The Algorithms of Image Processing and Analysis in the Textile Fabrics Abrasion Assessment

Abstract

1. Introduction

2. Related Works

3. Materials and Methods

3.1. Test Materials

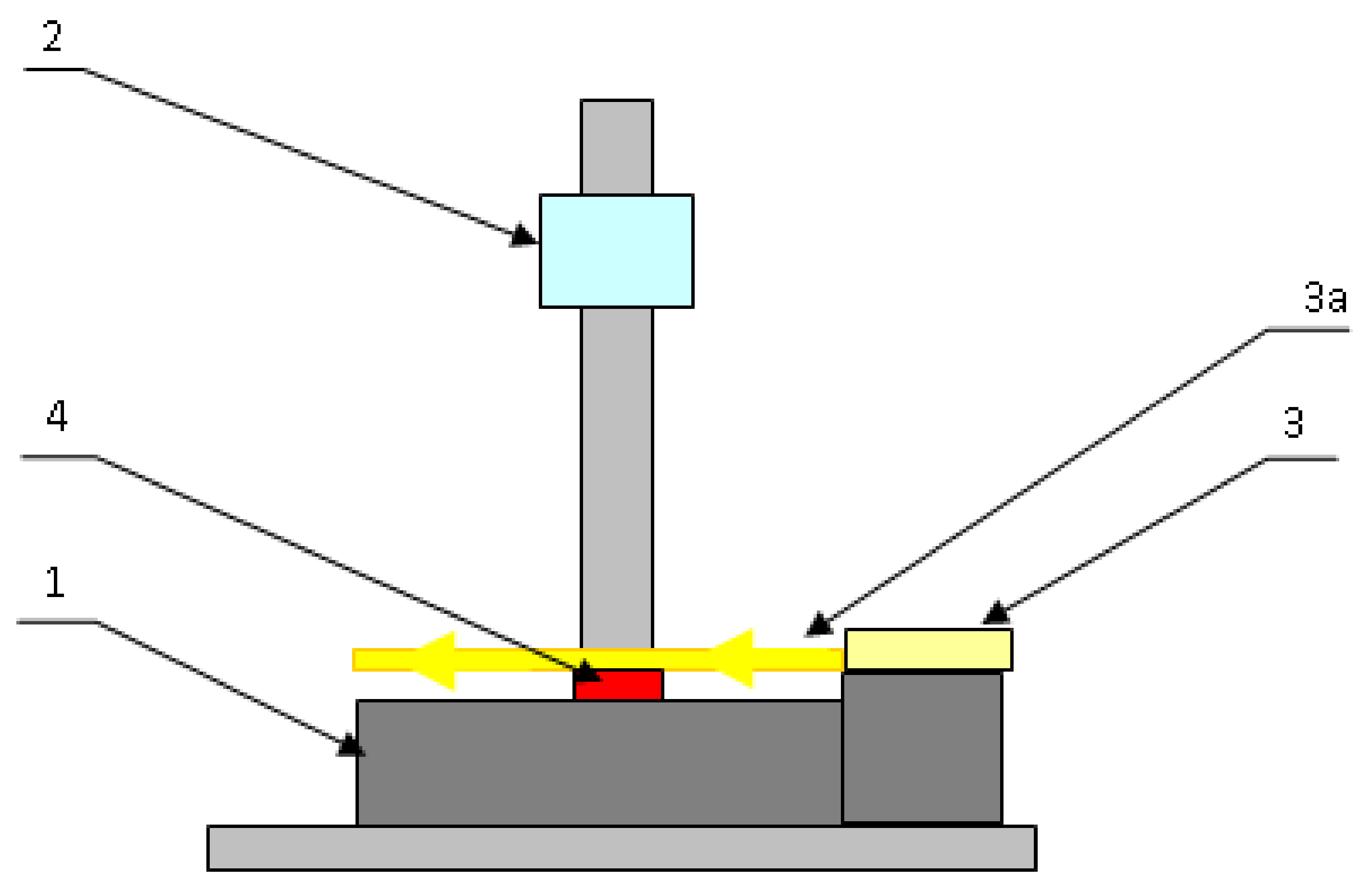

3.2. Experiment

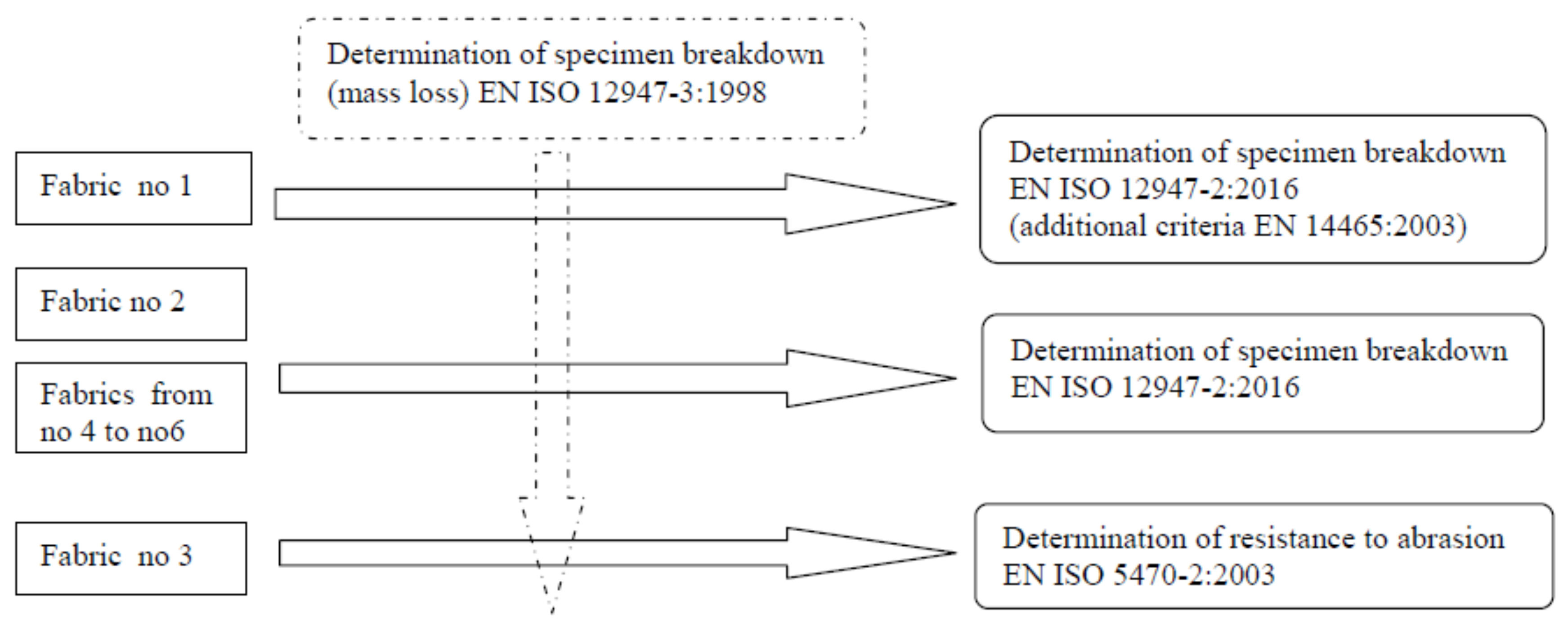

- determination of abrasion resistance according to: EN ISO 12947-2:2016 (Fabrics 2,4,5,6), EN 14465:2003 Appendix A (fabric 1) and EN ISO 5470-2:2003 for Fabric 3,

- determination of the loss of mass during the abrasion process according to EN ISO 12947-3:1998 for all fabrics;

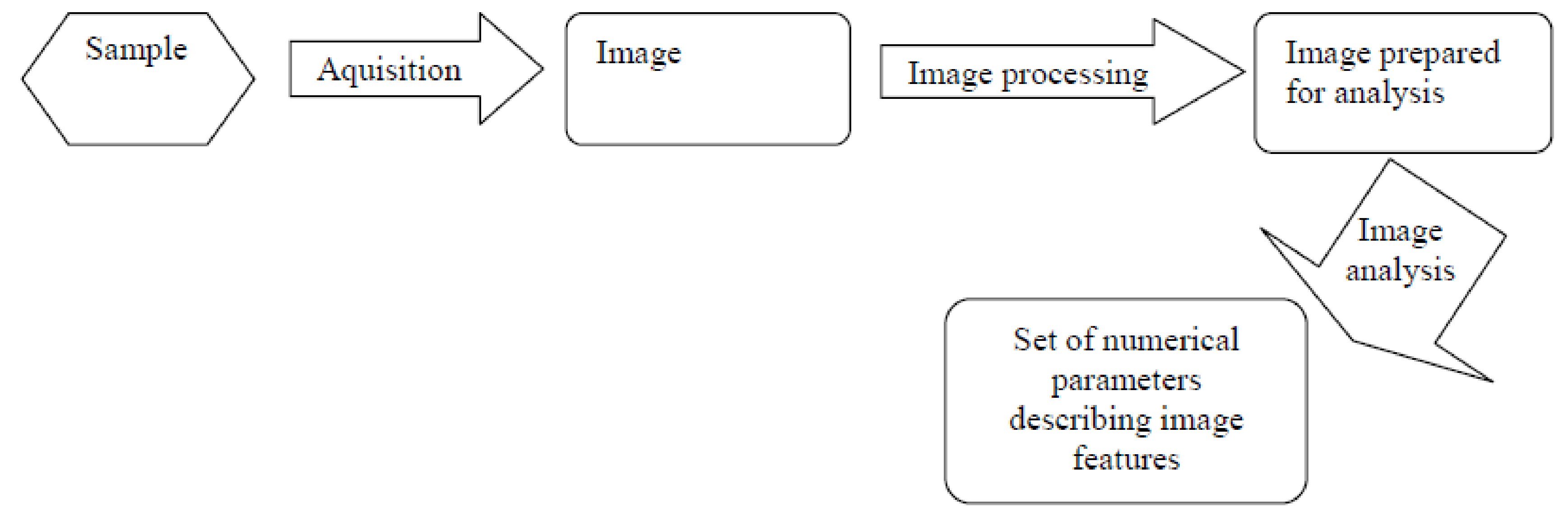

- acquisition of image samples during the whole abrasion process, after each interval according to an adequate standard;

- processing of images to prepare them for the next step of evaluation using the instrumental method;

- preliminary test, involving the previous mentioned algorithms: FHT transform, high- and low- pass filtering, Gabor filtering and calculations of histogram-based parameters;

- choice of algorithm, which is the most sensitive as possible to surface changes occurring during each stage of the abrasion process for all tested fabrics;

- analysis of numerical values collected from the image analysis of the instrumental method and their assessment in the scope of sensitivity to abrasion-type surface changes;

- comparative analysis of results obtained by both instrumental (the best algorithm) and standard methods.

4. Results

- Fabric 1 showed gradual damage of pile and progressive colour fade (grade 4 after initial 3000 rubs–assessment according to standard requirements for upholstery fabrics), which caused the loss of aesthetic properties without reaching the breakage criteria described in the standard,

- Fabric 2 showed intense damage of singular filaments in threads after just 6000 rubs, which caused the occurrence of a dense pile-like structure on the fabric surface made of damaged filaments. This structure significantly decreased the aesthetic properties of the fabric and additionally, its colour changed. According to the standard, the breakage criteria were not reached up to more than 50,000 rubs.

- ++ algorithm was sensitive to surface changes occurring on the sample during the abrasion process;

- + algorithm was potentially sensitive to surface changes existing on the sample surface during the abrasion process, but not for each fabric (which generally decreases its effectiveness)

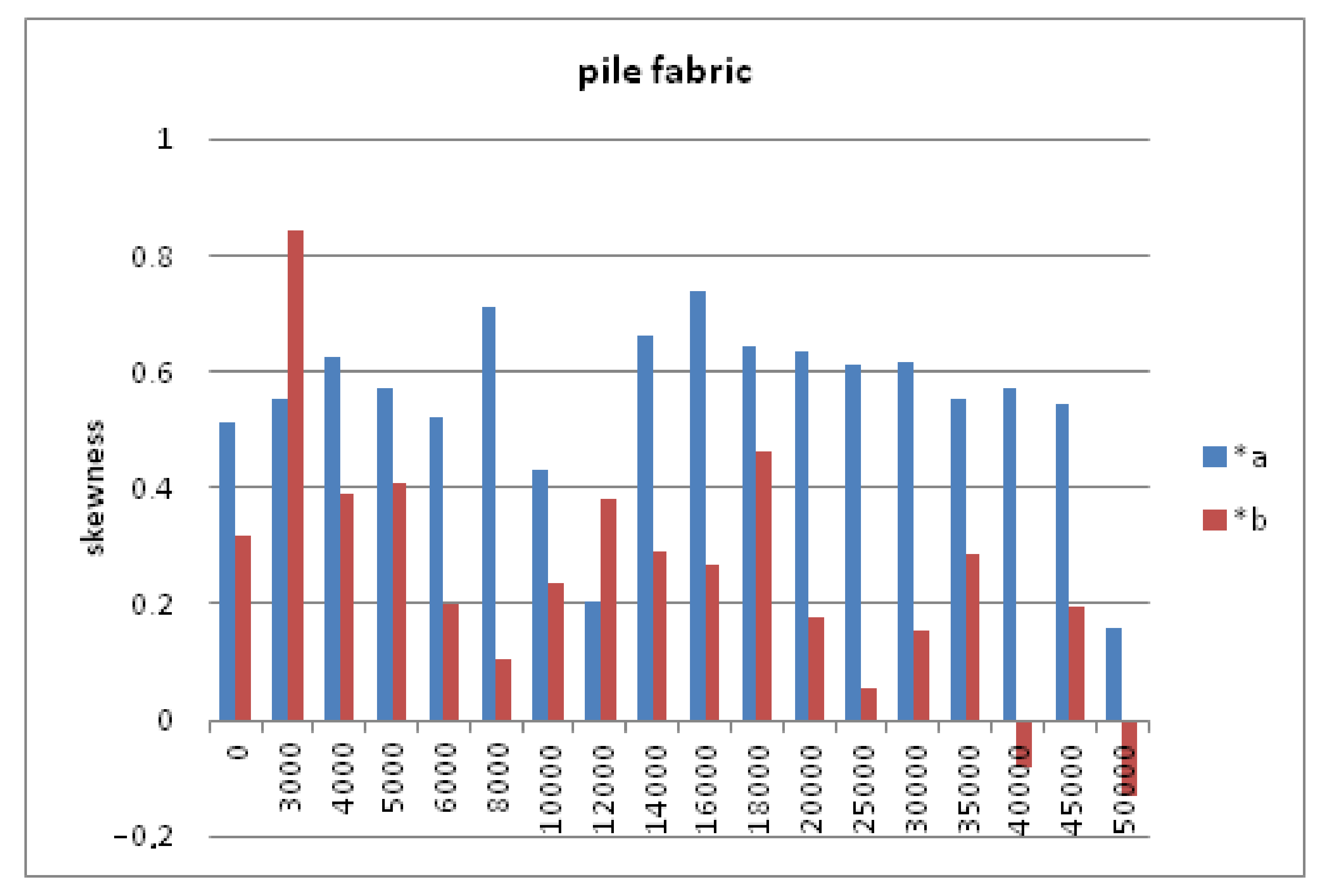

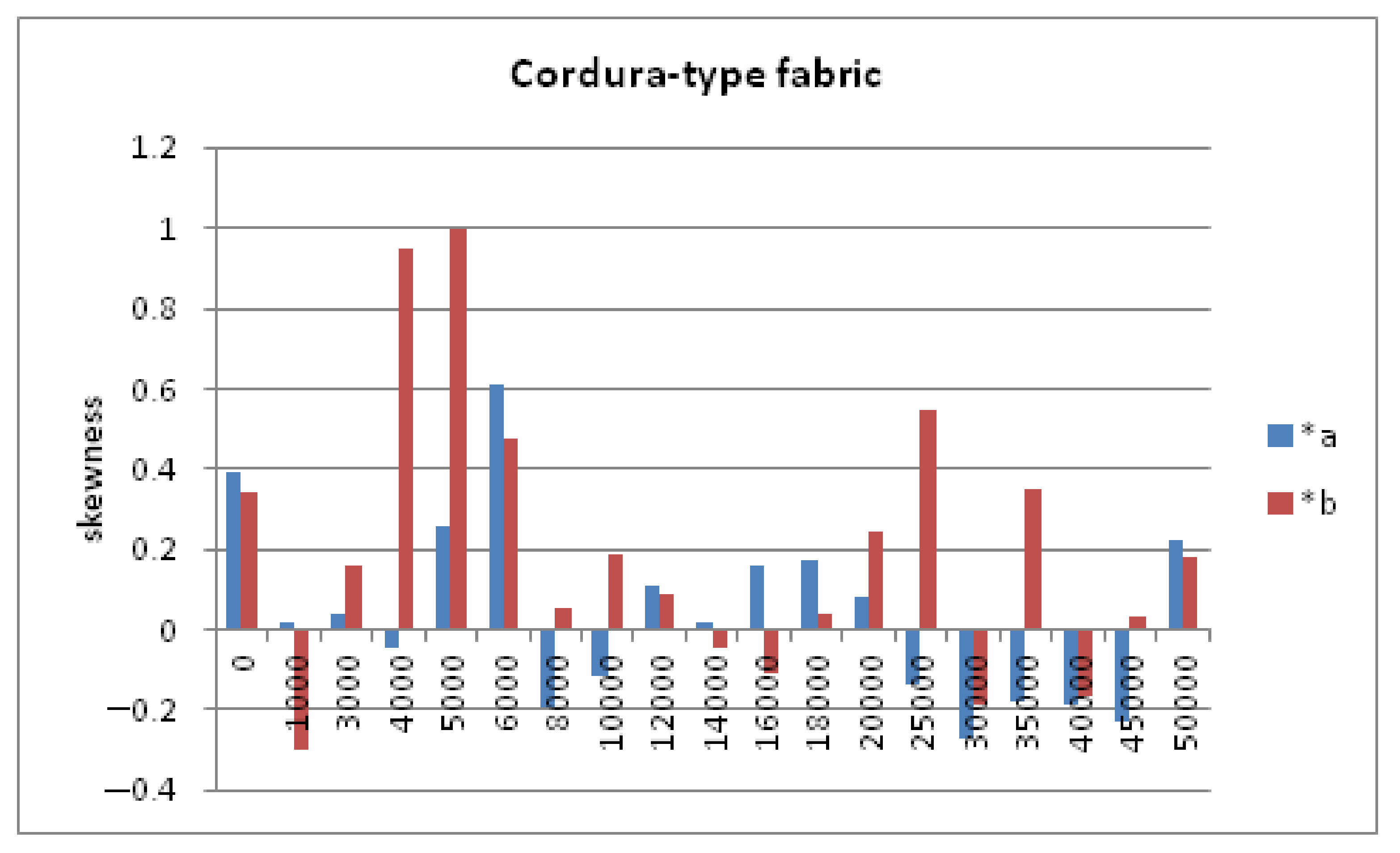

- Skewness values for image channel *a of Fabric 1 were positive, which means a left skewed brightness level curve and a higher contribution of green component in the sample’s colour. However, the skewness for *b channel fluctuated, which should be connected with surface changes. The *b skewness values altered after each rub, which corresponded to the brush of pile fibres and their colour changes caused by the abrasion process. The skewness underwent a cyclic alteration during the abrasion process; very low values were observed, for example, for channel *b, after 8000 and 25,000 rubs. It was found that some part of the pile fibres was gone (loss of fibre mass) and the pile surface faded. Consequently, at the end of the test, skewness is negative and the sample’s surface was becoming redder. It is connected to the significant colour change of Fabric 1 (fade caused by the abrasion process) and the clearly visible loss of pile fibres.

- Skewness cycle changes reflected Fabric 1 surface structure. The pile was extremely fragile to any abrasion-like movement, causing alteration in the position angle of singe pile fibres (pile brush) and a loss of colour.

5. Discussion

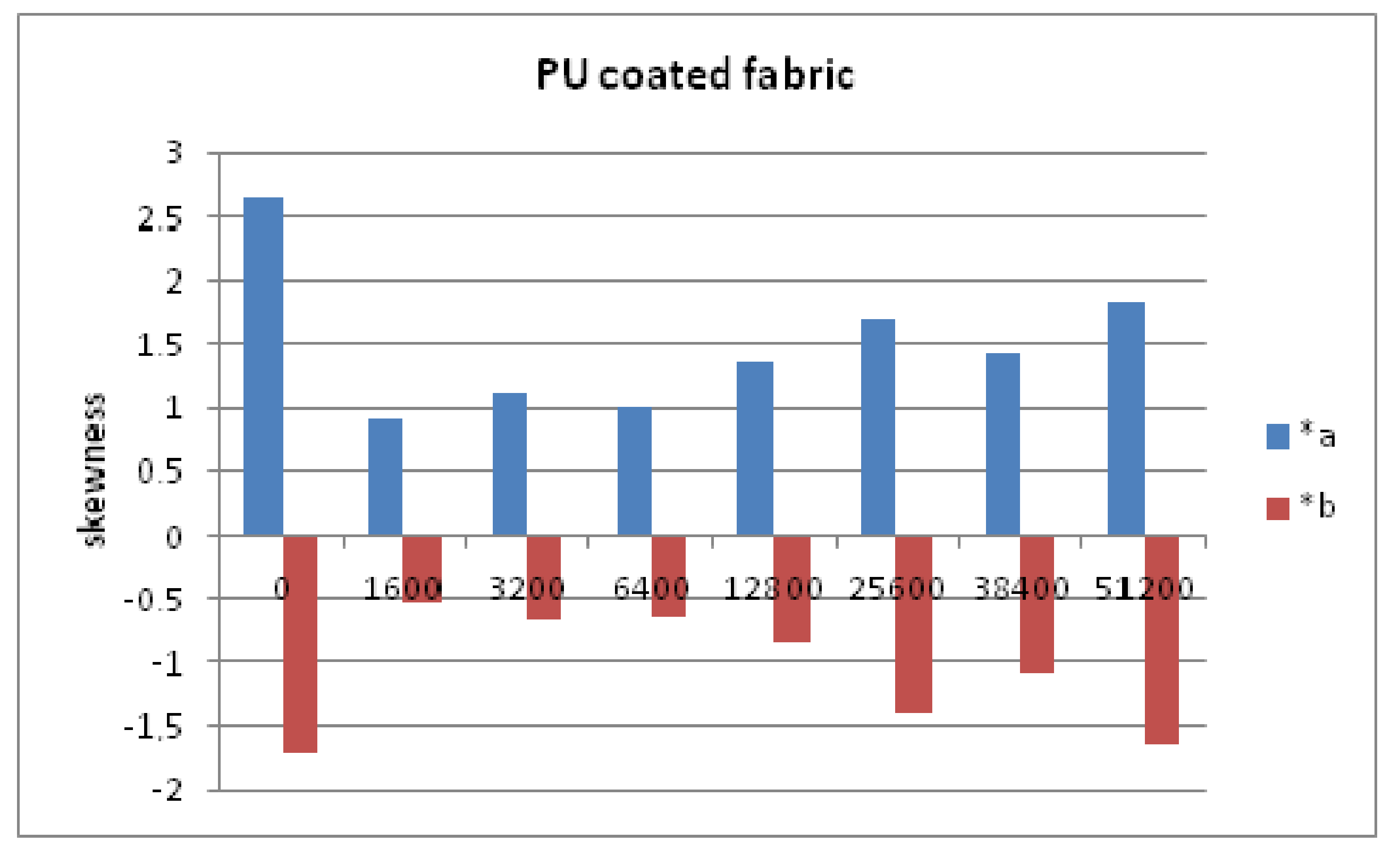

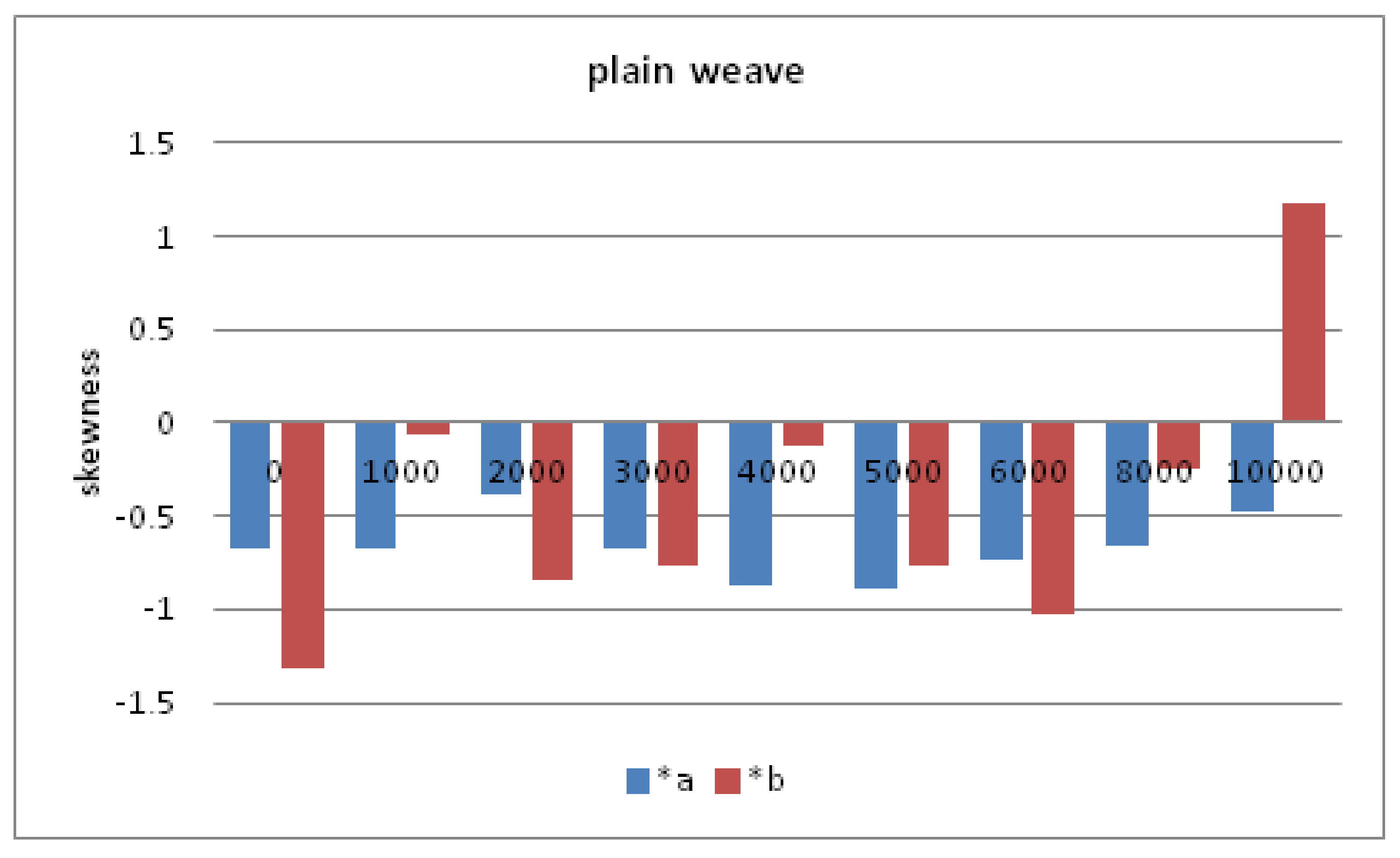

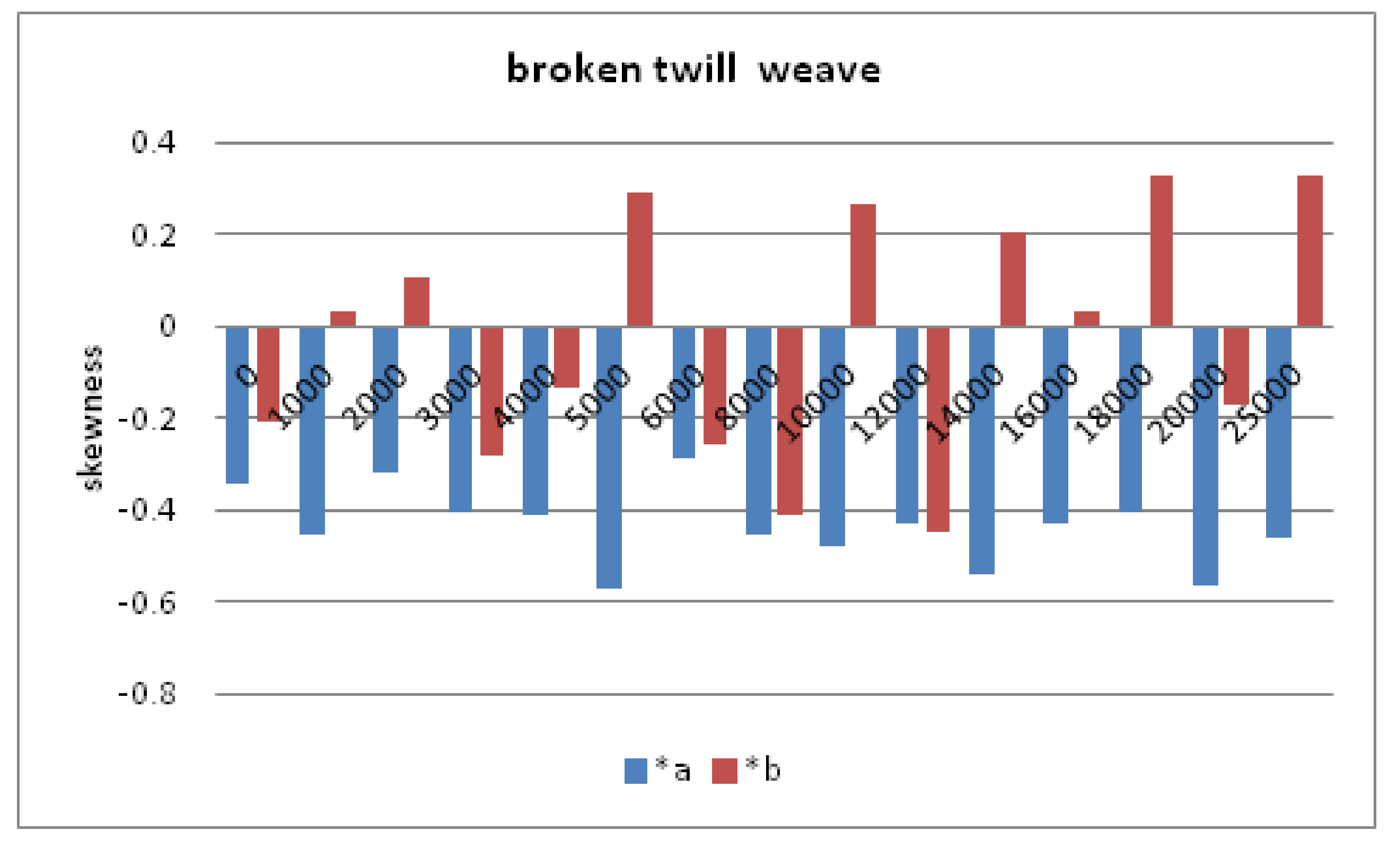

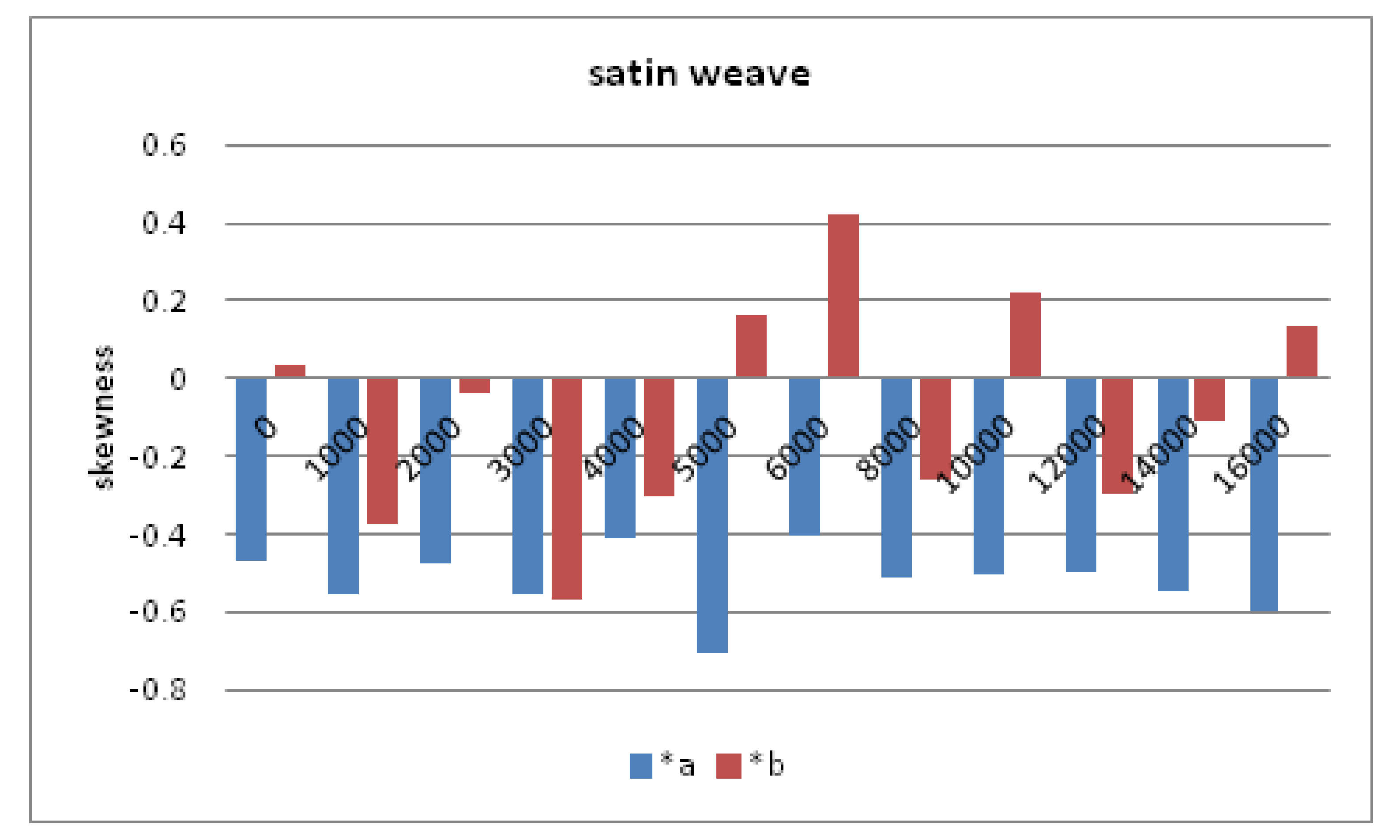

- Among all algorithms investigated within this work, the best outcomes gave calculations based on the brightness level histogram. The skewness, measured for CIELAB channels *a and *b showed sensitivity to surface alterations, such as protruding fibres, pills, relocated and thinning threads, missing places in the fabric as a result of broken thread and colour changes;

- In most cases, when skewness changed significantly, especially its sign, the surface texture was altered, e.g., pilling occurred, threads were relocated and became thinner or damaged;

- Effects of image global transformation—FHT transform, wavelet transform—did not allow for evaluating surface modifications caused by the abrasion process;

- Implementation of Gabor filtering, despite its similarity to human eye perception, did not give a sharper image of the abraded samples, with better visible signs of abrasion-caused damaged. However, beyond the visual effect, further attempts to express surface changes numerically did not give positive results. Gabor filtering was effective in pile fabric surface evaluation only, because of typical surface changes for this structure (smoothing, abrading of pile, colour fading).

6. Conclusions

Funding

Conflicts of Interest

References

- Camlibel, O.; Avinc, A.O.; Yavas, A. Antibacterial, UV protection, flame retardancy and coloration properties of cotton fabrics coated with polyacrylate polymer containing various iron ores. J. Text. Inst. 2018, 109, 1424–1433. [Google Scholar] [CrossRef]

- Mojsov, K. Enzymatic scouring and bleaching of cotton terry fabrics–opportunity of the improvement on some physicochemical and mechanical properties of the fabrics. J. Nat. Fibers 2018, 15, 740–751. [Google Scholar] [CrossRef]

- Yu, J.; Seipel, S.; Nierstrasz, V.A. Digital inkjet functionalization of water-repellent textile for smart textile application. J. Text. Inst. 2018, 53, 13216–13229. [Google Scholar] [CrossRef]

- Gao, H.; Minh, P.T.; Wang, H.; Nguyen, T.; Sharma, S. High-performance flexible yarn for wearable piezoelectric nanogenerators. Smart Mater. Struct. 2018, 27, 095018. [Google Scholar] [CrossRef]

- Wang, H.; Tang, H.; Gao, Q.; Liu, T.; Xie, H. An investigation of electronic fabrics for monitoring clothing based on ECG signal acquisition. J. Silk 2018, 55, 57–61. [Google Scholar]

- Wei, Z.; Tao, X.-M.; Chen, S.; Shang, S.; Chan, H.L.W.; Choy, S.H. Highly durable all-fiber nanogenerator for mechanical energy harvesting. Energy Environ. Sci. 2013, 6, 2631–2638. [Google Scholar]

- Li, X.; Lin, Z.-H.; Cheng, G.; Wen, X.; Liu, Y.; Niu, S.; Wang, L.Z. 3D Fiber-Based Hybrid Nanogenerator for Energy Harvesting and as a Self-Powered Pressure Sensor. ACS Nano 2014, 86, 10674–10681. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Wang, Z.L. Reviving Vibration Energy Harvesting and Self-Powered Sensing by a Triboelectric Nanogenerator. Joule 2017, 1, 480–521. [Google Scholar] [CrossRef]

- Zhang, N.; Chen, J.; Huang, Y.; Guo, W.; Yang, J.; Du, J.; Fan, X.; Tao, C. A Wearable All- Solid Photovoltaic Textile. Adv. Mater. 2016, 28, 263–269. [Google Scholar] [CrossRef] [PubMed]

- Jeyaraj, P.R.; Samuel Nadar, E.R. Computer vision for automatic detection and classification of fabric defect employing deep learning algorithm. Int. J. Cloth. Sci. Technol. 2019, 31, 510–521. [Google Scholar] [CrossRef]

- Jing, J.-F.; Ma, H.; Zhang, H.-H. Automatic fabric defect detection using a deep convolutional neural network. Color. Technol. 2019, 135, 213–223. [Google Scholar] [CrossRef]

- EN ISO 12947-3 Textiles. Determination of the Abrasion Resistance of Fabrics by the Martindale Method–Part 3: Determination of Mass Loss; International Organization for Standardization: Geneva, Switzerland, 1998. [Google Scholar]

- EN ISO 12947-2 Textiles. Determination of the Abrasion Resistance of Fabrics by the Martindale Method. Part 2: Determination of Specimen Breakdown; International Organization for Standardization: Geneva, Switzerland, 2016. [Google Scholar]

- EN ISO 12947-4 Textiles. Determination of the Abrasion Resistance of Fabrics by the Martindale Method. Part 4: Assessment of Appearance Change; International Organization for Standardization: Geneva, Switzerland, 1998. [Google Scholar]

- Manich, A.; Castellar, M.; Sauri, R. Abrasion Kinetics of Wool and Blended Fabrics. Text. Res. J. 2001, 71, 469–474. [Google Scholar] [CrossRef]

- Ceven, E.; Ozdemir, O. Evaluation of Chenille Yarn Abrasion Behavior with Abrasion Tests and Image Analysis. Text. Res. J. 2006, 76, 315–321. [Google Scholar] [CrossRef]

- Leucker, K.; Amtmann, J.; Schubert, D.W. Novel objective test method for the abrasion and pilling behaviour of low basis weight spunbond polypropylene nonwoven. Polym. Test. 2018, 69, 175–181. [Google Scholar] [CrossRef]

- Naderpour, F.; Mirjalili, S.; Sharzehee, M. The Investigation on the influence of DMDHEU on the wrinkle and abrasion resistance of cotton fabrics using image processing. Text. Res. J. 2009, 79, 1571–1577. [Google Scholar] [CrossRef]

- Akgun, M. Assessment of the surface roughness of cotton fabrics through different yarn and fabric structural properties. Fibers Polym. 2014, 15, 405–413. [Google Scholar] [CrossRef]

- Akgun, M. Effect of yarn filament fineness on the surface roughness of polyester woven fabrics. J. Eng. Fibers Fabr. 2015, 10, 121–128. [Google Scholar] [CrossRef]

- Texture Analysis for Magnetic Resonance Imaging; Hajek, M., Dezortowa, M., Materka, A., Eds.; Med4publishing s.r.o: Prague, Chech Republic, 2006; ISBN ISBN 80-903660-0-7. [Google Scholar]

- EN ISO 5470-2 Rubber or plastics coated fabrics. Determination of Abrasion Resistance. Part 2: Martindale Abrader; International Standard International Organization for Standardization: Geneva, Switzerland, 2003. [Google Scholar]

| Fabric | Composition | Construction and Utility Purpose | Finishing | M, g/m |

|---|---|---|---|---|

1  | 100 PES | upholstery pile fabric | raising fabric | 325 |

2  | 100 PES | technical textile, Cordura-type fabric | standard | 412 |

3  | 100 PU | technical textile, plain weave | coated fabric | 651 |

4  | 100 CO | fabric dedicated for garment, plain weave | bleached | 172 |

5  | 100 CO | fabric dedicated for garment, broken twill weave | bleached | 200 |

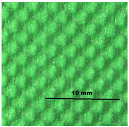

6  | 100 CO | fabric dedicated for garment, satin weave | bleached | 188 |

| Fabric No | Abrasion Resistance, Rubs | The Mean Loss of Mass, g |

|---|---|---|

| 1 | 45,000 | 0.013 |

| 2 | >50,000 | 0.030 |

| 3 | 51,200 grade 1 (slight vividness changes) | 0.009 |

| 4 | 10,000 | 0.013 |

| 5 | sample 1-20,000; sample 2 and 3-25,000 | 0.029 |

| 6 | 14,000 | 0.015 |

| Fabric No | Gabor Transform | Histogram Parameters |

|---|---|---|

| 1 | ++ | + |

| 2 | + | ++ |

| 3 | + | ++ |

| 4 | + | ++ |

| 5 | + | ++ |

| 6 | + | ++ |

© 2019 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jasińska, I. The Algorithms of Image Processing and Analysis in the Textile Fabrics Abrasion Assessment. Appl. Sci. 2019, 9, 3791. https://doi.org/10.3390/app9183791

Jasińska I. The Algorithms of Image Processing and Analysis in the Textile Fabrics Abrasion Assessment. Applied Sciences. 2019; 9(18):3791. https://doi.org/10.3390/app9183791

Chicago/Turabian StyleJasińska, Izabela. 2019. "The Algorithms of Image Processing and Analysis in the Textile Fabrics Abrasion Assessment" Applied Sciences 9, no. 18: 3791. https://doi.org/10.3390/app9183791

APA StyleJasińska, I. (2019). The Algorithms of Image Processing and Analysis in the Textile Fabrics Abrasion Assessment. Applied Sciences, 9(18), 3791. https://doi.org/10.3390/app9183791