Analysis on Mechanical Properties of Recycled Aggregate Concrete Members after Exposure to High Temperatures

Abstract

:1. Introduction

2. Experimental Program

2.1. Materials

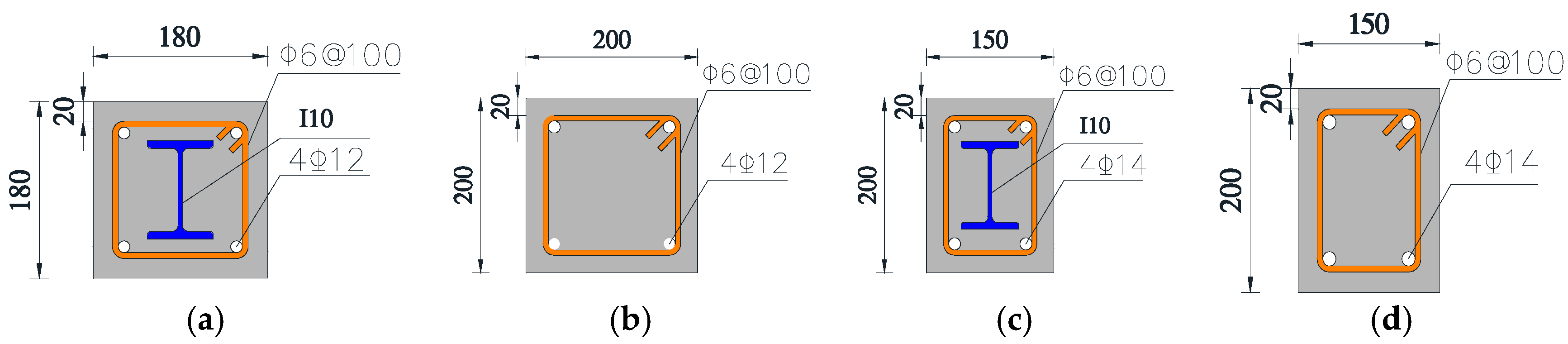

2.2. Specimen Preparation

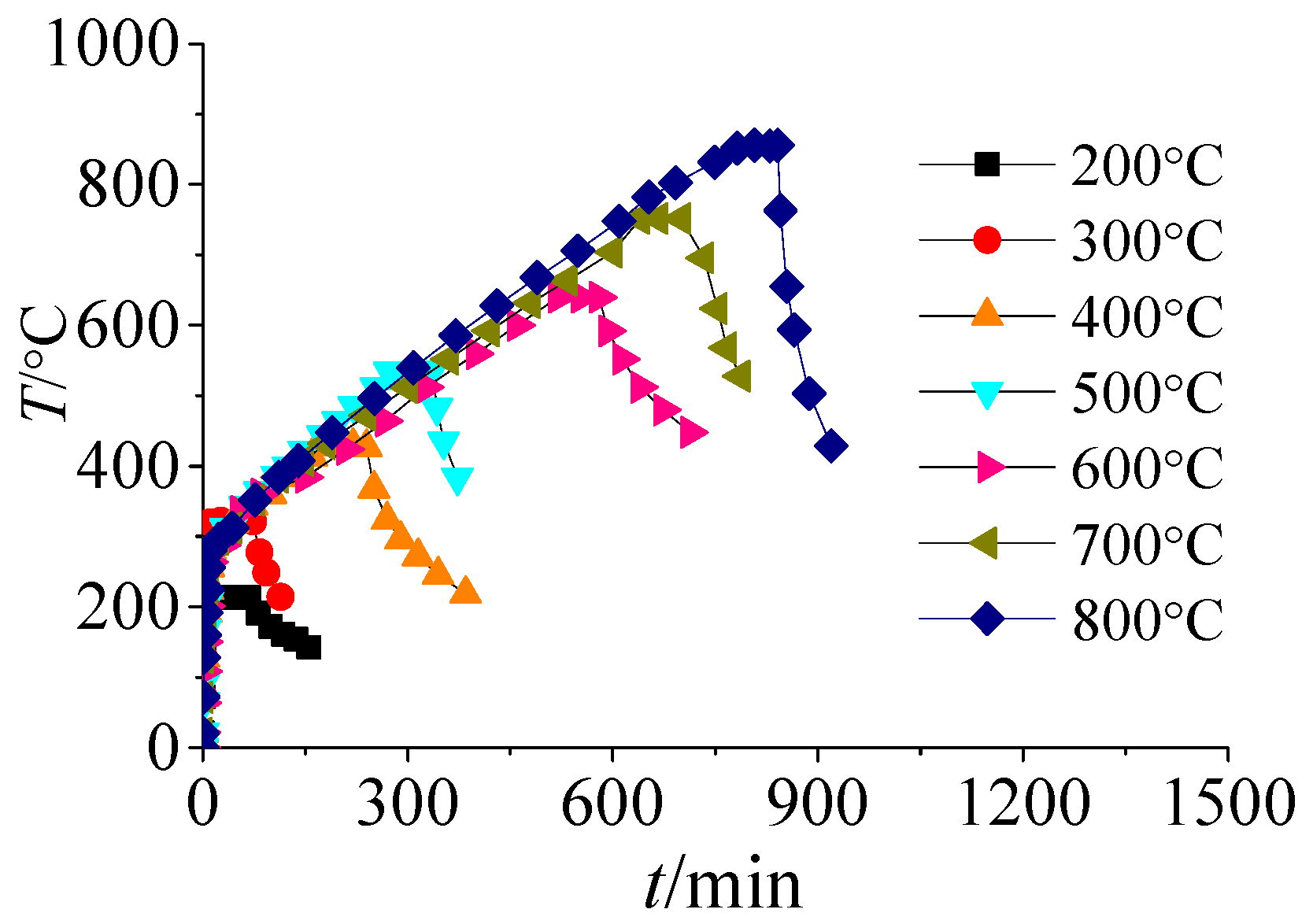

2.3. Thermal Exposure

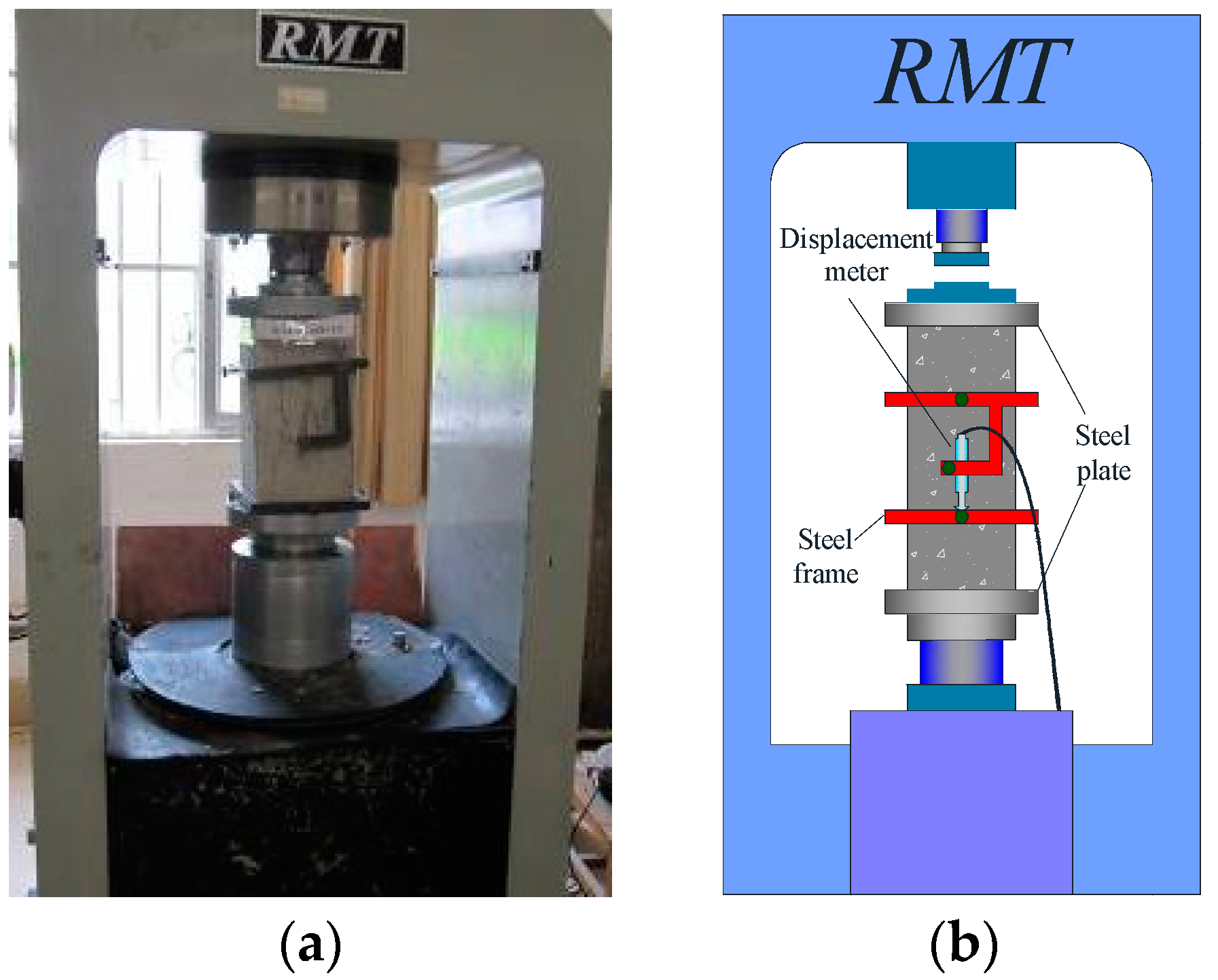

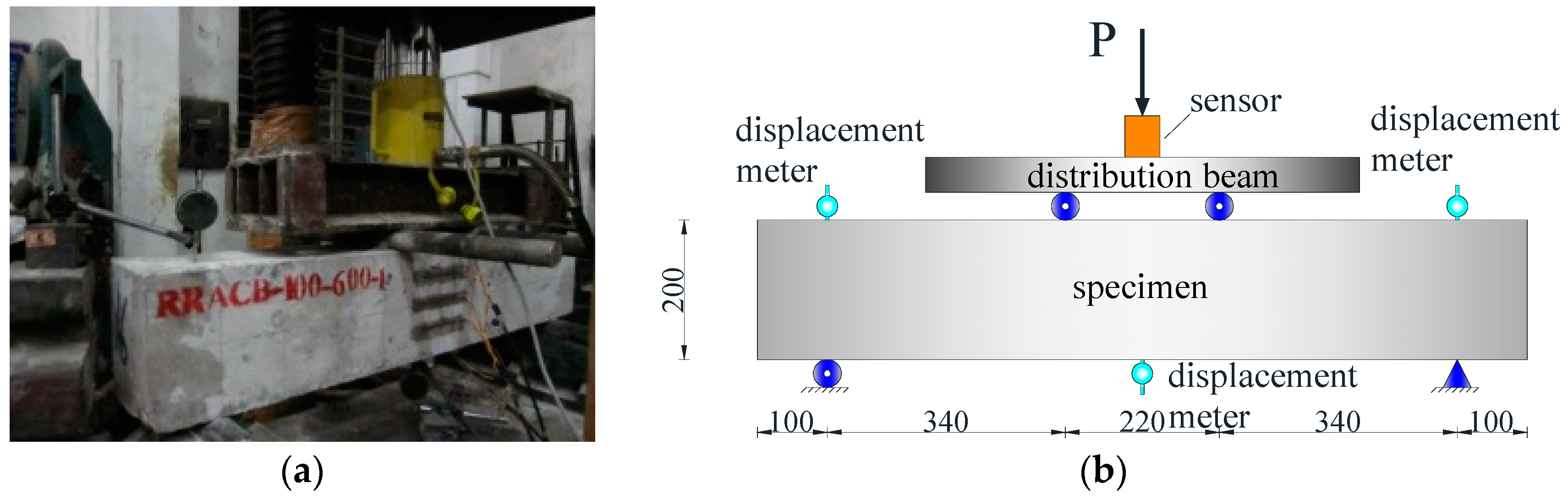

2.4. Load Equipment and Test Method

3. Test Results and Analysis

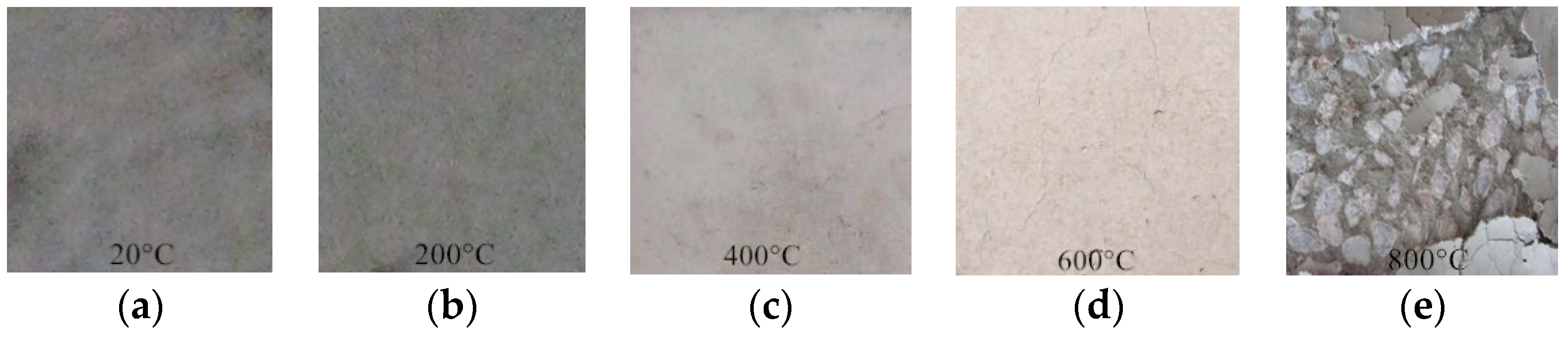

3.1. Change in Appearance

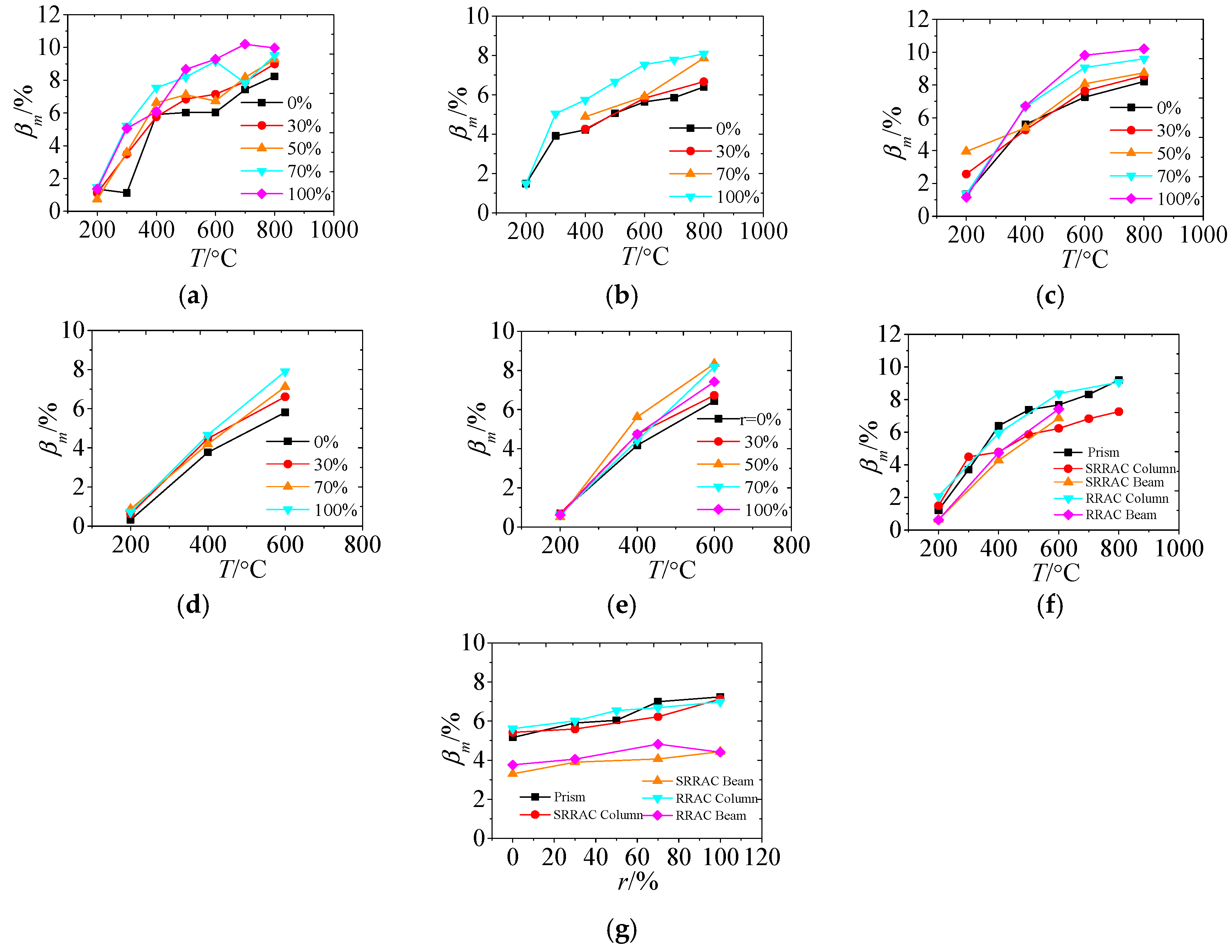

3.2. Mass Loss

3.3. Analysis of Measured Curves

3.3.1. Stress-Strain Curves of RAC Prism Specimens

3.3.2. Load-Displacement Curves of SRRAC Columns

- (1)

- Elastic stage: Both the section steel and the concrete are in the elastic deformation range, and the deformation of the two is coordinated, and no crack is generated on the concrete surface.

- (2)

- Elastic-plastic stage: After the load exceeds the elastic limit, due to the occurrence and continuous development of cracks on the concrete surface, the section steel and the longitudinal steel bar gradually yield, and the load-displacement changes nonlinearly. At this stage, the bond crack begins to appear, that is, the bond and slip of the steel and concrete are more obvious.

- (3)

- Stiffness strengthening section: For specimens with a temperature greater than 600 °C, the load-displacement curves of specimens will show a significant increase in curvature before the elastic limit is reached, that is, the stiffness strengthening stage. This is because after the higher temperature, the free water in the internal void of the concrete evaporates, making the concrete loose. During the loading process, as the load increases, the loose concrete is gradually compacted, thus the stiffness of the specimens is improved.

- (4)

- Descending section: After the limit point is exceeded, the bearing capacity of the specimens is obviously reduced due to the gradual withdrawal of the protective layer concrete. The decreasing extent is related to the temperature. The higher the temperature is, the smaller the decreasing amplitude is.

- (5)

- Residual stage: After entering this stage, with the increase of displacement, the decrease of load tends to be gentle, the concrete at longitudinal reinforcement and protective layer has basically withdrawn from work, and the residual strength is provided by section steel and concrete in core area.

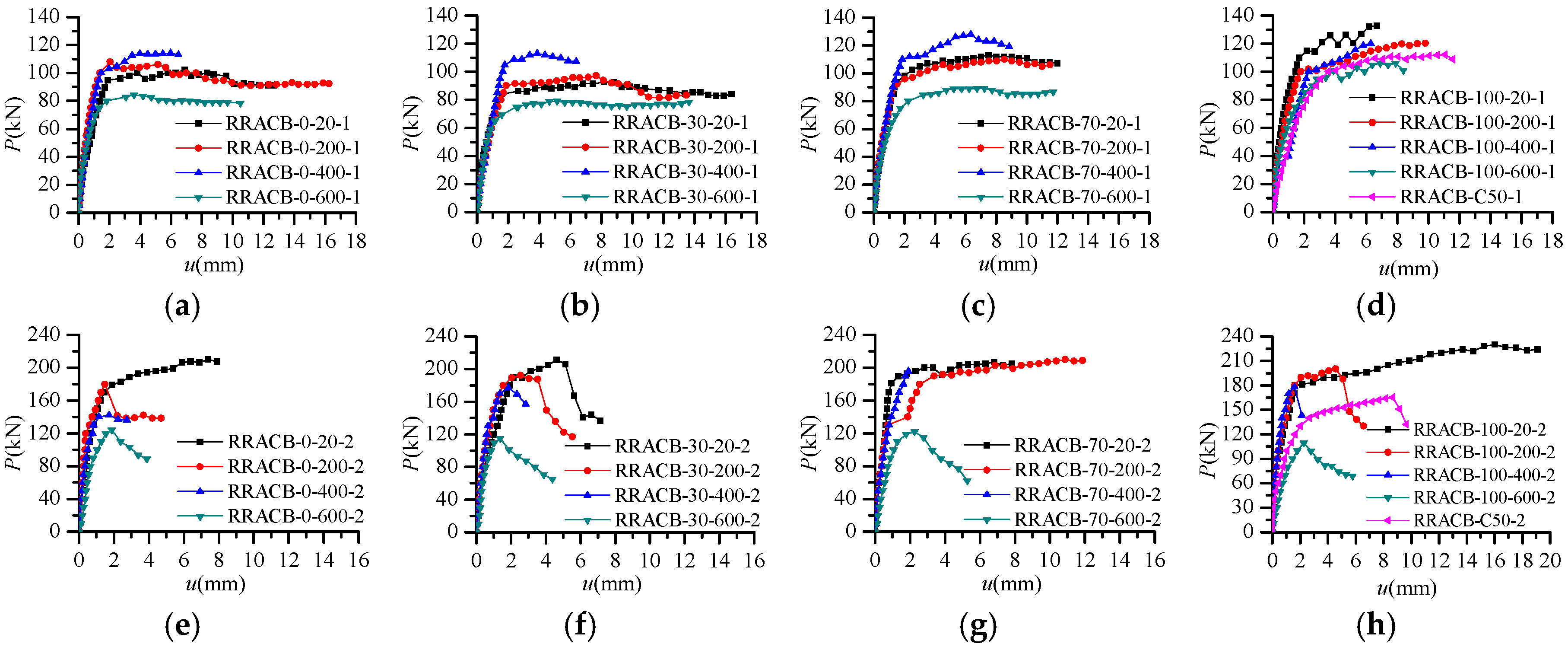

3.3.3. Load-Displacement Curves of RRAC Columns

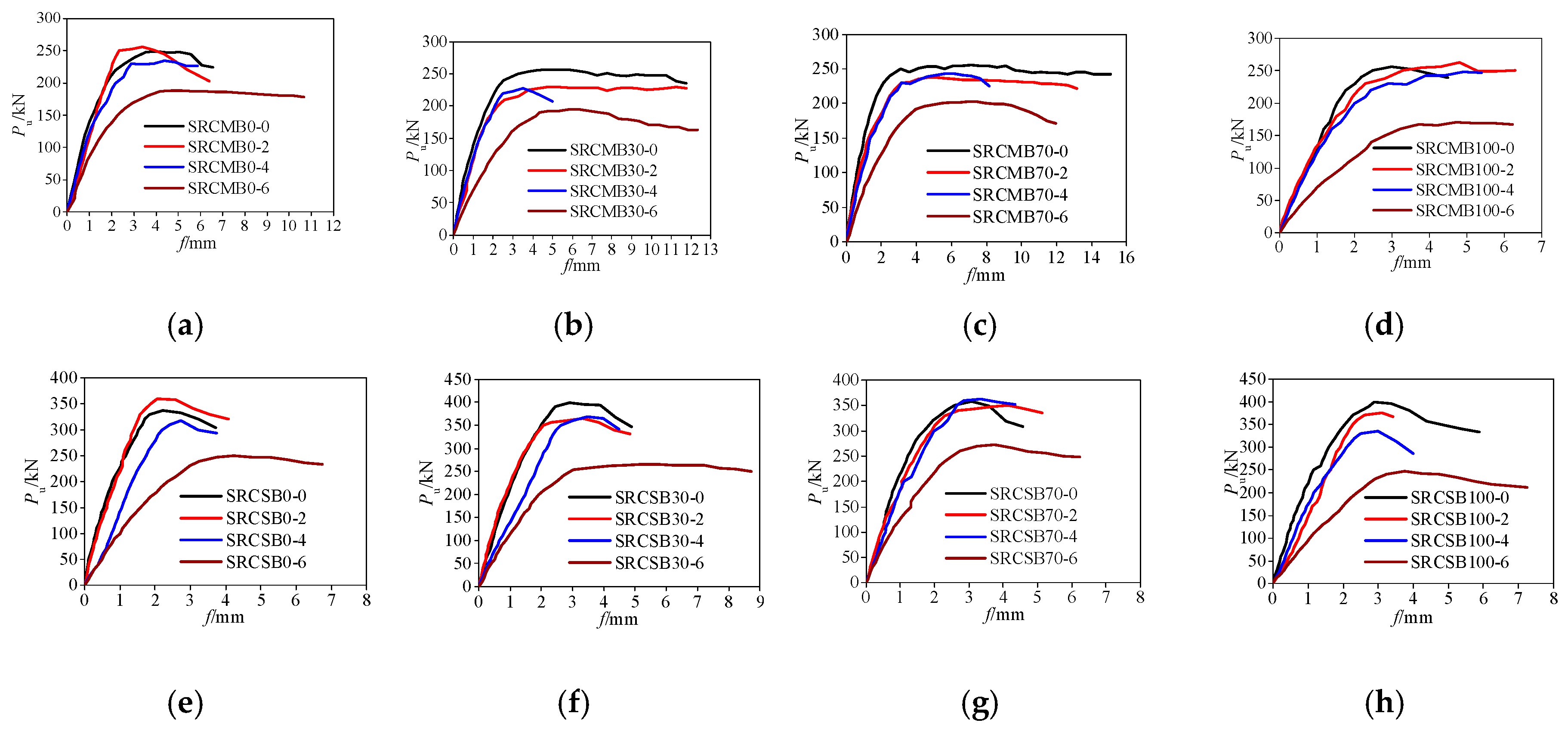

3.3.4. Load-Deflection Curves of SRRAC Beams

3.3.5. Load-Deflection Curve of RRAC Beams

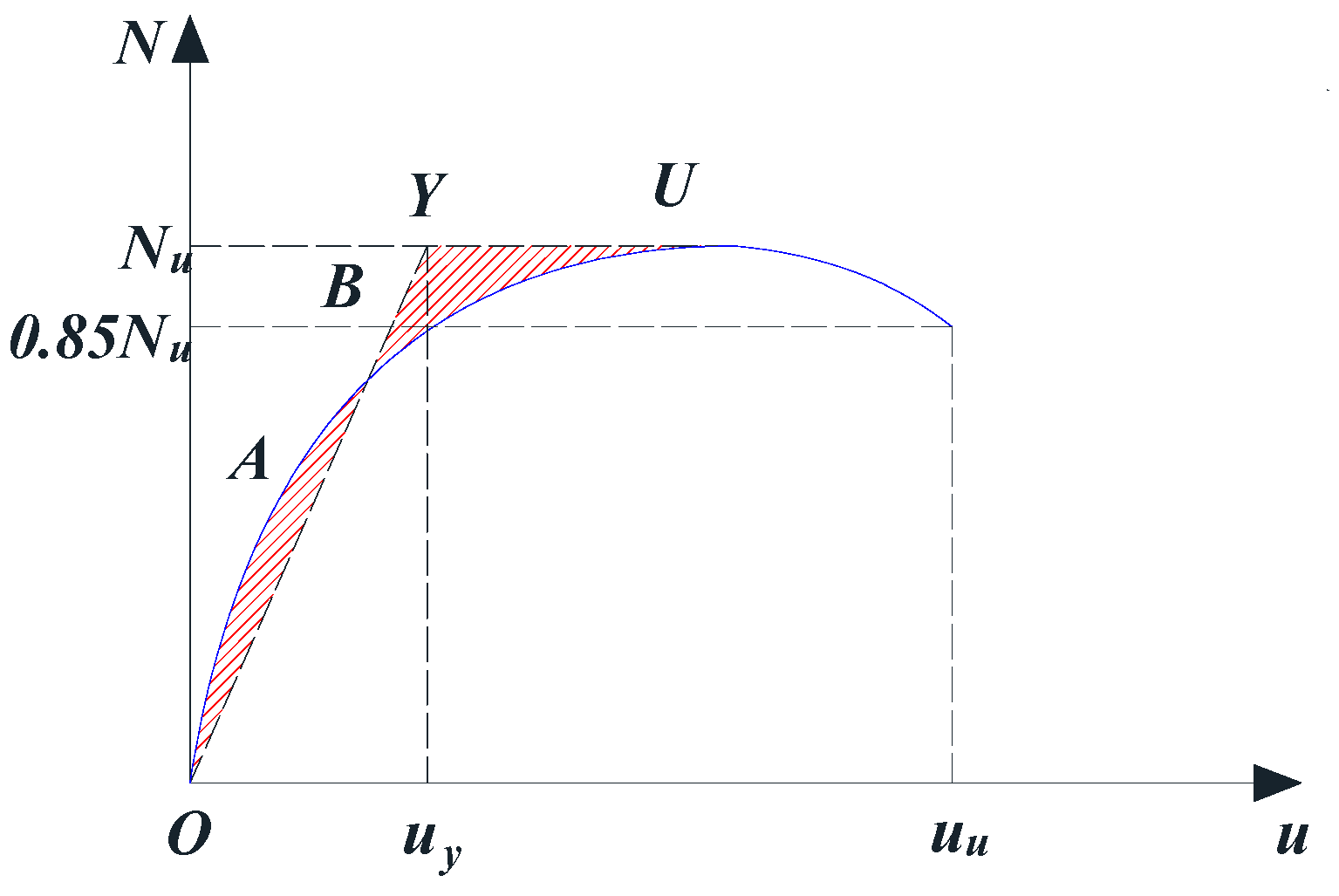

3.4. Mechanical Properties

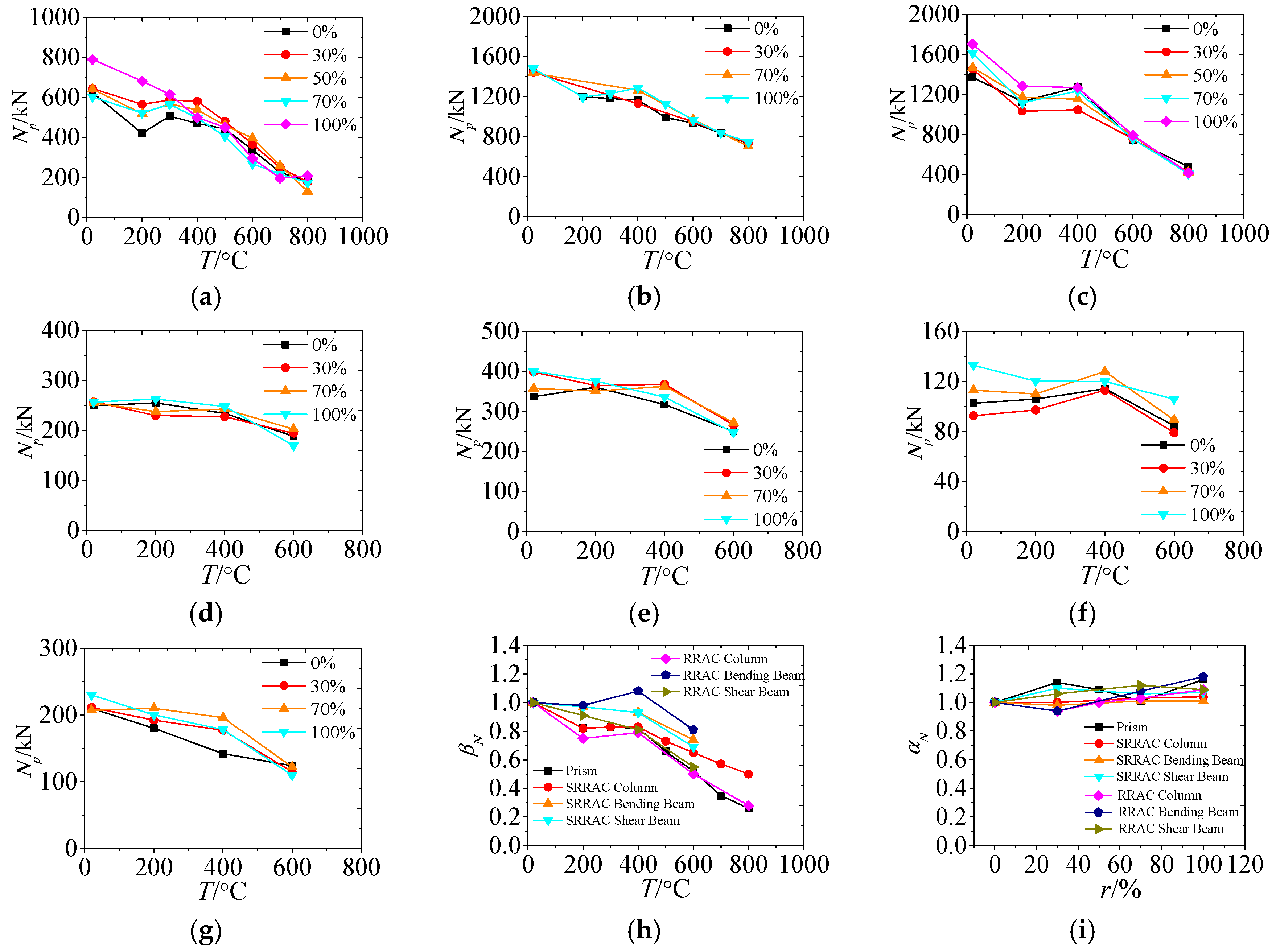

3.4.1. Degradation of Bearing Capacity

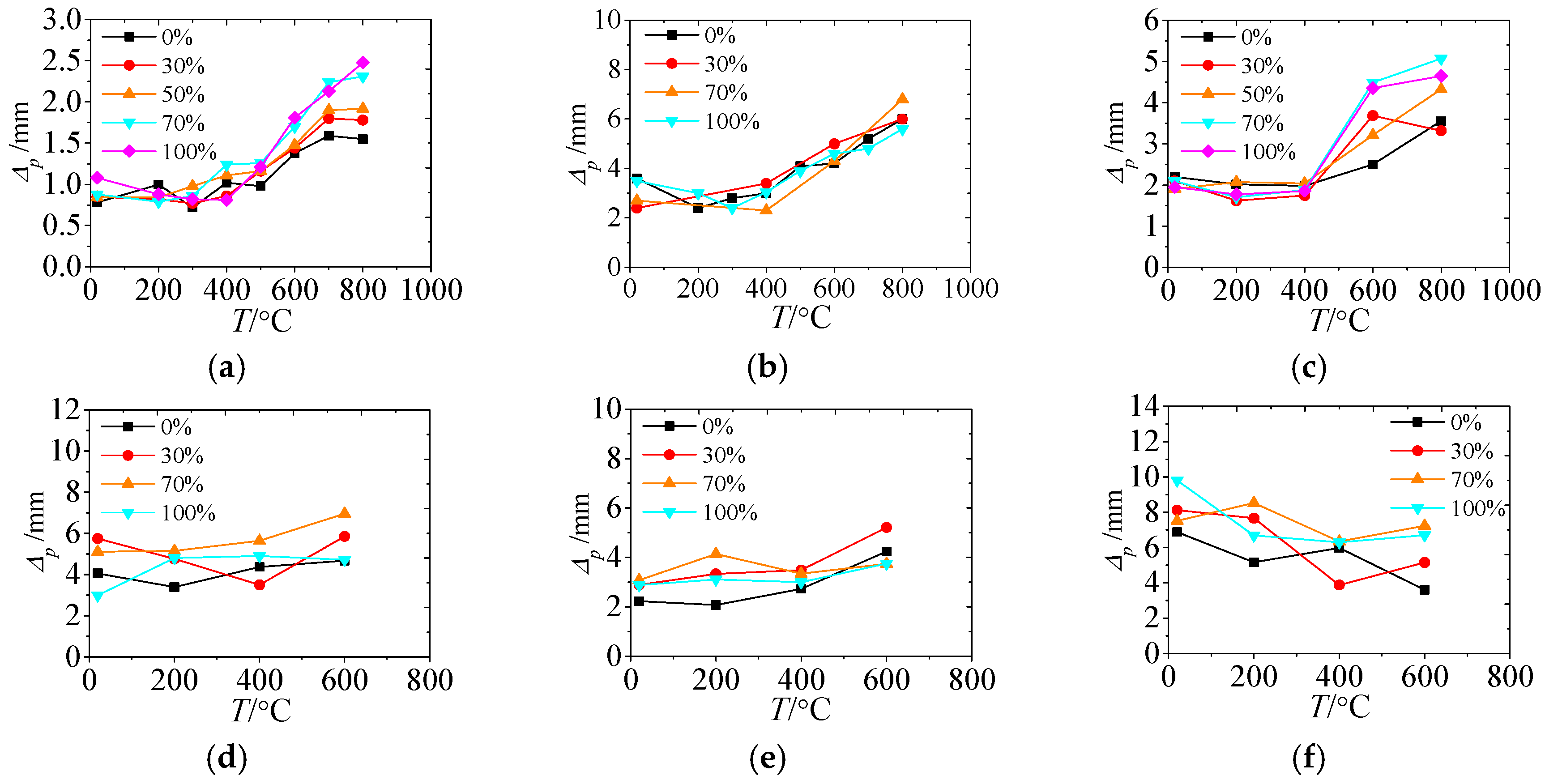

3.4.2. Peak Deformation

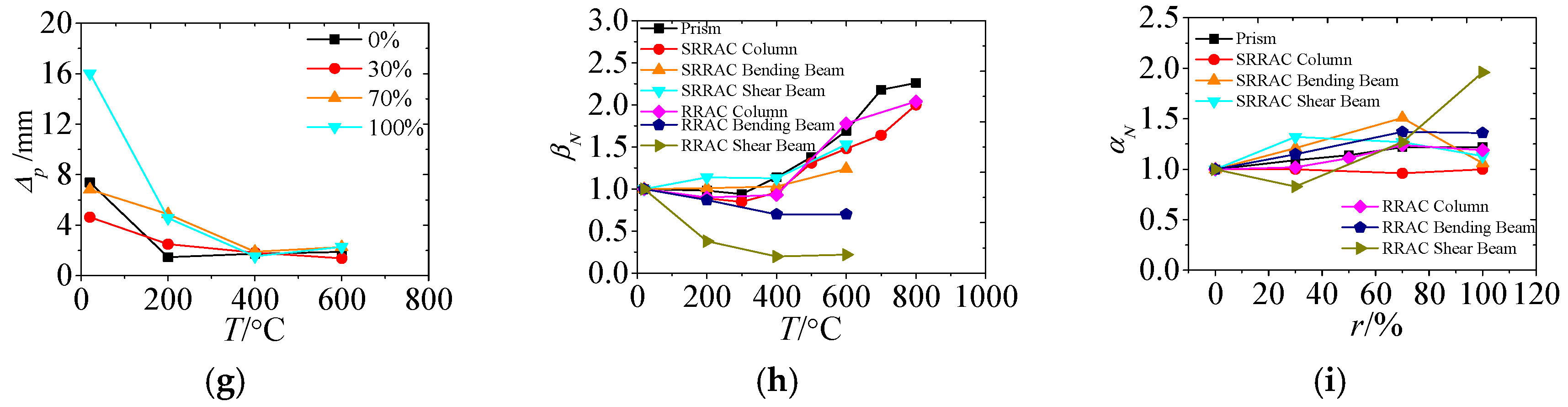

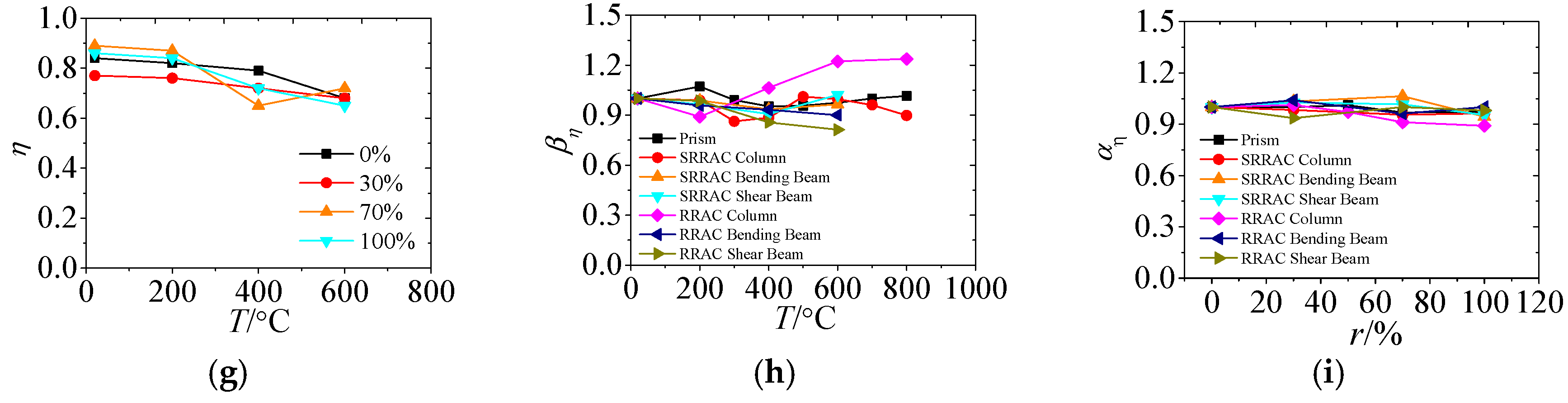

3.4.3. Ductility

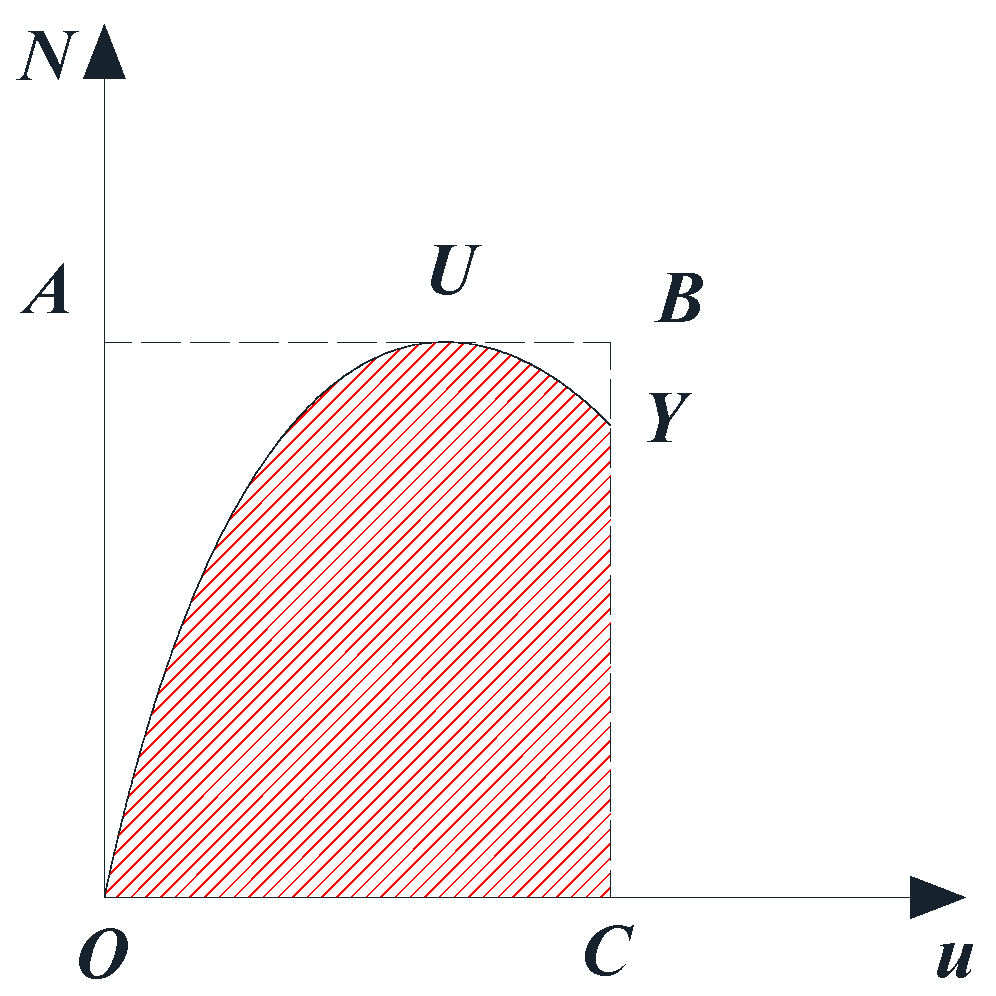

3.4.4. Energy Dissipation

4. Conclusions

- (1)

- After the RAC undergoes high temperatures, its apparent physical changes are obvious: The color changes from blue ash to grayish white, cracking occurs when the temperature reaches 600 °C and bursting and spalling occurs when the temperature reaches 800 °C, the quality of RAC is reduced, and this phenomenon is more significant with the increase of temperature and replacement percentage.

- (2)

- The mechanical properties of RAC prism specimens and RAC members degrade significantly after subjection to high temperatures, especially the bearing capacity. Among the different member, the shear performance of prism specimens and RRAC beams degrade fastest, while the flexural performance of the RRAC and SRRAC beams degrade slowest.

- (3)

- Among different member, the mass loss ratio of RRAC members is slightly larger than that of SRRAC members with the increase of temperature.

- (4)

- The change of the bearing capacity of RRAC columns with the increase of temperature is roughly the same as that of SRRAC members, but the bearing capacity degradation of RRAC beams is more serious than that of SRRAC members. The effect of the replacement percentage on the bearing capacity of RRAC members is basically the same as that of SRRAC members.

- (5)

- With the increase of temperature, the variation process of the peak deformation of RRAC columns is roughly equivalent to that of the SRRAC members. However, the increase of temperature makes the deformation capacity of RRAC beams gradually decrease, which is beneficial to the improvement of SRRAC members. The effect of the replacement percentage on the bearing capacity of RRAC members is roughly equivalent to that of SRRAC members.

- (6)

- With the increase of temperature, the ductility of RRAC columns and RRAC bending beams is slightly better than that of SRRAC members, but the ductility of RRAC shear beams is worse than that of SRRAC members. The replacement percentage has a greater influence on the displacement ductility coefficient of RRAC shear beams than that of SRRAC members, and the displacement ductility coefficients of columns and flexural beams are approximately the same with the increase of replacement percentage.

- (7)

- The influence of temperature on energy dissipation coefficient of RRAC members is greater than that of SRRAC members, the effect of replacement percentage on the energy dissipation coefficient of RAC members is not obvious.

5. Suggestion

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abbas, A.; Fathifazl, G.; Isgor, O.B.; Razaqpur, A.G.; Fouriner, B.; Foo, S. Environmental benefits of green concrete. In Proceedings of the Climate Change Conference, Ottawa, ON, Canada, 2006; pp. 1–8. [Google Scholar]

- Behera, M.; Bhattacharyya, S.K.; Minocha, A.K.; Deoliya, R.; Maiti, S. Recycled aggregate from C&D waste & its use in concrete—A breakthrough towards sustainability in construction sector: A review. Constr. Build. Mater. 2014, 68, 501–516. [Google Scholar]

- Pedro, D.; Brito, J.D.; Evangelista, L. Influence of the use of recycled concrete aggregates from different sources on structural concrete. Constr. Build. Mater. 2014, 71, 141–151. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Li, W.G.; Poon, C.S. Recent studies on mechanical properties of recycled aggregate concrete in China—A review. Sci. China-Technol. Sci. 2012, 55, 1463–1480. [Google Scholar] [CrossRef]

- Topcu, I.B. Physical and mechanical properties of concrete produced with waste concrete. Cem. Concr. Res. 1997, 27, 1817–1823. [Google Scholar] [CrossRef]

- Gomez-Soberon, J.M. Porosity of recycled concrete with substitution of recycled concrete aggregate: An experimental study. Cem. Concr. Res. 2002, 32, 1301–1311. [Google Scholar] [CrossRef]

- Poon, C.S.; Shui, Z.H.; Lam, L. Effect of microstructure of ITZ on compressive strength of concrete prepared with recycled aggregates. Constr. Build. Mater. 2004, 18, 461–468. [Google Scholar] [CrossRef]

- Xiao, J.; Jiabin, L.; Zhang, C. Mechanical properties of recycled aggregate concrete under uniaxial loading. Cem. Concr. Res. 2005, 35, 1187–1194. [Google Scholar] [CrossRef]

- Khatib, J.M. Properties of concrete incorporating fine recycled aggregate. Cem. Concr. Res. 2005, 35, 763–769. [Google Scholar] [CrossRef]

- ACI Committee 555. Removal and reuse of hardened concrete. ACI Mater. J. 2002, 99, 300–325. [Google Scholar]

- Dhir, R.K.; Limbachiya, M.C.; Leelawat, T. Suitability of recycled concrete aggregate for use in BS 5328 designated mixes. Proc. Inst. Civ. Eng. Struct. Build. 1999, 134, 257–274. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D. Compressive behavior of reinforced concrete columns with recycled aggregate under uniaxial loading. Eng. Struct. 2012, 41, 285–293. [Google Scholar] [CrossRef]

- Choi, W.C.; Yun, H.D. Long-term deflection and flexural behavior of reinforced concrete beams with recycled aggregate. Mater. Des. 2013, 51, 742–750. [Google Scholar] [CrossRef]

- Knaack, A.M.; Kurama, Y.C. Behavior of Reinforced Concrete Beams with Recycled Concrete Coarse Aggregates. J. Struct. Eng. 2015, 141, 1–12. [Google Scholar] [CrossRef]

- Valeria, C.; Viviana, L.; Giacomo, M. Behavior of beam-column joints made of recycled-aggregate concrete under cyclic loading. Constr. Build. Mater. 2011, 25, 1877–1882. [Google Scholar]

- Ma, H.; Xue, J.; Zhang, X. Seismic performance of steel-reinforced recycled concrete columns under low cyclic loads. Constr. Build. Mater. 2013, 48, 229–237. [Google Scholar] [CrossRef]

- Xiao, J.Z.; Sun, Y.D.; Falkner, H. Seismic performance of frame structures with recycled aggregate concrete. Eng. Struct. 2006, 28, 1–8. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, A.A. Recycled concrete exposed to high temperatures. Mag. Concr. Res. 2006, 58, 675–682. [Google Scholar] [CrossRef]

- Zega, C.J.; Di Maio, A.A. Recycled concrete made with different natural coarse aggregates exposed to high temperature. Constr. Build. Mater. 2009, 23, 2047–2052. [Google Scholar] [CrossRef]

- Hachemi, S.; Ounis, A. Performance of concrete containing crushed brick aggregate exposed to different fire temperatures. Eur. J. Environ. Civ. Eng. 2015, 19, 805–824. [Google Scholar] [CrossRef]

- Terro, M.J. Properties of concrete made with recycled crushed glass at elevated temperatures. Build. Environ. 2006, 41, 633–639. [Google Scholar] [CrossRef]

- Xiao, Z.; Ling, T.C.; Poon, C.S.; Kou, S.C.; Wang, Q.; Huang, R. Properties of partition wall blocks prepared with high percentages of recycled clay brick after exposure to elevated temperatures. Constr. Build. Mater. 2013, 49, 56–61. [Google Scholar] [CrossRef]

- Kou, S.C.; Poon, C.S.; Etxeberria, M. Residue strength, water absorption and pore size distributions of recycled aggregate concrete after exposure to elevated temperatures. Cem. Concr. Compos. 2014, 53, 73–82. [Google Scholar] [CrossRef]

| r/% | Strength Grade | Water Cement Ratio | Sand Percentage | Mix Proportion: kg/m3 | ||||

|---|---|---|---|---|---|---|---|---|

| Cement | Water | Sand | NCA | RCA | ||||

| 0 | C30 | 0.43 | 0.32 | 500 | 215 | 532 | 1129 | 0 |

| 30 | 790 | 339 | ||||||

| 50 | 565 | 564 | ||||||

| 70 | 339 | 790 | ||||||

| 100 | 0 | 1129 | ||||||

| Specimens Number | r/% | T/°C | βm/% | Np/kN | Δp/mm | μ | η |

|---|---|---|---|---|---|---|---|

| P0-0 | 0 | 20 | - | 623.5 | 0.78 | 1.45 | 0.65 |

| P0-2 | 0 | 200 | 1.35 | 420.1 | 1.00 | 1.75 | 0.71 |

| P0-3 | 0 | 300 | 1.13 | 506.7 | 0.72 | 1.20 | 0.60 |

| P0-4 | 0 | 400 | 5.91 | 469.6 | 1.02 | 1.31 | 0.63 |

| P0-5 | 0 | 500 | 6.03 | 442.6 | 0.98 | 1.38 | 0.61 |

| P0-6 | 0 | 600 | 6.04 | 337.1 | 1.38 | 1.35 | 0.62 |

| P0-7 | 0 | 700 | 7.43 | 225.7 | 1.59 | 1.53 | 0.67 |

| P0-8 | 0 | 800 | 8.24 | 181.1 | 1.55 | 1.40 | 0.65 |

| P30-0 | 30 | 20 | - | 644.0 | 0.85 | 1.44 | 0.65 |

| P30-2 | 30 | 200 | 1.13 | 565.0 | 0.82 | 1.55 | 0.68 |

| P30-3 | 30 | 300 | 3.50 | 586.8 | 0.77 | 1.42 | 0.65 |

| P30-4 | 30 | 400 | 5.77 | 580.3 | 0.86 | 1.17 | 0.60 |

| P30-5 | 30 | 500 | 6.85 | 480.6 | 1.16 | 1.35 | 0.63 |

| P30-6 | 30 | 600 | 7.14 | 365.2 | 1.44 | 1.39 | 0.64 |

| P30-7 | 30 | 700 | 7.91 | 250.2 | 1.80 | 1.43 | 0.65 |

| P30-8 | 30 | 800 | 8.99 | 177.3 | 1.78 | 1.48 | 0.64 |

| P50-0 | 50 | 20 | - | 640.1 | 0.84 | 1.55 | 0.70 |

| P50-2 | 50 | 200 | 0.74 | 518.6 | 0.84 | 1.73 | 0.70 |

| P50-3 | 50 | 300 | 3.60 | 567.7 | 0.98 | 1.52 | 0.67 |

| P50-4 | 50 | 400 | 6.63 | 536.9 | 1.11 | 1.35 | 0.63 |

| P50-5 | 50 | 500 | 7.11 | 460.4 | 1.16 | 1.27 | 0.61 |

| P50-6 | 50 | 600 | 6.73 | 396.7 | 1.48 | 1.30 | 0.59 |

| P50-7 | 50 | 700 | 8.17 | 258.8 | 1.90 | 1.45 | 0.65 |

| P50-8 | 50 | 800 | 9.27 | 130.3 | 1.92 | 1.44 | 0.65 |

| P70-0 | 70 | 20 | - | 602.6 | 0.88 | 1.33 | 0.62 |

| P70-2 | 70 | 200 | 1.48 | 522.2 | 0.79 | 1.87 | 0.64 |

| P70-3 | 70 | 300 | 5.22 | 565.4 | 0.86 | 1.23 | 0.61 |

| P70-4 | 70 | 400 | 7.54 | 496.8 | 1.24 | 1.25 | 0.61 |

| P70-5 | 70 | 500 | 8.19 | 405.0 | 1.26 | 1.32 | 0.60 |

| P70-6 | 70 | 600 | 9.16 | 267.5 | 1.70 | 1.37 | 0.64 |

| P70-7 | 70 | 700 | 7.83 | 216.9 | 2.24 | 1.30 | 0.61 |

| P70-8 | 70 | 800 | 9.52 | 174.8 | 2.31 | 1.41 | 0.65 |

| P100-0 | 100 | 20 | - | 788.6 | 1.08 | 1.24 | 0.59 |

| P100-2 | 100 | 200 | 1.37 | 681.5 | 0.88 | 1.2 | 0.61 |

| P100-3 | 100 | 300 | 5.06 | 614.7 | 0.82 | 1.25 | 0.65 |

| P100-4 | 100 | 400 | 6.08 | 498.8 | 0.81 | 1.46 | 0.59 |

| P100-5 | 100 | 500 | 8.67 | 450.2 | 1.21 | 1.32 | 0.62 |

| P100-6 | 100 | 600 | 9.29 | 295.2 | 1.81 | 1.41 | 0.64 |

| P100-7 | 100 | 700 | 10.20 | 196.7 | 2.13 | 1.39 | 0.63 |

| P100-8 | 100 | 800 | 9.97 | 208.6 | 2.48 | 1.53 | 0.67 |

| Specimens Number | r/% | T/°C | βm/% | Np/kN | Δp/mm | μ | η |

|---|---|---|---|---|---|---|---|

| SRRAC0-20-1 | 0 | 20 | - | 1476.5 | 3.60 | 2.27 | 0.78 |

| SRRAC0-200 | 0 | 200 | 1.49 | 1199.8 | 2.40 | 1.75 | 0.70 |

| SRRAC0-300 | 0 | 300 | 3.92 | 1180.7 | 2.80 | 0.82 | 0.60 |

| SRRAC0-400 | 0 | 400 | 4.22 | 1166.5 | 3.00 | 1.27 | 0.62 |

| SRRAC0-500 | 0 | 500 | 5.06 | 991.3 | 4.10 | 1.71 | 0.74 |

| SRRAC0-600-1 | 0 | 600 | 5.64 | 933.7 | 4.20 | 1.68 | 0.70 |

| SRRAC0-700 | 0 | 700 | 5.86 | 835.1 | 5.20 | 1.73 | 0.70 |

| SRRAC0-800 | 0 | 800 | 6.40 | 729.5 | 6.00 | 1.76 | 0.69 |

| SRRAC30-20-1 | 30 | 20 | - | 1444.4 | 2.40 | 1.36 | 0.64 |

| SRRAC30-400 | 30 | 400 | 4.26 | 1130.9 | 3.40 | 1.90 | 0.73 |

| SRRAC30-600 | 30 | 600 | 5.83 | 949.1 | 5.00 | 1.84 | 0.74 |

| SRRAC30-800 | 30 | 800 | 6.67 | 734.3 | 6.00 | 0.89 | 0.61 |

| SRRAC70-20-1 | 70 | 20 | - | 1433.9 | 2.70 | 2.23 | 0.75 |

| SRRAC70-400 | 70 | 400 | 4.88 | 1262.4 | 2.30 | 1.21 | 0.58 |

| SRRAC70-600 | 70 | 600 | 5.92 | 970.7 | 4.30 | 1.53 | 0.68 |

| SRRAC70-800 | 70 | 800 | 7.87 | 702.9 | 6.80 | 1.02 | 0.63 |

| SRRAC100-20-1 | 100 | 20 | - | 1480.9 | 3.50 | 1.93 | 0.68 |

| SRRAC100-200 | 100 | 200 | 1.49 | 1195.6 | 3.00 | 1.92 | 0.71 |

| SRRAC100-300 | 100 | 300 | 5.05 | 1229.9 | 2.40 | 1.37 | 0.63 |

| SRRAC100-400 | 100 | 400 | 5.74 | 1287.9 | 3.05 | 1.21 | 0.59 |

| SRRAC100-500 | 100 | 500 | 6.66 | 1125.6 | 3.90 | 1.68 | 0.70 |

| SRRAC100-600-1 | 100 | 600 | 7.54 | 963.2 | 4.60 | 1.75 | 0.72 |

| SRRAC100-700 | 100 | 700 | 7.79 | 837.1 | 4.80 | 1.74 | 0.67 |

| SRRAC100-800 | 100 | 800 | 8.08 | 747.3 | 5.60 | 2.17 | 0.63 |

| Specimens Number | r/% | T/°C | βm/% | Np/kN | Δp/mm | μ | η |

|---|---|---|---|---|---|---|---|

| RRAC0-0 | 0 | 20 | - | 1372.0 | 2.20 | 1.23 | 0.67 |

| RRAC0-2 | 0 | 200 | 1.34 | 1128.1 | 2.02 | 1.17 | 0.62 |

| RRAC0-4 | 0 | 400 | 5.60 | 1273.4 | 1.98 | 1.54 | 0.85 |

| RRAC0-6 | 0 | 600 | 7.26 | 748.1 | 2.50 | 1.50 | 0.87 |

| RRAC0-8 | 0 | 800 | 8.22 | 478.2 | 3.56 | 1.75 | 0.86 |

| RRAC30-0 | 30 | 20 | - | 1454.0 | 2.10 | 1.28 | 0.74 |

| RRAC30-2 | 30 | 200 | 2.57 | 1034.2 | 1.62 | 1.23 | 0.67 |

| RRAC30-4 | 30 | 400 | 5.26 | 1047.2 | 1.75 | 1.46 | 0.80 |

| RRAC30-6 | 30 | 600 | 7.64 | 757.5 | 3.69 | 1.89 | 0.88 |

| RRAC30-8 | 30 | 800 | 8.57 | 428.4 | 3.32 | 1.52 | 0.83 |

| RRAC50-0 | 50 | 20 | - | 1469.0 | 1.91 | 1.56 | 0.75 |

| RRAC50-2 | 50 | 200 | 3.95 | 1172.9 | 2.07 | 1.10 | 0.60 |

| RRAC50-4 | 50 | 400 | 5.39 | 1152.3 | 2.04 | 1.46 | 0.84 |

| RRAC50-6 | 50 | 600 | 8.08 | 784.6 | 3.21 | 1.93 | 0.85 |

| RRAC50-8 | 50 | 800 | 8.75 | 423.2 | 4.33 | 1.83 | 0.87 |

| RRAC70-0 | 70 | 20 | - | 1613.0 | 2.09 | 1.22 | 0.66 |

| RRAC70-2 | 70 | 200 | 1.36 | 1117.1 | 1.71 | 1.09 | 0.60 |

| RRAC70-4 | 70 | 400 | 6.67 | 1233.2 | 1.89 | 1.16 | 0.61 |

| RRAC70-6 | 70 | 600 | 9.07 | 755.6 | 4.49 | 1.41 | 0.80 |

| RRAC70-8 | 70 | 800 | 9.60 | 410.6 | 5.07 | 1.59 | 0.86 |

| RRAC100-0 | 100 | 20 | - | 1702.5 | 1.95 | 1.18 | 0.63 |

| RRAC100-2 | 100 | 200 | 1.15 | 1284.2 | 1.77 | 1.07 | 0.58 |

| RRAC100-4 | 100 | 400 | 6.72 | 1268.6 | 1.86 | 1.01 | 0.57 |

| RRAC100-6 | 100 | 600 | 9.82 | 794.0 | 4.35 | 1.46 | 0.82 |

| RRAC100-8 | 100 | 800 | 10.2 | 417.3 | 4.65 | 1.26 | 0.85 |

| Specimens Number | Shear Span Ratio | r/% | T/°C | βm/% | Np/kN | Δp/mm | μ | η |

|---|---|---|---|---|---|---|---|---|

| SRCMB0-0 | 2.0 | 0 | 20 | - | 249.5 | 4.06 | 3.01 | 0.82 |

| SRCMB0-2 | 2.0 | 0 | 200 | 0.32 | 255.4 | 3.39 | 2.36 | 0.77 |

| SRCMB0-4 | 2.0 | 0 | 400 | 3.77 | 234.0 | 4.37 | 2.50 | 0.8 |

| SRCMB0-6 | 2.0 | 0 | 600 | 5.81 | 188.4 | 4.67 | 3.83 | 0.86 |

| SRCMB30-0 | 2.0 | 30 | 20 | - | 257.2 | 5.75 | 5.31 | 0.89 |

| SRCMB30-2 | 2.0 | 30 | 200 | 0.62 | 230.0 | 4.76 | 4.89 | 0.89 |

| SRCMB30-4 | 2.0 | 30 | 400 | 4.47 | 227.6 | 3.50 | 2.34 | 0.77 |

| SRCMB30-6 | 2.0 | 30 | 600 | 6.61 | 194.5 | 5.85 | 3.29 | 0.81 |

| SRCMB70-0 | 2.0 | 70 | 20 | - | 255.3 | 7.11 | 7.23 | 0.91 |

| SRCMB70-2 | 2.0 | 70 | 200 | 0.88 | 237.9 | 5.15 | 5.52 | 0.89 |

| SRCMB70-4 | 2.0 | 70 | 400 | 4.19 | 242.7 | 5.64 | 2.99 | 0.83 |

| SRCMB70-6 | 2.0 | 70 | 600 | 7.12 | 202.8 | 6.95 | 3.32 | 0.83 |

| SRCMB100-0 | 2.0 | 100 | 20 | - | 256.7 | 2.99 | 2.16 | 0.76 |

| SRCMB100-2 | 2.0 | 100 | 200 | 0.72 | 263.0 | 4.80 | 2.55 | 0.79 |

| SRCMB100-4 | 2.0 | 100 | 400 | 4.66 | 248.0 | 4.90 | 2.13 | 0.76 |

| SRCMB100-6 | 2.0 | 100 | 600 | 7.91 | 170.0 | 4.71 | 2.11 | 0.76 |

| SRCSB0-0 | 1.2 | 0 | 20 | - | 336.9 | 2.23 | 2.51 | 0.79 |

| SRCSB0-2 | 1.2 | 0 | 200 | 0.28 | 360.1 | 2.07 | 2.52 | 0.78 |

| SRCSB0-4 | 1.2 | 0 | 400 | 4.03 | 317.1 | 2.73 | 1.62 | 0.68 |

| SRCSB0-6 | 1.2 | 0 | 600 | 5.67 | 250.0 | 4.24 | 2.35 | 0.78 |

| SRCSB30-0 | 1.2 | 30 | 20 | - | 398.4 | 2.89 | 2.37 | 0.77 |

| SRCSB30-2 | 1.2 | 30 | 200 | 0.9 | 364.4 | 3.33 | 2.73 | 0.8 |

| SRCSB30-4 | 1.2 | 30 | 400 | 4.37 | 368.0 | 3.49 | 1.68 | 0.7 |

| SRCSB30-6 | 1.2 | 30 | 600 | 6.78 | 266.0 | 5.21 | 3.10 | 0.84 |

| SRCSB70-0 | 1.2 | 70 | 20 | - | 357.7 | 3.08 | 2.42 | 0.77 |

| SRCSB70-2 | 1.2 | 70 | 200 | 0.86 | 350.9 | 4.14 | 2.46 | 0.79 |

| SRCSB70-4 | 1.2 | 70 | 400 | 3.96 | 362.7 | 3.34 | 1.84 | 0.73 |

| SRCSB70-6 | 1.2 | 70 | 600 | 7.18 | 272.0 | 3.74 | 2.60 | 0.79 |

| SRCSB100-0 | 1.2 | 100 | 20 | - | 400.0 | 2.88 | 2.81 | 0.78 |

| SRCSB100-2 | 1.2 | 100 | 200 | 0.47 | 375.5 | 3.11 | 1.36 | 0.63 |

| SRCSB100-4 | 1.2 | 100 | 400 | 4.83 | 336.0 | 3.00 | 1.84 | 0.71 |

| SRCSB100-6 | 1.2 | 100 | 600 | 7.81 | 247.0 | 3.75 | 2.50 | 0.77 |

| Specimens Number | Shear Span Ratio | r/% | T/°C | βm/% | Np/kN | Δp/mm | μ | η |

|---|---|---|---|---|---|---|---|---|

| RRACB-0-20-1 | 2.0 | 0 | 20 | - | 102.5 | 6.88 | 2.09 | 0.85 |

| RRACB-0-200-1 | 2.0 | 0 | 200 | 0.89 | 106.0 | 5.16 | 1.67 | 0.70 |

| RRACB-0-400-1 | 2.0 | 0 | 400 | 3.77 | 114.2 | 5.98 | 3.40 | 0.86 |

| RRACB-0-600-1 | 2.0 | 0 | 600 | 6.40 | 84.6 | 3.61 | 2.87 | 0.83 |

| RRACB-30-20-1 | 2.0 | 30 | 20 | - | 92.6 | 8.12 | 4.29 | 0.89 |

| RRACB-30-200-1 | 2.0 | 30 | 200 | 0.49 | 97.2 | 7.66 | 3.66 | 0.86 |

| RRACB-30-400-1 | 2.0 | 30 | 400 | 4.74 | 113.0 | 3.88 | 2.12 | 0.77 |

| RRACB-30-600-1 | 2.0 | 30 | 600 | 6.63 | 79.1 | 5.15 | 3.34 | 0.85 |

| RRACB-70-20-1 | 2.0 | 70 | 20 | - | 113.0 | 7.51 | 3.44 | 0.86 |

| RRACB-70-200-1 | 2.0 | 70 | 200 | 0.44 | 110.0 | 8.52 | 3.90 | 0.87 |

| RRACB-70-400-1 | 2.0 | 70 | 400 | 5.83 | 128.0 | 6.35 | 2.64 | 0.81 |

| RRACB-70-600-1 | 2.0 | 70 | 600 | 8.18 | 89.2 | 7.23 | 3.00 | 0.58 |

| RRACB-100-20-1 | 2.0 | 100 | 20 | - | 132.9 | 9.80 | 2.84 | 0.82 |

| RRACB-100-200-1 | 2.0 | 100 | 200 | 0.56 | 120.3 | 6.69 | 3.46 | 0.85 |

| RRACB-100-400-1 | 2.0 | 100 | 400 | 4.91 | 120.0 | 6.30 | 3.10 | 0.75 |

| RRACB-100-600-1 | 2.0 | 100 | 600 | 8.76 | 106.0 | 6.70 | 3.05 | 0.82 |

| RRACB-0-20-2 | 1.2 | 0 | 20 | - | 210.0 | 7.39 | 3.34 | 0.84 |

| RRACB-0-200-2 | 1.2 | 0 | 200 | 0.48 | 180.0 | 1.47 | 1.66 | 0.82 |

| RRACB-0-400-2 | 1.2 | 0 | 400 | 4.57 | 142.0 | 1.73 | 1.71 | 0.79 |

| RRACB-0-600-2 | 1.2 | 0 | 600 | 6.46 | 124.0 | 1.88 | 1.54 | 0.68 |

| RRACB-30-20-2 | 1.2 | 30 | 20 | - | 211.3 | 4.63 | 2.14 | 0.77 |

| RRACB-30-200-2 | 1.2 | 30 | 200 | 0.86 | 192.3 | 2.50 | 2.06 | 0.76 |

| RRACB-30-400-2 | 1.2 | 30 | 400 | 4.73 | 177.0 | 1.84 | 1.75 | 0.72 |

| RRACB-30-600-2 | 1.2 | 30 | 600 | 6.83 | 115.0 | 1.37 | 1.56 | 0.68 |

| RRACB-70-20-2 | 1.2 | 70 | 20 | - | 207.0 | 6.82 | 4.74 | 0.89 |

| RRACB-70-200-2 | 1.2 | 70 | 200 | 0.55 | 210.0 | 4.87 | 3.65 | 0.87 |

| RRACB-70-400-2 | 1.2 | 70 | 400 | 5.41 | 196.0 | 1.90 | 1.44 | 0.65 |

| RRACB-70-600-2 | 1.2 | 70 | 600 | 8.49 | 122.0 | 2.27 | 1.77 | 0.72 |

| RRACB-100-20-2 | 1.2 | 100 | 20 | - | 230.0 | 16.02 | 3.44 | 0.86 |

| RRACB-100-200-2 | 1.2 | 100 | 200 | 0.69 | 200.0 | 4.57 | 3.05 | 0.84 |

| RRACB-100-400-2 | 1.2 | 100 | 400 | 3.92 | 178.0 | 1.54 | 1.77 | 0.72 |

| RRACB-100-600-2 | 1.2 | 100 | 600 | 7.59 | 109.5 | 2.28 | 1.44 | 0.65 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Zhou, J.; Ye, P.; Liang, Y. Analysis on Mechanical Properties of Recycled Aggregate Concrete Members after Exposure to High Temperatures. Appl. Sci. 2019, 9, 2057. https://doi.org/10.3390/app9102057

Chen Z, Zhou J, Ye P, Liang Y. Analysis on Mechanical Properties of Recycled Aggregate Concrete Members after Exposure to High Temperatures. Applied Sciences. 2019; 9(10):2057. https://doi.org/10.3390/app9102057

Chicago/Turabian StyleChen, Zongping, Ji Zhou, Peihuan Ye, and Ying Liang. 2019. "Analysis on Mechanical Properties of Recycled Aggregate Concrete Members after Exposure to High Temperatures" Applied Sciences 9, no. 10: 2057. https://doi.org/10.3390/app9102057

APA StyleChen, Z., Zhou, J., Ye, P., & Liang, Y. (2019). Analysis on Mechanical Properties of Recycled Aggregate Concrete Members after Exposure to High Temperatures. Applied Sciences, 9(10), 2057. https://doi.org/10.3390/app9102057