A New Modeling Method of Angle Measurement for Intelligent Ball Joint Based on BP-RBF Algorithm

Abstract

:1. Introduction

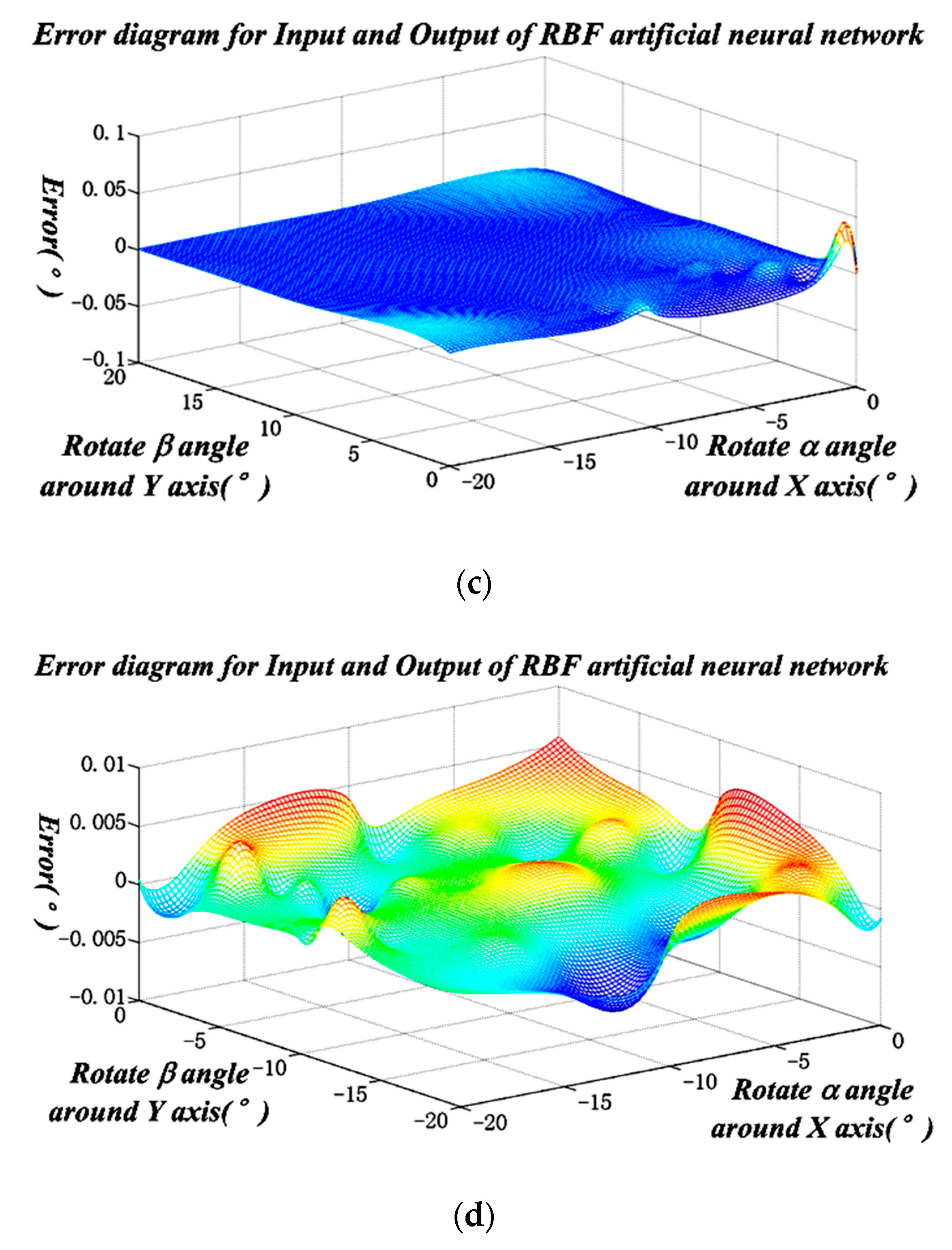

2. Simulation Analysis of Artificial Neural Network (ANN) Modeling

2.1. Selection of ANN

2.2. Simulating Realization of ANN

- In the measurement range of [−20~20°], the output magnetic induction intensity of the Hall sensor collected at intervals of one unit acted as the input of the ANN to build the model, while the angle corresponding to (α,β) was used as the output of the ANN to build the model. Because the sigmoid function is sensitive to the slight changes in the middle and the recognition degree of ANN is better, the sigmoid function was used to scale the data into the interval [−1,1].

- According to the training rules of the ANN, the initial parameters (W,b) of the ANN were arbitrary numbers in (0,1), whether the W and b represented all weighting matrices and bias vectors in ANN, respectively. The output of the first training (α1,β1) was calculated, then the parameters (W,b) were updated according to the function of the ANN itself. After several iterations, the parameters of ANN (W,b) which minimized the error output function were obtained.

- When all the training data of the neural network were finished and the output error was minimized after simulation, and the output achieved the required accuracy, the ANN modeling was complete.

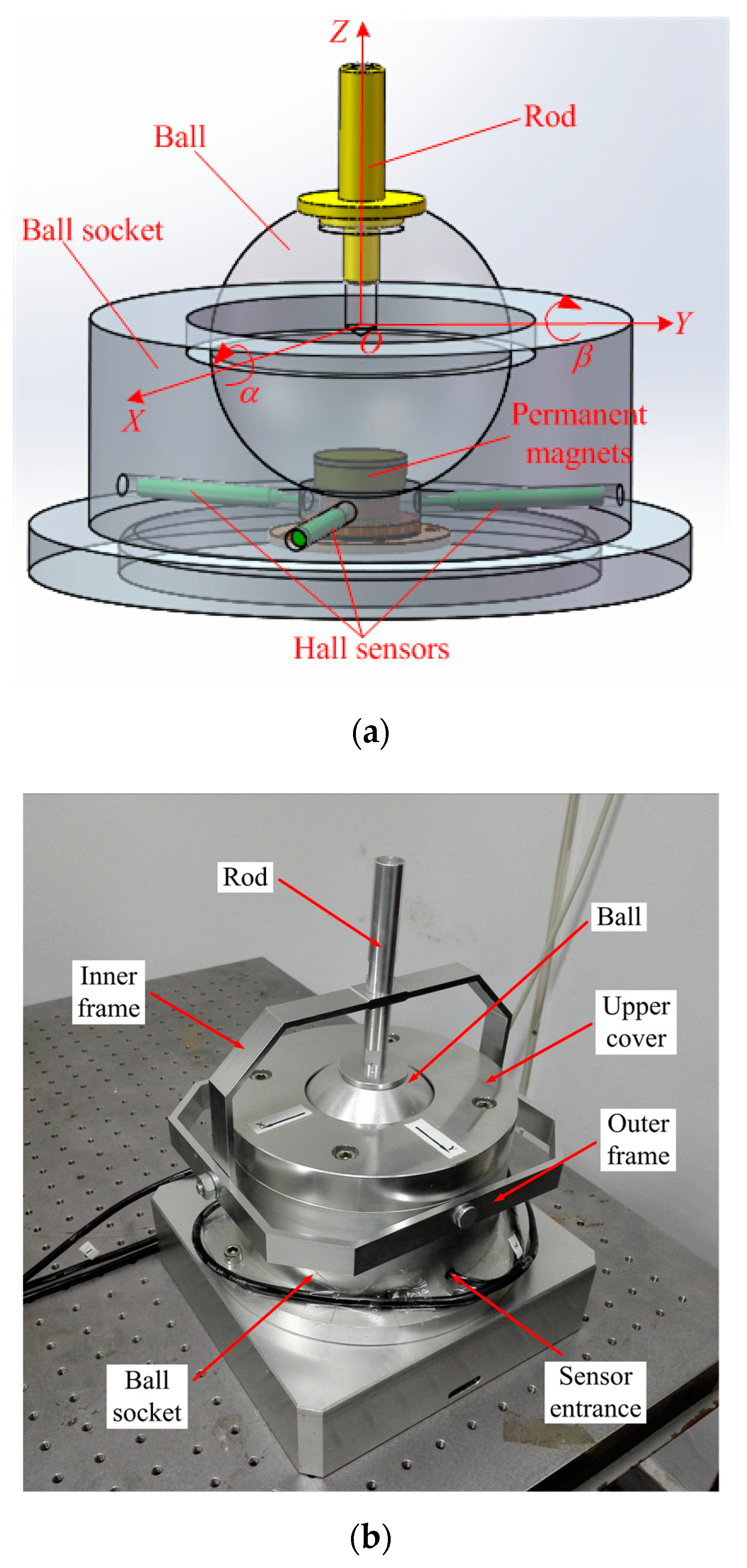

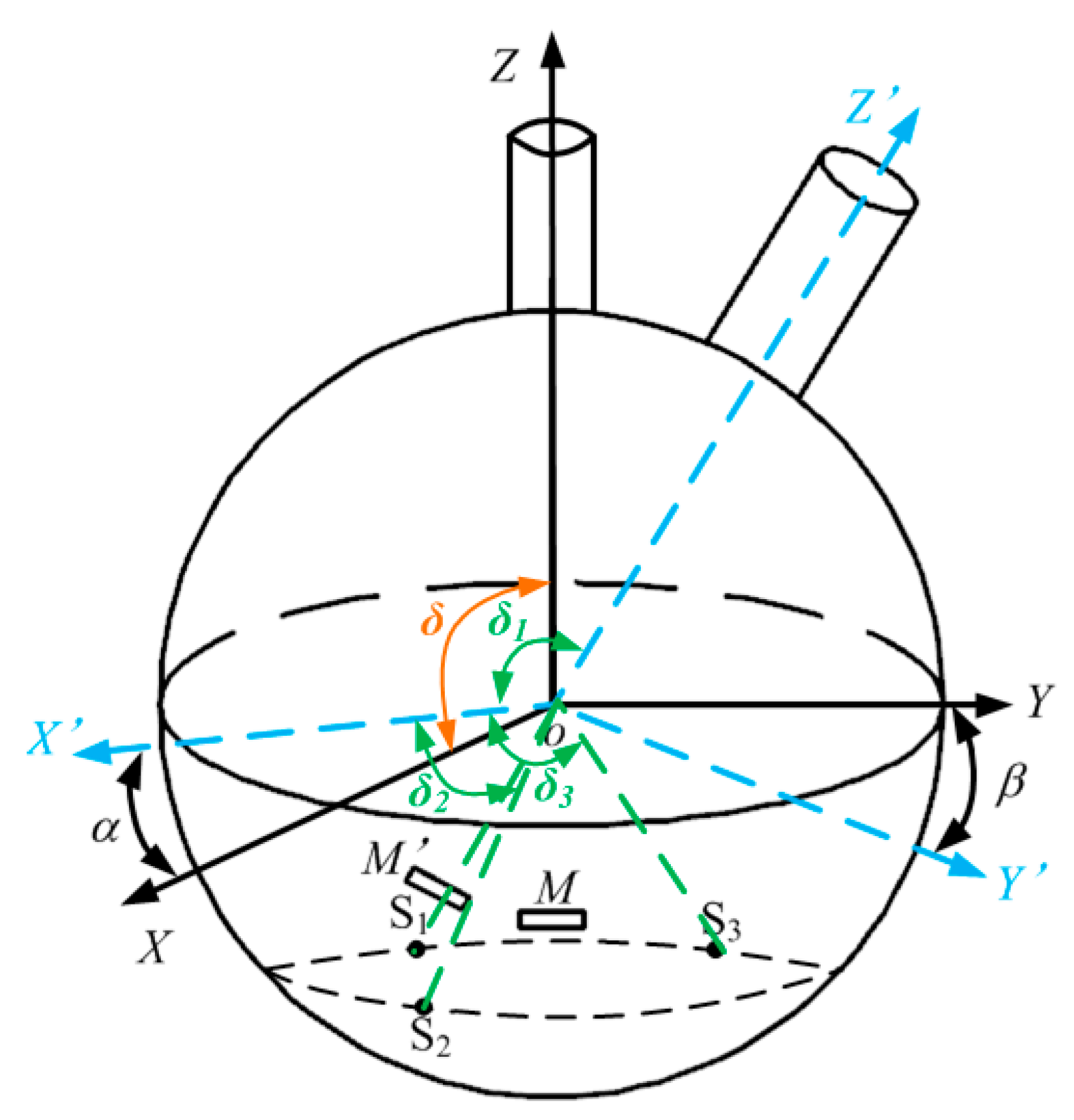

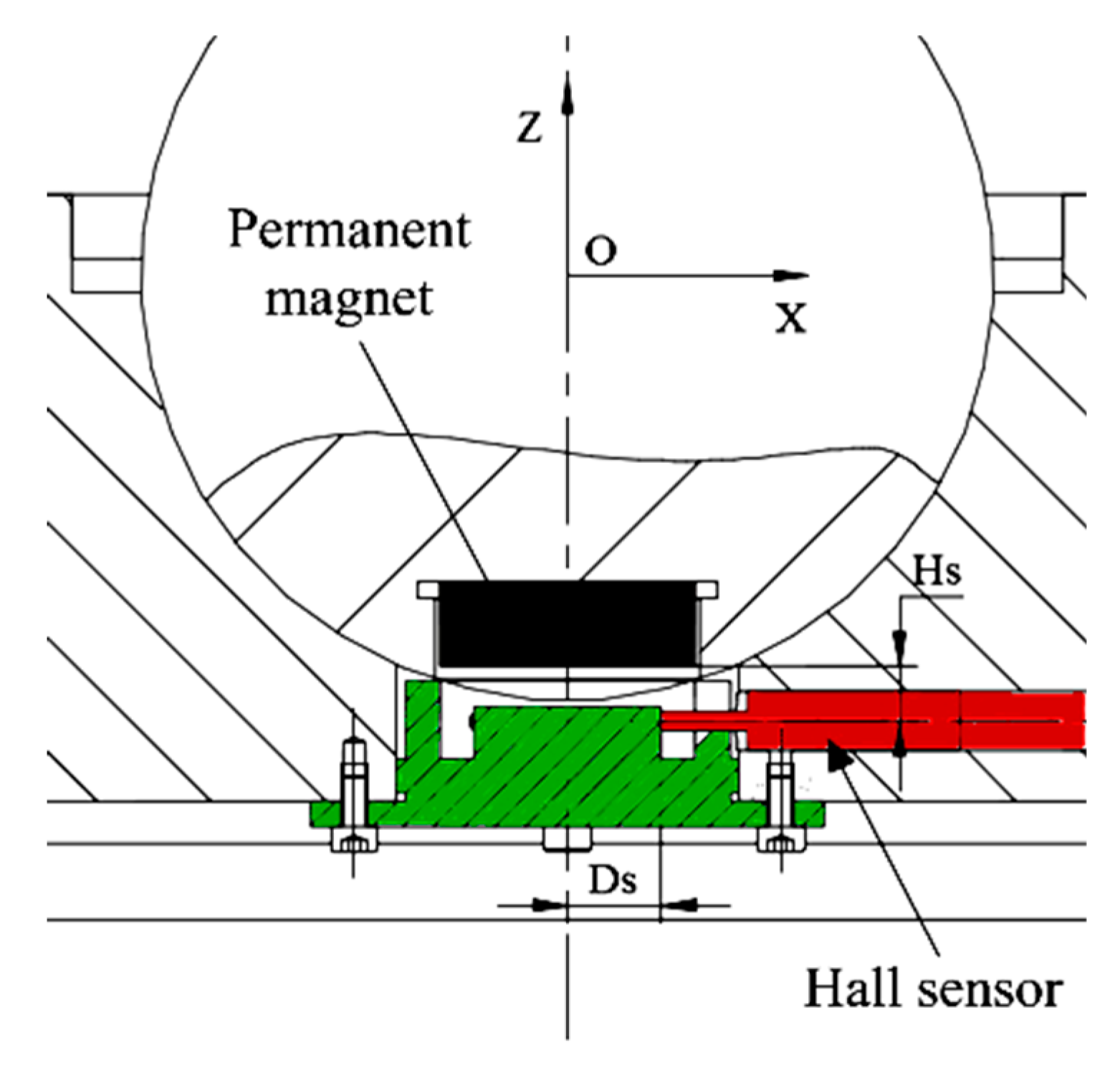

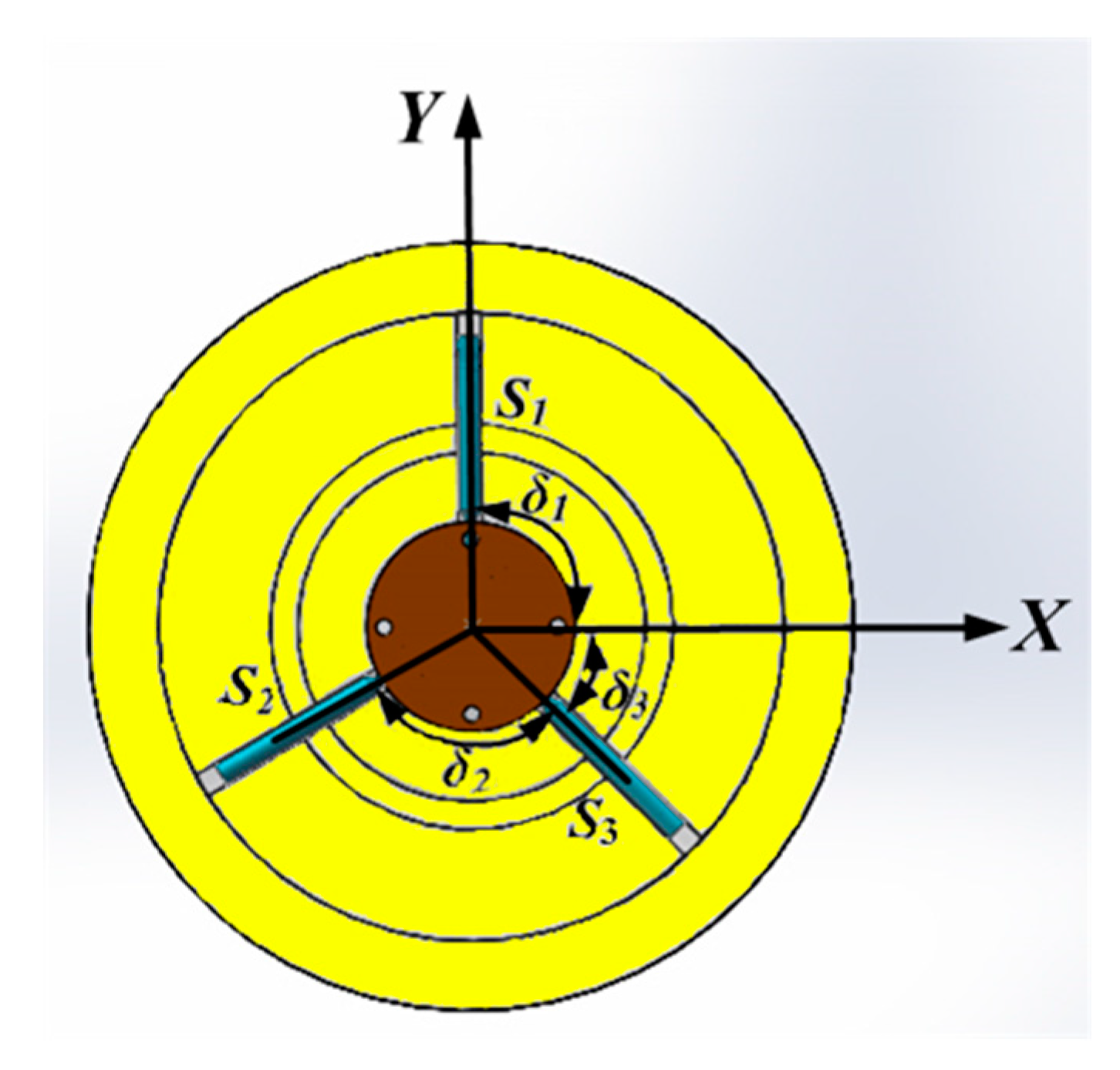

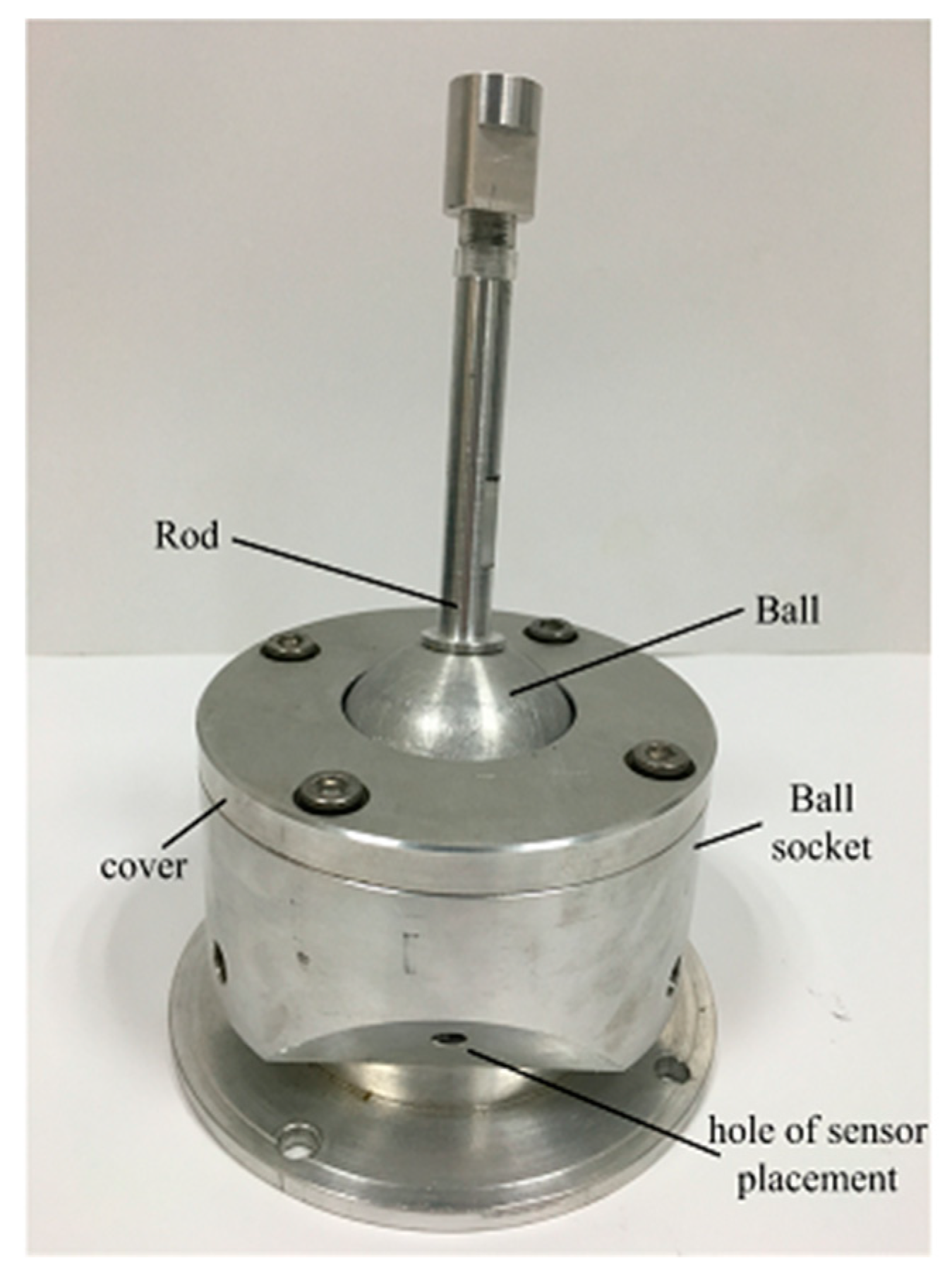

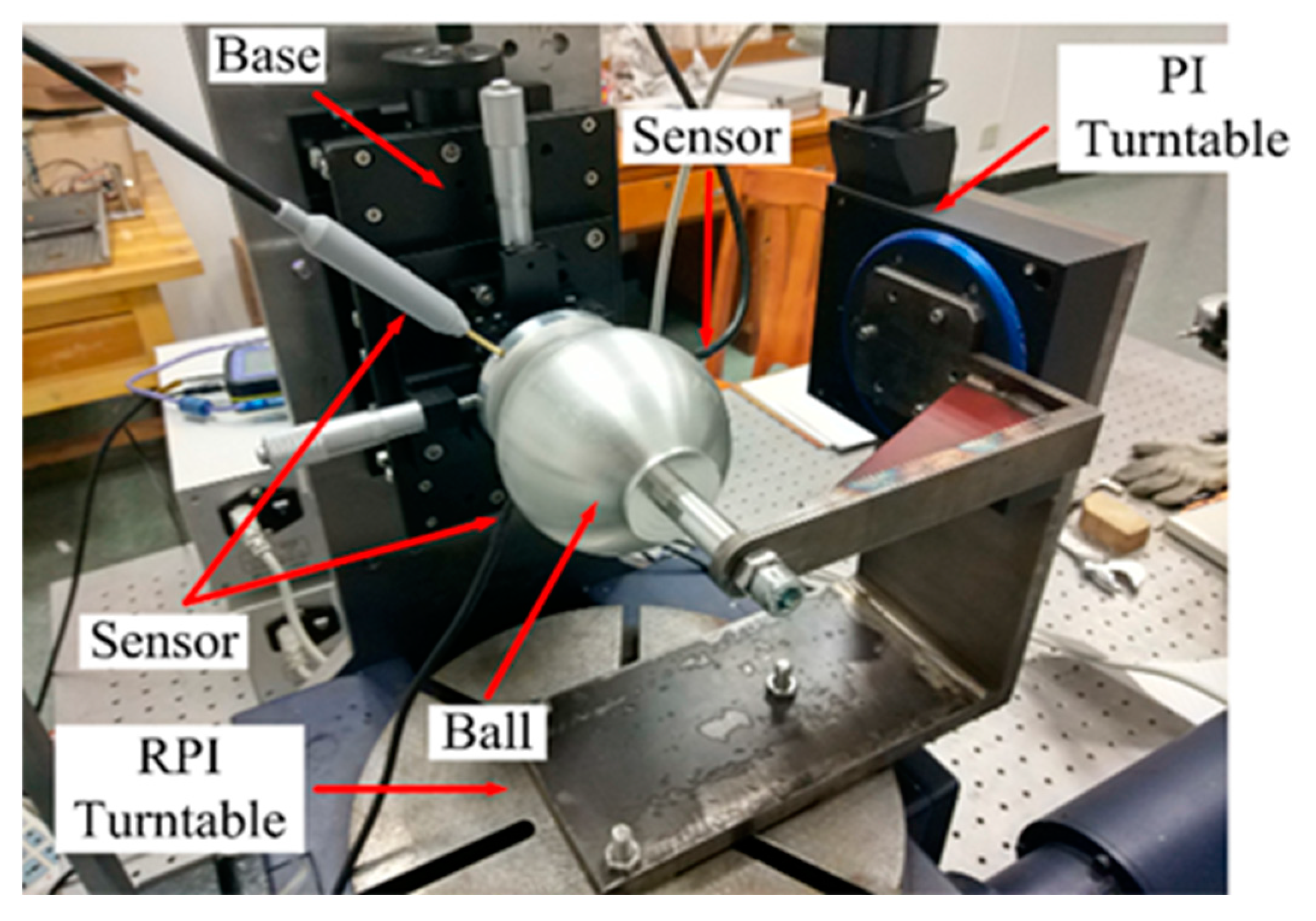

3. Prototype Development

3.1. Design of Mechanical Part of Measuring Prototype

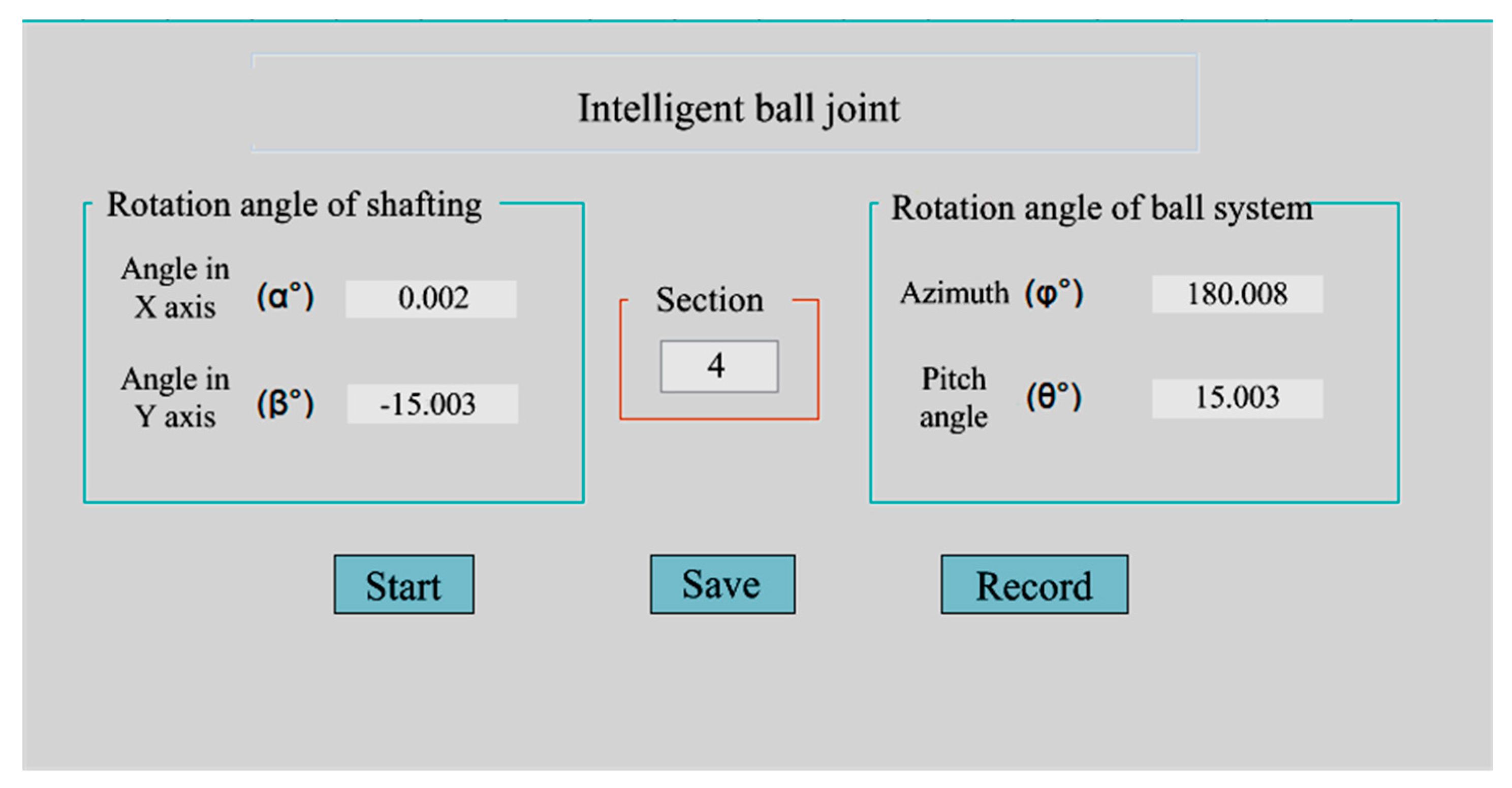

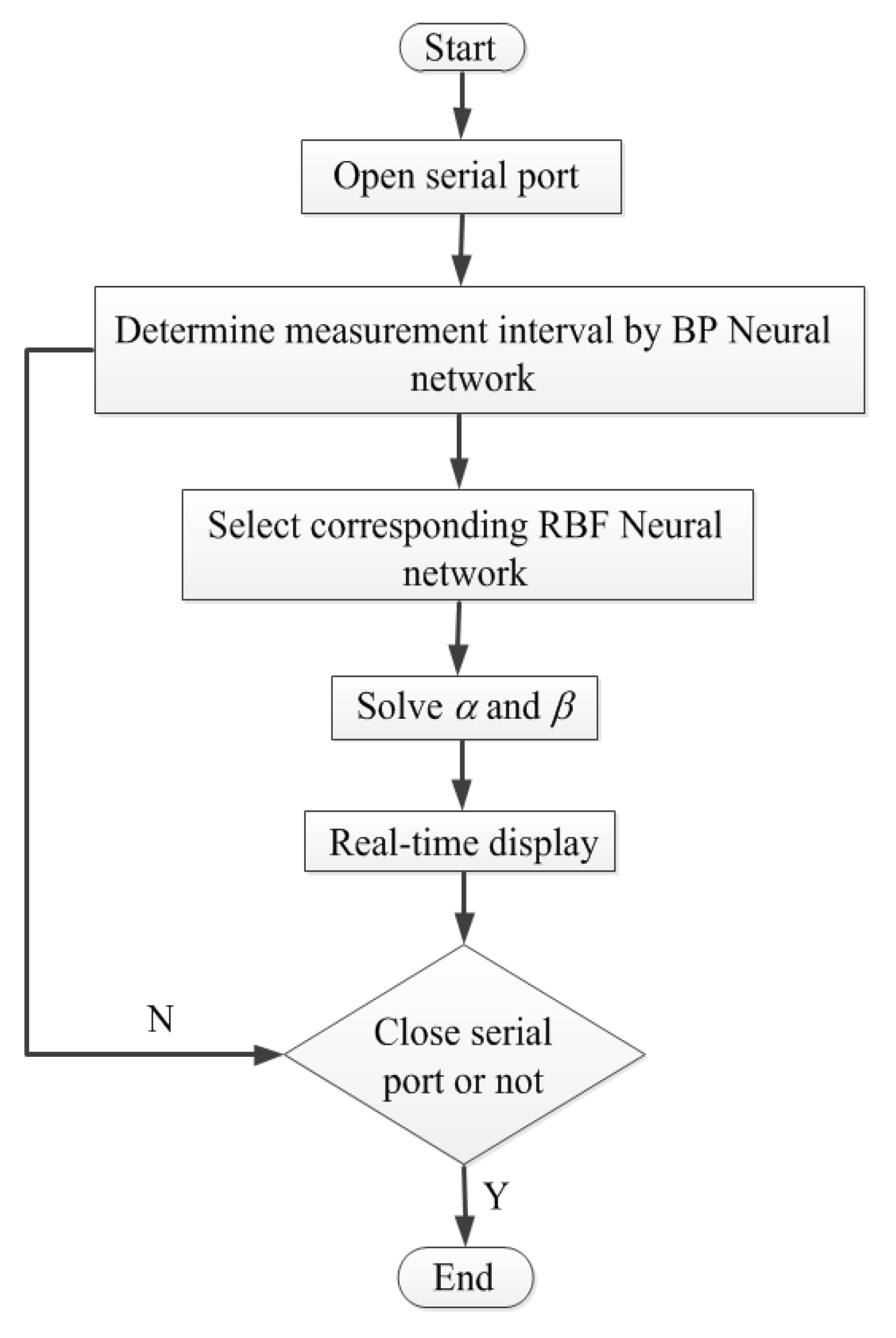

3.2. Design of Measurement Software

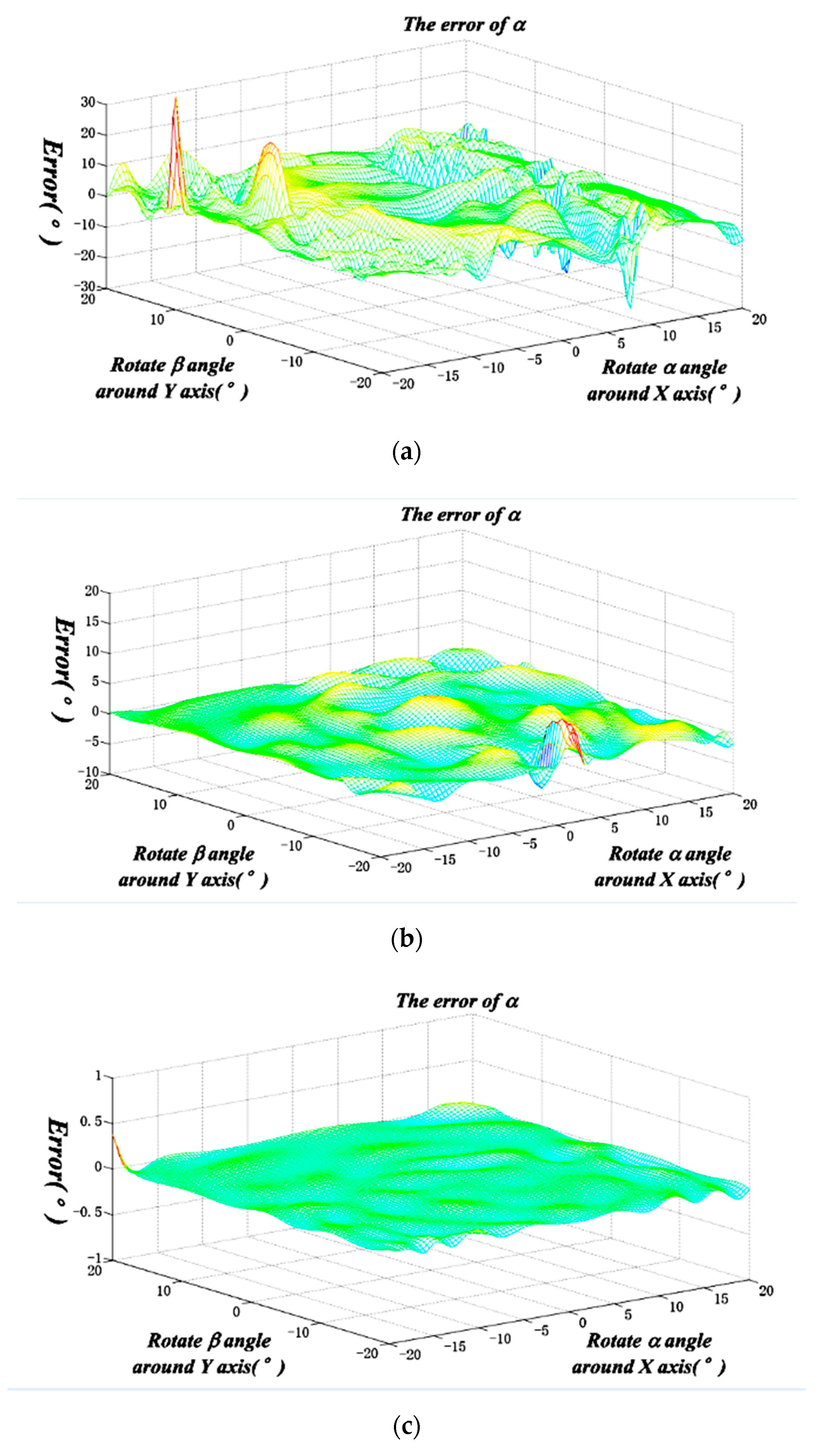

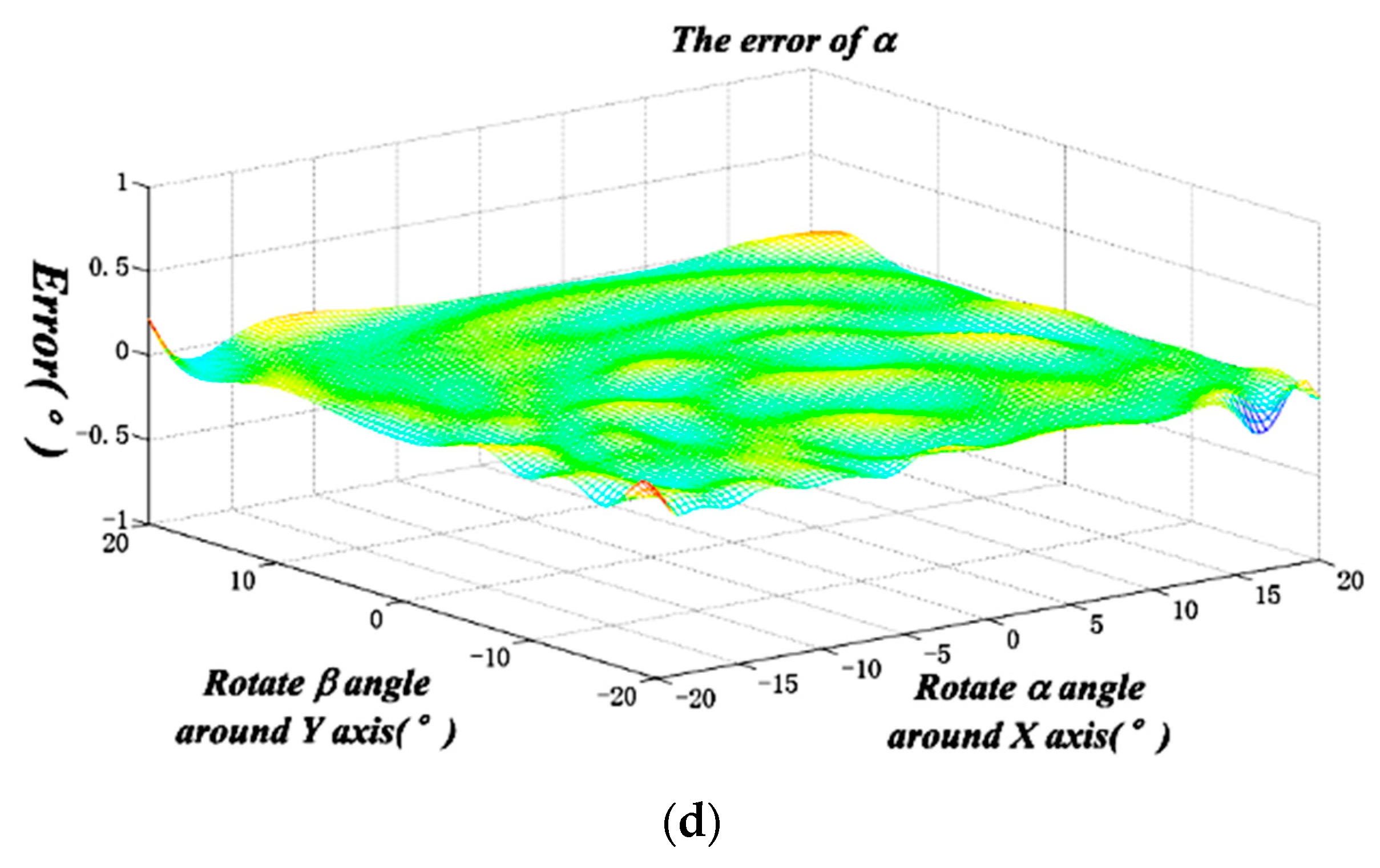

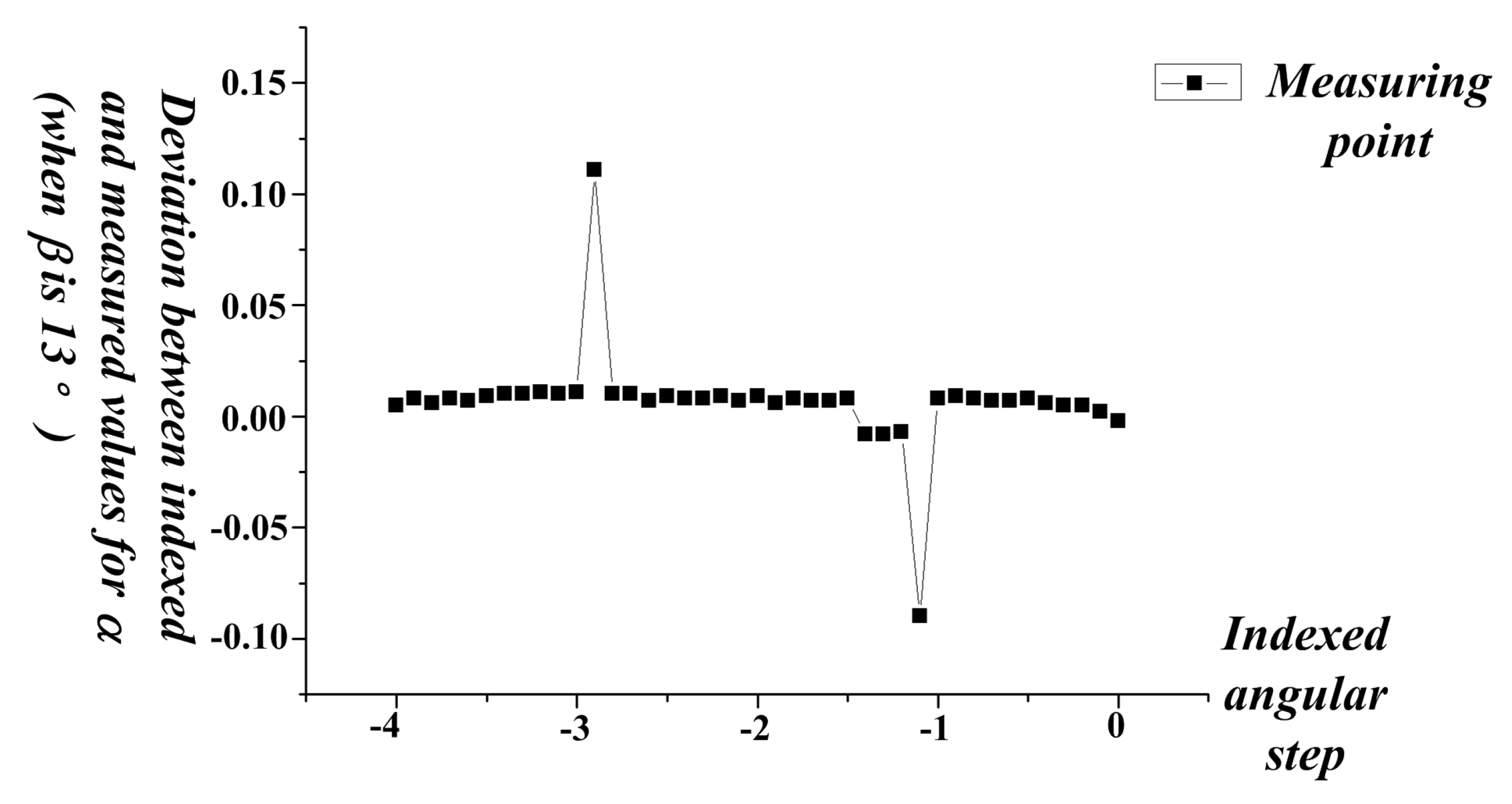

4. Training Modeling and Experimental Testing

5. Conclusions

- The RBF ANN was used to construct the relationship between the input and output of the intelligent ball joint measurement model. According to the technical characteristics and requirements of the ANN, a new prototype of intelligent ball joint was rematched and developed.

- The BP ANN was used to divide the measuring space of the intelligent ball joint into four sections. The whole algorithm comprises the front-end BP ANN partition algorithm and the back-end RBF ANN calculation angle algorithm. It optimizes the number of inputs and hidden layers of the ANN, and it improves the calculation accuracy.

- The experimental data show that, compared with the traditional analytical model, the measurement accuracy of the intelligent ball joint is improved by using ANN. At the same time, the manufacturing accuracy requirement and the assembly of the ball joint are reduced, and the real-time performance of the measurement method is increased.

- Python language was used to compile the upper computer interface of the intelligent ball joint, which meets the training, learning, and modeling requirements in the measurement of a ball joint, and basically achieves the real-time display of the rotation angle. This study reminds us that in precision measurement or sensor development, it is not necessary to establish traditional analytical models, and various intelligent algorithms may be a new choice.

Author Contributions

Funding

Conflicts of Interest

Abbreviations

| PM | Permanent magnet |

| EMCM | Equivalent magnetic charge method |

| ANN | Artificial Neural Network |

| BP | Back Propagation |

| RBF | Radial Basis Function |

References

- Hu, P.; Lu, Y. Measurement method of rotation angle and clearance in intelligent spherical hinge. Meas. Sci. Technol. 2018, 29, 6. [Google Scholar] [CrossRef]

- Hu, P.; Wang, L. A measurement method for ball joint spatial rotation angle. Sens. Mater. 2015, 27. [Google Scholar] [CrossRef]

- Yang, C.Y.; Yen, M.H.; Chou, M.T.; Huang, Z.J.; Chen, S.K. Non-spherical ball-socket joint design for Delta-type robots. Mechatronics 2017, 45, 21–25. [Google Scholar] [CrossRef]

- Xu, C.D.; Jiang, S.Y. Analysis of Static and Dynamic Characteristic of Hydrostatic Spherical Hinge. J. Tribol. 2015, 137, 021701. [Google Scholar] [CrossRef]

- Er, S.; Tez, M. Problems of artificial neural network. J. Surg. Res. 2017, 222, 225. [Google Scholar] [CrossRef] [PubMed]

- Villarrubia, G.; Paz, J.F.D.; Chamoso, P.; De la Prieta, F. Artificial neural networks used in optimization problems. Neurocomputing 2018, 272, 10–16. [Google Scholar] [CrossRef]

- Cıbuk, M.; Budak, U.; Guo, Y.; Cevdet Ince, M.; Sengur, A. Efficient deep features selections and classification for flower species recognition. Measurement 2019, 137, 7–13. [Google Scholar] [CrossRef]

- Dedović, M.M.; Dautbašić, N.; Mujezinović, A. Application of Artificial Neural Network and Empirical Mode Decomposition for Predications of Hourly Values of Active Power Consumption. Lect. Notes Netw. Syst. 2019, 59, 86–97. [Google Scholar] [CrossRef]

- Ilić, S.; Selakov, A.; Vukmirović, S.; Erdeljan, A.; Kulić, F. Short-term load forecasting in large scale electrical utility using artificial neural network. J. Sci. Ind. Res. 2013, 72, 739–745. [Google Scholar]

- Petrovskiy, D.; Barashkov, A.; Sobolevsky, V.; Sokolov, B.; Pjatkov, V. On the real time logistics monitoring system development using artificial neural network. In Proceedings of the 20th International Conference on Harbor, Maritime & Multimodal Logistics Modelling and Simulation (HMS2018), Budapest, Hungary, 17–19 September 2018; pp. 14–20. [Google Scholar]

- Caciotta, M.; Giarnetti, S.; Leccese, F.; Orioni, B.; Oreggia, M.; Pucci, C.; Rametta, S. Flavors mapping by Kohonen network classification of Panel Tests of Extra Virgin Olive Oil. Measurement 2016, 78, 366–372. [Google Scholar] [CrossRef]

- Caciotta, M.; Giarnetti, S.; Leccese, F. Hybrid neural network system for electric load forecasting of telecomunication station. In Proceedings of the 19th IMEKO XIX World Congress, Lisbon, Portugal, 6–11 September 2009; pp. 586–590. [Google Scholar]

- Zhang, L.; Wang, F.; Sun, T.; Xu, B. A constrained optimization method based on BP neural network. Neural Comput. Appl. 2016, 7, 1–9. [Google Scholar] [CrossRef]

- Mirinejad, H.; Inanc, T. An RBF collocation method for solving optimal control problems. Robot. Auton. Syst. 2017, 87, 219–225. [Google Scholar] [CrossRef]

- Li, D.-J.; Li, Y.-Y.; Fu, Y. Gesture recognition based on BP neural network improved by chaotic genetic algorithm. Int. J. Autom. Comput. 2018, 15, 267–276. [Google Scholar] [CrossRef]

- Geng, X.; Lu, S.; Jiang, M.; Sui, Q.; Lv, S.; Xiao, H.; Jia, Y.; Jia, L. Research on FBG-Based CFRP Structural damage edentification using BP neural network. Photonic Sens. 2018, 8, 168–175. [Google Scholar] [CrossRef]

- Yin, L.; He, Y.; Dong, X.; Lu, Z. Adaptive Chaotic Prediction Algorithm of RBF Neural Network Filtering Model Based on Phase Space Reconstruction. J. Comput. 2013, 8, 1449–1455. [Google Scholar] [CrossRef]

- Wen, H.; Xie, W.; Pei, J.; Guan, L. An incremental learning algorithm for the hybrid RBF-BP network classifier. EURASIP J. Adv. Signal Process. 2016, 2016, 57. [Google Scholar] [CrossRef]

| Actual Value β (°) | Deviation Value β (°) | Actual Value β (°) | Deviation Value β (°) |

|---|---|---|---|

| −6.990 | −0.005 | −6.810 | −0.003 |

| −6.980 | −0.005 | −6.800 | −0.004 |

| −6.970 | −0.003 | −6.790 | −0.004 |

| −6.960 | −0.002 | −6.780 | −0.004 |

| −6.950 | −0.003 | −6.770 | −0.005 |

| −6.940 | −0.003 | −6.760 | −0.006 |

| −6.930 | −0.004 | −6.750 | −0.006 |

| −6.920 | −0.006 | −6.740 | −0.003 |

| −6.910 | −0.006 | −6.730 | −0.003 |

| −6.900 | −0.003 | −6.720 | −0.004 |

| −6.890 | −0.003 | −6.710 | −0.004 |

| −6.880 | −0.004 | −6.700 | −0.004 |

| −6.870 | −0.004 | −6.690 | −0.004 |

| −6.860 | −0.004 | −6.680 | −0.004 |

| −6.850 | −0.006 | −6.670 | −0.005 |

| −6.840 | −0.005 | −6.660 | −0.005 |

| −6.830 | −0.006 | −6.650 | −0.006 |

| −6.820 | −0.004 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, P.-H.; Lu, Z.-X.; Zhang, Y.-Q.; Liu, S.-L.; Dang, X.-M. A New Modeling Method of Angle Measurement for Intelligent Ball Joint Based on BP-RBF Algorithm. Appl. Sci. 2019, 9, 2850. https://doi.org/10.3390/app9142850

Hu P-H, Lu Z-X, Zhang Y-Q, Liu S-L, Dang X-M. A New Modeling Method of Angle Measurement for Intelligent Ball Joint Based on BP-RBF Algorithm. Applied Sciences. 2019; 9(14):2850. https://doi.org/10.3390/app9142850

Chicago/Turabian StyleHu, Peng-Hao, Ze-Xun Lu, Yuan-Qi Zhang, Shan-Lin Liu, and Xue-Ming Dang. 2019. "A New Modeling Method of Angle Measurement for Intelligent Ball Joint Based on BP-RBF Algorithm" Applied Sciences 9, no. 14: 2850. https://doi.org/10.3390/app9142850

APA StyleHu, P.-H., Lu, Z.-X., Zhang, Y.-Q., Liu, S.-L., & Dang, X.-M. (2019). A New Modeling Method of Angle Measurement for Intelligent Ball Joint Based on BP-RBF Algorithm. Applied Sciences, 9(14), 2850. https://doi.org/10.3390/app9142850