [Google Scholar] [CrossRef]

- Jena, R.K. Examining the factors affecting the adoption of blockchain technology in the banking sector: An extended UTAUT model. Int. J. Financ. Stud. 2022, 10, 90. [Google Scholar] [CrossRef]

- Zhong, Y.; Oh, S.; Moon, H.C. Service transformation under industry 4.0: Investigating acceptance of facial recognition payment through an extended technology acceptance model. Technol. Soc. 2021, 64, 101515. [Google Scholar] [CrossRef]

- Chatterjee, S.; Rana, N.P.; Dwivedi, Y.K.; Baabdullah, A.M. Understanding AI adoption in manufacturing and production firms using an integrated TAM-TOE model. Technol. Forecast. Soc. Change 2021, 170, 120880. [Google Scholar] [CrossRef]

- Ghonimy, M.E.H. Factors Influencing the Decision to Adopt Blockchain Technology; Capella University: Minneapolis, MN, USA, 2021. [Google Scholar]

- Selçuk, S. Technology Acceptance Model to Evaluate Factors Affecting Adoption of the Industrial Internet of Things (IIoT) by the Industrial Professionals. Master’s Thesis, Middle East Technical University (Turkey), Ankara, Türkiye, 2021. [Google Scholar]

- Kumar Bhardwaj, A.; Garg, A.; Gajpal, Y. Determinants of blockchain technology adoption in supply chains by small and medium enterprises (SMEs) in India. Math. Probl. Eng. 2021, 2021, 5537395. [Google Scholar] [CrossRef]

- Park, K.O. A study on sustainable usage intention of blockchain in the big data era: Logistics and supply chain management companies. Sustainability 2020, 12, 10670. [Google Scholar] [CrossRef]

- Juan-Pedro, C.-S. Acceptance and use of big data techniques in services companies. J. Retail. Consum. Serv. 2020, 52, 101888. [Google Scholar]

- Nguyen, X.T.; LUU, Q.K. Factors affecting adoption of industry 4.0 by small-and medium-sized enterprises: A case in Ho Chi Minh city, Vietnam. J. Asian Financ. Econ. Bus. 2020, 7, 255–264. [Google Scholar] [CrossRef]

- Cao, D.; Tao, H.; Wang, Y.; Tarhini, A.; Xia, S. Acceptance of automation manufacturing technology in China: An examination of perceived norm and organizational efficacy. Prod. Plan. Control 2020, 31, 660–672. [Google Scholar] [CrossRef]

- Kamble, S.; Gunasekaran, A.; Arha, H. Understanding the Blockchain technology adoption in supply chains-Indian context. Int. J. Prod. Res. 2019, 57, 2009–2033. [Google Scholar] [CrossRef]

- Alhashmi, S.F.; Salloum, S.A.; Abdallah, S. Critical success factors for implementing artificial intelligence (AI) projects in Dubai Government United Arab Emirates (UAE) health sector: Applying the extended technology acceptance model (TAM). In Proceedings of the International conference on advanced intelligent systems and informatics, Cairo, Egypt, 26–28 October 2019; pp. 393–405. [Google Scholar]

- Morienyane, L.D.; Marnewick, A. Technology Acceptance Model of Internet of Things for Water Management at a local municipality. In Proceedings of the 2019 IEEE Technology & Engineering Management Conference (TEMSCON), Atlanta, GA, USA, 12–14 June 2019; pp. 1–6. [Google Scholar]

- Gibson, A. Assessment of Acceptance Factors Impacting Adoption and Use of Business Intelligence and Analytics Systems among Small and Medium-Size US Manufacturing Organizations; Capella University: Minneapolis, MN, USA, 2019. [Google Scholar]

- Narwane, V.S.; Narkhede, B.E.; Raut, R.D.; Gardas, B.B.; Priyadarshinee, P.; Kavre, M.S. To identify the determinants of the CloudIoT technologies adoption in the Indian MSMEs: Structural equation modelling approach. Int. J. Bus. Inf. Syst. 2019, 31, 322–353. [Google Scholar] [CrossRef]

- Moester, D. Securing the Future for the Manufacturing Industry: Towards the Adoption of the Smart Industry. Master’s Thesis, University of Twente, Enschede, The Netherlands, 2017. [Google Scholar]

- Soon, K.W.K.; Lee, C.A.; Boursier, P. A study of the determinants affecting adoption of big data using integrated Technology Acceptance Model (TAM) and diffusion of innovation (DOI) in Malaysia. Int. J. Appl. Bus. Econ. Res. 2016, 14, 17–47. [Google Scholar]

- Gangwar, H.; Date, H.; Ramaswamy, R. Understanding determinants of cloud computing adoption using an integrated TAM-TOE model. J. Enterp. Inf. Manag. 2015, 28, 107–130. [Google Scholar] [CrossRef]

- Sternad, S.; Bobek, S. Impacts of TAM-based external factors on ERP acceptance. Procedia Technol. 2013, 9, 33–42. [Google Scholar] [CrossRef]

- Groot, C.; Hooghiemstra, A.M.; Raijmakers, P.G.; van Berckel, B.N.; Scheltens, P.; Scherder, E.J.; van der Flier, W.M.; Ossenkoppele, R. The effect of physical activity on cognitive function in patients with dementia: A meta-analysis of randomized control trials. Ageing Res. Rev. 2016, 25, 13–23. [Google Scholar] [CrossRef]

- Furuya-Kanamori, L.; Xu, C.; Lin, L.; Doan, T.; Chu, H.; Thalib, L.; Doi, S.A. P value–driven methods were underpowered to detect publication bias: Analysis of Cochrane review meta-analyses. J. Clin. Epidemiol. 2020, 118, 86–92. [Google Scholar] [CrossRef]

- Begg, C.B.; Mazumdar, M. Operating characteristics of a rank correlation test for publication bias. Biometrics 1994, 50, 1088–1101. [Google Scholar] [CrossRef]

- Schepers, J.; Wetzels, M. A meta-analysis of the technology acceptance model: Investigating subjective norm and moderation effects. Inf. Manag. 2007, 44, 90–103. [Google Scholar] [CrossRef]

- Peng, L.; Chan, A.H. A meta-analysis of the relationship between ageing and occupational safety and health. Saf. Sci. 2019, 112, 162–172. [Google Scholar] [CrossRef]

- Castiglione, A.; Cimmino, L.; Di Nardo, M.; Murino, T. Optimising production efficiency: Managing flexibility in Industry 4.0 systems via simulation. Comput. Ind. Eng. 2024, 197, 110540. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, J.; Liu, Q. A meta-analysis of mobile commerce adoption and the moderating effect of culture. Comput. Hum. Behav. 2012, 28, 1902–1911. [Google Scholar] [CrossRef]

- Qalati, S.A.; Yuan, L.W.; Khan, M.A.S.; Anwar, F. A mediated model on the adoption of social media and SMEs’ performance in developing countries. Technol. Soc. 2021, 64, 101513. [Google Scholar] [CrossRef]

- Batubara, F.R.; Ubacht, J.; Janssen, M. Challenges of blockchain technology adoption for e-government: A systematic literature review. In Proceedings of the 19th Annual International Conference on Digital Government Research: Governance in the Data Age, Delft, The Netherlands, 30 May–1 June 2018; pp. 1–9. [Google Scholar]

- Anazawa, M. Inequality in resource allocation and population dynamics models. R. Soc. Open Sci. 2019, 6, 182178. [Google Scholar] [CrossRef] [PubMed]

- Xie, S.Y.; Flake, J.K.; Hehman, E. Perceiver and target characteristics contribute to impression formation differently across race and gender. J. Personal. Soc. Psychol. 2019, 117, 364. [Google Scholar] [CrossRef]

- Winquist, L.A.; Mohr, C.D.; Kenny, D.A. The female positivity effect in the perception of others. J. Res. Personal. 1998, 32, 370–388. [Google Scholar] [CrossRef]

- Adisa, T.A.; Gbadamosi, G.; Adekoya, O.D. Gender apartheid: The challenges of breaking into “man’s world”. Gend. Work Organ. 2021, 28, 2216–2234. [Google Scholar] [CrossRef]

- Ismagilova, E.; Rana, N.P.; Slade, E.L.; Dwivedi, Y.K. A meta-analysis of the factors affecting eWOM providing behaviour. Eur. J. Mark. 2021, 55, 1067–1102. [Google Scholar] [CrossRef]

- Bartodziej, C.J.; Bartodziej, C.J. The Concept Industry 4.0; Springer: Berlin/Heidelberg, Germany, 2017. [Google Scholar]

- Zheng, P.; Wang, H.; Sang, Z.; Zhong, R.Y.; Liu, Y.; Liu, C.; Mubarok, K.; Yu, S.; Xu, X. Smart manufacturing systems for Industry 4.0: Conceptual framework, scenarios, and future perspectives. Front. Mech. Eng. 2018, 13, 137–150. [Google Scholar] [CrossRef]

- Baena, F.; Guarin, A.; Mora, J.; Sauza, J.; Retat, S. Learning factory: The path to industry 4.0. Procedia Manuf. 2017, 9, 73–80. [Google Scholar] [CrossRef]

- Mathieson, K. Predicting user intentions: Comparing the technology acceptance model with the theory of planned behavior. Inf. Syst. Res. 1991, 2, 173–191. [Google Scholar] [CrossRef]

- Ronaghi, M.H.; Forouharfar, A. A contextualized study of the usage of the Internet of things (IoTs) in smart farming in a typical Middle Eastern country within the context of Unified Theory of Acceptance and Use of Technology model (UTAUT). Technol. Soc. 2020, 63, 101415. [Google Scholar] [CrossRef]

- Ajibade, P. Technology acceptance model limitations and criticisms: Exploring the practical applications and use in technology-related studies, mixed-method, and qualitative researches. Libr. Philos. Pract. 2018, 9, 1–13. [Google Scholar]

| References | Sample Size | Type | Geographic Region | Organization Size | Organization Sector | Gender (M/All Participants) | Age (Years) |

|---|---|---|---|---|---|---|---|

| [111] | 208 | Journal | Asia | NA | Service | 0.43 | 27.95 |

| [112] | 71 | Journal | Asia | NA | Service | 0.32 | 33.3943 |

| [113] | 228 | Journal | Asia | NA | Service | NA | NA |

| [114] | 418 | Journal | Asia | NA | NA | 0.31 | 22.2 |

| [115] | 1641 | Journal | Europe | NA | Service | 0.41 | NA |

| [116] | 499 | Journal | NA | NA | Multisector | NA | NA |

| [117] | 263 | Journal | Asia | NA | Service | 0.45 | 32.7 |

| [118] | 170 | Journal | Asia | Small–medium | Service | NA | NA |

| [119] | 226 | Journal | Europe | NA | Service | 0.52 | 48.6 |

| [120] | 110 | Journal | Africa | NA | Industry | 0.73 | NA |

| [121] | 293 | Journal | Asia | NA | NA | 0.42 | 20 |

| [16] | 207 | Journal | Asia | Small–medium | Industry | NA | NA |

| [122] | 108 | Journal | Europe | Small–medium | NA | NA | NA |

| [123] | 470 | Journal | Asia | Large | Service | 0.26 | 24.4 |

| [124] | 241 | Journal | NA | NA | Industry | 0.69 | 39.5 |

| [125] | 202 | Journal | Asia | Small–medium | Multisector | NA | NA |

| [126] | 349 | Journal | Africa | NA | Industry | NA | 37.6 |

| [127] | 388 | Journal | Asia | NA | Service | 0.61 | 35.6 |

| [128] | 138 | Journal | South America | Small–medium | Multisector | NA | NA |

| [129] | 381 | Journal | Asia | NA | Service | 0.74 | 36.8 |

| [89] | 117 | Journal | Europe | Large | Industry | NA | NA |

| [130] | 247 | Journal | Asia | NA | Service | 0.62 | 29.8956 |

| [131] | 340 | Journal | Asia | Large | Industry | NA | NA |

| [17] | 685 | Journal | Asia | Large | Industry | 0.82 | 32.8 |

| [132] | 170 | Thesis | North America | NA | Service | 0.85 | 38 |

| [133] | 342 | Thesis | NA | Large | Multisector | NA | NA |

| [134] | 216 | Journal | Asia | Small–medium | Multisector | NA | NA |

| [135] | 172 | Journal | Asia | NA | Service | 0.88 | 41.9 |

| [18] | 114 | Journal | Asia | Small–medium | Multisector | 0.36 | 30.1 |

| [136] | 199 | Journal | Europe | Large | Service | NA | NA |

| [91] | 282 | Journal | Asia | NA | Industry | 0.78 | 33.8 |

| [137] | 282 | Journal | Asia | Small–medium | NA | NA | NA |

| [19] | 158 | Journal | Asia | Small–medium | Agriculture | NA | NA |

| [138] | 258 | Journal | Asia | Large | Industry | NA | NA |

| [139] | 181 | Journal | Asia | NA | Multisector | NA | NA |

| [140] | 53 | Conference | Asia | NA | Service | 0.26 | 32.3 |

| [141] | 37 | Conference | Africa | NA | Service | 0.78 | 41.8 |

| [142] | 138 | Thesis | North America | Small–medium | Industry | 0.54 | 40.9 |

| [143] | 500 | Journal | Asia | Small–medium | Industry | 0.64 | NA |

| [93] | 150 | Journal | Asia | Large | NA | NA | NA |

| [20] | 72 | Journal | Asia | Small–medium | NA | 0.82 | 34.4 |

| [92] | 90 | Journal | Asia | NA | Service | 0.52 | 38.8 |

| [64] | 168 | Journal | Asia | NA | Service | NA | NA |

| [144] | 43 | Thesis | NA | Small–medium | Industry | NA | NA |

| [145] | 311 | Journal | Asia | NA | NA | 0.6 | 33.2 |

| [146] | 280 | Journal | Asia | Large | Multisector | NA | NA |

| [147] | 293 | Conference | Europe | Small–medium | Multisector | 0.52 | 33.4 |

| Characteristics | Statistical Results | Characteristics | Statistical Results |

|---|---|---|---|

| Total sample size | 12,509 | Organization size | |

| Average age (years) | 34.16832917 | Small–medium | 14 |

| Gender (M/all participants) | Large | 11 | |

| M/all participants > 0.5 | 17 | NA | 22 |

| M/all participants < 0.5 | 9 | Organization sector | |

| NA | 21 | Agriculture | 1 |

| Geographical region | Industry | 13 | |

| Asia | 32 | Service | 18 |

| Europe | 6 | Multisector | 8 |

| South America | 1 | NA | 7 |

| North America | 2 | ||

| Africa | 3 | ||

| NA | 4 |

| Direct Effects | Number of Studies | Cumulative Sample Size | Sample Size (Min–Max) | Correlations (Min–Max) | Q | df | I2 (%) |

|---|---|---|---|---|---|---|---|

| PU–BI | 43 | 9753 | 37–1641 | −0.655–0.892 | 2064.869 *** | 42 | 97.97 |

| PEOU–BI | 43 | 9845 | 37–500 | −0.067–0.817 | 704.616 *** | 42 | 94.04 |

| SI–BI | 12 | 4810 | 71–1641 | 0.067–0.725 | 277.447 *** | 11 | 96.04 |

| Random Effects Model | Fixed Effects Model | |||||

|---|---|---|---|---|---|---|

| Direct effects | PU–BI | PEOU–BI | SI–BI | PU–BI | PEOU–BI | SI–BI |

| No. of studies | 43 | 43 | 12 | 43 | 43 | 12 |

| Total of sample studies | 9753 | 9845 | 4810 | 9753 | 9845 | 4810 |

| Effect size | 0.528 *** | 0.469 *** | 0.487 *** | 0.475 *** | 0.444 *** | 0.467 *** |

| 95% CI | (0.420, 0.621) | (0.402, 0.531) | (0.363, 0.594) | (0.460, 0.490) | (0.429, 0.461) | (0.445, 0.489) |

| Z-value | 8.256 | 12.049 | 6.851 | 51.323 | 47.133 | 34.982 |

| Direct effects | PU–BI | PEOU–BI | SI–BI | PU–BI | PEOU–BI | SI–BI |

| Direct Effects | Number of Studies | Fail-Safe N | Begg p-Value |

|---|---|---|---|

| PU–BI | 43 | 31,161 | 0.125 |

| PEOU–BI | 43 | 24,596 | 0.173 |

| SI–BI | 12 | 3186 | 0.392 |

| Relationship | Moderators | No. of Studies | Effect Size | 95% CI | Z-Value | p-Value | |

|---|---|---|---|---|---|---|---|

| PU–BI | Geographical region | Africa | 3 | 0.669 | (0.086, 0.910) | 2.193 | 0.028 |

| Asia | 29 | 0.524 | (0.422, 0.613) | 8.651 | 0.000 | ||

| Europe | 4 | 0.595 | (0.526, 0.656) | 13.399 | 0.000 | ||

| NA | 4 | 0.328 | (−0.468, 0.830) | 0.787 | 0.431 | ||

| North America | 2 | 0.501 | (−0.697, 0.961) | 0.764 | 0.445 | ||

| South America | 1 | 0.712 | (0.618, 0.786) | 10.355 | 0.000 | ||

| Organization size | Large | 8 | 0.598 | (0.398, 0.744) | 5.038 | 0.000 | |

| NA | 21 | 0.474 | (0.287, 0.626) | 4.581 | 0.000 | ||

| Small–medium | 14 | 0.562 | (0.397, 0.692) | 5.774 | 0.000 | ||

| Organization sector | Agriculture | 1 | 0.214 | (0.060, 0.358) | 2.706 | 0.007 | |

| Industry | 10 | 0.577 | (0.337, 0.747) | 4.195 | 0.000 | ||

| Multisector | 10 | 0.562 | (0.196, 0.791) | 2.849 | 0.004 | ||

| NA | 7 | 0.522 | (0.308, 0.686) | 4.342 | 0.000 | ||

| Service | 15 | 0.491 | (0.360, 0.603) | 6.543 | 0.000 | ||

| PEOU–BI | Geographical region | Africa | 3 | 0.562 | (0.263, 0.763) | 3.398 | 0.001 |

| Asia | 28 | 0.448 | (0.360, 0.529) | 8.969 | 0.000 | ||

| Europe | 5 | 0.543 | (0.331, 0.703) | 4.502 | 0.000 | ||

| NA | 4 | 0.369 | (0.125, 0.571) | 2.897 | 0.004 | ||

| North America | 2 | 0.524 | (0.016, 0.817) | 2.015 | 0.044 | ||

| South America | 1 | 0.629 | (0.516, 0.720) | 8.595 | 0.000 | ||

| Organization size | Large | 8 | 0.519 | (0.340, 0.661) | 5.118 | 0.000 | |

| NA | 21 | 0.463 | (0.373, 0.545) | 8.918 | 0.000 | ||

| Small–medium | 14 | 0.445 | (0.324, 0.551) | 6.611 | 0.000 | ||

| Organization sector | Agriculture | 1 | 0.214 | (0.060, 0.358) | 2.706 | 0.007 | |

| Industry | 10 | 0.473 | (0.298, 0.618) | 4.870 | 0.000 | ||

| Multisector | 10 | 0.434 | (0.308, 0.545) | 6.230 | 0.000 | ||

| NA | 7 | 0.437 | (0.220, 0.612) | 3.756 | 0.000 | ||

| Service | 15 | 0.518 | (0.439, 0.590) | 10.949 | 0.000 | ||

| SI–BI | Geographical region | Asia | 8 | 0.402 | (0.233, 0.548) | 4.417 | 0.000 |

| Europe | 3 | 0.594 | (0.469, 0.695) | 7.677 | 0.000 | ||

| North America | 1 | 0.725 | (0.635, 0.796) | 10.667 | 0.000 | ||

| Organization size | Large | 2 | 0.393 | (0.173, 0.575) | 3.386 | 0.001 | |

| NA | 8 | 0.519 | (0.401, 0.620) | 7.505 | 0.000 | ||

| Small–medium | 2 | 0.454 | (−0.332, 0.868) | 1.150 | 0.250 | ||

| Organization sector | Industry | 4 | 0.339 | (0.084, 0.522) | 2.574 | 0.010 | |

| NA | 1 | 0.650 | (0.591, 0.702) | 15.794 | 0.000 | ||

| Service | 7 | 0.538 | (0.453, 0.614) | 10.384 | 0.000 | ||

| Relationship | Covariate | Coefficient | Z-Value | 2-Sided p-Value |

|---|---|---|---|---|

| PU–BI | Gender | |||

| Intercept | 1.008 | 3.40 | 0.0007 | |

| gender | −0.721 | −1.57 | 0.1175 | |

| Age | ||||

| Intercept | 1.171 | 3.49 | 0.0005 | |

| Age | −0.0167 | −1.69 | 0.0907 | |

| PEOU–BI | Gender | |||

| Intercept | 0.554 | 2.04 | 0.0412 | |

| gender | −0.094 | −0.22 | 0.8262 | |

| Age | ||||

| Intercept | 0.526 | 1.73 | 0.0828 | |

| Age | 0.001 | 0.12 | 0.9017 | |

| SI–BI | Gender | |||

| Intercept | 1.344 | 2.54 | 0.0112 | |

| gender | −1.356 | −1.79 | 0.0738 | |

| Age | ||||

| Intercept | 0.3189 | 0.59 | 0.5521 | |

| Age | 0.0071 | 0.49 | 0.6261 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zou, W.; Man, S.-S.; Hu, W.; Zhou, S.; Chan, H.-S. Factors Influencing the Acceptance of Industry 4.0 Technologies in Various Sectors: A Systematic Review and Meta-Analysis. Appl. Sci. 2025, 15, 4866. https://doi.org/10.3390/app15094866

Zou W, Man S-S, Hu W, Zhou S, Chan H-S. Factors Influencing the Acceptance of Industry 4.0 Technologies in Various Sectors: A Systematic Review and Meta-Analysis. Applied Sciences. 2025; 15(9):4866. https://doi.org/10.3390/app15094866

Chicago/Turabian StyleZou, Wenxuan, Siu-Shing Man, Wenbo Hu, Shuzhang Zhou, and Hoi-Shou (Alan) Chan. 2025. "Factors Influencing the Acceptance of Industry 4.0 Technologies in Various Sectors: A Systematic Review and Meta-Analysis" Applied Sciences 15, no. 9: 4866. https://doi.org/10.3390/app15094866

APA StyleZou, W., Man, S.-S., Hu, W., Zhou, S., & Chan, H.-S. (2025). Factors Influencing the Acceptance of Industry 4.0 Technologies in Various Sectors: A Systematic Review and Meta-Analysis. Applied Sciences, 15(9), 4866. https://doi.org/10.3390/app15094866