Thermal Performance Evaluation of Fatty Acid Ester and Paraffin Based Mixed SSPCMs Using Exfoliated Graphite Nanoplatelets (xGnP)

Abstract

:1. Introduction

2. Experimental

2.1. Materials

2.2. Preparation

2.3. Characterization Techniques

3. Results and Discussion

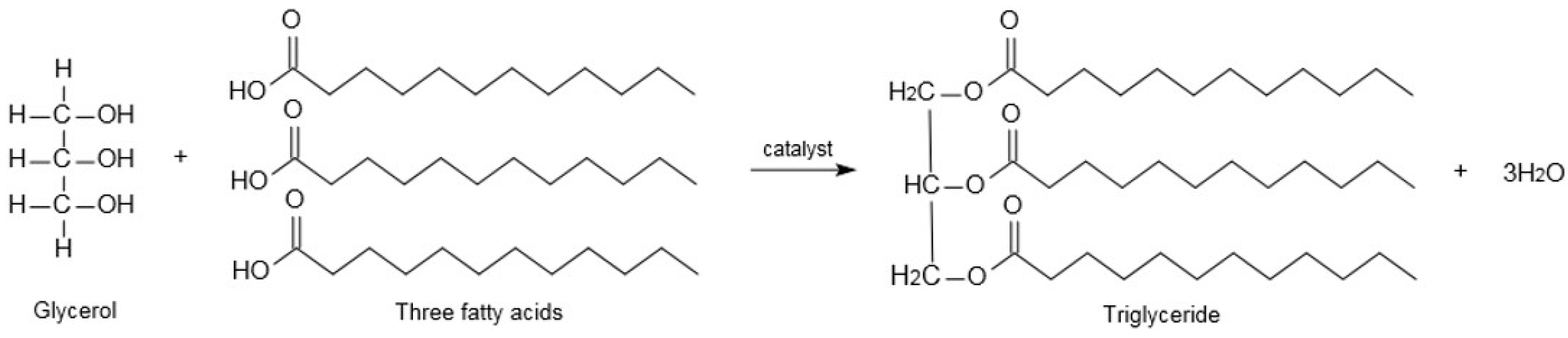

3.1. Microstructure of the Fatty Acid Ester and Paraffin Based Mixed SSPCMs

3.2. FT-IR Analysis of the Fatty Acid Ester and Paraffin Based Mixed SSPCMs

3.3. Thermal Properties Analysis

3.4. Thermal Stability Analysis

3.5. Thermal Conductivity Analysis

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| PCM | Phase change material |

| SSPCM | Shape-stabilized phase change material |

| xGnP | Exfoliated graphite nano platelets |

| TES | Thermal energy storage |

| SHS | Sensible heat storage |

| LHTES | Latent heat thermal energy storage |

| SEM | Scanning electron microscopy |

| FT-IR | Fourier transform infrared spectroscopy |

| DSC | Differential scanning calorimetry |

| TGA | Thermogravimetric analysis |

References

- Zhang, Y.; Zhou, G.; Lin, K.; Zhang, Q.; Di, H. Application of latent heat thermal energy storage in buildings: State-of-the-art and outlook. Build. Environ. 2007, 42, 2197–2209. [Google Scholar] [CrossRef]

- Sharma, A.; Tyagi, V.V.; Chen, C.R.; Buddhi, D. Review on thermal energy storage with phase change materials and applications. Renew. Sustain. Energy Rev. 2009, 13, 3183–3145. [Google Scholar] [CrossRef]

- Rodriguez-Ubinas, E.; Ruiz-Valero, L.; Vega, S.; Neila, J. Applications of phase change material in highly energy-efficient houses. Energy Build. 2012, 50, 49–62. [Google Scholar] [CrossRef]

- Soares, N.; Costa, J.J.; Gaspar, A.R.; Santos, P. Review of passive PCM latent heat thermal energy storage systems towards buildings′ energy efficiency. Energy Build. 2013, 59, 82–103. [Google Scholar] [CrossRef]

- Zhang, P.; Xiao, X.; Ma, Z.W. A review of the composite phase change materials: Fabrication, characterization, mathematical modeling and application to performance enhancement. Appl. Energy 2016, 165, 472–510. [Google Scholar] [CrossRef]

- Jeon, J.; Lee, J.; Seo, J.; Jeong, S. Application of PCM thermal energy storage system to reduce building energy consumption. J. Therm. Anal. Calorim. 2013, 111, 279–288. [Google Scholar] [CrossRef]

- Aydın, A.A.; Okutan, H. High-chain fatty acid esters of myristyl alcohol with odd carbon number: Novel organic phase change materials for thermal energy storage—2. Sol. Energy Mater. Sol. Cells 2011, 95, 2417–2423. [Google Scholar]

- Zhang, Z.; Fang, X. Study on paraffin/expanded graphite composite phase change thermal energy storage material. Energy Convers. Manag. 2006, 47, 303–310. [Google Scholar] [CrossRef]

- Sarı, A.; Karaipekli, A. Thermal conductivity and latent heat thermal energy storage characteristics of paraffin/expanded graphite composite as phase change material. Appl. Therm. Eng. 2007, 27, 1271–1277. [Google Scholar] [CrossRef]

- Karaipekli, A.; Sarı, A. Preparation and characterization of fatty acid ester/building material composites for thermal energy storage in buildings. Energy Build. 2011, 43, 1952–1959. [Google Scholar] [CrossRef]

- Jeong, S.; Lee, J.; Seo, J.; Kim, S. Thermal performance evaluation of Bio-based shape stabilized PCM with boron nitride for energy saving. Int. J. Heat Mass Transf. 2014, 71, 245–250. [Google Scholar] [CrossRef]

- Chen, Y.; Nguyen, D.; Shen, M.; Yip, M.; Tai, N. Thermal characterizations of the graphite nanosheets reinforced paraffin phase-change composites. Compos. A Appl. Sci. 2013, 44, 40–46. [Google Scholar] [CrossRef]

- Oya, T.; Nomura, T.; Okinaka, N.; Akiyama, T. Phase change composite based on porous nickel and erythritol. Appl. Therm. Eng. 2012, 40, 373–377. [Google Scholar] [CrossRef]

- Kim, S.; Paek, S.; Jeong, S.; Lee, J.; Kim, S. Thermal performance enhancement of mortar mixed with octadecane/xGnP SSPCM to save building energy consumption. Sol. Energy Mater. Sol. Cells 2014, 122, 257–263. [Google Scholar] [CrossRef]

- Zhong, Y.; Guo, Q.; Li, S.; Shi, J.; Liu, L. Heat transfer enhancement of paraffin wax using graphite foam for thermal energy storage. Sol. Energy Mater. Sol. Cells 2010, 94, 1011–1014. [Google Scholar] [CrossRef]

- Lafdi, K.; Mesalhy, O.; Elgafy, A. Graphite foams infiltrated with phase change materials as alternative materials for space and terrestrial thermal energy storage applications. Carbon 2008, 46, 159–168. [Google Scholar] [CrossRef]

- Jeon, J.; Jeong, S.; Lee, J.; Seo, J.; Kim, S. High thermal performance composite PCMs loading xGnP for application to building using radiant floor heating system. Sol. Energy Mater. Sol. Cells 2012, 101, 51–56. [Google Scholar] [CrossRef]

- Jeong, S.; Jeon, J.; Cha, J.; Kim, J.; Kim, S. Preparation and evaluation of thermal enhanced silica fume by incorporating organic PCM, for application to concrete. Energy Build. 2013, 62, 190–195. [Google Scholar] [CrossRef]

- Kim, S.; Drzal, L.T. High latent heat storage and high thermal conductive phase change materials using exfoliated graphite nanoplatelets. Sol. Energy Mater. Sol. Cells 2009, 93, 136–142. [Google Scholar] [CrossRef]

- Fukushima, H. Graphite Nanoreinforcements in Polymer Nanocomposites. Ph.D. Thesis, Michigan State University, East Lansing, MI, USA, 2003. [Google Scholar]

- Kalaitzidou, K. Exfoliated Graphite Nanoplatelets as Reinforcement for Multifunctional Polypropylene Nanocomposites. Ph.D. Thesis, Michigan State University, East Lansing, MI, USA, 2006. [Google Scholar]

- Kalaitzidou, K.; Fukushima, H.; Drzal, L.T. Multifunctional polypropylene composites produced by incorporation of exfoliated graphite nanoplatelets. Carbon 2007, 45, 1446–1452. [Google Scholar] [CrossRef]

- Jeong, S.; Chang, S.J.; We, S.; Kim, S. Energy efficient thermal storage montmorillonite with phase change material containing exfoliated graphite nanoplatelets. Sol. Energy Mater. Sol. Cells 2015, 139, 65–70. [Google Scholar] [CrossRef]

- Wi, S.; Seo, J.; Jeong, S.; Chang, S.J.; Kang, Y.; Kim, S. Thermal properties of shape-stabilized phase change materials using fatty acid ester and exfoliated graphite nanoplatelets for saving energy in buildings. Sol. Energy Mater. Sol. Cells 2015, 143, 168–173. [Google Scholar] [CrossRef]

- Kim, H.; Lee, B.; Choi, S.; Kim, S.; Kim, H. The effect of types of maleic anhydride-grafted polypropylene (MAPP) on the interfacial adhesion properties of bio-flour-filled polypropylene composites. Compos. A Appl. Sci. 2007, 38, 1473–1482. [Google Scholar] [CrossRef]

- Lee, B.; Kim, H.; Yang, H. Polymerization of aniline on bacterial cellulose and characterization of bacterial cellulose/polyaniline nanocomposite films. Curr. Appl. Phys. 2012, 12, 75–80. [Google Scholar] [CrossRef]

- Cha, J.; Seo, J.; Kim, S. Building materials thermal conductivity measurement and correlation with heat flow meter, laser flash analysis and TCi. J. Therm. Anal. Calorim. 2012, 109, 295–300. [Google Scholar] [CrossRef]

- Kim, S.; Chang, S.J.; Chung, O.; Jeong, S.; Kim, S. Thermal characteristics of mortar containing hexadecane/xGnP SSPCM and energy storage behaviors of envelopes integrated with enhanced heat storage composites for energy efficient buildings. Energy Build. 2014, 70, 472–479. [Google Scholar] [CrossRef]

| Property | Value | |

|---|---|---|

| Coconut Oil | n-Hexadecane | |

| Melting point (°C) | 26.78 | 20.84 |

| Latent heat of melting (J/g) | 110.4 | 254.7 |

| Thermal conductivity (W/mK) | 0.321 | 0.154 |

| Property | Value |

|---|---|

| Surface area (m2/g) | 20.41 |

| Bulk density (g/cm3) | 0.0053–0.010 |

| Pore volume (cm3/g) | 0.081 |

| Thermal conductivity (W/mK) | 2–300 |

| Specific heat capacity (J/kgK) | 710 |

| Bonding | Wave Number Range (cm−1) |

|---|---|

| –CH3 | 2919–2920 |

| –CH2 | 2850–2851 |

| C=O | 1735–1744 |

| C–O | 1149–1160 |

| Mixed SSPCM (Coconut Oil: n-hexadecane) | Melting Point (°C) | Freezing Point (°C) | Latent Heat (J/g) | |

|---|---|---|---|---|

| Melting | Freezing | |||

| 70:30 (wt %) | 12.53 | 5.55 | 89.06 | 92.82 |

| 50:50 (wt %) | 14.51 | 6.54 | 104.30 | 106.20 |

| 30:70 (wt %) | 16.92 | 10.31 | 124.50 | 123.40 |

| SSPCM | Melting Point (°C) | Freezing Point (°C) | Latent Heat (J/g) | |

|---|---|---|---|---|

| Melting | Freezing | |||

| Coconut oil/xGnP | 26.93 | 14.95 | 82.34 | 77.64 |

| n-hexadecane/xGnP | 21.80 | 14.60 | 96.40 | 94.80 |

| Mixed SSPCM (Coconut Oil: n-hexadecane) | First Peak of Derivative Weight (°C) | Second Peak of Derivative Weight (°C) | Total Decomposition Rate (%) |

|---|---|---|---|

| 70:30 (wt %) | 165.14 | 363.68 | 71.59 |

| 50:50 (wt %) | 172.62 | 357.68 | 70.73 |

| 30:70 (wt %) | 178.38 | 339.79 | 68.53 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, H.; Jeong, S.-G.; Chang, S.J.; Kang, Y.; Wi, S.; Kim, S. Thermal Performance Evaluation of Fatty Acid Ester and Paraffin Based Mixed SSPCMs Using Exfoliated Graphite Nanoplatelets (xGnP). Appl. Sci. 2016, 6, 106. https://doi.org/10.3390/app6040106

Lee H, Jeong S-G, Chang SJ, Kang Y, Wi S, Kim S. Thermal Performance Evaluation of Fatty Acid Ester and Paraffin Based Mixed SSPCMs Using Exfoliated Graphite Nanoplatelets (xGnP). Applied Sciences. 2016; 6(4):106. https://doi.org/10.3390/app6040106

Chicago/Turabian StyleLee, Hwayoung, Su-Gwang Jeong, Seong Jin Chang, Yujin Kang, Seunghwan Wi, and Sumin Kim. 2016. "Thermal Performance Evaluation of Fatty Acid Ester and Paraffin Based Mixed SSPCMs Using Exfoliated Graphite Nanoplatelets (xGnP)" Applied Sciences 6, no. 4: 106. https://doi.org/10.3390/app6040106

APA StyleLee, H., Jeong, S.-G., Chang, S. J., Kang, Y., Wi, S., & Kim, S. (2016). Thermal Performance Evaluation of Fatty Acid Ester and Paraffin Based Mixed SSPCMs Using Exfoliated Graphite Nanoplatelets (xGnP). Applied Sciences, 6(4), 106. https://doi.org/10.3390/app6040106