Abstract

In this study, effects of pretreatment of corn stover (CS) with sodium hydroxide (NaOH) combined with calcium oxide (CaO) on anaerobic co-digestion of swine manure and CS for biogas production were investigated. Different pretreated-CSs were prepared by adding different doses of NaOH and CaO to CS: Treat-CSA (0.10 g NaOH/g CS), Treat-CSB ((0.075 g NaOH + 0.05 g CaO)/g CS), Treat-CSC ((0.05 g NaOH + 0.05 g CaO)/g CS), and Treat-CSD ((0.025 g NaOH + 0.1 g CaO)/g CS). Lignin removal rate, biomass recovery, reduced sugar, methane yield, DT80 (digestion time when biogas achieved 80% of the total biogas), composition of residues, and cost-efficiency were measured to characterize CS after pretreatment and to evaluate the performance of co-digestors fed with swine manure and differently-pretreated CS. The results showed that Treat-CSB showed an excellent lignin removal efficiency and biomass recovery, resulting in the highest methane yield in its co-digestion with swine manure. Since the net benefit of Treat-CSB was calculated to be the highest (i.e., $1.89/ton total solids), therefore, we believe the co-digestion of Treat-CSB and swine manure for biogas production be an effective valorization option for the wastes.

1. Introduction

The production of biofuels from renewable resources, such as agricultural crops, woody and herbaceous biomass, and waste materials, are critical in sustaining the world’s economy and responding to global climate change. [1] Corn stover (CS), as one of these renewable resources, is a valuable feed-stock for the production of bio-products due to its easy renewability, low cost and abundance in the nature [2,3,4]. It is one of the most abundant agricultural wastes; as of 2015, its production reached 224.6 million tons only in China [5]. CS can be transformed to biogas by anaerobic digestion, which can potentially replace fossil fuels in heat and power generation [6]. Conversion of biomass to biogas involves a series of biological processes in the anaerobic digestion. Hydrolytic bacterium hydrolyzes the biodegradable material of biomass at first, and then methanogens generate biogas from hydrolyzed material under anaerobic conditions [7]. Material biodegradability is the most important factor in anaerobic digestion, while numerous factors can affect the efficiency of digestion [6,8]. Lignin is found to be one of main reasons which result in the difficulty in anaerobic digestion of biomass like CS; there is a strong negative correlation with conversion rate of polysaccharides [9,10]. Lignin is a complex aromatic polymer present in the cell wall of CS that prevents microbial action into the interior of lignocelluloses [11]. An effective pretreatment step prior to biogas conversion is necessarily required to reduce resistance by altering the chemical and structural features of the biomass [12]. Therefore, pretreatment of lignin is very important to produce biogas from biomass. The purpose of pretreatment process is not only to separate lignin from cellulose and hemicelluloses of lignocelluloses, but also simultaneously reduces cellulose crystallinity and increases the porosity of the biomass [13].

Sodium hydroxide (NaOH) pretreatment has been reported as one of the most effective chemical methods for improving biomass biodegradability [12,14,15], and is advantageous since it is conducted at a milder temperature compared to other pretreatment technologies (including physical, chemical, biological, and so on) [1,4,13,16,17,18,19]. Compared to acid pretreatment, the solubility of cellulose is not increased to lesser degree with the alkali pretreatment [1,18,20]. Saponification reactions of intermolecular ester bonds cross-linking cellulose and hemicelluloses or lignin occur in the lignocelluloses materials during the NaOH pretreatment process [21]. It decreases the crystallinity of cellulose and degree of sugar polymerization by disrupting the lignin structure [22]. The increased substrate porosity and carbohydrate exposure can make biomass more accessible to cellulolytic microorganisms compared to raw materials [23], resulting in improved biogas production. For example, the degradation rate of lignin and biogas yield of CS could be improved by 46.2% and 48.5%, respectively, after the pretreatment of CS with 7.5% NaOH [24]. The pretreatment of CS with NaOH combined with methanol significantly enhanced the enzyme accessibility of CS, resulting in 97.5% glucan and 55.0% lignin removal efficiency, respectively [25]. When CS was pretreated with 2% NaOH combined with 78 mg/L ozone at 80 °C, the enzymatic hydrolysis degree of the cellulose in CS could be improved, achieving the maximum lignin removal rate of 88.9% [26]. However, NaOH pretreatment alone is inefficient for large-scale applications mainly due to its cost and strong alkalinity. The considerable loss of cellulose and hemicellulose was also reported during NaOH pretreatment [5]. Although 86.1% lignin was removed by NaOH pretreatment, 93.8% hemicellulose that could be converted to sugar was lost at the same time [27].

Comparing with NaOH, CaO is considered a cheaper pretreatment alternative in the market; it can provide a certain alkalinity as calcium hydroxide (Ca(OH)2) while reacting with water [20]. For example, biofibers pretreated with 6% CaO could increase methane production by 66% compared to untreated biofibers within 10 days [28]. The ethanol yield was improved 74% within 79 h when leaf star rice straw was pretreated with CaO and fermented at 30 °C [20]. Regarding the Ca(OH)2 dose in pretreatment, a ratio of Ca(OH)2 to NaOH of 7%~10% was reported to be the optimum for the pretreatment of extruded rice straw [29]. Degradation of 44% of lignin was also observed when sugarcane bagasse was pretreated by 8.5% Ca(OH)2 [27]. In another study, 10% Ca(OH)2 and an isothermal treatment time of 106.3 min could extract 70% of lignin from the hydrothermally treated sweet sorghum bagasse [30]. A total of 87.5% of the initial lignin was removed with 0.073 g Ca(OH)2 per g of raw corn stover (RCS)at a mild temperature (e.g., 25~55 °C), while cellulose being not affected by the CaO pretreatment [31]. The reason that CaO shows a lower pretreatment efficiency is its weak alkalinity and the calcium-lignin complex which delays the lignin removal [32].

CaO is less expensive than NaOH while NaOH provides high alkalinity in the pretreatment, therefore, a mixture of CaO and NaOH was used for cost-effectively pretreating CS. In a study, CS was pretreated with a mixture of CaO and NaOH, and more of it could be converted to sugar than that pretreated only with NaOH [33]. CaO was also added to reduce the dose of the costly NaOH in an alkaline pretreatment of switch grass without a negative effect on the pretreatment efficiency observed [34,35,36].

Until now, however, research on CS pretreatment by a mixture of CS and NaOH only focused on its effect on sugar and ethanol production [34,37]. There is a lack of research and knowledge on the effect of the pretreatment of CS by the mixture of CaO and NaOH on biogas production. Research on the economics of CS pretreatment, especially the CS pretreatment using a mixture of CaO and NaOH, has seldom been done. Therefore, in this study, NaOH combined with CaO was applied for the pretreatment of CS which was used as a feedstock along with swine manure for the mesophilic anaerobic co-digestion. Methane yield, biomass recovery, lignin content, reduced sugar, DT80, and residue composition were measured to evaluate the effects of the CS pretreatment by the NaOH and CaO mixture and the potential cost-effectiveness.

2. Experimental Section

2.1. Materials

Corn stover used in this study was collected from Luhe County, Nanjing, China. The collected CS sample was air-dried and milled using a hammer mill (FW100, Taisite Co., Tianjin, China) with 1 mm screen in the lab. The milled CS was sealed in a plastic bag and stored at room temperature (approximately 21 °C). Swine manure was collected from a farm in Luhe County and stored in a refrigerator at 4 °C. The inoculums for the test were obtained from a working digester fed with CS as a feed. The chemical compositions of the feeds and inoculum were analyzed and listed in Table 1.

Table 1.

Chemical composition of the materials used in the test.

2.2. Pretreatment

Ten grams of CS, which had been oven-dried at 105 °C for 8 h was placed in 150 mL serum bottles. Then, different doses of NaOH and CaO were added to the serum bottles; the added doses were 0.10 g NaOH/g CS, (0.075 g NaOH + 0.05 g CaO)/g CS, (0.05 g NaOH + 0.05 g CaO)/g CS, and (0.025 g NaOH + 0.1 g CaO)/g CS, and the treatments were indexed as Treat-CSA, Treat-B, Treat-C, and Treat-D, respectively. Then, about 100 mL deionized (DI) water was added into each of the bottles and completely mixed. After DI water was added, all the serum bottles were sealed to prevent water evaporation and placed in a water bath. Then, the bottles were stirred at 120 rpm for 6 h at room temperature for CS pretreatment. The pretreated CS was, then, recovered via centrifugation and subsequently dried in an oven at 105 °C for 8 h [38]. The dried CS was stored in a sealed plastic bag at 4 °C until it was used for digestion tests.

2.3. Digestion

The pretreated CS and RCS were digested along with swine manure in 150 mL serum bottles; these digestion tests were performed in duplicates. The C/N ratio of the substrate (CS and swine manure) was 25/1, which was believed to be beneficial for anaerobic digestion. The required amount of CS was placed into a bottle for the digestion test along with 80 mL swine manure and 20 mL inoculum. The prepared digesters were placed in a bath shaker operated at a temperature of 35 °C and at a shaking speed of 120 rpm.

2.4. Analytical Procedures

The composition of CS was measured to evaluate the effect of NaOH and/or CaO pretreatment. The lignin content of CS was measured according to the analytical procedures established by the National Renewable Energy Laboratory. The reducing sugars of CS were measured using the 3,5–dinitrosalicylic acid (DNS) method adapted from Miller (1959) and Ghose (1987) [34]. The daily biogas production for each digester was recorded via the water displacement method, and the related cumulative biogas production was calculated. Each biogas production datum was collected as the average of duplicate samples. The biogas samples were taken from the gas collection line and analyzed for the methane content using a gas chromatograph (GC17A, Shimadzu, Kyoto, Japan) equipped with a thermal conductivity detector. The volume of daily-produced methane was then calculated as a datum for biogas production and methane content. Total carbon (TC), total nitrogen (TN), and total Kjeldahl nitrogen were determined using the analyzer (Bran and Luebbe Digital Auto Analyzer III System, Shanghai, China) [39,40]. Chemical oxygen demand (COD) was measured using a HACH Dr/2010 spectrophotometer (Shanghai, China). Each of the data was calculated as the average of three samples in the test [41].

2.5. Energy and Cost Analysis

The methane yield based on the initial total solids (TS) of CS biomass was calculated using [33]:

CH4 yield (L/kg initial TS) = CH4 yield (L/kg volatile solids (VS)) × VS × Dry matter recovery

Energy production from CS biomass was calculated as the product of the initial TS-based methane yield, the lower heating value of methane (33 kJ/L at 25 °C and 101 kPa ), and an assumed effective electric efficiency of 0.6 for a combined heat and power, and the average electricity price ($2.91 × 10−5/kJ) [33]. The revenue due to the pretreatment was calculated by subtracting the amount of electricity generation for untreated CS from that of pretreated CS. The cost for the chemical treatment was estimated based on the loading ratio and price of CaO ($70/ton) [20] and NaOH ($450/ton) [42]. The revenue due to pretreatment minus the cost for the chemical treatment was determined and reported as the net benefit from the pretreatment [41].

3. Results and Discussion

3.1. Effect of Pretreatment Using Alkaline

The lignin content of RCS, the lignin removal efficiency and biomass recovery from CS of each NaOH and CaO pretreatment were analyzed and summarized in Table 2.

Table 2.

Effect of corn stover (CS) pretreated with NaOH and CaO.

As shown in Table 2, the lignin content of RCS was 23.7% ± 0.23% before alkaline pretreatment, but it dropped to 13.2% ± 0.48% (Treat-CSA), 13.1% ± 0.17% (Treat-CSB), 16.1% ± 0.22% (Treat-CSC) and 17.8% ± 0.87% (Treat-CSD) after pretreatment. However, the lignin removal efficiency declined from 44.5% ± 2.11% to 24.8% ± 3.83% as the amount of NaOH in the pretreatment decreased. This result indicated that NaOH was effective in degrading lignin in CS. Removal of lignin can improve the accessibility of enzyme or hydrolytic anaerobic microbes during the CS digestion [22,43].

It is noticeable that CaO was also effective in lignin degradation during the CS pretreatment. The lignin removal efficiency of Treat-CSB reached 44.6% ± 0.75%, which was comparable with that of Treat-CSA (44.5% ± 2.11%). However, Treat-CSC and Treat-CSD showed less lignin removal efficiencies: 32.0% ± 0.97%, 24.8% ± 3.83% for Treat-SCS and Treat-CSD, respectively. This is because CaO effectively increased the alkalinity of the reactor system while being added in the pretreatment to obtain more alkalinity. The similar effort of 10%~20% lignin removal rate was reported while Coastal Bermudagrass pretreated with different CaO loadings (0.02~0.20 g of dry biomass) [36]. The lignin removal efficiency for CS decreased from 44.6% ± 0.75% to 24.8% ± 3.8% as the NaOH dose reduced while the CaO dose increased in the CS pretreatment. This result is due to the poor solubility of Ca(OH)2, which cannot provide enough alkalinity to decompose lignin of CS [32].

Biomass recovery is a parameter which determines the total amount of biomass that can be potentially converted to biogas during digestion [33]. The biomass recovery was 72.0% ± 1.14%, 73.1% ± 0.08%, 78.3% ± 2.01% and 81.6% ± 1.21% for Treat-CSA, Treat-CSB, Treat-CSC and Treat-CSD, respectively (Table 2). The co-digestion of the NaOH-pretreated CS (Treat-CSA) and swine manure showed the lowest biomass recovery probably because more lignin and hemicellulose in CS was completely degraded during the NaOH pretreatment [34]. However, biomass recovery was obviously increased by replacing some of NaOH with CaO, because CaO inhibits degradation of hemicellulose in the reaction system [2]. CaO enables the formation of calcium linkages within the biomass structure to reduce the solubilization of biomass components under alkaline attack [33,44].

3.2. Anaerobic Co-Digestion.

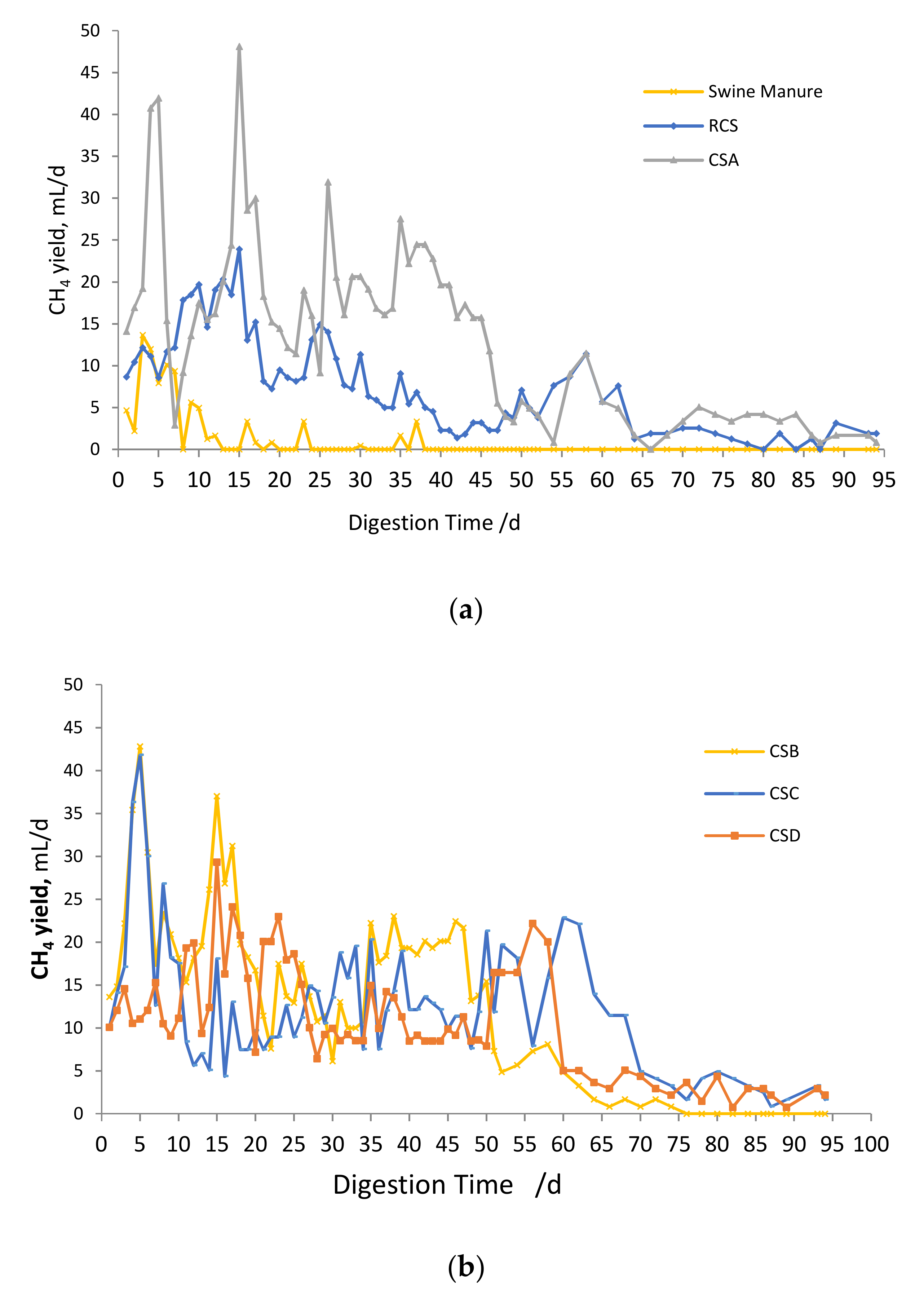

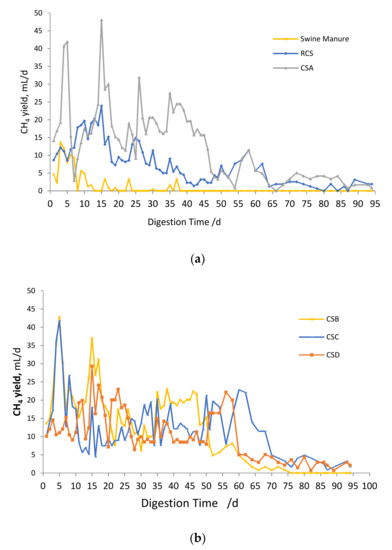

The methane yield in the digestion represents the effect of CS pretreatment. The daily methane yield is presented in Figure 1a,b.

Figure 1.

Methane Yield of Anaerobic co-digestion of swine manure and differently-treated CS, (a): Methane yield of co-digestion of swine manure, RCS and CSA; (b) methane yield of anaerobic digestion of CSB, CSC and CSD.

From Figure 1a, when Treat-CSA was co-digested with swine manure, methane yield increased from 14 mL/d on Day 1 to 42 mL/d on Day 5, and then it gradually decreased to the lowest point probably due to the vigorous acidification phenomenon, which is common in batch-type anaerobic digestion. After that, methane yield sharply increased to 48 mL/d and maintained the high yield for about 30 days. The co-digestion of RCS and swine manure showed relatively lower methane yield than that of Treat-CSA and swine manure in the beginning, only because of the light acidification phenomenon.

From Figure 1b, methane yield of the bottles with Treat-CSB and swine manure showed a similar trend to that of the ones with Treat-CSA and swine manure; high methane yield in the beginning of the co-digestion. However, for co-digestion reactors with CS pretreated with more CaO and less NaOH (i.e., Treat-CSC and Treat-CSD), the methane yield was obviously lower than that of the co-digestion with Treat-CSB. In the digestion processes, hydrolytic bacteria can rapidly access the internal cellulose of CS to make more easily biodegradable organics that can be converted to methane in the beginning of digestion [44]. However, the methane yield rapidly decreased to a very low point after the high yield because of the heavy acidification phenomenon producing considerable excess fatty acids. The pH value of the digestion liquid sharply decreased and inhibited the activity of the methane-producing bacteria [45,46]. In the last stage where little biodegradable biomass was available, a very low methane yield (only about 0~3 mL/d) could be observed. On the other hand, the co-digestion with RCS produced more methane in the last stage (i.e., about 5~21 mL), indicating that cellulose and hemicelluloses in the RCS were slowly hydrolyzed over time [35].

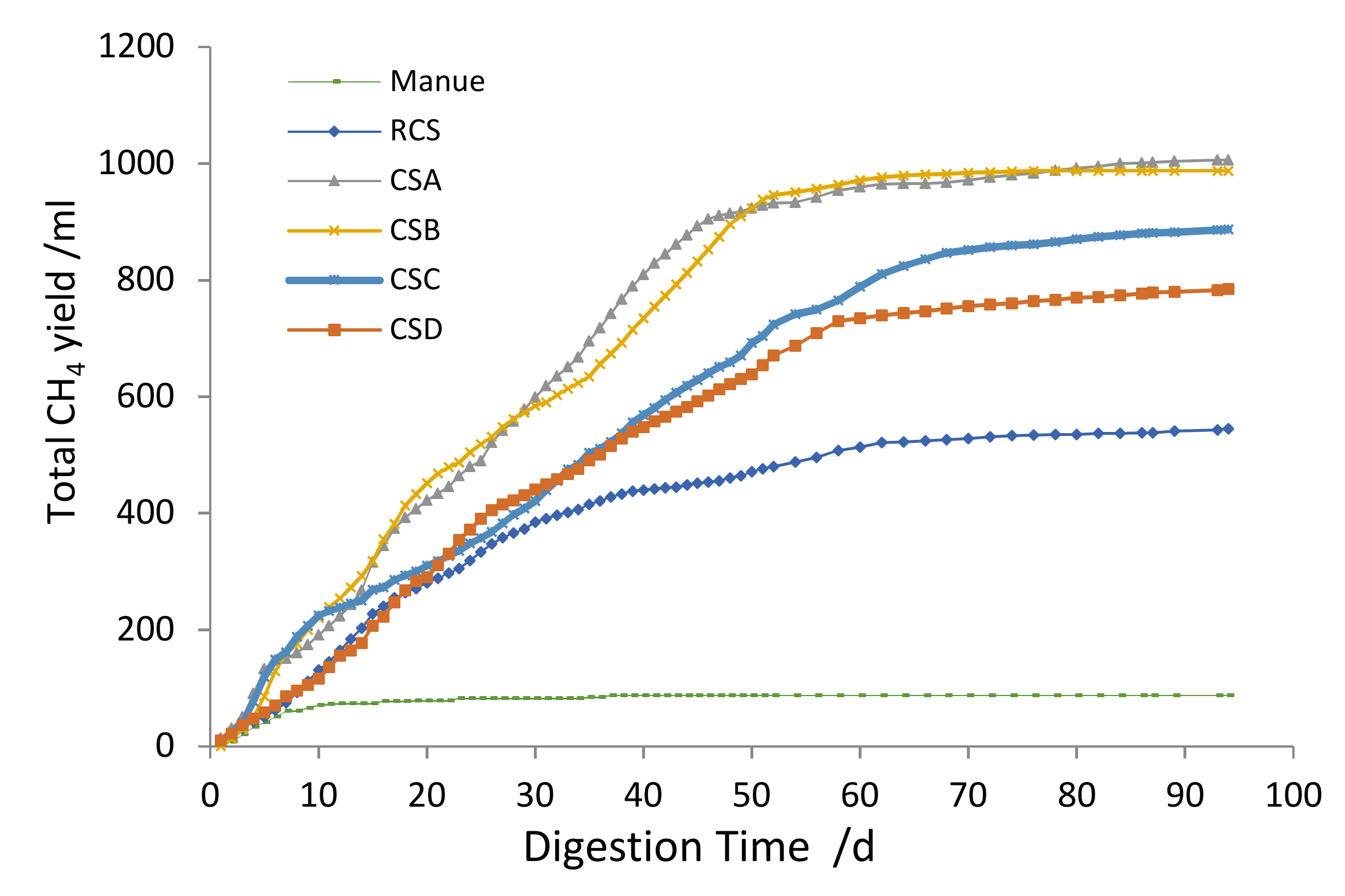

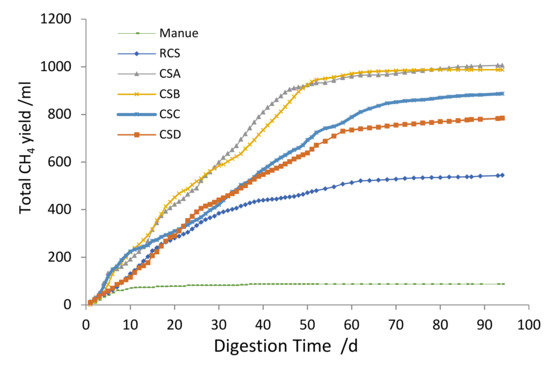

The cumulative amount of methane produced from the anaerobic co-digestion with Treat-CSA, Treat-CSB, Treat-CSC, and Treat-CSD was 987, 1007, 885 and 783 mL, respectively (Figure 2). On the other hand, only 545 mL methane was produced from the co-digestion with RCS, which was only 55% of that from the co-digestion with Treat-CSB. This indicates that addition of alkaline to the pretreatment of feedstock could effectively improve methane yield through decreasing lignin content of CS [6].

Figure 2.

Total methane yield of digestion.

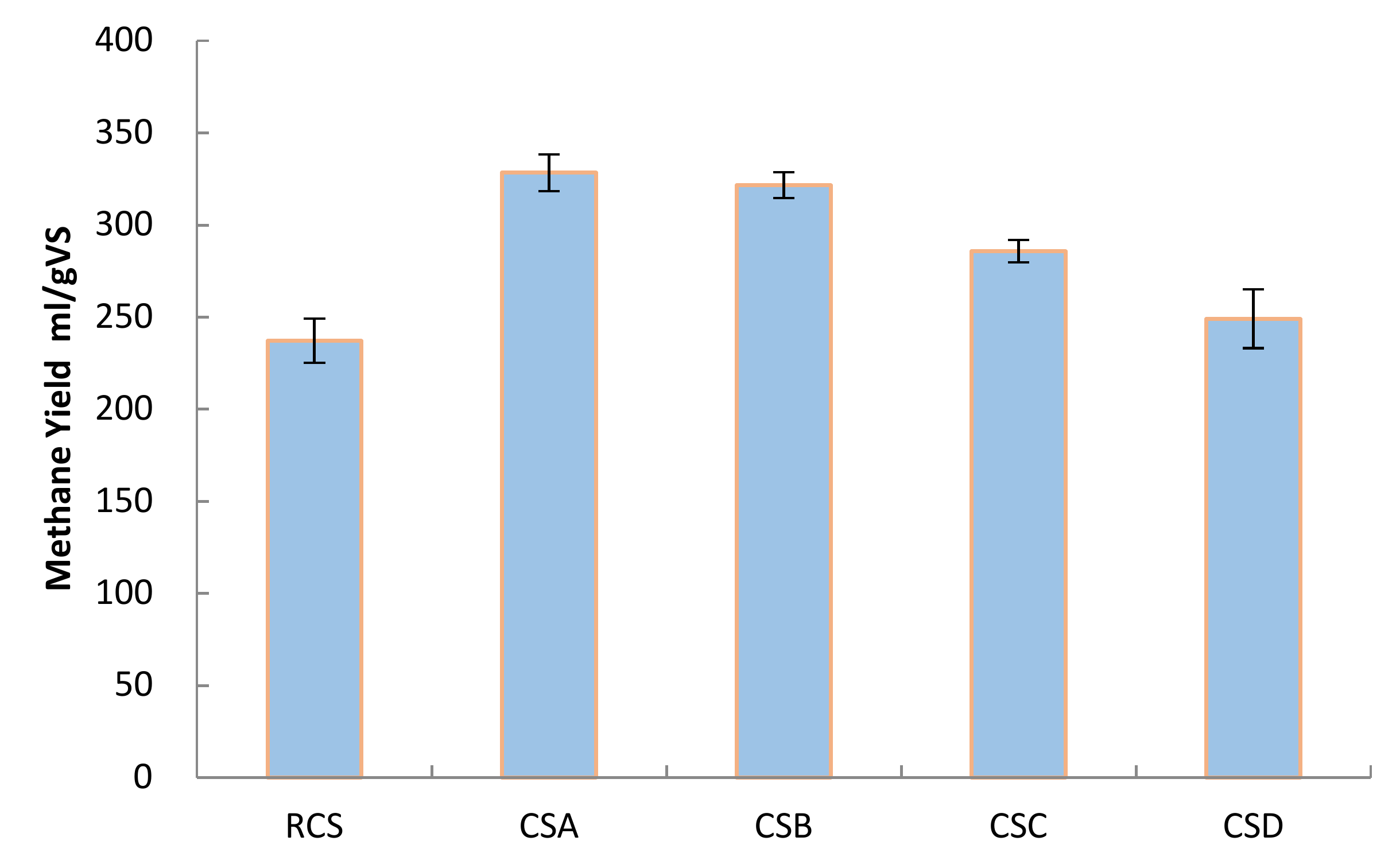

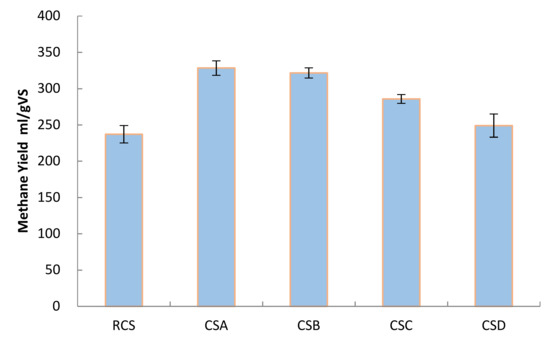

The methane yield per gram of VS is an important parameter to estimate the net biogas production of anaerobic digestion. The methane yield was calculated with the methane content and the daily biogas yield of each reactor. After anaerobic digestion for 94 days, the methane yield of the co-digestion with Treat-CSA was 328 mL/g VS, while that of the co-digestion with RCS was only 237 mL/g VS (Figure 3). Methane yields of the co-digestions with alkaline-treated CS were from 5.1% to 38.5% higher than that of the co-digestion with RCS. A similar study was performed by Thomas et al. [47], in which the CaO-pretreated miscanthus had been co-digested with cattle manure in a dry leach bed reactor to result in 37% more methane production. This means that alkaline pretreatment of CS is an effective way to result in higher methane production from the co-digestion fed with CS [48]. Especially, the co-digestion of swine manure and Treat-CSB showed higher methane yield of 322 mL/g VS, whereas those with Treat-CSC and Treat-CSD only produced methane yields of 286 and 249 mL/g VS, respectively. When the sugarcane bagasse pretreated with 8.5% Ca(OH)2 was digested, 47% higher methane yield was obtained comparing to that of the digestion of the untreated [27]. The similar methane yield (212 ~ 340 mL/g VS) was also obtained from the anaerobic digestion of CS as a single feedstock [49,50].

Figure 3.

Methane yield per gram VS of RCS and treated CSs.

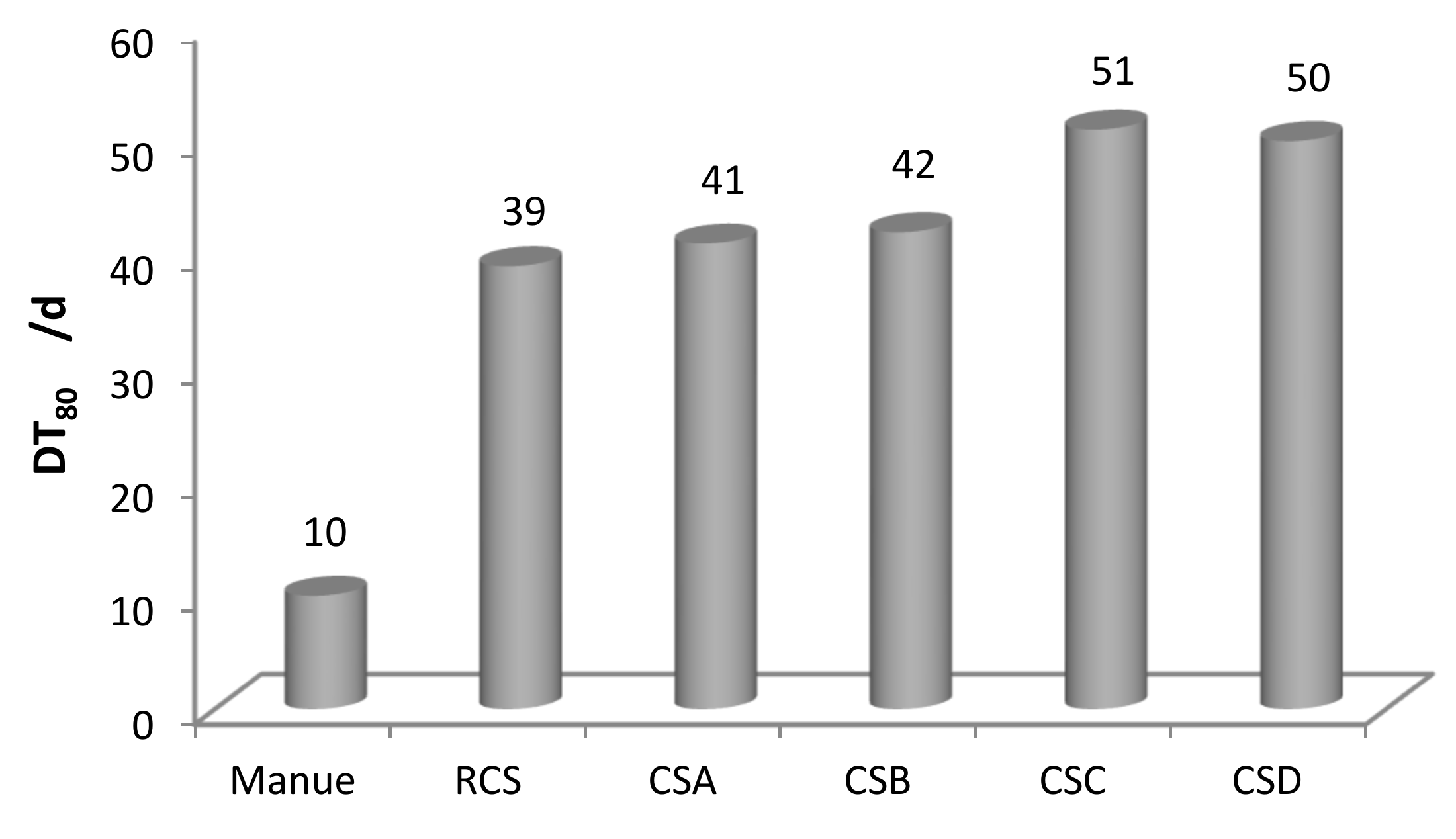

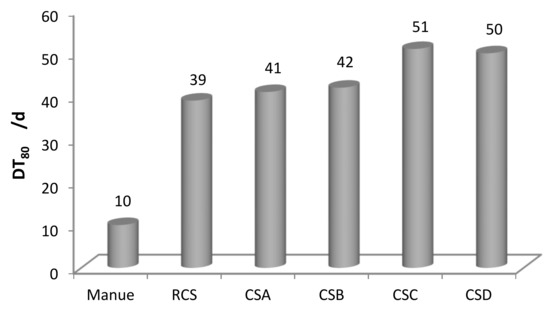

3.3. Digestion Time (DT80)

Digestion time is an indicator for the efficiency of an anaerobic digestion process. For a given loading rate of biomass, the degree of fermentation completion is one of the main factors in the process of anaerobic digestion. It is not economical to run anaerobic digesters with a long hydraulic retention time, since very little biogas is produced in the last stage. Digestion time (DT80) was defined as the number of days required to generate 80% of potential biogas [12,51]. The co-digestions with Treat-CSA, Treat-CSB, Treat-CSC, and Treat-CSD took 40, 41, 50, and 51 days, respectively, to generate 80% of potential biogas (Figure 4). DT80 of the co-digestors fed with Treat-CSA and Treat-CSB were smaller than those of digesters fed with Treat-CSC and Treat-CSD, meaning that digestion time can be shorten, if feedstock is properly treated. Although the digestors fed with swine manure only or both swine manure and RCS showed much shorter DT80 (i.e., 10 and 39 d for swine manure only and mixture of swine manure and RCS, respectively) than others, they produced much less methane since most lignin and celluloses in CS were not transformed for biogas production.

Figure 4.

Digestion time (DT80) of digestion.

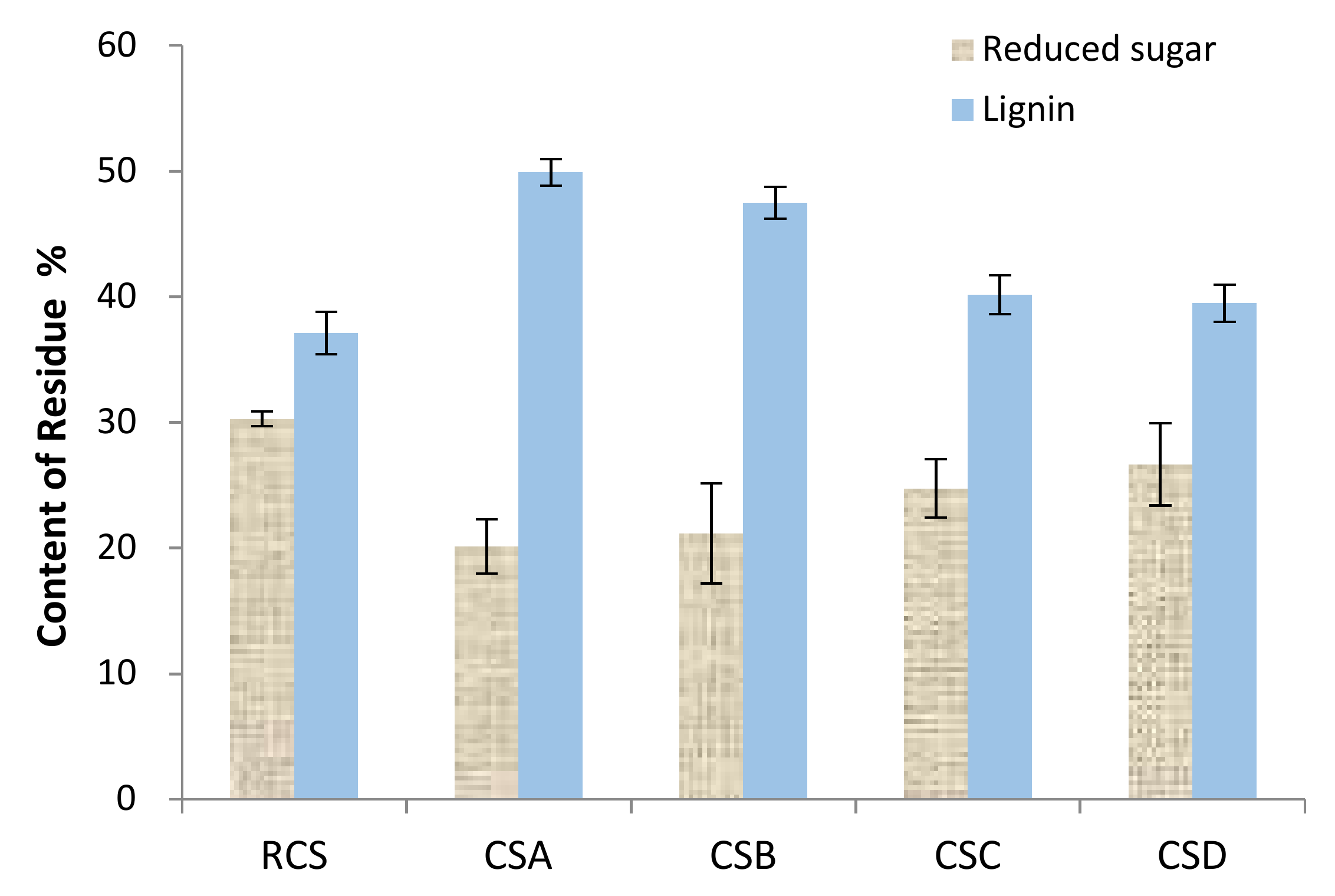

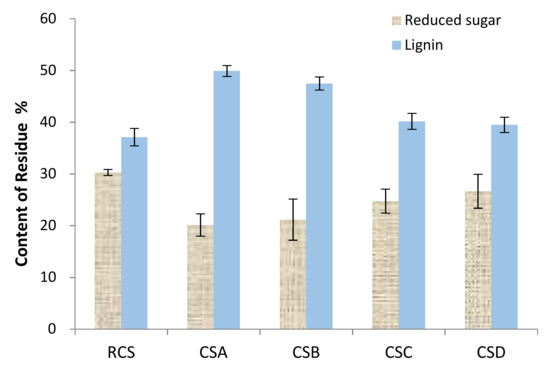

3.4. Reducing Sugar and Lignin Content of CS after Digesting

The reducing sugar and lignin content of CS residue after co-digestion were measured to evaluate the effect of the CS pretreatment on the performance of the co-digestion of swine manure and CS. Reducing sugar, which is converted from cellulose and hemicelluloses by a chemical method, can represent the content of cellulose and hemicelluloses in CS. [33] In fact, the loss of reducing sugars can be correlated with biogas generation because sugars are easily converted to biogas by anaerobic microorganisms [52].

The reducing sugar content of RCS was reduced from 50.7% (Table 1) to 30.3% of RCS after the anaerobic co-digestion (Figure 5). However, it decreased about 3.6%~13.9% for the pretreated CSs after anaerobic digestion. The results indicated that more cellulose and hemicelluloses in the pretreated CS were converted to biogas than those of RCS [37]. Corn stover pretreated with NaOH only (Treat-CSA) showed the highest effectiveness (Figure 5).

Figure 5.

Comparison of reduced sugar and lignin contents of CS residue after digestion.

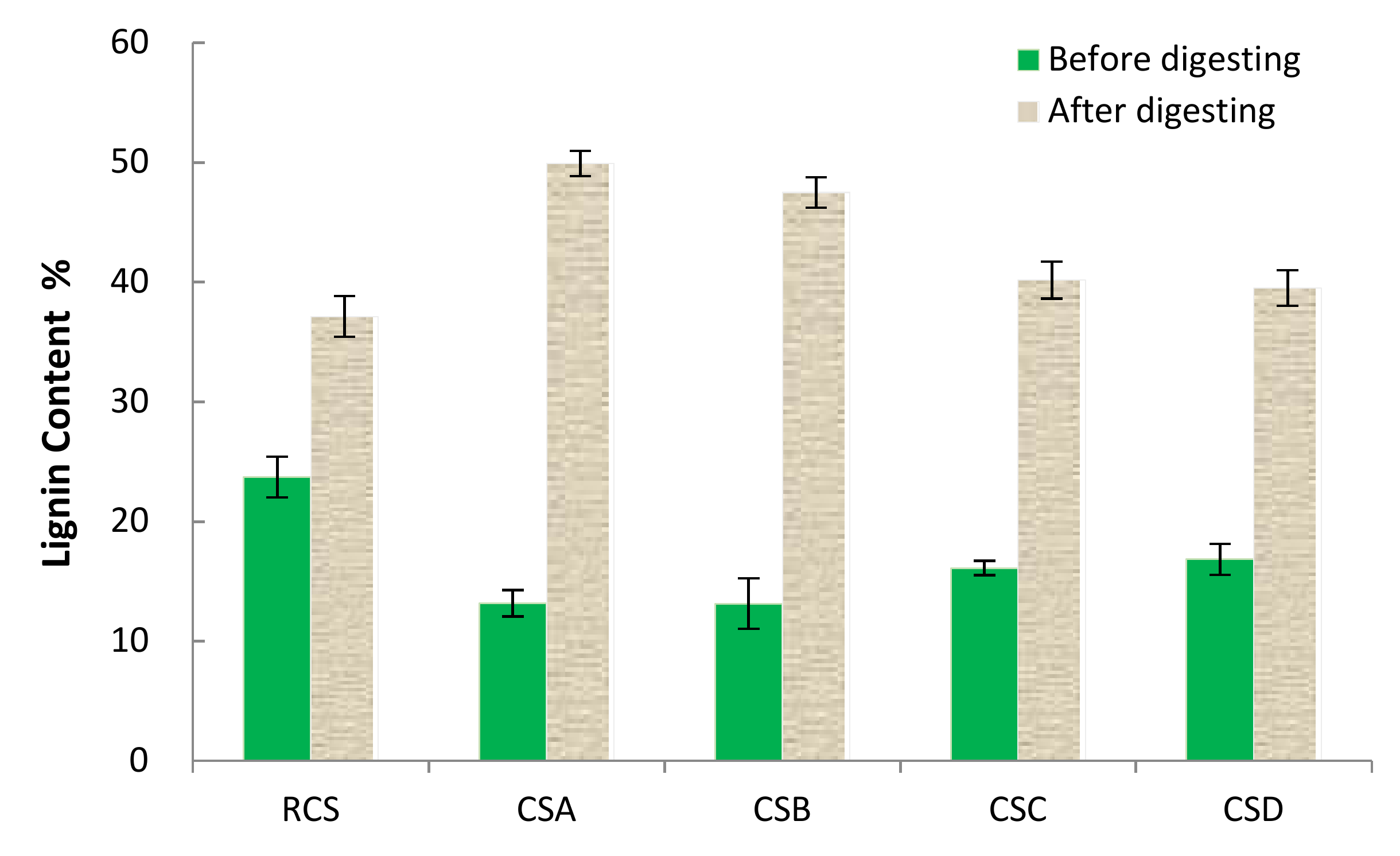

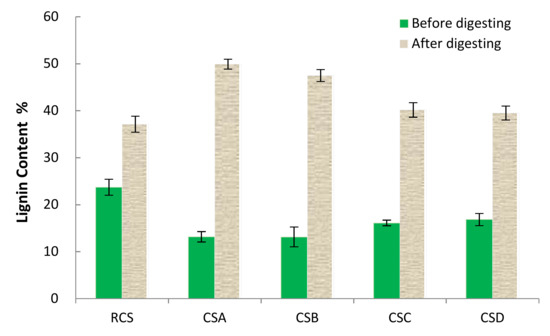

The lignin content of CS was 37.12%~49.92% in the residue after digestion (Figure 6). RCS showed the maximum reducing sugars (30.28%) and lower lignin content (37.12%) in the residue because of incomplete digestion of CS. However, Treat-CSA and Treat-CSB showed lower reducing sugar (21.19%) and higher lignin content (47.49%) compared with others.

Figure 6.

Comparison of lignin content of CS before and after digesting.

D-value, the difference of lignin content of feedstock before and after digestion, is used for evaluating the extent of digestion [53]. A larger D-value means that more cellulose and hemicelluloses were converted to biogas in anaerobic digestion [54]. Compared to 23.7% lignin content of RCS, alkaline-pretreated CS showed lignin content of 13.14%~16.68%. However, after digestion, Treat-CSA showed 49.92% lignin content and the largest D-value (36.75%). The D-value for the RCS was only 13.40% with the lowest biogas production. This indicates that the loss of cellulose and hemicelluloses of CS had been converted to biogas, and a larger D-value means more biogas production [55]. This also indicated that addition of NaOH and CaO can help more CS to be converted to reducing sugars for biogas production [9,32]. It also means that CaO can effectively replace NaOH and provide supplementary alkalinity [34,56].

3.5. Cost-Efficiency Analysis

As shown in Table 3, the biomass energy produced from the co-digestions fed with Treat-RCS, Treat-CSA, Treat-CSB, Treat-CSC and Treat-CSD was 4681.76, 6170.87, 6043.21 and 5371.55 kJ/kg initial TS, respectively. The digester with RCS could harvest energy of 4694.75 kJ/kg TS, which would incur revenue of $136.62/ton TS from electricity generation. When 0.1 g NaOH was added in the CS pretreatment (Treat-CSA), the energy production could be significantly improved to 6170.87 kJ/kg TS and the revenue from electricity generation was increased to $179.57/ton TS. Therefore, Treat-CSA could earn more revenue ($42.96/ton TS) compared to the digestion of RCS. However, the chemical cost ($45/ton TS) associated with the pretreatment made the net benefit negative (i.e., –$2.04/ton TS).

Table 3.

Effect of CaO and Na(OH) pretreatments on net benefit of electricity generation from methane of CS digestion.

On the other hand, when the NaOH dose was decreased to 0.075 g NaOH by adding 0.05 g CaO in the CS pretreatment (Treat-CSB), the energy production of the biomass was significantly improved to 6040 kJ/kg TS and the benefit from electricity generation was increased to $176/ton TS. Therefore, Treat-CSB could incur more revenue ($39.0/ton TS), compared to the digestion with RCS. Considering the chemical cost of $37.4/ton TS, the net benefit could be calculated as $1.9/ton TS. Since the relatively lower biogas production, Treat-CSC and Treat-CSD also resulted in negative net revenues: –$6.4 and –$18.8/ton TS for Treat-CSC and Treat-CSD, respectively. A similar study has been carried out to report that NaOH pretreatment of CS resulted in a negative net benefit while CS pretreated with Ca(OH)2 not only improved the methane yield by up to 1.4-fold, but also obtained a net benefit of $1.1–5.8/ton dry biomass [40].

4. Conclusions

The benefit of NaOH combined CaO for the CS pretreatment was investigated to enhance the biogas production. In short, Treat-CSB was chosen as the optimum pretreatment option, since it could obtain high lignin removal efficiency and biomass recovery. In addition, when Treat-CSB was co-digested with swine manure, higher methane yield could be obtained, which was similar to that of the co-digester fed with CS pretreated with NaOH only. This result means that CaO addition could effectively reduce the use of expensive NaOH in the CS pretreatment while not deteriorating biogas yield; a net benefit of $1.9/ton TS could be earned. In short, pretreatment of CS with NaOH combined CaO is a cost-effective pretreatment option for the CS anaerobic digestion.

Authors Contribution

Methodology, Z.Y.; Software, S.Z.; Validation, H.K., P.C. and Y.S.; Formal Analysis, Z.Y.; Investigation, Z.G. and H.X.; Writing-Original Draft Preparation, Z.Y.; Writing-Review & Editing, H.K.; Visualization, H.K.; Supervision, Z.Y.; Project Administration, Z.Y.; Funding Acquisition, H.K. and Z.Y.

Acknowledgments

The authors are greatly grateful to the funding support from National Natural Science Foundation of China (No. 51508268). H. Kim was financially supported by the Korea Institute of Energy Technology Evaluation and Planning (No. 20173010092510).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Zhang, R.; Liu, F.; Liu, H.; Zhang, D. Pretreatment of Corn Stover with Diluted Nitric Acid for the Enhancement of Acidogenic Fermentation. Energy Fuel. 2018, 32, 425–430. [Google Scholar] [CrossRef]

- Yang, M.; Rehman, M.S.U.; Yan, T.; Khan, A.U.; Oleskowicz-Popiel, P.; Xu, X.; Cui, P.; Xu, J. Treatment of different parts of corn stover for high yield and lower polydispersity lignin extraction with high-boiling alkaline solvent. Bioresour. Technol. 2018, 249, 737–743. [Google Scholar] [CrossRef] [PubMed]

- Zhao, Y.; Damgaard, A.; Christensen, T.H. Bioethanol from corn stover—A review and technical assessment of alternative biotechnologies. Prog. Energy Combust. 2018, 67, 275–291. [Google Scholar] [CrossRef]

- Kiran, L.K.; James, D.M. Availability of corn stover as a sustainable feedstock for bioethanol production. Bioresour. Technol. 2003, 88, 17–25. [Google Scholar]

- Liu, C.M.; Wachemo, A.C.; Yuan, H.R.; Zou, D.X.; Liu, Y.P.; Zhang, L.; Pang, Y.Z.; Li, X.J. Evaluation of methane yield using acidogenic effluent of NaOH pretreated corn stover in anaerobic digestion. Renew. Energy 2018, 116, 224–233. [Google Scholar] [CrossRef]

- Weiland, P. Biogas production: Current state and perspectives. Appl. Microbiol. Biot. 2010, 85, 849–860. [Google Scholar] [CrossRef] [PubMed]

- Cheng, J.J.; Timilsina, G.R. Status and barriers of advanced biofuel technologies: A review. Renew. Energy 2011, 36, 3541–3549. [Google Scholar] [CrossRef]

- Mouthier, T.; Appeldoorn, M.M.; Pel, H.; Schols, H.A.; Gruppen, H.; Kabel, M.A. Corn stover lignin is modified differently by acetic acid compared to sulfuric acid. Ind. Crop. Prod. 2018, 121, 160–168. [Google Scholar] [CrossRef]

- Qiao, X.; Zhao, C.; Shao, Q.; Hassan, M. Structural Characterization of Corn Stover Lignin after Hydrogen Peroxide Presoaking Prior to Ammonia Fiber Expansion Pretreatment. Energy Fuel. 2018, 32, 6022–6030. [Google Scholar] [CrossRef]

- Jaramillo, I.; Sanchez, A. Mass Flow Dynamic Modeling and Residence Time Control of a Continuous Tubular Reactor for Biomass Pretreatment. ACS Sustain. Chem. Eng. 2018, 6, 8570–8577. [Google Scholar] [CrossRef]

- An, S.; Li, W.; Liu, Q.; Xia, Y.; Zhang, T.; Huang, F.; Lin, Q.; Chen, L. Combined dilute hydrochloric acid and alkaline wet oxidation pretreatment to improve sugar recovery of corn stover. Bioresour. Technol. 2019, 271, 283–288. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Li, L.; Zheng, M.; Fu, G.; Lar, J.S. Anaerobic Co-Digestion of Cattle Manure with Corn Stover Pretreated by Sodium Hydroxide for Efficient Biogas Production. Energy Fuel. 2009, 23, 4635–4639. [Google Scholar] [CrossRef]

- Li, J.; Lu, M.; Guo, X.; Zhang, H.; Li, Y.; Han, L. Insights into the improvement of alkaline hydrogen peroxide (AHP) pretreatment on the enzymatic hydrolysis of corn stover: Chemical and microstructural analyses. Bioresour. Technol. 2018, 265, 1–7. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Li, B.; Mu, X. A review of alkali-based pretreatment to enhance enzymatic saccharification for lignocellulosic biomass conversion. Ind. Eng. Chem. Res. 2016, 55, 8691–8705. [Google Scholar] [CrossRef]

- Meng, X.; Sun, Q.; Kosa, M.; Huang, F.; Pu, Y.; Ragauskas, A.J. Physicochemical Structural Changes of Poplar and Switchgrass during Biomass Pretreatment and Enzymatic Hydrolysis. ACS Sustain. Chem. Eng. 2016, 4, 4563–4572. [Google Scholar] [CrossRef]

- Jensen, M.M.; Djajadi, D.T.; Torri, C.; Rasmussen, H.B.; Madsen, R.B.; Venturini, E.; Vassura, I.; Becker, J.; Iversen, B.B.; Meyer, A.S.; et al. Hydrothermal Liquefaction of Enzymatic Hydrolysis Lignin: Biomass Pretreatment Severity Affects Lignin Valorization. ACS Sustain. Chem. Eng. 2018, 6, 5940–5949. [Google Scholar] [CrossRef]

- Bhalla, A.; Bansal, N.; Pattathil, S.; Li, M.; Shen, W.; Particka, C.A.; Karlen, S.D.; Phongpreecha, T.; Semaan, R.R.; Gonzales-Vigil, E.; et al. Engineered Lignin in Poplar Biomass Facilitates Cu-Catalyzed Alkaline-Oxidative Pretreatment. ACS Sustain. Chem. Eng. 2018, 6, 2932–2941. [Google Scholar] [CrossRef]

- Liu, H.; Pang, B.; Zhao, Y.; Lu, J.; Han, Y.; Wang, H. Comparative study of two different alkali-mechanical pretreatments of corn stover for bioethanol production. Fuel 2018, 221, 21–27. [Google Scholar] [CrossRef]

- Karp, E.M.; Donohoe, B.S.; Brien, M.H.O.; Ciesielski, P.N.; Mittal, A.; Biddy, M.J.; Beckham, G.T. Alkaline Pretreatment of Corn Stover: Bench-Scale Fractionation and Stream Characterization. ACS Sustain. Chem. Eng. 2014, 2, 1481–1491. [Google Scholar] [CrossRef]

- Kumar, A.K.; Sharma, S. Recent updates on different methods of pretreatment of lignocellulosic feedstocks: A review. Bioresour. Bioprocess. 2017, 4, 7. [Google Scholar] [CrossRef]

- Cuvilas, C.A.; Yang, W. Spruce Pretreatment for Thermal Application: Water, Alkaline, and Diluted Acid Hydrolysis. Energy Fuel 2012, 26, 6426–6431. [Google Scholar] [CrossRef]

- Li, J.; Zhang, M.; Li, J.; Wang, D. Corn stover pretreatment by metal oxides for improving lignin removal and reducing sugar degradation and water usage. Bioresour. Technol. 2018, 263, 232–241. [Google Scholar] [CrossRef] [PubMed]

- You, Z.; Wei, T.; Cheng, J.J. Improving Anaerobic Codigestion of Corn Stover Using Sodium Hydroxide Pretreatment. Energy Fuel 2014, 28, 549–555. [Google Scholar] [CrossRef]

- Zhu, J.; Wan, C.; Li, Y. Enhanced solid-state anaerobic digestion of corn stover by alkaline pretreatment. Bioresour. Technol. 2010, 101, 7523–7528. [Google Scholar] [CrossRef] [PubMed]

- Yuan, W.; Gong, Z.; Wang, G.; Zhou, W.; Liu, Y.; Wang, X.; Zhao, M. Alkaline organosolv pretreatment of corn stover for enhancing the enzymatic digestibility. Bioresour. Technol. 2018, 265, 464–470. [Google Scholar] [CrossRef] [PubMed]

- Fang, S.; Wang, W.; Tong, S.; Zhang, C.; Liu, P. Evaluation of the Effects of Isolated Lignin on Cellulose Enzymatic Hydrolysis of Corn Stover Pretreatment by NaOH Combined with Ozone. Molecules 2018, 23, 1495. [Google Scholar] [CrossRef] [PubMed]

- Mustafa, A.M.; Li, H.; Radwan, A.A.; Sheng, K.; Chen, X. Effect of hydrothermal and Ca(OH)2 pretreatments on anaerobic digestion of sugarcane bagasse for biogas production. Bioresour. Technol. 2018, 259, 54–60. [Google Scholar] [CrossRef] [PubMed]

- Bruni, E.; Jensen, A.P.; Angelidaki, I. Comparative study of mechanical, hydrothermal, chemical and enzymatic treatments of digested biofibers to improve biogas production. Bioresour. Technol. 2010, 101, 8713–8717. [Google Scholar] [CrossRef] [PubMed]

- Gu, Y.; Zhang, Y.; Zhou, X. Effect of Ca(OH)2 pretreatment on extruded rice straw anaerobic digestion. Bioresour. Technol. 2015, 196, 116–122. [Google Scholar] [CrossRef] [PubMed]

- Kurian, J.K.; Gariepy, Y.; Lefsrud, M.; Orsat, V.; Seguin, P.; Yaylayan, V.; Raghavan, G.S.V. Experimental Study on Calcium Hydroxide-Assisted Delignification of Hydrothermally Treated Sweet Sorghum Bagasse. Int. J. Chem. Eng. 2014, 2014, 1–9. [Google Scholar] [CrossRef]

- Kim, S.; Holtzapple, M.T. Lime pretreatment and enzymatic hydrolysis of corn stover. Bioresour. Technol. 2005, 96, 1994–2006. [Google Scholar] [CrossRef] [PubMed]

- Malmierca, S.; Díez-Antolínez, R.; Paniagua, A.I.; Martín, M. Technoeconomic Study of Biobutanol AB Production. 1. Biomass Pretreatment and Hydrolysis. Ind. Eng. Chem. Res. 2017, 56, 1518–1524. [Google Scholar] [CrossRef]

- Zhang, X.; Xu, J.; Cheng, J.J. Pretreatment of Corn Stover for Sugar Production with Combined Alkaline Reagents. Energy Fuel 2011, 25, 4796–4802. [Google Scholar] [CrossRef]

- Xu, J.; Cheng, J.J. Pretreatment of switchgrass for sugar production with the combination of sodium hydroxide and lime. Bioresour. Technol. 2011, 102, 3861–3868. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Cheng, J.J.; Sharma-Shivappa, R.R.; Burns, J.C. Lime pretreatment of switchgrass at mild temperatures for ethanol production. Bioresour. Technol. 2010, 101, 2900–2903. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; Cheng, J.J. Lime Pretreatment of Coastal Bermudagrass for Bioethanol Production. Energy Fuel 2011, 25, 1830–1836. [Google Scholar] [CrossRef]

- Dahadha, S.; Amin, Z.; Lakeh, A.A.B.; Elbeshbishy, E. Evaluation of Different Pretreatment Processes of Lignocellulosic Biomass for Enhanced Biomethane Production. Energy Fuel 2017, 31, 10335–10347. [Google Scholar] [CrossRef]

- Hassan, M.; Umar, M.; Mamat, T.; Muhayodin, F.; Talha, Z.; Mehryar, E.; Ahmad, F.; Ding, W.; Zhao, C. Methane Enhancement through Sequential Thermochemical and Sonication Pretreatment for Corn Stover with Anaerobic Sludge. Energy Fuel 2017, 31, 6145–6153. [Google Scholar] [CrossRef]

- Kuhn, E.M.; O’Brien, M.H.; Ciesielski, P.N.; Schell, D.J. Pilot-Scale Batch Alkaline Pretreatment of Corn Stover. ACS Sustain. Chem. Eng. 2015, 4, 944–956. [Google Scholar] [CrossRef]

- Jiang, D.; Ge, X.; Zhang, Q.; Zhou, X.; Chen, Z.; Keener, H.; Li, Y. Comparison of sodium hydroxide and calcium hydroxide pretreatments of giant reed for enhanced enzymatic digestibility and methane production. Bioresour. Technol. 2017, 244, 1150–1157. [Google Scholar] [CrossRef] [PubMed]

- Kumar, D.; Murthy, G.S. Impact of pretreatment and downstream processing technologies on economics and energy in cellulosic ethanol production. Biotechnol. Biofuels 2011, 4, 2–19. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Wachemo, A.C.; Tong, H.; Shi, S.; Zhang, L.; Yuan, H.; Li, X. Biogas production and microbial community properties during anaerobic digestion of corn stover at different temperatures. Bioresour. Technol. 2018, 261, 93–103. [Google Scholar] [CrossRef] [PubMed]

- Yu, H.; Min, Z.; Jia, O.; Yang, S. Comparative Study on Four Chemical Pretreatment Methods for an Efficient Saccharification of Corn Stover. Energy Fuel 2014, 28, 4282–4287. [Google Scholar] [CrossRef]

- Mittal, A.; Katahira, R.; Donohoe, B.S.; Black, B.A.; Pattathil, S.; Stringer, J.M.; Beckham, G.T. Alkaline Peroxide Delignification of Corn Stover. ACS Sustain. Chem. Eng. 2017, 5, 6310–6321. [Google Scholar] [CrossRef]

- Mittal, A.; Katahira, R.; Donohoe, B.S.; Pattathil, S.; Kandemkavil, S.; Reed, M.L.; Biddy, M.J.; Beckham, G.T. Ammonia Pretreatment of Corn Stover Enables Facile Lignin Extraction. ACS Sustain. Chem. Eng. 2017, 5, 2544–2561. [Google Scholar] [CrossRef]

- Bali, G.; Meng, X.; Deneff, J.I.; Sun, Q.; Ragauskas, A.J. The Effect of Alkaline Pretreatment Methods on Cellulose Structure and Accessibility. ChemSusChem 2015, 8, 275–279. [Google Scholar] [CrossRef]

- Thomas, H.; Seira, J.; Escudié, R.; Carrère, H. Lime Pretreatment of Miscanthus: Impact on BMP and Batch Dry Co-Digestion with Cattle Manure. Molecules 2018, 23, 1608. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, R.; He, Y.; Liu, X.; Chen, C.; Liu, G. Thermophilic Solid-State Anaerobic Digestion of Alkaline-Pretreated Corn Stover. Energy Fuel 2014, 28, 3759–3765. [Google Scholar] [CrossRef]

- Li, L.; Yang, X.; Li, X.; Zheng, M.; Chen, J.; Zhang, Z. The influence of inoculum sources on anaerobic biogasification of NaOH-treated corn stover. Energy Sources Part A Recovery Util. Environ. Eff. 2011, 33, 138–144. [Google Scholar] [CrossRef]

- Zheng, M.; Li, L.; Li, X.; Xiong, J.; Mei, T. The effects of alkaline pretreatment parameters on anaerobic biogasification of corn stover. Energy Sources Part A Recovery Util. Environ. Eff. 2010, 32, 1918–1925. [Google Scholar] [CrossRef]

- Zheng, M.X.; Li, X.J.; Li, L.Q.; Yang, X.J.; He, Y.F. Enhancing anaerobic biogasification of corn stover through wet state NaOH pretreatment. Bioresour. Technol. 2009, 100, 5140–5145. [Google Scholar] [CrossRef] [PubMed]

- Pang, Y.Z.; Liu, Y.P.; Li, X.J.; Wang, K.S.; Yuan, H.R. Improving Biodegradability and Biogas Production of Corn Stover through Sodium Hydroxide Solid State Pretreatment. Energy Fuel 2008, 22, 2761–2766. [Google Scholar] [CrossRef]

- Solé-Bundó, M.; Carrère, H.; Garfí, M.; Ferrer, I. Enhancement of microalgae anaerobic digestion by thermo-alkaline pretreatment with lime (CaO). Algal Res. 2017, 24, 199–206. [Google Scholar] [CrossRef]

- Wang, Z.; Xu, J.; Pandey, P.; Cheng, J.J.; Li, R.; Qu, R. Improvement of Sugar Production from Transgenic Switchgrass with Low-Temperature Alkali Pretreatment. Energy Fuel 2012, 26, 3054–3061. [Google Scholar] [CrossRef]

- Qu, T.; Zhang, X.; Gu, X.; Han, L.; Ji, G.; Chen, X.; Xiao, W. Ball Milling for Biomass Fractionation and Pretreatment with Aqueous Hydroxide Solutions. ACS Sustain. Chem. Eng. 2017, 5, 7733–7742. [Google Scholar] [CrossRef]

- Gong, W.; Liu, C.; Mu, X.; Du, H.; Lv, D.; Li, B.; Han, S. Hydrogen Peroxide-Assisted Sodium Carbonate Pretreatment for the Enhancement of Enzymatic Saccharification of Corn Stover. ACS Sustain. Chem. Eng. 2015, 3, 3477–3485. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).