Field Emission from Carbon Nanostructures

Abstract

:1. Introduction

Field Emission

2. Field Emission from Carbon Nanostructures

2.1. Field Emission Technology Development

2.2. Carbon Allotropes

2.3. Field Enhancement Factor,

2.4. Emission from CNT Films

2.5. Emission from Individual Nanotubes

2.6. Field Emission from Diamond and Related Structures

2.7. Emission from Graphene and Graphitic Materials

3. Conclusions

Acknowledgments

Conflicts of Interest

References

- Saito, Y.; Hata, K.; Takakura, A.; Yotani, J.; Uemura, S. Field emission of carbon nanotubes and its application as electron sources of ultra-high luminance light-source devices. Phys. B Condens. Matter 2002, 323, 30–37. [Google Scholar] [CrossRef]

- Talin, A.A.; Dean, K.A.; Jaskie, J.E. Field emission displays: A critical review. Solid-State Electron. 2001, 45, 963–976. [Google Scholar] [CrossRef]

- Wang, Q.H.; Yan, M.; Chang, R.P.H. Flat panel display prototype using gated carbon nanotube field emitters. Appl. Phys. Lett. 2001, 78, 1294–1296. [Google Scholar] [CrossRef]

- Swanson, L.W.; Schwind, G.A. A Review of Field Electron Source Use in Electron Microscopes. Microsc. Microanal. 2005, 11. [Google Scholar] [CrossRef]

- Fursey, G.N. Field Emission in Vacuum Microelectronics; Microdevices; Kluwer Academic/Plenum Publishers: New York, NY, USA, 2005; ISBN 978-0-306-47450-7. [Google Scholar]

- Radauscher, E.J.; Gilchrist, K.H.; Di Dona, S.T.; Russell, Z.E.; Piascik, J.R.; Amsden, J.J.; Parker, C.B.; Stoner, B.R.; Glass, J.T. The improved perfomance of field emission vacuum microelectronic devices for integrated circuits. IEEE Trans. Electron Dev. 2016, 63, 3753–3760. [Google Scholar] [CrossRef]

- Murphy, E.L.; Good, R.H. Thermionic Emission, Field Emission, and the Transition Region. Phys. Rev. 1956, 102, 1464–1473. [Google Scholar] [CrossRef]

- Yamamoto, S. Fundamental physics of vacuum electron sources. Rep. Prog. Phys. 2006, 69, 181–232. [Google Scholar] [CrossRef]

- Gomer, R. Field Emission and Field Ionization; Harvard University Press: Cambridge, MA, USA, 1961. [Google Scholar]

- Fowler, R.H.; Nordheim, L. Electron Emission in Intense Electric Fields. Proc. R. Soc. A Math. Phys. Eng. Sci. 1928, 119, 173–181. [Google Scholar] [CrossRef]

- Froman, N. JWKB Approximation: Contributions to the Theory; Elsevier Science Publishing Co Inc.: Amsterdam, The Netherlands, 1965. [Google Scholar]

- Di Bartolomeo, A.; Scarfato, A.; Giubileo, F.; Bobba, F.; Biasiucci, M.; Cucolo, A.M.; Santucci, S.; Passacantando, M. A local field emission study of partially aligned carbon-nanotubes by atomic force microscope probe. Carbon 2007, 45, 2957–2971. [Google Scholar] [CrossRef]

- Passacantando, M.; Bussolotti, F.; Santucci, S.; Di Bartolomeo, A.; Giubileo, F.; Iemmo, L.; Cucolo, A.M. Field emission from a selected multiwall carbon nanotube. Nanotechnology 2008, 19, 395701. [Google Scholar] [CrossRef] [PubMed]

- Edgcombe, C.J. Development of Fowler-Nordheim theory for a spherical field emitter. Phys. Rev. B 2005, 72. [Google Scholar] [CrossRef]

- Edgcombe, C.J.; Johansen, A.M. Current–voltage characteristics of nonplanar cold field emitters. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2003, 21, 1519. [Google Scholar] [CrossRef]

- Forbes, R.G. Call for experimental test of a revised mathematical form for empirical field emission current-voltage characteristics. Appl. Phys. Lett. 2008, 92, 193105. [Google Scholar] [CrossRef] [Green Version]

- Forbes, R.G.; Deane, J.H.B. Reformulation of the standard theory of Fowler–Nordheim tunnelling and cold field electron emission. Proc. R. Soc. A Math. Phys. Eng. Sci. 2007, 463, 2907–2927. [Google Scholar] [CrossRef]

- Forbes, R.G. Extraction of emission parameters for large-area field emitters, using a technically complete Fowler–Nordheim-type equation. Nanotechnology 2012, 23, 095706. [Google Scholar] [CrossRef] [PubMed]

- Jensen, K.L. Exchange-correlation, dipole, and image charge potentials for electron sources: Temperature and field variation of the barrier height. J. Appl. Phys. 1999, 85, 2667–2680. [Google Scholar] [CrossRef]

- Lang, N.D.; Yacoby, A.; Imry, Y. Theory of a single-atom point source for electrons. Phys. Rev. Lett. 1989, 63, 1499–1502. [Google Scholar] [CrossRef] [PubMed]

- Gohda, Y.; Nakamura, Y.; Watanabe, K.; Watanabe, S. Self-Consistent Density Functional Calculation of Field Emission Currents from Metals. Phys. Rev. Lett. 2000, 85, 1750–1753. [Google Scholar] [CrossRef] [PubMed]

- Maiti, A.; Andzelm, J.; Tanpipat, N.; von Allmen, P. Effect of Adsorbates on Field Emission from Carbon Nanotubes. Phys. Rev. Lett. 2001, 87. [Google Scholar] [CrossRef]

- Han, S.; Lee, M.H.; Ihm, J. Dynamical simulation of field emission in nanostructures. Phys. Rev. B 2002, 65. [Google Scholar] [CrossRef]

- Tada, K.; Watanabe, K. Ab Initio Study of Field Emission from Graphitic Ribbons. Phys. Rev. Lett. 2002, 88. [Google Scholar] [CrossRef] [PubMed]

- Choi, Y.; Michan, M.; Johnson, J.L.; Naieni, A.K.; Ural, A.; Nojeh, A. Field-emission properties of individual GaN nanowires grown by chemical vapor deposition. J. Appl. Phys. 2012, 111, 044308. [Google Scholar] [CrossRef]

- Lee, C.J.; Lee, T.J.; Lyu, S.C.; Zhang, Y.; Ruh, H.; Lee, H.J. Field emission from well-aligned zinc oxide nanowires grown at low temperature. Appl. Phys. Lett. 2002, 81, 3648–3650. [Google Scholar] [CrossRef]

- Giubileo, F.; Di Bartolomeo, A.; Iemmo, L.; Luongo, G.; Passacantando, M.; Koivusalo, E.; Hakkarainen, T.; Guina, M. Field Emission from Self-Catalyzed GaAs Nanowires. Nanomaterials 2017, 7, 275. [Google Scholar] [CrossRef] [PubMed]

- Wang, B.; Zheng, Z.; Wu, H.; Zhu, L. Field emission properties and growth mechanism of In2O3 nanostructures. Nanoscale Res. Lett. 2014, 9, 111. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Passacantando, M.; Niu, G.; Schlykow, V.; Lupina, G.; Giubileo, F.; Schroeder, T. Observation of field emission from GeSn nanoparticles epitaxially grown on silicon nanopillar arrays. Nanotechnology 2016, 27, 485707. [Google Scholar] [CrossRef] [PubMed]

- Iemmo, L.; Di Bartolomeo, A.; Giubileo, F.; Luongo, G.; Passacantando, M.; Niu, G.; Hatami, F.; Skibitzki, O.; Schroeder, T. Graphene enhanced field emission from InP nanocrystals. Nanotechnology 2017, 28, 495705. [Google Scholar] [CrossRef] [PubMed]

- Lin, P.-H.; Sie, C.-L.; Chen, C.-A.; Chang, H.-C.; Shih, Y.-T.; Chang, H.-Y.; Su, W.-J.; Lee, K.-Y. Field Emission Characteristics of the Structure of Vertically Aligned Carbon Nanotube Bundles. Nanoscale Res. Lett. 2015, 10. [Google Scholar] [CrossRef] [PubMed]

- Giubileo, F.; Di Bartolomeo, A.; Scarfato, A.; Iemmo, L.; Bobba, F.; Passacantando, M.; Santucci, S.; Cucolo, A.M. Local probing of the field emission stability of vertically aligned multi-walled carbon nanotubes. Carbon 2009, 47, 1074–1080. [Google Scholar] [CrossRef]

- Wang, M.S.; Peng, L.-M.; Wang, J.Y.; Chen, Q. Electron Field Emission Characteristics and Field Evaporation of a Single Carbon Nanotube. J. Phys. Chem. B 2005, 109, 110–113. [Google Scholar] [CrossRef] [PubMed]

- Di, Y.; Xiao, M.; Zhang, X.; Wang, Q.; Li, C.; Lei, W.; Cui, Y. Large and stable emission current from synthesized carbon nanotube/fiber network. J. Appl. Phys. 2014, 115, 064305. [Google Scholar] [CrossRef]

- Giubileo, F.; Di Bartolomeo, A.; Sarno, M.; Altavilla, C.; Santandrea, S.; Ciambelli, P.; Cucolo, A.M. Field emission properties of as-grown multiwalled carbon nanotube films. Carbon 2012, 50, 163–169. [Google Scholar] [CrossRef]

- Giubileo, F.; Iemmo, L.; Luongo, G.; Martucciello, N.; Raimondo, M.; Guadagno, L.; Passacantando, M.; Lafdi, K.; Di Bartolomeo, A. Transport and field emission properties of buckypapers obtained from aligned carbon nanotubes. J. Mater. Sci. 2017, 52, 6459–6468. [Google Scholar] [CrossRef]

- Kumar, S.; Duesberg, G.S.; Pratap, R.; Raghavan, S. Graphene field emission devices. Appl. Phys. Lett. 2014, 105, 103107. [Google Scholar] [CrossRef]

- Santandrea, S.; Giubileo, F.; Grossi, V.; Santucci, S.; Passacantando, M.; Schroeder, T.; Lupina, G.; Di Bartolomeo, A. Field emission from single and few-layer graphene flakes. Appl. Phys. Lett. 2011, 98, 163109. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Giubileo, F.; Iemmo, L.; Romeo, F.; Russo, S.; Unal, S.; Passacantando, M.; Grossi, V.; Cucolo, A.M. Leakage and field emission in side-gate graphene field effect transistors. Appl. Phys. Lett. 2016, 109, 023510. [Google Scholar] [CrossRef]

- Urban, F.; Passacantando, M.; Giubileo, F.; Iemmo, L.; Di Bartolomeo, A. Transport and Field Emission Properties of MoS2 Bilayers. Nanomaterials 2018, 8, 151. [Google Scholar] [CrossRef] [PubMed]

- Suryawanshi, S.R.; Pawbake, A.S.; Pawar, M.S.; Jadkar, S.R.; More, M.A.; Late, D.J. Enhanced field emission behavior of layered MoSe2. Mater. Res. Express 2016, 3, 035003. [Google Scholar] [CrossRef]

- Yuasa, K.; Shimoi, A.; Ohba, I.; Oshima, C. Modified Fowler–Nordheim field emission formulae from a nonplanar emitter model. Surf. Sci. 2002, 520, 18–28. [Google Scholar] [CrossRef]

- Spindt, C.A. A Thin-Film Field-Emission Cathode. J. Appl. Phys. 1968, 39, 3504–3505. [Google Scholar] [CrossRef]

- Ghis, A.; Meyer, R.; Rambaud, P.; Levy, F.; Leroux, T. Sealed vacuum devices: Fluorescent microtip displays. IEEE Trans. Electron Devices 1991, 38, 2320–2322. [Google Scholar] [CrossRef]

- Fan, Y.; Rose, M. Field Emission Displays (FEDs). In Handbook of Visual Display Technology; Chen, J., Cranton, W., Fihn, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2012; pp. 1071–1104. ISBN 978-3-540-79566-7. [Google Scholar]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Bethune, D.S.; Kiang, C.H.; de Vries, M.S.; Gorman, G.; Savoy, R.; Vazquez, J.; Beyers, R. Cobalt-catalysed growth of carbon nanotubes with single-atomic-layer walls. Nature 1993, 363, 605–607. [Google Scholar] [CrossRef]

- Iijima, S.; Ichihashi, T. Single-shell carbon nanotubes of 1-nm diameter. Nature 1993, 363, 603–605. [Google Scholar] [CrossRef]

- Wind, S.J.; Appenzeller, J.; Martel, R.; Derycke, V.; Avouris, P. Vertical scaling of carbon nanotube field-effect transistors using top gate electrodes. Appl. Phys. Lett. 2002, 80, 3817–3819. [Google Scholar] [CrossRef]

- Franklin, A.D.; Luisier, M.; Han, S.-J.; Tulevski, G.; Breslin, C.M.; Gignac, L.; Lundstrom, M.S.; Haensch, W. Sub-10 nm Carbon Nanotube Transistor. Nano Lett. 2012, 12, 758–762. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Rinzan, M.; Boyd, A.K.; Yang, Y.; Guadagno, L.; Giubileo, F.; Barbara, P. Electrical properties and memory effects of field-effect transistors from networks of single- and double-walled carbon nanotubes. Nanotechnology 2010, 21, 115204. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Yang, Y.; Rinzan, M.B.M.; Boyd, A.K.; Barbara, P. Record Endurance for Single-Walled Carbon Nanotube–Based Memory Cell. Nanoscale Res. Lett. 2010, 5, 1852–1855. [Google Scholar] [CrossRef] [PubMed]

- Dai, H.; Hafner, J.H.; Rinzler, A.G.; Colbert, D.T.; Smalley, R.E. Nanotubes as nanoprobes in scanning probe microscopy. Nature 1996, 384, 147–150. [Google Scholar] [CrossRef]

- Zhou, P.; Yang, X.; He, L.; Hao, Z.; Luo, W.; Xiong, B.; Xu, X.; Niu, C.; Yan, M.; Mai, L. The Young’s modulus of high-aspect-ratio carbon/carbon nanotube composite microcantilevers by experimental and modeling validation. Appl. Phys. Lett. 2015, 106, 111908. [Google Scholar] [CrossRef]

- Gao, X.P.; Lan, Y.; Pan, G.L.; Wu, F.; Qu, J.Q.; Song, D.Y.; Shen, P.W. Electrochemical Hydrogen Storage by Carbon Nanotubes Decorated with Metallic Nickel. Electrochem. Solid-State Lett. 2001, 4, A173. [Google Scholar] [CrossRef]

- Kaempgen, M.; Chan, C.K.; Ma, J.; Cui, Y.; Gruner, G. Printable Thin Film Supercapacitors Using Single-Walled Carbon Nanotubes. Nano Lett. 2009, 9, 1872–1876. [Google Scholar] [CrossRef] [PubMed]

- Dai, L.; Chang, D.W.; Baek, J.-B.; Lu, W. Carbon Nanomaterials for Advanced Energy Conversion and Storage. Small 2012, 8, 1130–1166. [Google Scholar] [CrossRef] [PubMed]

- King, P.J.; Higgins, T.M.; De, S.; Nicoloso, N.; Coleman, J.N. Percolation Effects in Supercapacitors with Thin, Transparent Carbon Nanotube Electrodes. ACS Nano 2012, 6, 1732–1741. [Google Scholar] [CrossRef] [PubMed]

- Wu, Z. Transparent, Conductive Carbon Nanotube Films. Science 2004, 305, 1273–1276. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Ryu, K.; Liu, X.; Polikarpov, E.; Ly, J.; Tompson, M.E.; Zhou, C. Transparent, Conductive, and Flexible Carbon Nanotube Films and Their Application in Organic Light-Emitting Diodes. Nano Lett. 2006, 6, 1880–1886. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Wei, J.; Vajtai, R.; Ajayan, P.M.; Barrera, E.V. Iodine doped carbon nanotube cables exceeding specific electrical conductivity of metals. Sci. Rep. 2011, 1. [Google Scholar] [CrossRef] [PubMed]

- Rinzler, A.G.; Hafner, J.H.; Nikolaev, P.; Nordlander, P.; Colbert, D.T.; Smalley, R.E.; Lou, L.; Kim, S.G.; Tomanek, D. Unraveling Nanotubes: Field Emission from an Atomic Wire. Science 1995, 269, 1550–1553. [Google Scholar] [CrossRef] [PubMed]

- De Heer, W.A.; Châtelain, A.; Ugarte, D. A Carbon Nanotube Field-Emission Electron Source. Science 1995, 270, 1179–1180. [Google Scholar] [CrossRef]

- Wang, X.; Li, Q.; Xie, J.; Jin, Z.; Wang, J.; Li, Y.; Jiang, K.; Fan, S. Fabrication of Ultralong and Electrically Uniform Single-Walled Carbon Nanotubes on Clean Substrates. Nano Lett. 2009, 9, 3137–3141. [Google Scholar] [CrossRef] [PubMed]

- Lan, Y.; Wang, Y.; Ren, Z.F. Physics and applications of aligned carbon nanotubes. Adv. Phys. 2011, 60, 553–678. [Google Scholar] [CrossRef]

- Nishikawa, O.; Tomitori, M.; Iwawaki, F. High resolution tunneling microscopies: From FEM to STS. Surf. Sci. 1992, 266, 204–213. [Google Scholar] [CrossRef]

- Xu, N.S.; Huq, S.E. Novel cold cathode materials and applications. Mater. Sci. Eng. R Rep. 2005, 48, 47–189. [Google Scholar] [CrossRef]

- Sugie, H.; Tanemura, M.; Filip, V.; Iwata, K.; Takahashi, K.; Okuyama, F. Carbon nanotubes as electron source in an X-ray tube. Appl. Phys. Lett. 2001, 78, 2578–2580. [Google Scholar] [CrossRef]

- Yue, G.Z.; Qiu, Q.; Gao, B.; Cheng, Y.; Zhang, J.; Shimoda, H.; Chang, S.; Lu, J.P.; Zhou, O. Generation of continuous and pulsed diagnostic imaging X-ray radiation using a carbon-nanotube-based field-emission cathode. Appl. Phys. Lett. 2002, 81, 355–357. [Google Scholar] [CrossRef]

- Choi, W.B.; Chung, D.S.; Kang, J.H.; Kim, H.Y.; Jin, Y.W.; Han, I.T.; Lee, Y.H.; Jung, J.E.; Lee, N.S.; Park, G.S.; et al. Fully sealed, high-brightness carbon-nanotube field-emission display. Appl. Phys. Lett. 1999, 75, 3129–3131. [Google Scholar] [CrossRef]

- Baughman, R.H. Carbon Nanotubes—The Route toward Applications. Science 2002, 297, 787–792. [Google Scholar] [CrossRef] [PubMed]

- Dresselhaus, M.S.; Dresselhaus, G.; Avouris, P. (Eds.) Carbon Nanotubes Synthesis, Structure, Properties, and Applications. In Topics in Applied Physics; Springer: Berlin/Heidelberg, Germany, 2001; Volume 80, ISBN 978-3-540-41086-7. [Google Scholar]

- Charlier, J.-C.; Blase, X.; Roche, S. Electronic and transport properties of nanotubes. Rev. Mod. Phys. 2007, 79, 677–732. [Google Scholar] [CrossRef]

- Edgcombe, C.J.; Valdre, U. Microscopy and computational modelling to elucidate the enhancement factor for field electron emitters. J. Microsc. 2001, 203, 188–194. [Google Scholar] [CrossRef]

- Bonard, J.-M.; Maier, F.; Stöckli, T.; Châtelain, A.; de Heer, W.A.; Salvetat, J.-P.; Forró, L. Field emission properties of multiwalled carbon nanotubes. Ultramicroscopy 1998, 73, 7–15. [Google Scholar] [CrossRef]

- Smith, R.C.; Silva, S.R.P. Interpretation of the field enhancement factor for electron emission from carbon nanotubes. J. Appl. Phys. 2009, 106, 014314. [Google Scholar] [CrossRef]

- Wang, M.; Li, Z.H.; Shang, X.F.; Wang, X.Q.; Xu, Y.B. Field-enhancement factor for carbon nanotube array. J. Appl. Phys. 2005, 98, 014315. [Google Scholar] [CrossRef]

- Wang, X.Q.; Wang, M.; He, P.M.; Xu, Y.B.; Li, Z.H. Model calculation for the field enhancement factor of carbon nanotube. J. Appl. Phys. 2004, 96, 6752–6755. [Google Scholar] [CrossRef]

- DeHeer, W.A.; Bacsa, W.S.; Chatelain, A.; Gerfin, T.; Humphrey-Baker, R.; Forro, L.; Ugarte, D. Aligned Carbon Nanotube Films: Production and Optical and Electronic Properties. Science 1995, 268, 845–847. [Google Scholar] [CrossRef] [PubMed]

- Bower, C.; Zhou, O.; Zhu, W.; Ramirez, A.G.; Kochanski, G.P.; Jin, S. Fabrication and Field Emission Properties of Carbon Nanotube Cathodes. MRS Proc. 1999, 593. [Google Scholar] [CrossRef]

- Collins, P.G.; Zettl, A. A simple and robust electron beam source from carbon nanotubes. Appl. Phys. Lett. 1996, 69, 1969–1971. [Google Scholar] [CrossRef]

- Wang, L.; Chen, Y.; Chen, T.; Que, W.; Sun, Z. Optimization of field emission properties of carbon nanotubes cathodes by electrophoretic deposition. Mater. Lett. 2007, 61, 1265–1269. [Google Scholar] [CrossRef]

- Feng, T.; Dai, L.; Jiang, J.; Wang, X.; Liu, X.; Zou, S.; Li, Q.; Xu, J. Memory emission of printed carbon nanotube cathodes. Appl. Phys. Lett. 2006, 88, 203108. [Google Scholar] [CrossRef]

- Wang, Q.H.; Setlur, A.A.; Lauerhaas, J.M.; Dai, J.Y.; Seelig, E.W.; Chang, R.P.H. A nanotube-based field-emission flat panel display. Appl. Phys. Lett. 1998, 72, 2912–2913. [Google Scholar] [CrossRef]

- Burghard, M.; Duesberg, G.; Philipp, G.; Muster, J.; Roth, S. Controlled Adsorption of Carbon Nanotubes on Chemically Modified Electrode Arrays. Adv. Mater. 1998, 10, 584–588. [Google Scholar] [CrossRef]

- Bonard, J.-M.; Kind, H.; Stöckli, T.; Nilsson, L.-O. Field emission from carbon nanotubes: The first five years. Solid-State Electron. 2001, 45, 893–914. [Google Scholar] [CrossRef]

- Bonard, J.-M.; Croci, M.; Klinke, C.; Kurt, R.; Noury, O.; Weiss, N. Carbon nanotube films as electron field emitters. Carbon 2002, 40, 1715–1728. [Google Scholar] [CrossRef]

- Zhu, W.; Bower, C.; Zhou, O.; Kochanski, G.; Jin, S. Large current density from carbon nanotube field emitters. Appl. Phys. Lett. 1999, 75, 873–875. [Google Scholar] [CrossRef]

- Obraztsov, A.N.; Volkov, A.P.; Pavlovskii, I.Y.; Chuvilin, A.L.; Rudina, N.A.; Kuznetsov, V.L. Role of the curvature of atomic layers in electron field emission from graphitic nanostructured carbon. J. Exp. Theor. Phys. Lett. 1999, 69, 411–417. [Google Scholar] [CrossRef]

- Nilsson, L.; Groening, O.; Emmenegger, C.; Kuettel, O.; Schaller, E.; Schlapbach, L.; Kind, H.; Bonard, J.-M.; Kern, K. Scanning field emission from patterned carbon nanotube films. Appl. Phys. Lett. 2000, 76, 2071–2073. [Google Scholar] [CrossRef]

- Ito, F.; Tomihari, Y.; Okada, Y.; Konuma, K.; Okamoto, A. Carbon-nanotube-based triode-field-emission displays using gated emitter structure. IEEE Electron Device Lett. 2001, 22, 426–428. [Google Scholar] [CrossRef]

- Chung, D.-S.; Park, S.H.; Lee, H.W.; Choi, J.H.; Cha, S.N.; Kim, J.W.; Jang, J.E.; Min, K.W.; Cho, S.H.; Yoon, M.J.; et al. Carbon nanotube electron emitters with a gated structure using backside exposure processes. Appl. Phys. Lett. 2002, 80, 4045–4047. [Google Scholar] [CrossRef]

- Thong, J.T.L.; Oon, C.H.; Eng, W.K.; Zhang, W.D.; Gan, L.M. High-current field emission from a vertically aligned carbon nanotube field emitter array. Appl. Phys. Lett. 2001, 79, 2811–2813. [Google Scholar] [CrossRef]

- Jo, S.H.; Tu, Y.; Huang, Z.P.; Carnahan, D.L.; Huang, J.Y.; Wang, D.Z.; Ren, Z.F. Correlation of field emission and surface microstructure of vertically aligned carbon nanotubes. Appl. Phys. Lett. 2004, 84, 413–415. [Google Scholar] [CrossRef]

- Sveningsson, M.; Morjan, R.E.; Nerushev, O.; Campbell, E.E.B. Electron field emission from multi-walled carbon nanotubes. Carbon 2004, 42, 1165–1168. [Google Scholar] [CrossRef]

- Saito, Y.; Uemura, S. Field emission from carbon nanotubes and its application to electron sources. Carbon 2000, 38, 169–182. [Google Scholar] [CrossRef]

- Fursey, G. Field emission in vacuum micro-electronics. Appl. Surf. Sci. 2003, 215, 113–134. [Google Scholar] [CrossRef]

- Kwo, J.L.; Yokoyama, M.; Wang, W.C.; Chuang, F.Y.; Lin, I.N. Characteristics of flat panel display using carbon nanotubes as electron emitters. Diam. Relat. Mater. 2000, 9, 1270–1274. [Google Scholar] [CrossRef]

- Li, C.; Zhang, Y.; Mann, M.; Hasko, D.; Lei, W.; Wang, B.; Chu, D.; Pribat, D.; Amaratunga, G.A.J.; Milne, W.I. High emission current density, vertically aligned carbon nanotube mesh, field emitter array. Appl. Phys. Lett. 2010, 97, 113107. [Google Scholar] [CrossRef]

- Wadhawan, A.; Stallcup, R.E.; Stephens, K.F.; Perez, J.M.; Akwani, I.A. Effects of O2, Ar, and H2 gases on the field-emission properties of single-walled and multiwalled carbon nanotubes. Appl. Phys. Lett. 2001, 79, 1867–1869. [Google Scholar] [CrossRef]

- Purcell, S.T.; Vincent, P.; Journet, C.; Binh, V.T. Hot Nanotubes: Stable Heating of Individual Multiwall Carbon Nanotubes to 2000 K Induced by the Field-Emission Current. Phys. Rev. Lett. 2002, 88. [Google Scholar] [CrossRef] [PubMed]

- Bonard, J.-M.; Klinke, C.; Dean, K.A.; Coll, B.F. Degradation and failure of carbon nanotube field emitters. Phys. Rev. B 2003, 67. [Google Scholar] [CrossRef]

- Dean, K.A.; Chalamala, B.R. The environmental stability of field emission from single-walled carbon nanotubes. Appl. Phys. Lett. 1999, 75, 3017–3019. [Google Scholar] [CrossRef]

- Suga, H.; Abe, H.; Tanaka, M.; Shimizu, T.; Ohno, T.; Nishioka, Y.; Tokumoto, H. Stable multiwalled carbon nanotube electron emitter operating in low vacuum. Surf. Interface Anal. 2006, 38, 1763–1767. [Google Scholar] [CrossRef]

- Kita, S.; Sakai, Y.; Endo, T.; Sugimoto, W.; Goto, H. Stabilization of field electron emission from carbon nanofibers using ballast resistance. J. Vac. Sci. Technol. Nanotechnol. Microelectron. Mater. Process. Meas. Phenom. 2012, 30, 031801. [Google Scholar] [CrossRef]

- Shimoi, N.; Estrada, A.L.; Tanaka, Y.; Tohji, K. Properties of a field emission lighting plane employing highly crystalline single-walled carbon nanotubes fabricated by simple processes. Carbon 2013, 65, 228–235. [Google Scholar] [CrossRef]

- Shimoi, N.; Tohji, K. Current-Fluctuation Mechanism of Field Emitters Using Metallic Single-Walled Carbon Nanotubes with High Crystallinity. Appl. Sci. 2017, 7, 1322. [Google Scholar] [CrossRef]

- Smith, R.C.; Cox, D.C.; Silva, S.R.P. Electron field emission from a single carbon nanotube: Effects of anode location. Appl. Phys. Lett. 2005, 87, 103112. [Google Scholar] [CrossRef] [Green Version]

- Xu, Z.; Bai, X.D.; Wang, E.G.; Wang, Z.L. Field emission of individual carbon nanotube with in situ tip image and real work function. Appl. Phys. Lett. 2005, 87, 163106. [Google Scholar] [CrossRef]

- Nojeh, A.; Wong, W.-K.; Yieh, E.; Pease, R.F.; Dai, H. Electron beam stimulated field-emission from single-walled carbon nanotubes. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2004, 22, 3124. [Google Scholar] [CrossRef]

- Bonard, J.-M.; Salvetat, J.-P.; Stöckli, T.; de Heer, W.A.; Forró, L.; Châtelain, A. Field emission from single-wall carbon nanotube films. Appl. Phys. Lett. 1998, 73, 918–920. [Google Scholar] [CrossRef]

- Kuzumaki, T.; Takamura, Y.; Ichinose, H.; Horiike, Y. Structural change at the carbon-nanotube tip by field emission. Appl. Phys. Lett. 2001, 78, 3699–3701. [Google Scholar] [CrossRef]

- Robertson, J. Realistic applications of CNTs. Mater. Today 2004, 7, 46–52. [Google Scholar] [CrossRef]

- Smith, R.C.; Carey, J.D.; Forrest, R.D.; Silva, S.R.P. Effect of aspect ratio and anode location on the field emission properties of a single tip based emitter. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2005, 23, 632. [Google Scholar] [CrossRef] [Green Version]

- Bonard, J.-M.; Dean, K.A.; Coll, B.F.; Klinke, C. Field Emission of Individual Carbon Nanotubes in the Scanning Electron Microscope. Phys. Rev. Lett. 2002, 89. [Google Scholar] [CrossRef] [PubMed]

- Milne, W.I.; Teo, K.B.K.; Chhowalla, M.; Amaratunga, G.A.J.; Lee, S.B.; Hasko, D.G.; Ahmed, H.; Groening, O.; Legagneux, P.; Gangloff, L.; et al. Electrical and field emission investigation of individual carbon nanotubes from plasma enhanced chemical vapour deposition. Diam. Relat. Mater. 2003, 12, 422–428. [Google Scholar] [CrossRef]

- Minh, P.N.; Tuyen, L.T.T.; Ono, T.; Miyashita, H.; Suzuki, Y.; Mimura, H.; Esashi, M. Selective growth of carbon nanotubes on Si microfabricated tips and application for electron field emitters. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2003, 21, 1705. [Google Scholar] [CrossRef]

- She, J.C.; Xu, N.S.; Deng, S.Z.; Chen, J.; Bishop, H.; Huq, S.E.; Wang, L.; Zhong, D.Y.; Wang, E.G. Vacuum breakdown of carbon-nanotube field emitters on a silicon tip. Appl. Phys. Lett. 2003, 83, 2671–2673. [Google Scholar] [CrossRef]

- Jin, C.; Wang, J.; Wang, M.; Su, J.; Peng, L.-M. In-situ studies of electron field emission of single carbon nanotubes inside the TEM. Carbon 2005, 43, 1026–1031. [Google Scholar] [CrossRef]

- Hii, K.-F.; Ryan Vallance, R.; Chikkamaranahalli, S.B.; Pinar Mengüç, M.; Rao, A.M. Characterizing field emission from individual carbon nanotubes at small distances. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 2006, 24, 1081. [Google Scholar] [CrossRef]

- Wang, C.; Garcia, A.; Ingram, D.C.; Lake, M.; Kordesch, M.E. Cold field emission from CVD diamond films observed in emission electron microscopy. Electron. Lett. 1991, 27, 1459. [Google Scholar] [CrossRef]

- Xu, N.S.; Tzeng, Y.; Latham, R.V. A diagnostic study of the field emission characteristics of individual micro-emitters in CVD diamond films. J. Phys. D Appl. Phys. 1994, 27, 1988–1991. [Google Scholar] [CrossRef]

- Geis, M.W.; Gregory, J.A.; Pate, B.B. Capacitance-voltage measurements on metal-SiO/sub 2/-diamond structures fabricated with. IEEE Trans. Electron Devices 1991, 38, 619–626. [Google Scholar] [CrossRef]

- Lettington, A.H.; Steeds, J.W. (Eds.) Thin Film Diamond, 1st ed.; Chapman & Hall for the Royal Society: London, UK; New York, NY, USA, 1994; ISBN 978-0-412-49630-1. [Google Scholar]

- Xu, N. Field emission from diamond and related films. Ultramicroscopy 1999, 79, 59–72. [Google Scholar] [CrossRef]

- Staryga, E.; Jarzynska, D.; Fabisiak, K.; Banaszak, A. Field emission from diamond and diamond-like carbon films. J. Superhard Mater. 2007, 29, 189–197. [Google Scholar] [CrossRef]

- Robertson, J. Electron affinity of carbon systems. Diam. Relat. Mater. 1996, 5, 797–801. [Google Scholar] [CrossRef]

- Jou, S.; Doerr, H.J.; Bunshah, R.F. Electron emission characterization of diamond thin films grown from a solid carbon source. Thin Solid Films 1996, 280, 256–261. [Google Scholar] [CrossRef]

- Karabutov, A.; Frolov, V.; Pimenov, S.; Konov, V. Grain boundary field electron emission from CVD diamond films. Diam. Relat. Mater. 1999, 8, 763–767. [Google Scholar] [CrossRef]

- Zhirnov, V.V. Field emission from silicon spikes with diamond coatings. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1995, 13, 418. [Google Scholar] [CrossRef]

- Cui, J.B.; Ristein, J.; Ley, L. Electron Affinity of the Bare and Hydrogen Covered Single Crystal Diamond (111) Surface. Phys. Rev. Lett. 1998, 81, 429–432. [Google Scholar] [CrossRef]

- Xu, N.S.; Latham, R.V. Coherently scattered hot electrons emitted from MIM graphite microstructures deposited on broad-area vacuum-insulated high-voltage electrodes. J. Phys. D Appl. Phys. 1986, 19, 477–482. [Google Scholar] [CrossRef]

- Gröning, O.; Küttel, O.M.; Gröning, P.; Schlapbach, L. Field emission spectroscopy from discharge activated chemical vapor deposition diamond. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1999, 17, 1064. [Google Scholar] [CrossRef]

- Geis, M.W.; Twichell, J.C.; Efremow, N.N.; Krohn, K.; Lyszczarz, T.M. Comparison of electric field emission from nitrogen-doped, type Ib diamond, and boron-doped diamond. Appl. Phys. Lett. 1996, 68, 2294–2296. [Google Scholar] [CrossRef]

- Geis, M.W. Diamond emitters fabrication and theory. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1996, 14, 2060. [Google Scholar] [CrossRef]

- Zhu, W. Electron field emission from chemical vapor deposited diamond. J. Vac. Sci. Technol. B Microelectron. Nanometer Struct. 1996, 14, 2011. [Google Scholar] [CrossRef]

- Lacher, F.; Wild, C.; Behr, D.; Koidl, P. Electron field emission from thin fine-grained CVD diamond films. Diam. Relat. Mater. 1997, 6, 1111–1116. [Google Scholar] [CrossRef]

- Ralchenko, V.; Karabutov, A.; Vlasov, I.; Frolov, V.; Konov, V.; Gordeev, S.; Zhukov, S.; Dementjev, A. Diamond–carbon nanocomposites: Applications for diamond film deposition and field electron emission. Diam. Relat. Mater. 1999, 8, 1496–1501. [Google Scholar] [CrossRef]

- Karabutov, A.V.; Frolov, V.D.; Konov, V.I. Diamond/sp2-bonded carbon structures: Quantum well field electron emission? Diam. Relat. Mater. 2001, 10, 840–846. [Google Scholar] [CrossRef]

- Zhu, W.; Kochanski, G.P.; Jin, S.; Seibles, L. Defect-enhanced electron field emission from chemical vapor deposited diamond. J. Appl. Phys. 1995, 78, 2707–2711. [Google Scholar] [CrossRef]

- Geis, M.W.; Twichell, J.C.; Macaulay, J.; Okano, K. Electron field emission from diamond and other carbon materials after H2, O2, and Cs treatment. Appl. Phys. Lett. 1995, 67, 1328–1330. [Google Scholar] [CrossRef]

- Takeuchi, D.; Koizumi, S.; Makino, T.; Kato, H.; Ogura, M.; Ohashi, H.; Okushi, H.; Yamasaki, S. Negative electron affinity of diamond and its application to high voltage vacuum power switches: NEA of diamond and its application to a high voltage vacuum power switch. Phys. Status Solidi A 2013, 210, 1961–1975. [Google Scholar] [CrossRef]

- Takeuchi, D.; Nebel, C.E.; Yamasaki, S. Photoelectron emission from diamond. Phys. Status Solidi A 2006, 203, 3100–3106. [Google Scholar] [CrossRef]

- Takeuchi, D.; Ogura, M.; Ri, S.-G.; Kato, H.; Okushi, H.; Yamasaki, S. Electron emission suppression from hydrogen-terminated n-type diamond. Diam. Relat. Mater. 2008, 17, 986–988. [Google Scholar] [CrossRef]

- Takeuchi, D.; Nebel, C.E.; Yamasaki, S. Photoelectron emission properties of hydrogen terminated intrinsic diamond. J. Appl. Phys. 2006, 99, 086102. [Google Scholar] [CrossRef]

- Takeuchi, D.; Kato, H.; Ri, G.S.; Yamada, T.; Vinod, P.R.; Hwang, D.; Nebel, C.E.; Okushi, H.; Yamasaki, S. Direct observation of negative electron affinity in hydrogen-terminated diamond surfaces. Appl. Phys. Lett. 2005, 86, 152103. [Google Scholar] [CrossRef]

- Koizumi, S. Ultraviolet Emission from a Diamond pn Junction. Science 2001, 292, 1899–1901. [Google Scholar] [CrossRef] [PubMed]

- Kono, S.; Koizumi, S. Images and Energy Distributions of Electrons Emitted from a Diamond pn-Junction Diode. e-J. Surf. Sci. Nanotechnol. 2009, 7, 660–664. [Google Scholar] [CrossRef]

- Novoselov, K.S. Electric Field Effect in Atomically Thin Carbon Films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Giubileo, F.; Romeo, F.; Sabatino, P.; Carapella, G.; Iemmo, L.; Schroeder, T.; Lupina, G. Graphene field effect transistors with niobium contacts and asymmetric transfer characteristics. Nanotechnology 2015, 26, 475202. [Google Scholar] [CrossRef] [PubMed]

- Giubileo, F.; Di Bartolomeo, A. The role of contact resistance in graphene field-effect devices. Prog. Surf. Sci. 2017, 92, 143–175. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Giubileo, F.; Iemmo, L.; Romeo, F.; Santandrea, S.; Gambardella, U. Transfer characteristics and contact resistance in Ni- and Ti-contacted graphene-based field-effect transistors. J. Phys. Condens. Matter 2013, 25, 155303. [Google Scholar] [CrossRef] [PubMed]

- Di Bartolomeo, A.; Giubileo, F.; Luongo, G.; Iemmo, L.; Martucciello, N.; Niu, G.; Fraschke, M.; Skibitzki, O.; Schroeder, T.; Lupina, G. Tunable Schottky barrier and high responsivity in graphene/Si-nanotip optoelectronic device. 2D Mater. 2016, 4, 015024. [Google Scholar] [CrossRef]

- Di Bartolomeo, A.; Luongo, G.; Giubileo, F.; Funicello, N.; Niu, G.; Schroeder, T.; Lisker, M.; Lupina, G. Hybrid graphene/silicon Schottky photodiode with intrinsic gating effect. 2D Mater. 2017, 4, 025075. [Google Scholar] [CrossRef]

- Vargas-Bernal, R. State-of-the-Art Electronic Devices Based on Graphene. In Nanoelectronics and Materials Development; Kar, A., Ed.; InTech: Rijeka, Croatia, 2016; ISBN 978-953-51-2525-9. [Google Scholar]

- Giubileo, F.; Martucciello, N.; Di Bartolomeo, A. Focus on graphene and related materials. Nanotechnology 2017, 28, 410201. [Google Scholar] [CrossRef] [PubMed]

- Lee, S.W.; Lee, S.S.; Yang, E.-H. A Study on Field Emission Characteristics of Planar Graphene Layers Obtained from a Highly Oriented Pyrolyzed Graphite Block. Nanoscale Res. Lett. 2009, 4, 1218–1221. [Google Scholar] [CrossRef] [PubMed]

- Qian, M.; Feng, T.; Ding, H.; Lin, L.; Li, H.; Chen, Y.; Sun, Z. Electron field emission from screen-printed graphene films. Nanotechnology 2009, 20, 425702. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.; Zeng, B.; Wu, Z.; Zhu, J.; Liu, X. Improved field emission property of graphene paper by plasma treatment. Appl. Phys. Lett. 2010, 97, 033109. [Google Scholar] [CrossRef]

- Xiao, Z.; She, J.; Deng, S.; Tang, Z.; Li, Z.; Lu, J.; Xu, N. Field Electron Emission Characteristics and Physical Mechanism of Individual Single-Layer Graphene. ACS Nano 2010, 4, 6332–6336. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Wang, Q.; Tao, Z.; Qi, Z.; Zhai, Y.; Wu, S.; Zhang, X.; Lei, W. Field Emission of Wet Transferred Suspended Graphene Fabricated on Interdigitated Electrodes. ACS Appl. Mater. Interfaces 2016, 8, 3295–3300. [Google Scholar] [CrossRef] [PubMed]

- Eda, G.; Emrah Unalan, H.; Rupesinghe, N.; Amaratunga, G.A.J.; Chhowalla, M. Field emission from graphene based composite thin films. Appl. Phys. Lett. 2008, 93, 233502. [Google Scholar] [CrossRef]

- Stratakis, E.; Eda, G.; Yamaguchi, H.; Kymakis, E.; Fotakis, C.; Chhowalla, M. Free-standing graphene on microstructured silicon vertices for enhanced field emission properties. Nanoscale 2012, 4, 3069. [Google Scholar] [CrossRef] [PubMed]

- Malesevic, A.; Kemps, R.; Vanhulsel, A.; Chowdhury, M.P.; Volodin, A.; Van Haesendonck, C. Field emission from vertically aligned few-layer graphene. J. Appl. Phys. 2008, 104, 084301. [Google Scholar] [CrossRef]

- Wu, Z.-S.; Pei, S.; Ren, W.; Tang, D.; Gao, L.; Liu, B.; Li, F.; Liu, C.; Cheng, H.-M. Field Emission of Single-Layer Graphene Films Prepared by Electrophoretic Deposition. Adv. Mater. 2009, 21, 1756–1760. [Google Scholar] [CrossRef]

- Wang, K.; Feng, T.; Qian, M.; Ding, H.; Chen, Y.; Sun, Z. The field emission of vacuum filtered graphene films reduced by microwave. Appl. Surf. Sci. 2011, 257, 5808–5812. [Google Scholar] [CrossRef]

- Pandey, S.; Rai, P.; Patole, S.; Gunes, F.; Kwon, G.-D.; Yoo, J.-B.; Nikolaev, P.; Arepalli, S. Improved electron field emission from morphologically disordered monolayer graphene. Appl. Phys. Lett. 2012, 100, 043104. [Google Scholar] [CrossRef]

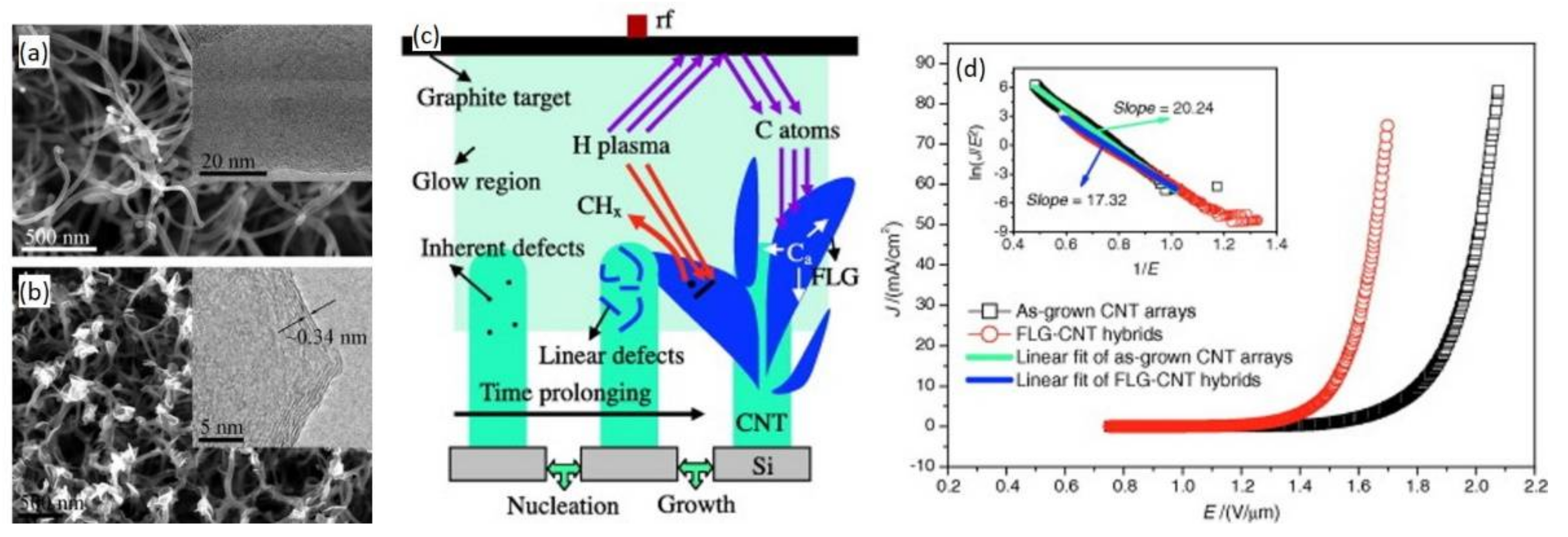

- Deng, J.; Zheng, R.; Yang, Y.; Zhao, Y.; Cheng, G. Excellent field emission characteristics from few-layer graphene–carbon nanotube hybrids synthesized using radio frequency hydrogen plasma sputtering deposition. Carbon 2012, 50, 4732–4737. [Google Scholar] [CrossRef]

- Deng, J.; Zheng, R.; Zhao, Y.; Cheng, G. Vapor–Solid Growth of Few-Layer Graphene Using Radio Frequency Sputtering Deposition and Its Application on Field Emission. ACS Nano 2012, 6, 3727–3733. [Google Scholar] [CrossRef] [PubMed]

- Ye, D.; Moussa, S.; Ferguson, J.D.; Baski, A.A.; El-Shall, M.S. Highly Efficient Electron Field Emission from Graphene Oxide Sheets Supported by Nickel Nanotip Arrays. Nano Lett. 2012, 12, 1265–1268. [Google Scholar] [CrossRef] [PubMed]

- Lv, S.; Li, Z.; Liao, J.; Wang, G.; Li, M.; Miao, W. Optimizing Field Emission Properties of the Hybrid Structures of Graphene Stretched on Patterned and Size-controllable SiNWs. Sci. Rep. 2015, 5. [Google Scholar] [CrossRef] [PubMed]

- Palnitkar, U.A.; Kashid, R.V.; More, M.A.; Joag, D.S.; Panchakarla, L.S.; Rao, C.N.R. Remarkably low turn-on field emission in undoped, nitrogen-doped, and boron-doped graphene. Appl. Phys. Lett. 2010, 97, 063102. [Google Scholar] [CrossRef]

- Qi, J.L.; Wang, X.; Zheng, W.T.; Tian, H.W.; Hu, C.Q.; Peng, Y.S. Ar plasma treatment on few layer graphene sheets for enhancing their field emission properties. J. Phys. D Appl. Phys. 2010, 43, 055302. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhu, M.Y.; Outlaw, R.A.; Zhao, X.; Manos, D.M.; Holloway, B.C.; Mammana, V.P. Free-standing subnanometer graphite sheets. Appl. Phys. Lett. 2004, 85, 1265–1267. [Google Scholar] [CrossRef]

- Panchakarla, L.S.; Subrahmanyam, K.S.; Saha, S.K.; Govindaraj, A.; Krishnamurthy, H.R.; Waghmare, U.V.; Rao, C.N.R. Synthesis, Structure, and Properties of Boron- and Nitrogen-Doped Graphene. Adv. Mater. 2009, 21, 4726–4730. [Google Scholar] [CrossRef]

- Huang, C.-K.; Ou, Y.; Bie, Y.; Zhao, Q.; Yu, D. Well-aligned graphene arrays for field emission displays. Appl. Phys. Lett. 2011, 98, 263104. [Google Scholar] [CrossRef]

- Lin, J.-C.; Huang, B.-R.; Lin, T.-C. Hybrid structure of graphene sheets/ZnO nanorods for enhancing electron field emission properties. Appl. Surf. Sci. 2014, 289, 384–387. [Google Scholar] [CrossRef]

| CNT Length () | CNT Radius () | CNT Apex-Anode Distance () | Setup | Turn-on Voltage (V) or Field (V/) | Ref. | |

|---|---|---|---|---|---|---|

| 3.2 | 17 | 0.06–5 | TIP | 230–460 | 47–185 V | [115] |

| 5.83 | 24 | 10 | TIP | 208 | 270 V | [116] |

| 0.5 | 15–20 | 10–50 | TIP | 500–750 | 60–260 V | [117] |

| 1.5 | 20 | 20 | P-P | 200–500 | 150–400 V | [118] |

| 3.9 | 15.8 | 0.40 | P-P | 300 | 100 V | [109] |

| 8 | 40 | 1–60 | TIP | 100–800 | 40–5 V/ | [108] |

| 1.3 | 50 | 0.29 | P-P | 140 | 90 V | [119] |

| 2.1 | 30 | 1.4–13.5 | P-P | 100–700 | 50–70 V | [120] |

| 5 | 30 | 0.8 | TIP | 110 | 30 V/ | [13] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giubileo, F.; Di Bartolomeo, A.; Iemmo, L.; Luongo, G.; Urban, F. Field Emission from Carbon Nanostructures. Appl. Sci. 2018, 8, 526. https://doi.org/10.3390/app8040526

Giubileo F, Di Bartolomeo A, Iemmo L, Luongo G, Urban F. Field Emission from Carbon Nanostructures. Applied Sciences. 2018; 8(4):526. https://doi.org/10.3390/app8040526

Chicago/Turabian StyleGiubileo, Filippo, Antonio Di Bartolomeo, Laura Iemmo, Giuseppe Luongo, and Francesca Urban. 2018. "Field Emission from Carbon Nanostructures" Applied Sciences 8, no. 4: 526. https://doi.org/10.3390/app8040526