Abstract

Due to the negative effects that derive from large impervious surfaces in urban areas, pervious concrete has been developed, and has become an environmentally friendly pavement material. As a porous and permeable material, pervious concrete presents an overwhelming advantage in solving urban problems, such as flooding, groundwater decline, urban heat island phenomena, etc. Waste crumb rubber has been verified as a feasible modifier for pavement material. The objective of this paper is to explore the effects of rubber particle size and incorporation level on the permeability, mechanical properties, and freeze–thaw resistance of pervious concrete. Two kinds of rubbers (fine and coarse) with four incorporation levels (2%, 4%, 6%, and 8%) are used in the experiment. Permeability, compressive strength, flexural strength, flexural strain, and freeze–thaw resistance are tested. The results indicate that the addition of rubber slightly decreases strength and permeability, but significantly enhances ductility and freeze-thaw resistance. Fine crumb rubber with a suitable incorporation level could remarkably improve the ductility and freeze–thaw resistance of pervious concrete without sacrificing excessively strength and permeability.

1. Introduction

Global urbanization is the inevitable outcome of rapid social and economic development. The speed of urbanization has reached an unprecedented level over the past few decades. During the progress of urbanization, impervious pavement materials, such as cement concrete and asphalt concrete, have expanded rapidly, and almost all city areas have been covered with these impermeable materials, thereby causing major and fatal urban flooding [1,2,3]. Multiple flood disasters have proven that conventional rainwater management approaches and existing flooding defense structures are ineffective. It is extremely urgent to seek new solutions for the mitigation of flooding impacts and urban water management [4,5,6,7]. Pervious concrete, as an important part of a sponge city, was developed as an alternative to traditional impervious pavement materials [8,9]. Its porous structure enables storm water to permeate into the ground and mitigate storm water runoff. Due to its unique structure, pervious concrete has had many other advantages with regard to alleviating the urban heat island effect, reducing noise pollution, improving water quality, and maintaining the urban ecological balance [10,11,12]. These advantages have made pervious concrete an environmentally friendly and sustainable material in paving applications.

The development of the automotive industry has led to worldwide pollution from waste tires. Incineration is the most simple and direct way to dispose of waste tires. However, this method will cause serious environmental pollution and is forbidden in many countries [13,14]. Lots of effort has been made to recycle and reuse waste tires in a more environmentally friendly and economical way [15]. Generally, it is an effective method to smash tires into crumb rubber or tire chips and use them as additives in pavement materials. The main component of waste tires is cross-linker copolymer, which has a certain recovery deformation ability [16,17,18]. Waste tire rubbers are usually classified into different particle sizes, and are used as partial or full aggregate replacements in pavement materials. They have been used as additives in ordinary cement concrete and asphalt concrete for many years and are verified as a positive material in improving ductility and freeze–thaw durability [19,20,21].

Many studies have been conducted on waste tire rubbers as an additive in traditional cement concrete and asphalt concrete. The effect of rubber addition on the properties of mixtures is related to rubber type, particle size, and incorporation level [15]. In general, rubber incorporation into cement concrete and asphalt concrete has a negative effect on the concrete’s mechanical properties. However, it can greatly improve concrete’s anti-deformation ability and durability, which makes rubber modification widely used as an additive. Granulated rubber has generally been used as the replacement for fine aggregate in concrete. The addition of rubber has always resulted in a decrease of compressive strength and flexural strength, and strength loss increases with the increasing rubber content [22,23,24]. However, it is not absolute; crumb rubber treated with an NaOH solution significantly improves the compressive strength of rubber-modified concrete [25]. With regards to the durability of rubber-modified concrete, the addition of rubber has been positive in enhancing freeze–thaw, impact, abrasion, and acid attack resistance [22,23,24,25]. There are many mature studies about rubber-modified concrete, but fewer on rubber-modified pervious concrete [26]. Bonicelli et al. [27] studied the effect of rubber particle sizes and dosages on the density and indirect tensile strength of rubber-modified pervious concrete. Crumb rubbers of 0.08–1 mm and 0.6–2.5 mm were used to replace the coarse aggregate with the equivalent volume method. The dosages were 5% and 10%. The results of the experiment indicate that coarse rubber has a greater positive effect on the density and indirect tensile strength than fine rubber. Mondal and Biligiri [28] conducted experiments to investigate the hydrological, functional, and structural characteristics of crumb rubber-modified pervious concrete with four dosages of crumb rubber. It was used to replace the coarse aggregate. Permeability, abrasion resistance, and compressive strength were measured, and the results showed that the addition of rubber enhanced the abrasion resistance, but decreased compressive strength and permeability compared to the unmodified control mixtures. Gesoglu et al. [29] studied the mechanical properties, ductility, and damping capacity of rubber-modified pervious concrete using tire chips, crumb rubber, and fine crumb rubber. The replacement levels of the coarse aggregate were 10% and 20% with the equivalent volume method. The results of the tests indicate that the addition of rubber decreases the compressive strength, flexural strength, and elastic modulus, but significantly increase ductility and damping capacity. In another research conducted by Gesoglu et al. [30], abrasion and freeze–thaw resistance of pervious concretes were investigated with the same rubber particle size and volume content. The test results revealed that the addition of rubber significantly enhanced the abrasion and freeze–thaw resistance of pervious concrete, and fine rubber was superior to coarse rubber.

There are few studies concentrating on rubber-modified pervious concrete at present, and the properties of rubber-modified pervious concrete still need systematic and comprehensive research. The influence of aggregate size, porosity, and water to binder ratio on strength, permeability, and freeze–thaw durability of pervious concrete were investigated by our group [31]. Based on our previous study and existing research by other scholars, this paper investigates the effect of rubber particle size (fine and coarse) and dosage (2%, 4%, 6%, and 8%) on the properties of pervious concrete. Permeability, compressive strength, flexural strength, flexural strain, and freeze–thaw resistance tests were carried out on rubber-modified pervious concrete.

2. Materials and Methods

2.1. Materials and Mix Design

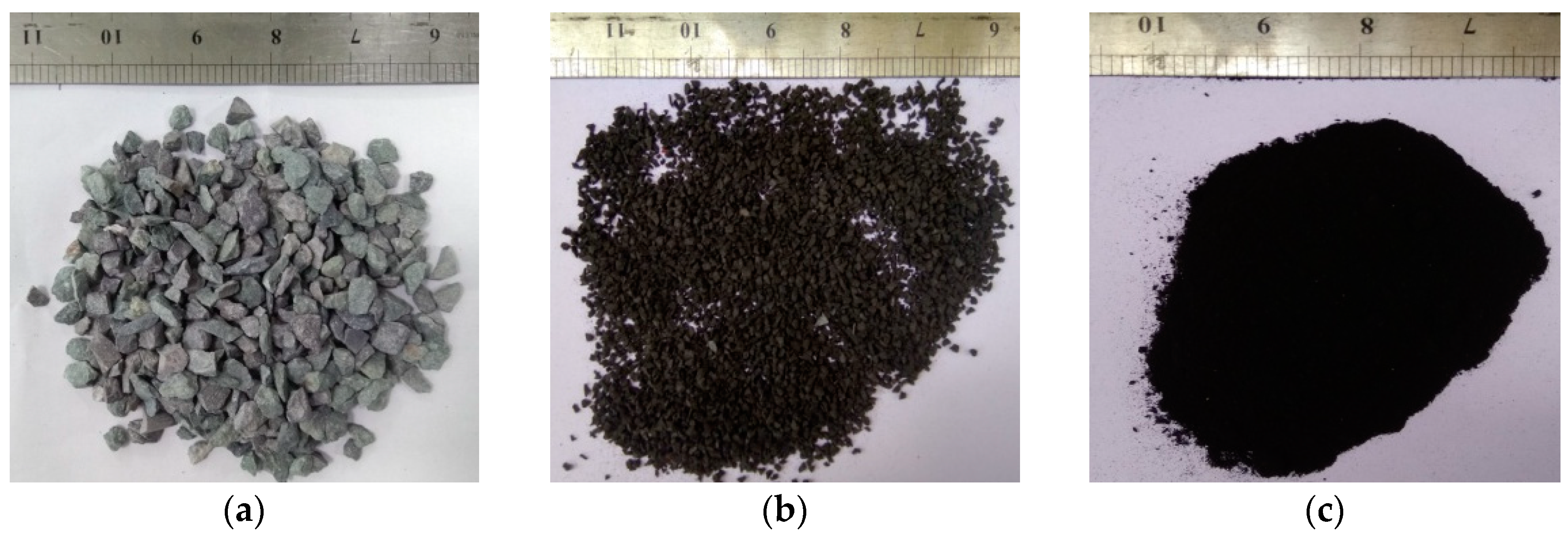

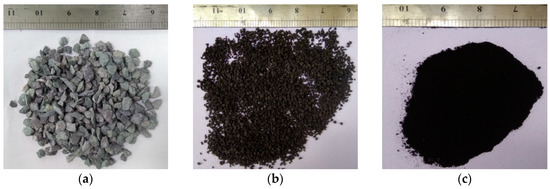

Portland cement (P.O 42.5) was used in the experiment, and its physical properties and chemical composition are shown in Table 1 and Table 2. The coarse aggregate used was a mono-sized natural granite coarse aggregate of 4.75–9.5 mm, and its properties are shown in Table 3. Two kinds of crumb rubbers, namely coarse crumb rubber (CCR) and fine crumb rubber (FCR), obtained from scrap tires, were utilized to produce rubber-modified pervious concrete (RMPC). CCR and FCR have particle sizes of 1–3 mm and 40 mesh, respectively. The coarse aggregate and crumb rubbers are shown in Figure 1.

Table 1.

Physical properties of Portland cement.

Table 2.

Chemical composition of Portland cement.

Table 3.

Properties of natural granite coarse aggregate.

Figure 1.

Coarse aggregate and crumb rubbers: (a) coarse aggregate, (b) coarse crumb rubber, and (c) fine crumb rubber.

A control pervious concrete (CPC) and RMPC were designed according to the national standard [32]. Generally, designed porosity, water to binder ratio, and aggregate size of pervious concrete are the parameters needed for the mix design. Based on previous research conducted by our research group [31], in this study, the aggregate size, designed porosity, and water to binder ratio were chosen as 4.75–9.5 mm, 15%, and 0.30, respectively. CCR and FCR were incorporated by the weight of cement. The incorporation levels were 2%, 4%, 6%, and 8%. In addition, a polycarboxylic acid superplasticizer was applied. The dosage of superplasticizer was 0.8% of the mass of cement. The mix ratio is shown in Table 4.

Table 4.

Mix ratio of pervious concrete (in kg/m3).

2.2. Specimen Preparation

The specimens used in the experiments were prepared in the lab. Nine tests were designed. In each group, there were three 100 × 100 × 100 mm cubic specimens for compressive strength and permeability tests, three 100 × 100 × 400 mm prismatic specimens for flexural strength and flexural stain tests, and twelve 100 × 100 × 100 mm cubic specimens for freeze–thaw cycle tests. All the specimens of each group were one-time mixed and moulded. The detailed preparation procedures are as follows: (a) the materials (coarse aggregate, cement, rubber, superplasticizer, and water) were prepared for each group; (b) the coarse aggregate and crumb rubber were mixed for 30 s; (b) half the water was added to the mixer and stirred for 30 s; (c) the cement was put into the mixer and mixed for 40 s; (d) the rest of the water and superplasticizer were added and stirred for 50 s; and (e) the specimens were moulded with the rodding method. All specimens were demoulded after 24 h. Then, all specimens were put into a standard curing room and cured with a relative humidity of 95% and a temperature of 20 ± 2 °C. The specimens for permeability, compressive strength, flexural strength, and flexural strain tests were standard cured for 28 days. Specimens for the freeze–thaw cycles were standard cured for 24 days and submerge cured for 4 days. All tests were immediately conducted at 28 days.

2.3. Testing Methods

In order to evaluate the properties of RMPC, permeability, compressive strength, flexural strength, flexural stain (flexural stain refers to the flexural stain at the peak in the following text), and freeze-thaw cycle tests were conducted in the lab.

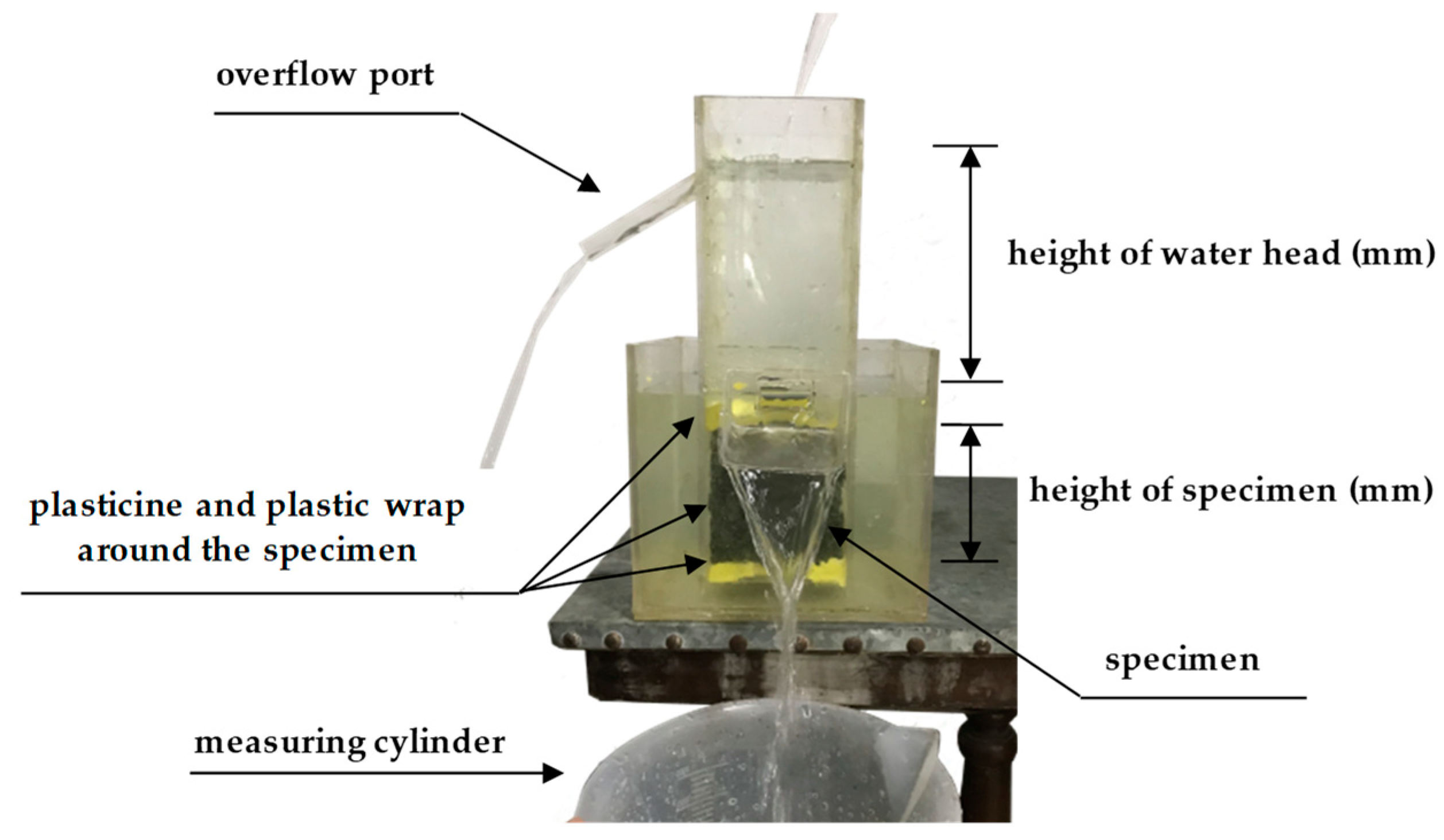

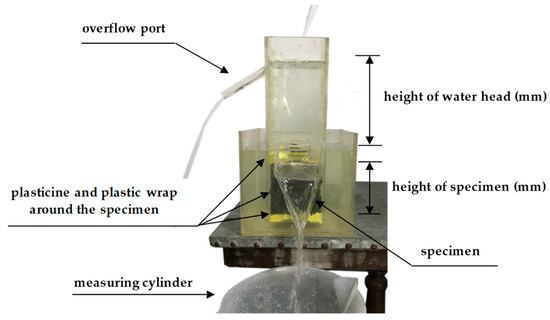

The constant head permeability test was used to determine the permeability coefficient of pervious concrete according to the national standard [32]. The temperature of the permeability test was 20 ± 2 °C. A depiction of the permeability test apparatus is shown in Figure 2. In addition, water flow along the lateral side of the specimen has crucial influence on the permeability assessment, which could be eliminated by installing plasticine and plastic wrap around the specimen. The test procedures were as follows: (a) put the specimen sealed with plastic wrap around it into the permeability test apparatus; (b) seal the junction of the specimen and apparatus with plasticine; (c) inject water into the instrument until the height the of water head is constant; (d) collect permeable water in 300 s. Three parallel tests were conducted in each group. The permeability coefficient can be calculated by the following equation:

where k is the permeability coefficient (mm/s); Q is the discharged amount of water in t time (mm3); L is the height of the specimen (mm); A is the upper surface area of the specimen (mm2); H is the height of water head (mm), and H = 150 mm; and t is the time (s), with t = 300 s.

Figure 2.

Permeability test apparatus.

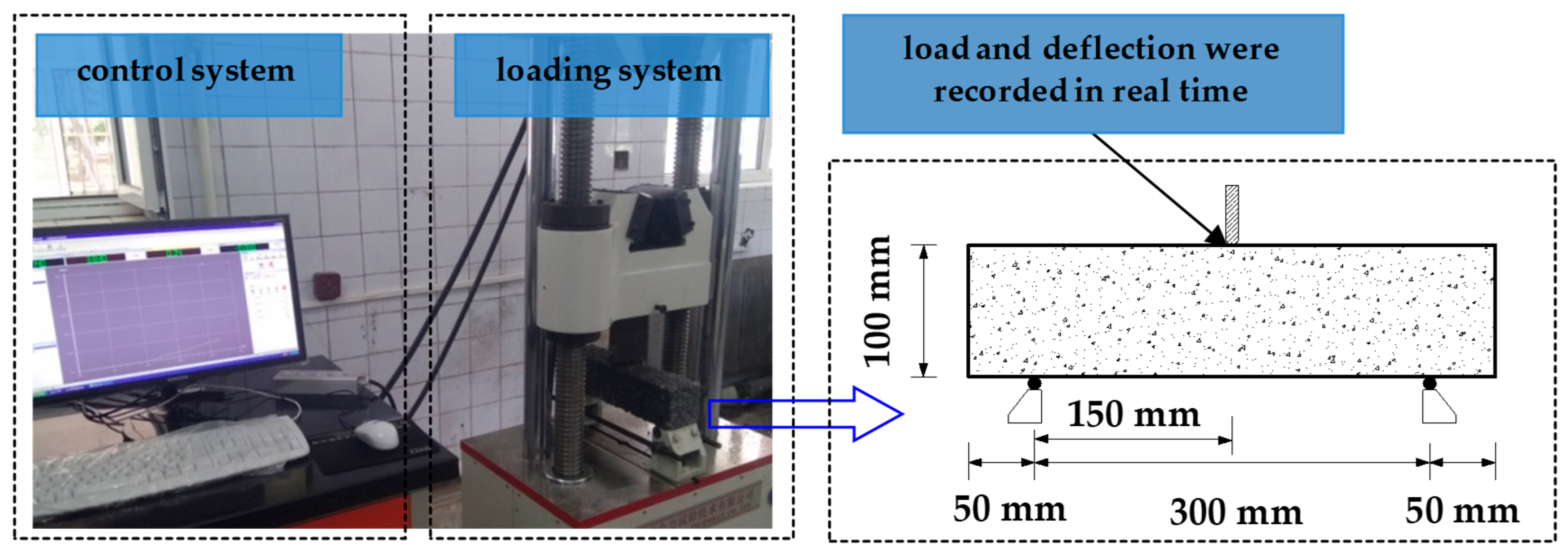

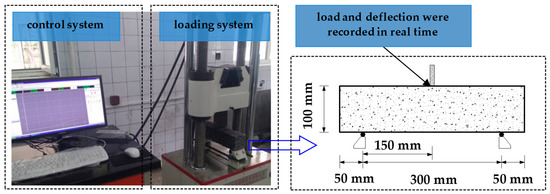

Compressive strength and flexural strength at the age of 28 days were tested according to the national standard [33]. Three parallel tests were conducted in each group. The specimens for the permeability test were used to determine the compressive strength. Flexural strength and flexural strain were determined using a closed-loop, servo-controlled hydraulic testing system in the three-point bending mode. The distance between the two supporting points is 300 mm, and the distance from the loading point to each supporting point is 150 mm. The load and deflection of the specimen could be recorded in real time by the testing system. The load and deflection were recorded throughout the entire process; the specimen began to bear the load until it broke. The loading rate for the flexural test was set as 0.05 kN/s. The testing system is shown in Figure 3. The flexural strength and flexural strain were determined by the following equations:

where is the flexural strength of the specimen (MPa); is the flexural strain of the specimen; P is the failure load (N); L is the distance between the two supporting points (mm), L = 300 mm; b is the section width of the specimen (mm), and b = 100 mm; h is the height of the specimen (mm), with h = 100 mm; and ∆ is the deflection corresponding to P (mm).

Figure 3.

Closed-loop, servo-controlled hydraulic testing system.

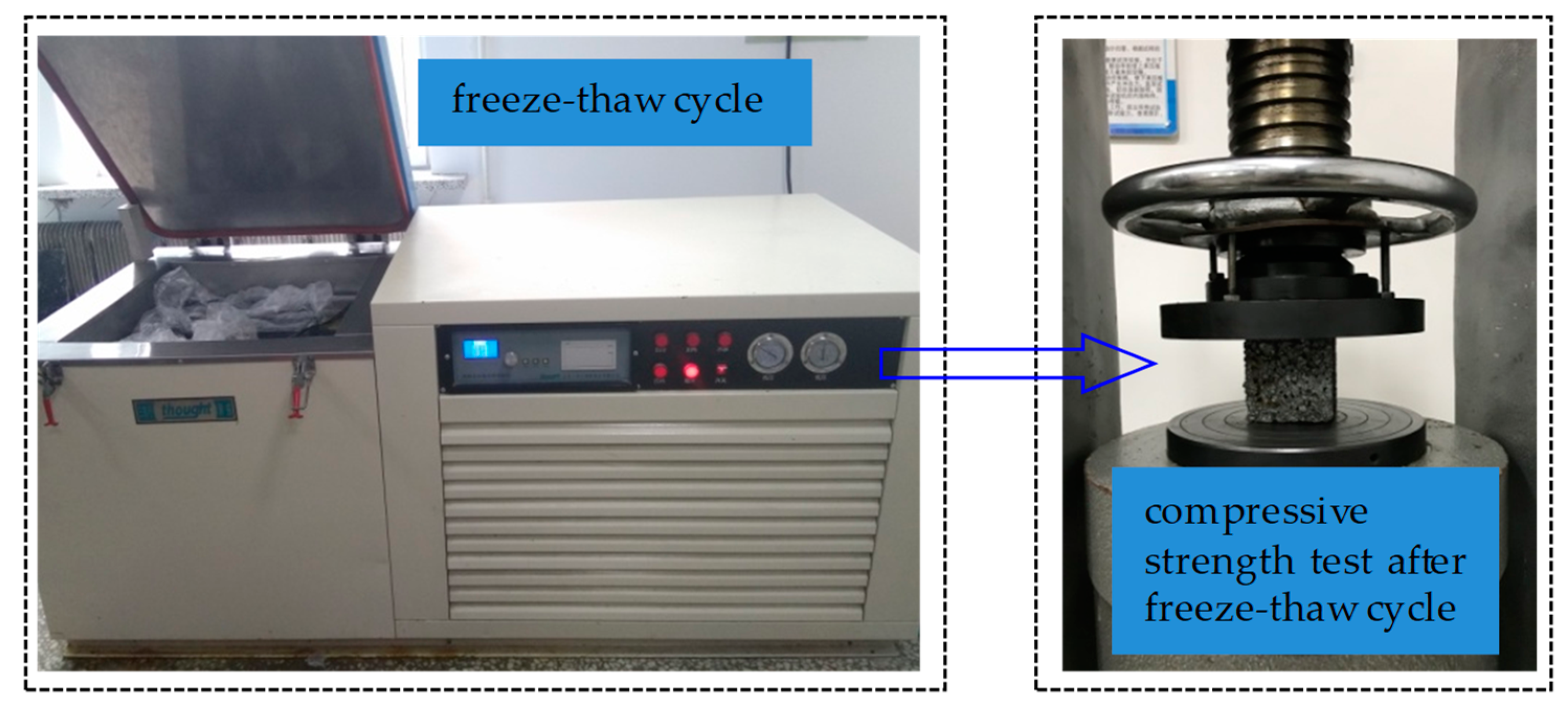

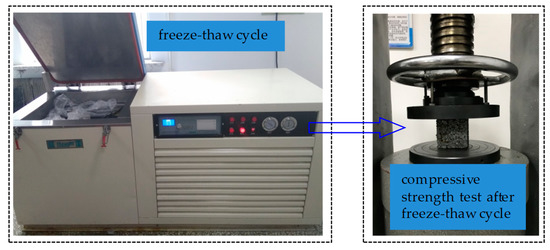

The freeze–thaw test was conducted according to the national standard [34]. The fast freezing method was followed to assess the freeze–thaw resistance. Three parallel tests were conducted in each group. The upper and lower limits of the temperature were set to −18 °C and 5 °C, respectively. 2.5–4 h were needed to complete one freeze–thaw cycle. Due to the special porous structure, there were some problems in the measurement of the relative dynamic elastic modulus. According to the national standard [34], the tester should be in contact with the specified position on the surface of the specimen. The porous surface of pervious concrete makes it difficult to guarantee good contact, which can cause experiment errors. On the other hand, the test method based on the national standard is designed for ordinary concrete, and it is not applicable for porous concrete. The relative dynamic elastic modulus test on pervious concrete conducted by our group indicates that the results are highly discrete, and do not adequately characterize the decay of the freeze–thaw property. Based on the freeze–thaw test results in the previous study [31], pervious concrete has a different failure pattern under freeze–thaw conditions, compared to ordinary concrete. Therefore, the compressive strength loss rate was used as an evaluation index, instead of relative dynamic elastic modulus and mass loss. The compressive strength was measured every 25 freeze–thaw cycles. The freeze–thaw test is shown in Figure 4.

Figure 4.

Freeze–thaw cycle and compressive strength test after a freeze–thaw cycle.

3. Results and Discussions

Table 5.

Mechanical properties and permeability results for rubber-modified pervious concrete (RMPC).

Table 6.

Freeze–thaw results of RMPC.

3.1. Influence of Crumb Rubber on Pervious Concrete Properties

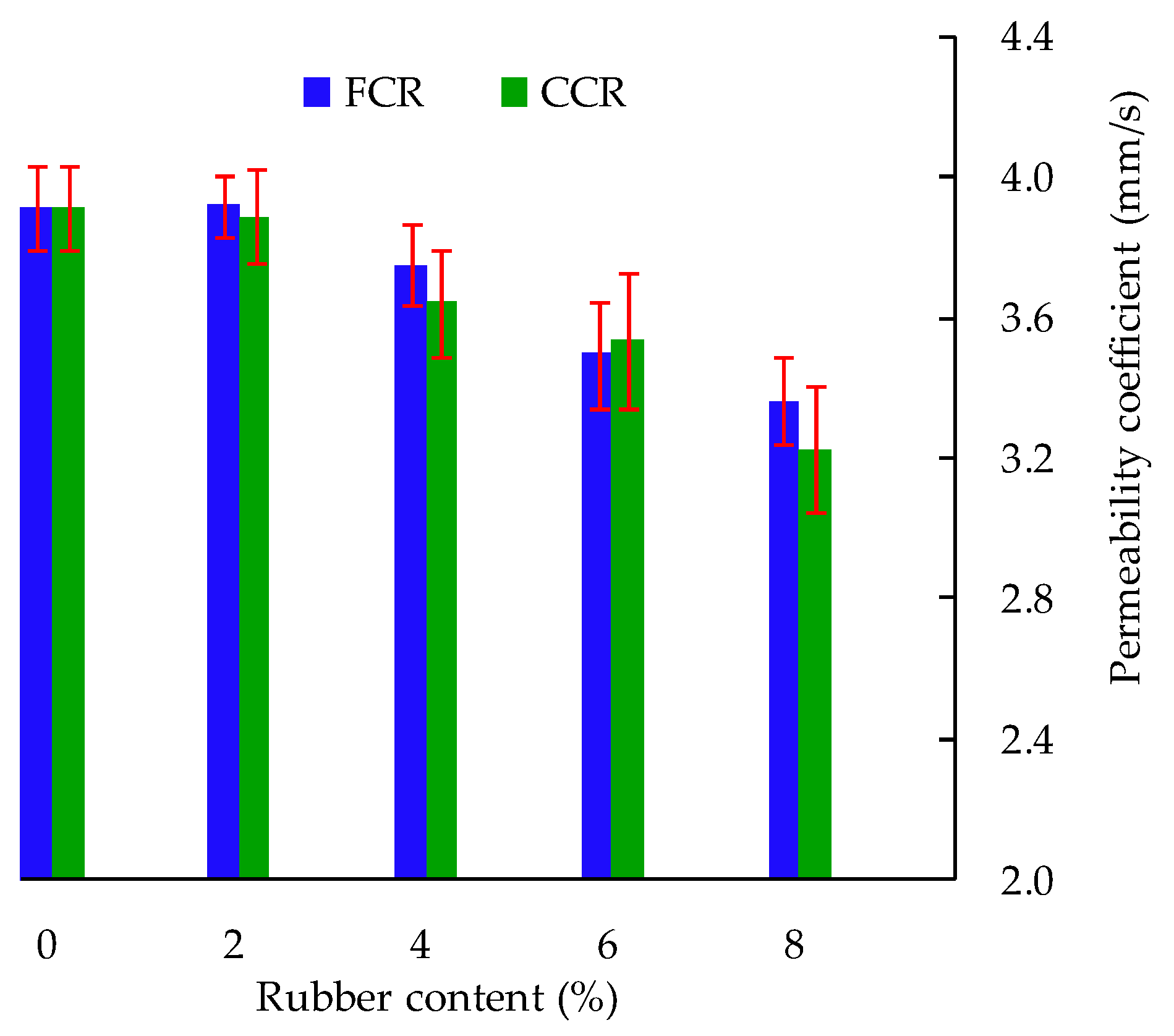

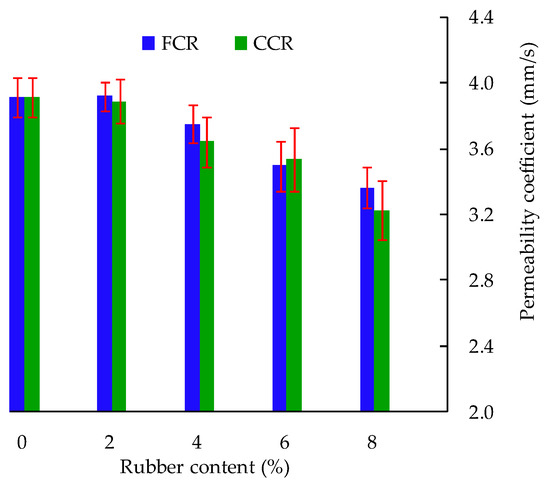

3.1.1. Permeability

The variations in the permeability coefficient of pervious concrete versus rubber content are shown in Figure 5. It can be concluded that the addition of rubber decreases the permeability coefficient of RMPC. This is because the incorporation of rubber leads to a reduction of porosity. Porosity is the most crucial factor for the permeability of pervious concrete. Compared to CPC, with a permeability coefficient of 3.91 mm/s, the permeability coefficients of CCR- and FCR-modified mixtures are 3.23–3.89 mm/s and 3.36–3.92 mm/s, respectively. When the incorporation levels of the rubber are the same, the permeability coefficients of CCR- and FCR-modified mixtures have almost no difference, which means the rubber particle size has little effect on the permeability coefficient. This is consistent with the conclusion reported by Liu et al. [31].

Figure 5.

Permeability coefficient of RMPC versus rubber content.

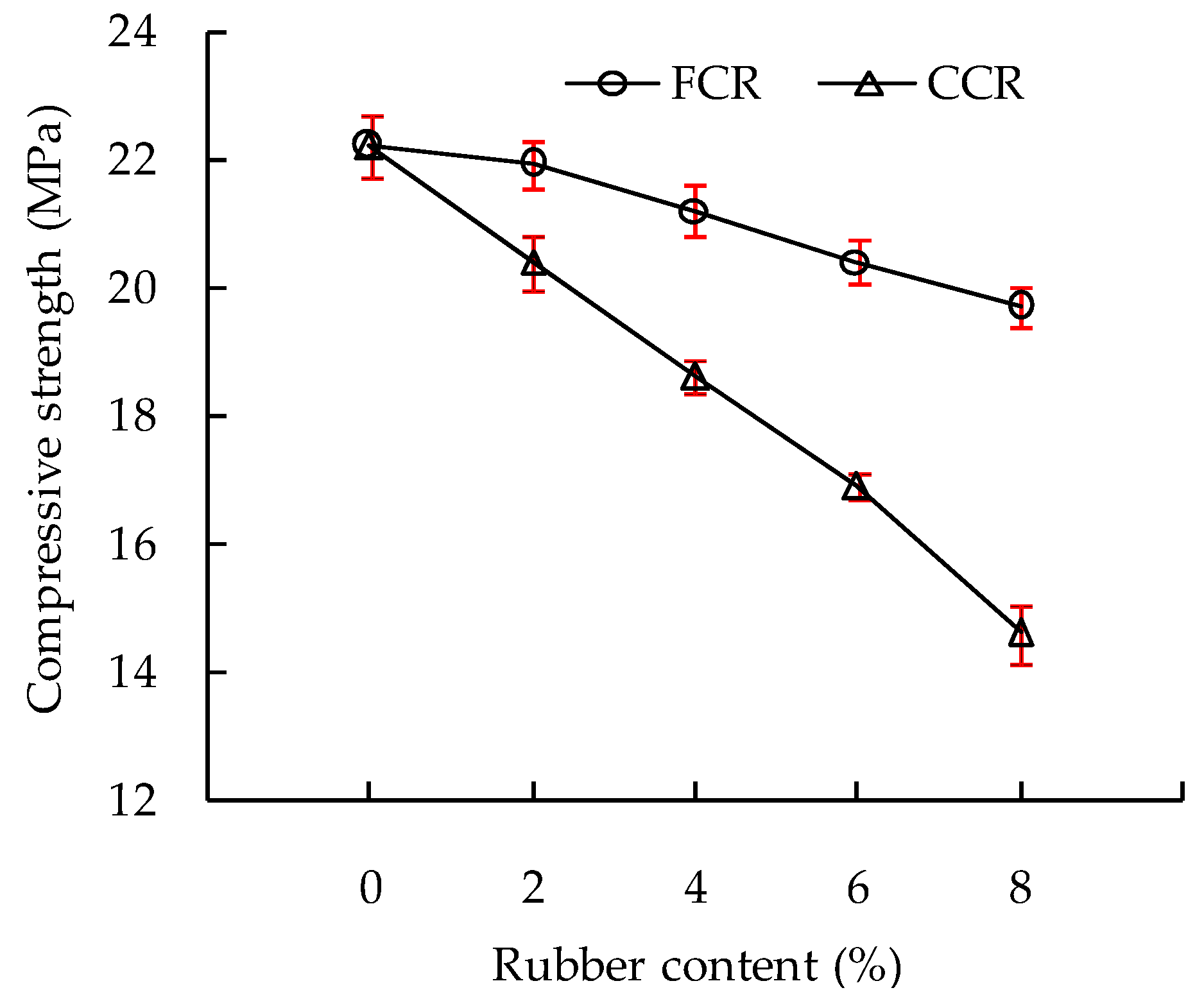

3.1.2. Compressive Strength

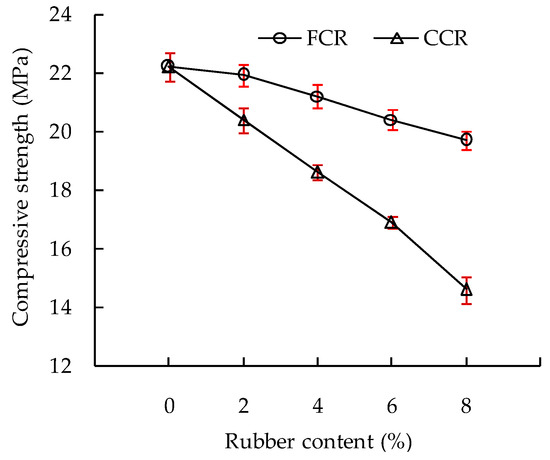

The addition of rubber has a negative effect on the compressive strength of pervious concrete, which can be seen in Figure 6. It can be seen that both rubber particle size and rubber content have a strong effect on compressive strength. The compressive strength of RMPC decreases with the increase of rubber content. Compared to CPC, with a compressive strength of 22.2 MPa, the compressive strengths of CCR- and FCR-modified mixtures are 14.6–20.4 MPa and 19.7–21.9 MPa, respectively. As we all know, the compressive strength of pervious concrete comes from the bonding force and strength of coarse aggregate; the addition of rubber weakens the bonding force between the aggregate and cement paste, and results in a reduction of compressive strength.

Figure 6.

Compressive strength of RMPC versus rubber content.

The effect of rubber particle size on compressive strength can also be found in Figure 6. The CCR-modified mixture has lower compressive strength than the FCR-modified mixture at the same incorporation level. The maximum difference between CCR- and FCR-modified mixtures is 5.1 MPa at the 8% level, which means that the small rubber particle is more advantageous to the compressive strength of RMPC. This is because the roles of FCR and CCR in pervious concrete are quite different. Generally, pervious concrete consists of a coarse aggregate framework and cement paste. CCR exists as a framework in pervious concrete by replacing the coarse aggregate; FCR plays the role of a filler rather than the framework. The addition of CCR weakens the role of the framework in strength formation. The adverse impact of FCR on compressive strength is lower compared to CCR. Figure 6 also indicates that the difference in compressive strength between CCR- and FCR-modified mixtures increases with the increasing incorporation level. This is because the adverse impact of rubber on compressive strength increases with the increasing rubber content. FCR-modified mixtures have a maximum strength loss of 11% at the 8% incorporation level, which means that FCR is more effective in modifying pervious concrete without sacrificing excessively compressive strength.

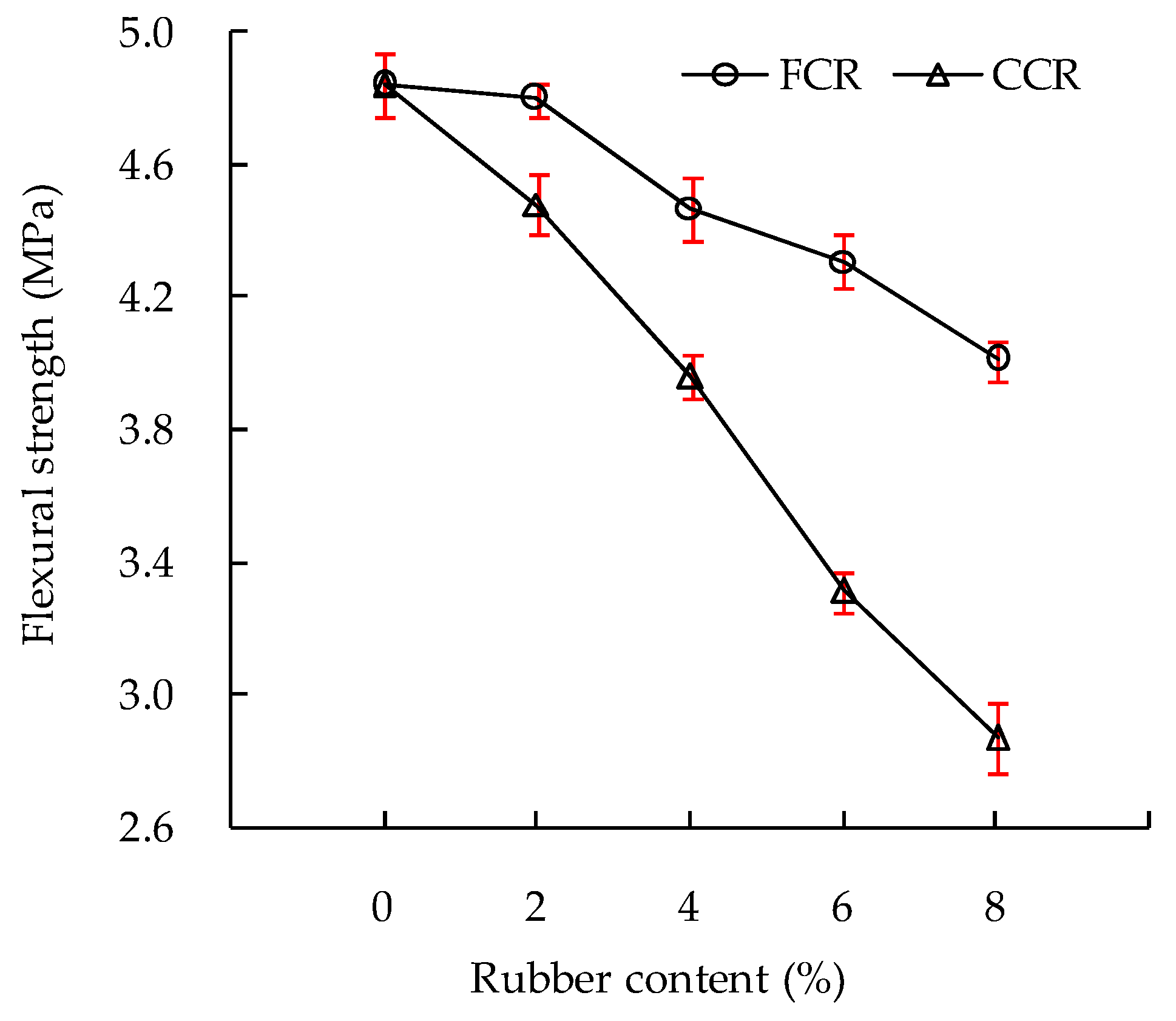

3.1.3. Flexural Strength

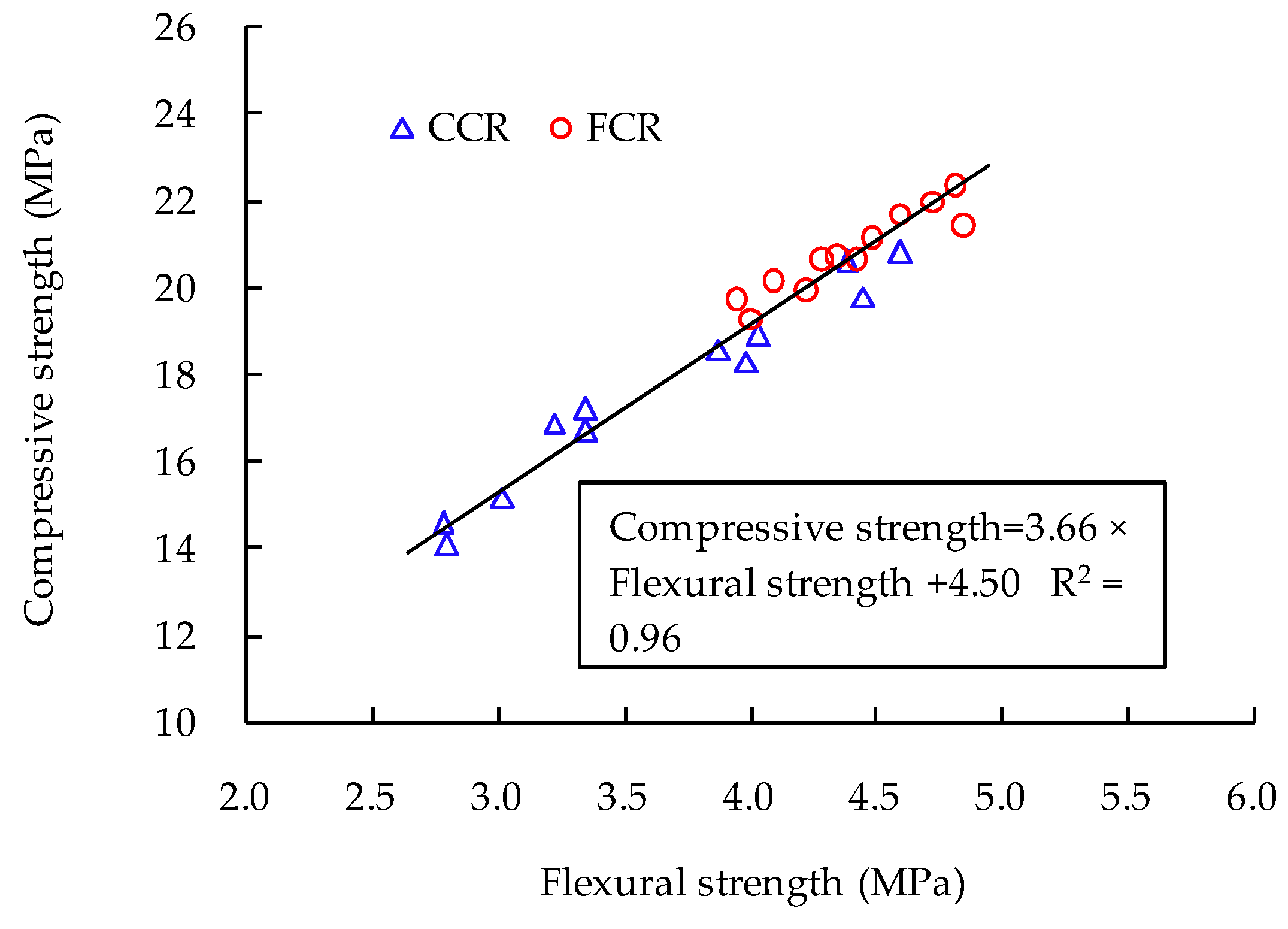

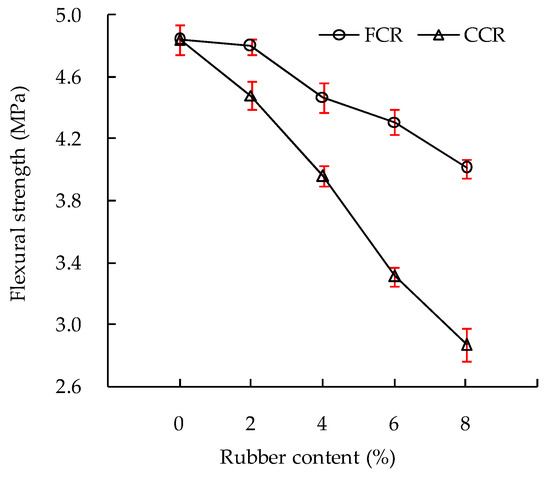

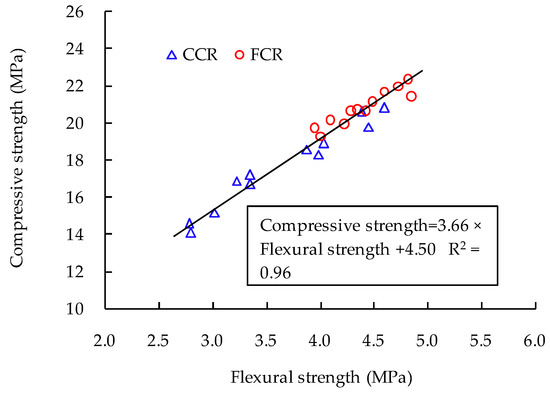

As can be seen in Figure 7, the effect of rubber content on the flexural strength of RMPC is the same as on its effect on compressive strength. Figure 7 illustrates that the adverse impact of rubber on flexural strength also comes from rubber content and rubber particle size. Flexural strength decreases with the increasing rubber content. When rubber content changes from 0% to 8%, the flexural strength of the CCR-modified mixture decreases from 4.84 MPa to 2.87 MPa (40.7% loss), and the FCR-modified mixture decreases from 4.84 MPa to 4.01 MPa (17.1% loss), respectively. When the incorporation level is the same, FCR-modified mixtures have a slightly higher flexural strength than CCR, which means that FCR is relatively advantageous for flexural strength. The influence mechanism of rubber on flexural strength is consistent with compressive strength. The relationship between compressive strength and flexural strength of RMPC is listed in Figure 8. The linear regression equation can be used to describe the relationship well. The linear relationship between compressive strength and flexural strength of pervious concrete is the same as ordinary concrete.

Figure 7.

Flexural strength of RMPC versus rubber content.

Figure 8.

Flexural strength of RMPC versus rubber content.

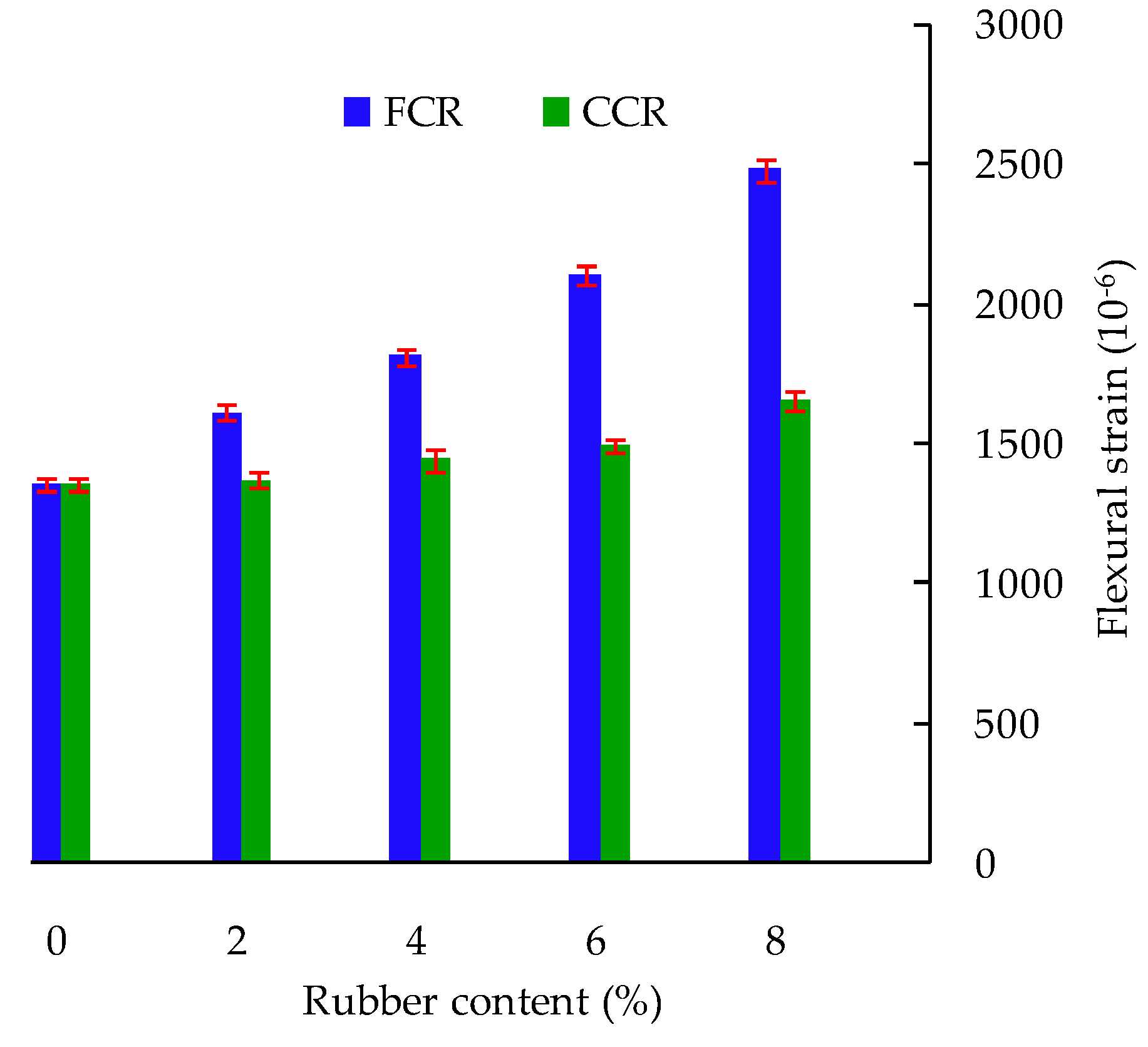

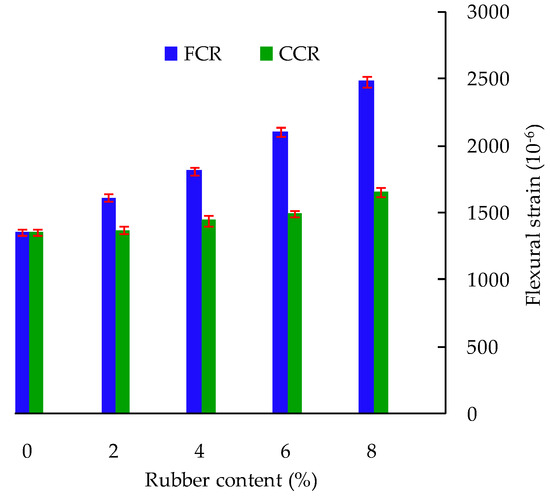

3.1.4. Flexural Strain

Figure 9 illustrates that the flexural strain results for CPC and RMPC increase with increasing rubber content. Generally, flexural strain is a crucial index that characterizes the toughness and ductility of pervious concrete, and a higher flexural strain means greater ductility. As a result, there is an obvious improvement in the flexural strain of RMPC, due to the addition of rubber. This is because the addition of the rubber reduces the stiffness and modulus of elasticity of concrete, thereby making pervious concrete more deformable under flexural load. It is obvious in Figure 9 that the higher the dosage of rubber, the greater the flexural strain.

Figure 9.

Flexural strain of RMPC versus rubber content.

Figure 9 also shows that rubber particle size has a significant effect on flexural strain. Compared to pervious concrete without rubber, FCR has a considerably large improvement, with a maximum flexural strain increase of 42%, while CCR has a slight increase in flexural strain. This is because, as mentioned above, the role of CCR and FCR in pervious concrete is different.

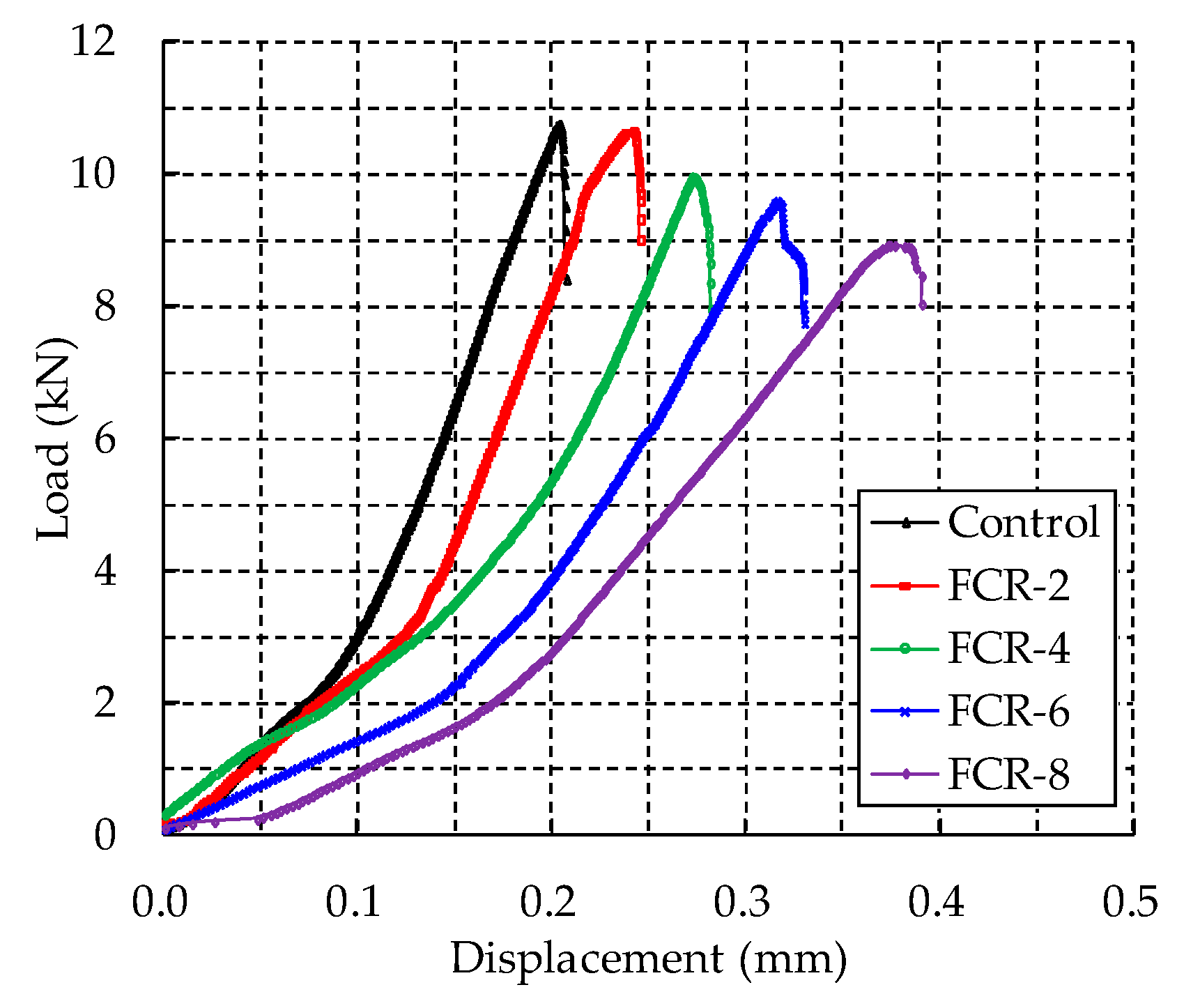

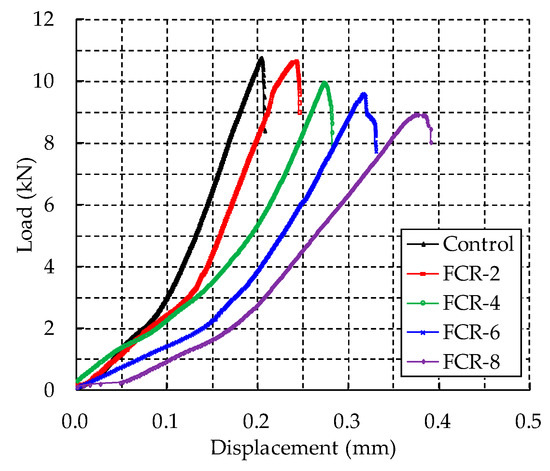

The improvement can also be reflected in the load-displacement curves of FCR-modified mixtures, as shown in Figure 10. When the FCR incorporation level increases from 0% to 8%, the failure load or peak load decrease, the load-displacement curves gradually shift to the right, and deformation increases. This indicates that although the addition of rubber reduces flexural strength, the ductility of pervious concrete is significantly improved.

Figure 10.

Load-displacement curves of fine crumb rubber (FCR)-modified mixtures.

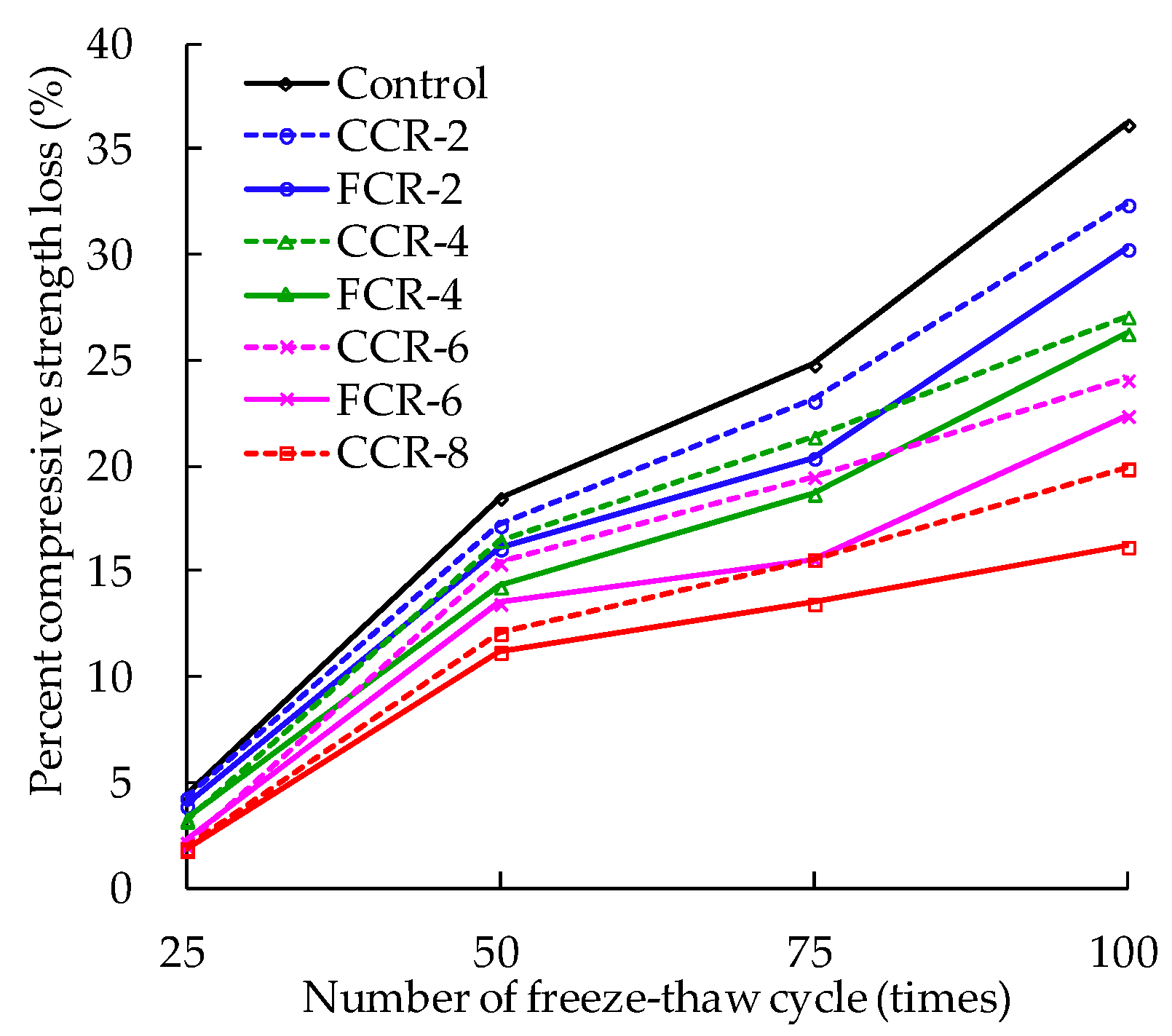

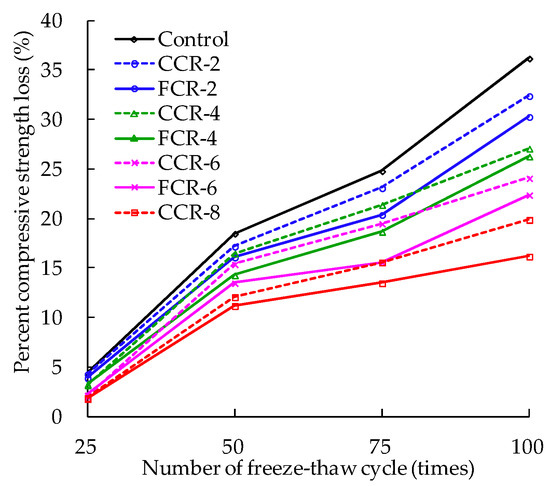

3.1.5. Freeze–Thaw Resistance

The compressive strength loss ratio of CPC and RMPC under freeze–thaw cycles is shown in Figure 11. It can be clearly seen that the compressive strength loss ratios for all mixtures increased with the increasing freeze–thaw cycles. This is because the bonding between the aggregate and cement paste is weakened due to the freeze–thaw cycles. On the other hand, the pore water in the specimen freezes and expands when the specimen suffers freezing, which results in cracks in the concrete. All of these changes are expressed at the macro level as a reduction in compressive strength. The weakening effect of the freeze–thaw cycles on the compressive strength is more and more obvious as the freeze–thaw cycles increase. It is obvious that the strength loss is smaller when the freeze–thaw cycle is lower.

Figure 11.

Compressive strength loss ratio of control pervious concrete (CPC) and RMPC under freeze–thaw cycles.

Furthermore, the content of rubber has a significant effect on the freeze–thaw resistance of pervious concrete. The improvement of the freeze–thaw resistance is obvious as rubber content increases. RMPC has lower strength loss ratios at each freeze–thaw level compared to CPC. The reason is that the addition of rubber reduces the stiffness of concrete and makes concrete a flexible material. Based on this fact, RMPC could better release frozen-heave force and reduce the damage caused by freezing, thus enhancing freeze–thaw resistance.

The test results indicate that rubber particles also have an important effect on freeze–thaw resistance. FCR-modified mixtures present better freeze–thaw resistance compared to CCR-modified mixture at the same level of freeze–thaw cycle, which indicates that smaller rubber particles are more advantageous for freeze–thaw resistance. This is because FCR makes the distribution of frozen-heave force more uniform, which avoids stress concentration and results in a lower frozen-heave force in FCR-modified mixtures.

4. Conclusions

Pervious concrete modified by crumb rubber with different rubber particle sizes and incorporation levels were investigated in the lab. Permeability, compressive strength, flexural strength, flexural strain, and freeze–thaw cycle tests were conducted. The influences of rubber content and particle size on pervious concrete properties were analyzed. Based on the test results, the following conclusions can be drawn.

- The permeability of rubber-modified pervious concrete is lower than that of control pervious concrete. The permeability decreases slightly with the increasing rubber content. Rubber particle size has little effect on permeability.

- The addition of rubber has a negative impact on the compressive strength of pervious concrete. Compressive strength decreases with the increase of rubber incorporation level. Although the addition of rubber reduces the compressive strength of the pervious concrete, it can still meet the requirements of non-structural use. Fine crumb rubber is more advantageous than coarse crumb rubber in modifying pervious concrete without sacrificing excessively compressive strength.

- The influence of rubber content on flexural strength is the same as on compressive strength. There is an obvious linear relationship between the compressive strength and flexural strength of rubber-modified pervious concrete. The addition of rubber enhances the flexural strain of pervious concrete. Flexural strain increases with the increasing rubber incorporation level. Fine crumb rubber significantly improves ductility without severely compromising the compressive strength, contrary to coarse crumb rubber.

- Freeze–thaw resistance of pervious concrete can be improved by the addition of crumb rubber. Rubber-modified pervious concrete has a better freeze–thaw resistance than that of control pervious concrete when subjected to the same freeze–thaw cycles. A high rubber incorporation level generates a high freeze–thaw resistance. Fine crumb rubber is superior to coarse crumb rubber in improving the freeze–thaw resistance of pervious concrete.

Author Contributions

Conceptualization: H.L.; investigation: G.L. and Y.G.; writing (original draf): H.L., G.L., and H.W.; writing (review and editing): Y.G.

Funding

This research was funded by the Science Technology Development Program of Jilin Province (grant number 3D518E022417) and the Transportation Science and Technology Program of Jilin Province (grant number 2018-1-9).

Acknowledgments

The authors would like to appreciate anonymous reviewers for their constructive suggestions and comments to improve the quality of the paper.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Piao, S.L.; Ciais, P.; Huang, Y.; Shen, Z.H.; Peng, S.S.; Li, J.S.; Zhou, L.P.; Liu, H.Y.; Ma, Y.C.; Ding, Y.H.; et al. The impacts of climate change on water resources and agriculture in China. Nature 2010, 467, 43–51. [Google Scholar] [CrossRef] [PubMed]

- Richards, D.R.; Edwards, P.J. Using water management infrastructure to address both flood risk and the urban heat island. Int. J. Water. Resour. D 2017, 34, 490–498. [Google Scholar] [CrossRef]

- Ho, H.L.; Huang, R.; Hwang, H.C.; Lin, W.T.; Hsu, H.W. Waste-based pervious concrete for climate-resilient pavements. Materials 2018, 11, 900. [Google Scholar] [CrossRef] [PubMed]

- Zhu, Z.H.; Chen, X.H. Evaluating the effects of low impact development practices on urban flooding under different rainfall intensities. Water 2017, 9, 548. [Google Scholar] [CrossRef]

- Hu, M.C.; Zhang, X.Q.; Siu, Y.L.; Li, Y.; Tanaka, K.; Yang, H. Flood mitigation by permeable pavements in Chinese sponge city construction. Water 2018, 10, 172. [Google Scholar] [CrossRef]

- Du, S.Q.; Shi, P.J.; Rompaey, A.V.; Wen, J.H. Quantifying the impact of impervious surface location on flood peak discharge in urban areas. Nat. Hazards 2015, 76, 1457–1471. [Google Scholar] [CrossRef]

- Huang, C.L.; Hsu, N.S.; Wei, C.C.; Luo, W.J. Optimal spatial design of capacity and quantity of rainwater harvesting systems for urban flood mitigation. Water 2015, 7, 5173–5202. [Google Scholar] [CrossRef]

- Liu, H.; Jia, Y.W.; Niu, C.W. “Sponge city” concept helps solve China’s urban water problems. Environ. Earth. Sci. 2017, 76, 473. [Google Scholar] [CrossRef]

- Xia, J.; Zhang, Y.Y.; Xiong, L.H.; He, S.; Wang, L.F.; Yu, Z.B. Opportunities and challenges of the sponge city construction related to urban water issues in China. Sci. China Earth. Sci. 2017, 60, 652–658. [Google Scholar] [CrossRef]

- Kim, H.K.; Lee, H.K. Acoustic absorption modeling of porous concrete considering the Gradation and shape of aggregate sand void ratio. J. Sound Vib. 2010, 329, 866–879. [Google Scholar] [CrossRef]

- García, G.D.C.; Treviño, R.B.; Fontaneda, L.A.S.; Muñoz, P.P. Influence of pervious pavement systems on heat dissipation from a horizontal geothermal system. Eur. J. Environ. Eng. 2013, 17, 956–967. [Google Scholar] [CrossRef]

- Ngohpok, C.; Sata, V.; Satiennam, T.; Klungboonkrong, P.; Chindaprasirt, P. Mechanical properties, thermal conductivity, and sound absorption of pervious concrete containing recycled concrete and bottom ash aggregates. KSCE J. Civ. Eng. 2018, 22, 1369–1376. [Google Scholar] [CrossRef]

- Siddique, R.; Naik, T.R. Properties of concrete containing scrap-tire rubber–an overview. Waste Manag. 2004, 24, 563–569. [Google Scholar] [CrossRef] [PubMed]

- Sukontasukkul, P.; Chaikaew, C. Properties of concrete pedestrian block mixed with crumb rubber. Constr. Build. Mater. 2006, 20, 450–457. [Google Scholar] [CrossRef]

- Shakrani, S.A.; Ayob, A.; Rahim, M.A.A. Applications of waste material in the pervious concrete pavement: A review. In Proceedings of the 3rd Electronic and Green Materials International Conference, Aonang Krabi, Thailand, 29–30 April 2017. [Google Scholar]

- Son, K.S.; Hajirasouliha, I.; Pilakoutas, K. Strength and deformability of waste tyre rubber-filled reinforced concrete columns. Constr. Build. Mater. 2011, 25, 218–226. [Google Scholar] [CrossRef]

- Segre, N.; Joekes, I. Use of tire rubber particles as addition to cement paste. Cem. Concr. Res. 2000, 30, 1421–1425. [Google Scholar] [CrossRef]

- Wongsa, A.; Sata, V.; Nematollahi, B.; Sanjayan, J.; Chindaprasirt, P. Mechanical and thermal properties of lightweight geopolymer mortar incorporating crumb rubber. J. Clean. Prod. 2018, 195, 1069–1080. [Google Scholar] [CrossRef]

- Pasandín, A.R.; Pérez, I. Fatigue performance of bituminous mixtures made with recycled concrete aggregates and waste tire rubber. Constr. Build. Mater. 2017, 157, 26–33. [Google Scholar] [CrossRef]

- Wang, X.; Xia, J.; Nanayakkara, O.; Li, Y.S. Properties of high-performance cementitious composites containing recycled rubber crumb. Constr. Build. Mater. 2017, 156, 1127–1136. [Google Scholar] [CrossRef]

- Meddah, A.; Bensaci, H.; Beddar, M.; Bali, A. Study of the effects of mechanical and chemical treatment of rubber on the performance of rubberized roller-compacted concrete pavement. Innov. Infrastruct. Solut. 2017, 2, 17. [Google Scholar] [CrossRef]

- Gonen, T. Freezing-thawing and impact resistance of concretes containing waste crumb rubbers. Constr. Build. Mater. 2018, 177, 436–442. [Google Scholar] [CrossRef]

- Bisht, K.; Ramana, P.V. Evaluation of mechanical and durability properties of crumb rubber concrete. Constr. Build. Mater. 2017, 155, 811–817. [Google Scholar] [CrossRef]

- Azevedo, F.; Pacheco-Torgal, F.; Jesus, C.; De Aguiar, J.B.; Camões, A.F. Properties and durability of HPC with tyre rubber wastes. Constr. Build. Mater. 2012, 34, 186–191. [Google Scholar] [CrossRef]

- Guo, S.; Dai, Q.; Si, R.; Sun, X.; Lu, C. Evaluation of properties and performance of rubber-modified concrete for recycling of waste scrap tire. J. Clean. Prod. 2017, 148, 681–689. [Google Scholar] [CrossRef]

- Chandrappa, A.K.; Biligiri, K.P. Pervious concrete as a sustainable pavement material—Research findings and future prospects: A state-of-the-art review. Constr. Build. Mater. 2016, 111, 262–274. [Google Scholar] [CrossRef]

- Bonicelli, A.; Fuentes, L.G.; Bermejo, I.K.D. Laboratory investigation on the effects of natural fine aggregates and recycled waste tire rubber in pervious concrete to develop more sustainable pavement materials. In Proceedings of the World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium, Prague, Czech Republic, 12–16 June 2017. [Google Scholar]

- Mondal, S.; Biligiri, K.P. Crumb rubber and silica fume inclusions in pervious concrete pavement systems: Evaluation of hydrological, functional, and structural properties. J. Test. Eval. 2018, 46, 892–905. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Khoshnaw, G.; Ipek, S. Investigating properties of pervious concretes containing waste tire rubbers. Constr. Build. Mater. 2014, 63, 206–213. [Google Scholar] [CrossRef]

- Gesoglu, M.; Güneyisi, E.; Khoshnaw, G.; Ipek, S. Abrasion and freezing–thawing resistance of pervious concretes containing waste rubbers. Constr. Build. Mater. 2014, 73, 19–24. [Google Scholar] [CrossRef]

- Liu, H.B.; Luo, G.B.; Wei, H.B.; Yu, H. Strength, permeability, and freeze-thaw durability of pervious concrete with different aggregate sizes, porosities, and water-binder ratios. Appl. Sci. 2018, 8, 1217. [Google Scholar] [CrossRef]

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Technical Specification for Pervious Cement Concrete Pavement; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Method of Mechanical Properties on Ordinary Concrete; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2002. (In Chinese)

- Ministry of Housing and Urban-Rural Construction of the People’s Republic of China. Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete; Ministry of Housing and Urban-Ural Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).