Featured Application

A potential application is to develop a slow release fertilizer of biochar pellet type based on selected optimum biochar pellet.

Abstract

For the recycling of biomass conversion materials, this experiment was conducted to investigate plant nutrient releasing characteristics, and to determine an optimum blended ratio of biochar for producing a biochar pellet based on a column leaching study. The treatments consisted of only pig manure compost (PMC) as a control, pig manure compost pellets (PMCP), and biochar pellets (BCP) blended with biochar and pig manure compost with the following ratios: 9:1, 8:2, 4:6, and 2:8. Results showed that the accumulated amount of ammonium nitrogen (NH4-N) was in order of PMC > PMCP > BCP (2:8) > BCP (4:6) > BCP (8:2) > BCP (9:1) ratios. The highest accumulated amounts of phosphate phosphorus (PO4-P) and potassium (K) were 1953 and 1917 mg L−1 in the PMC and PMCP, but the lowest in the BCP (9:1) were 223 and 1078 mg L−1, respectively. It was shown that the highest accumulated amount of silicon dioxide (SiO2) was 2329 mg L−1 in the BCP (8:2), but the lowest in the PMC was 985 mg L−1. The estimations for accumulated NH4-N, PO4-P, K, and SiO2 releasing amounts in all the treatments were significantly fitted with a modified Hyperbola model. The optimum mixing rate was estimated to be BCP (2:8). Therefore, biochar pellets might be useful in obtaining basic information on slow-release fertilizer for sustainable agriculture.

1. Introduction

Technology of carbon sequestration (C seq.) and mitigation of carbon dioxide equivalency (CO2-equiv.) emissions need to be developed by using by-products of agricultural biomass through carbon-recycle systems in cropland. By-products from agricultural biomass consist of carbonaceous materials such as rice hulls, crop residues, trimming branches, animal waste, and bio-waste from fruit and vegetable markets. In Korea’s agricultural sector, the total potential biomass production is estimated at 58,010 Gg yr−1 [1], which can be converted into a less non-degradable form through biomass conversion technology.

Biochar, a porous and carbonaceous material obtained from biomass conversion with thermal treatment under limited oxygen, is one practical option for soil carbon sequestration. It contains a non-degradable structural carbon with double bonds and an aromatic ring that cannot be broken down by microbial organism activities [2]. The produced biochar could be utilized for several purposes [3] However, in its application, 30% is lost due to wind, while 25% is lost during spreading in cropland [4]. On the other hand, one disadvantage of biochar application in the field is the presence of fine dust caused by wind during the spreading of biochar, which could affect farmer’s respiratory organs.

The application of 5% biochar produced at 700 °C had the most significant C seq. during rice and leaf beet cultivation [5]. For cropland C seq., Shin et al. [6] reported that C seq. is highest at 2.3 tons ha−1 in corn fields incorporated with biochar and cow manure compost. The mitigation of CO2-equiv. emission is estimated at 7.3 to 8.4 T ha−1 and profits ranged from $57 to $163 when incorporated with 2600 kg ha−1 of biochar in corn fields.

Biochar’s effects in agro-ecology have been suggested to come from the plant’s sorption and retention abilities of available nutrients [7]. Biochar from holm oak tree (Quercus ilex) increased ammonium nitrogen (NH4-N) adsorption in sandy acrisol associated with humid and tropical climates, but had no effect on nitrate nitrogen (NO3-N) sorption in the column experiment [8]. However, the largest amount of sorption of NH4-N and binding strength, constant for biochar derived from rice husks, have been calculated as 0.5 mg L−1 and 0.03 mg L−1, respectively [9]. Shin [10] reported that rates of nitrogen (N) mineralization and nitrification are low in corn fields incorporated with biochar, compared to plots with different organic composts alone. These could be attributed to the sorption capacity of NH4-N to biochar.

Phosphorous (P) and potassium (K) are essential elements for both crop growth and the maintenance of crop productivity [11,12]. The maximum sorption amount and binding strength constant of PO4-P are estimated at 0.1 mg L−1 and 0.06 mg L−1, respectively, for biochar derived from oak tree [13]. K deficiency in soil is mainly due to presence of 90% to 98% of insoluble K forms or due to the high soluble form of the available K [14,15,16,17]. Crop residues of rice and sugarcane contain applicable amounts of silicon (Si) [18,19]. Si plays an important role in plant cell wall strength and insect defense, as well as nutrient uptake improvement [20,21,22]. Plant silicon is thought to be a recycling Si pool that can be accumulated in surface soil after litter fall and recovered from plant decomposition [23].

A biochar pellet is one option to reduce fine dust and biochar loss by strong wind and intensive rainfall, thus decreasing handling and storage costs [24]. For soil incorporation, poultry litter was mixed, pelletized, and slowly pyrolyzed to produce biochar pellets [25]. Shin et al. [26] indicated that biochar pellets mixed with organic compost could be a promising option for soil C seq. and control of major plant nutrients during crop cultivation. Biochar pellets mixed with various ratios of pig manure compost was induced, and its sorption capacity and kinetic models have already been investigated [26]. For sorption test of NH4-N with various loading rates, it has been shown that the maximum sorption of NH4-N in the biochar pellet is 2.94 mg g−1 where lettuce yield increased at approximately 13% relative to the control. However, there is little information on major plant releasing nutrient from the biochar pellet during leaching periods.

For the releasing model, Loney and Tabatabaie presented the leaching behavior of heavy metals from solidified and stabilized forms of biofilms using Michaelis–Menten kinetics [27]. The used model predictions confirmed that Michaelis–Meten-type kinetics is probably the most dominant mechanism for the leaching of heavy metals from cement based waste forms. Furthermore, Michaelis–Menten kinetics has been used to explore the nitrogen deposition and climate change with laboratory manipulations [28].

It is hypothesized that (1) blended biochar pellets could prolong the nutrient releasing period, and could be affected by their nutrient releasing characteristics. In addition, (2) tests should be conducted to see whether biochar pellets fit a modified Hyperbola model.

Therefore, this experiment was conducted to investigate the plant nutrient releasing characteristics, and to determine an optimum blended rate of biochar for the production of biochar pellets using a modified Hyperbola model.

2. Materials and Methods

2.1. Biochar Pellet Production

Biochar from rice hull was collected from a local farming cooperative society in Go-Chang, JenBok, Korea. The pig manure compost was purchased from the company (NOUSBO Co., Suwon, Korea) having a nationwide distribution network. The biochar was produced from a pyrolysis system and applied with “top to bottom method”. This pyrolysis system consisted of rice hull burning from the upper part, thus almost excluded oxygen from outside of the system. The loading volume of rice hull was 1.5 m3, and the temperature of pyrolysis process ranged from 400 to 500 °C during 4 h. The produced biochar was ground in a grinder and roller to pass through a 2 mm sieve before analysis. Physiochemical properties of biochar and pig manure compost used are presented in Table 1. The biochar was generally alkaline in nature (pH 9.8) and low in total nitrogen (TN) (2.0 g kg−1). The content of total hydrogen (T-H) and H: C ratios were 17.6 g kg−1 and 0.031, respectively.

Table 1.

Characteristics of biochar and pig manure compost used 1.

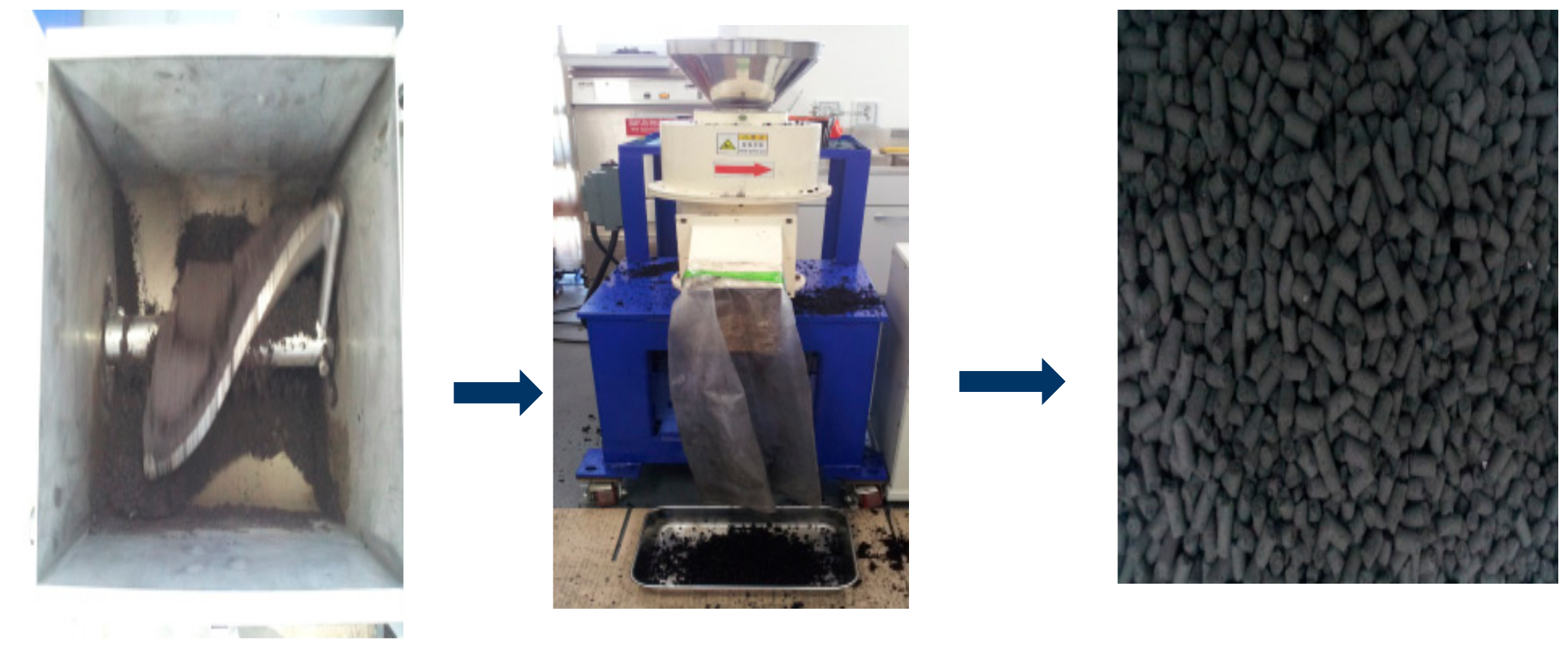

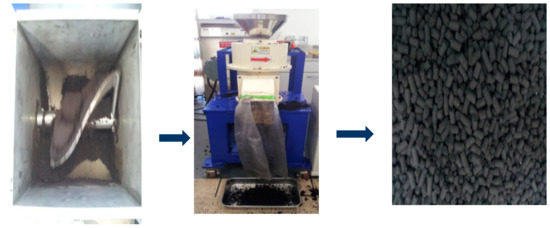

Prior to pelletizing, biochar was sieved using a series of sieves (0.5 mm to 5 mm) to measure the particle distribution. It was then blended with pig manure compost as a binder to produce a biochar pellet. The combination ratios of biochar and pig manure compost were 9:1, 8:2, 6:4, and 2:8 (w/w), and the size of biochar pellet was Ø 0.51 cm × 0.78 cm. The blended materials (total weight = 2.5 kg) were thoroughly mixed using an agitator (SungChang Co., KyungGi, Korea) for 5 min. Then, while continuously mixing, the combination was sprayed with 1000 mL of deionized water for 10 min. The biochar pellet produced through the pellet machine (7.5 KW, 10 HP, KumKang Engineering Pellet Mill Co., DaeGu, Korea) with the combination of biochar and pig manure compost is described in the Figure 1.

Figure 1.

Processing diagram of the biochar pellet with different combinations of biochar and pig manure compost described by Shin et al. (2018) [26].

2.2. Batch Experiment for Nutrient Leaching Test

The treatments consisted of pig manure compost (PMC) as a control, pig manure compost pellet (PMCP), and various ratios of biochar pellets (BCP) blended with 2:8, 4:6, 8:2, and 9:1 of biochar/pig manure compost (w/w) in order to test the feasibility of developing a slow-release fertilizer.

For the nutrient releasing experiment, the size of the glass column was Ø 24 mm × 40 cm with each column filled with 5 g of PMC, PMCP and different blended BCP, respectively. The column was poured into 50 mL of deionized water, completely drained, and then immediately refilled after certain retention time. The water samples were collected at 50 mL of drained water through the column until 84 days of leaching periods.

2.3. Chemical Analysis

The biochar and pig manure compost was taken to the National Institute of Agricultural Sciences (NIAS) to analyze the chemical properties. The pH and EC (electrical conductivity) of the biochar and pig manure compost was measured using a pH/EC meter (Orion 4 star, Thermo scientific, Singapore) at a 1:20 solid/water ratio (biochar:de-ionized H2O) after shaking for 30 min in a water bath (P/NTS-3000, Eyela, Kyoto, Japan) at 140 rpm. The analytical chemical properties, such as total carbon (TC) and total organic carbon (TOC), were analyzed by a TOC analyzer (Elementar Vario EL II, Hanau, Germany) for biochar and pig manure compost. Total hydrogen was analyzed by Elemental Analyzer (Vario MACRO cube, Elementar, Langenselbold, Germany). Total P, K, and Si in the biochar and pig manure compost were measured by inductively coupled plasma atomic emission spectrometry (ICP-AES, IntegraXL, GBC LTd., Braeside, Australia) after samples were digested with nitric and hydrochloric acids.

The collected water samples were filtered using Whatman #2 filter paper, and then analyzed for NH4-N, PO4-P, K, and SiO2 by using a UV spectrophotometer (C-Mac Co., Jenmin Dong, Dae-Jen, Korea) [26] through whole leaching periods.

2.4. Releasing Models

Michaelis–Menten, a general used model of substrate based kinetics, describes a saturating function of substrate concentration with parameters Vmax, the maximum reaction velocity, and kM, the half saturation constant, which corresponds to the substrate concentration [S] when Vmax/2. This model was used to predict the accumulated amounts of released material as a function of leaching periods. Therefore, a modified Hyperbola model from Michaelis–Menten equation used is shown below;

Y: accumulated concentration (mg L−1); Amax: maximum accumulated concentration (mg L−1); t1/2(Amax): required time to reach 1/2 Amax; t: leaching periods (days).

Y = Amax [t]/(t1/2(Amax) + [t])

2.5. Statistical Analysis

The statistical analyses for total water-soluble amounts of NH4-N, PO4-P, K, and SiO2 were performed using a one-way ANOVA with 6 levels, using SAS version 9.0 (SAS Institute, Carry, NC, USA). Duncan multiple range test was used for accessing significant differences (p < 0.0001) among treatment means during leaching periods. Means of variables were compared with parameters among treatments by using the above equation according to p-values < 0.0001 after analysis of variances (ANOVA). The validity of a modified Hyperbola model for each parameter was assured for normal distribution by Shapiro–Wilk test (p < 0.05). The releasing model for each nutrient was established by data analysis using SigmaPlot 12 (Systat Software, Inc., San Jose, CA, USA). The model used was calculated using the equation based on correlation coefficient values (R2).

3. Results

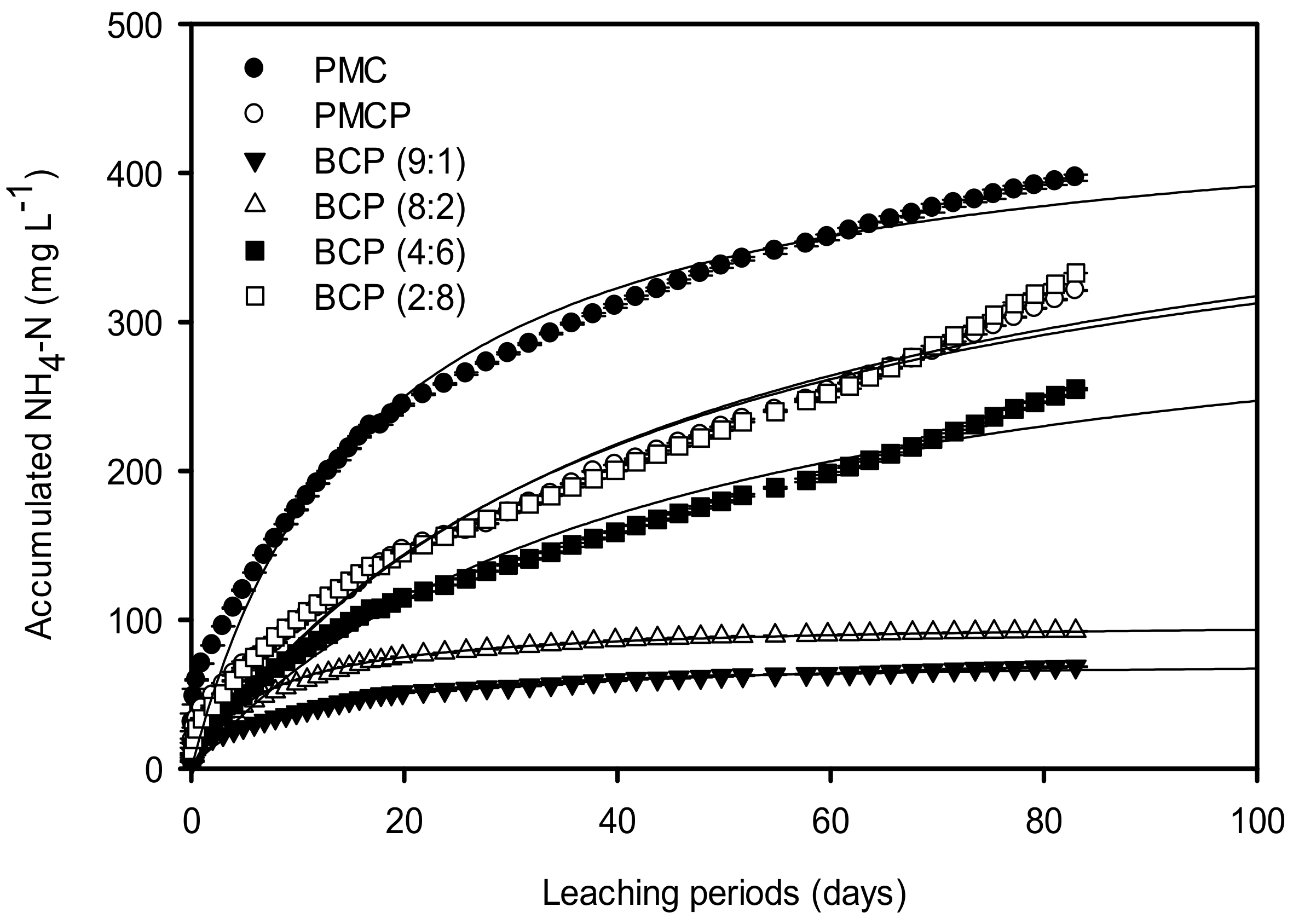

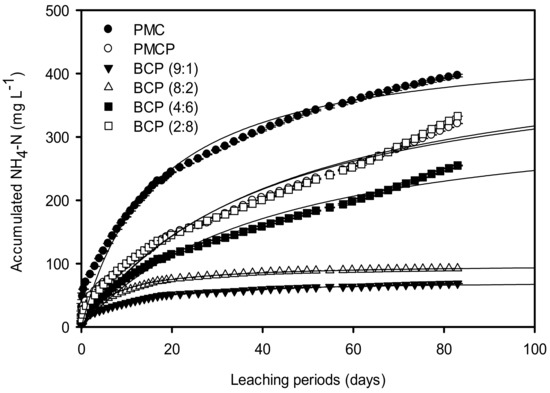

It was observed that the more biochar contained within the biochar pellet, the greater sorption of NH4-N. For accumulated NH4-N releasing amount, the order was PMC > PMCP ≥ BCP (2:8) > BCP (4:6) > BCP (8:2) > BCP (9:1) ratios, and the highest accumulated amount in the PMC was 397 mg L−1 (Figure 2).

Figure 2.

Effects of NH4-N accumulated concentrations in the releasing water from biochar pellet blended with various ratios of pig manure compost during leaching periods.

The estimation parameters for an accumulated NH4-N releasing amount from different types of biochar pellets are presented in Table 2. The model was significantly correlated with the R2 values between the observed and estimated values. The maximum accumulated NH4-N releasing amount was observed in PMC even if same amount of pig manure compost between PMC and PMCP was used in the leaching column. This might be due to the increase mass of pig manure compost. However, the required time to reach half of the maximum accumulated amount in PMC was taken only 16 at days, but was 41 days in PMCP. Therefore, pelletization could reduce the releasing rates of NH4-N even if the same loading amount of material was used. The greater accumulated amount and longer leaching periods were observed in the BCP (2:8 and 4:6). The estimated releasing model was significantly fitted with all treatments (Table 2).

Table 2.

Estimation model for accumulated NH4-N releasing from different combination rates of biochar pellets.

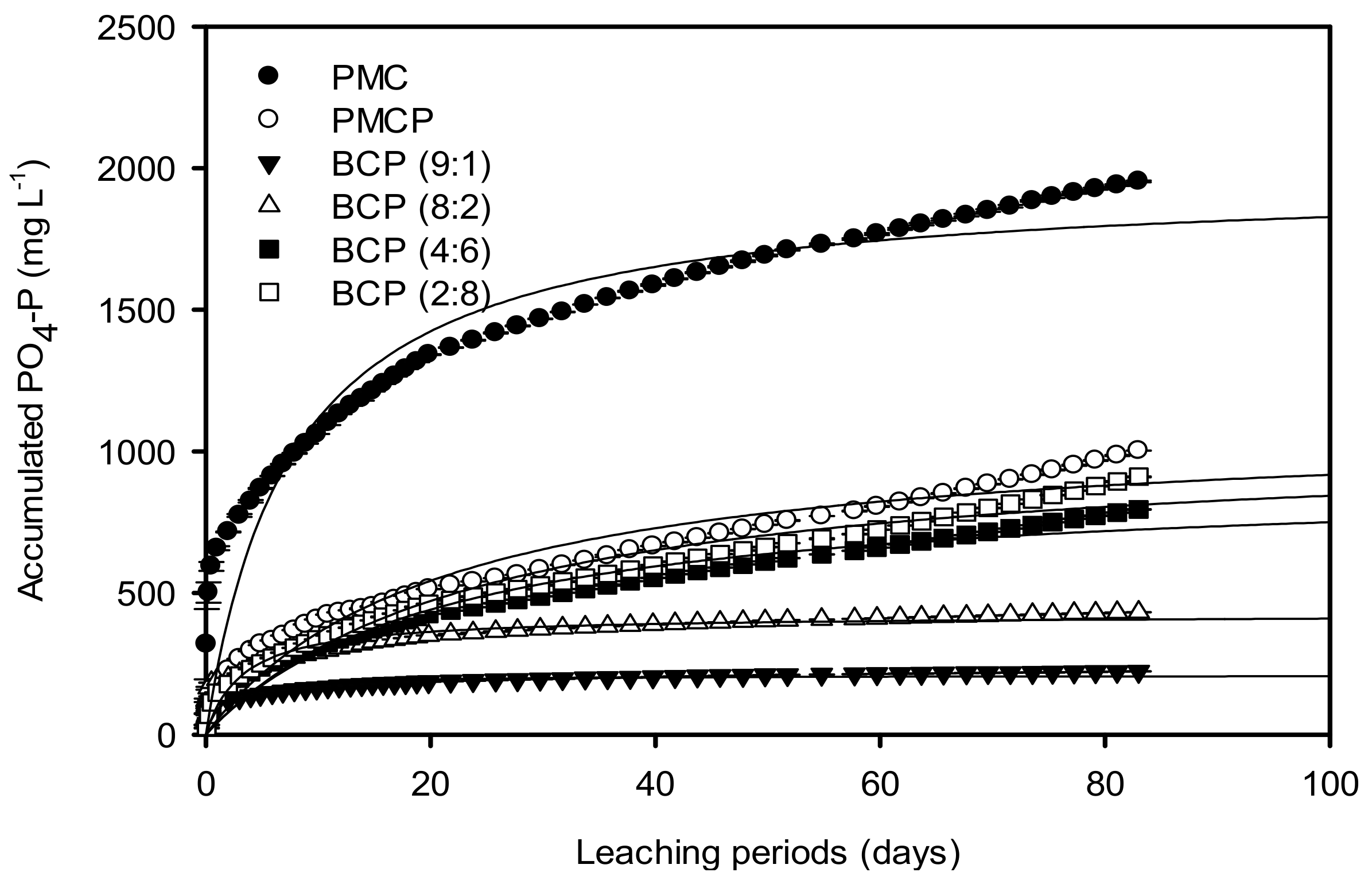

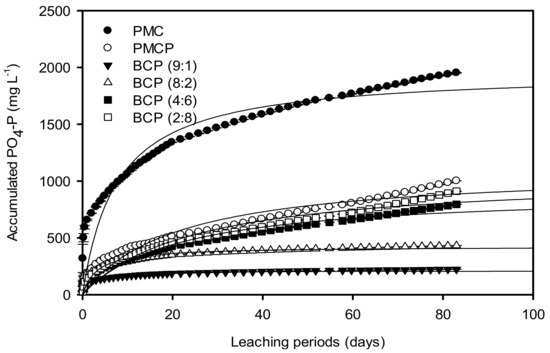

The accumulated amount of PO4-P was not significantly different with biochar pellets which contained 0 to 40% of biochar during leaching periods. It was shown that the highest accumulated amount of PO4-P in the PMC was 1953 mg L−1 and the lowest in the BCP (9:1 ratio) was 223 mg L−1 (Figure 3). This could be attributed to the high concentration of PO4-P in the PMC. However, this could also result in the slower release of PO4-P in the PMCP than that found in the PMC because of the change in the physical characteristics in pelletization of pig manure compost.

Figure 3.

Effects of accumulated PO4-P concentrations in the releasing water from biochar pellet blended with various ratio of pig manure compost.

The curves fit was derived from the estimation model calculated by a modified equation based on correlation coefficient values (R2). The estimation models for accumulated PO4-P releasing amount from different ratios of biochar pellets showed that estimation values from a modified equation were significantly correlated with the observed values for accumulated PO4-P releasing amount in all treatments (Table 3). The required time of 1/2 maximum accumulated PO4-P amount was taken 21 days in the PMCP and BCP (4:6). Similar patterns for the estimation model were observed in the accumulated NH4-N releasing models (Table 2 and Table 3). The estimated releasing model has significantly fit with all the treatments (Table 3).

Table 3.

Estimation model for accumulated PO4-P releasing amount from different types of biochar pellets.

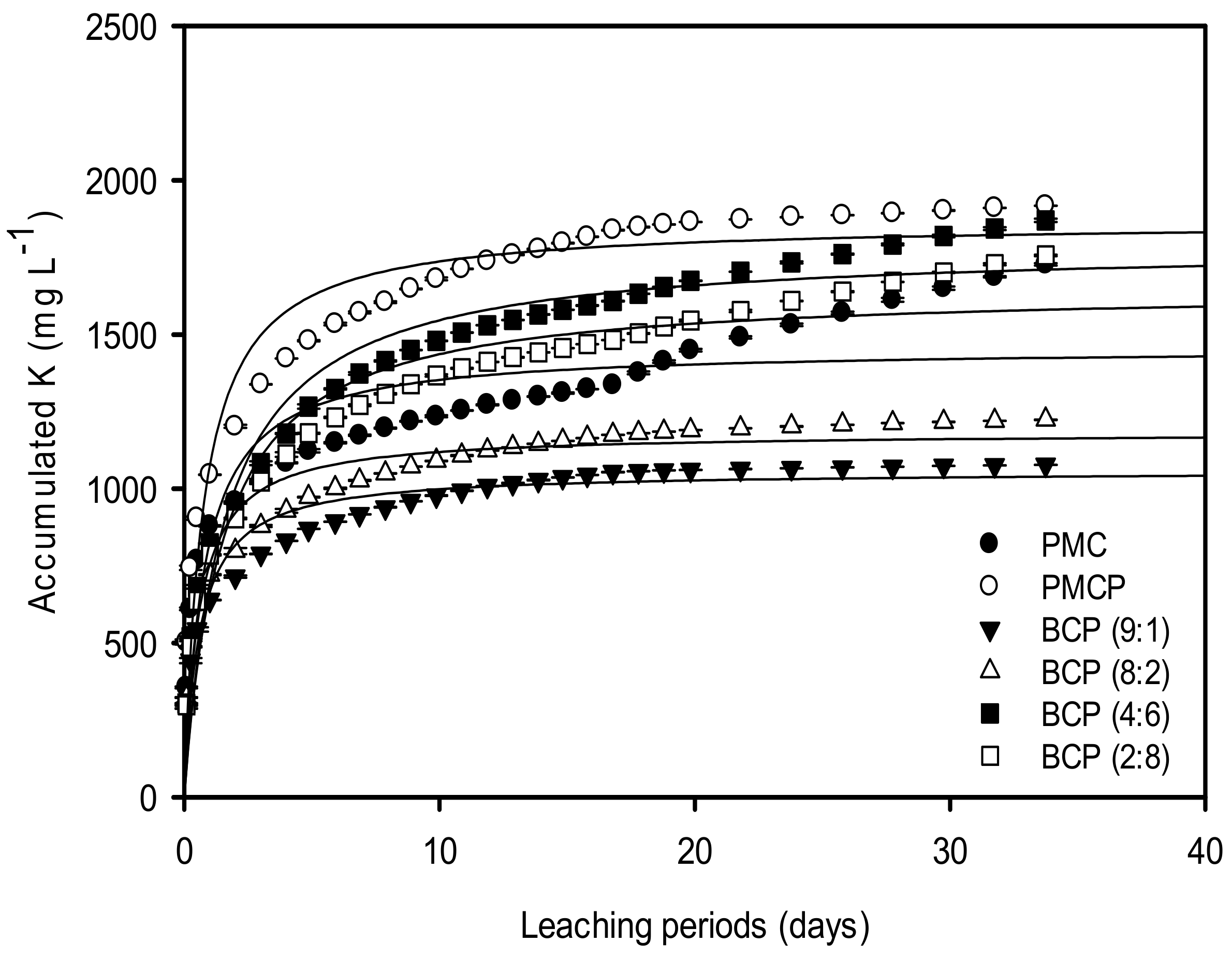

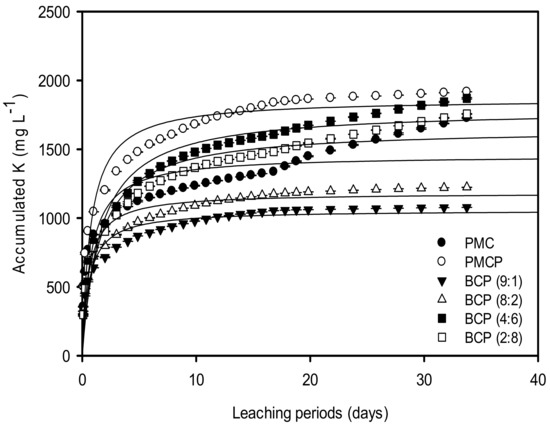

The highest accumulated amount of K in the PMCP was 1917 mg L−1 and the lowest in the BCP (9:1) was 1078 mg L−1. It appeared that accumulated amounts of K abruptly increased at the early leaching stage, and gradually increased at later stages (Figure 4).

Figure 4.

Effects of accumulated K concentrations in the releasing water from biochar pellet blended with various ratios of pig manure compost.

The estimation model for K accumulated amount from different types of biochar pellets is presented in Table 4. The estimation values calculated from the modified equation were significantly correlated with the observed values for K releasing, regardless of combinations of biochar pellets. Most of K was released within 2 days of leaching periods. The estimated releasing model for the modified equation significantly fits with all the treatments (Table 4).

Table 4.

Estimation model for accumulated K releasing amount from different types of biochar pellets.

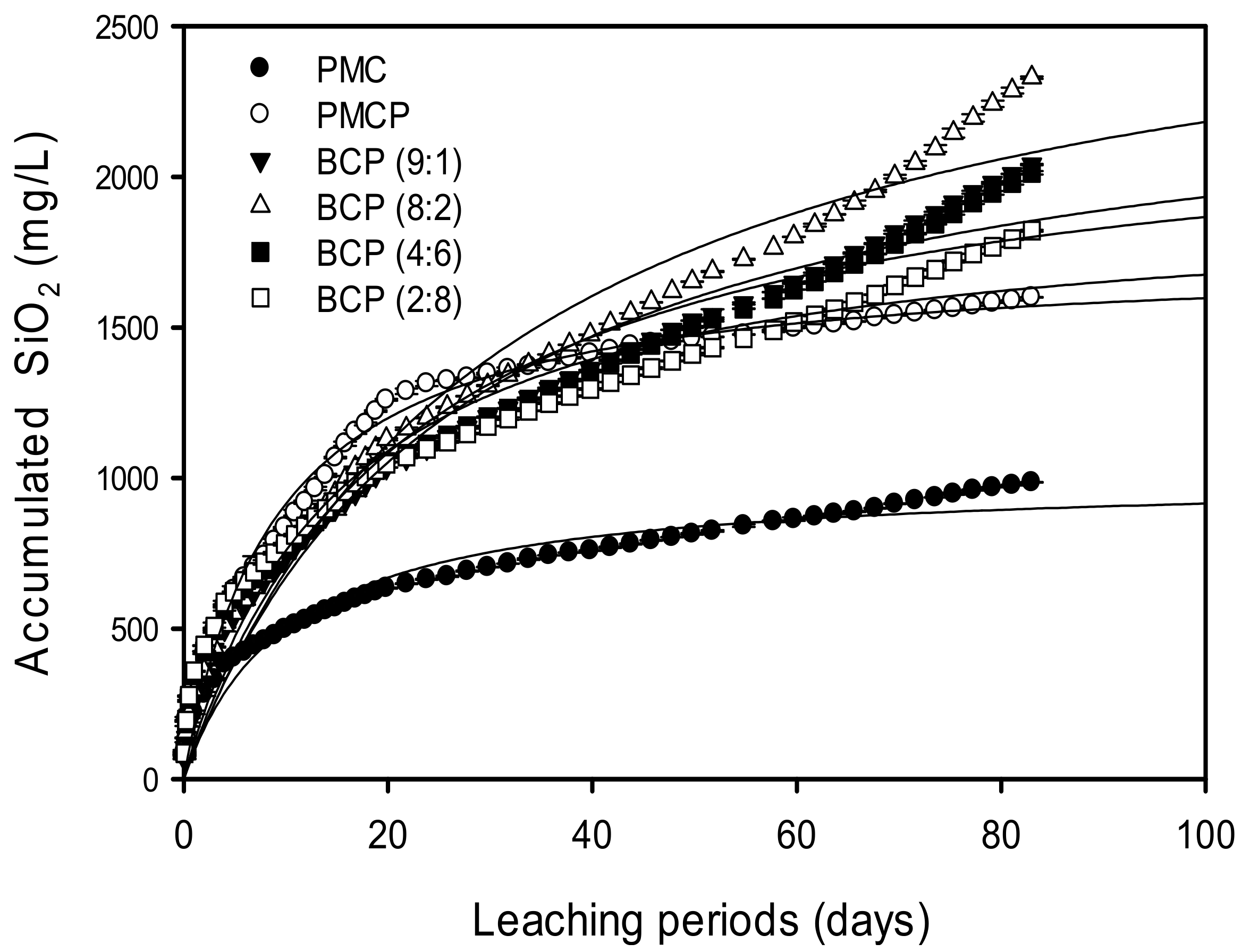

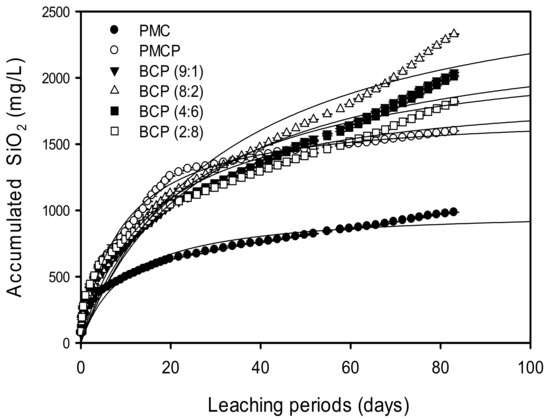

It has appeared that the highest accumulated amount of SiO2 in the PMCP was 1259 mg L−1, but the lowest in the PMC was 634 mg L−1 at 20 days of leaching periods (Figure 5). Following this, it then decreased after that period even if it did not contain biochar from rice hull. The estimation model for accumulated SiO2 releasing amount from different BCP is presented in Table 5. The estimation values calculated from a modified equation were significantly correlated with the observed values for accumulated SiO2 releasing amount regardless of combination rates of biochar pellets. The estimated releasing model equation was had a highly significant fit with whole treatments (Table 5).

Figure 5.

Effects of accumulated SiO2 concentrations in the releasing water from biochar pellet blended with various ratios of pig manure compost during leaching periods.

Table 5.

Estimation model for accumulated SiO2 releasing amount from different types of biochar pellets.

It was observed that the estimation model for accumulated NH4-N, PO4-P, and SiO2 releasing amounts in the biochar pellet was a significantly fit with this modified equation regardless of combination ratios of biochar and pig manure compost. In aspect of 1/2 releasing amount, the BCP (8:2) could be better for crop uptake and reduced application amount of Si fertilizer.

The total water soluble amounts of NH4-N, PO4-P in PMC were significantly higher than those of PMCP, but soluble amounts of K and SiO2 in PMC were significantly lower than those of PMCP during leaching period (Table 6). However, it is observed that accumulated amounts of water soluble NH4-N, PO4-P, K and SiO2 were usually greater in the BCP (2:8 and 4:6) compared to the PMC (Table 6).

Table 6.

Comparisons of total water-soluble accumulated amounts of NH4-N, PO4-P, K, and SiO2 for different treatments during leaching periods.

4. Discussion

4.1. Patterns of Accumulated NH4-N Releasing Amount with Different Pellets and Application of a Modified Hyperbola Model

Nitrogen fertilizers generally occur in chemical transformations such as ammonification, nitrification, denitrification, nitrogen fixation, and immobilization in soil [29,30]. Urea is widely applied as nitrogen fertilizer due to the rapid release of N to soil, from which plants use only 40%, and 60% is lost in different ways [31]. The maximum evaporative loss was estimated to be from 26.5% to 29.4%, which contributes to greenhouse gases. Therefore, a slow N releasing fertilizer is the best way to minimize N2O emission from soil [32]. In the NH4-N accumulation amount during leaching periods, it was observed that the greater biochar, the less releasing amount there is. This reason for this might be attributed to the NH4-N sorption in the biochar. This finding might be attributed to the previous experimental result, showing that the higher the amount of biochar contained in the pellet, the greater the sorption of NH4-N [26]. It might be assumed that Mg, NH4-N, and PO4-P in the biochar and pig manure compost could be synthesized to struvite [Mg (NH4)2PO4·6H2O] as slow-release fertilizer during processing time of biochar pellet. Prakongkep et al. (2015) reported that the soluble compounds of total Mg and total P contained 1% to 21% and 1% to 33%, respectively, in biochar [33].

For applying the releasing model of a modified Hyperbola model, it was observed that there was a basic law that greatly reduced the NH4-N release from the BCP treatments compared to the PMC because of changes of its physical properties with pelletization. In addition to the biochar pellets with various combination rates of pig manure compost, the accumulated NH4-N and PO4-P releasing amounts in the BCP treatments decreased from 49% to 91% and from 61% to 91.3% more than those of the PMC, respectively. Therefore, these biochar pellets had more potential ability on greenhouse gas emission reduction, as well as eutrophication than that of PMC when applied to cropland for agricultural sustainability.

4.2. Pattern of Accumulated PO4-P, K and SiO2 Releasing Amounts with Different Pellets and Appication of a Modified Hyperbola Model

A large amount of nitrogen and phosphate fertilizer is applied to soil every year to increase soil fertility. Yearly, the present consumption of rock phosphorous as fertilizer is over one million tons [34]. Excessive phosphorous in lakes and ponds is a major cause of eutrophication, which occurs on a global scale and destroys aquatic ecosystems [35]. Accelerated eutrophication not only affects aquatic ecosystems, but also indirectly inhibits economic progress [36]. Muriate of potassium chloride (KCl) is applied as a dominant chemical fertilizer to supply available K to crops [37]. Si is usually taken up by plant as an uncharged monosilicic acid (H4SiO4), and polymerized silica gel (SiO2-nH2O) is known to be as high as 90% of soluble phytolith formed in plants [38]. Biochar application increased soil and plant available Si content in the shoot of crops [39,40]. Biochar pellet is important in improving the sustainable agricultural ecosystem by providing plant nutrients as well as carbon sequestration.

For total water-soluble accumulated amounts of major plant nutrients, there was high level of significant difference (p < 0.0001) among all treatments (Table 6). It was observed that the total water-soluble accumulated amounts in the BCP (2:8) were significantly highest for NH4-N, PO4-P, K, and SiO2 except for the BCP (8:2) compared to the PMC. For applying a modified Hyperbola model, the slightly reduced releasing PO4-P fitted with this modified equation from the PMCP treatment compared to the PMC according to pelletization of pig manure compost. Furthermore, even though the accumulated PO4-P in the BCP (4:6) reduced by 74.4% compared to the PMC, there was not much difference due to decreased input of pig manure compost with low releasing and binding ability. In the result of estimating the K releasing model, the releasing K amounts slightly decreased from 4.3% to 45.3% in the BCP treatments except for the BCP (4:6) compared to the PMC. However, the releasing SiO2 amounts in the BCP (4:6 and 2:8) increased by 21.8% and 30.3%, respectively, compared to the PMC. It was determined that greater releasing amount and longer releasing periods were observed in the BCP (2:8 and 4:6) based on modified Hyperbola model. However, all the plant nutrients except BCP (9:1 and 8:2) need to extend the leaching periods for equilibrium state with the other treatments.

Overall, the releasing pattern of major plant nutrient for pelletization of pig manure compost could be proposed, as Shin’s principal releasing law that NH4-N and PO4-P releasing accumulated amount in the PMCP are decreased relative to the PMC, but SiO2 in the PMCP increased compared to the PMC, with modified Hyperbola model.

However, the nutrient release pattern of biochar pellet was usually highly influenced by soil environment. Therefore, there is a need to develop a slow-release fertilizer of biochar pellet type based on selected optimum biochar pellet. For further study, an assessment of agro environmental impacts for slow-release fertilizer of biochar pellet type during crop cultivation will be performed.

5. Conclusions

This experiment was conducted to investigate the nutrient releasing characteristics, and to determine an optimum ratio for processing biochar pellets based on a modified Hyperbola model in terms of potential mitigation of greenhouse gas emissions and carbon sequestration. For accumulation amount of NH4-N releasing, the order was PMC > PMCP > BCP (2:8) > BCP (4:6) > BCP (8:2) > BCP (9:1) ratios, and the highest accumulated amount in the PMC treatment was 397 mg L−1. For the accumulation amount of NH4-N in the BCP during leaching periods, it was shown that the greater the amount of biochar contained the greater accumulated amount except for BCP (2:8). The highest accumulated amounts of PO4-P and K in the PMC were 1953 and 1727 mg L−1, and the lowest in BCP (9:1) were 223 and 1078 mg L−1, respectively. The highest accumulated amount of SiO2 in the BCP (8:2) was 1307 mg L−1, but the lowest in the PMC was 704 mg L−1 at 30 days of leaching periods.

For releasing model for pellets, the releasing patterns of major plant nutrients could be proposed as Shin’s principal releasing law that NH4-N and PO4-P releasing accumulated amounts in the PMCP are decreased, but SiO2 in the PMCP significantly increased compared to the PMC as control. The optimum blended rate was estimated to be BCP (2:8) for major releasing plant nutrients based on a modified Hyperbola model.

Therefore, the biochar pellet might be used for further research on slow-release fertilizer for sustainable agriculture.

Author Contributions

J.S. and S.P. compiled numerical tables and graphs and completed the writing of this paper. Finally, the writing was reviewed by J.S.

Funding

This research was funded by the National Institute of Agricultural Sciences, Rural Development Administration beyond Research Program of Agricultural Science & Technology Development (Project No. PJ013814012018).

Conflicts of Interest

The author declares no conflict of interest.

References

- Shin, J.; Hong, S.; Kim, S.; Yang, J.; Lee, S.; Li, F. Estimation of potential methane production through the mass balance equations from agricultural biomass in Korea. Appl. Biol. Chem. 2016, 59, 765–773. [Google Scholar] [CrossRef]

- Liu, W.J.; Jiang, H.; Yu, H.Q. Development of biochar-based functional materials: Toward a sustainable platform carbon material. Chem. Rev. 2015, 115, 12251–12285. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhang, L.; Li, A. Hydrothermal co-carbonization of sewage sludge and pinewood sawdust for nutrient-rich hydrochar production: Synergistic effects and products characterization. J. Environ. Manag. 2017, 201, 52–62. [Google Scholar] [CrossRef] [PubMed]

- Husk, B.; Major, J. Commercial Scale Agricultural Biochar Field Trial in Quebec, Canada, Over Two Years: Effects of Biochar on Soil Fertility, Biology, Crop Productivity and Quality; Blue Leaf Inc.: Drummondville, QC, Canada, 2008. [Google Scholar]

- Lai, W.; Lai, C.; Ke, G.; Chung, R.; Chen, C.; Cheng, C.; Pai, C.; Chen, S.; Chen, C. The effects of woodchip biochar application on crop yield, carbon sequestration and greenhouse gas emissions from soils planted with rice or leaf beet. J. Taiwan Inst. Chem. Eng. 2013, 44, 1039–1044. [Google Scholar] [CrossRef]

- Shin, J.D.; Hong, S.G.; Lee, S.; Hong, S.; Lee, J. Estimation of soil carbon sequestration and profit analysis on mitigation of CO2-eq. emission in cropland cooperated with compost and biochar. Appl. Biol. Chem. 2017, 60, 467–472. [Google Scholar] [CrossRef]

- Ding, Y.; Liu, Y.; Liu, S.; Li, Z.; Tan, X.; Huang, X.; Zeng, G.; Zhou, L.; Zheng, B. Biochar to improve soil fertility. A review. Agron. Sustain. Dev. 2016, 36, 36. [Google Scholar] [CrossRef]

- Teutscherova, N.; Houska, J.; Navas, M.; Masaguer, A.; Benito, M.; Vazquez, E. Leaching ammonium and nitrate from Acrisol and calcisol amended with holm oak biochar: A column study. Geoderma 2018, 323, 136–145. [Google Scholar] [CrossRef]

- Choi, Y.; Shin, J.; Lee, S.; Kim, S. Adsorption characteristics of aqueous ammonium using rice hull-derived biochar. Korean J. Environ. Agric. 2015, 34, 115–160. [Google Scholar] [CrossRef]

- Shin, J.D. Nitrogen transformation in soil cooperated with organic composts and bio-char during corn (Zea mays) cultivation. J. Korea Org. Resour. Recycl. Assoc. 2014, 22, 33–40. [Google Scholar]

- Almeelbi, T.; Bezbaruah, A. Nanoparticle-sorbed phosphate: Iron and phosphate bioavailability studies with spinacia oleracea and selenastrum capricornutum. ACS Sustain. Chem. Eng. 2014, 2, 1625–1632. [Google Scholar] [CrossRef]

- Zhao, L.; Cao, X.; Zheng, W.; Scott, J.W.; Sharma, B.K.; Chen, X. Copyrolysis of biomass with phosphate fertilizers to improve biochar carbon retention, slow nutrient release, and stabilize heavy metals in soil. ACS Sustain. Chem. Eng. 2016, 4, 1630–1636. [Google Scholar] [CrossRef]

- Choi, Y.; Kim, S.; Shin, J. Adsorption characteristics of aqueous phosphate using biochar derived from oak tree. J. Korea Org. Resour. Recycl. Assoc. 2015, 23, 60–67. [Google Scholar] [CrossRef]

- Kumar, D. Definitional Glossary of Agricultural Terms; IK International Pvt Ltd.: Delhi, India, 2008; Volume 1, p. 218. [Google Scholar]

- Romheld, V.; Kirkby, E.A. Research on potassium in agriculture: Needs and prospects. Plant Soil 2010, 335, 155–180. [Google Scholar] [CrossRef]

- Kinekar, B.K. Potassium fertilizer situation in India: Current use and perspectives. Karnataka J. Agric. Sci. 2011, 24, 1–6. [Google Scholar]

- Zorb, C.; Senbayram, M.; Peiter, E. Potassium in agriculture status and perspectives. J. Plant Physiol. 2014, 171, 656–669. [Google Scholar] [CrossRef] [PubMed]

- Savant, N.K.; Korndörfer, G.H.; Datnoff, L.E.; Snyder, G.H. Silicon nutrition and sugarcane production: A review. J. Plant Nutr. 1999, 22, 1853–1903. [Google Scholar] [CrossRef]

- Currie, H.A.; Perry, C.C. Silica in plants: Biological, biochemical and chemical studies. Ann. Bot. 2007, 100, 1383–1389. [Google Scholar] [CrossRef] [PubMed]

- Ma, J.F.; Yamaji, N. Silicon uptake and accumulation in higher plants. Trends Plant Sci. 2006, 11, 392–397. [Google Scholar] [CrossRef] [PubMed]

- Epstein, E. Silicon: Its manifold roles in plants. Ann. Appl. Biol. 2009, 155, 155–160. [Google Scholar] [CrossRef]

- Guntzer, F.; Keller, C.; Meunier, J.-D. Benefits of plant silicon for crops: A review. Agron. Sustain. Dev. 2012, 32, 201–213. [Google Scholar] [CrossRef]

- Houben, D.; Sonnet, P.; Cornelis, J.T. Biochar from Miscanthus: A potential silicon fertilizer. Plant Soil 2013, 374, 871–882. [Google Scholar] [CrossRef]

- Reza, M.T.; Lynam, L.G.; Vasquez, V.R.; Coronella, C.J. Pelletization of biochar from hydrothermally carbonized wood. Environ. Progress Sustain. Energy 2012, 31, 225–234. [Google Scholar] [CrossRef]

- Cantrell, K.B.; Martin, J.H., II. Poultry litter and switchgrass blending and pelleting characteristics for biochar production. Trans. ASABE 2012, 57, 543–553. [Google Scholar]

- Shin, J.; Choi, E.; Jang, E.S.; Hong, S.G.; Lee, S.; Ravindran, B. Adsorption characteristics of ammonium nitrogen and plant responses to biochar pellet. Sustainability 2018, 10, 1331. [Google Scholar] [CrossRef]

- Loney, M.W.; Tabatabaie, M. Mathematical modeling of heavy metals removal from bio-film coated cylindrical cement base waste forms. Chem. Prod. Process Model. 2015, 10, 229–236. [Google Scholar] [CrossRef]

- Eberwein, J.; Shen, W.; Jenerette, D. Michaelis-Menten kinetics of soil respiration feedbacks to nitrogen deposition and climate change in subtropical forests. Sci. Rep. 2017, 7, 1752. [Google Scholar] [CrossRef] [PubMed]

- Martens, D.A.; Dick, W.A. Recovery of fertilizer nitrogen from continuous corn soils under contrasting tillage management. Biol. Fertil. Soils 2003, 38, 144–153. [Google Scholar] [CrossRef]

- Ortega, R.A.; Westfall, D.G.; Peterson, G.A. Climatic gradient, cropping system, and crop residues impact on carbon and nitrogen mineralization in no-till soils. Commun. Soil Sci. Plant Anal. 2005, 36, 2875–2887. [Google Scholar] [CrossRef]

- Liang, X.Q.; Chen, Y.X.; Li, H.; Tian, G.M.; Ni, W.Z.; He, M.M.; Zhang, Z.J. Modeling transport and fate of nitrogen from urea applied to a near-trench paddy field. Environ. Pollut. 2007, 50, 313–320. [Google Scholar] [CrossRef] [PubMed]

- Chu, H.; Hosen, Y.; Yagi, K. N2O, CH4 and CO2 fluxes in winter barely field of Japanese Andisol as affected by N fertilizer management. Soil Biol. Biochem. 2007, 39, 330–339. [Google Scholar] [CrossRef]

- Prakongkep, N.; Gilkes, R.J.; Wiriyakinateekul, W. Forms and solubility of plant nutrient elements in tropical plant waste biochars. J. Plant Nutr. Soil Sci. 2015, 178, 732–740. [Google Scholar] [CrossRef]

- Rahman, M.M.; Liu, Y.H.; Kwang, J.H.; Ra, C.S. Recovery of struvite from animal wastewater and its nutrient leaching loss in soil. J. Hazard. Mater. 2011, 186, 2026–2030. [Google Scholar] [CrossRef] [PubMed]

- Ramanan, V.; Thiyagarajan, S.K.; Raji, K.; Suresh, R.; Ramamurthy, P. Outright green synthesis of fluorescent carbon dots from eutrophic algal blooms for in vitro imaging. ACS Sustain. Chem. Eng. 2016, 4, 4724–4731. [Google Scholar] [CrossRef]

- Schindler, D.W.; Carpenter, S.R.; Chpra, S.C.; Hecky, R.E.; Orihel, D.M. Reducing phosphorous to curb lake eutrophication is a success. Environ. Sci. Technol. 2016, 50, 8923–8929. [Google Scholar] [CrossRef] [PubMed]

- Bahadur, I.; Meena, V.S.; Kumar, S. Importance and application of potassium bio-fertilizer in Indian agriculture. Int. J. Res. Biol. Sci. 2014, 3, 80–85. [Google Scholar]

- Song, Z.; Wang, H.; Strong, P.J.; Shan, S. Increase of available soil silicon by Si-rich manure for sustainable rice production. Agron. Sustain. Dev. 2014, 34, 813–819. [Google Scholar] [CrossRef]

- Liu, X.; Li, L.; Bian, R.; Chen, D.; Qu, J.; Wanjiru Kibue, G.; Pan, G.; Zhang, X.; Zheng, J.; Zheng, J. Effect of biochar amendment on soil-silicon availability and rice uptake. J. Plant Nutr. Soil Sci. 2014, 177, 91–96. [Google Scholar] [CrossRef]

- Abbas, T.; Rizwan, M.; Ali, S.; Zia-ur-Rehman, M.; Qayyum, M.F.; Abbas, F.; Hannan, F.; Rinklebe, J.; Ok, Y.S. Effect of biochar on cadmium bioavailability and uptake in wheat (Triticum aestivum L.) grown in a soil with aged contamination. Ecotoxicol. Environ. Saf. 2017, 140, 37–47. [Google Scholar] [CrossRef] [PubMed]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).