CO2 with Mechanical Subcooling vs. CO2 Cascade Cycles for Medium Temperature Commercial Refrigeration Applications Thermodynamic Analysis

Abstract

:1. Introduction

2. Refrigeration Cycles, Models and Assumptions

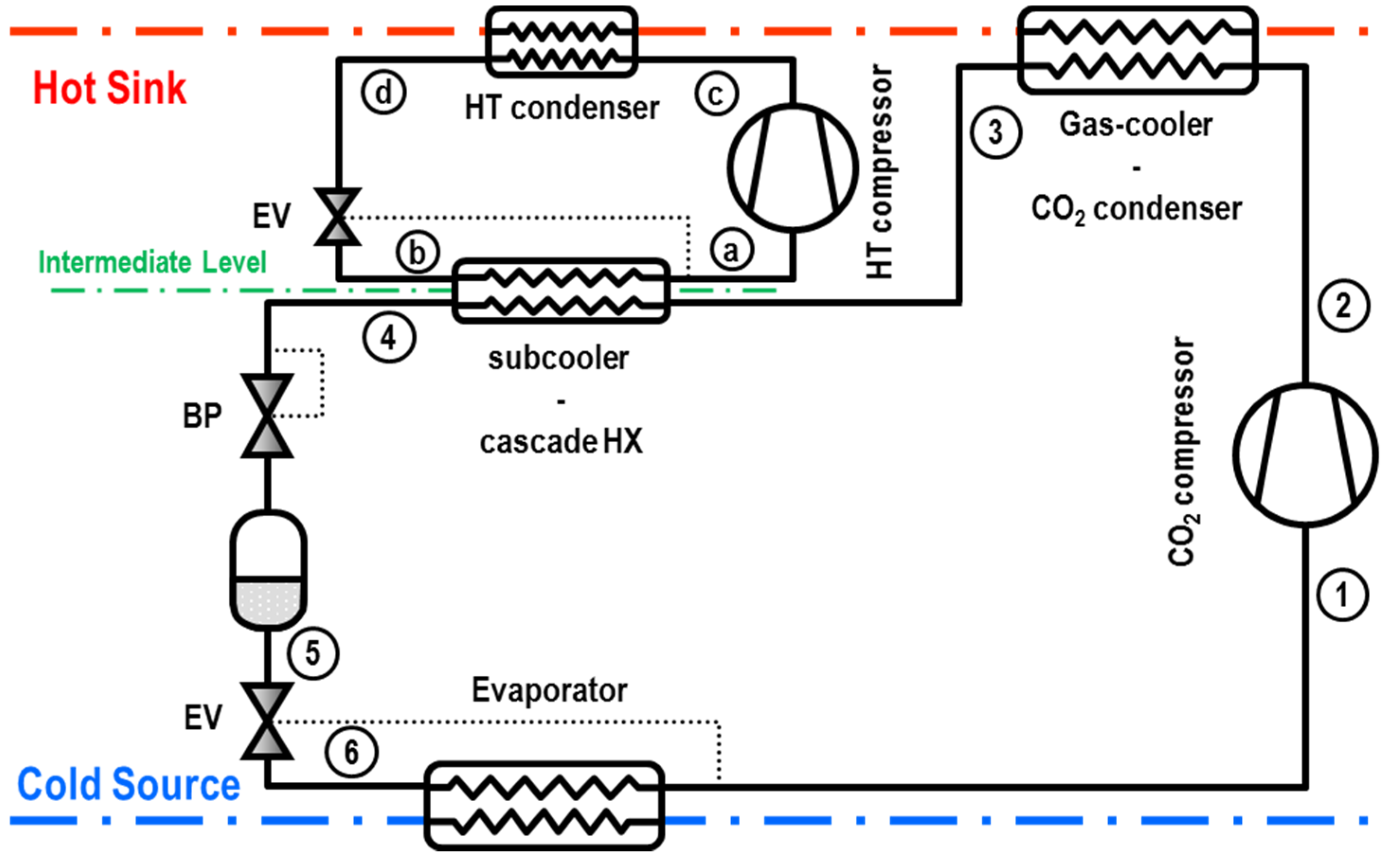

- A main cycle, working with CO2 as refrigerant, which absorbs energy from the cold source.

- A CO2 compressor, subcritical-rated for the cascade configuration and transcritical-rated for the MS configuration.

- A CO2 gas-cooler, which performs heat rejection to the hot sink.

- A second CO2 heat exchanger acting as CO2 condenser for the cascade system and as CO2 subcooler for the MS configuration.

- An expansion system: composed of the ‘vessel + expansion valve’ for the cascade configuration and of a ‘back-pressure + vessel + expansion valve’ for the MS cycle.

- An auxiliary single-stage refrigeration cycle: working with another refrigerant (HCs, HFOs, NH3, HFCs) as high temperature cycle in the cascade configuration and as dedicated mechanical subcooling cycle for the MS configuration. The auxiliary system, whose refrigerant is not distributed to the cooling appliances, absorbs heat from the intermediate temperature level and performs heat rejection to the same hot sink as the main cycle. In the cascade configuration, the auxiliary cycle performs CO2 condensation and in the MS it only subcools the CO2 at the exit of the gas-cooler.

2.1. CO2 Refrigeration Cycle with Mechanical Subcooling (MS Cycle)

2.2. Cascade Refrigeration Cycle

2.3. Calculation Models and Assumptions

3. Results

3.1. Operating Conditions of the CO2 Cycle with Mechanical Subcooling

3.2. Operating Conditions of the Cascade Cycle

4. Discussion of Results

4.1. Recommended Operating Conditions

4.2. Operation in Different Climate Conditions

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Nomenclature

| Casc | cascade cycle with CO2 as low temperature refrigerant |

| COP | coefficient of performance |

| FQ | cooling load fraction inside a temperature BIN |

| GWP | Global warming potential |

| HX | heat exchanger |

| h | specific enthalpy, kJ·kg−1 |

| NH | number of hours inside a temperature BIN |

| nbin | number of temperature bins |

| MS | CO2 cycle with mechanical subcooling |

| mass flow rate, kg·s−1 | |

| P | pressure, bar |

| PC | compressor power consumption, kW |

| cooling capacity, kW | |

| SUB | degree of subcooling at the subcooler, K |

| T | temperature, °C |

| t | compression ratio |

| TEWI | total equivalent warming impact |

| compressor displacement, m3·h−1 | |

| GREEK SYMBOLS | |

| ηG | overall compressor efficiency |

| Δ | increment |

| ε | heat exchanger efficiency |

| SUBSCRIPTS | |

| CO2 | referring to CO2 cycle |

| crit | critical point |

| env | environment |

| gc | gas-cooler |

| H | hot sink |

| high | refers to pressure at gas-cooler and subcooler or cascade heat exchanger |

| I | intermediate temperature level |

| K | condensing level |

| L | cold source, low temperature cycle |

| MS | referring to the dedicated mechanical subcooling cycle |

| O | evaporating level |

| R1234yf | referring to the R1234yf cycle |

| sat | saturation |

References and Notes

- European Commission. Regulation (EU) No 517/2014 of the European Parliament and of the Council of 16 April 2014 on Fluorinated Greenhouse Gases and Repealing Regulation (EC) No 842/2006, 2014.

- Hafner, A.; Hemmingsen, A.K. R744 refrigeration technologies for supermarkets in warm climates. In Proceedings of the 24th IIR International Congress of Refrigeration, Yokohama, Japan, 16–22 August 2015. [Google Scholar]

- Kim, M.H.; Pettersen, J.; Bullard, C.W. Fundamental process and system design issues in CO2 vapor compression systems. Prog. Energy Combust. Sci. 2004, 30, 119–174. [Google Scholar] [CrossRef]

- Jia, X.; Zhang, B.; Pu, L.; Guo, B.; Peng, X. Improved rotary vane expander for trans-critical CO2 cycle by introducing high-pressure gas into the vane slots. Int. J. Refrig. 2011, 34, 732–741. [Google Scholar] [CrossRef]

- Hu, J.; Li, M.; Zhao, L.; Xia, B.; Ma, L. Improvement and experimental research of CO2 two-rolling piston expander. Energy 2015, 93, 2199–2207. [Google Scholar] [CrossRef]

- Elbel, S.; Lawrence, N. Review of recent developments in advanced ejector technology. Int. J. Refrig. 2016, 62, 1–18. [Google Scholar] [CrossRef]

- Hafner, A.; Banasiak, K.; Herdlitschka, T.; Fredslund, K.; Girotto, S.; Haida, M.; Smolka, J. ‘R744 Ejector System Case: Italian Supermarket, Spiazzo’, in Refrigeration Science and Technology. 2016; 471–478. [Google Scholar]

- Lawrence, N.; Elbel, S. ‘Experimental Study on Control Methods for Transcritical Co2 Two-Phase Ejector Systems at Off-Design Conditions’, in Refrigeration Science and Technology. 2016; 511–518. [Google Scholar]

- Karampour, M.; Sawalha, S. ‘Integration of Heating and Air Conditioning into a Co2 Trans-Critical Booster System with Parallel Compression Part I: Evaluation of Key Operating Parameters Using Field Measurements’, in Refrigeration Science and Technology. 2016; 323–331. [Google Scholar]

- Aprea, C.; Greco, A.; Maiorino, A. The application of a desiccant wheel to increase the energetic performances of a transcritical cycle. Energy Convers. Manag. 2015, 89, 222–230. [Google Scholar] [CrossRef]

- Arora, A.; Singh, N.K.; Monga, S.; Kumar, O. Energy and exergy analysis of a combined transcritical CO2 compression refrigeration and single effect H2O-LiBr vapour absorption system. Int. J. Exergy 2011, 9, 453–471. [Google Scholar] [CrossRef]

- Sanz-Kock, C.; Llopis, R.; Sánchez, D.; Cabello, R.; Torrella, E. Experimental evaluation of a R134a/CO2 cascade refrigeration plant. Appl. Therm. Eng. 2014, 73, 39–48. [Google Scholar] [CrossRef]

- Peñarrocha, I.; Llopis, R.; Tárrega, L.; Sánchez, D.; Cabello, R. A new approach to optimize the energy efficiency of CO2 transcritical refrigeration plants. Appl. Therm. Eng. 2014, 67, 137–146. [Google Scholar] [CrossRef]

- Llopis, R.; Sánchez, D.; Sanz-Kock, C.; Cabello, R.; Torrella, E. Energy and environmental comparison of two-stage solutions for commercial refrigeration at low temperature: Fluids and systems. Appl. Energy 2015, 138, 133–142. [Google Scholar] [CrossRef]

- Hafner, A.; Hemmingsen, A.K.; Van De Ven, A. ‘R744 Refrigeration System Configurations for Supermarkets in Warm Climates’, in Refrigeration Science and Technology. 2014; 125–133. [Google Scholar]

- Gullo, P.; Elmegaard, B.; Cortella, G. Energy and environmental performance assessment of R744 booster supermarket refrigeration systems operating in warm climates. Int. J. Refrig. 2016, 64, 61–79. [Google Scholar] [CrossRef] [Green Version]

- Llopis, R.; Cabello, R.; Sánchez, D.; Torrella, E. Energy improvements of CO2 transcritical refrigeration cycles using dedicated mechanical subcooling. Int. J. Refrig. 2015, 55, 129–141. [Google Scholar] [CrossRef]

- Nebot-Andrés, L.; Llopis, R.; Sánchez, D.; Cabello, R. Experimental evaluation of a dedicated mechanical subcooling system in a CO2 transcritical refrigeration cycle, Refrigeration Science and Technology. 2016; 965–972. [Google Scholar]

- Eikevik, T.M.; Bertelsen, S.; Haugsdal, S.; Tolstorebrov, I.; Jensen, S. ‘Co2 Refrigeration System with Integrated Propan Subcooler for Supermarkets in Warm Climate’, in Refrigeration Science and Technology. 2016; 211–218. [Google Scholar]

- Ge, Y.T.; Tassou, S.A.; Santosa, I.D.; Tsamos, K. Design optimisation of CO2 gas cooler/condenser in a refrigeration system. Appl. Energy 2015, 160, 973–981. [Google Scholar] [CrossRef]

- Shao, L.L.; Zhang, C.L. Thermodynamic transition from subcritical to transcritical CO2 cycle. Int. J. Refrig. 2016, 64, 123–129. [Google Scholar] [CrossRef]

- Tsamos, K.M.; Ge, Y.T.; Santosa, I.D.M.C.; Tassou, S.A. Experimental investigation of gas cooler/condenser designs and effects on a CO2 booster system. Appl. Energy. 2017, 186, 470–479. [Google Scholar] [CrossRef]

- Sánchez, D.; Patiño, J.; Sanz-Kock, C.; Llopis, R.; Cabello, R.; Torrella, E. Energetic evaluation of a CO2 refrigeration plant working in supercritical and subcritical conditions. Appl. Therm. Eng. 2014, 66, 227–238. [Google Scholar] [CrossRef]

- Dopazo, J.A.; Fernández-Seara, J. Experimental evaluation of a cascade refrigeration system prototype with CO2 and NH3 for freezing process applications. Int. J. Refrig. 2011, 34, 257–267. [Google Scholar] [CrossRef]

- Aprea, C.; Greco, A.; Maiorino, A. An experimental investigation on the substitution of HFC134a with HFO1234YF in a domestic refrigerator. Appl. Therm. Eng. 2016, 106, 959–967. [Google Scholar] [CrossRef]

- Sánchez, D.; Torrella, E.; Cabello, R.; Llopis, R. Influence of the superheat associated to a semihermetic compressor of a transcritical CO2 refrigeration plant. Appl. Therm. Eng. 2010, 30, 302–309. [Google Scholar] [CrossRef]

- Llopis, R.; Nebot-Andrés, L.; Cabello, R.; Sánchez, D.; Catalán-Gil, J. Experimental evaluation of a CO2 transcritical refrigeration plant with dedicated mechanical subcooling. Int. J. Refrig. 2016, 69, 361–368. [Google Scholar] [CrossRef]

- Lemmon, E.W.; Huber, M.L.; McLinden, M.O. REFPROP, NIST Standard Reference Database 23, v.9.1; National Institute of Standards: Gaithersburg, MD, USA, 2013.

- Torrella, E.; Llopis, R.; Cabello, R. Experimental evaluation of the inter-stage conditions of a two-stage refrigeration cycle using a compound compressor. Int. J. Refrig. 2009, 32, 307–315. [Google Scholar] [CrossRef]

- Lee, T.S.; Liu, C.H.; Chen, T.W. Thermodynamic analysis of optimal condensing temperature of cascade-condenser in CO2/NH3 cascade refrigeration systems. Int. J. Refrig. 2006, 29, 1100–1108. [Google Scholar] [CrossRef]

- Minetto, S.; Rossetti, A.; Girotto, S.; Marinetti, S. ‘Seasonal Performance of Supermarket Refrigeration Systems’, in Refrigeration Science and Technology. 2016; 455–462. [Google Scholar]

- The Australian Institute of Refrigeration, Air Conditioning and Heating (AIRAH), Methods of calculating Total Equivalent Warming Impact (TEWI) 2012. Available online: http://www.airah.org.au/imis15_prod/Content_Files/BestPracticeGuides/Best_Practice_Tewi_June2012.pdf (accessed on 21 April 2017).

- Ministry of Housing, Royal Decree 314/2006, Spanish Technical Building Code. HE Enegy Saving Document. Available online: http://www.codigotecnico.org/ (accessed on 17 March 2017).

| City | León | Pamplona | Teruel | Albacete | La Coruña | Barcelona | Granada | Toledo | Castellón de la Plana | Sevilla | Málaga | Almería | ||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Spanish climatic region | E1 | D1 | D2 | D3 | C1 | C2 | C3 | C4 | B3 | B4 | A3 | A4 | ||

| Average annual temperature (°C) | 10.79 | 12.22 | 11.55 | 13.51 | 14.14 | 15.37 | 14.88 | 15.57 | 16.74 | 18.25 | 17.99 | 18.54 | ||

| Temperature BIN | AC cooling load (%) | Commercial cooling load (%) | Annual hours inside the temperature BIN | |||||||||||

| <−3 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| −3 to −1 | 0 | 0.5 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| −1 to 1 | 0 | 0.5 | 248 | 0 | 391 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 1 to 3 | 0 | 0.5 | 990 | 341 | 878 | 633 | 0 | 0 | 248 | 155 | 0 | 0 | 0 | 0 |

| 3 to 5 | 0 | 0.5 | 936 | 962 | 875 | 847 | 0 | 0 | 692 | 602 | 0 | 0 | 0 | 0 |

| 5 to 7 | 0 | 0.5 | 847 | 1114 | 633 | 817 | 0 | 540 | 843 | 663 | 124 | 62 | 0 | 0 |

| 7 to 9 | 0 | 0.5 | 915 | 819 | 887 | 571 | 537 | 909 | 571 | 876 | 903 | 754 | 62 | 0 |

| 9 to 11 | 0 | 0.5 | 818 | 884 | 734 | 981 | 1697 | 1057 | 827 | 663 | 968 | 846 | 996 | 810 |

| 11 to 13 | 0 | 0.5 | 943 | 846 | 751 | 604 | 1364 | 819 | 668 | 949 | 813 | 785 | 1055 | 943 |

| 13 to 15 | 0 | 0.5 | 826 | 944 | 855 | 756 | 1553 | 1063 | 851 | 572 | 854 | 789 | 941 | 933 |

| 15 to 17 | 0 | 0.5 | 552 | 765 | 733 | 669 | 1556 | 824 | 814 | 638 | 943 | 858 | 884 | 975 |

| 17 to 19 | 0 | 0.5 | 492 | 615 | 522 | 705 | 950 | 817 | 795 | 578 | 909 | 841 | 1061 | 1094 |

| 19 to 21 | 0 | 0.5 | 244 | 430 | 430 | 583 | 673 | 1046 | 612 | 764 | 976 | 1008 | 1002 | 851 |

| 21 to 23 | 0.2 | 0.5 | 304 | 274 | 213 | 339 | 430 | 613 | 307 | 615 | 800 | 581 | 919 | 1068 |

| 23 to 25 | 0.4 | 0.6 | 304 | 304 | 244 | 306 | 0 | 518 | 461 | 431 | 552 | 581 | 738 | 800 |

| 25 to 27 | 0.6 | 0.7 | 155 | 276 | 273 | 273 | 0 | 337 | 214 | 275 | 394 | 523 | 397 | 488 |

| 27 to 29 | 0.8 | 0.8 | 186 | 186 | 217 | 304 | 0 | 217 | 243 | 183 | 338 | 275 | 426 | 458 |

| 29 to 31 | 1 | 0.9 | 0 | 0 | 124 | 124 | 0 | 0 | 273 | 393 | 186 | 243 | 279 | 340 |

| 31 to 33 | 1 | 1 | 0 | 0 | 0 | 217 | 0 | 0 | 124 | 155 | 0 | 304 | 0 | 0 |

| >33 | 1 | 1 | 0 | 0 | 0 | 31 | 0 | 0 | 217 | 248 | 0 | 310 | 0 | 0 |

| Climatic Region | E1 | D1 | D2 | D3 | C1 | C2 | C3 | C4 | B3 | B4 | A3 | A4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cascade cycle annual averaged COP | ||||||||||||

| To = 5 °C (AC) | 3.74 | 3.72 | 3.57 | 3.41 | 4.30 | 3.79 | 3.33 | 3.33 | 3.66 | 3.34 | 3.63 | 3.63 |

| To = 0 °C | 4.51 | 4.45 | 4.42 | 4.23 | 4.53 | 4.26 | 4.13 | 4.04 | 4.11 | 3.87 | 4.00 | 3.94 |

| To = −5 °C | 3.75 | 3.70 | 3.68 | 3.54 | 3.77 | 3.56 | 3.46 | 3.39 | 3.45 | 3.26 | 3.37 | 3.32 |

| To = −10 °C | 3.18 | 3.14 | 3.12 | 3.01 | 3.19 | 3.03 | 2.95 | 2.90 | 2.95 | 2.80 | 2.88 | 2.84 |

| To = −15 °C | 2.73 | 2.70 | 2.69 | 2.60 | 2.74 | 2.61 | 2.55 | 2.51 | 2.54 | 2.42 | 2.49 | 2.46 |

| To = −20 °C | 2.37 | 2.35 | 2.33 | 2.26 | 2.38 | 2.27 | 2.22 | 2.18 | 2.22 | 2.12 | 2.17 | 2.15 |

| MS cycle annual averaged COP | ||||||||||||

| To = 5 °C (AC) | 3.92 | 3.88 | 3.65 | 3.43 | 4.82 | 4.00 | 3.32 | 3.33 | 3.80 | 3.34 | 3.76 | 3.76 |

| To = 0 °C | 5.65 | 5.52 | 5.48 | 5.14 | 5.67 | 5.16 | 4.97 | 4.81 | 4.89 | 4.49 | 4.68 | 4.56 |

| To = −5 °C | 4.38 | 4.29 | 4.26 | 4.02 | 4.40 | 4.04 | 3.89 | 3.78 | 3.85 | 3.55 | 3.70 | 3.62 |

| To = −10 °C | 3.50 | 3.44 | 3.41 | 3.23 | 3.52 | 3.25 | 3.14 | 3.06 | 3.11 | 2.89 | 3.00 | 2.94 |

| To = −15 °C | 2.86 | 2.81 | 2.79 | 2.65 | 2.87 | 2.67 | 2.58 | 2.51 | 2.56 | 2.38 | 2.48 | 2.43 |

| To = −20 °C | 2.36 | 2.32 | 2.30 | 2.19 | 2.37 | 2.21 | 2.13 | 2.08 | 2.12 | 1.98 | 2.06 | 2.02 |

| Climatic region | E1 | D1 | D2 | D3 | C1 | C2 | C3 | C4 | B3 | B4 | A3 | A4 |

| Cascade cycle annual averaged COP | ||||||||||||

| To = 5 °C (AC) | 3.74 | 3.72 | 3.57 | 3.41 | 4.30 | 3.79 | 3.33 | 3.33 | 3.66 | 3.34 | 3.63 | 3.63 |

| To = 0 °C | 4.51 | 4.45 | 4.42 | 4.23 | 4.53 | 4.26 | 4.13 | 4.04 | 4.11 | 3.87 | 4.00 | 3.94 |

| To = −5 °C | 3.75 | 3.70 | 3.68 | 3.54 | 3.77 | 3.56 | 3.46 | 3.39 | 3.45 | 3.26 | 3.37 | 3.32 |

| To = −10 °C | 3.18 | 3.14 | 3.12 | 3.01 | 3.19 | 3.03 | 2.95 | 2.90 | 2.95 | 2.80 | 2.88 | 2.84 |

| To = −15 °C | 2.73 | 2.70 | 2.69 | 2.60 | 2.74 | 2.61 | 2.55 | 2.51 | 2.54 | 2.42 | 2.49 | 2.46 |

| To = −20 °C | 2.37 | 2.35 | 2.33 | 2.26 | 2.38 | 2.27 | 2.22 | 2.18 | 2.22 | 2.12 | 2.17 | 2.15 |

| MS cycle annual averaged COP | ||||||||||||

| To = 5 °C (AC) | 3.92 | 3.88 | 3.65 | 3.43 | 4.82 | 4.00 | 3.32 | 3.33 | 3.80 | 3.34 | 3.76 | 3.76 |

| To = 0 °C | 5.65 | 5.52 | 5.48 | 5.14 | 5.67 | 5.16 | 4.97 | 4.81 | 4.89 | 4.49 | 4.68 | 4.56 |

| To = −5 °C | 4.38 | 4.29 | 4.26 | 4.02 | 4.40 | 4.04 | 3.89 | 3.78 | 3.85 | 3.55 | 3.70 | 3.62 |

| To = −10 °C | 3.50 | 3.44 | 3.41 | 3.23 | 3.52 | 3.25 | 3.14 | 3.06 | 3.11 | 2.89 | 3.00 | 2.94 |

| To = −15 °C | 2.86 | 2.81 | 2.79 | 2.65 | 2.87 | 2.67 | 2.58 | 2.51 | 2.56 | 2.38 | 2.48 | 2.43 |

| To = −20 °C | 2.36 | 2.32 | 2.30 | 2.19 | 2.37 | 2.21 | 2.13 | 2.08 | 2.12 | 1.98 | 2.06 | 2.02 |

| Climatic Region | E1 | D1 | D2 | D3 | C1 | C2 | C3 | C4 | B3 | B4 | A3 | A4 |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cascade cycle | ||||||||||||

| To = 5 °C (AC) | −4.7 | −4.3 | −3.1 | −2.6 | −10.9 | −5.2 | −2.5 | −2.8 | −4.3 | −2.7 | −4.2 | −4.1 |

| To = 0 °C | −20.2 | −19.6 | −19.6 | −18.2 | −20.0 | −17.5 | −17.4 | −16.6 | −16.2 | −14.6 | −14.9 | −14.2 |

| To = −5 °C | −14.6 | −14.1 | −14.1 | −12.9 | −14.3 | −12.3 | −12.3 | −11.6 | −11.2 | −10.0 | −10.1 | −9.5 |

| To = −10 °C | −9.7 | −9.3 | −9.3 | −8.4 | −9.3 | −7.8 | −7.9 | −7.4 | −6.9 | −6.1 | −6.2 | −5.7 |

| To = −15 °C | −5.5 | −5.2 | −5.2 | −4.6 | −5.0 | −4.1 | −4.2 | −4.0 | −3.6 | −3.1 | −3.1 | −2.8 |

| To = −20 °C | −1.4 | −1.3 | −1.3 | −1.1 | −1.1 | −1.0 | −1.0 | −1.0 | −0.8 | −0.7 | −0.7 | −0.6 |

| MS cycle | ||||||||||||

| To = 5 °C (AC) | −0.2 | −0.2 | −0.8 | −2.0 | 0.0 | −0.1 | −2.7 | −2.8 | −0.7 | −2.7 | −0.8 | −0.8 |

| To = 0 °C | −0.1 | −0.1 | −0.2 | −0.5 | 0.0 | −0.1 | −0.7 | −0.9 | −0.4 | −1.1 | −0.5 | −0.6 |

| To = −5 °C | −0.3 | −0.3 | −0.5 | −1.0 | 0.0 | −0.5 | −1.3 | −1.5 | −0.8 | −1.9 | −1.1 | −1.3 |

| To = −10 °C | −0.6 | −0.7 | −0.9 | −1.6 | −0.1 | −1.0 | −2.0 | −2.4 | −1.6 | −3.1 | −2.1 | −2.4 |

| To = −15 °C | −1.1 | −1.3 | −1.5 | −2.5 | −0.4 | −2.0 | −3.1 | −3.7 | −2.9 | −4.7 | −3.6 | −4.1 |

| To = −20 °C | −1.9 | −2.4 | −2.6 | −4.0 | −1.5 | −3.8 | −4.8 | −5.6 | −5.0 | −7.1 | −6.1 | −6.7 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nebot-Andrés, L.; Llopis, R.; Sánchez, D.; Catalán-Gil, J.; Cabello, R. CO2 with Mechanical Subcooling vs. CO2 Cascade Cycles for Medium Temperature Commercial Refrigeration Applications Thermodynamic Analysis. Appl. Sci. 2017, 7, 955. https://doi.org/10.3390/app7090955

Nebot-Andrés L, Llopis R, Sánchez D, Catalán-Gil J, Cabello R. CO2 with Mechanical Subcooling vs. CO2 Cascade Cycles for Medium Temperature Commercial Refrigeration Applications Thermodynamic Analysis. Applied Sciences. 2017; 7(9):955. https://doi.org/10.3390/app7090955

Chicago/Turabian StyleNebot-Andrés, Laura, Rodrigo Llopis, Daniel Sánchez, Jesús Catalán-Gil, and Ramón Cabello. 2017. "CO2 with Mechanical Subcooling vs. CO2 Cascade Cycles for Medium Temperature Commercial Refrigeration Applications Thermodynamic Analysis" Applied Sciences 7, no. 9: 955. https://doi.org/10.3390/app7090955

APA StyleNebot-Andrés, L., Llopis, R., Sánchez, D., Catalán-Gil, J., & Cabello, R. (2017). CO2 with Mechanical Subcooling vs. CO2 Cascade Cycles for Medium Temperature Commercial Refrigeration Applications Thermodynamic Analysis. Applied Sciences, 7(9), 955. https://doi.org/10.3390/app7090955