Novel Design and Lateral Stability Tracking Control of a Four-Wheeled Rollator

Abstract

:Featured Application

Abstract

1. Introduction

2. Novel Rollator Mechanical Design with Kano-TRIZ

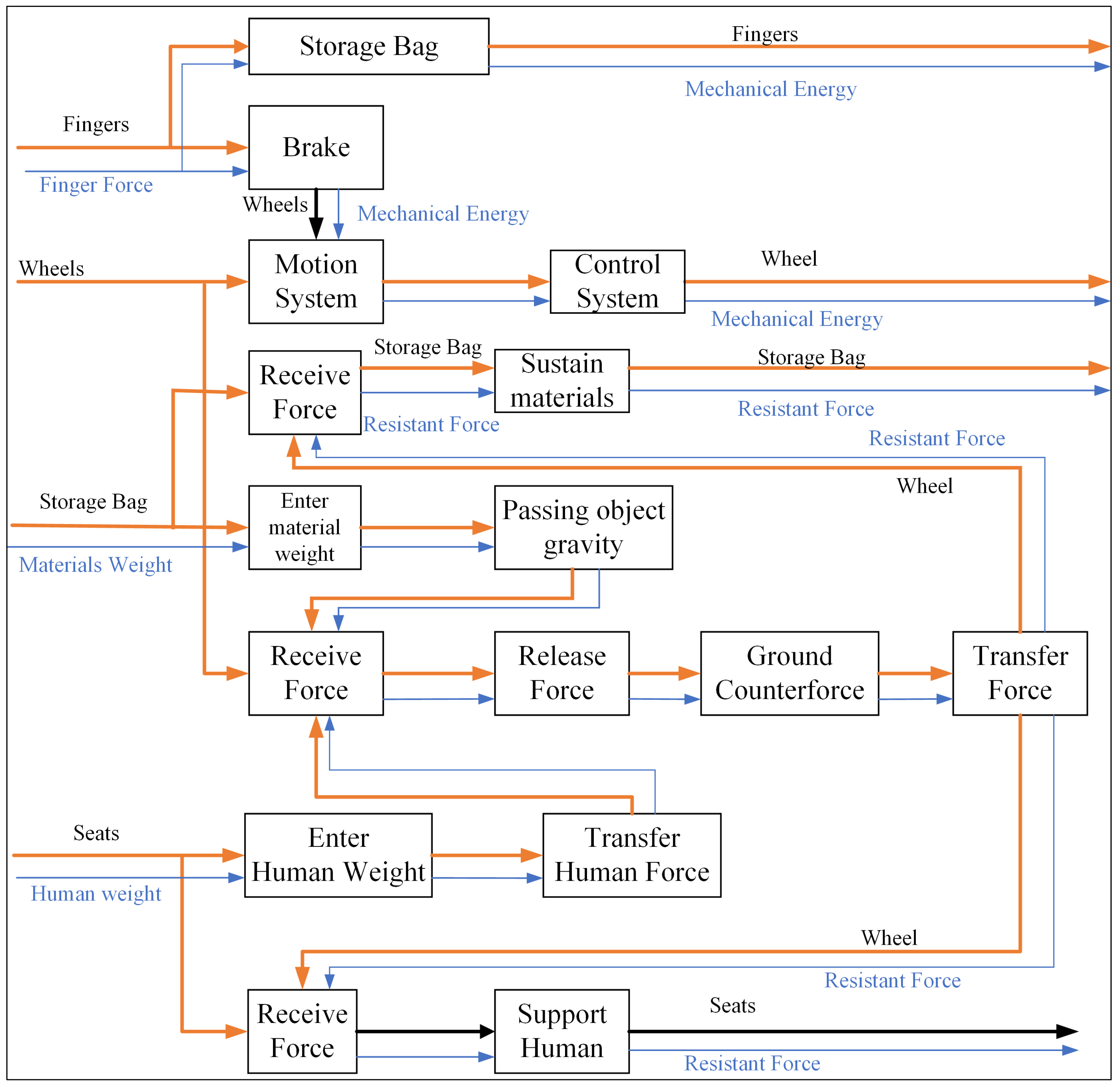

2.1. Functional Mechanical Design

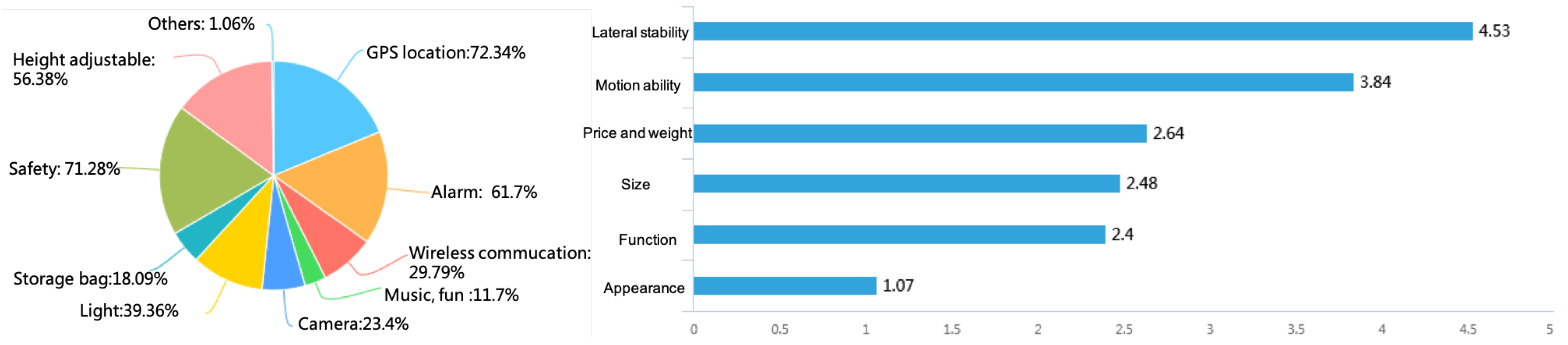

2.2. Kano Model Analysis

- TRIZ translates specific product technical features into technical features that engineering designers can understand;

- The Kano model is used to analyze the function demand after the survey of user requirements;

- The QFD evaluation method with the design of the quality house (HOQ) is carried out to transform the user’s requirements to product demand.

2.3. Structural Details of Modeling, Structure and Materials

3. Lateral Stability Tracking Control of Designed Rollator

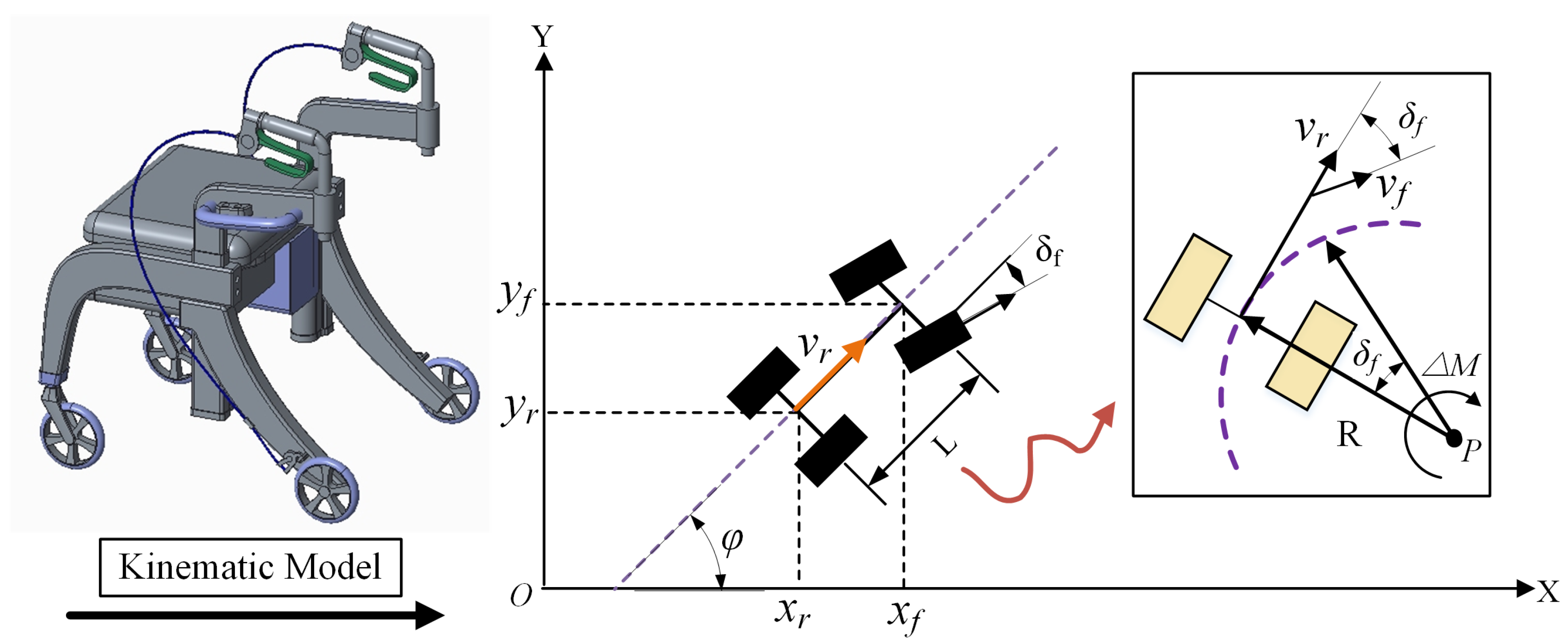

3.1. Rollator Kinematic Model

3.2. Rollator Dynamic Model and Tire Model

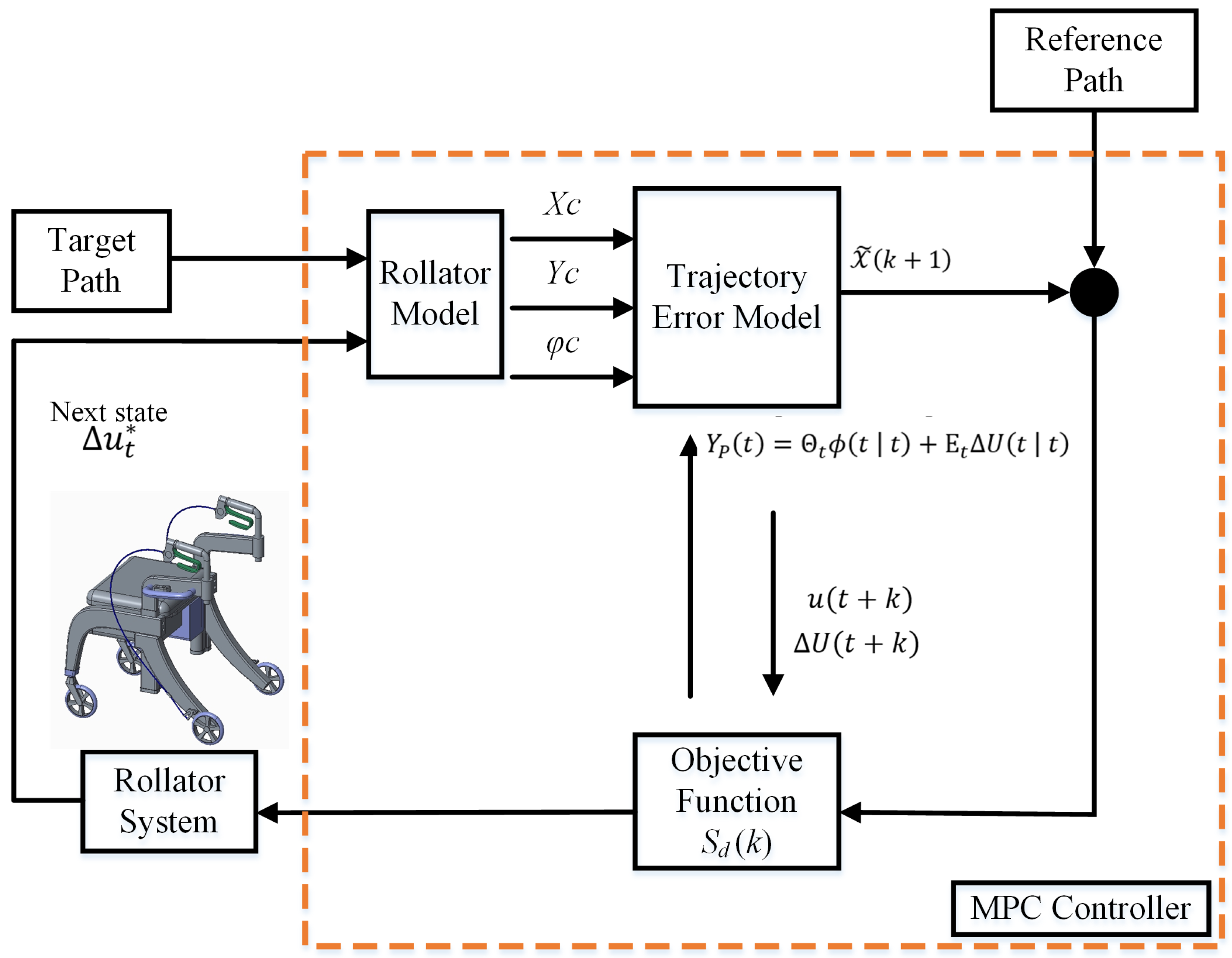

3.3. Lateral Controller Development

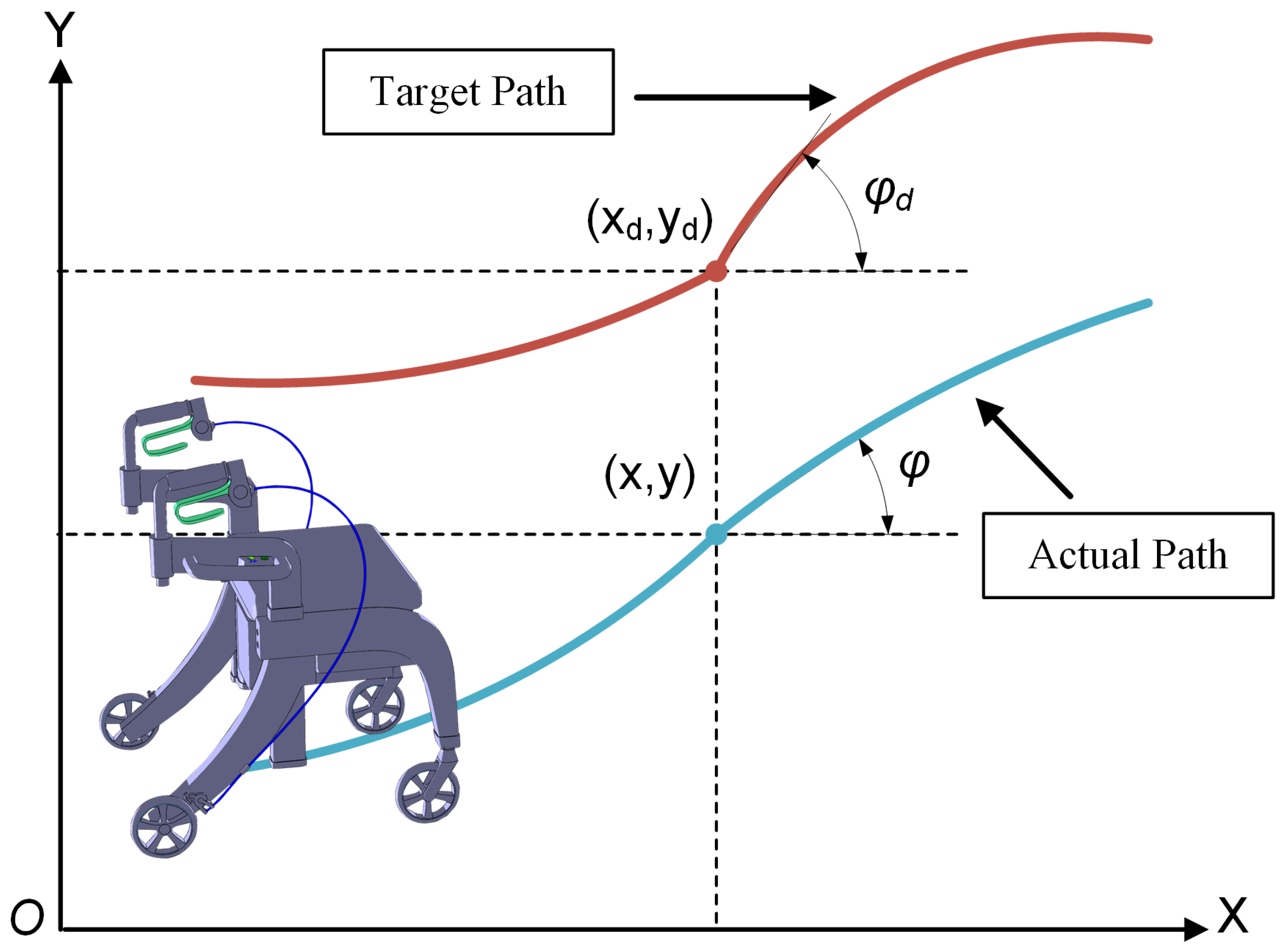

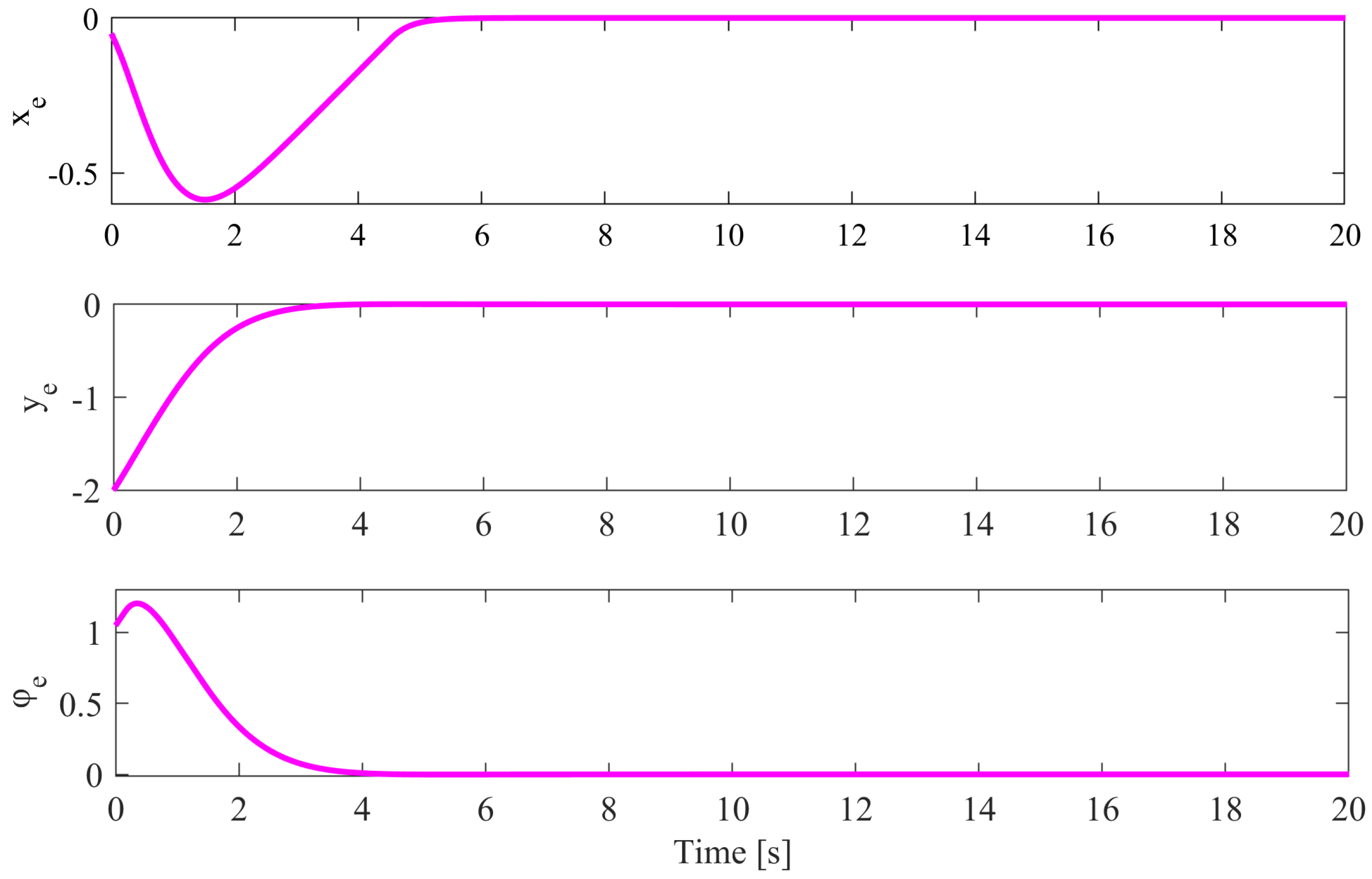

3.3.1. Trajectory Error Function

3.3.2. Objective Function Design

3.3.3. Control Constraint Design

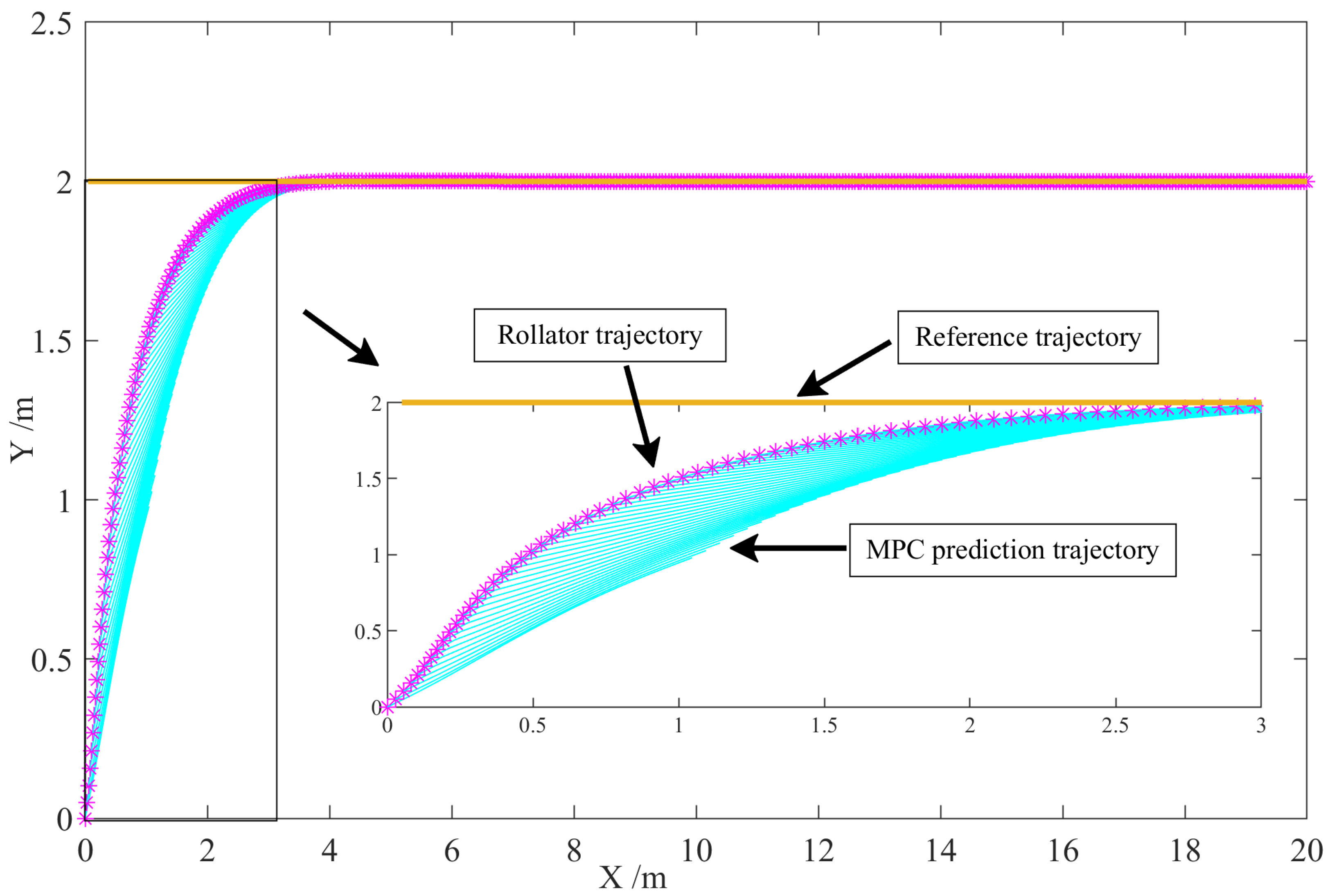

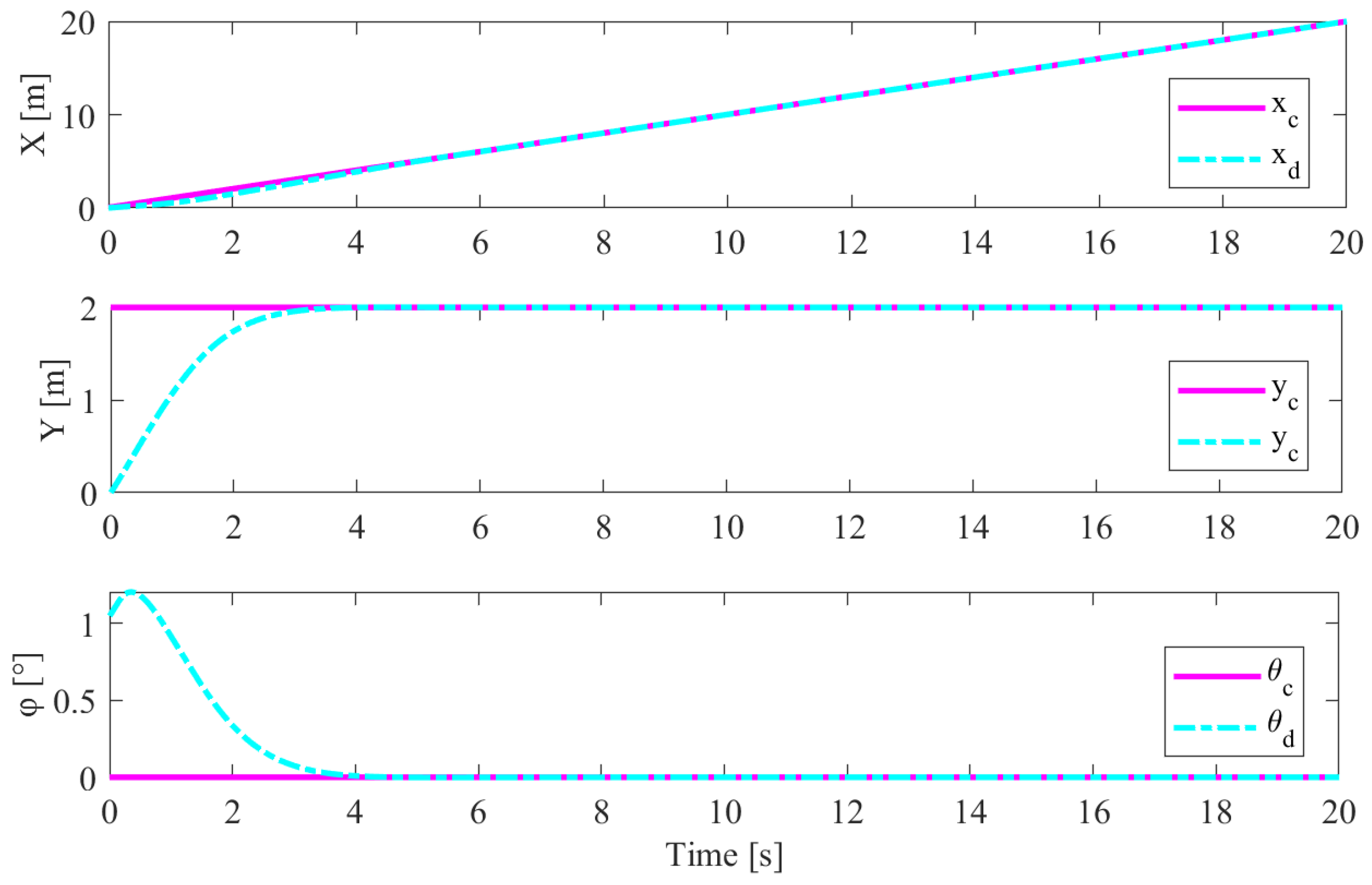

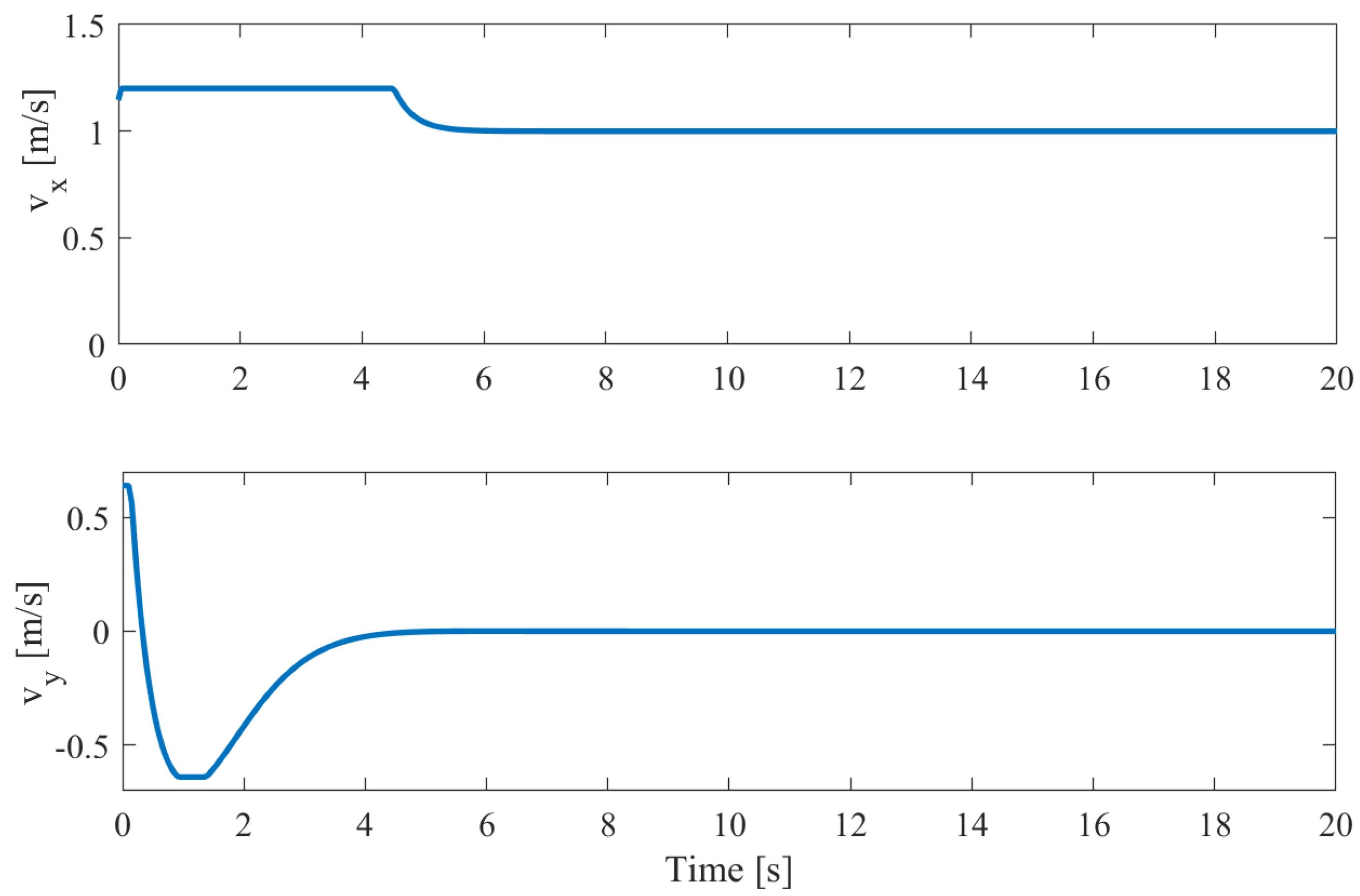

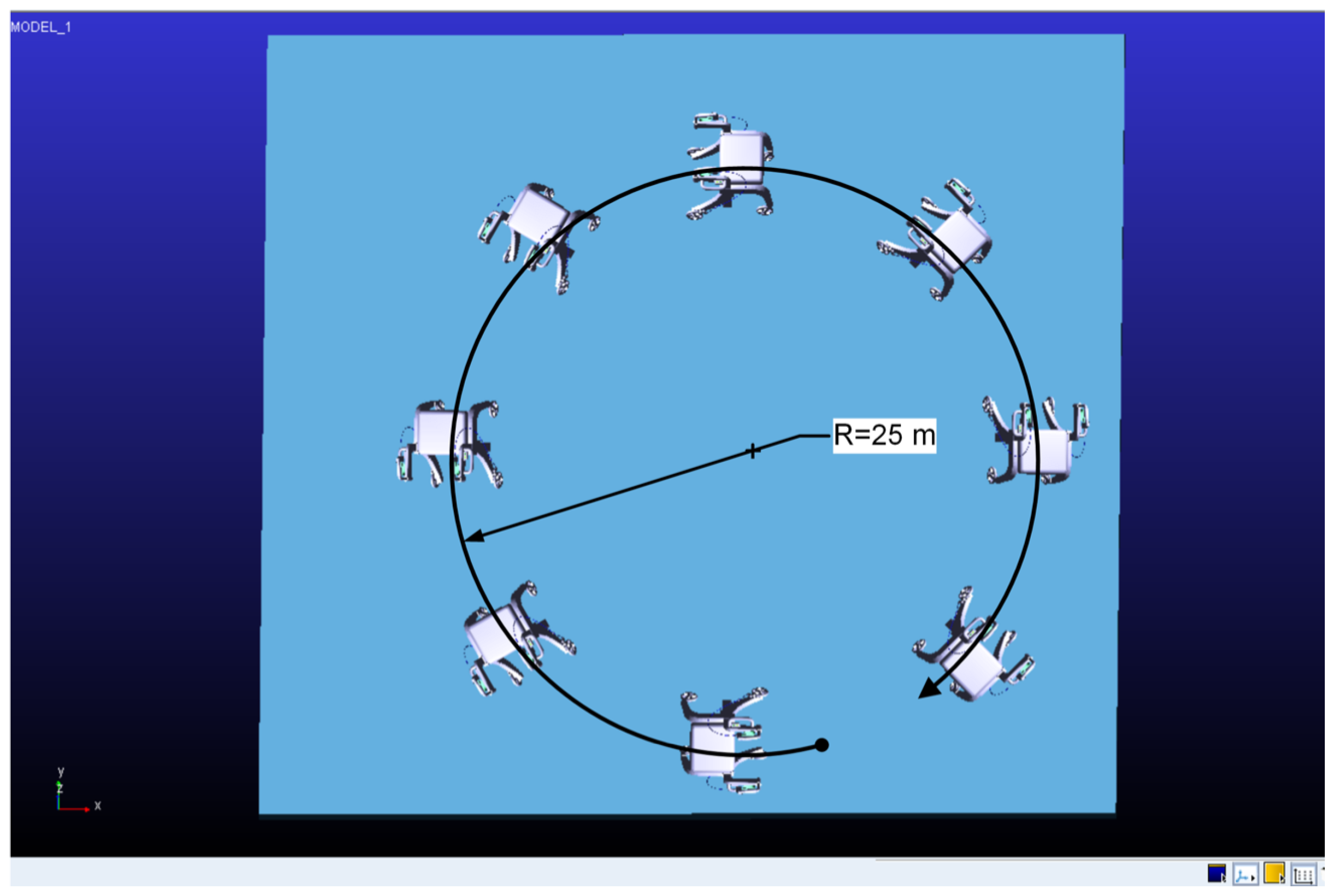

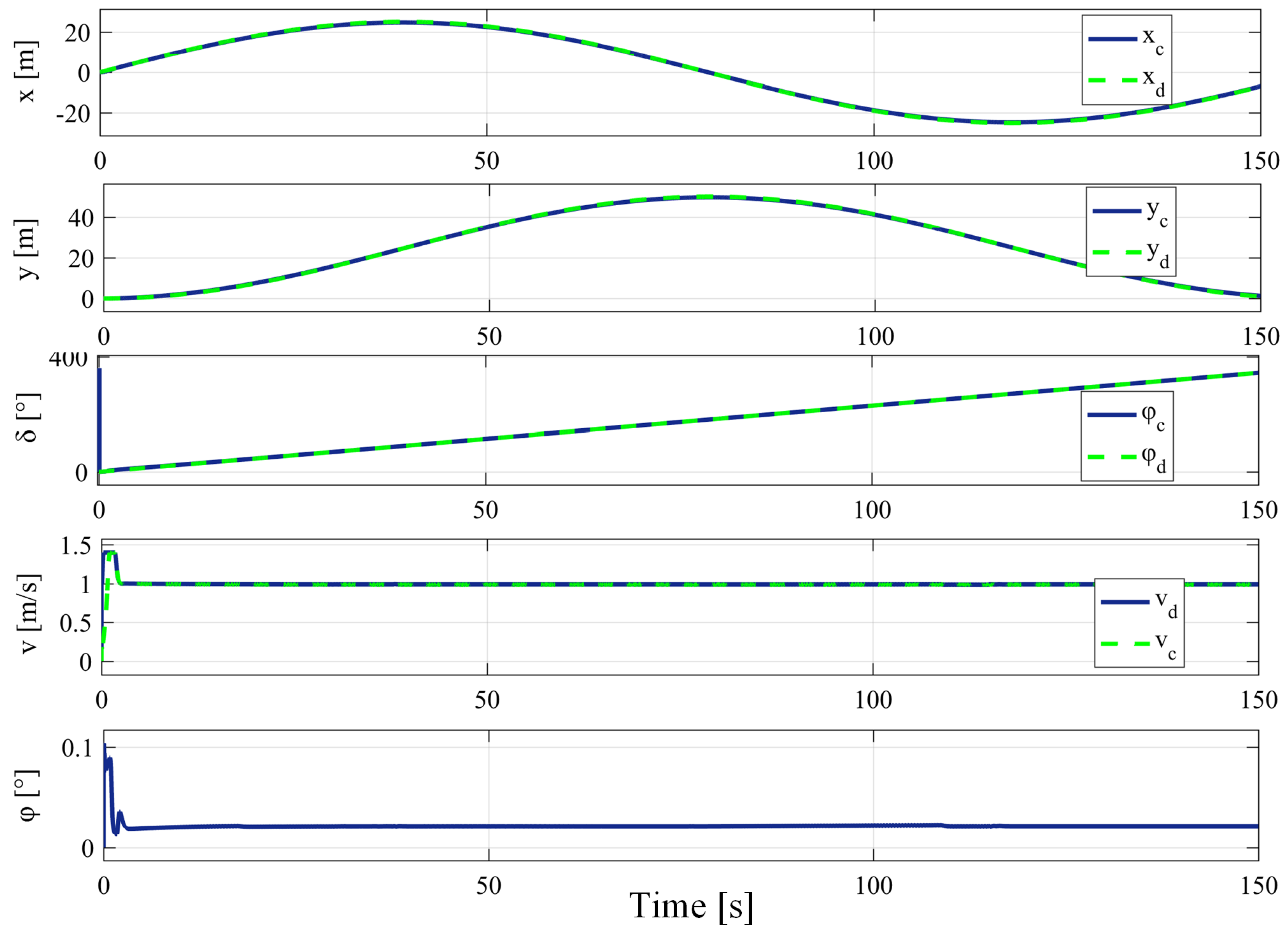

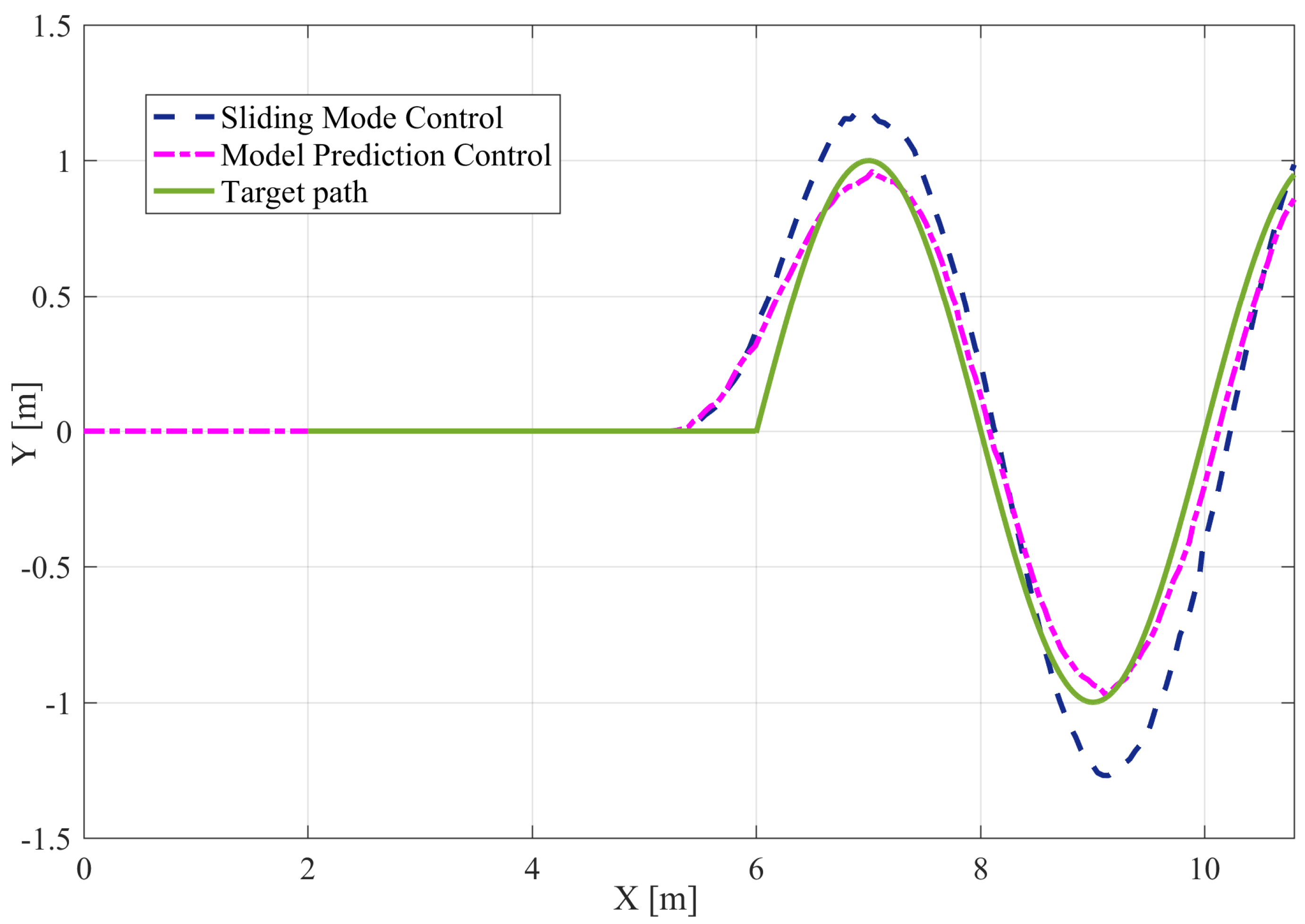

4. Results and Discussion

5. Conclusions and Future Work

- An integrated system of four-wheeled rollator is designed to meet the requirements of the elderly by introducing a novel mechanical design theory that integrates the advantages of Kano Model Analysis with the Theory of Inventive Problem Solving (TRIZ).

- A lateral stability tracking control approach based on an MPC scheme is performed to validate the control feasibility of the novel designed four-wheeled rollator, which is introduced to achieve the high safety requirements of the elderly walker.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| QFD | Quality Function Deployment |

| MPC | Model Predictive Control |

| TRIZ | Theory of Inventive Problem Solving |

| PID | Proportional-Integral-Derivative |

References

- Probst, V.S.; Troosters, T.; Coosemans, I.; Spruit, M.A.; de Oliveira Pitta, F.; Decramer, M.; Gosselink, R. Mechanisms of improvement in exercise capacity using a rollator in patients with COPD. Chest 2004, 126, 1102–1107. [Google Scholar] [CrossRef] [PubMed]

- VanWye, W.R.; Hoover, D.L. Management of a patient’s gait abnormality using smartphone technology in-clinic for improved qualitative analysis: A case report. Physiother. Theory Pract. 2018, 34, 403–410. [Google Scholar] [CrossRef] [PubMed]

- Kulyukin, V.; Kutiyanawala, A.; LoPresti, E.; Matthews, J.; Simpson, R. iWalker: Toward a rollator-mounted wayfinding system for the elderly. In Proceedings of the 2008 IEEE International Conference on RFID, Las Vegas, NV, USA, 16–17 April 2008; pp. 303–311. [Google Scholar]

- Su, H.; Li, Z.; Li, G.; Yang, C. EMG-Based neural network control of an upper-limb power-assist exoskeleton robot. In Proceedings of the 10th International Symposium on Neural Networks, Dalian, China, 4–6 July 2013; pp. 204–211. [Google Scholar]

- Zhang, H.; Ye, C. RGB-D camera based walking pattern recognition by support vector machines for a smart rollator. Int. J. Intell. Robot. Appl. 2017, 1, 32–42. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lee, A.L.; Beauchamp, M.K.; Goldstein, R.S.; Brooks, D. Clinical and Physiological Effects of Rollators in Individuals with Chronic Obstructive Pulmonary Disease: A Systematic Review. J. Cardiopulm. Rehabil. Prev. 2018, 38, 366–373. [Google Scholar] [CrossRef] [PubMed]

- Modise, T.D.; Steyn, N.; Hamam, Y. Human feet tracking in arranging the navigation of a robotic rollator. In Proceedings of the 2017 IEEE AFRICON, Cape Town, South Africa, 18–20 September 2017; pp. 88–93. [Google Scholar]

- Ballesteros, J.; Urdiales, C.; Martinez, A.B.; Tirado, M. Automatic assessment of a rollator-user’s condition during rehabilitation using the i-Walker platform. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 2009–2017. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Enayati, N.; Vantadori, L.; Spinoglio, A.; Ferrigno, G.; De Momi, E. Online human-like redundancy optimization for tele-operated anthropomorphic manipulators. Int. J. Adv. Robot. Syst. 2018, 15. [Google Scholar] [CrossRef]

- Hu, M.; Yang, K.; Taguchi, S. Enhancing robust design with the aid of TRIZ and axiomatic design (Part I). TRIZ J. 2000. [Google Scholar] [CrossRef]

- Borgianni, Y.; Matt, D.T. Axiomatic design and TRIZ: Deficiencies of their integrated use and future opportunities. Procedia CIRP 2015, 34, 1–6. [Google Scholar] [CrossRef]

- Lee, C.H.; Wang, Y.H.; Trappey, A.J. Service design for intelligent parking based on theory of inventive problem solving and service blueprint. Adv. Eng. Inform. 2015, 29, 295–306. [Google Scholar] [CrossRef]

- Altshuller, G. The Innovation Algorithm: TRIZ, Systematic Innovation and Technical Creativity; Technical Innovation Center, Inc.: Worcester, MA, USA, 1999. [Google Scholar]

- Zouaoua, D.; Crubleau, P.; Choulier, D.; Richir, S. Application of evolution laws. Procedia Eng. 2015, 131, 922–932. [Google Scholar] [CrossRef]

- Vinodh, S.; Kamala, V.; Jayakrishna, K. Integration of ECQFD, TRIZ, and AHP for innovative and sustainable product development. Appl. Math. Model. 2014, 38, 2758–2770. [Google Scholar] [CrossRef]

- Filippi, S.; Barattin, D. Exploiting TRIZ tools in interaction design. Procedia Eng. 2015, 131, 71–85. [Google Scholar] [CrossRef]

- Pokhrel, C.; Cruz, C.; Ramirez, Y.; Kraslawski, A. Adaptation of TRIZ contradiction matrix for solving problems in process engineering. Chem. Eng. Res. Des. 2015, 103, 3–10. [Google Scholar] [CrossRef]

- Brad, S.; Brad, E. Enhancing SWOT analysis with TRIZ-based tools to integrate systematic innovation in early task design. Procedia Eng. 2015, 131, 616–625. [Google Scholar] [CrossRef]

- Van Pelt, A.; Hey, J. Using TRIZ and human-centered design for consumer product development. Procedia Eng. 2011, 9, 688–693. [Google Scholar] [CrossRef]

- Wu, Y.; Wang, C.; Zhou, L.; Ou, L. A simulation of vehicle lateral stability based on fuzzy PID control. In Proceedings of the 2009 International Conference on Measuring Technology and Mechatronics Automation, Zhangjiajie, China, 11–12 April 2009; pp. 194–199. [Google Scholar]

- Han, G.; Fu, W.; Wang, W.; Wu, Z. The lateral tracking control for the intelligent vehicle based on adaptive PID neural network. Sensors 2017, 17, 1244. [Google Scholar] [CrossRef] [PubMed]

- Guo, J.; Li, L.; Li, K.; Wang, R. An adaptive fuzzy-sliding lateral control strategy of automated vehicles based on vision navigation. Veh. Syst. Dyn. 2013, 51, 1502–1517. [Google Scholar] [CrossRef]

- Onieva, E.; Naranjo, J.E.; Milanés, V.; Alonso, J.; García, R.; Pérez, J. Automatic lateral control for unmanned vehicles via genetic algorithms. Appl. Soft Comput. 2011, 11, 1303–1309. [Google Scholar] [CrossRef] [Green Version]

- Gutjahr, B.; Gröll, L.; Werling, M. Lateral vehicle trajectory optimization using constrained linear time-varying MPC. IEEE Trans. Intell. Transp. Syst. 2017, 18, 1586–1595. [Google Scholar] [CrossRef]

- Nahidi, A.; Kasaiezadeh, A.; Khosravani, S.; Khajepour, A.; Chen, S.K.; Litkouhi, B. Modular integrated longitudinal and lateral vehicle stability control for electric vehicles. Mechatronics 2017, 44, 60–70. [Google Scholar] [CrossRef]

- Zhao, S.; Li, Y.; Zheng, L.; Lu, S. Vehicle lateral stability control based on sliding mode control. In Proceedings of the 2007 IEEE International Conference on Automation and Logistics, Jinan, China, 18–21 August 2007; pp. 638–642. [Google Scholar]

- Ho, M.; Chan, P.; Rad, A.B.; Shirazi, M.; Cina, M. A novel fused neural network controller for lateral control of autonomous vehicles. Appl. Soft Comput. 2012, 12, 3514–3525. [Google Scholar] [CrossRef]

- Wang, R.; Jing, H.; Wang, J.; Chadli, M.; Chen, N. Robust output-feedback based vehicle lateral motion control considering network-induced delay and tire force saturation. Neurocomputing 2016, 214, 409–419. [Google Scholar] [CrossRef]

- Vezzetti, E.; Moos, S.; Kretli, S. A product lifecycle management methodology for supporting knowledge reuse in the consumer packaged goods domain. Comput. Aided Des. 2011, 43, 1902–1911. [Google Scholar] [CrossRef] [Green Version]

- Cascini, G.; Rissone, P. Plastics design: Integrating TRIZ creativity and semantic knowledge portals. J. Eng. Des. 2004, 15, 405–424. [Google Scholar] [CrossRef]

- Yi, K.; Liang, X.; He, Y.; Yang, L.; Han, J. Active-Model-Based Control for the Quadrotor Carrying a Changed Slung Load. Electronics 2019, 8, 461. [Google Scholar] [CrossRef]

- Gong, J.; Jiang, Y.; Xu, W. Model Predictive Control for Self-Driving Vehicles; Beijing Institute of Technology Press: Beijing, China, 2014. [Google Scholar]

- Jiang, L. Path tracking of automatic parking system based on sliding mode control. Trans. Chin. Soc. Agric. Mach. 2019, 50, 356–364. [Google Scholar]

- Shen, W.; Pan, Z.; Li, M.; Peng, H. A Lateral Control Method for Wheel-Footed Robot Based on Sliding Mode Control and Steering Prediction. IEEE Access 2018, 6, 58086–58095. [Google Scholar] [CrossRef]

- Li, Z.; Yang, C.; Su, C.; Deng, J.; Zhang, W. Vision-Based Model Predictive Control for Steering of a Nonholonomic Mobile Robot. IEEE Trans. Control Syst. Technol. 2016, 24, 553–564. [Google Scholar] [CrossRef]

- Ke, F.; Li, Z.; Yang, C. Robust Tube-Based Predictive Control for Visual Servoing of Constrained Differential-Drive Mobile Robots. IEEE Trans. Ind. Electron. 2018, 65, 3437–3446. [Google Scholar] [CrossRef]

- Luo, J.; Liu, C.; Yang, C. Estimation of EMG-Based Force Using a Neural-Network-Based Approach. IEEE Access 2019, 126, 64856–64865. [Google Scholar] [CrossRef]

- Alkjær, T.; Larsen, P.K.; Pedersen, G.; Nielsen, L.H.; Simonsen, E.B. Biomechanical analysis of rollator walking. Biomed. Eng. Online 2006, 5, 2. [Google Scholar] [CrossRef] [PubMed]

- Su, H.; Li, S.; Manivannan, J.; Bascetta, L.; Ferrigno, G.; De Momi, E. Manipulability Optimization Control of a Serial Redundant Robot for Robot-assisted Minimally Invasive Surgery. In Proceedings of the 2019 IEEE International Conference on Robotics and Automation, Montreal, QC, Canada, 20–24 May 2008; pp. 303–310. [Google Scholar]

- Su, H.; Sandoval, J.; Makhdoomi, M.; Ferrigno, G.; De Momi, E. Safety-enhanced human-robot interaction control of redundant robot for teleoperated minimally invasive surgery. In Proceedings of the 2018 IEEE International Conference on Robotics and Automation (ICRA), Brisbane, Australia, 21–25 May 2018; pp. 6611–6616. [Google Scholar]

- Su, H.; Sandoval, J.; Vieyres, P.; Poisson, G.; Ferrigno, G.; De Momi, E. Safety-enhanced collaborative framework for tele-operated minimally invasive surgery using a 7-DoF torque-controlled robot. Int. J. Control Autom. Syst. 2018, 16, 2915–2923. [Google Scholar] [CrossRef]

- Su, H.; Yang, C.; Ferrigno, G.; De Momi, E. Improved Human—Robot Collaborative Control of Redundant Robot for Teleoperated Minimally Invasive Surgery. IEEE Robot. Autom. Lett. 2019, 4, 1447–1453. [Google Scholar] [CrossRef]

- Yang, C.; Luo, J.; Pan, Y.; Liu, Z.; Su, C.Y. Personalized variable gain control with tremor attenuation for robot teleoperation. IEEE Trans. Syst. Man Cybern. Syst. 2017, 48, 1759–1770. [Google Scholar] [CrossRef]

- Li, Z.; Su, C.Y.; Li, G.; Su, H. Fuzzy approximation-based adaptive backstepping control of an exoskeleton for human upper limbs. IEEE Trans. Fuzzy Syst. 2014, 23, 555–566. [Google Scholar] [CrossRef]

- Li, Z.; Xiao, S.; Ge, S.S.; Su, H. Constrained multilegged robot system modeling and fuzzy control with uncertain kinematics and dynamics incorporating foot force optimization. IEEE Trans. Syst. Man Cybern. Syst. 2015, 46, 1–15. [Google Scholar] [CrossRef]

- Luo, J.; Yang, C.; Wang, N.; Wang, M. Enhanced teleoperation performance using hybrid control and virtual fixture. Int. J. Syst. Sci. 2019, 50, 451–462. [Google Scholar] [CrossRef]

- Luo, J.; Yang, C.; Su, H.; Liu, C. A Robot Learning Method with Physiological Interface for Teleoperation Systems. Appl. Sci. 2019, 9, 2099. [Google Scholar] [CrossRef]

- Zhang, L.; Li, Z.; Yang, C. Adaptive neural network based variable stiffness control of uncertain robotic systems using disturbance observer. IEEE Trans. Ind. Electron. 2016, 64, 2236–2245. [Google Scholar] [CrossRef]

- Yang, J.; Su, H.; Li, Z.; Ao, D.; Song, R. Adaptive control with a fuzzy tuner for cable-based rehabilitation robot. Int. J. Control Autom. Syst. 2016, 14, 865–875. [Google Scholar] [CrossRef]

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Li, J.; Hu, Z.; Qi, W.; Zhang, L.; Hu, Y.; Su, H.; Ferrigno, G.; Momi, E.D. Novel Design and Lateral Stability Tracking Control of a Four-Wheeled Rollator. Appl. Sci. 2019, 9, 2327. https://doi.org/10.3390/app9112327

Zhang X, Li J, Hu Z, Qi W, Zhang L, Hu Y, Su H, Ferrigno G, Momi ED. Novel Design and Lateral Stability Tracking Control of a Four-Wheeled Rollator. Applied Sciences. 2019; 9(11):2327. https://doi.org/10.3390/app9112327

Chicago/Turabian StyleZhang, Xin, Jiehao Li, Zhenhuan Hu, Wen Qi, Longbin Zhang, Yingbai Hu, Hang Su, Giancarlo Ferrigno, and Elena De Momi. 2019. "Novel Design and Lateral Stability Tracking Control of a Four-Wheeled Rollator" Applied Sciences 9, no. 11: 2327. https://doi.org/10.3390/app9112327

APA StyleZhang, X., Li, J., Hu, Z., Qi, W., Zhang, L., Hu, Y., Su, H., Ferrigno, G., & Momi, E. D. (2019). Novel Design and Lateral Stability Tracking Control of a Four-Wheeled Rollator. Applied Sciences, 9(11), 2327. https://doi.org/10.3390/app9112327