Quality Monitoring and Analysis of Xinjiang ‘Korla’ Fragrant Pear in Cold Chain Logistics and Home Storage with Multi-Sensor Technology †

Abstract

:1. Introduction

2. Materials and Methods

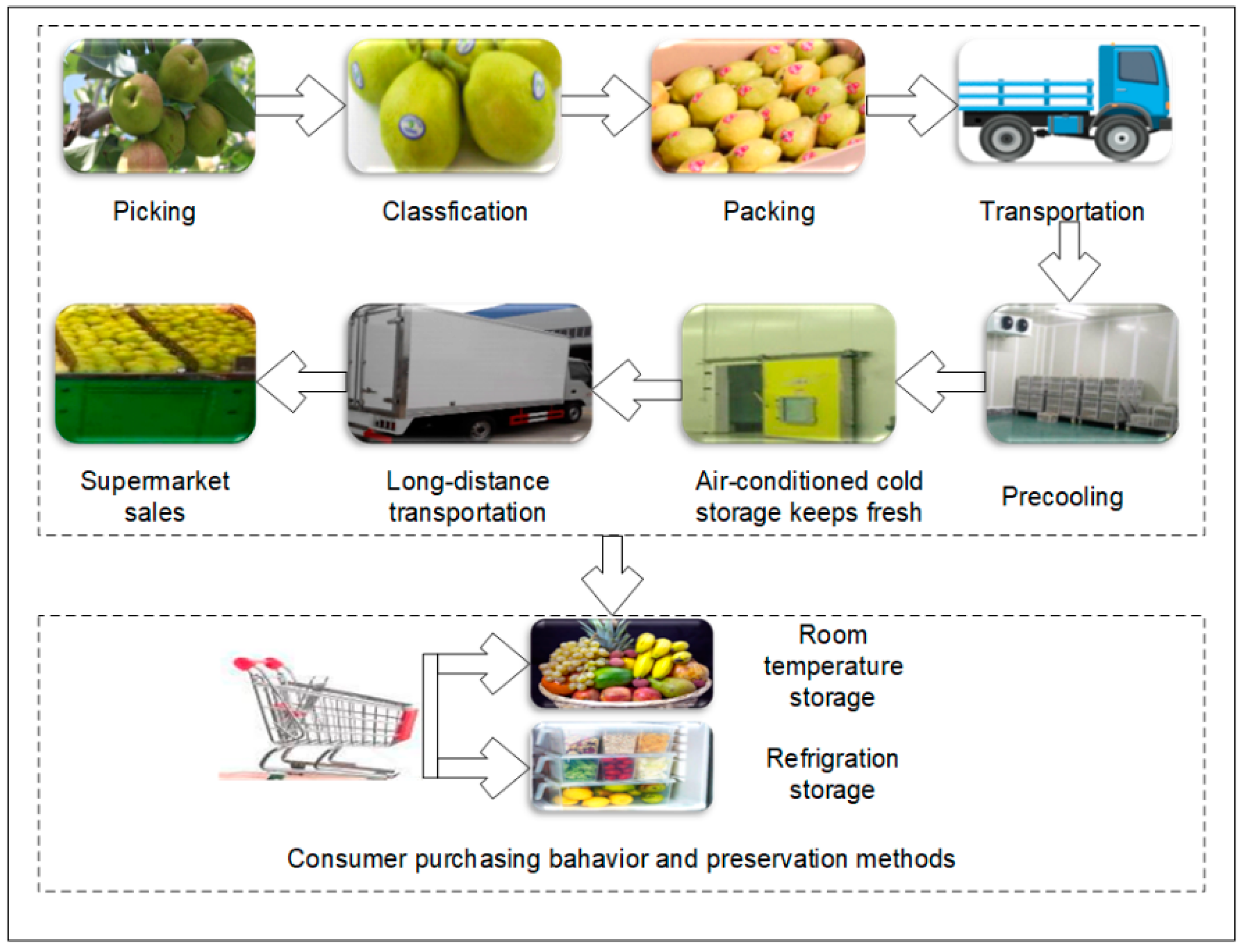

2.1. Cold Chain Example

- Step 1: Harvest of ‘Korla’ fragrant pears. The test harvest began on 28 August, and the official harvest of fragrant pears began on 2 September, during which the average ambient temperature was 25 °C in Korla. Farmers pick ripe fragrant pears of which total soluble solids are above 11.0%, then grade them by weight and surface damage, and finally pack them.

- Step 2: Packed fragrant pears are transported through ordinary transport to the cold store for precooling in less than 24 hours. Fragrant pears are deposited in the normal atmosphere without refrigeration because of short-distance transport.

- Step 3: Fragrant pears are precooled in the cold store. To reduce the field heat brought by the harvested pears, enhance the storage quality, and reduce quality deterioration during storage, fragrant pears are usually precooled at 4 °C for about 48 hours.

- Step 4: Fragrant pears are stored in the cold store with suitable temperature (0 °C) and relative humidity (90%) until being transported to the market. This stage lasts about three days.

- Step 5: Transport of fragrant pears. In this process, fragrant pears are transported using refrigerated trucks at 4 °C from Korla to Beijing. This stage lasts about five days.

- Step 6: Sale in the market. After being transported to the market, fragrant pears will go through temporary storage for display and sale, they are neatly placed in the freezer at 10 °C for customers to choose.

- Step 7: Store fragrant pears at customers’ home. If fragrant pears cannot be eaten up in a short time, consumers usually put them in the refrigerator at 5 °C or preserve them at room temperature.

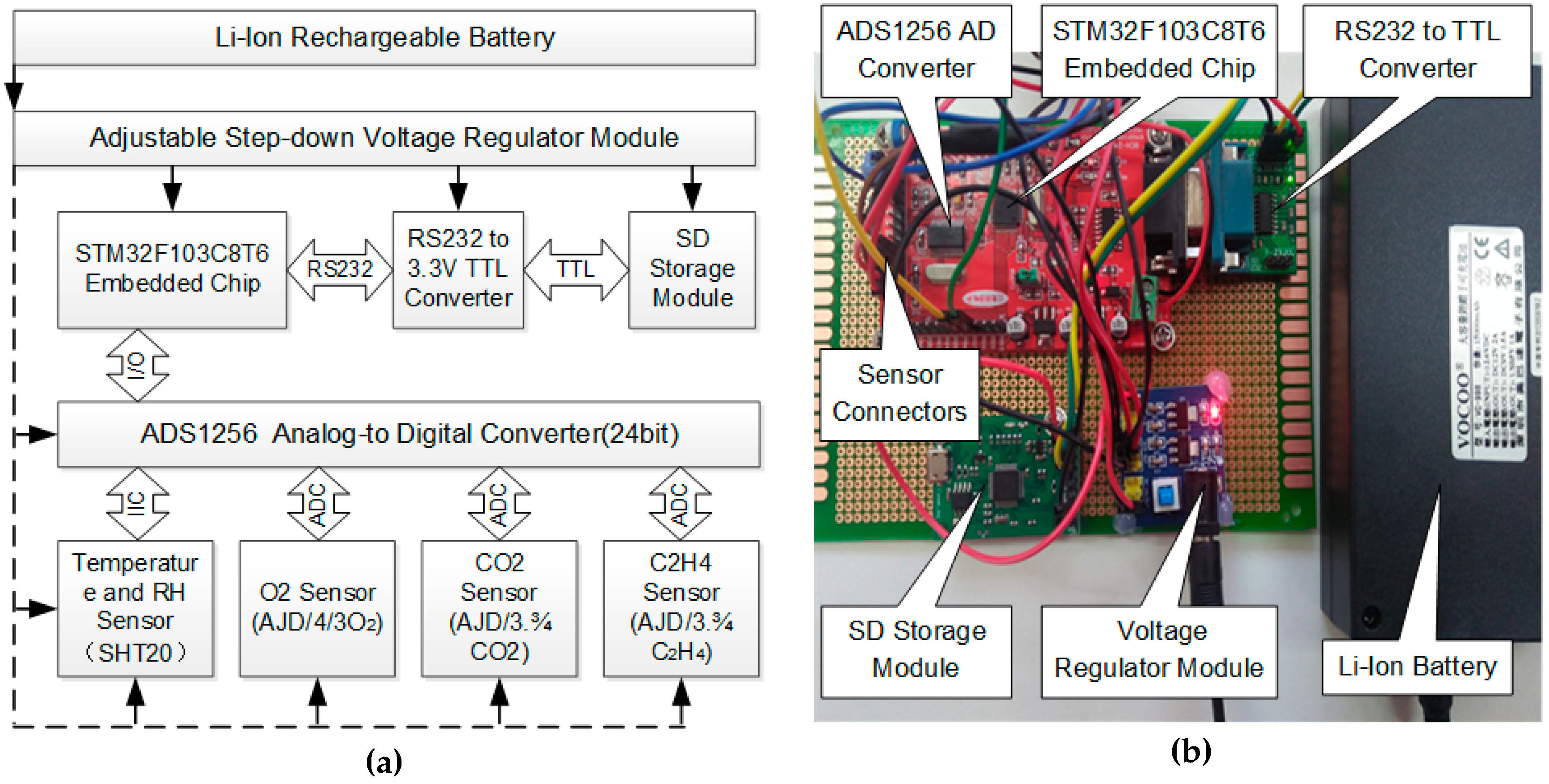

2.2. The Multi-Sensor Monitoring Detector Design for Cold Chain Logistics Data Acquisition

2.3. Implementation Scenario

2.4. Quality Evaluation Methods

2.5. Classification Function of BPNN

3. Results and Discussion

3.1. Temperature and Humidity Analysis of Fragrant Pears Cold Chain Logistics

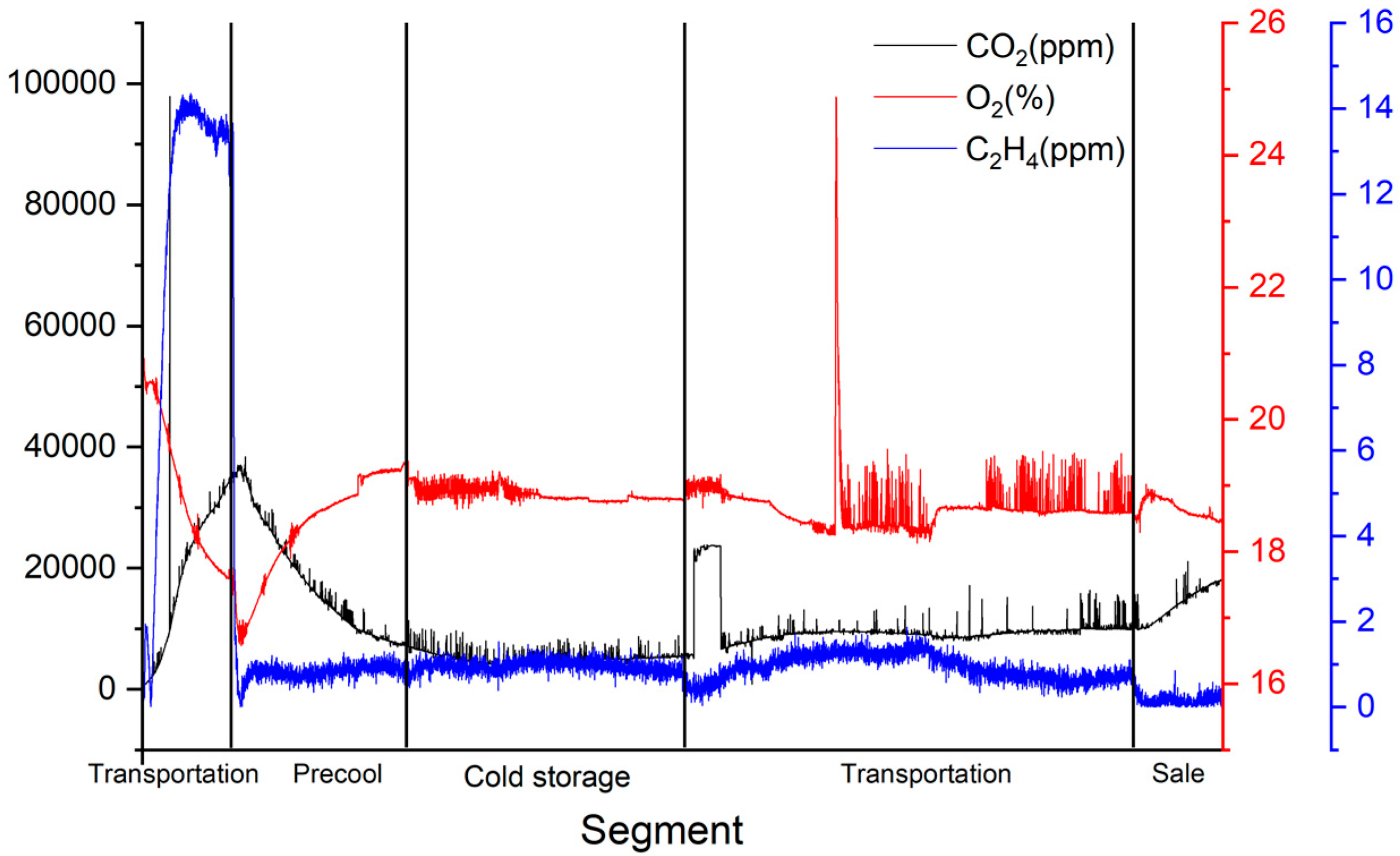

3.2. CO2, O2 and C2H4 Concentration Analysis of Fragrant Pear Cold Chain Logistics

3.3. Quality Evaluation Results of the Fragrant Pear Cold Chain Logistics

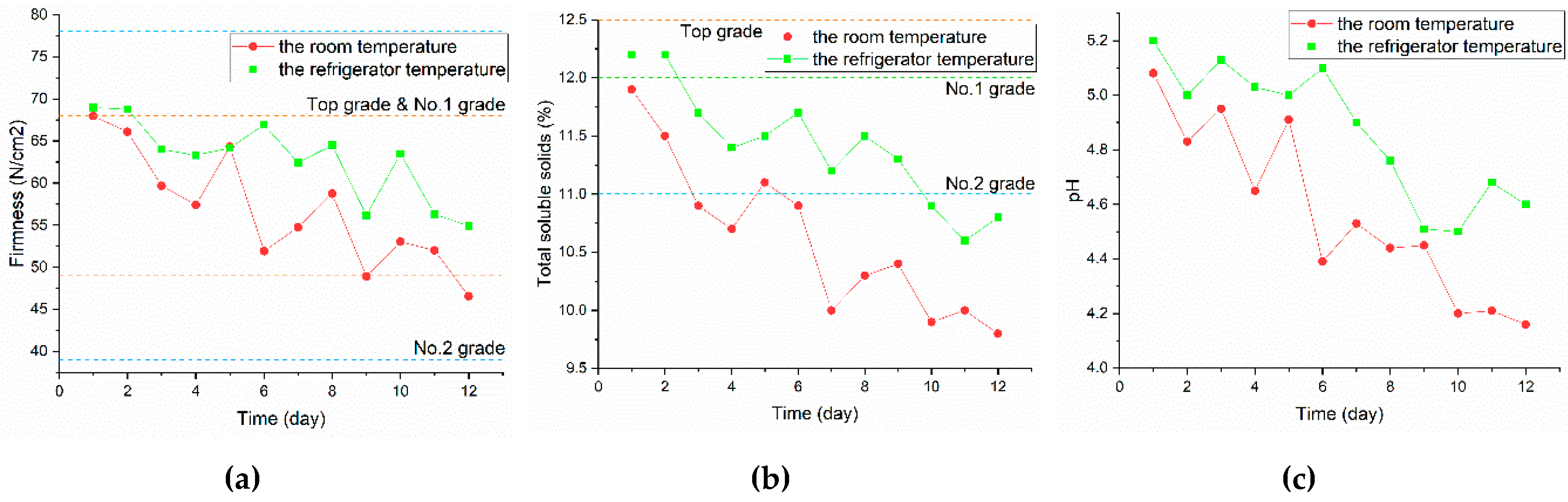

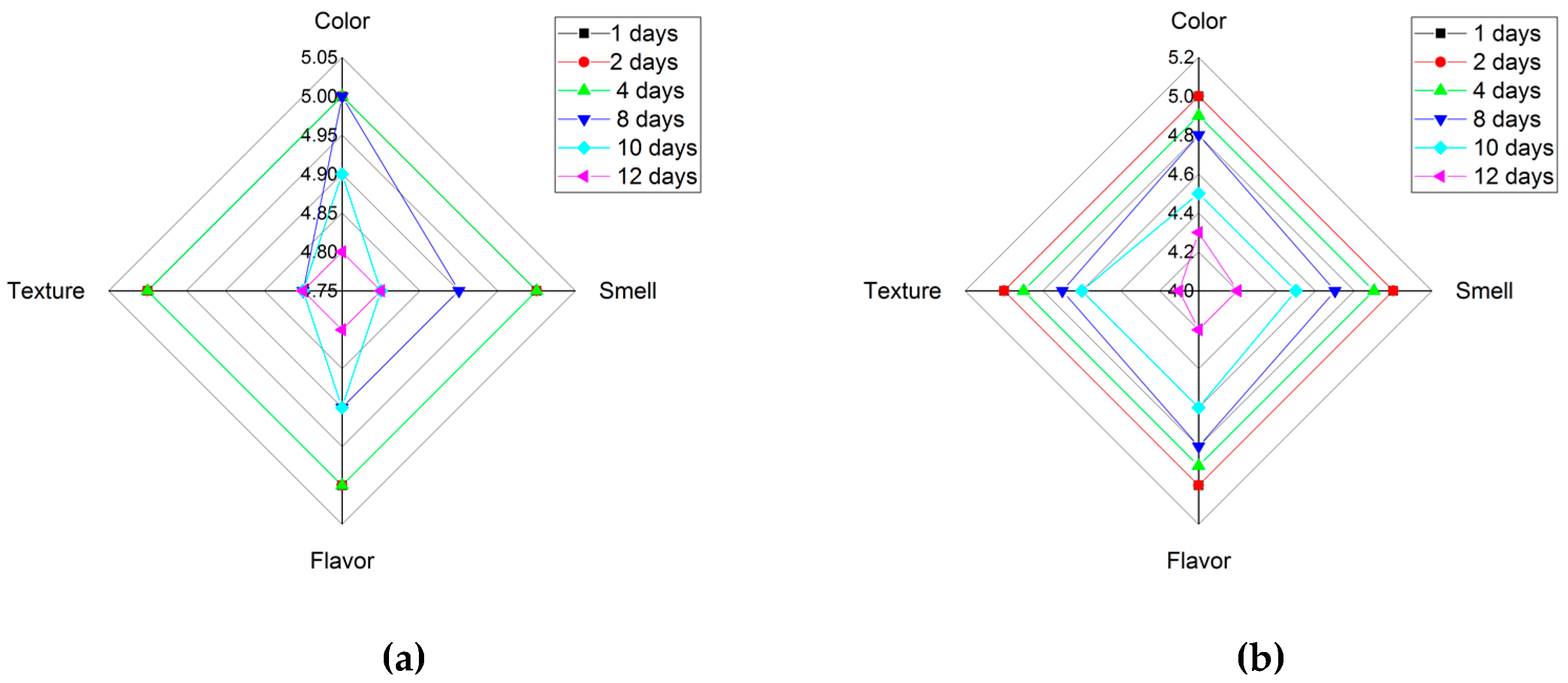

3.4. Quality Evaluation Results of Different Home Storage Conditions

3.5. BPNN for Home Storage Conditions Classification

4. Conclusions

- The multi-sensor monitoring detector offers highly accurate processing and highly efficient storage of continuous sensor data without the requirement of a complicated infrastructure. The cold chain is monitored by the detection of temperature, humidity, CO2, O2, and C2H4. Managers of the cold chain are benefitted by the detection of critical microenvironment parameters which make it more effective to control the safety and quality to the fragrant pear cold chain.

- The ‘Korla’ fragrant pear cold chain from Korla to Beijing lasted 12 days and consisted of six segments. The environment fluctuation analysis of ‘Korla’ fragrant pear cold chain suggests that the variation in critical microenvironment parameters was significant among different segments, their monitoring is useful for improving the quality control and transparency of fragrant pear cold chain. The evaluation of the quality of ‘Korla’ fragrant pears in the cold chain suggests that the fragrant pears were well preserved.

- The ‘Korla’ fragrant pear cold chain from Korla to Beijing lasted 12 days and consisted of six segments. The result of this study suggests the fragrant pears were well preserved based on the environment fluctuation analysis of gas characteristics. The analysis results provide some theoretical basis for the assessment of the pear quality cold chain logistics.

- The BPNN, whose classification accuracy is 97%, has shown good and reasonable classification accuracies that are capable of distinguishing the storage conditions of ‘Korla’ fragrant pear. This work illustrates that the classification method is feasible for different storage conditions, and provides a theoretical basis for the classification of gas parameters in microenvironment.

Author Contributions

Funding

Conflicts of Interest

References

- Gittins, C.; Calvo, P.; Miranda, M.; Barda, N. Developing a sensory descriptive panel for pear quality evaluation. Acta Hortic. 2011, 909, 617–624. [Google Scholar] [CrossRef]

- Mirabdulbaghi, M. Investigations on determination of nutritional status of pear trees according to a new index-deviation from optimum percentage (DOP). Cercet. Agron. Mold. 2014, 47, 83–98. [Google Scholar] [CrossRef]

- Predieri, S.; Gatti, E.; Rapparini, F.; Cavicchi, L.; Colombo, R. Sensory evaluation from a consumer perspective and its application to ‘Abate Fetel’pear fruit quality. Acta Hortic. 2005, 671, 349–354. [Google Scholar] [CrossRef]

- Zhang, H.; Rui, Y.-K. Nutritional composition of the speciality “frozen pear” from the Northeastern of China. J. Verbrauch. Lebensm. 2010, 5, 345–346. [Google Scholar] [CrossRef]

- Goedhals-Gerber, L.; Stander, C.; Van Dyk, F. Maintaining cold chain integrity: Temperature breaks within fruit reefer containers in the Cape Town Container Terminal. S. Afr. Bus. Rev. 2017, 21, 362–384. [Google Scholar]

- Scholtz, I.; Korsten, L. Profile of Penicillium species in the pear supply chain. Plant Pathol. 2016, 65, 1126–1132. [Google Scholar] [CrossRef]

- Wang, X.; Matetić, M.; Zhou, H.; Zhang, X.; Jemrić, T. Postharvest quality monitoring and variance analysis of peach and nectarine cold chain with multi-sensors technology. Appl. Sci. 2017, 7, 133. [Google Scholar] [CrossRef]

- Chaudhuri, A.; Dukovska-Popovska, I.; Subramanian, N.; Chan, H.K.; Bai, R. Decision-making in cold chain logistics using data analytics: A literature review. Int. J. Logist. Manag. 2018, 29, 839–861. [Google Scholar] [CrossRef]

- Mercier, S.; Villeneuve, S.; Mondor, M.; Uysal, I. Time–temperature management along the food cold chain: A review of recent developments. Compr. Rev. Food Sci. Food Saf. 2017, 16, 647–667. [Google Scholar] [CrossRef]

- Ma, C.; Fu, Z.; Xu, M.; Trebar, M.; Zhang, X. Evaluation on home storage performance of table grape based on sensory quality and consumers’ satisfaction. J. Food Sci. Technol. 2016, 53, 1363–1370. [Google Scholar] [CrossRef] [PubMed]

- Draganić, A.; Orović, I.; Stanković, S.; Zhang, X.; Wang, X. Compressive sensing approach in the table grape cold chain logistics. In Proceedings of the 2017 6th Mediterranean Conference on Embedded Computing (MECO), Bar, Montenegro, 11–15 June 2017; pp. 1–4. [Google Scholar]

- Ke, D.; Yahia, E.; Mateos, M.; Kader, A.A. Ethanolic fermentation of ‘Bartlett’ pears as influenced by ripening stage and atmospheric composition. J. Am. Soc. Hortic. Sci. 1994, 119, 976–982. [Google Scholar] [CrossRef]

- El-Sharkawy, I.; Jones, B.; Li, Z.; Lelièvre, J.-M.; Pech, J.-C.; Latché, A. Isolation and characterization of four ethylene perception elements and their expression during ripening in pears (Pyrus communis L.) with/without cold requirement. J. Exp. Bot. 2003, 54, 1615–1625. [Google Scholar] [CrossRef] [PubMed]

- Larrigaudière, C.; Vilaplana, R.; Soria, Y.; Recasens, I. Oxidative behaviour of Blanquilla pears treated with 1-methylcyclopropene during cold storage. J. Sci. Food Agric. 2004, 84, 1871–1877. [Google Scholar] [CrossRef]

- Pal, A.; Kant, K. Internet of Perishable Logistics: Building Smart Fresh Food Supply Chain Networks. IEEE Access 2019, 7, 17675–17695. [Google Scholar] [CrossRef]

- Saquet, A.; Streif, J.; Bangerth, F. Energy metabolism and membrane lipid alterations in relation to brown heart development in ‘Conference’ pears during delayed controlled atmosphere storage. Postharvest Biol. Technol. 2003, 30, 123–132. [Google Scholar] [CrossRef]

- Jia, X.; Wang, W.; Tong, W.; Du, Y.; Wang, Z. Effect of modified atmosphere packaging on postharvest physiology and quality of ‘korla xiangli’ pears during storage. Sci. Agric. Sin. 2016, 49, 4785–4796. [Google Scholar]

- Carullo, A.; Corbellini, S.; Parvis, M.; Vallan, A. A wireless sensor network for cold-chain monitoring. IEEE Trans. Instrum. Meas. 2008, 58, 1405–1411. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, R.; Chen, T.E.; Yi, T. The WSN real-time monitoring system for agricultural products cold-chain logistics. In Proceedings of the International Conference on Computer and Computing Technologies in Agriculture, Beijing, China, 16–19 September 2014; pp. 255–261. [Google Scholar]

- Badia-Melis, R.; Mc Carthy, U.; Ruiz-Garcia, L.; Garcia-Hierro, J.; Villalba, J.R. New trends in cold chain monitoring applications—A review. Food Control 2018, 86, 170–182. [Google Scholar] [CrossRef]

- Li, Q.; Meng, Q.; Cai, J.; Yoshino, H.; Mochida, A. Predicting hourly cooling load in the building: A comparison of support vector machine and different artificial neural networks. Energy Convers. Manag. 2009, 50, 90–96. [Google Scholar] [CrossRef]

- Xiao, L.; Sitian, C.; Hong, L.; Sha, H.; Daqiang, Z. A survey on gas sensing technology. Sensors 2012, 12, 9635–9665. [Google Scholar]

- Wang, X.; He, Q.; Matetic, M.; Jemric, T.; Zhang, X. Development and evaluation on a wireless multi-gas-sensors system for improving traceability and transparency of table grape cold chain. Comput. Electron. Agric. 2017, 135, 195–207. [Google Scholar] [CrossRef]

- Kim, W.R.; Aung, M.M.; Chang, Y.S.; Makatsoris, C. Freshness Gauge based cold storage management: A method for adjusting temperature and humidity levels for food quality. Food Control 2015, 47, 510–519. [Google Scholar] [CrossRef]

- Xiao, X.; Fu, Z.; Zhang, Y.; Peng, Z.; Zhang, X. Developing an intelligent traceability system for aquatic products in cold chain logistics integrated WSN with SPC. J. Food Process. Preserv. 2016, 40, 1448–1458. [Google Scholar] [CrossRef]

- Xu, S.; Lü, E.; Lu, H.; Zhou, Z.; Wang, Y.; Yang, J.; Wang, Y. Quality detection of litchi stored in different environments using an electronic nose. Sensors 2016, 16, 852. [Google Scholar] [CrossRef] [PubMed]

- Hong, X.; Wang, J.; Hai, Z. Discrimination and prediction of multiple beef freshness indexes based on electronic nose. Sens. Actuators B Chem. 2012, 161, 381–389. [Google Scholar] [CrossRef]

- Abirami, S.; Ramalingam, V.; Palanivel, S. Species classification of aquatic plants using GRNN and BPNN. AI Soc. 2014, 29, 45–52. [Google Scholar] [CrossRef]

- Dai, H.; MacBeth, C. Effects of learning parameters on learning procedure and performance of a BPNN. Neural Netw. 1997, 10, 1505–1521. [Google Scholar] [CrossRef]

- Zhang, E.; Hou, L.; Shen, C.; Shi, Y.; Zhang, Y. Sound quality prediction of vehicle interior noise and mathematical modeling using a back propagation neural network (BPNN) based on particle swarm optimization (PSO). Meas. Sci. Technol. 2015, 27, 015801. [Google Scholar] [CrossRef]

- Hou, J.; Zhang, Y.; Sun, Y.; Xu, N.; Leng, Y. Prediction of Firmness and pH for “Golden Delicious” Apple Based on Elasticity Index from Modal Analysis. J. Food Sci. 2018, 83, 661–669. [Google Scholar] [CrossRef]

- Xiao, C.; Zhu, L.; Luo, W.; Song, X.; Deng, Y. Combined action of pure oxygen pretreatment and chitosan coating incorporated with rosemary extracts on the quality of fresh-cut pears. Food Chem. 2010, 121, 1003–1009. [Google Scholar] [CrossRef]

- Xiao, X.; Wang, X.; Zhang, X.; Chen, E.; Li, J. Effect of the quality property of table grapes in cold chain logistics-integrated WSN and AOW. Appl. Sci. 2015, 5, 747–760. [Google Scholar] [CrossRef]

- Xiao, Z.; Luo, Y.; Luo, Y.; Wang, Q. Combined effects of sodium chlorite dip treatment and chitosan coatings on the quality of fresh-cut d’Anjou pears. Postharvest Biol. Technol. 2011, 62, 319–326. [Google Scholar] [CrossRef]

- Qi, L.; Xu, M.; Fu, Z.; Mira, T.; Zhang, X. C2SLDS: A WSN-based perishable food shelf-life prediction and LSFO strategy decision support system in cold chain logistics. Food Control 2014, 38, 19–29. [Google Scholar] [CrossRef]

- Aishwarya, D.; Babu, C.N. Prediction of Time Series Data Using GA-BPNN Based Hybrid ANN Model. In Proceedings of the 2017 IEEE 7th International Advance Computing Conference (IACC), Hyderabad, India, 5–7 January 2017; pp. 848–853. [Google Scholar]

- Yu, H.; Wang, J.; Yao, C.; Zhang, H.; Yu, Y. Quality grade identification of green tea using E-nose by CA and ANN. LWT Food Sci. Technol. 2008, 41, 1268–1273. [Google Scholar] [CrossRef]

- Ministry of Agriculture of the People’s Republic of China. Kurle Fragrant Pear: NY/T 585-2002; Standards Press of China: Beijing, China, 2002.

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Product of Geographical Indication- Kuerle Fragrant Pear: GB/T 19859-2005; Standards Press of China: Beijing, China, 2005.

- Ma, S. Effect of Storage Temperatures on the Quality of Kuerle Pear. Food Res. Dev. 2013, 34, 254–257. [Google Scholar]

| Sensor | Sensor Type | Principle | Measurement Range | Resolution | Output | Response Time |

|---|---|---|---|---|---|---|

| Temperature sensor | SHT20 | Capacitive | -40 + 125 °C | 0.04 °C | I2C | T63 < 8 s |

| Relative humidity sensor | SHT20 | Band gap | 0–100%RH | 0.04%RH | I2C | T63 < 30 s |

| CO2 gas sensor | AJD/5/5CO2 | Electrochemical | 0–5.00% | 1 ppm | 0.4–2 V | T90 < 30 s |

| O2 gas sensor | AJD/4/3O2 | Electrochemical | 0–30% | 0.1% | 0.4–2 V | T90 < 30 s |

| C2H4 gas sensor | AJD/3/C2H4 | Electrochemical | 0–100 ppm | 0.1 ppm | 0.4–2 V | T90 < 30 s |

| Parameters | Color | Smell | Flavor | Texture | |

|---|---|---|---|---|---|

| Acceptability | Scores | ||||

| Like | 5 | Keep the fruit color brilliant and well | Pure fruit aroma | Pure fruit flavor, long aftertaste, refreshing | Crisp and plump, juicy |

| Neither like nor dislike | 3 | Have the light yellow color that this product should have | Less fragrant, feels average | Sweet and delicious, lack of aftertaste | Soft and juiceless |

| Dislike | 1 | Dim surface | Mixed aroma, unpleasant smell, | Not harmonious sweetness and slight astringency | Coarse dry pulp |

| Values | Fragrant Pear Cold Chain Logistics | National Standard | Industry Standard | ||||||

|---|---|---|---|---|---|---|---|---|---|

| Parameters | Transportation | Precool | Cold Storage | Transportation | Sale | Up to Standard | Top Grade | No.1 Grade | No.2 Grade |

| Firmness (N/cm2) | 66.33 | 68.54 | 65.07 | 62.52 | 65.46 | 45–75 | 49–68 | 49–68 | 39–78 |

| Total soluble solids (%) | 12.96 | 11.80 | 12.03 | 12.20 | 11.60 | ≥11.5 | ≥12.5 | ≥12.0 | ≥11.0 |

| pH | 5.26 | 5.15 | 5.5 | 5.10 | 5.07 | - | - | - | - |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, J.; Zhang, X.; Li, Z.; Zhang, X.; Jemric, T.; Wang, X. Quality Monitoring and Analysis of Xinjiang ‘Korla’ Fragrant Pear in Cold Chain Logistics and Home Storage with Multi-Sensor Technology. Appl. Sci. 2019, 9, 3895. https://doi.org/10.3390/app9183895

Liu J, Zhang X, Li Z, Zhang X, Jemric T, Wang X. Quality Monitoring and Analysis of Xinjiang ‘Korla’ Fragrant Pear in Cold Chain Logistics and Home Storage with Multi-Sensor Technology. Applied Sciences. 2019; 9(18):3895. https://doi.org/10.3390/app9183895

Chicago/Turabian StyleLiu, Jingjing, Xu Zhang, Zhigang Li, Xiaoshuan Zhang, Tomislav Jemric, and Xiang Wang. 2019. "Quality Monitoring and Analysis of Xinjiang ‘Korla’ Fragrant Pear in Cold Chain Logistics and Home Storage with Multi-Sensor Technology" Applied Sciences 9, no. 18: 3895. https://doi.org/10.3390/app9183895