Feasibility Study of Steel Bar Corrosion Monitoring Using a Piezoceramic Transducer Enabled Time Reversal Method

Abstract

:1. Introduction

2. Piezoceramic Transducer and Monitoring Principle

2.1. Piezoceramic Transducer

2.2. Time Reversal (TR) Method

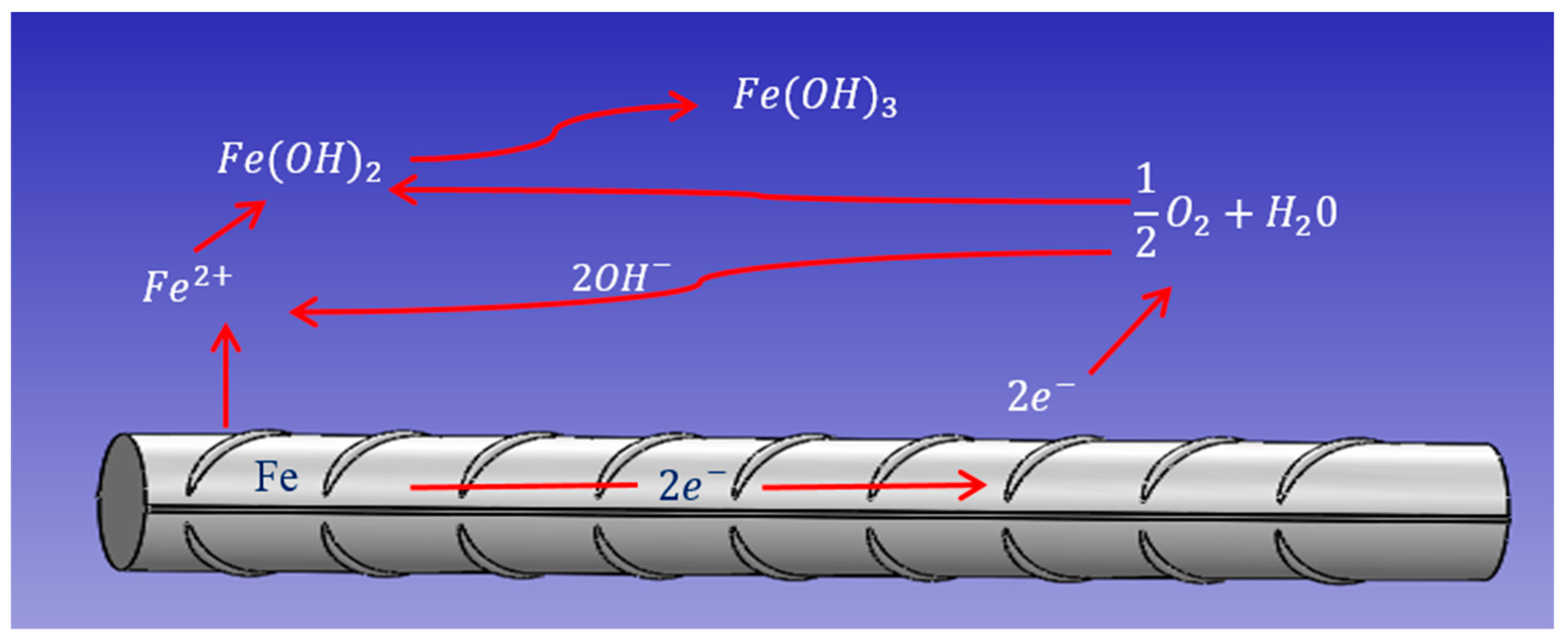

2.3. The Accelerated Steel Bar Corrosion Experiment

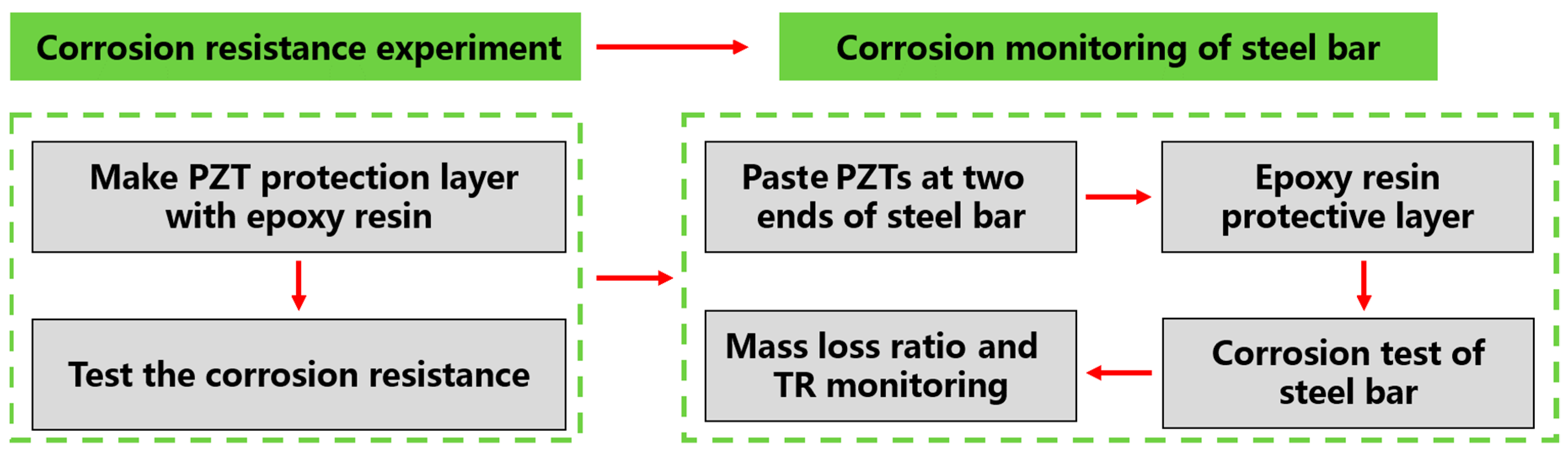

3. Experimental Setup

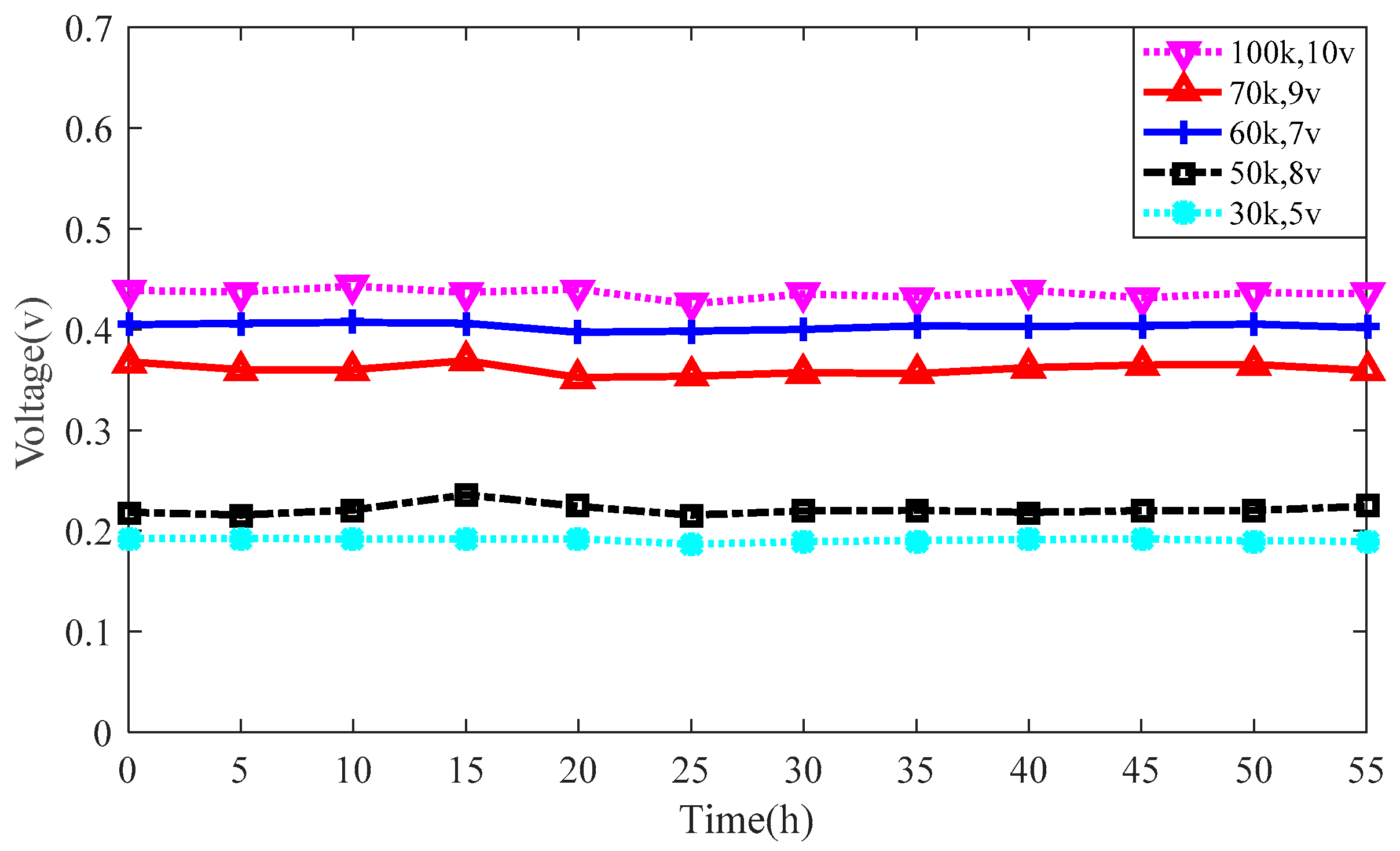

3.1. Corrosion Resistance of the Resin-Protected Piezoceramic Transducers

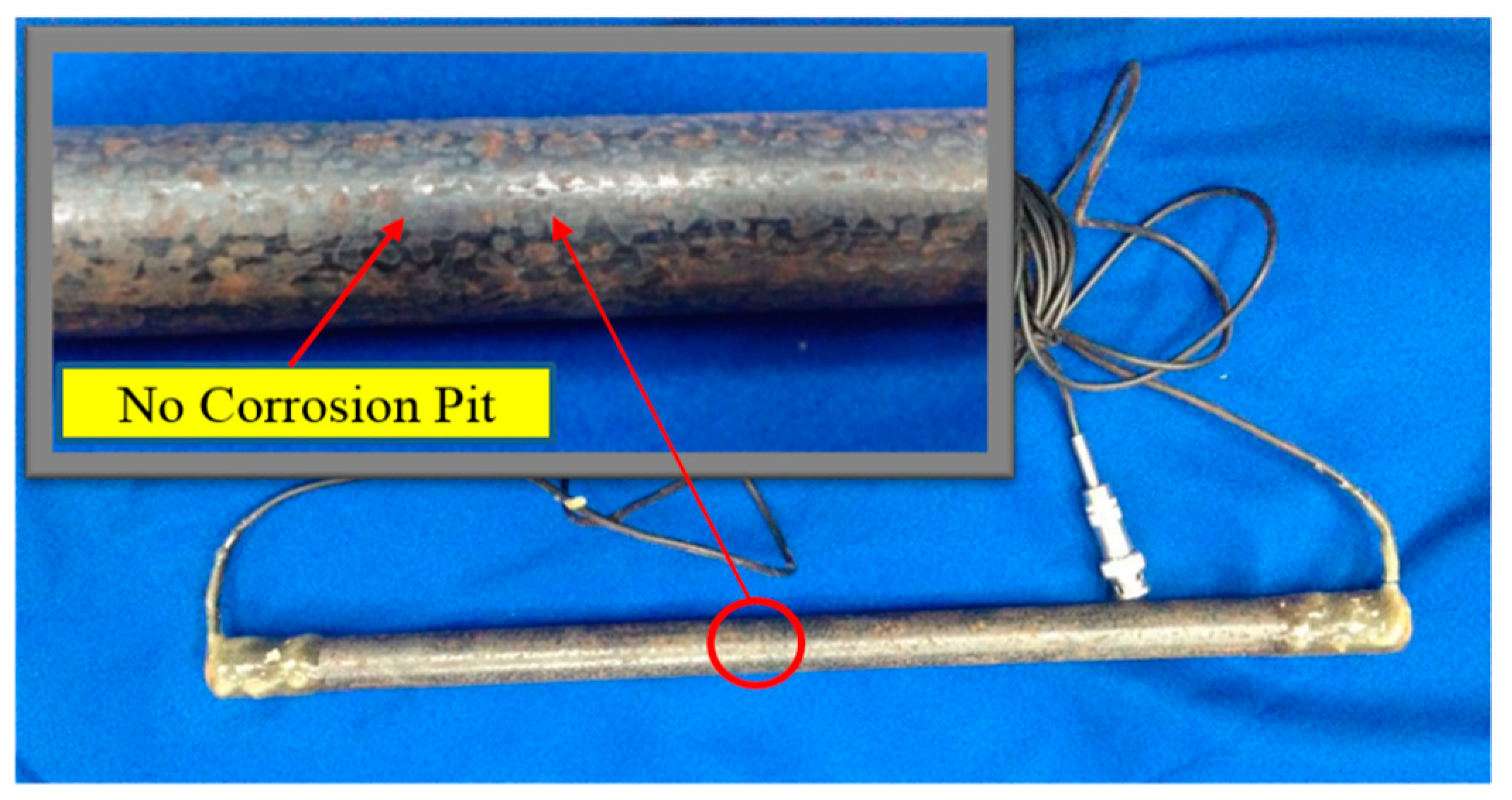

3.2. Detection of Corrosion in Steel Bars

4. Conclusions and Future Work

Author Contributions

Funding

Conflicts of Interest

References

- Park, R.; Paulay, T. Reinforced Concrete Structures; John Wiley & Sons: Hoboken, NJ, USA, 1975. [Google Scholar]

- Zheng, Y. Investigation of Ultimate Strength of Deck Slabs in Steel-Concrete Bridges. ACI Struct. J. 2010, 107, 82–91. [Google Scholar]

- Park, Y.; Kim, Y.H.; Lee, S.H. Long-Term Flexural Behaviors of GFRP Reinforced Concrete Beams Exposed to Accelerated Aging Exposure Conditions. Polymers 2014, 6, 1773–1793. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.; Zhang, L.F.; Xia, L.P. Investigation of the behaviour of flexible and ductile ECC link slab reinforced with FRP. Constr. Build. Mater. 2018, 166, 694–711. [Google Scholar] [CrossRef]

- Mccague, C.; Fabian, M.; Karimi, M.; Bravo, M.; Jaroszewicz, L.R.; Mergo, P.; Sun, T.; Grattan, K.T.V. Novel Sensor Design Using Photonic Crystal Fibres for Monitoring the Onset of Corrosion in Reinforced Concrete Structures. J. Lightw. Sci. Technol. 2014, 32, 891–896. [Google Scholar] [CrossRef] [Green Version]

- Pantazopoulou, S.J.; Papoulia, K.D. Modeling Cover Cracking Due to Reinforcement Corrosion in RC Structures. J. Eng. Mech. 2001, 127, 342–351. [Google Scholar] [CrossRef]

- Figueira, R. Electrochemical Sensors for Monitoring the Corrosion Conditions of Reinforced Concrete Structures: A Review. Appl. Sci. 2017, 7, 1157. [Google Scholar] [CrossRef]

- Lynch, J.P. A Summary Review of Wireless Sensors and Sensor Networks for Structural Health Monitoring. Shock Vib. Dig. 2006, 38, 91–128. [Google Scholar] [CrossRef]

- Song, G.; Wang, C.; Wang, B. Structural Health Monitoring (SHM) of Civil Structures. Appl. Sci. 2017, 7, 789. [Google Scholar] [CrossRef]

- Qiao, G.; Sun, G.; Hong, Y.; Liu, T.; Guan, X. Corrosion in Reinforced Concrete Panels: Wireless Monitoring and Wavelet-Based Analysis. Sensors 2014, 14, 3395–3407. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Legat, A. Monitoring of steel corrosion in concrete by electrode arrays and electrical resistance probes. Electrochim. Acta 2007, 52, 7590–7598. [Google Scholar] [CrossRef]

- Liu, W.; Hunsperger, R.G.; Chajes, M.J.; Folliard, K.J.; Kunz, E. Corrosion Detection of Steel Cables using Time Domain Reflectometry. J. Mater. Civ. Eng. 2002, 14, 217–223. [Google Scholar] [CrossRef]

- Marinetti, S.; Vavilov, V. IR thermographic detection and characterization of hidden corrosion in metals: General analysis. Corros. Sci. 2010, 52, 865–872. [Google Scholar] [CrossRef]

- Leung, C.K.Y.; Tai, W.K.; Chen, L. A Novel Optical Fiber Sensor for Steel Corrosion in Concrete Structures. Sensors 2008, 8, 1960–1976. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Review of Nondestructive Testing Methods for Condition Monitoring of Concrete Structures. J. Constr. Eng. (USA) 2013. [Google Scholar] [CrossRef]

- Dong, S.; Liao, Y.; Tian, Q. Intensity-based optical fiber sensor for monitoring corrosion of aluminum alloys. Appl. Opt. 2005, 44, 5773–5777. [Google Scholar] [CrossRef] [PubMed]

- Leelalerkiet, V.; Kyung, J.W.; Ohtsu, M.; Yokota, M. Analysis of half-cell potential measurement for corrosion of reinforced concrete. Constr. Build. Mater. 2004, 18, 155–1623. [Google Scholar] [CrossRef]

- Sathiyanarayanan, S.; Natarajan, P.; Saravanan, K.; Srinivasan, S.; Venkatachari, G. Corrosion monitoring of steel in concrete by galvanostatic pulse technique. Cem. Concr. Compos. 2006, 28, 630–637. [Google Scholar] [CrossRef]

- Vedalakshmi, R.; Dolli, H.; Palaniswamy, N. Embeddable corrosion rate-measuring sensor for assessing the corrosion risk of steel in concrete structures. Struct. Control Health Monit. 2010, 16, 441–459. [Google Scholar] [CrossRef]

- Duarte, R.G.; Castela, A.S.; Neves, R.; Freire, L.; Montemor, M.F. Corrosion Behavior of Stainless Steel Rebars Embedded in Concrete: An Electrochemical Impedance Spectroscopy Study. Electrochim. Acta 2014, 124, 218–224. [Google Scholar] [CrossRef]

- Verma, S.K.; Bhadauria, S.S.; Akhtar, S. Monitoring corrosion of steel bars in reinforced concrete structures. Sci. World J. 2014, 2014, 957904. [Google Scholar] [CrossRef] [PubMed]

- Sharma, S.; Mukherjee, A. Ultrasonic guided waves for monitoring corrosion in submerged plates. Struct. Control Health Monit. 2015, 22, 19–35. [Google Scholar] [CrossRef]

- Miller, T.H.; Kundu, T.; Huang, J.; Grill, J.Y. A new guided wave-based technique for corrosion monitoring in reinforced concrete. Struct. Health Monit. 2013, 12, 35–47. [Google Scholar] [CrossRef]

- Ervin, B.L.; Bernhard, J.T.; Kuchma, D.A.; Reis, H. Estimation of general corrosion damage to steel reinforced mortar using frequency sweeps of guided mechanical waves. Insight Non-Destr. Test. Cond. Monit. 2006, 48, 682–692. [Google Scholar] [CrossRef]

- Moustafa, A.; Niri, E.D.; Farhidzadeh, A.; Salamone, S. Corrosion monitoring of post-tensioned concrete structures using fractal analysis of guided ultrasonic waves. Struct. Control Health Monit. 2014, 21, 438–448. [Google Scholar] [CrossRef]

- Vélez, W.; Matta, F.; Ziehl, P. Acoustic emission monitoring of early corrosion in prestressed concrete piles. Struct. Control Health Monit. 2015, 22, 873–887. [Google Scholar] [CrossRef]

- Tian, Z.; Huo, L.; Gao, W.; Song, G.; Li, H. Grouting monitoring of post-tensioning tendon duct using PZT enabled time-reversal method. Measurement 2017, 122, 513–521. [Google Scholar] [CrossRef]

- Zhang, L.; Wang, C.; Huo, L.; Song, G. Health monitoring of cuplok scaffold joint connection using piezoceramic transducers and time reversal method. Smart Mater. Struct. 2016, 25, 035010. [Google Scholar] [CrossRef]

- Mustapha, S. Damage detection in rebar-reinforced concrete beams based on time reversal of guided waves. Struct. Health Monit. 2014, 13, 347–358. [Google Scholar] [CrossRef]

- Qiu, L.; Yuan, S.; Zhang, X.; Wang, Y. A time reversal focusing based impact imaging method and its evaluation on complex composite structures. Smart Mater. Struct. 2011, 20, 105014. [Google Scholar] [CrossRef]

- Hong, X.; Song, G.; Ruan, J.; Zhang, Z.; Wu, S.; Liu, G. Active monitoring of pipeline tapered thread connection based on time reversal using piezoceramic transducers. Smart Struct. Syst. 2016, 18, 643–662. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, D.; Zhou, Z. Time reversal method for guidedwaves with multimode and multipath on corrosion defect detection in wire. Appl. Sci. 2017, 7, 424. [Google Scholar] [CrossRef]

- On, B.; Im, S.; Seo, I. Performance of Time Reversal Based Underwater Target Detection in Shallow Water. Appl. Sci. 2017, 7, 1180. [Google Scholar] [CrossRef]

- Li, H.N.; Yi, T.H.; Ren, L.; Li, D.S.; Huo, L.S. Reviews on innovations and applications in structural health monitoring for infrastructures. Struct. Monit. Maint. 2014, 1, 1–45. [Google Scholar] [CrossRef]

- Kong, Q.; Robert, R.; Silva, P.; Mo, Y.L. Cyclic Crack Monitoring of a Reinforced Concrete Column under Simulated Pseudo-Dynamic Loading Using Piezoceramic-Based Smart Aggregates. Appl. Sci. 2016, 6, 341. [Google Scholar] [CrossRef]

- Huo, L.; Li, X.; Li, H.; Wang, Z.; Song, G. Dynamic Modelling of Embeddable Piezoceramic Transducers. Sensors 2017, 17, 2801. [Google Scholar] [CrossRef] [PubMed]

- Jung, Y.; Kwak, J.H.; Lee, Y.H.; Kim, W.D.; Hur, S. Development of a multi-channel piezoelectric acoustic sensor based on an artificial basilar membrane. Sensors 2013, 14, 117–128. [Google Scholar] [CrossRef] [PubMed]

- Shao, J.; Wang, T.; Yin, H.; Yang, D.; Li, Y. Bolt Looseness Detection Based on Piezoelectric Impedance Frequency Shift. Appl. Sci. 2016, 6, 298. [Google Scholar] [CrossRef]

- Hu, X.; Zhu, H.; Wang, D. A Study of Concrete Slab Damage Detection Based on the Electromechanical Impedance Method. Sensors 2014, 14, 19897–19909. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jiang, T.; Kong, Q.; Wang, W.; Huo, L.; Song, G. Monitoring of Grouting Compactness in a Post-Tensioning Tendon Duct Using Piezoceramic Transducers. Sensors 2016, 16, 1343. [Google Scholar] [CrossRef] [PubMed]

- Wang, G. Analysis of bimorph piezoelectric beam energy harvesters using Timoshenko and Euler–Bernoulli beam theory. J. Intell. Mater. Syst. Struct. 2013, 24, 226–239. [Google Scholar] [CrossRef]

- Kim, H.S.; Kim, J.H.; Kim, J. A review of piezoelectric energy harvesting based on vibration. Int. J. Precis. Eng. Manuf. 2011, 12, 1129–1141. [Google Scholar] [CrossRef]

- Liang, J.; Liao, W.H. Improved Design and Analysis of Self-Powered Synchronized Switch Interface Circuit for Piezoelectric Energy Harvesting Systems. IEEE Trans. Ind. Electron. 2011, 59, 1950–1960. [Google Scholar] [CrossRef]

- Malakooti, M.H.; Sodano, H.A. Piezoelectric energy harvesting through shear mode operation. Smart Mater. Struct. 2015, 24, 055005. [Google Scholar] [CrossRef]

- Jeong, C.K.; Baek, C.; Kingon, A.I.; Park, K.I.; Kim, S.H. Lead-free perovskite nanowire-employed piezopolymer for highly efficient flexible nanocomposite energy harvester. Small 2018, 14, e1704022. [Google Scholar] [CrossRef] [PubMed]

- Han, J.H.; Bae, K.M.; Hong, S.K.; Park, H.; Kwak, J.H.; Wang, H.S.; Joe, D.J.; Park, J.H.; Jung, Y.H.; Hur, S.; et al. Machine learning-based self-powered acoustic sensor for speaker recognition. Nano Energy 2018, 53, 658–665. [Google Scholar] [CrossRef]

- Park, K.I.; Chang, K.J.; Na, K.K.; Lee, K.J. Stretchable piezoelectric nanocomposite generator. Nano Converg. 2016, 3, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Song, G.; Qiao, P.Z.; Binienda, W.K.; Zou, G.P. Active vibration damping of composite beam using smart sensors and actuators. J. Aerosp. Eng. 2002, 15, 97–103. [Google Scholar] [CrossRef]

- Song, G.; Gu, H. Active vibration suppression of a smart flexible beam using a sliding mode based controller. J. Vib. Control 2007, 13, 1095–1107. [Google Scholar] [CrossRef]

- Du, G.F.; Kong, Q.Z.; Lai, T.; Song, G. Feasibility Study on Crack Detection of Pipelines Using Piezoceramic Transducers. Int. J. Distrib. Sens. Netw. 2013, 7, 631715. [Google Scholar] [CrossRef]

- Broda, D.; Staszewski, W.J.; Martowicz, A.; Uhl, T.; Silberschmidt, V.V. Modelling of nonlinear crack–wave interactions for damage detection based on ultrasound—A review. J. Sound Vib. 2014, 333, 1097–1118. [Google Scholar] [CrossRef]

- Xu, J.; Hao, J.; Li, H.; Luo, M.; Guo, W.; Li, W. Experimental Damage Identification of a Model Reticulated Shell. Appl. Sci. 2017, 7, 362. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, X.; Hao, H.; Ou, J. Guided wave propagation and spectral element method for debonding damage assessment in RC structures. J. Sound Vib. 2009, 324, 751–772. [Google Scholar] [CrossRef]

- Zou, D.; Liu, T.; Qiao, G.; Huang, Y.; Li, B. An Experimental Study on the Performance of Piezoceramic-Based Smart Aggregate in Water Environment. IEEE Sens. J. 2014, 14, 943–944. [Google Scholar] [CrossRef] [Green Version]

- Venugopal, V.P.; Wang, G. Modeling and analysis of Lamb wave propagation in a beam under Lead Zirconate Titanate actuation and sensing. J. Intell. Mater. Syst. Struct. 2015, 26, 1679–1698. [Google Scholar] [CrossRef]

- Zou, D.; Liu, T.; Liang, C.; Huang, Y.; Zhang, F.; Du, C. An experimental investigation on the health monitoring of concrete structures using piezoelectric transducers at various environmental temperatures. J. Intell. Mater. Syst. Struct. 2015, 26, 1028–1034. [Google Scholar] [CrossRef]

- Jiang, T.; Kong, Q.; Patil, D.; Luo, Z.; Huo, L.; Song, G. Detection of Debonding Between Fiber Reinforced Polymer Bar and Concrete Structure Using Piezoceramic Transducers and Wavelet Packet Analysis. IEEE Sens. J. 2017, 17, 1992–1998. [Google Scholar] [CrossRef]

- Liao, W.; Wang, J.X.; Song, G.; Gu, H.; Olmi, C.; Mo, Y.L.; Chang, K.C.; Loh, C.H. Structural health monitoring of concrete columns subjected to seismic excitations using piezoceramic-based sensors. Smart Mater. Struct. 2011, 20, 125015. [Google Scholar] [CrossRef]

- Hu, Y.; Yang, Y. Wave propagation modeling of the PZT sensing region for structural health monitoring. Smart Mater. Struct. 2007, 16, 706. [Google Scholar] [CrossRef]

- Yang, Y.; Annamdas, V.G.M.; Wang, C.; Zhou, Y. Application of Multiplexed FBG and PZT Impedance Sensors for Health Monitoring of Rocks. Sensors 2008, 8, 271–289. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhang, C.; Yu, X.; Alexander, L.; Zhang, Y.; Rajamani, R.; Garg, N. Piezoelectric active sensing system for crack detection in concrete structure. J. Civ. Struct. Health Monit. 2016, 6, 129–139. [Google Scholar] [CrossRef]

- Xu, B.; Zhang, T.; Song, G.; Gu, H. Active interface debonding detection of a concrete-filled steel tube with piezoelectric technologies using wavelet packet analysis. Mech. Syst. Signal Proc. 2013, 36, 7–17. [Google Scholar] [CrossRef]

- Song, G.; Gu, H.; Mo, Y.L. Smart aggregates: Multi-functional sensors for concrete structures—A tutorial and a review. Smart Mater. Struct. 2008, 17, 033001. [Google Scholar] [CrossRef]

- Feng, Q.; Kong, Q.; Huo, L.; Song, G. Crack detection and leakage monitoring on reinforced concrete pipe. Smart Mater. Struct. 2015, 24, 115020. [Google Scholar] [CrossRef]

- Song, G.; Li, W.; Wang, B.; Ho, S.C.M. A Review of Rock Bolt Monitoring Using Smart Sensors. Sensors 2017, 17, 776. [Google Scholar] [CrossRef] [PubMed]

- Yin, H.; Wang, T.; Yang, D.; Liu, S.; Shao, J.; Li, Y. A Smart Washer for Bolt Looseness Monitoring Based on Piezoelectric Active Sensing Method. Appl. Sci. 2016, 6, 320. [Google Scholar] [CrossRef]

- Huo, L.; Wang, B.; Chen, D.; Song, G. Monitoring of Pre-Load on Rock Bolt Using Piezoceramic-Transducer Enabled Time Reversal Method. Sensors 2017, 17, 2467. [Google Scholar] [CrossRef] [PubMed]

- Ing, R.K.; Fink, M. Time-reversed Lamb waves. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1998, 45, 1032. [Google Scholar] [CrossRef] [PubMed]

- Huo, L.; Chen, D.; Kong, Q.; Li, H.; Song, G. Smart washer—A piezoceramic-based transducer to monitor looseness of bolted connection. Smart Mater. Struct. 2017, 26, 025033. [Google Scholar] [CrossRef]

- Byun, G.; Song, H.; Kim, J. Virtual Source Array-Based Multiple Time-Reversal Focusing. Appl. Sci. 2018, 8, 99. [Google Scholar] [CrossRef]

- Fink, M. Time reversal of ultrasonic fields. I. Basic principles. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1992, 39, 555–566. [Google Scholar] [CrossRef] [PubMed]

- Maaddawy, T.A.E.; Soudki, K.A. Effectiveness of Impressed Current Technique to Simulate Corrosion of Steel Reinforcement in Concrete. J. Mater. Civ. Eng. 2003, 15, 41–47. [Google Scholar] [CrossRef]

- Ahmad, S. Reinforcement corrosion in concrete structures, its monitoring and service life prediction—A review. Cem. Concr. Compos. 2003, 25, 459–471. [Google Scholar] [CrossRef]

| The Mass Loss Ratio (%) | The Magnitude of Focused Signal (50 KHz) | The Magnitude of Focused Signal (60 KHz) | The Magnitude of Focused Signal (70 KHz) |

|---|---|---|---|

| 0 | 0.2399 | 0.2311 | 0.2142 |

| 0.88 | 0.2132 | 0.2132 | 0.1972 |

| 2.11 | 0.2057 | 0.1997 | 0.1804 |

| 3.19 | 0.1953 | 0.1846 | 0.1747 |

| 4.10 | 0.1915 | 0.1776 | 0.1692 |

| 5.54 | 0.1788 | 0.1703 | 0.1597 |

| 6.61 | 0.1687 | 0.1601 | 0.1456 |

| 7.80 | 0.1541 | 0.1505 | 0.1367 |

| 8.80 | 0.1483 | 0.1403 | 0.1261 |

| 9.90 | 0.1362 | 0.1284 | 0.1132 |

| 10.89 | 0.1257 | 0.1173 | 0.1012 |

| The Mass Loss Ratio (%) | The Magnitude of Focused Signal (50 KHz) | The Magnitude of Focused Signal (60 KHz) | The Magnitude of Focused Signal (70 KHz) |

|---|---|---|---|

| 0 | 0.2311 | 0.2136 | 0.261 |

| 1.05 | 0.2101 | 0.1902 | 0.2507 |

| 2.38 | 0.1941 | 0.1706 | 0.2331 |

| 3.30 | 0.183 | 0.1575 | 0.2161 |

| 4.31 | 0.1577 | 0.1421 | 0.1944 |

| 5.18 | 0.144 | 0.1358 | 0.1829 |

| 6.22 | 0.1281 | 0.1248 | 0.1621 |

| 7.45 | 0.1165 | 0.1077 | 0.1444 |

| 8.42 | 0.1051 | 0.092 | 0.1244 |

| 9.61 | 0.087 | 0.0756 | 0.1009 |

| 10.78 | 0.067 | 0.0621 | 0.0813 |

| The Mass Loss Ratio (%) | The Magnitude of Focused Signal (50 KHz) | The Magnitude of Focused Signal (60 KHz) | The Magnitude of Focused Signal (70 KHz) |

|---|---|---|---|

| 0 | 0.5752 | 0.5578 | 0.5982 |

| 1.03 | 0.5425 | 0.5148 | 0.5546 |

| 1.99 | 0.5141 | 0.4822 | 0.5071 |

| 2.76 | 0.4833 | 0.4495 | 0.4823 |

| 3.90 | 0.4389 | 0.4153 | 0.4398 |

| 5.09 | 0.4008 | 0.3863 | 0.3878 |

| 6.18 | 0.3523 | 0.3455 | 0.3401 |

| 7.47 | 0.3201 | 0.3067 | 0.3102 |

| 8.52 | 0.289 | 0.2851 | 0.2648 |

| 9.691 | 0.2524 | 0.2472 | 0.2254 |

| 10.93 | 0.210 | 0.2113 | 0.1751 |

| The Mass Loss Ratio (%) | The Magnitude of Focused Signal (50 KHz) | The Magnitude of Focused Signal (60 KHz) | The Magnitude of Focused Signal (70 KHz) |

|---|---|---|---|

| 0 | 0.3881 | 0.3658 | 0.3718 |

| 0.90 | 0.3628 | 0.3586 | 0.3603 |

| 1.76 | 0.3510 | 0.3483 | 0.3481 |

| 2.72 | 0.3201 | 0.3391 | 0.3261 |

| 3.84 | 0.2962 | 0.3247 | 0.3099 |

| 5.02 | 0.2722 | 0.3183 | 0.2812 |

| 6.13 | 0.2431 | 0.3021 | 0.2632 |

| 7.32 | 0.2259 | 0.2918 | 0.2504 |

| 8.49 | 0.1952 | 0.2842 | 0.221 |

| 9.69 | 0.1701 | 0.2728 | 0.2001 |

| 10.84 | 0.1552 | 0.2572 | 0.1826 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huo, L.; Li, C.; Jiang, T.; Li, H.-N. Feasibility Study of Steel Bar Corrosion Monitoring Using a Piezoceramic Transducer Enabled Time Reversal Method. Appl. Sci. 2018, 8, 2304. https://doi.org/10.3390/app8112304

Huo L, Li C, Jiang T, Li H-N. Feasibility Study of Steel Bar Corrosion Monitoring Using a Piezoceramic Transducer Enabled Time Reversal Method. Applied Sciences. 2018; 8(11):2304. https://doi.org/10.3390/app8112304

Chicago/Turabian StyleHuo, Linsheng, Chuanbo Li, Tianyong Jiang, and Hong-Nan Li. 2018. "Feasibility Study of Steel Bar Corrosion Monitoring Using a Piezoceramic Transducer Enabled Time Reversal Method" Applied Sciences 8, no. 11: 2304. https://doi.org/10.3390/app8112304

APA StyleHuo, L., Li, C., Jiang, T., & Li, H. -N. (2018). Feasibility Study of Steel Bar Corrosion Monitoring Using a Piezoceramic Transducer Enabled Time Reversal Method. Applied Sciences, 8(11), 2304. https://doi.org/10.3390/app8112304