Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes

Abstract

:1. Introduction

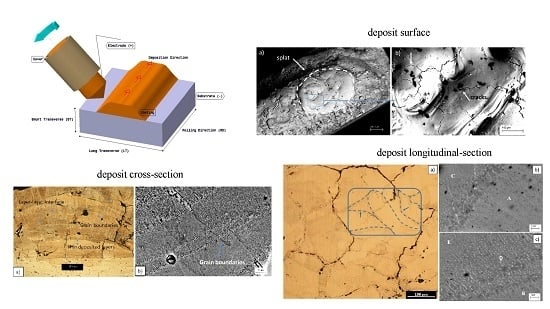

2. Experimental Setup

3. Results and Discussion

3.1. Microstructure of AA2024 Al-Cu-Mg Alloy

3.2. Surface Morphology

3.3. Microstructure

3.4. Mechanical Characterization

3.5. Analysis of Defects

3.6. Effect of the Parameters Electric on Substrate/Deposit Interface Behavior

4. Conclusions

- (1)

- They have layer-by-layer microstructure, and all layers are characterized by a fine and mixed microstructure both cellular and equiaxed. The cell size is not uniform along the deposit.

- (2)

- The grains are columnar and parallel to the growth direction of the deposit. Their size is not uniform and they spread through more than one layer whose microstructure is mixed.

- (3)

- The average hardness values do not change significantly with process parameters. The great standard deviation in average hardness is due to the strong variations microstructural within the thickness.

- (4)

- The defects have small dimensions whose size reduces with the increasing Es at a fixed frequency. When increasing the heat input, the defectiveness is reduced due to higher volume of re-melted substrate, the higher volume of molten splat and the lower space between the splats.

- (5)

- The substrate/deposit interface is characterized by the presence of cracks which extend into the substrate preferentially along the grain boundaries. The average length of cracks increases with frequency and Es.

- (6)

- Within the experimental plan developed in this study, the best energy value (Es) to deposit 2024 alloy on homologue substrate reducing both the inner porosity and the length of the interface cracks, is 0.9 J.

Author Contributions

Conflicts of Interest

References

- Frangini, S.; Masci, A. A study on the effect of a dynamic contact force control for improving electrospark coating properties. Surf. Coat. Technol. 2010, 204, 2613–2623. [Google Scholar] [CrossRef]

- Hasanabadi, F.M.; Ghaini, M.F.; Ebrahimnia, M.; Shahverdi, H.R. Production of amorphous and nanocrystalline iron based coatings by electro-spark deposition process. Surf. Coat. Technol. 2015, 270, 95–101. [Google Scholar] [CrossRef]

- Campanelli, S.L.; Angelastro, A.; Signorile, C.G.; Casalino, G. Investigation on direct laser powder deposition of 18 Ni (300) marage steel using mathematical model and experimental characterization. J. Adv. Manuf. Technol. 2017, 89, 885–895. [Google Scholar] [CrossRef]

- Angelastro, A.; Campanelli, S.L.; Casalino, G. Statistical analysis and optimization of direct metal laser deposition of 227-F Colmonoy nickel alloy. Opt. Laser Technol. 2017, 94, 138–145. [Google Scholar] [CrossRef]

- Verbitchi, V.; Ciuca, C.; Cojocaru, R. Electro-Spark Coating with Special Materials. Nonconv. Technol. Rev. 2011, 1, 57–62. [Google Scholar]

- Davis, J.R. ASM Specialty Handbook: Aluminum and Aluminum Alloy; ASM International: Almere, The Netherlands, 1993. [Google Scholar]

- Onjukka, R. Welding vs. Riveting—Which Has the Fatigue Life for Airplanes. Weld. J. 1996, 75, 29–33. [Google Scholar]

- Kou, S. Welding Metallurgy and Weldability of High Strength Aluminum Alloys; Welding Research Council Bulletin: Madison, WI, USA, 1986. [Google Scholar]

- Ghaini, M.F.; Sheikhi, M.; Torkamany, M.J.; Sabbaghzadeh, J. The relation between liquation and solidification cracks in pulsed laser welding of 2024 aluminium alloy. Mater. Sci. Eng. A 2009, 519, 167–171. [Google Scholar] [CrossRef]

- Norman, A.F.; Drazhner, V.; Prangnell, P.B. Effect of welding parameters on the solidification microstructure of autogenous TIG welds in an Al-Cu-Mg-Mn alloy. Mater. Sci. Eng. A 1999, 259, 53–64. [Google Scholar] [CrossRef]

- Oates, W.R. (Ed.) Materials and Applications, 8th ed.; AWS: Miami, FL, USA, 1972; pp. 1–28. [Google Scholar]

- Zhao, H.; White, D.R.; DebRoy, T. Current issues and problems in laser welding of automotive aluminium alloys. Int. Mater. Rev. 1999, 44, 238–266. [Google Scholar] [CrossRef]

- Cao, X.; Wallace, W.; Immarigeon, J.P.; Poon, C. Research and Progress in Laser Welding of Wrought Aluminum Alloys. II. Metallurgical Microstructures, Defects, and Mechanical Properties. Mater. Manuf. Process. 2003, 18, 23–49. [Google Scholar] [CrossRef]

- Brochu, M.; Heard, D.W.; Milligan, J.; Cadney, S. Bulk nanostructure and amorphous metallic components using the electrospark welding process. Assem. Autom. 2010, 30, 248–256. [Google Scholar] [CrossRef]

- Champagne, V.; Pepi, M.; Edwards, B. Electrospark Deposition for the Repair of Army Main Battle Tank Components; Army Research Laboratory: Adelphi, MD, USA, 2006. [Google Scholar]

- Johnson, R.N. Robust coatings for corrosion and wear: The electrospark deposition process. In Proceedings of the Tri- service conf. on corrosion, Myrtle Beach, SC, USA, 15–19 September 1999; pp. 341–410. [Google Scholar]

- Cadney, S. Welding and Weld Repair of Nanostructured and Amorphous Materials. Master′s Thesis, McGill University, Montreal, QC, Canada, 2007. [Google Scholar]

- Brochu, M.; Portillo, J.G.; Milligan, J.; Head, D.W. Development of Metastable Solidification Structures Using the Electrospark Deposition Process. Open Surf. Sci. J. 2011, 3, 105–114. [Google Scholar] [CrossRef]

- Perju, M.C.; Vizureanu, P.; Nejneru, C. The study of energy transfer on thin layers achieved by electro-spark deposition with tic electrode. In Proceedings of the International Conference of Scientific Paper Afases, Brasov, Romania, 22–24 May 2014. [Google Scholar]

- Thamer, A.D.; Hafiz, M.H.; Mahdi, B.S. Mechanism of Building-Up Deposited Layer during Electro-Spark Deposition. J. Surf. Eng. Mater. Adv. Technol. 2012, 2, 258–263. [Google Scholar] [CrossRef]

- Liu, D.Y.; Gao, W.; Li, Z.W.; Zhang, H.F.; Hu, Z.Q. Electro-spark Deposition of Fe-based Amorphous Alloy Coatings. Mater. Lett. 2007, 61, 165–167. [Google Scholar] [CrossRef]

- Xie, Y.J.; Wang, M.C.; Huang, D.W. Comparative study of microstructural characteristics of electrospark and Nd:YAG laser epitaxially growing coatings. Appl. Surf. Sci. 2007, 253, 6149–6156. [Google Scholar] [CrossRef]

- Xie, Y.J.; Wang, M.C. Epitaxial MCrAlY coating on a Ni-base superalloy produced by electrospark deposition. Surf. Coat. Technol. 2006, 201, 3564–3570. [Google Scholar] [CrossRef]

- Xie, Y.J.; Wang, M.C. Microstructural morphology of electrospark deposition layer of a high gamma prime superalloy. Surf. Coat. Technol. 2006, 201, 691–698. [Google Scholar] [CrossRef]

- Chen, C.J.; Wang, M.C.; Wang, D.S.; Liu, Y.M. Study on corrosion characteristic of high-energy micro-arc alloying of Al-Y electrode on AZ31 magnesium alloy. Trans. Mater. Heat Treat. 2007, 28, 106–110. [Google Scholar]

- Heard, D.W.; Brochu, M. Development of a nanostructure microstructure in the Al-Ni system using the electrospark deposition process. J. Mater. Process. Technol. 2010, 210, 892–898. [Google Scholar] [CrossRef]

- Cadney, S.; Brochu, M. Formation of amorphous Zr41.2Ti13.8Ni10Cu12.5Be22.5 coatings via the ElectroSpark Deposition process. Intermetallics 2008, 16, 518–523. [Google Scholar] [CrossRef]

- Xie, Y.J.; Wang, M.C. Isothermal oxidation behavior of electrospark deposited MCrAlX-type coatings on a Ni-based superalloy. J. Alloy Compd. 2009, 480, 454–461. [Google Scholar] [CrossRef]

- Xie, Y.J.; Wang, M.C. A feasibility study of preparing MCrAlX/BN composite coatings by electrospark deposition process. J. Alloy Compd. 2009, 484, 21–24. [Google Scholar] [CrossRef]

- Mondolfo, L.F. Aluminium Alloys: Structure and Properties; Butter-Worth: London, UK, 1976. [Google Scholar]

- Chen, Z.; Zhou, Y. Surface modification of resistance welding electrode by electro-spark deposited composite coatings: Part I. Coating characterization. Surf. Coat. Technol. 2006, 201, 1503–1510. [Google Scholar] [CrossRef]

- Wang, J.S.; Meng, H.M.; Yu, H.Y.; Fan, Z.S.; Sun, D.B. Characterization and wear behavior of WC-0.8Co coating on cast steel rolls by electro-spark deposition. Int. J. Miner. Metall. Mater. 2009, 16, 707. [Google Scholar]

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification, 4th ed.; CRC Press: Boca Raton, FL, USA, 1998. [Google Scholar]

- Porter, D.A.; Easterling, K.E. Phase Transformations in Metals and Alloys; CRC Press: Boca Raton, FL, USA, 1992. [Google Scholar]

- Messler, R.W., Jr. Principles of Welding; John Wiley & Sons: Hoboken, NJ, USA, 1999. [Google Scholar]

- Ebrahimnia, M.; Ghaini, M.F.; Xie, Y.J.; Shahverdi, H. Microstructural characteristics of the built-up layer of a precipitation hardened nickel based superalloy by electrospark deposition. Surf. Coat. Technol. 2014, 258, 515–523. [Google Scholar] [CrossRef]

- Tang, S.K. The Process Fundamentals and Parameters of Electro-Spark Deposition. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2009. [Google Scholar]

- Tušek, J.; Kosec, L.; Lešnjak, A.; Muhič, T. Electrospark Deposition for Die Repair. Metalurgija 2012, 51, 17–20. [Google Scholar]

- Huang, C.; Cao, G.; Kou, S. Liquation cracking in partial penetration aluminium welds: Assessing tendencies to liquate, crack and backfill. Sci. Technol. Weld. Join. 2004, 9, 149–157. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy; John Wiley & Sons: Hoboken, NJ, USA, 2002. [Google Scholar]

| Composition | Ti | Zn | Fe | Cr | Si | Cu | Mn | Mg | Other | Al |

|---|---|---|---|---|---|---|---|---|---|---|

| AA2024 | <0.15 | <0.25 | <0.5 | <0.5 | <0.5 | 3.8–4.9 | 0.3–0.9 | 1.2–1.8 | <0.15 | Bal. |

| n° | Voltage [V] | Capacitance [μm] | Frequency [Hz] | Es [J] |

|---|---|---|---|---|

| 1 | V1 | C2 | F1 | 0.5 |

| 2 | V1 | C2 | F2 | 0.5 |

| 3 | V1 | C2 | F3 | 0.5 |

| 4 | V2 | C1 | F1 | 0.9 |

| 5 | V2 | C1 | F2 | 0.9 |

| 6 | V2 | C1 | F3 | 0.9 |

| 7 | V2 | C2 | F1 | 1.125 |

| 8 | V2 | C2 | F2 | 1.125 |

| 9 | V2 | C2 | F3 | 1.125 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Leo, P.; Renna, G.; Casalino, G. Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes. Appl. Sci. 2017, 7, 945. https://doi.org/10.3390/app7090945

Leo P, Renna G, Casalino G. Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes. Applied Sciences. 2017; 7(9):945. https://doi.org/10.3390/app7090945

Chicago/Turabian StyleLeo, Paola, Gilda Renna, and Giuseppe Casalino. 2017. "Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes" Applied Sciences 7, no. 9: 945. https://doi.org/10.3390/app7090945

APA StyleLeo, P., Renna, G., & Casalino, G. (2017). Study of the Direct Metal Deposition of AA2024 by ElectroSpark for Coating and Reparation Scopes. Applied Sciences, 7(9), 945. https://doi.org/10.3390/app7090945